Abstract

Three-phase gliding arc discharge reactors are devices in which it is difficult to maintain stable plasma parameters, be it electrically, physically, or chemically. The main cause of plasma instability is the source, which is freely burning arcs in a three-phase system. In addition, these arcs burn at low currents and are intensively cooled, further increasing their instability. These instabilities translate into the electrical characteristics of the plasma reactor. The analysis for the four gases nitrogen, argon, helium, and air shows that the type of plasma-generating gas and its physical parameters have a strong influence on the operational characteristics of the plasma reactor. Current–voltage, power and frequency characteristics of the plasma reactor were plotted experimentally. Characteristics obtained in this way make it possible to determine the areas of effective operation of the plasma reactor, and to estimate the quality of the generated plasma. Based on the characteristics obtained, a method of controlling the plasma parameters can be developed.

1. Introduction

When conducting any process using plasma, knowledge of its properties and mastery of the methods for obtaining it should be ensured. Plasma research focuses on obtaining controlled plasmochemical reactions [1,2,3,4,5]. The constancy of the parameters of the generated plasma largely determines the reproducibility of the processes carried out with its participation [6].

For technical purposes, low-temperature plasma is generated, most often by electrical discharge in a gas, in devices called plasma reactors [7,8]. Plasma generated in this way is seeing more and more applications in many fields of science and industry. New types of plasma reactors are being developed, and existing ones are being streamlined and improved.

One of the more promising technologies is the use of low-temperature plasma generated at atmospheric pressure in plasma reactors with gliding arc discharge. Currently, research on plasma reactors with gliding arc discharge is mainly focused on their application possibilities. Reactors of this type are used to treat hazardous, municipal, industrial, and medical waste [9,10]. Gliding arc discharge reactors are used to treat flue gases from industrial processes such as incinerators, cement kilns and power plants [11,12,13]. These devices provide a platform for the synthesis of materials, nanotubes, and nanoparticles [14,15]. They can be used for the surface modification and coating of materials [16,17]. They are used in medical applications [18,19,20,21,22].

Despite the great popularity of gliding arc discharge plasma reactors, they have not been ranked in terms of their design, the powers used, the voltages and currents, and the parameters of the plasma generated. There are also no general guidelines on how to supply reactors with electricity and plasma-generating gases. As a result, each reactor design must be analyzed separately in terms of operating characteristics and application possibilities.

The plasma parameters necessary for the correct course of the reaction are obtained by controlling the conditions under which the electrical discharge burns, i.e., the design of the plasma reactor, the design and parameters of the electrical power supply system, and the physical and chemical parameters of the plasma-generating gases. The article [23] investigated the dependence of gliding arc discharge characteristics and arc column motion on reactor configuration parameters based on numerical simulations and laboratory experimental results. It was found that changing the distance between the electrodes and the vertical distance between the electrodes and the inlet nozzle of the process gas affects the speed of the arc column and its extension, as well as the amount of electricity consumed by the arc. Similar studies on the dynamic effect of plasma gas on the arc discharge were conducted in [24]. The paper [25] sought to elucidate the fundamental mechanisms of non-equilibrium alternating current gliding arc discharge by investigating the effects of gas composition and pressure on its characteristics using electrical and optical methods. It was found that the effects of pressure on the gliding arc discharge characteristics differed depending on the gas composition when the same AC supply was used. The effect of gas type on the characteristics of a gliding arc discharge was also studied in the work of [26,27]. In the article [28], an arc discharge burning in air, natural gas and a mixture of the two was studied. The results presented in this paper describe the dependence of the breakdown voltage, frequency of discharges, and conversion rates of methane and molecular oxygen with respect to the variation in the mass flow rate and discharge current. The effect of gas flow on the movement of the arc column and the change in its characteristics and parameters was also studied in the work of [29]. The cited articles show that controlling the parameters of the plasma-generating gas is key to obtaining the desired plasma properties and achieving the intended effects of the process carried out with its participation. An important element in the plasma generation process is the proper selection of the plasma-generating gas [30,31,32,33].

This paper analyzes the operation of a plasma rheter with the four most common process gases, namely, argon, helium, nitrogen and air. Argon is one of the most commonly used gases in arc plasmotrons due to its inert nature and availability [34,35,36,37]. Nitrogen is used in arc plasmotrons for applications where a nitrogen-rich plasma is desired, such as in nitriding processes for hardening the surface of materials or in the plasma synthesis of nitrogen-containing compounds [38,39]. Helium as a plasma-forming gas is sometimes used in arc plasmotrons for applications where high thermal conductivity is required [40,41]. Oxygen can be used in processes requiring an oxidizing environment [42,43]. Hydrogen is often used in arc plasmotrons because of its ability to produce highly reactive plasma [44,45]. It is used in processes such as plasma cleaning, surface activation and chemical vapor deposition. In some cases, air can be used in arc plasmotrons as a plasma-forming gas, especially in reactors where plasma is produced at atmospheric pressure [46,47]. Air plasma can be used for a variety of applications, including surface cleaning, sterilization, and contaminant removal.

Plasma-generating gas is a factor that is common to all solutions of plasma reactors with gliding arc discharge. A given gas for each plasma reactor has the same parameters: chemical composition, dielectric strength, ionization potential, electrical and thermal conductivity. By analyzing the operation of one plasma reactor design with a given plasma-generating gas, one can draw general conclusions that will be valid for the entire range of devices of this type. In this article, the effects of the type of plasma gas on the performance characteristics of a three-phase plasma reactor with a gliding arc discharge were studied.

Particular attention was paid to the ability of individual gases to generate plasmas in them with the most stable electrical, physical and chemical parameters possible. The second problem that was considered is the possibility of obtaining good control properties of the discharge parameters. The plasma reactor and the plasma generated in it were analyzed in terms of electrical characteristics. The basic characteristic of a plasma reactor is the current–voltage characteristic. The purpose of this study was to plot a family of such characteristics for different plasma-generating gases and their different volume flows through the reactor’s discharge chamber. Also plotted was a family of power characteristics illustrating the possibility of adjusting the power of the discharge in the reactor both by changing the electrical parameters and the composition of the process gas and adjusting its dynamic parameters. Since strong correlations were observed between the various electrical and physical chemical parameters of the gases, the characteristics of their interactions were plotted. Complementing the control characteristics of the plasma reactor are frequency characteristics. The study indicates that by changing the frequency of the supply voltage, many parameters of the generated plasma can be influenced.

This study made it possible to draw conclusions about the possibility of controlling the operation of the plasma reactor, the power of the electric discharge and the parameters of the plasma.

2. Plasma Reactor with Gliding Arc Discharge

Gliding arc discharge plasma reactors are devices in which it is difficult to maintain stable plasma parameters [48,49,50]. The generated plasma is most often electrically, physically and chemically unstable. The instability of the plasma is due to the principle of operation of this type of reactors. This operation is based on cycles consisting of ignition, development and quenching of a free electric arc [51,52]. The discharge at ignition has the character of a short arc burning perpendicular to the electrodes, which is in thermodynamic equilibrium. Under the influence of the gas’s dynamic forces acting on the arc column, its movement along the electrodes takes place. As a result of several increases in length and volume, the discharge reaches the state of a long arc with a relatively wide column, located in a state of disequilibrium. The development of the discharge is strongly influenced by the Lorenz forces acting on it. The arc develops as long as the power supply system is able to cover the energy loss from the discharge to the environment. During reactor operation, the length of the free arc, its position in space, its volume, and its electrical and thermal parameters are constantly changing.

In gliding arc discharge reactors, the most common arcs are those that burn at low currents and relatively low voltages, and are intensively cooled, and therefore produce low-temperature discharges [53,54]. By design, the discharges must be cold enough not to melt electrode material and reactor structural components. At the same time, the discharges burning in the reactor must have a temperature suitable for the plasmochemical reactions being conducted. Such arcs can be obtained at sufficiently low current values, but there are specific voltage and current values, depending on the type of gas, its thermodynamic parameters and the distance between electrodes, below which the arc goes out.

In low-current arcs, small changes in the parameters of the electricity supply, or in the physical and chemical parameters of the process gases, lead to changes in the arc burning conditions, which in turn induce self-regulatory reactions in the plasma that change the arc structure and its characteristics. Due to the inhomogeneous structure, both in the cross-section and longitudinally, weak-current arcs are difficult to analyze in terms of physical and chemical parameters. As a result, it is difficult to unambiguously determine plasma parameters. This makes the arc difficult to control from the point of view of maintaining the required characteristics necessary for plasma processes. Free arc plasma is characterized by relatively low-quality technological and energy parameters [55], and the arc itself adversely affects the power grid. Low-temperature arcs generate a lot of electromagnetic interference, voltage sinks and surges, overvoltage, noise and harmonic distortion in the voltage and current [56].

A free arc burning in a two-electrode system is practically useless for many technological applications. The length of the free arc, its position in space, its volume and the characteristics of the plasma generated with it are constantly randomly changing. This makes the arc uncontrollable from the standpoint of maintaining the required characteristics necessary for plasma processes.

Improving plasma characteristics and increasing the active surface area of the gliding arc can be achieved by increasing the number of electrodes to three, six or more. The most commonly used electrode configuration in gliding arc discharge reactors is the three-electrode arrangement. This is because the generally available three-phase grid naturally forces the use of a three-electrode arrangement. Compared to a single-phase arc, free-burning electric arcs in a three-phase system are far less stable in terms of their configuration, shape and structure in the cross-section and longitudinal section [57]. However, when analyzing these arcs in terms of averaged plasma parameters, better plasma characteristics are obtained than with a single-phase arc.

When analyzing the effect of gas type on the operating characteristics of a plasma reactor, it is important to keep in mind the possibility of impurities in the gas. The electrical discharge processes occurring in plasma reactors are very significantly affected by the purity of the plasma-generating gas. Even trace amounts of admixtures with low ionization potential can clearly change the value of the electron spatial ionization coefficient of the gas, and change the discharge ignition voltage and operating characteristics of the plasma reactor. In gases, we also see the phenomenon of ions sticking to impurities (dust, steam, etc.) and the formation of slow Langevin ions. The research presented in the article was carried out using gases of 99.999% purity. However, it should be borne in mind that during reactor operation, electrode erosion products enter the process gases, which can significantly change the characteristics of the arc discharge. In an electric arc, electron emission from the cathode is primarily thermal. In the areas adjacent to the arc and to the electrodes, the temperature value is close to, and sometimes higher than, the melting point of the electrode material. Although intensive cooling of the electrodes takes place in gliding arc discharge reactors, a stream of electrode material vapor is ejected from the arc spots, which is then carried away by the plasma-generating gas. Therefore, the materials used for electrodes must meet a number of requirements, such as high melting point, low concentration of contained gases and unnecessary easily vaporized admixtures. Electrodes must also be made of materials that have low exit work, high chemical stability, and high stability of surface structure. In the case of plasma reactors with gliding arc discharge, the speed at which the electrode spots move across the surface of the electrodes is of great importance. This speed depends on the thermal inertia of the electrode surface layer. Electrode plasmas do not tend to move over the surface of pure tungsten, carbon and such metals as cadmium, zinc, lead, manganese, while they move very quickly over the surface of electrodes made of copper, iron, nickel, silver, and gold. The materials used for electrodes should provide a compromise between the high speed of movement of electrode spots and the conversion of low emissions into process gases of pollutants that are a product of their erosion.

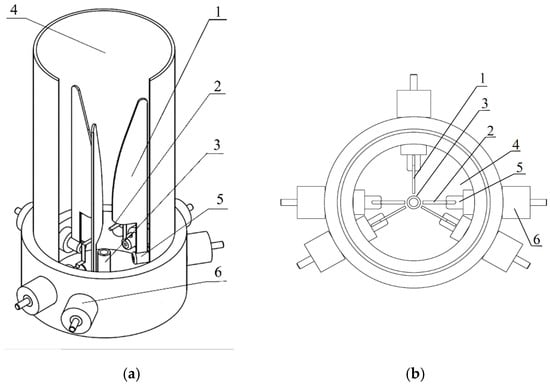

The design of a three-electrode plasma reactor with gliding arc discharge is shown in Figure 1. Table 1 lists the technical parameters.

Figure 1.

Three-electrode sliding arc discharge plasma reactor: (a) cross-sectional drawing through the discharge chamber, (b) top view of the reactor, (1—working electrode, 2—ignition electrode, 3—gas inflow nozzle, 4—discharge chamber, 5—electrode holder and current feedthrough, 6—insulator).

Table 1.

Reactor parameters.

3. Reactor Process Gas Supply System

The plasma parameters necessary for the correct course of the reaction are obtained by controlling the conditions under which the electrical discharge in the reactor burns. The physical and chemical parameters of the plasma-generating gases have a great influence on the plasma properties [58]. The system for supplying the reactor with process gases is therefore an important part of the plasma generation system.

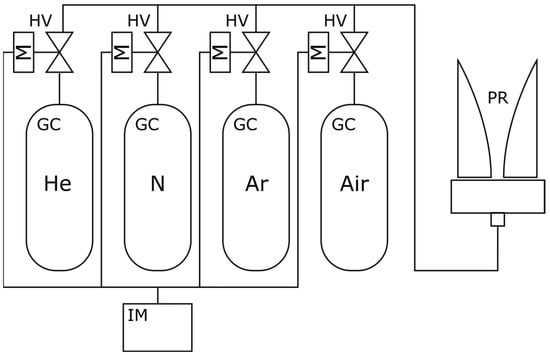

A schematic diagram of the plasma reactor’s plasma-generating gas supply system is shown in Figure 2. The system includes four cylinders of technical gases containing argon, nitrogen, helium, and air. The dosing of plasma-generating gas to the plasmotron’s discharge chamber is carried out through Bronkhorst’s EL-FLOW mass flow meters and flow controllers: F-202AV-M20-AAD-44-V with a flow rate of up to 15 m3/h, F-201AV-50K-AAD-44-V with a flow rate of up to 2 m3/h, and F-201CV-1K0-AAD-44-V with a flow rate of up to 0.06 m3/h. Adjustments of the valve settings are carried out using E-7300-AAA and 12-AAA electronic control modules mounted in the E-7300 type cassette.

Figure 2.

Plasma reactor plasma gas supply system; PR—plasma reactor; IM—control and measurement module; HV—flow regulator; GC—gas cylinder.

Plasma gas flow through the discharge chamber of a plasma reactor can be used to stabilize the geometric and physical parameters of the arc discharge. However, this requires an analysis of the gas flow through the discharge chamber of the plasma reactor, and an attempt to design it and the structural elements of the plasma reactor in terms of the required aerodynamic characteristics.

4. Electricity Supply System

Through the power supply system, it is possible to influence the power of the discharge, the temperature of the generated plasma, the degree of ionization of the gas, and thus the electrical and thermal parameters of the discharge occurring in the plasma reactor [59,60].

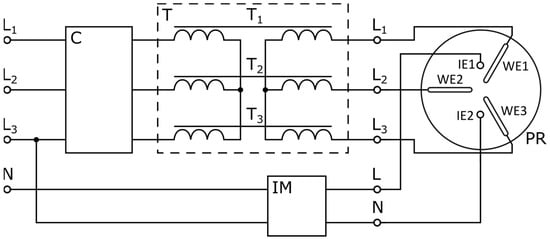

During the tests, the plasma reactor was supplied with electricity from a ZF-10 power supply device, the schematic diagram of which is shown in Figure 3 and the technical parameters of which are given in Table 2. This power supply device consists of an AC/DC/AC power electronic converter, three voltage step-up transformers and an ignition module. The power electronic converter includes a three-phase AC/DC transistor rectifier in a 6T + 6D arrangement, a DC intermediate bus and a six-phase transistor inverter. The rectifier additionally has a built-in PFC circuit to improve the power factor. The inverter can operate as a six-phase or as a three-phase inverter. The inverter allows for adjusting the output current and frequency of the output voltage. The rated output voltage of the inverter is 300 V, the rated current is 10 A, and the frequency control range is from 10 Hz to 200 Hz. The inverter does not include the possibility of controlling the value of the output voltage. Controlling the power of the plasma reactor by changing the supply voltage is much less favorable than by changing the current of the electrodes. This is due to the fact that the voltage of a stable burning discharge is fixed at a certain value and does not depend on changes in current over a wide range.

Figure 3.

ZF-10 plasma reactor power supply; C—AC/DC/AC converter, T—matching transformers, IM—ignition module, PR—plasma reactor, IE—ignition electrodes, WE—working electrodes.

Table 2.

Parameters of the ZF-10 power system.

Since the arc does not have the ability to self-regulate current, its limitation must occur outside the discharge itself. The most advantageous way to control the power of the plasma reactor is by changing the value of the current supplying its working electrodes. Controlling the value of the current is also greatly facilitated by its almost sinusoidal waveform. The voltage of the discharge burning in the reactor, on the other hand, undergoes strong deformation, which is characteristic of intensively cooled electric arcs.

The voltage from the output of the converter is increased to the value required by the plasma reactor by three single-phase transformers. The windings of the primary and secondary sides of the transformers were wound concentrically on a single column of core. The cores were made from coiled and braided amorphous material Metglas 2605SA1. The windings of the transformers were connected in a three-phase star–star arrangement, and on the secondary side were connected to the working electrodes of the plasma reactor. The rated output voltage of the transformers is 1.2 kV and the rated current is 2.9 A. The power of one transformer is 3.5 kVA. The transformers have an enlarged dissipation reactance, meaning that the discharge current does not exceed the value appropriate for the plasma process in progress, and at the same time there is no excessive reduction in the power of the plasma reactor.

The way in which the discharge develops in a plasma reactor can be influenced by changing the frequency of the voltage supplying the working electrodes in the inverter. As a result of the increase in frequency, the cycle time of the plasma reactor is shortened, the power of the electrical discharge is reduced, and the area of active plasma interaction is reduced.

The ignition module is a commercial system from Danfoss with the name EBI4-052F4030. This module is used to power the ignition electrodes of the plasma reactor. The rated output voltage of the ignition module is 15 kV and the rated current is 40 mA.

5. Measurement System and Test Methodology

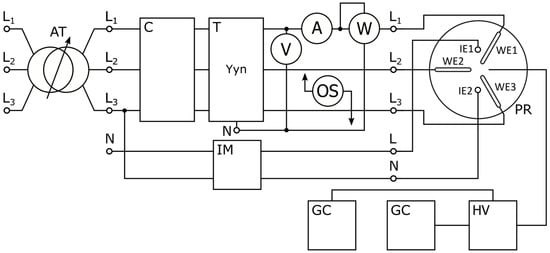

The study, which aimed to find out the operating characteristics of the plasma reactor when fed with different plasma gases, was carried out in the measurement system shown in Figure 4.

Figure 4.

Measurement system for determining the operating characteristics of a plasma reactor; C—AC/DC/AC converter, T—matching transformers, IM—ignition module, PR—plasma reactor, IE—ignition electrodes, WE—working electrodes, IM—control and measurement module, HV—flow regulator, GC—gas cylinder, AT—autotransformer, OS—oscilloscope.

The system was powered by a 400 V three-phase power network through a 23.4 kVA ATS-FAZ3-23 autotransformer (Merserwis, Warsaw, Poland). The measurements were performed using LM-3 voltmeters (Merazet, Poznan, Poland), LE-3 ammeters (Merazet, Poznan, Poland), LW-1 wattmeters (Merazet, Poznan, Poland), DPO3054 oscilloscope (Tektronix, Beaverton, OR, USA), and P6015A high-voltage (Tektronix, Beaverton, OR, USA) and TCP0030 current probes (Tektronix, Beaverton, OR, USA).

The regulation of the electrical parameters of the plasma reactor power supply was carried out by changing the settings of the AC/DC/AC converter. Current, voltage and frequency were regulated. The selection of the plasma-generating gas and the determination of its volumetric flow through the discharge chamber of the plasma reactor were carried out by means of appropriate settings of the flow regulators.

6. Characteristics of the Plasma Reactor

The research was directed toward obtaining current–voltage characteristics of the plasma reactor for four selected plasma-forming gases, i.e., argon, helium, nitrogen, and air. These characteristics make it possible to determine the voltage and current ranges for efficient plasma reactor operation and the resistance of the arc column. The possibility of adjusting the discharge power depending on the type of plasma-generating gas was also analyzed. The ability of the plasma reactor to regulate the discharge power by changing the value of the current supplying its electrodes, as well as by changing the frequency of the supply voltage, was taken into account. The study also took into account the effect on the performance characteristics of the plasma reactor of changes in the volume flows of plasma-generating gases.

6.1. Current–Voltage Characteristics of the Plasma Reactor

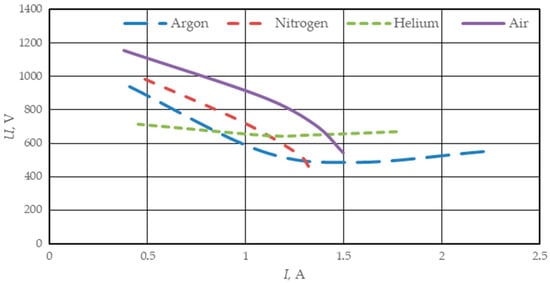

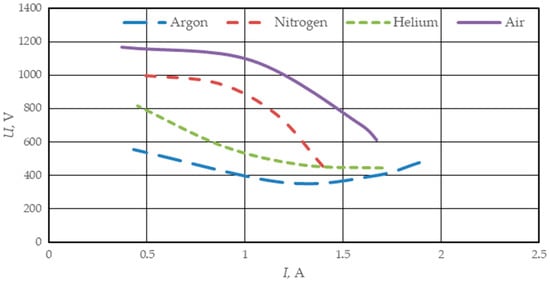

The current–voltage characteristics of the operating plasma reactor are shown in Figure 4 and Figure 5. The characteristics were plotted as a function of changes in the rms value of the current supplying the plasma reactor from 0 to 2.5 A at a supply voltage frequency of 50 Hz. The current supplying the plasma reactor was controlled by the settings of the AC/DC/AC converter. Due to the characteristics of the intermediate transformers and the properties of the electrical discharge itself, there is no direct relationship between the current settings on the power supply and the value of the arc current. Current adjustments on the inverter were made to achieve the required value of the discharge current, and at the same time not to exceed the current rating of the primary side of the transformers. Due to the current limitation of the transformers for some plasma gases, under certain conditions, it was not possible to achieve the assumed values of the discharge current.

Figure 5.

Current–voltage characteristics of the plasma reactor for V = 1.1 m3/h.

Argon, nitrogen, helium and air were used as plasma-forming gases. The characteristics shown in Figure 5 and Figure 6 were plotted for gas volume flows of 1.1 m3/h and 2.1 m3/h. The rms voltage of the burning electrical discharge was measured as phase, i.e., between the working electrodes of the reactor and the neutral point of the star-connected secondary windings of the matching transformers.

Figure 6.

Current–voltage characteristics of the plasma reactor for V = 2.1 m3/h.

The voltage changes recorded on the current–voltage characteristics are the result of self-regulatory reactions in the plasma changing the structure of the arc and its characteristics, as well as supplying the reactor from transformers with increased dissipation reactance. The beginnings of the characteristics determine the values of voltages and currents at which the electric discharge in the plasma reactor is ignited. The ends of the characteristics determine the values of currents and voltages at which the currents on the primary side of the transformers exceeded the rated values, and further increases in the discharge current would threaten to damage the windings.

For all plasma gases considered, falling current–voltage characteristics were obtained with increasing discharge current. In an electric arc, electron emission from the electrodes is thermal in nature; hence, with increasing discharge current, the voltage needed to sustain its burning decreases.

The course of the characteristics is clearly influenced by the volume flow rates of plasma-forming gases. The most susceptible to voltage changes are discharges burning in nitrogen and air. The smallest arc voltage changes were recorded for helium. Helium as a plasma-forming gas provides the most stable arc parameters over the entire range of current control and applied gas volume flows. Along with argon, helium also provides the widest range of discharge current control.

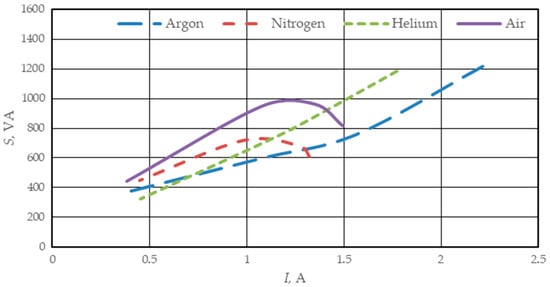

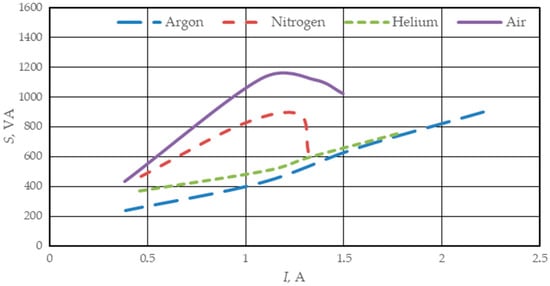

In the region of stable operation of the plasma reactor, i.e., in the range of a fixed value of the discharge voltage and gas volume flow, the power of the arc depends only on the value of the current with which the working electrodes are supplied. Therefore, it is most advantageous to control the power of the plasma device by changing the value of the current of the electrodes. Figure 7 and Figure 8 show the characteristics of changes in the power of the plasma reactor as a function of changes in the current supplied to the electrodes for gas volume flows of 1.1 m3/h and 2.1 m3/h.

Figure 7.

Power characteristics of the plasma reactor for V = 1.1 m3/h.

Figure 8.

Power characteristics of the plasma reactor for V = 2.1 m3/h.

For noble gases, an almost linear increase in reactor power is obtained with increasing arc current. For nitrogen and air, the power characteristics fall at their ends.

The obtained operating characteristics of the plasma reactor indicate that noble gases (in this case argon and helium) allow better control of the parameters of the generated plasma. These gases allow a wide and almost linear range of control of the current and power of the electrical discharge with relatively small changes in its voltage.

6.2. Effect of Gas Flow on Plasma Reactor Characteristics

Changing the volume flow of gas through the reactor discharge chamber affects the temperature of the generated plasma. In turn, for a given gas flow rate and constant power supplied to the arc, the value of the plasma temperature depends on the type of gas used. The highest temperatures are achievable with mono-atomic gases and noble gases, as they do not need to be supplied with dissociation energy to break down multi-atomic particles.

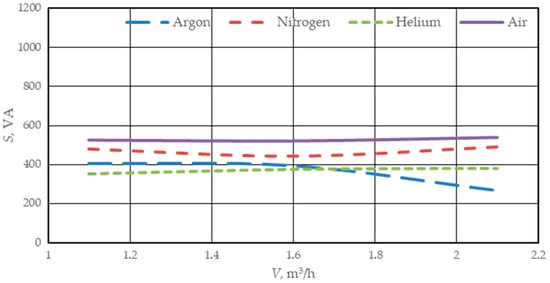

Figure 9 and Figure 10 show the waveforms of changes in discharge power in the plasma reactor as a function of changes in the volume flow of plasma-generating gases. Measurements were made for electrode supply currents equal to 0.5 A and 1.2 A. It should be borne in mind that the gas entering the discharge chamber of the plasmotron through the nozzle undergoes expansion, and on its way encounters the structural elements of the reactor. As a result, the distribution of gas parameters is inhomogeneous both in cross-section and along the length of the discharge chamber.

Figure 9.

Power characteristics of the plasma reactor for different gas flows and for I = 0.5 A.

Figure 10.

Power characteristics of the plasma reactor for different gas flows and for I = 1.2 A.

For all plasma gases, with an increase in their volume flow, changes in the power of the discharge in the reactor are observed. These changes are relatively small for small values of the currents supplying the plasma reactor electrodes and increase with increasing values of these currents. However, the courses of these changes are different. For discharges burning in noble gases, there is an initial increase and then a decrease in their power with increasing gas flow. For nitrogen and air, the situation is reversed.

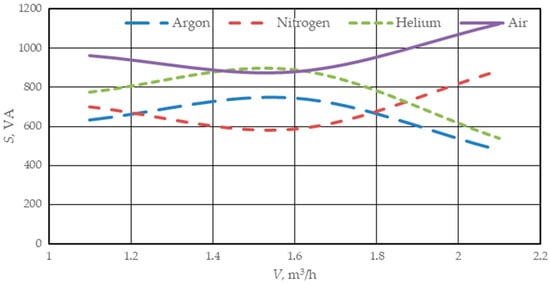

With an increase in the volume flow of plasma-generating gases, there are also changes in the arc voltage. Characteristics of these changes are shown in Figure 11 and Figure 12. Measurements were made for electrode feed currents of 0.5 A and 1.2 A.

Figure 11.

Discharge voltage characteristics for different gas flows and for I = 0.5 A.

Figure 12.

Discharge voltage characteristics for different gas flows and for I = 1.2 A.

For small current values, the increase in gas volume flows is accompanied by relatively small and linear changes in arc voltage. Larger changes were observed only for argon. At a current of 1.2 A, significant changes in arc voltage were observed for all plasma gases. Differences between individual gases are seen in the courses of these changes. For noble gases, initially, with an increase in their volumetric flows, there is a slight increase in arc voltage, and after exceeding a flow of 1.6 m3/h there is a marked decrease. For nitrogen and air, a decrease in voltage is observed initially, and after exceeding a flow of 1.6 m3/h, its increase is observed.

6.3. Analysis of Frequency Characteristics

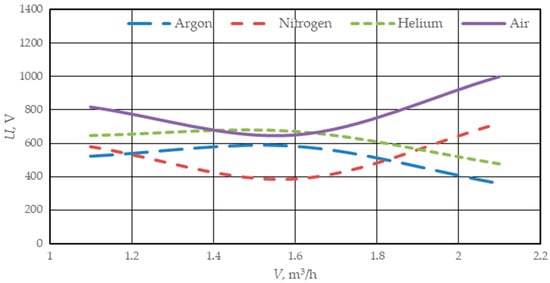

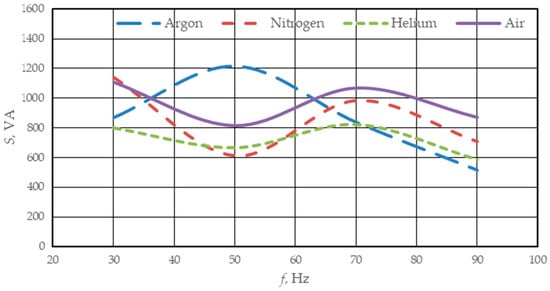

The characteristics of a three-phase plasma reactor can be shaped by changing the frequency of the voltage supplying the working electrodes. Changing the frequency of the voltage supplying the working electrodes of the plasma reactor affects the way the discharge develops. As a result of an increase in frequency, the duty cycle of the plasma reactor shortens and, consequently, the active area of plasma interaction decreases. Characteristics of changes in discharge power as a function of frequency changes are shown in Figure 13 and Figure 14. Measurements were made for the two values of gas volume flow rate of 1.1 m3/h and 2.1 m3/h. The voltage frequency was varied from 30 Hz to 90 Hz.

Figure 13.

Changes in discharge power as a function of voltage frequency for V = 1.1 m3/h.

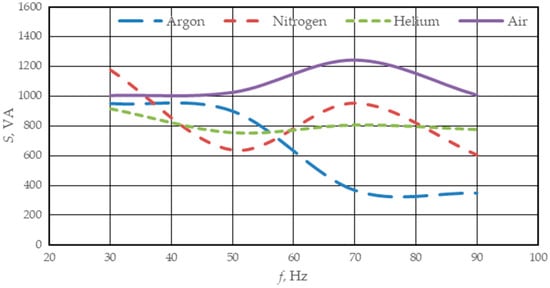

Figure 14.

Changes in discharge power as a function of voltage frequency for V = 2.1 m3/h.

At frequencies lower than 30 Hz, there is a significant extension in the plasma reactor cycle. The discharge gliding on the electrodes after reaching the end of the electrodes and stopping is not immediately extinguished, but develops into a long arc column. As a result, there is significant erosion in the ends of the electrodes and a long pause in the cyclic operation of the plasma reactor. Increasing the frequency of the supply voltage above 90 Hz results in a significant reduction in the duration of the reactor cycle and the restriction of the discharge area to a small space in the lower zone of the electrodes.

From the characteristics shown in Figure 13 and Figure 14, it can be seen that a change in the frequency of the arc voltage is associated with large changes and fluctuations in its power. These changes intensify with an increase in the volume flow of gases. The sources of these changes are changes in the current supplying the discharge and changes in its voltage. The smallest changes in the power of the electric discharge with changes in voltage frequency are observed for helium. The levels of change in the power of the discharge burning in helium are also slightly affected by the value of the gas volume flow.

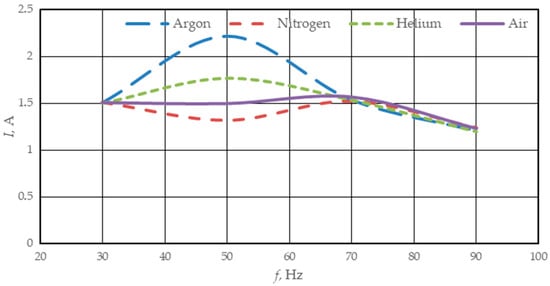

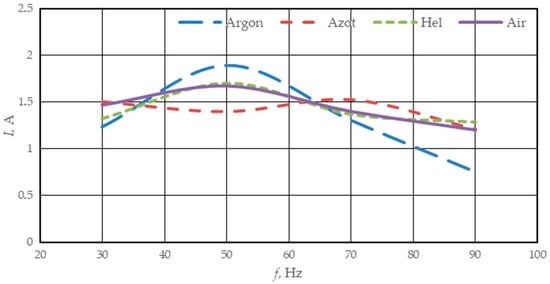

Figure 15 and Figure 16 show the changes in discharge current as a function of changes in arc voltage frequency. The largest changes in arc current with changes in arc voltage frequency occur for argon. For other gases, the ranges of current changes are similar to each other.

Figure 15.

Changes in arc current as a function of frequency for V = 1.1 m3/h.

Figure 16.

Changes in arc current as a function of frequency for V = 2.1 m3/h.

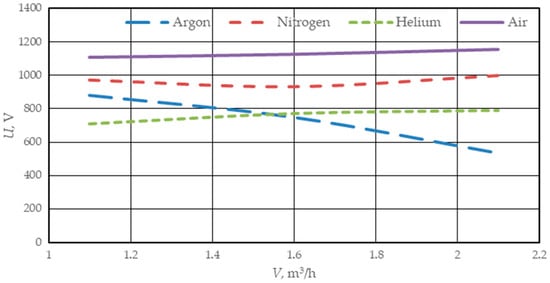

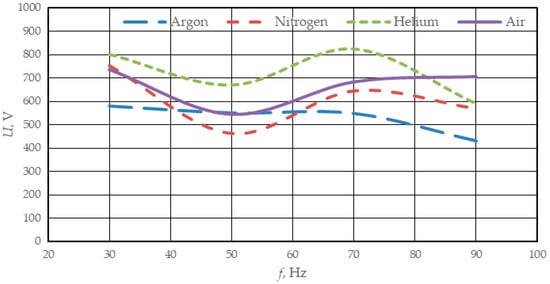

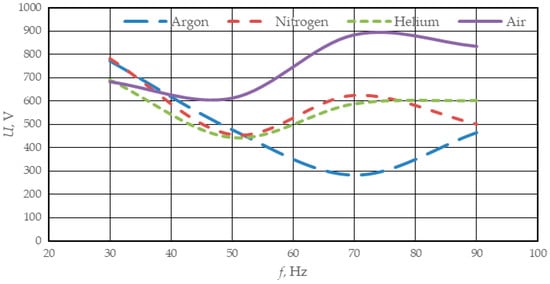

Changing the frequency of the reactor supply voltage involves large changes in the arc voltage. The courses of these changes are shown in Figure 17 and Figure 18.

Figure 17.

Changes in arc voltage as a function of frequency for V = 1.1 m3/h.

Figure 18.

Changes in arc voltage as a function of frequency for V = 2.1 m3/h.

From the obtained characteristics, it can be seen that for all plasma gases, the regulation of the discharge power in the plasma reactor by means of changes in the frequency of the supply voltage is not very effective. From the obtained characteristics, it is difficult to draw clear conclusions about the range of changes in discharge power with increasing voltage frequency. It is also difficult to assess the influence of the type of gas on the obtained characteristics. However, it should be borne in mind that during the experiments, the current supplying the electrodes of the plasma reactor was not kept constant. The changes in its value and the changes in the value of the current, which occur with a change in the voltage frequency, are the result of self-regulatory reactions in the plasma. The regulation of the discharge power could be effective if the arc current was under constant control, and its value maintained at a constant level.

Obtaining unambiguously analyzable frequency characteristics for the plasma gases used would allow a wide range of possibilities for shaping the plasma parameters in the reactor. This would raise the possibility of regulating the power of the discharge in the reactor, the temperature of the plasma, as well as the duration of the plasma reactor cycle and the volume of the plasma.

7. Conclusions

This paper analyzes the effect of plasma gas type on the operating characteristics of a three-phase gliding arc discharge plasma reactor. The control of plasma parameters is crucial for achieving the intended effects of the process conducted with its participation. The conducted studies show that gliding arc discharge plasma reactors are devices in which it is difficult to maintain stable plasma parameters electrically, physically and chemically. Control over the plasma parameters can be achieved by changing the geometry of the plasma reactor’s structural elements (electrodes, discharge chamber, gas inflow nozzle), the design and parameters of the electrical power supply system, and the physical and chemical parameters of the plasma-generating gases.

The conducted studies indicate that the performance characteristics of plasma reactors with gliding arc discharge, the stability of the burning discharge in them and the plasma generated by the process can be largely influenced by selecting the chemical composition and gas dynamic parameters of the plasma-generating gas. While making adjustments to the parameters of the process gas, it is necessary to have the parameters of the reactor’s power supply under control at the same time. Studies show strong correlations between the chemical and gas-dynamic parameters of plasma-generating gases and the electrical parameters of the arc discharge. Changing the power of the discharge while maintaining its other parameters raises the need to simultaneously adjust both the parameters of the electrical power supply and the parameters of the plasma-generating gas.

Of the gases considered, helium is the most desirable process gas for gliding arc discharge plasma reactors. This gas provides the most stable arc performance over the entire range of current control, supply voltage frequency and volume flows used. For helium, the most linear operating characteristics of the plasma reactor are also obtained. Argon does not perform much worse in this respect. Argon, as a plasma-generating gas, provides the widest range of control of the arc current and therefore its temperature. Arc burning in nitrogen and air is difficult in terms of controlling the parameters. The operating characteristics of the plasma reactor obtained for these gases are strongly nonlinear, and the range of arc current control is very narrow. Strongly nonlinear frequency characteristics of burning arcs were obtained for all analyzed gases. The nonlinearity of these characteristics can make it much more difficult to regulate the plasma volume by varying the frequency of the voltage supplying the reactor.

The conducted research shows that the development of a method for controlling plasma parameters in plasma reactors with gliding arc discharge is a complex and multithreaded problem. Despite the strong nonlinearities in the operating characteristics of the plasma reactor, the unpredictability of the arc behavior and the large number of influencing factors, it is possible to fully control the plasma parameters. This control must be based on knowledge of the operating characteristics of the plasma reactor, taking into account the simultaneous control of the parameters of the supply of electricity to the reactor, as well as the parameters of the supply of plasma gases.

Author Contributions

Conceptualization, G.K., H.D.S. and O.B.; methodology, G.K. and O.B.; validation, G.K., H.D.S. and O.B.; formal analysis, G.K.; investigation, G.K., H.D.S. and O.B.; resources, G.K. and H.D.S.; data curation, G.K. and O.B.; writing—original draft preparation, G.K. and H.D.S.; writing—review and editing, G.K. and O.B.; visualization, G.K.; supervision, G.K. and H.D.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Lublin University of Technology grants numbers FD 20/EE-2/416, FD-20/EE-2/406 FD-20/EE-2/401 and 5/GnG/2022 intended for research activities within the “Automatics, Electronics and Electrical Engineering” scientific discipline.

Data Availability Statement

The original contributions presented in the study are included in the article. The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bhuiyan, S.I.; Wang, K.; Baky, M.A.H.; Kraus, J.; Jemison, H.; Staack, D. Controlling Parameters in the Efficiency of Hydrogen Production via Electrification with Multi-Phase Plasma Processing Technology. Energies 2023, 16, 5509. [Google Scholar] [CrossRef]

- Johnson, M.J.; Brown, G.H.; Boris, D.R.; Petrova, T.B.; Walton, S.G. Two Atmospheric Pressure Plasma Jets Driven by Phase-Shifted Voltages: A Method to Control Plasma Properties at the Plasma–Surface Interface. IEEE Trans. Plasma Sci. 2022, 50, 2961–2971. [Google Scholar] [CrossRef]

- Titov, E.; Bodrikov, I.; Titov, D. Control of the Energy Impact of Electric Discharges in a Liquid Phase. Energies 2023, 16, 1683. [Google Scholar] [CrossRef]

- Tachibana, K.; Hanabata, R.; Furuki, T.; Ichiki, R.; Kanazawa, S.; Kocik, M. Development and Evaluation of Newly Designed Coaxial Cylindrical Plasma Reactor with Liquid Flow Control and Post-Discharge Reactions for Water Treatment. Energies 2022, 15, 4028. [Google Scholar] [CrossRef]

- Wang, B.; Yan, X.; Xiong, Z. Temperature Control Strategies of Atmospheric Plasma Jet for Tissue Treatment. IEEE Trans. Radiat. Plasma Med. Sci. 2024, 8, 105–112. [Google Scholar] [CrossRef]

- Domonkos, M.; Tichá, P.; Trejbal, J.; Demo, P. Applications of Cold Atmospheric Pressure Plasma Technology in Medicine, Agriculture and Food Industry. Appl. Sci. 2021, 11, 4809. [Google Scholar] [CrossRef]

- Hnatiuc, E.; Astanei, D.; Ursache, M.; Hnatiuc, B.J.-L.; Brisset, J.-L. review over the cold plasma reactors and their applications. In Proceedings of the 2012 International Conference and Exposition on Electrical and Power Engineering, Iasi, Romania, 25–27 October 2012; pp. 497–502. [Google Scholar] [CrossRef]

- Stryczewska, H.D.; Stępień, M.A.; Boiko, O. Plasma and Superconductivity for the Sustainable Development of Energy and the Environment. Energies 2022, 15, 4092. [Google Scholar] [CrossRef]

- Ren, Y.; Li, X.; Lu, S.; Yan, J. Solid Hazardous Waste Treatment and Material Modification by Vortex Gliding Arc Plasma. IEEE Trans. Plasma Sci. 2014, 42, 2750–2751. [Google Scholar] [CrossRef]

- Gong, X.; Lin, Y.; Li, X.; Wu, A.; Zhang, H.; Yan, J.; Du, C. Decomposition of volatile organic compounds using gliding arc discharge plasma. J. Air Waste Manag. Assoc. 2020, 70, 138–157. [Google Scholar] [CrossRef]

- Yang, G.; Shao, Z.; Cao, Y.; Wang, D.; Fu, J. Research of the treatment of flue gas desulfurization by gliding arc discharge plasma in thermal power plants. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016. [Google Scholar] [CrossRef]

- Yamamoto, I.; Yamamoto, K.; Shimizu, K.; Fujiyama, Y.; Tsunoda, K.; Mizuno, A. Wet type plasma reactor for incinerator. In Proceedings of the Conference Record of 1998 IEEE Industry Applications Conference. Thirty-Third IAS Annual Meeting (Cat. No.98CH36242), St. Louis, MO, USA, 12–15 October 1998; Volume 3, pp. 1861–1864. [Google Scholar] [CrossRef]

- Gururani, P.; Bhatnagar, P.; Bisht, B.; Kumar, V.; Joshi, N.C.; Tomar, M.S.; Pathak, B. Cold plasma technology: Advanced and sustainable approach for wastewater treatment. Environ. Sci. Pollut. Res. 2021, 28, 65062–65082. [Google Scholar] [CrossRef]

- Li, D.; Wang, C.; Lu, Z.; Song, M.; Xia, W.; Xia, W. Synthesis of graphene flakes using a non-thermal plasma based on magnetically stabilized gliding arc discharge. Fullerenes. Nanotub. Carbon Nanostructures 2020, 28, 846–856. [Google Scholar] [CrossRef]

- Xintong Ma, X.; Sirui Li, S.; Rohit Chaudhary, R.; Volker Hessel, V.; Fausto Gallucci, F. Carbon Nanosheets Synthesis in a Gliding Arc Reactor: On the Reaction Routes and Process Parameters. Plasma Chem. Plasma Process. 2021, 41, 191–209. [Google Scholar]

- Gospodinova, D.; Neznakomova, M.; Shopov, M.; Dineff, P. Atmospheric Plasma Surface Treatment of Polyester Nonwoven Lightweight Fabrics for Apparel, Advertising and Shopping Bags. In Proceedings of the 15th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 16–19 September 2023; pp. 1–6. [Google Scholar]

- Kusano, Y.; Zhu, J.J.; Ehn, A.; Li, Z.S.; Aldén, M.; Salewski, M.; Leipold, F.; Bardenshtein, A.; Krebs, N. Observation of gliding arc surface treatment. Surf. Eng. 2015, 31, 282–288. [Google Scholar] [CrossRef]

- Laroussi, M.; Bekeschus, S.; Keidar, M.; Bogaerts, A.; Fridman, A.; Lu, X.; Ostrikov, K.; Hori, M.; Stapelmann, K.; Miller, V.; et al. Low-temperature plasma for biology, hygiene, and medicine: Perspective and roadmap. IEEE Trans. Radiat. Plasma Med. Sci. 2022, 6, 127–157. [Google Scholar] [CrossRef]

- Kazemi, A.; Nicol, M.J.; Bilén, S.G.; Kirimanjeswara, G.S.; Knecht, S.D. Cold Atmospheric Plasma Medicine: Applications, Challenges, and Opportunities for Predictive Control. Plasma 2024, 7, 233–257. [Google Scholar] [CrossRef]

- Lata, S.; Chakravorty, S.; Mitra, T.; Pradhan, P.K.; Mohanty, S.; Patel, P.; Jha, E.; Panda, P.K.; Verma, S.K.; Suar, M. Aurora Borealis in dentistry: The applications of cold plasma in biomedicine. Mater. Today Bio 2022, 13, 100200. [Google Scholar] [CrossRef] [PubMed]

- Stryczewska, H.D.; Boiko, O. Applications of Plasma Produced with Electrical Discharges in Gases for Agriculture and Biomedicine. Appl. Sci. 2022, 12, 4405. [Google Scholar] [CrossRef]

- Sakudo, A.; Yagyu, Y.; Onodera, T. Disinfection and Sterilization Using Plasma Technology: Fundamentals and Future Perspectives for Biological Applications. Int. J. Mol. Sci. 2019, 20, 5216. [Google Scholar] [CrossRef] [PubMed]

- Bo, Z.; Yan, J.H.; Li, X.D.; Chi, Y.; Chéron, B.; Cen, K.F. The Dependence of Gliding Arc Gas Discharge Characteristics on Reactor Geometrical Configuration. Plasma Chem. Plasma Process. 2007, 27, 691–700. [Google Scholar] [CrossRef]

- Ananthanarasimhan, J.; Lakshminarayana, R.; Anand, M.S.; Dasappa, S. Influence of gas dynamics on arc dynamics and the discharge power of a rotating gliding arc. Plasma Sources Sci. Technol. 2019, 28, 8. [Google Scholar] [CrossRef]

- Kong, C.; Gao, J.; Ehn, A.; Aldén, M.; Li, Z. Understanding the characteristics of non-equilibrium alternating current gliding arc discharge in a variety of gas mixtures (air, N2, Ar, Ar/O2, and Ar/CH4) at elevated pressures (1–5 atm). Phys. Plasmas 2022, 29, 033502. [Google Scholar] [CrossRef]

- El-Zein, A.; Talaat, M.; El-Aragi, G.; El-Amawy, A. Electrical Characteristics of Nonthermal Gliding Arc Discharge Reactor in Argon and Nitrogen Gases. IEEE Trans. Plasma Sci. 2016, 44, 1155–1159. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, F.; Tu, X.; Bo, Z.; Cen, K.; Li, X. Characteristics of Atmospheric Pressure Rotating Gliding Arc Plasmas. Plasma Sci. Technol. 2016, 18, 5. [Google Scholar] [CrossRef]

- Sagas, J.C.; Neto, A.H.; Pereira Filho, A.C.; Maciel, H.S.; Lacava, P.T. Basic Characteristics of Gliding-Arc Discharges in Air and Natural Gas. IEEE Trans. Plasma Sci. 2011, 39, 775–780. [Google Scholar] [CrossRef]

- Sun, S.R.; Kolev, S.; Wang, H.X.; Bogaerts, A.A. Coupled gas flow-plasma model for a gliding arc: Investigations of the back-breakdown phenomenon and its effect on the gliding arc characteristics. Plasma Sources Sci. Technol. 2016, 26, 1. [Google Scholar] [CrossRef]

- Taylor, K.J.; Yun, S.; Tynan, G.R. Control of plasma parameters by using noble gas admixtures. J. Vac. Sci. Technol. A 2004, 22, 2131–2138. [Google Scholar] [CrossRef]

- Murphy, A.B. Thermal plasmas in gas mixtures. J. Phys. D Appl. Phys. 2001, 34, 20. [Google Scholar] [CrossRef]

- Xu, W.; Van Alphen, S.; Galvita, V.V.; Meynen, V.; Bogaerts, A. Effect of Gas Composition on Temperature and CO2 Conversion in a Gliding Arc Plasmatron reactor: Insights for Post-Plasma Catalysis from Experiments and Computation. ChemSusChem 2024, e202400169. [Google Scholar] [CrossRef] [PubMed]

- Bolouki, N.; Kuan, W.-H.; Huang, Y.-Y.; Hsieh, J.-H. Characterizations of a Plasma-Water System Generated by Repetitive Microsecond Pulsed Discharge with Air, Nitrogen, Oxygen, and Argon Gases Species. Appl. Sci. 2021, 11, 6158. [Google Scholar] [CrossRef]

- Lamichhane, P.; Acharya, T.R.; Kaushik, N.; Nguyen, L.N.; Lim, J.S.; Hessel, V.; Kaushik, N.K.; Choi, E.H. Non-thermal argon plasma jets of various lengths for selective reactive oxygen and nitrogen species production. J. Environ. Chem. Eng. 2022, 10, 107782. [Google Scholar] [CrossRef]

- Martusevich, A.K.; Surovegina, A.V.; Bocharin, I.V.; Nazarov, V.V.; Minenko, I.A.; Artamonov, M.Y. Cold Argon Athmospheric Plasma for Biomedicine: Biological Effects, Applications and Possibilities. Antioxidants 2022, 11, 1262. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, A.; Parvinzadeh Gashti, M.; Mirjalili, M.; Parsania, M. Argon and Argon–Oxygen Plasma Surface Modification of Gelatin Nanofibers for Tissue Engineering Applications. Membranes 2021, 11, 31. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Zhang, C.; Zhu, W.; Lu, X.; Shao, T. Ionization waves in nanosecond pulsed atmospheric pressure plasma jets in argon. High Volt. 2021, 6, 665–673. [Google Scholar] [CrossRef]

- Khomutova, U.V.; Korzhova, A.G.; Bryuzgina, A.A.; Laput, O.A.; Vasenina, I.V.; Akhmadeev, Y.H.; Shugurov, V.V.; Azhazha, I.I.; Shapovalova, Y.G.; Chernyavskii, A.V.; et al. Nitrogen Plasma Treatment of Composite Materials Based on Polylactic Acid and Hydroxyapatite. Polymers 2024, 16, 627. [Google Scholar] [CrossRef]

- Laput, O.A.; Vasenina, I.V.; Korzhova, A.G.; Bryuzgina, A.A.; Khomutova, U.V.; Tuyakova, S.G.; Akhmadeev, Y.H.; Shugurov, V.V.; Bolbasov, E.N.; Tverdokhlebov, S.I.; et al. Effect of Nitrogen Arc Discharge Plasma Treatment on Physicochemical Properties and Biocompatibility of PLA-Based Scaffolds. Polymers 2023, 15, 3381. [Google Scholar] [CrossRef] [PubMed]

- Murphy, A.B. Transport coefficients of helium and argon-helium plasmas. IEEE Trans. Plasma Sci. 1997, 25, 809–814. [Google Scholar] [CrossRef]

- Jonkers, J.; Van Der Mullen, J.A.M. The excitation temperature in (helium) plasmas. J. Quant. Spectrosc. Radiat. Transf. 1999, 61, 703–709. [Google Scholar] [CrossRef]

- Shkodra, B.; Demelash Abera, B.; Cantarella, G.; Douaki, A.; Avancini, E.; Petti, L.; Lugli, P. Flexible and Printed Electrochemical Immunosensor Coated with Oxygen Plasma Treated SWCNTs for Histamine Detection. Biosensors 2020, 10, 35. [Google Scholar] [CrossRef] [PubMed]

- Vesel, A.; Primc, G.; Zaplotnik, R.; Mozetič, M. Applications of highly non-equilibrium low-pressure oxygen plasma for treatment of polymers and polymer composites on an industrial scale. Plasma Phys. Control. Fusion 2020, 62, 2. [Google Scholar] [CrossRef]

- Kumagai, F.; Gotoh, K.; Miyamoto, S.; Kato, S.; Kutsukake, K.; Usami, N.; Kurokawa, Y. Bayesian optimization of hydrogen plasma treatment in silicon quantum dot multilayer and application to solar cells. Discov. Nano 2023, 18, 43. [Google Scholar] [CrossRef]

- Babichuk, I.S.; Semenenko, M.O.; Caballero, R.; Hladkovskyi, V.V.; Datsenko, O.I.; Yeshchenko, O.A.; Babichuk, I.V.; Lin, C.; Qiu, Y.; Redko, R.A.; et al. Influence of hydrogen plasma treatment on secondary phases in CZTS thin films for energy harvesting. Mater. Today Commun. 2021, 28, 102664. [Google Scholar] [CrossRef]

- Luo, L.; Chen, Y.; Zhou, M.; Shan, X.; Lu, J.; Zhao, X. Progress update on extending the durability of air plasma sprayed thermal barrier coatings. Ceram. Int. 2022, 48, 18021–18034. [Google Scholar] [CrossRef]

- Guo, P.; Liu, Y.; Li, J.; Zhang, N.; Zhou, M.; Li, Y.; Zhao, G.; Wang, N.; Wang, A.; Wang, Y.; et al. A novel atmospheric-pressure air plasma jet for wound healing. Int. Wound J. 2022, 19, 538–552. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.W.; Zhu, J.J.; Li, Z.S.; Aldén, M.; Leipold, F.; Salewski, M.; Kusano, Y. Optical diagnostics of a gliding arc. Opt. Express 2013, 21, 6028–6044. [Google Scholar] [CrossRef] [PubMed]

- Hao Zhang, H.; Zhu, F.; Li, X.; Du, C. Dynamic behavior of a rotating gliding arc plasma in nitrogen: Effects of gas flow rate and operating current. Plasma Sci. Technol. 2017, 19, 4. [Google Scholar] [CrossRef]

- Kusano, Y.; Salewski, M.; Leipold, F.; Zhu, J.; Ehn, A.; Li, Z.; Aldén, M. Stability of alternating current gliding arcs. Eur. Phys. J. D 2014, 68, 319. [Google Scholar] [CrossRef]

- Fridman, A.; Nester, S.; Kennedy, L.A.; Saveliev, A.; Mutaf-Yardimci, O. Gliding arc gas discharge. Prog. Energy Combust. Sci. 1999, 25, 211–231. [Google Scholar] [CrossRef]

- Mitsugi, F.; Furukawa, J.; Ohshima, T.; Kawasaki, H.; Kawasaki, T.; Aoqui, S.I.; Stryczewska, H.D. Observation of dynamic behavior of gliding arc discharge. Eur. Phys. J. Appl. Phys. 2013, 61, 24308. [Google Scholar] [CrossRef]

- Korolev, Y.D.; Frants, O.B.; Geyman, V.G.; Landl, N.V.; Kasyanov, V.S. Low-Current “Gliding Arc” in an Air Flow. IEEE Trans. Plasma Sci. 2011, 39, 3319–3325. [Google Scholar] [CrossRef]

- Richard, F.; Cormier, J.M.; Pellerin, S.; Chapelle, J. Physical study of a gliding arc discharge. J. Appl. Phys. 1996, 79, 2245–2250. [Google Scholar] [CrossRef]

- Babich, I.L.; Veklich, A.N.; Kryachko, L.A.; Minakova, R.B.; Osidach, V.E. Parameters of free-burning arc discharge plasma in air with silver-based electrodes. J. Appl. Spectrosc. 2006, 73, 426–431. [Google Scholar] [CrossRef]

- Komarzyniec, G.; Aftyka, M. Analysis of Plasma Reactor Interaction with the Power Grid Depending on the Power Supply Design. Appl. Sci. 2023, 13, 2279. [Google Scholar] [CrossRef]

- Xia, W.; Fulcheri, L.; Gonzalez-Aguilar, J.; Li, H.; Gruenberger, T. Characterization of a 3-Phase a.c. Free Burning Arc Plasma. Plasma Sources Sci. Technol. 2006, 8, 156. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, N.; Wang, S.; Sun, G. Effect of Flow Rate on the Characteristics of Atmospheric-Pressure AC Constant-Current Powered Gliding Arc Discharge. IEEE Trans. Plasma Sci. 2012, 49, 3113–3120. [Google Scholar] [CrossRef]

- Stryczewska, H.D. Supply Systems of Non-Thermal Plasma Reactors. Construction Review with Examples of Applications. Appl. Sci. 2020, 10, 3242. [Google Scholar] [CrossRef]

- Komarzyniec, G.; Stryczewska, H.D.; Krupski, P. The Influence of the Architecture of the Power System on the Operational Parameters of the Glidarc Plasma Reactor. In Proceedings of the 2019 IEEE Pulsed Power & Plasma Science (PPPS), Orlando, FL, USA, 23–29 June 2019; pp. 1–4. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).