Economic Consequences Based on Reversible and Irreversible Degradation of PV Park in the Harsh Climate Conditions of Iraq

Abstract

1. Introduction

- Reporting on the most common failure issues of PV systems installed in harsh climates based on 8 years of operation and maintenance tickets.

- Implementation of a realistic degradation rate based on location, and far from manufacturer’s assumptions which is currently in force.

- Quantifying the economic implications of PV system components (i.e., PV modules and inverters) failure and soiling rates in harsh climates using Iraq as a case study.

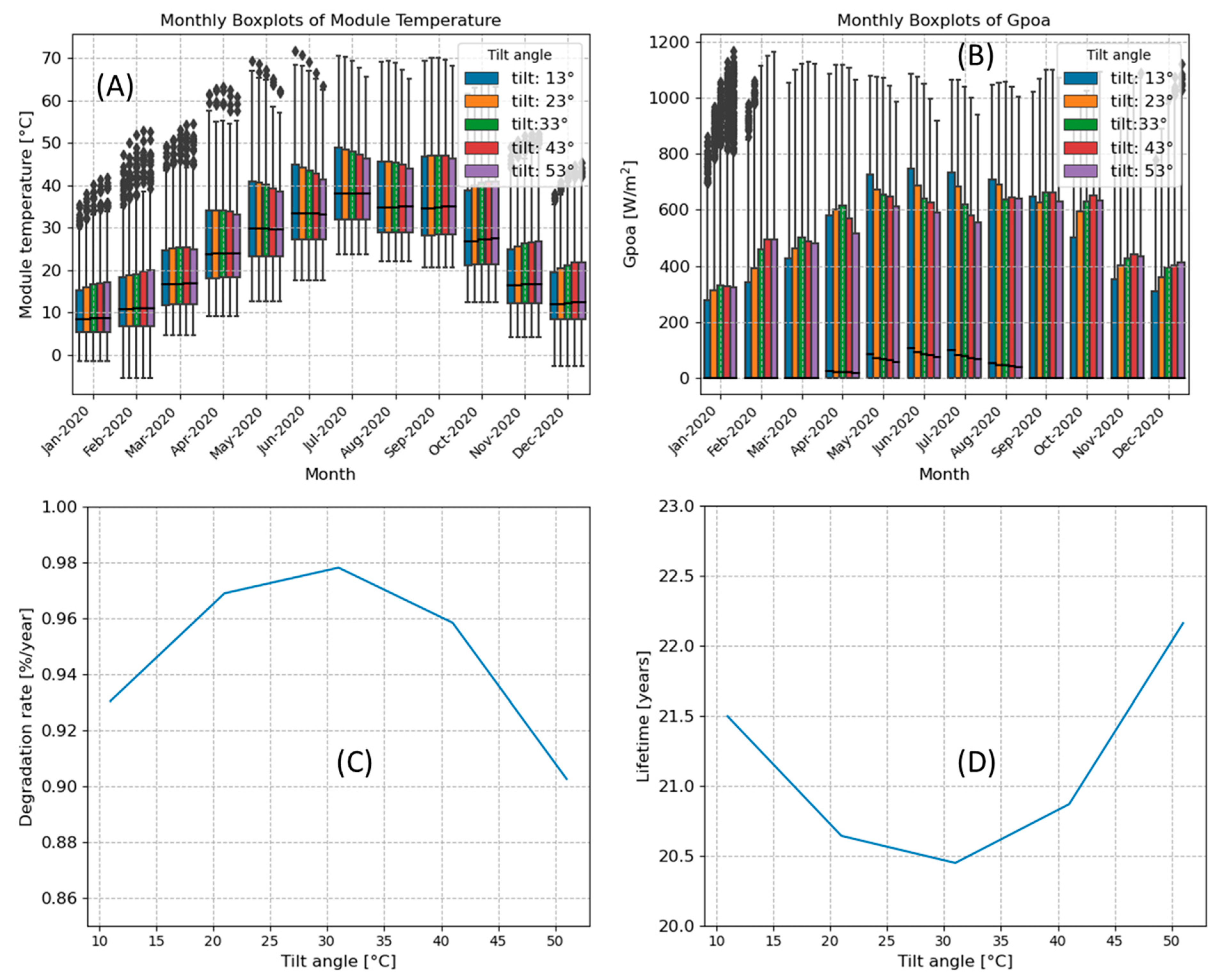

- Exploring the reliability and economic gain of optimal PV designs based on tilt angle to reduce soiling losses.

- Evaluating the most optimal cleaning strategy of PV plants in Iraq.

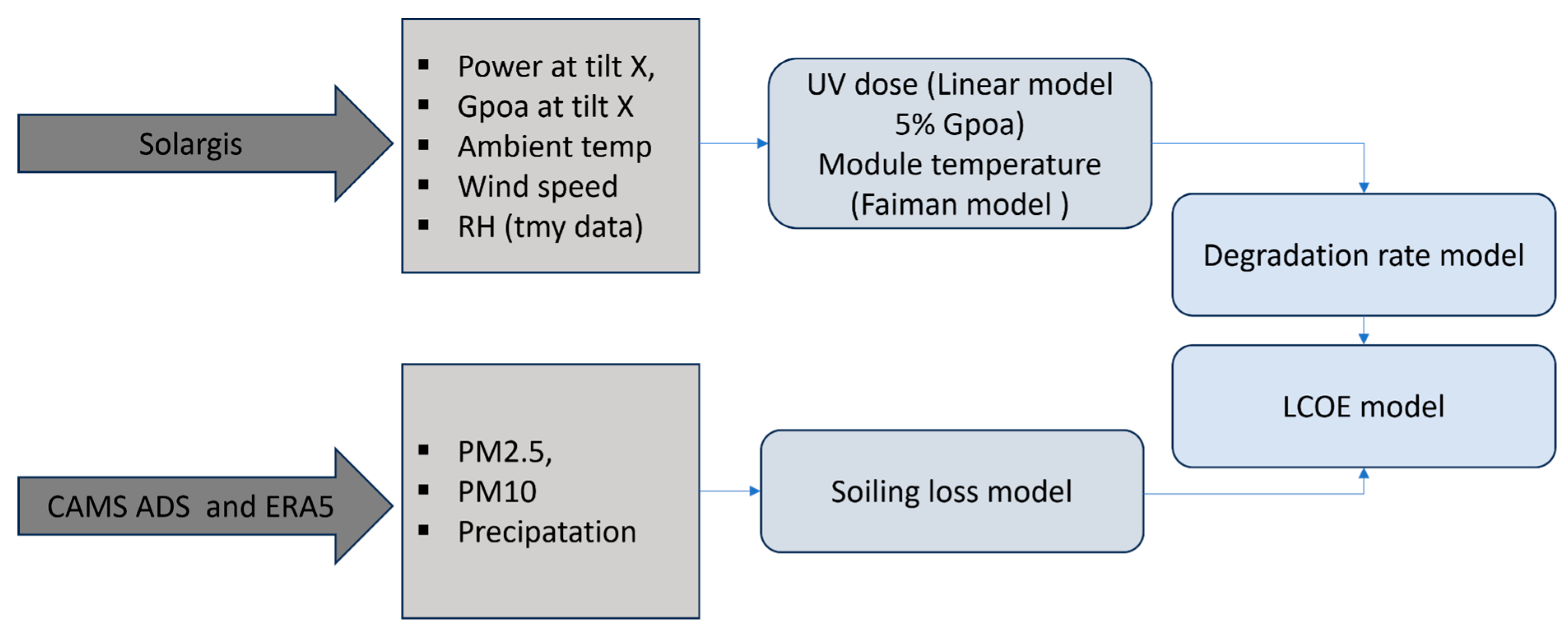

2. Methodology

2.1. Reversible and Irreversible Degradation Assessments of PV Systems in Iraq

2.1.1. Reversible Degradation Assessments

2.1.2. Irreversible Degradation Assessments

2.2. Data Used in This Study

2.3. Economic Analysis of PV Systems Installed in Iraq

2.4. Soiling Effect on LCOE

3. Results

3.1. Assessment of PV System Failure Modes and Severity Ranking

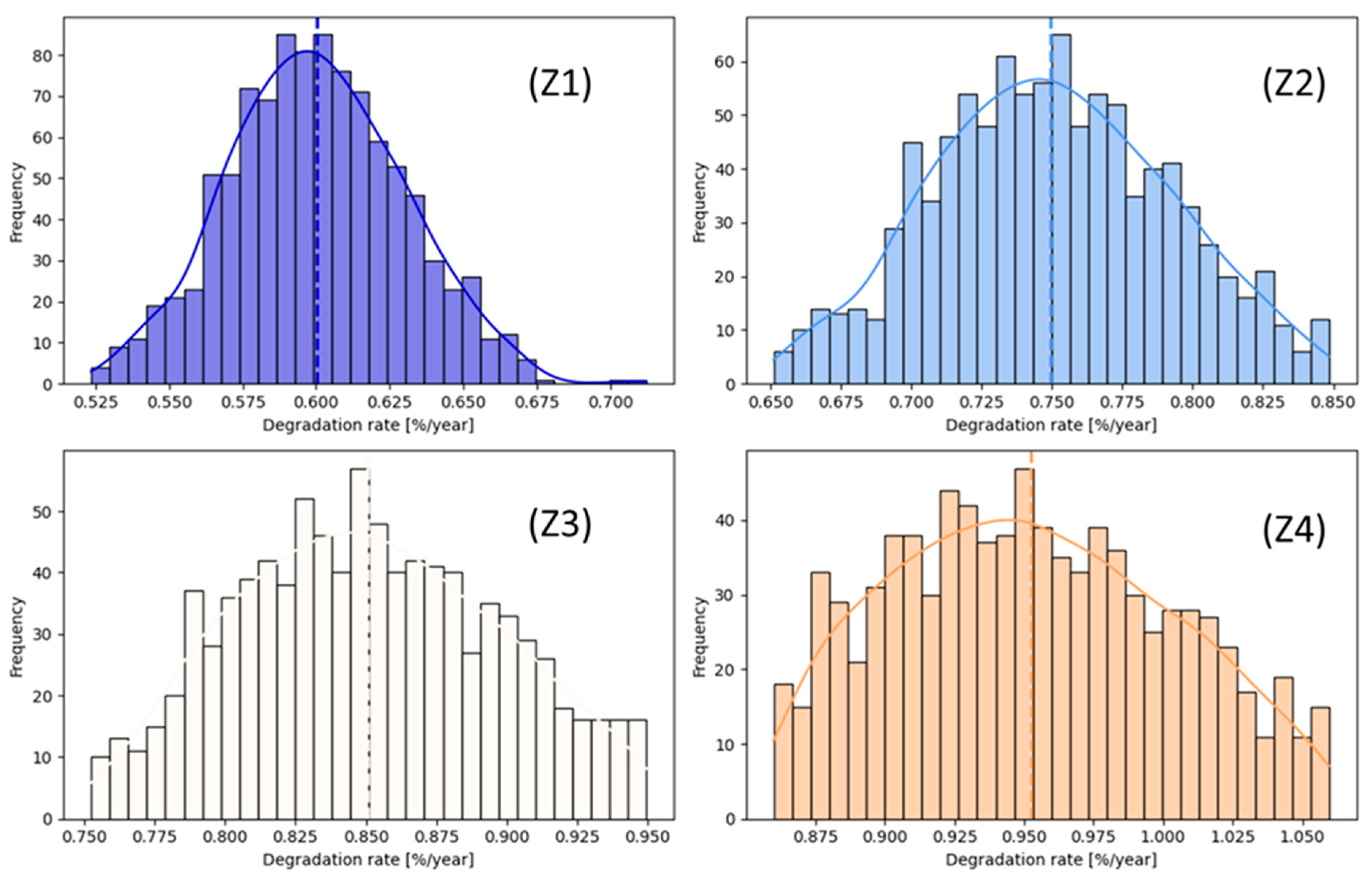

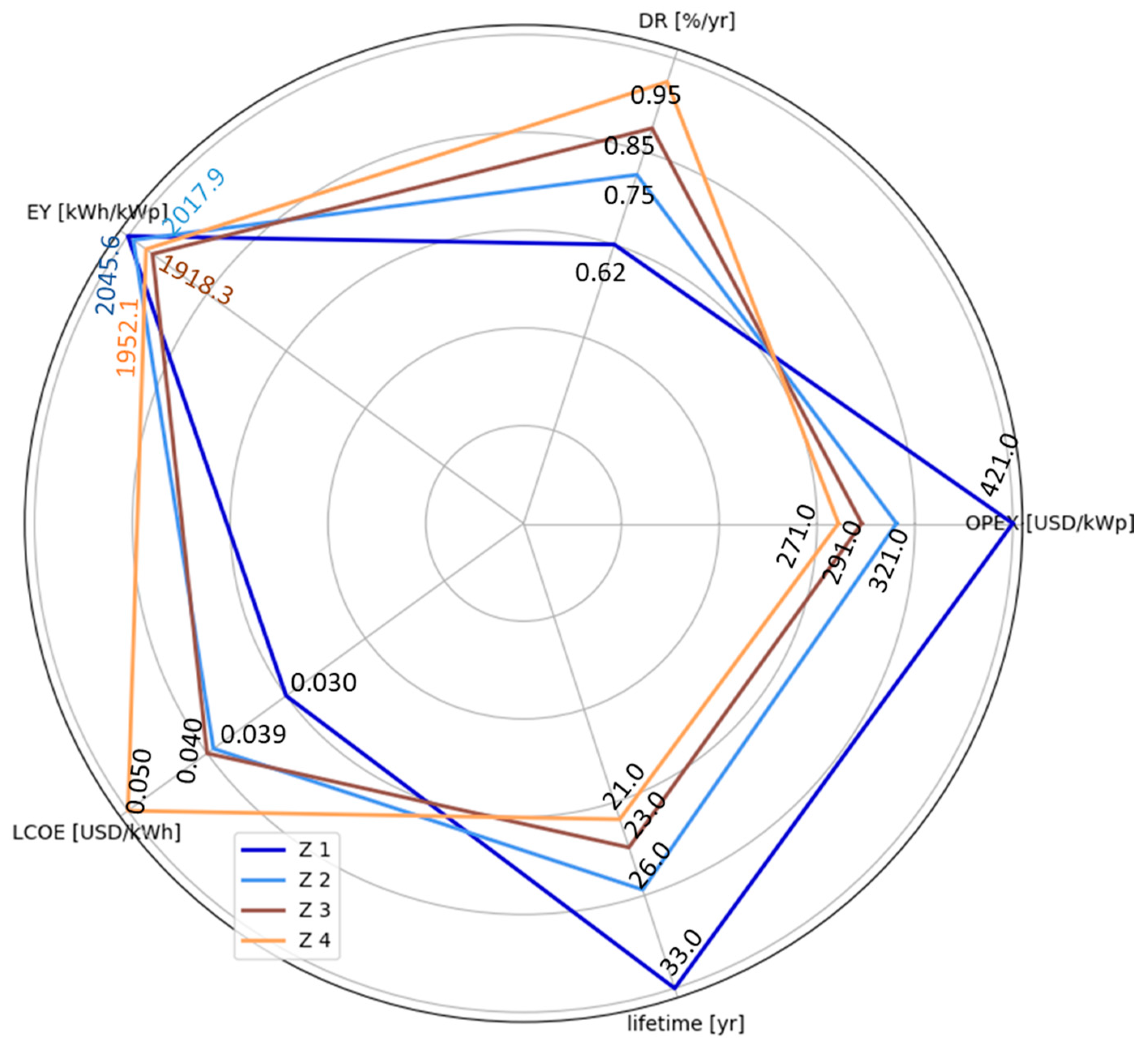

3.2. Assessing the Economic Impact of Degradation Rates

3.3. Economic Impact of Inverter Lifetime

3.4. Economic Impact of Soiling

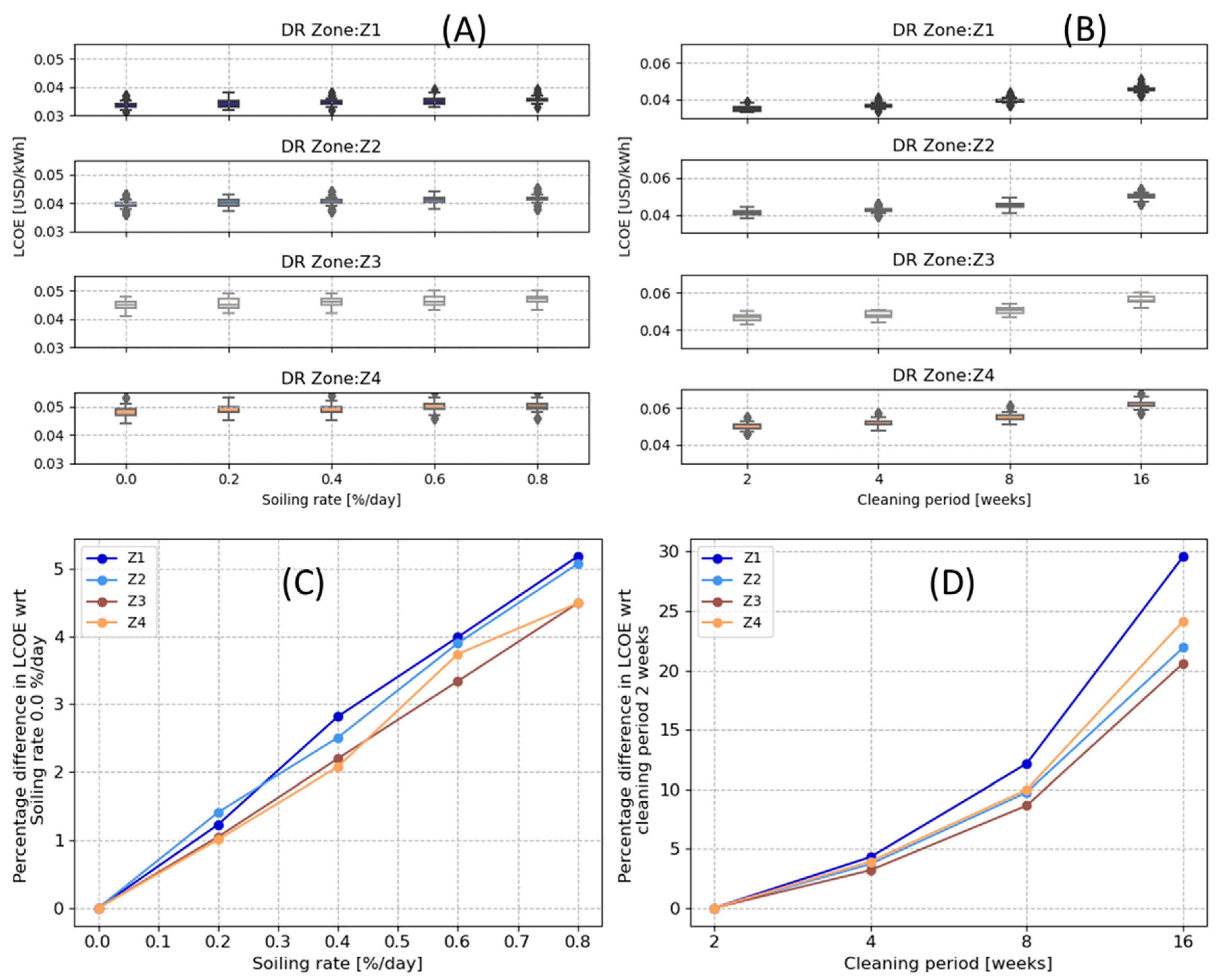

3.4.1. Soiling Rate Scenarios and Cleaning Schedule/Intervals

3.4.2. Evaluation of the Optimization Strategy to Reduce Economic Losses Due to Soiling

3.4.3. Evaluation of the Optimal Cleaning Strategy/Method in Desert Climates

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Istepanian, H. Solar Energy in Iraq from Outset to Offset. Iraq Energy Institute. Available online: https://iraqenergy.org/2018/10/18/solar-energy-in-iraq-from-outset-to-offset/ (accessed on 14 May 2024).

- International Monetary Fund. Middle East and Central Asia Dept. The Fiscal Cost of Iraq’s Electricity Sector and Potential Gains from Reform. IMF Staff Ctry. Rep. 2023, 2023, 14–25. [Google Scholar] [CrossRef]

- Al-Khafaji, H. Electricity Generation in Iraq … Problems and Solutions|Al-Bayan Center. Available online: https://www.bayancenter.org/en/2018/09/1694/ (accessed on 4 November 2023).

- Al-Douri, Y.; Abed, F.M. Solar energy status in Iraq: Abundant or not—Steps forward. J. Renew. Sustain. Energy 2016, 8, 025905. [Google Scholar] [CrossRef]

- IEA. Iraq’s Energy Sector: A Roadmap to a Brighter Future—Analysis. Available online: https://www.iea.org/reports/iraqs-energy-sector-a-roadmap-to-a-brighter-future (accessed on 10 July 2023).

- Hameed, M.A.; Kaaya, I.; Al-Jbori, M.; Matti, Q.; Scheer, R.; Gottschalg, R. Analysis and Prediction of the Performance and Reliability of PV Modules installed in harsh climates: Case study Iraq. Renew. Energy 2024, 228, 120577. [Google Scholar] [CrossRef]

- Hameed, M.A.; Alias, D.Q.M.; Obeid, A.S. Performance Evaluation and Simulation of ON-GRID PV Plant in Baghdad-Iraq. Int. J. Sci. Res. (IJSR) 2020, 10, 1310–1313. [Google Scholar]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates—An Analytical Review. Prog. Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- Dubey, R.; Chattopadhyay, S.; Kuthanazhi, V.; Kottantharayil, A.; Singh Solanki, C.; Arora, B.M.; Narasimhan, K.L.; Vasi, J.; Bora, B.; Singh, Y.K.; et al. Comprehensive study of performance degradation of field-mounted photovoltaic modules in India. Energy Sci. Eng. 2017, 5, 51–64. [Google Scholar] [CrossRef]

- Nobre, A.M.; Karthik, S.; Liew, W.Y.; Baker, R.; Malhotra, R.; Khor, A. Performance Evaluation of a Fleet of Photovoltaic Systems Across India and Southeast Asia. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 1372–1376. [Google Scholar] [CrossRef]

- Ascencio-Vásquez, J.; Kaaya, I.; Brecl, K.; Weiss, K.-A.; Topič, M. Global Climate Data Processing and Mapping of Degradation Mechanisms and Degradation Rates of PV Modules. Energies 2019, 12, 4749. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

- Figgis, B.; Ennaoui, A.; Ahzi, S.; Rémond, Y. Review of PV soiling particle mechanics in desert environments. Renew. Sustain. Energy Rev. 2017, 76, 872–881. [Google Scholar] [CrossRef]

- Cordero, R.R.; Damiani, A.; Laroze, D.; Macdonell, S.; Jorquera, J.; Sepúlveda, E.; Feron, S.; Llanillo, P.; Labbe, F.; Carrasco, J.; et al. Effects of soiling on photovoltaic (PV) modules in the Atacama Desert. Sci. Rep. 2018, 8, 1. [Google Scholar] [CrossRef]

- Shenouda, R.; Abd-Elhady, M.S.; Kandil, H.A. A review of dust accumulation on PV panels in the MENA and the Far East regions. J. Eng. Appl. Sci. 2022, 69, 8. [Google Scholar] [CrossRef]

- Jordan, D.C.; Silverman, T.J.; Wohlgemuth, J.H.; Kurtz, S.R.; VanSant, K.T. Photovoltaic failure and degradation modes. Prog. Photovolt. Res. Appl. 2017, 25, 318–326. [Google Scholar] [CrossRef]

- Tjengdrawira, C. Review and Gap Analyses of Technical Assumptions in PV Electricity Cost, Report on Current Practices in How Technical Assumptions Are Accounted in PV Investment Cost Calculation; TUV Rheinland: Hong Kong, China, 2016. [Google Scholar]

- Moser, D.; Lindig, S.; Richter, M. Uncertainty in Yield Assessments and PV LCOE; Technical Report 978-3-907281-06-2; International Energy Agency (IEA): Paris, France, 2020. [Google Scholar]

- Libra, M.; Mrázek, D.; Tyukhov, I.; Severová, L.; Poulek, V.; Mach, J.; Šubrt, T.; Beránek, V.; Svoboda, R.; Sedláček, J. Reduced real lifetime of PV panels—Economic consequences. Sol. Energy 2023, 259, 229–234. [Google Scholar] [CrossRef]

- Lindahl, J.; Lingfors, D.; Elmqvist, Å.; Mignon, I. Economic analysis of the early market of centralized photovoltaic parks in Sweden. Renew. Energy 2022, 185, 1192–1208. [Google Scholar] [CrossRef]

- Ali, F.; Ahmar, M.; Jiang, Y.; AlAhmad, M. A techno-economic assessment of hybrid energy systems in rural Pakistan. Energy 2021, 215, 119103. [Google Scholar] [CrossRef]

- Theristis, M.; Stein, J.S.; Deline, C.; Jordan, D.; Robinson, C.; Sekulic, W.; Anderberg, A.; Colvin, D.J.; Walters, J.; Seigneur, H.; et al. Onymous early-life performance degradation analysis of recent photovoltaic module technologies. Prog. Photovolt. Res. Appl. 2023, 31, 149–160. [Google Scholar] [CrossRef]

- Jordan, D.C.; Anderson, K.; Perry, K.; Muller, M.; Deceglie, M.; White, R.; Deline, C. Photovoltaic fleet degradation insights. Prog. Photovolt. Res. Appl. 2022, 30, 1166–1175. [Google Scholar] [CrossRef]

- Lindig, S.; Ascencio-Vásquez, J.; Leloux, J.; Moser, D.; Reinders, A. Performance Analysis and Degradation of a Large Fleet of PV Systems. IEEE J. Photovolt. 2021, 11, 1312–1318. [Google Scholar] [CrossRef]

- Gunda, T. Inverter Faults & Failures: Common Modes & Patterns. Sandia National Lab. (SNL-NM), Albuquerque, NM (United States), SAND2020-2323C. February 2020. Available online: https://www.osti.gov/biblio/1767382 (accessed on 15 December 2023).

- Cheng, J.; Tang, Y.; Yu, M. The reliability of solar energy generating system with inverters in series under common cause failure. Appl. Math. Model. 2019, 68, 509–522. [Google Scholar] [CrossRef]

- Bower, W. Inverters—Critical Photovoltaic Balance-of-System Components: Status, Issues Perspectives, and New-Millennium Opportunities. Prog. Photovolt. Res. Appl. 1999, 8, 113–126. Available online: https://www.osti.gov/biblio/7452 (accessed on 24 December 2023). [CrossRef]

- Ilse, K.; Micheli, L.; Figgis, B.W.; Lange, K.; Daßler, D.; Hanifi, H.; Wolfertstetter, F.; Naumann, V.; Hagendorf, C.; Gottschalg, R.; et al. Techno-Economic Assessment of Soiling Losses and Mitigation Strategies for Solar Power Generation. Joule 2019, 3, 2303–2321. [Google Scholar] [CrossRef]

- Javed, W.; Guo, B.; Figgis, B. Modeling of photovoltaic soiling loss as a function of environmental variables. Sol. Energy 2017, 157, 397–407. [Google Scholar] [CrossRef]

- Aghaei, M.; Fairbrother, A.; Gok, A.; Ahmad, S.; Kazim, S.; Lobato, K.; Oreski, G.; Reinders, A.H.M.E.; Schmitz, J.; Theelen, M.; et al. Review of degradation and failure phenomena in photovoltaic modules. Renew. Sustain. Energy Rev. 2022, 159, 112160. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R.; VanSant, K.; Newmiller, J. Compendium of photovoltaic degradation rates. Prog. Photovolt. Res. Appl. 2016, 24, 978–989. [Google Scholar] [CrossRef]

- Lelièvre, J.F.; Couderc, R.; Pinochet, N.; Sicot, L.; Munoz, D.; Kopecek, R.; Ferrada, P.; Marzo, A.; Olivares, D.; Valencia, F.; et al. Desert label development for improved reliability and durability of photovoltaic modules in harsh desert conditions. Sol. Energy Mater. Sol. Cells 2022, 236, 111508. [Google Scholar] [CrossRef]

- JRC Photovoltaic Geographical Information System (PVGIS)—European Commission. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/#TMY (accessed on 3 April 2023).

- Climate Reanalysis Copernicus. Available online: https://climate.copernicus.eu/climate-reanalysis (accessed on 30 January 2022).

- CAMS Global Reanalysis (EAC4). Available online: https://ads.atmosphere.copernicus.eu/cdsapp#!/dataset/cams-global-reanalysis-eac4?tab=overview (accessed on 21 January 2024).

- PVGIS Data Sources & Calculation Methods. Available online: https://joint-research-centre.ec.europa.eu/photovoltaic-geographical-information-system-pvgis/getting-started-pvgis/pvgis-data-sources-calculation-methods_en (accessed on 11 July 2023).

- Kimber, A.; Mitchell, L.; Nogradi, S.; Wenger, H. The Effect of Soiling on Large Grid-Connected Photovoltaic Systems in California and the Southwest Region of the United States. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conference, Waikoloa, HI, USA, 7–12 May 2006; pp. 2391–2395. [Google Scholar] [CrossRef]

- Coello, M.; Boyle, L. Simple Model for Predicting Time Series Soiling of Photovoltaic Panels. IEEE J. Photovolt. 2019, 9, 1382–1387. [Google Scholar] [CrossRef]

- Holmgren, W.F.; Hansen, C.W.; Mikofski, M.A. pvlib python: A python package for modeling solar energy systems. J. Open Source Softw. 2018, 3, 884. [Google Scholar] [CrossRef]

- Bessa, J.G.; Micheli, L.; Almonacid, F.; Fernández, E.F. Monitoring photovoltaic soiling: Assessment, challenges, and perspectives of current and potential strategies. iScience 2021, 24, 102165. [Google Scholar] [CrossRef]

- Micheli, L.; Almonacid, F.; Bessa, J.G.; Fernández-Solas, Á.; Fernández, E.F. The impact of extreme dust storms on the national photovoltaic energy supply. Sustain. Energy Technol. Assess. 2024, 62, 103607. [Google Scholar] [CrossRef]

- Faiman, D. Assessing the outdoor operating temperature of photovoltaic modules. Prog. Photovolt. Res. Appl. 2008, 16, 307–315. [Google Scholar] [CrossRef]

- Koehl, M.; Heck, M.; Wiesmeier, S.; Wirth, J. Modeling of the nominal operating cell temperature based on outdoor weathering. Sol. Energy Mater. Sol. Cells 2011, 95, 1638–1646. [Google Scholar] [CrossRef]

- Kaaya, I.; Köhl, M.; Mehilli, A.; de Cardona Mariano, S.; Weiss, K.A. Modeling Outdoor Service Lifetime Prediction of PV Modules: Effects of Combined Climatic Stressors on PV Module Power Degradation. IEEE J. Photovolt. 2019, 9, 1105–1112. [Google Scholar] [CrossRef]

- Weiß, K.-A.; Klimm, E.; Kaaya, I. Accelerated aging tests vs field performance of PV modules. Prog. Energy 2022, 4, 042009. [Google Scholar] [CrossRef]

- Sinha, A.; Qian, J.; Moffitt, S.L.; Hurst, K.; Terwilliger, K.; Miller, D.C.; Schelhas, L.T.; Hacke, P. UV-induced degradation of high-efficiency silicon PV modules with different cell architectures. Prog. Photovolt. Res. Appl. 2023, 31, 36–51. [Google Scholar] [CrossRef]

- Manohar, S.S.; Sahoo, A.; Subramaniam, A.; Panda, S.K. Condition monitoring of power electronic converters in power plants—A review. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Renewable Power Generation Costs in 2022. Available online: https://www.irena.org/Publications/2023/Aug/Renewable-Power-Generation-Costs-in-2022 (accessed on 22 January 2024).

- PVRADAR: Innovation for Utility-Scale PV. Available online: https://pvradar.com/ (accessed on 24 January 2024).

| Map Showing the Locations | Location (Lat./Lon.) | DR Zone (DR [%/Year]) |

|---|---|---|

| L1 (33.5°/41.0°) | Z1 (0.62 ± 0.1) |

| L2 (30.0°/45.0°) | Z2 (0.75 ± 0.1) | |

| L3 (33.0°/44.4°) | Z3 (0.85 ± 0.1) | |

| L4 (30.2°/47.5″) | Z4 (0.96 ± 0.1) |

| Variable | Quantity |

|---|---|

| Major effect on power and safety | 10 |

| Major effect on power or safety | 8 |

| Moderate effect on power or safety | 5 |

| Slight deterioration of performance and safety | 3 |

| Slight deterioration of performance or safety | 1 |

| Variable | Quantity |

|---|---|

| CAPEX | 1200 USD/kWp |

| OPEX | 10 USD/kWp |

| Inverter cost | 800 USD |

| Discount rate | 2.0% |

| Total system capacity (installed) | 1000 kWp |

| Total energy produced during the first year of operation | Location based |

| Degradation rate | Based on degradation zones |

| PV system lifetime | Based on degradation zones |

| Required Input | Quantity: Kimber Model | Quantity: H.S.U Model |

|---|---|---|

| Cleaning threshold | 5 mm/day | 5 mm/day [40] |

| Grace period | 10 days | |

| Maximum fraction of energy lost due to soiling | 0.8 [-] | - |

| Manual wash dates | Varied scenarios in this study | - |

| Soiling rate | Varied scenarios in this study | - |

| and | - | 0.039 and 0.008 [41] |

| Tilt angle ( | Varied scenarios in this study | - |

| PV System Component | No., Tickets/Unit | Severity Ranking | |

|---|---|---|---|

| Module | Metallization/Corrosion | 9 | 8 |

| Delamination | 148 | 5 | |

| Defect J.B. | 11 | 5 | |

| Backsheet discoloration | >2000 | 3 | |

| Encapsulant browning/brown spots | 1117 | 3 | |

| Backsheet defects (e.g cracking, adhesion) | 18 | 10 | |

| Permanent soiling | 172 calls | 8 | |

| Internal circuitry discoloration, solder bond fatigue | 84 | 8 | |

| Broken module | 6 | 10 | |

| Glass damage | 21 | 5 | |

| Inverter | Overheating (fan problem) | 5 | 10 |

| Short-circuiting | 2 | 10 | |

| Corroded terminals | 3 | 5 | |

| Dust on the combiner box | 12 | 5 | |

| Inverter malfunction | 36 | 3 | |

| Wiring | Sheath damage | 1 | 3 |

| Connector failure | 52 | 10 | |

| Hot stings | Hot strings and hotspots | All strings |

| Financial Parameter | Value | Component | Cost (USD) | Lifetime (Year) | No. per System |

|---|---|---|---|---|---|

| Energy sale price | 40.00 USD/MWh | Robot | 1100.00 | 10.00 | 1.00 |

| Fuel cost | 0.5 USD/L | Brush | 400.00 | 2.00 | 1.00 |

| Labor cost | 1 kUSD | Battery | 140.00 | 4.00 | 1.00 |

| Inflation rate | 2% | Docking station | 100.00 | -- | 1.00 |

| Discount rate | 6% | Bridge | 80.00 | -- | 3.00 |

| Project lifetime 30 years | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hameed, M.A.; Daßler, D.; Alias, Q.M.; Scheer, R.; Gottschalg, R. Economic Consequences Based on Reversible and Irreversible Degradation of PV Park in the Harsh Climate Conditions of Iraq. Energies 2024, 17, 2652. https://doi.org/10.3390/en17112652

Hameed MA, Daßler D, Alias QM, Scheer R, Gottschalg R. Economic Consequences Based on Reversible and Irreversible Degradation of PV Park in the Harsh Climate Conditions of Iraq. Energies. 2024; 17(11):2652. https://doi.org/10.3390/en17112652

Chicago/Turabian StyleHameed, Mohammed Adnan, David Daßler, Qais Matti Alias, Roland Scheer, and Ralph Gottschalg. 2024. "Economic Consequences Based on Reversible and Irreversible Degradation of PV Park in the Harsh Climate Conditions of Iraq" Energies 17, no. 11: 2652. https://doi.org/10.3390/en17112652

APA StyleHameed, M. A., Daßler, D., Alias, Q. M., Scheer, R., & Gottschalg, R. (2024). Economic Consequences Based on Reversible and Irreversible Degradation of PV Park in the Harsh Climate Conditions of Iraq. Energies, 17(11), 2652. https://doi.org/10.3390/en17112652