Review and Recent Advances in Metal Compounds as Potential High-Performance Anodes for Sodium Ion Batteries

Abstract

1. Introduction

2. Metal Compounds as Anode Materials for Sodium Ion Batteries

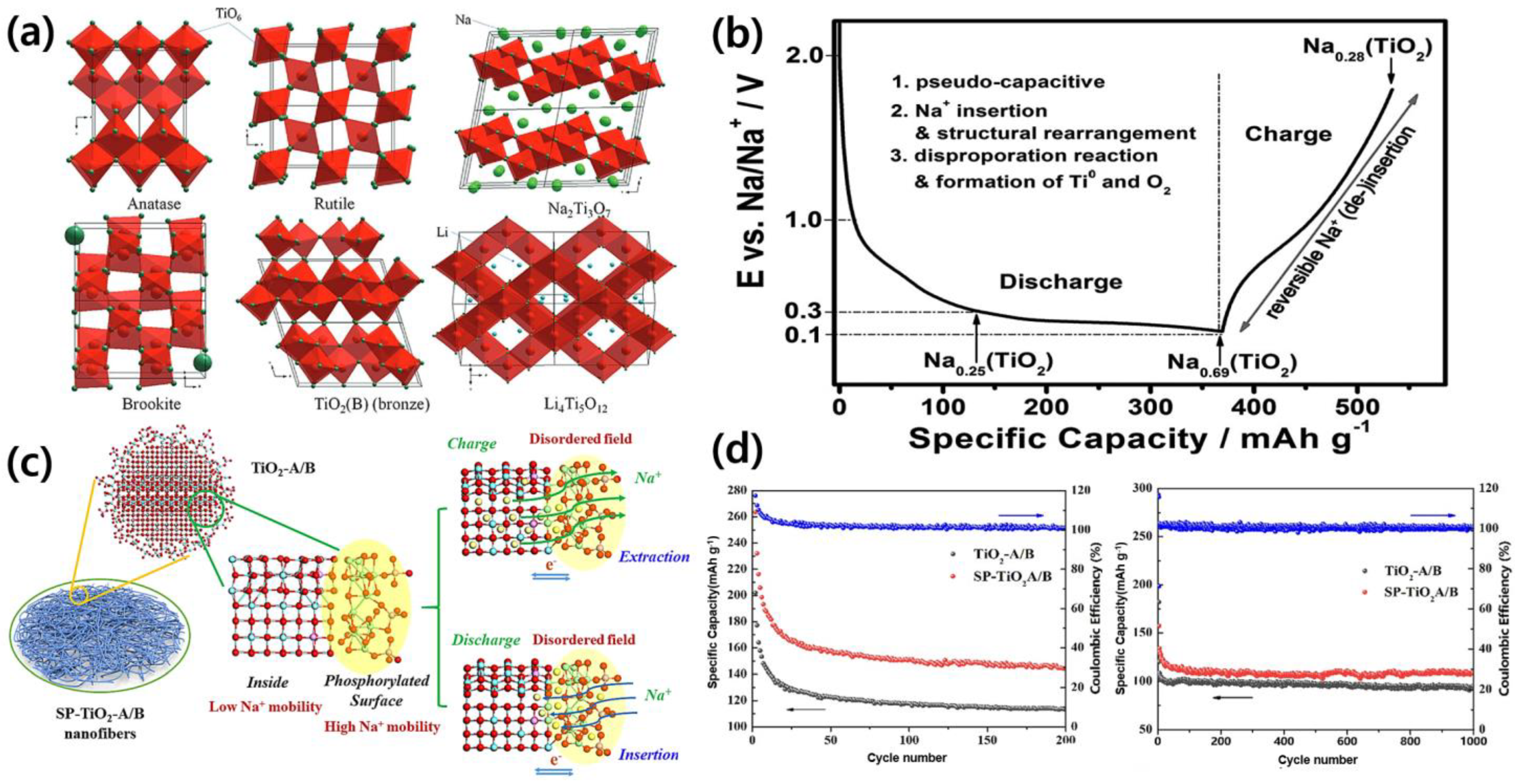

2.1. Metal Oxides

2.2. Metal Sulfides

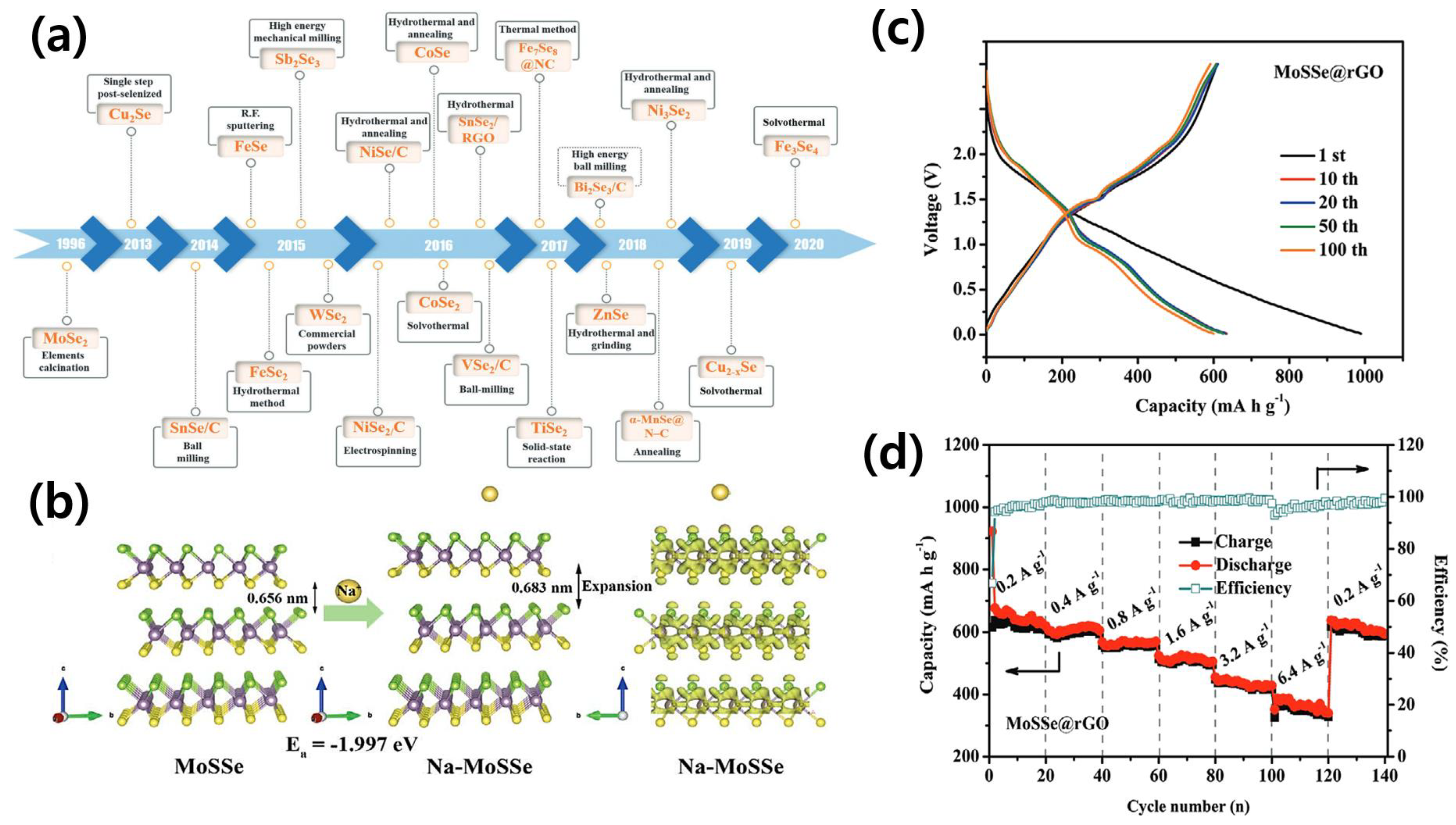

2.3. Metal Selenides

2.4. Metal Phosphides

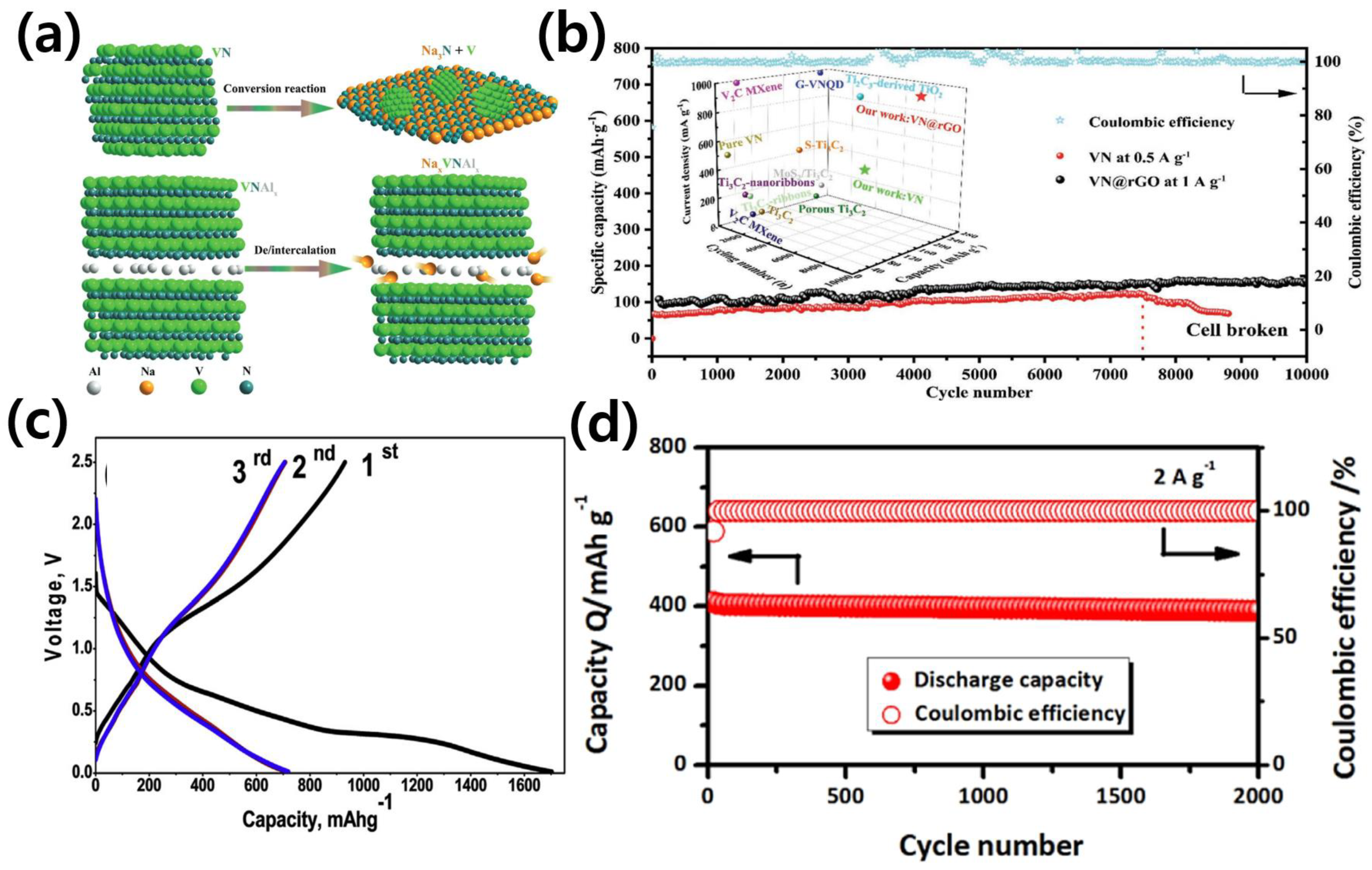

2.5. Metal Nitrides

2.6. Future Perspectives Regarding the Commercialization of SIBs

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ghosh, A. Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review. Energies 2020, 13, 2602. [Google Scholar] [CrossRef]

- Agubra, V.A.; Zuniga, L.; Flores, D.; Villareal, J.; Alcoutlabi, M. Composite Nanofibers as Advanced Materials for Li-Ion, Li-O2 and Li-S Batteries. Electrochim. Acta 2016, 192, 529–550. [Google Scholar] [CrossRef]

- Kwak, W.-J.; Rosy; Sharon, D.; Xia, C.; Kim, H.; Johnson, L.R.; Bruce, P.G.; Nazar, L.F.; Sun, Y.-K.; Frimer, A.A.; et al. Lithium–Oxygen Batteries and Related Systems: Potential, Status, and Future. Chem. Rev. 2020, 120, 6626–6683. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Shim, J.; Sun, H.-J.; Rim, H.-R.; Lee, H.-K.; Park, G. Nickel Decorated Bimetallic Catalysts Derived from Metal-Organic Frameworks as Cathode Materials for Rechargeable Zinc-Air Batteries. Mater. Lett. 2021, 283, 128781. [Google Scholar] [CrossRef]

- Stampatori, D.; Raimondi, P.P.; Noussan, M. Li-Ion Batteries: A Review of a Key Technology for Transport Decarbonization. Energies 2020, 13, 2638. [Google Scholar] [CrossRef]

- Chayambuka, K.; Mulder, G.; Danilov, D.L.; Notten, P.H.L. From Li-Ion Batteries toward Na-Ion Chemistries: Challenges and Opportunities. Adv. Energy Mater. 2020, 10, 2001310. [Google Scholar] [CrossRef]

- Perveen, T.; Siddiq, M.; Shahzad, N.; Ihsan, R.; Ahmad, A.; Shahzad, M.I. Prospects in Anode Materials for Sodium Ion Batteries—A Review. Renew. Sustain. Energy Rev. 2020, 119, 109549. [Google Scholar] [CrossRef]

- Fang, S.; Bresser, D.; Passerini, S. Transition Metal Oxide Anodes for Electrochemical Energy Storage in Lithium- and Sodium-Ion Batteries. Adv. Energy Mater. 2020, 10, 1902485. [Google Scholar] [CrossRef]

- Liu, D.X.; Cao, L.R.; Co, A.C. Demonstrating the Feasibility of Al as Anode Current Collector in Li-Ion Batteries Via in Situ Neutron Depth Profiling. Chem. Mater. 2016, 28, 556–563. [Google Scholar] [CrossRef]

- Nayak, P.K.; Yang, L.; Brehm, W.; Adelhelm, P. From Lithium-Ion to Sodium-Ion Batteries: Advantages, Challenges, and Surprises. Angew. Chem. Int. Ed. 2018, 57, 102–120. [Google Scholar] [CrossRef]

- Wang, L.; Tian, H.; Yao, X.; Cai, Y.; Gao, Z.; Su, Z. Research Progress and Modification Measures of Anode and Cathode Materials for Sodium-Ion Batteries. ChemElectroChem 2024, 11, e202300414. [Google Scholar] [CrossRef]

- Hwang, J.-Y.; Myung, S.-T.; Sun, Y.-K. Sodium-Ion Batteries: Present and Future. Chem. Soc. Rev. 2017, 46, 3529–3614. [Google Scholar] [CrossRef] [PubMed]

- Slater, M.D.; Kim, D.; Lee, E.; Johnson, C.S. Sodium-Ion Batteries. Adv. Funct. Mater. 2013, 23, 947–958. [Google Scholar] [CrossRef]

- Sawicki, M.; Shaw, L.L. Advances and Challenges of Sodium Ion Batteries as Post Lithium Ion Batteries. RSC Adv. 2015, 5, 53129–53154. [Google Scholar] [CrossRef]

- Li, M. Elevating the Practical Application of Sodium-Ion Batteries through Advanced Characterization Studies on Cathodes. Energies 2023, 16, 8004. [Google Scholar] [CrossRef]

- Sayahpour, B.; Hirsh, H.; Parab, S.; Nguyen, L.H.B.; Zhang, M.; Meng, Y.S. Perspective: Design of Cathode Materials for Sustainable Sodium-Ion Batteries. MRS Energy Sustain. 2022, 9, 183–197. [Google Scholar] [CrossRef]

- Divya, M.L.; Lee, Y.-S.; Aravindan, V. Solvent Co-Intercalation: An Emerging Mechanism in Li-, Na-, and K-Ion Capacitors. ACS Energy Lett. 2021, 6, 4228–4244. [Google Scholar] [CrossRef]

- Chen, X.; Zheng, Y.; Liu, W.; Zhang, C.; Li, S.; Li, J. High-Performance Sodium-Ion Batteries with a Hard Carbon Anode: Transition from the Half-Cell to Full-Cell Perspective. Nanoscale 2019, 11, 22196–22205. [Google Scholar] [CrossRef]

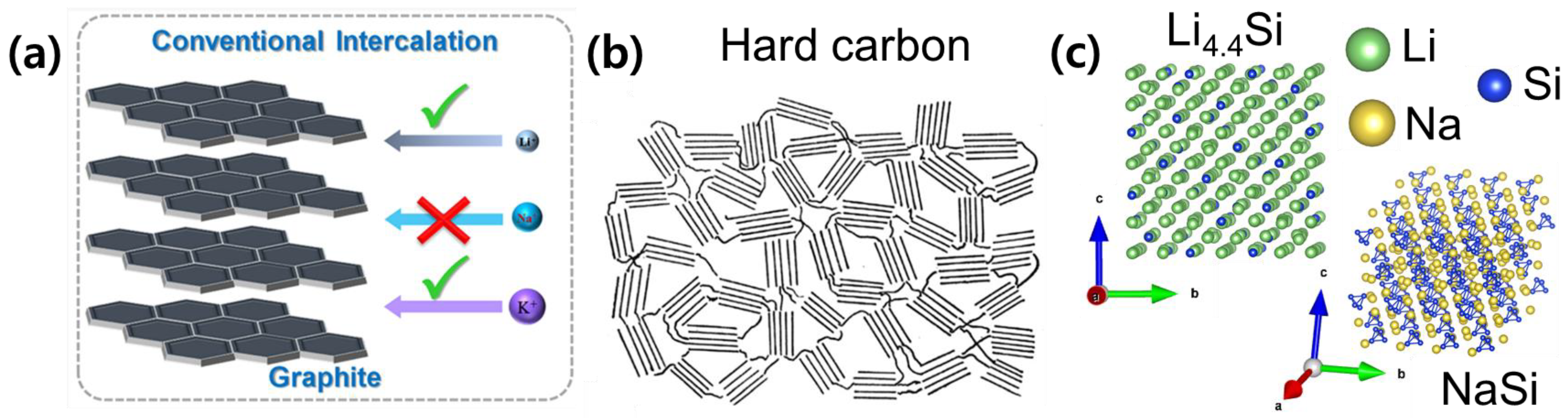

- Loaiza, L.C.; Monconduit, L.; Seznec, V. Si and Ge-Based Anode Materials for Li-, Na-, and K-Ion Batteries: A Perspective from Structure to Electrochemical Mechanism. Small 2020, 16, 1905260. [Google Scholar] [CrossRef]

- Moriwake, H.; Kuwabara, A.; Fisher, C.A.J.; Ikuhara, Y. Why Is Sodium-Intercalated Graphite Unstable? RSC Adv. 2017, 7, 36550–36554. [Google Scholar] [CrossRef]

- Yoon, G.; Kim, H.; Park, I.; Kang, K. Conditions for Reversible Na Intercalation in Graphite: Theoretical Studies on the Interplay among Guest Ions, Solvent, and Graphite Host. Adv. Energy Mater. 2017, 7, 1601519. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Adelhelm, P.; Titirici, M.-M.; Hu, Y.-S. Intercalation Chemistry of Graphite: Alkali Metal Ions and Beyond. Chem. Soc. Rev. 2019, 48, 4655–4687. [Google Scholar] [CrossRef]

- Jache, B.; Adelhelm, P. Use of Graphite as a Highly Reversible Electrode with Superior Cycle Life for Sodium-Ion Batteries by Making Use of Co-Intercalation Phenomena. Angew. Chem. Int. Ed. 2014, 53, 10169–10173. [Google Scholar] [CrossRef] [PubMed]

- Stevens, D.A.; Dahn, J.R. The Mechanisms of Lithium and Sodium Insertion in Carbon Materials. J. Electrochem. Soc. 2001, 148, A803. [Google Scholar] [CrossRef]

- Xu, Z.-L.; Yoon, G.; Park, K.-Y.; Park, H.; Tamwattana, O.; Joo Kim, S.; Seong, W.M.; Kang, K. Tailoring Sodium Intercalation in Graphite for High Energy and Power Sodium Ion Batteries. Nat. Commun. 2019, 10, 2598. [Google Scholar] [CrossRef]

- Dahbi, M.; Yabuuchi, N.; Kubota, K.; Tokiwa, K.; Komaba, S. Negative Electrodes for Na-Ion Batteries. Phys. Chem. Chem. Phys. 2014, 16, 15007–15028. [Google Scholar] [CrossRef] [PubMed]

- Qiao, S.; Zhou, Q.; Ma, M.; Liu, H.K.; Dou, S.X.; Chong, S. Advanced Anode Materials for Rechargeable Sodium-Ion Batteries. ACS Nano 2023, 17, 11220–11252. [Google Scholar] [CrossRef]

- Chayambuka, K.; Mulder, G.; Danilov, D.L.; Notten, P.H.L. Sodium-Ion Battery Materials and Electrochemical Properties Reviewed. Adv. Energy Mater. 2018, 8, 1800079. [Google Scholar] [CrossRef]

- Feng, K.; Li, M.; Liu, W.; Kashkooli, A.G.; Xiao, X.; Cai, M.; Chen, Z. Silicon-Based Anodes for Lithium-Ion Batteries: From Fundamentals to Practical Applications. Small 2018, 14, 1702737. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhao, C.; Lu, Y.; Li, Y.; Zheng, Y.; Qi, Y.; Rong, X.; Jiang, L.; Qi, X.; Shao, Y.; et al. Advanced Nanostructured Anode Materials for Sodium-Ion Batteries. Small 2017, 13, 1701835. [Google Scholar] [CrossRef]

- Ma, J.-M.; Li, Y.-T. Editorial for Advanced Energy Storage and Conversion Materials and Technologies. Rare Met. 2021, 40, 246–248. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, H. Recent Developments of Phosphorus-Based Anodes for Sodium Ion Batteries. J. Mater. Chem. A 2018, 6, 24013–24030. [Google Scholar] [CrossRef]

- Liu, W.; Zhi, H.; Yu, X. Recent Progress in Phosphorus Based Anode Materials for Lithium/Sodium Ion Batteries. Energy Storage Mater. 2019, 16, 290–322. [Google Scholar] [CrossRef]

- Zheng, X.; Bommier, C.; Luo, W.; Jiang, L.; Hao, Y.; Huang, Y. Sodium Metal Anodes for Room-Temperature Sodium-Ion Batteries: Applications, Challenges and Solutions. Energy Storage Mater. 2019, 16, 6–23. [Google Scholar] [CrossRef]

- Kim, S.-W.; Seo, D.-H.; Ma, X.; Ceder, G.; Kang, K. Electrode Materials for Rechargeable Sodium-Ion Batteries: Potential Alternatives to Current Lithium-Ion Batteries. Adv. Energy Mater. 2012, 2, 710–721. [Google Scholar] [CrossRef]

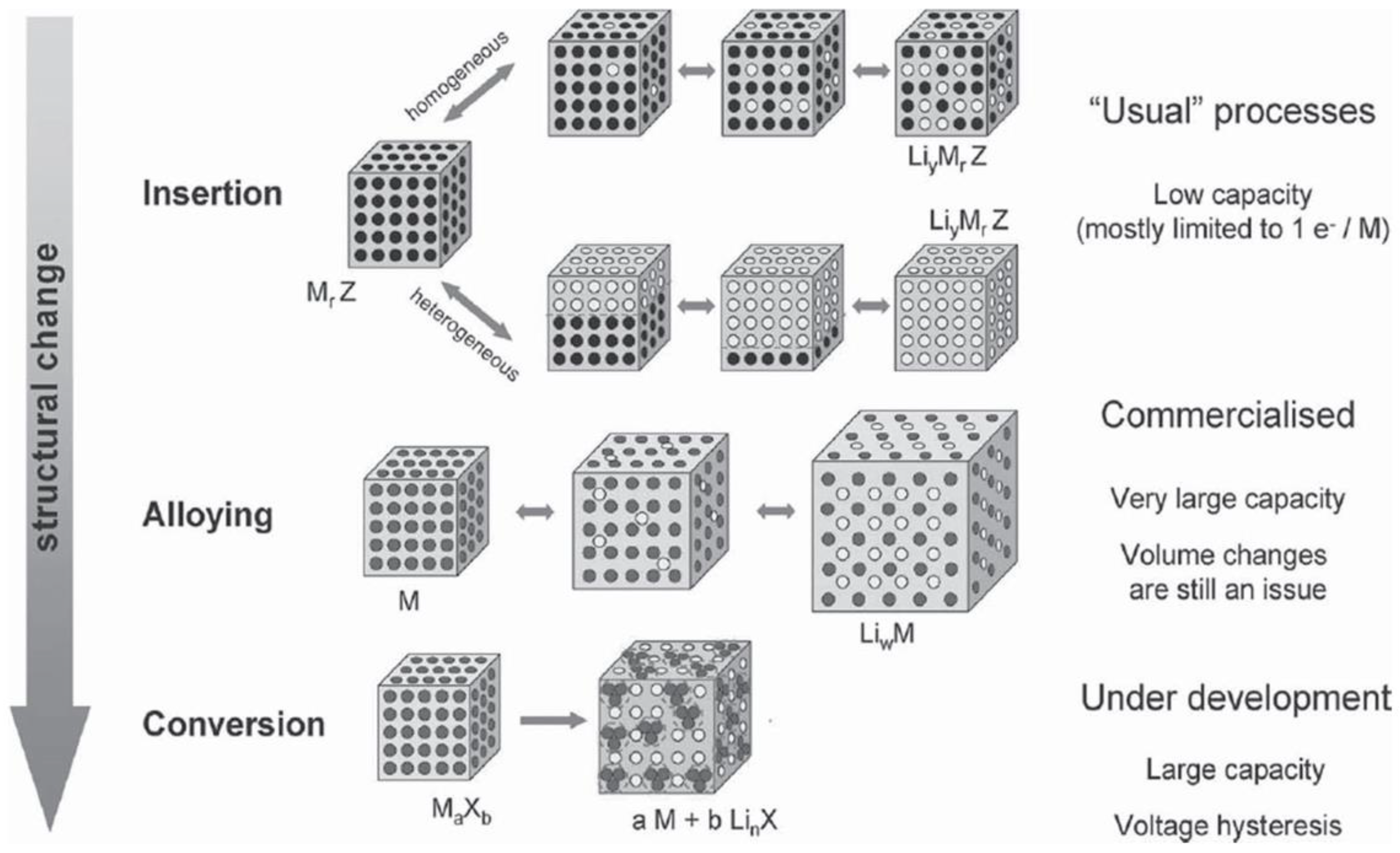

- Klein, F.; Jache, B.; Bhide, A.; Adelhelm, P. Conversion Reactions for Sodium-Ion Batteries. Phys. Chem. Chem. Phys. 2013, 15, 15876–15887. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, F.; Ming, F.; Alshareef, H.N. Sodium-Ion Battery Anodes: Status and Future Trends. EnergyChem 2019, 1, 100012. [Google Scholar] [CrossRef]

- Yu, L.; Wang, L.P.; Liao, H.; Wang, J.; Feng, Z.; Lev, O.; Loo, J.S.C.; Sougrati, M.T.; Xu, Z.J. Understanding Fundamentals and Reaction Mechanisms of Electrode Materials for Na-Ion Batteries. Small 2018, 14, 1703338. [Google Scholar] [CrossRef]

- Palacín, M.R. Recent Advances in Rechargeable Battery Materials: A Chemist’s Perspective. Chem. Soc. Rev. 2009, 38, 2565–2575. [Google Scholar] [CrossRef]

- Tan, S.; Jiang, Y.; Wei, Q.; Huang, Q.; Dai, Y.; Xiong, F.; Li, Q.; An, Q.; Xu, X.; Zhu, Z.; et al. Multidimensional Synergistic Nanoarchitecture Exhibiting Highly Stable and Ultrafast Sodium-Ion Storage. Adv. Mater. 2018, 30, 1707122. [Google Scholar] [CrossRef]

- He, G.; Li, L.; Manthiram, A. VO2/rGO Nanorods as a Potential Anode for Sodium- and Lithium-Ion Batteries. J. Mater. Chem. A 2015, 3, 14750–14758. [Google Scholar] [CrossRef]

- Allen, L.C. Electronegativity Is the Average One-Electron Energy of the Valence-Shell Electrons in Ground-State Free Atoms. J. Am. Chem. Soc. 1989, 111, 9003–9014. [Google Scholar] [CrossRef]

- Ni, Q.; Dong, R.; Bai, Y.; Wang, Z.; Ren, H.; Sean, S.; Wu, F.; Xu, H.; Wu, C. Superior Sodium-Storage Behavior of Flexible Anatase TiO2 Promoted by Oxygen Vacancies. Energy Storage Mater. 2020, 25, 903–911. [Google Scholar] [CrossRef]

- Lou, S.; Zhao, Y.; Wang, J.; Yin, G.; Du, C.; Sun, X. Ti-Based Oxide Anode Materials for Advanced Electrochemical Energy Storage: Lithium/Sodium Ion Batteries and Hybrid Pseudocapacitors. Small 2019, 15, 1904740. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.-G.; Du, R.; He, X.-X.; Wang, J.-C.; Qiao, Y.; Li, L.; Chou, S.-L. Recent Progress on Intercalation-Based Anode Materials for Low-Cost Sodium-Ion Batteries. ChemSusChem 2021, 14, 3724–3743. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Bresser, D.; Buchholz, D.; Giffin, G.A.; Castro, C.R.; Ochel, A.; Passerini, S. Unfolding the Mechanism of Sodium Insertion in Anatase TiO2 Nanoparticles. Adv. Energy Mater. 2015, 5, 1401142. [Google Scholar] [CrossRef]

- Lee, J.; Lee, J.K.; Chung, K.Y.; Jung, H.-G.; Kim, H.; Mun, J.; Choi, W. Electrochemical Investigations on TiO2-B Nanowires as a Promising High Capacity Anode for Sodium-Ion Batteries. Electrochim. Acta 2016, 200, 21–28. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, F.; Li, J.; Li, Y.; McLeod, J.A.; Liu, L. Influence of Crystal Phase on TiO2 Nanowire Anodes in Sodium Ion Batteries. J. Mater. Chem. A 2017, 5, 20005–20013. [Google Scholar] [CrossRef]

- Chen, B.; Meng, Y.; Xie, F.; He, F.; He, C.; Davey, K.; Zhao, N.; Qiao, S.-Z. 1d Sub-Nanotubes with Anatase/Bronze TiO2 Nanocrystal Wall for High-Rate and Long-Life Sodium-Ion Batteries. Adv. Mater. 2018, 30, 1804116. [Google Scholar] [CrossRef]

- Sui, Y.; Zeng, J.; Shi, Z.; Lu, S.; Zhang, X.; Wang, B.; Zhong, S.; Wu, L. Superior Sodium Storage in Anatase/Bronze TiO2 Nanofibers through Surface Phosphorylation. Appl. Surf. Sci. 2022, 606, 154982. [Google Scholar] [CrossRef]

- Chen, C.; Xu, H.; Zhou, T.; Guo, Z.; Chen, L.; Yan, M.; Mai, L.; Hu, P.; Cheng, S.; Huang, Y.; et al. Integrated Intercalation-Based and Interfacial Sodium Storage in Graphene-Wrapped Porous Li4Ti5O12 Nanofibers Composite Aerogel. Adv. Energy Mater. 2016, 6, 1600322. [Google Scholar] [CrossRef]

- Bai, X.; Wu, N.; Yu, G.; Li, T. Recent Advances in Anode Materials for Sodium-Ion Batteries. Inorganics 2023, 11, 289. [Google Scholar] [CrossRef]

- Yabuuchi, N.; Kubota, K.; Dahbi, M.; Komaba, S. Research Development on Sodium-Ion Batteries. Chem. Rev. 2014, 114, 11636–11682. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Hua, W.; Zhang, Z.; Zhong, B.; Yang, Z.; Feng, G.; Xiang, W.; Wu, Z.; Guo, X. Design and Synthesis of Layered Na2Ti3O7 and Tunnel Na2Ti6O13 Hybrid Structures with Enhanced Electrochemical Behavior for Sodium-Ion Batteries. Adv. Sci. 2018, 5, 1800519. [Google Scholar] [CrossRef]

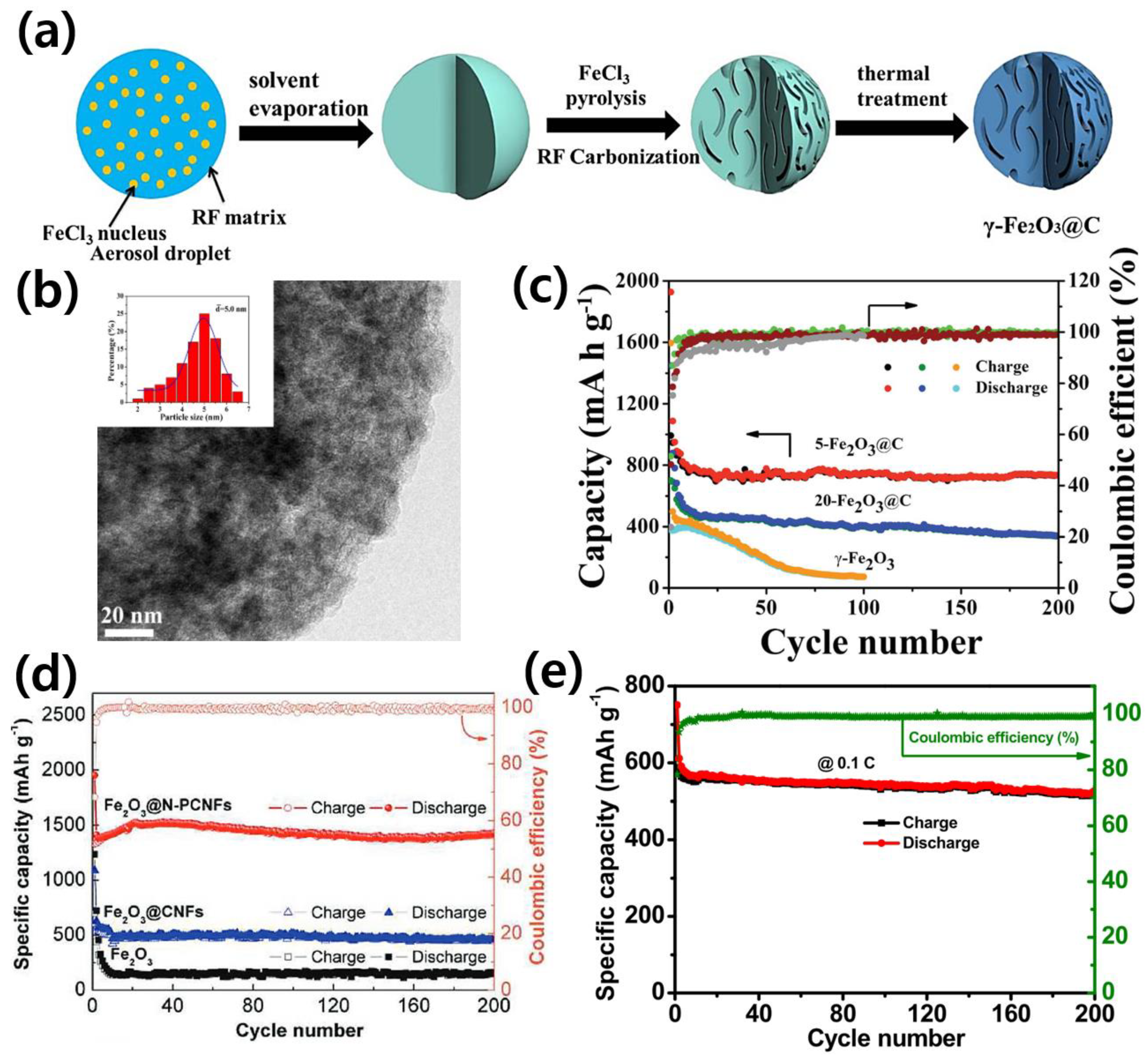

- Qi, S.; Xu, B.; Tiong, V.T.; Hu, J.; Ma, J. Progress on Iron Oxides and Chalcogenides as Anodes for Sodium-Ion Batteries. Chem. Eng. J. 2020, 379, 122261. [Google Scholar] [CrossRef]

- Zhang, N.; Han, X.; Liu, Y.; Hu, X.; Zhao, Q.; Chen, J. 3d Porous γ-Fe2O3@C Nanocomposite as High-Performance Anode Material of Na-Ion Batteries. Adv. Energy Mater. 2015, 5, 1401123. [Google Scholar] [CrossRef]

- Xia, G.; Gao, Q.; Sun, D.; Yu, X. Porous Carbon Nanofibers Encapsulated with Peapod-Like Hematite Nanoparticles for High-Rate and Long-Life Battery Anodes. Small 2017, 13, 1701561. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Jia, Y.; Liu, Z.-H. Go-Graphene Ink-Derived Hierarchical 3d-Graphene Architecture Supported Fe3O4 Nanodots as High-Performance Electrodes for Lithium/Sodium Storage and Supercapacitors. J. Colloid Interface Sci. 2019, 536, 463–473. [Google Scholar] [CrossRef] [PubMed]

- Qin, G.; Duan, J.; Yang, Y.; Liu, F. Magnetic Field Facilitated Resilient Chain-Like Fe3O4/C/Red P with Superior Sodium Storage Performance. ACS Appl. Mater. Interfaces 2018, 10, 6441–6452. [Google Scholar] [CrossRef]

- Mahamad Yusoff, N.F.; Idris, N.H.; Noerochim, L. Review on Recent Progress in Manganese-Based Anode Materials for Sodium-Ion Batteries. Int. J. Energy Res. 2022, 46, 667–683. [Google Scholar] [CrossRef]

- Weng, Y.-T.; Huang, T.-Y.; Lim, C.-H.; Shao, P.-S.; Hy, S.; Kuo, C.-Y.; Cheng, J.-H.; Hwang, B.-J.; Lee, J.-F.; Wu, N.-L. An Unexpected Large Capacity of Ultrafine Manganese Oxide as a Sodium-Ion Battery Anode. Nanoscale 2015, 7, 20075–20081. [Google Scholar] [CrossRef]

- Wang, L.; Wei, Z.; Mao, M.; Wang, H.; Li, Y.; Ma, J. Metal Oxide/Graphene Composite Anode Materials for Sodium-Ion Batteries. Energy Storage Mater. 2019, 16, 434–454. [Google Scholar] [CrossRef]

- Rui, X.; Tan, H.; Yan, Q. Nanostructured Metal Sulfides for Energy Storage. Nanoscale 2014, 6, 9889–9924. [Google Scholar] [CrossRef]

- Zhu, Q.; Xu, Q.; Du, M.; Zeng, X.; Zhong, G.; Qiu, B.; Zhang, J. Recent Progress of Metal Sulfide Photocatalysts for Solar Energy Conversion. Adv. Mater. 2022, 34, 2202929. [Google Scholar] [CrossRef]

- Yu, X.Y.; Lou, X.W. Mixed Metal Sulfides for Electrochemical Energy Storage and Conversion. Adv. Energy Mater. 2018, 8, 1701592. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, J.; Zhang, L.; Wan, H.; Qi, T.; Xia, D. Highly Conductive NiCo2S4 Urchin-Like Nanostructures for High-Rate Pseudocapacitors. Nanoscale 2013, 5, 8879–8883. [Google Scholar] [CrossRef]

- Lim, Y.V.; Li, X.L.; Yang, H.Y. Recent Tactics and Advances in the Application of Metal Sulfides as High-Performance Anode Materials for Rechargeable Sodium-Ion Batteries. Adv. Funct. Mater. 2021, 31, 2006761. [Google Scholar] [CrossRef]

- Xu, X.; Liu, W.; Kim, Y.; Cho, J. Nanostructured Transition Metal Sulfides for Lithium Ion Batteries: Progress and Challenges. Nano Today 2014, 9, 604–630. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, Q.; Chou, S.-L.; Dou, S.-X. Advances and Challenges in Metal Sulfides/Selenides for Next-Generation Rechargeable Sodium-Ion Batteries. Adv. Mater. 2017, 29, 1700606. [Google Scholar] [CrossRef]

- Kulka, A.; Hanc, A.; Walczak, K.; Płotek, J.; Sun, J.; Lu, L.; Borca, C.; Huthwelker, T. Direct Evidence of an Unanticipated Crystalline Phase Responsible for the High Performance of Few-Layered-MoS2 Anodes for Na-Ion Batteries. Energy Storage Mater. 2022, 48, 314–324. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, C.; Zhang, Q.; Liu, M. Recent Progress in the Design of Metal Sulfides as Anode Materials for Sodium Ion Batteries. Energy Storage Mater. 2019, 22, 66–95. [Google Scholar] [CrossRef]

- Choi, S.H.; Ko, Y.N.; Lee, J.-K.; Kang, Y.C. 3d MoS2–Graphene Microspheres Consisting of Multiple Nanospheres with Superior Sodium Ion Storage Properties. Adv. Funct. Mater. 2015, 25, 1780–1788. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, L.; Zhang, K.; Wang, J.; Cheng, F.; Tao, Z.; Chen, J. MoS2 Nanoflowers with Expanded Interlayers as High-Performance Anodes for Sodium-Ion Batteries. Angew. Chem. Int. Ed. 2014, 53, 12794–12798. [Google Scholar] [CrossRef] [PubMed]

- Samy, O.; El Moutaouakil, A. A Review on MoS2 Energy Applications: Recent Developments and Challenges. Energies 2021, 14, 4586. [Google Scholar] [CrossRef]

- Shi, Z.-T.; Kang, W.; Xu, J.; Sun, Y.-W.; Jiang, M.; Ng, T.-W.; Xue, H.-T.; Yu, D.Y.W.; Zhang, W.; Lee, C.-S. Hierarchical Nanotubes Assembled from MoS2-Carbon Monolayer Sandwiched Superstructure Nanosheets for High-Performance Sodium Ion Batteries. Nano Energy 2016, 22, 27–37. [Google Scholar] [CrossRef]

- David, L.; Bhandavat, R.; Singh, G. MoS2/Graphene Composite Paper for Sodium-Ion Battery Electrodes. ACS Nano 2014, 8, 1759–1770. [Google Scholar] [CrossRef]

- Li, L.; Zheng, Y.; Zhang, S.; Yang, J.; Shao, Z.; Guo, Z. Recent Progress on Sodium Ion Batteries: Potential High-Performance Anodes. Energy Environ. Sci. 2018, 11, 2310–2340. [Google Scholar] [CrossRef]

- Gong, Y.; Li, Y.; Li, Y.; Liu, M.; Bai, Y.; Wu, C. Metal Selenides Anode Materials for Sodium Ion Batteries: Synthesis, Modification, and Application. Small 2023, 19, 2206194. [Google Scholar] [CrossRef]

- Kumar, M.; Rani, S.; Singh, Y.; Gour, K.S.; Singh, V.N. Tin-Selenide as a Futuristic Material: Properties and Applications. RSC Adv. 2021, 11, 6477–6503. [Google Scholar] [CrossRef]

- Ali, Z.; Zhang, T.; Asif, M.; Zhao, L.; Yu, Y.; Hou, Y. Transition Metal Chalcogenide Anodes for Sodium Storage. Mater. Today 2020, 35, 131–167. [Google Scholar] [CrossRef]

- Hussain, I.; Sahoo, S.; Lamiel, C.; Nguyen, T.T.; Ahmed, M.; Xi, C.; Iqbal, S.; Ali, A.; Abbas, N.; Javed, M.S.; et al. Research Progress and Future Aspects: Metal Selenides as Effective Electrodes. Energy Storage Mater. 2022, 47, 13–43. [Google Scholar] [CrossRef]

- Zhai, Z.-B.; Huang, K.-J.; Wu, X. Superior Mixed Co-Cd Selenide Nanorods for High Performance Alkaline Battery-Supercapacitor Hybrid Energy Storage. Nano Energy 2018, 47, 89–95. [Google Scholar] [CrossRef]

- Liu, H.; Guo, H.; Liu, B.; Liang, M.; Lv, Z.; Adair, K.R.; Sun, X. Few-Layer MoSe2 Nanosheets with Expanded (002) Planes Confined in Hollow Carbon Nanospheres for Ultrahigh-Performance Na-Ion Batteries. Adv. Funct. Mater. 2018, 28, 1707480. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z.; Guan, M.; Wu, F.; Chen, R. Toward Rapid-Charging Sodium-Ion Batteries Using Hybrid-Phase Molybdenum Sulfide Selenide-Based Anodes. Adv. Mater. 2020, 32, 2003534. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-H.; Jung, C.-H.; Kim, W.-S.; Hong, S.-H. V4P7@C Nanocomposite as a High Performance Anode Material for Lithium-Ion Batteries. J. Power Sources 2018, 400, 204–211. [Google Scholar] [CrossRef]

- Chen, J.-H.; Whitmire, K.H. A Structural Survey of the Binary Transition Metal Phosphides and Arsenides of the d-Block Elements. Coord. Chem. Rev. 2018, 355, 271–327. [Google Scholar] [CrossRef]

- Gong, N.; Deng, C.; Wu, L.; Wan, B.; Wang, Z.; Li, Z.; Gou, H.; Gao, F. Structural Diversity and Electronic Properties of 3d Transition Metal Tetraphosphides, TMP4 (Tm = V, Cr, Mn, and Fe). Inorg. Chem. 2018, 57, 9385–9392. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Lin, C.; Zhao, X.S. Spherical Vanadium Phosphate Particles Grown on Carbon Fiber Cloth as Flexible Anode for High-Rate Li-Ion Batteries. Chem. Eng. J. 2020, 386, 123981. [Google Scholar] [CrossRef]

- Kim, H.-S.; Nam, K.-H.; Park, C.-M. Monoclinic Vanadium Diphosphide as a High-Performance Lithium-Ion Battery Anode. J. Alloys Compd. 2021, 875, 160061. [Google Scholar] [CrossRef]

- Kim, Y.-U.; Cho, B.W.; Sohn, H.-J. The Reaction Mechanism of Lithium Insertion in Vanadium Tetraphosphide: A Possible Anode Material in Lithium-Ion Batteries. J. Electrochem. Soc. 2005, 152, A1475. [Google Scholar] [CrossRef]

- Park, C.-M.; Kim, Y.-U.; Sohn, H.-J. Topotactic Li Insertion/Extraction in Hexagonal Vanadium Monophosphide. Chem. Mater. 2009, 21, 5566–5568. [Google Scholar] [CrossRef]

- Kim, K.-H.; Choi, J.; Hong, S.-H. Superior Electrochemical Sodium Storage of V4P7 Nanoparticles as an Anode for Rechargeable Sodium-Ion Batteries. Chem. Commun. 2019, 55, 3207–3210. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Ma, X.; Wang, G.; Long, X.; Li, Y.; Zhang, W.; Zhang, P. Carbon-Coated CoP3 Nanocomposites as Anode Materials for High-Performance Sodium-Ion Batteries. Appl. Surf. Sci. 2018, 445, 167–174. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, X.; Luo, B.; Zhang, Y.; Tang, Y.; Wang, H.; Wang, L. New Binder-Free Metal Phosphide–Carbon Felt Composite Anodes for Sodium-Ion Battery. Adv. Energy Mater. 2018, 8, 1801197. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.; Kim, K.-H.; Hong, S.-H. Chromium Tetraphosphide (CrP4) as a High-Performance Anode for Li Ion and Na Ion Batteries. J. Mater. Chem. A 2024, 12, 11463–11472. [Google Scholar] [CrossRef]

- Kim, S.-O.; Manthiram, A. The Facile Synthesis and Enhanced Sodium-Storage Performance of a Chemically Bonded CuP2/C Hybrid Anode. Chem. Commun. 2016, 52, 4337–4340. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Han, N.; Huang, W.; Li, J.; Ye, H.; Chen, F.; Li, Y. Nanostructured CuP2/C Composites as High-Performance Anode Materials for Sodium Ion Batteries. J. Mater. Chem. A 2015, 3, 21754–21759. [Google Scholar] [CrossRef]

- Zhang, W.; Dahbi, M.; Amagasa, S.; Yamada, Y.; Komaba, S. Iron Phosphide as Negative Electrode Material for Na-Ion Batteries. Electrochem. Commun. 2016, 69, 11–14. [Google Scholar] [CrossRef]

- Ning, Q.-L.; Hou, B.-H.; Wang, Y.-Y.; Liu, D.-S.; Luo, Z.-Z.; Li, W.-H.; Yang, Y.; Guo, J.-Z.; Wu, X.-L. Hierarchical GeP5/Carbon Nanocomposite with Dual-Carbon Conductive Network as Promising Anode Material for Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2018, 10, 36902–36909. [Google Scholar] [CrossRef]

- Kim, K.-H.; Hong, S.-H. Manganese Tetraphosphide (MnP4) as a High Capacity Anode for Lithium-Ion and Sodium-Ion Batteries. Adv. Energy Mater. 2021, 11, 2003609. [Google Scholar] [CrossRef]

- Kim, H.-H.; Kim, K.-H.; Hong, S.-H. Anion Exchanged NiP2−XSX Solid Solution as an Anode for Sodium Ion Battery. Chem. Eng. J. 2023, 455, 140798. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.-H.; Kim, H.-H.; Hong, S.-H. NiP2/C Nanocomposite as a High Performance Anode for Sodium Ion Batteries. Electrochim. Acta 2022, 403, 139686. [Google Scholar] [CrossRef]

- Ihsan-Ul-Haq, M.; Huang, H.; Cui, J.; Yao, S.; Wu, J.; Chong, W.G.; Huang, B.; Kim, J.-K. Chemical Interactions between Red P and Functional Groups in NiP3/CNT Composite Anodes for Enhanced Sodium Storage. J. Mater. Chem. A 2018, 6, 20184–20194. [Google Scholar] [CrossRef]

- Saddique, J.; Zhang, X.; Wu, T.; Wang, X.; Cheng, X.; Su, H.; Liu, S.; Zhang, L.; Li, G.; Zhang, Y.; et al. Enhanced Silicon Diphosphide-Carbon Composite Anode for Long-Cycle, High-Efficient Sodium Ion Batteries. ACS Appl. Energy Mater. 2019, 2, 2223–2229. [Google Scholar] [CrossRef]

- Fan, X.; Mao, J.; Zhu, Y.; Luo, C.; Suo, L.; Gao, T.; Han, F.; Liou, S.-C.; Wang, C. Superior Stable Self-Healing SnP3 Anode for Sodium-Ion Batteries. Adv. Energy Mater. 2015, 5, 1500174. [Google Scholar] [CrossRef]

- Choi, J.; Kim, W.-S.; Kim, K.-H.; Hong, S.-H. Sn4P3–C Nanospheres as High Capacitive and Ultra-Stable Anodes for Sodium Ion and Lithium Ion Batteries. J. Mater. Chem. A 2018, 6, 17437–17443. [Google Scholar] [CrossRef]

- Nam, K.-H.; Hwa, Y.; Park, C.-M. Zinc Phosphides as Outstanding Sodium-Ion Battery Anodes. ACS Appl. Mater. Interfaces 2020, 12, 15053–15062. [Google Scholar] [CrossRef]

- Wang, Y.; Fu, Q.; Li, C.; Li, H.; Tang, H. Nitrogen and Phosphorus Dual-Doped Graphene Aerogel Confined Monodisperse Iron Phosphide Nanodots as an Ultrafast and Long-Term Cycling Anode Material for Sodium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 15083–15091. [Google Scholar] [CrossRef]

- Boyanov, S.; Zitoun, D.; Ménétrier, M.; Jumas, J.C.; Womes, M.; Monconduit, L. Comparison of the Electrochemical Lithiation/Delitiation Mechanisms of FePx (X = 1, 2, 4) Based Electrodes in Li-Ion Batteries. J. Phys. Chem. C 2009, 113, 21441–21452. [Google Scholar] [CrossRef]

- Qian, J.; Xiong, Y.; Cao, Y.; Ai, X.; Yang, H. Synergistic Na-Storage Reactions in Sn4P3 as a High-Capacity, Cycle-Stable Anode of Na-Ion Batteries. Nano Lett. 2014, 14, 1865–1869. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S.; Kravchyk, K.; Ibáñez, M.; Krumeich, F.; Widmer, R.; Nasiou, D.; Meyns, M.; Llorca, J.; Arbiol, J.; et al. SnP Nanocrystals as Anode Materials for Na-Ion Batteries. J. Mater. Chem. A 2018, 6, 10958–10966. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, B.; Bai, J.; Tong, P.; Zhu, X.; Sun, Y. Transition Metal Nitrides in Lithium- and Sodium-Ion Batteries: Recent Progress and Perspectives. Adv. Mater. Interfaces 2022, 9, 2200606. [Google Scholar] [CrossRef]

- Kundu, D.; Krumeich, F.; Fotedar, R.; Nesper, R. A Nanocrystalline Nitride as an Insertion Anode for Li-Ion Batteries. J. Power Sources 2015, 278, 608–613. [Google Scholar] [CrossRef]

- Inagaki, M.; Toyoda, M.; Soneda, Y.; Morishita, T. Nitrogen-Doped Carbon Materials. Carbon 2018, 132, 104–140. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Guo, S.; Pinna, N. Graphene/N-Doped Carbon Sandwiched Nanosheets with Ultrahigh Nitrogen Doping for Boosting Lithium-Ion Batteries. J. Mater. Chem. A 2016, 4, 1423–1431. [Google Scholar] [CrossRef]

- Alpen, U.v.; Rabenau, A.; Talat, G.H. Ionic Conductivity in Li3N Single Crystals. Appl. Phys. Lett. 1977, 30, 621–623. [Google Scholar] [CrossRef]

- Balogun, M.-S.; Qiu, W.; Wang, W.; Fang, P.; Lu, X.; Tong, Y. Recent Advances in Metal Nitrides as High-Performance Electrode Materials for Energy Storage Devices. J. Mater. Chem. A 2015, 3, 1364–1387. [Google Scholar] [CrossRef]

- Luo, Y.; Li, T.; Zhang, H.; Liu, W.; Zhang, X.; Yan, J.; Zhang, H.; Li, X. Endogenous Symbiotic Li3N/Cellulose Skin to Extend the Cycle Life of Lithium Anode. Angew. Chem. Int. Ed. 2021, 60, 11718–11724. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Tian, M.; Zheng, X.; Wei, C.; Rummeli, M.H.; Strasser, P.; Yang, R. Cotton Pad Derived 3d Lithiophilic Carbon Host for Robust Li Metal Anode: In-Situ Generated Ionic Conductive Li3N Protective Decoration. Chem. Eng. J. 2022, 430, 132722. [Google Scholar] [CrossRef]

- Wan, M.; Duan, X.; Cui, H.; Du, J.; Fu, L.; Chen, Z.; Lu, Z.; Li, G.; Li, Y.; Mao, E.; et al. Stabilized Li Metal Anode with Robust C-Li3N Interphase for High Energy Density Batteries. Energy Storage Mater. 2022, 46, 563–569. [Google Scholar] [CrossRef]

- Dong, S.; Chen, X.; Gu, L.; Zhou, X.; Li, L.; Liu, Z.; Han, P.; Xu, H.; Yao, J.; Wang, H.; et al. One Dimensional MnO2/Titanium Nitride Nanotube Coaxial Arrays for High Performance Electrochemical Capacitive Energy Storage. Energy Environ. Sci. 2011, 4, 3502–3508. [Google Scholar] [CrossRef]

- Huang, H.; Gao, S.; Wu, A.-M.; Cheng, K.; Li, X.-N.; Gao, X.-X.; Zhao, J.-J.; Dong, X.-L.; Cao, G.-Z. Fe3N Constrained inside C Nanocages as an Anode for Li-Ion Batteries through Post-Synthesis Nitridation. Nano Energy 2017, 31, 74–83. [Google Scholar] [CrossRef]

- Gao, B.; Li, X.; Ding, K.; Huang, C.; Li, Q.; Chu, P.K.; Huo, K. Recent Progress in Nanostructured Transition Metal Nitrides for Advanced Electrochemical Energy Storage. J. Mater. Chem. A 2019, 7, 14–37. [Google Scholar] [CrossRef]

- Ajikumar, P.K.; Kamruddin, M.; Nithya, R.; Shankar, P.; Dash, S.; Tyagi, A.K.; Raj, B. Surface Nitridation of Ti and Cr in Ammonia Atmosphere. Scr. Mater. 2004, 51, 361–366. [Google Scholar] [CrossRef]

- Lengauer, W. Transition Metal Carbides, Nitrides, and Carbonitrides. In Handbook of Ceramic Hard Materials; Wiley: Hoboken, NJ, USA, 2000; pp. 202–252. [Google Scholar]

- Liu, M.; Zhang, Z.; Xie, Y.; Guo, Z.; Feng, H.; Liu, W.; Wang, H. Titanium Nitride as a Promising Sodium-Ion Battery Anode: Interface-Confined Preparation and Electrochemical Investigation. Dalton Trans. 2022, 51, 12855–12865. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Garcia-Araez, N.; Hector, A.L. Synthesis of Vanadium Nitride–Hard Carbon Composites from Cellulose and Their Performance for Sodium-Ion Batteries. ACS Appl. Energy Mater. 2020, 3, 4286–4294. [Google Scholar] [CrossRef]

- Zeng, F.; Lu, T.; He, W.; Chu, S.; Qu, Y.; Pan, Y. In-Situ Carbon Encapsulation of Ultrafine VN in Yolk-Shell Nanospheres for Highly Reversible Sodium Storage. Carbon 2021, 175, 289–298. [Google Scholar] [CrossRef]

- Wei, S.; Wang, C.; Chen, S.; Zhang, P.; Zhu, K.; Wu, C.; Song, P.; Wen, W.; Song, L. Dial the Mechanism Switch of VN from Conversion to Intercalation toward Long Cycling Sodium-Ion Battery. Adv. Energy Mater. 2020, 10, 1903712. [Google Scholar] [CrossRef]

- Sridhar, V.; Park, H. Manganese Nitride Stabilized on Reduced Graphene Oxide Substrate for High Performance Sodium Ion Batteries, Super-Capacitors and Emi Shielding. J. Alloys Compd. 2019, 808, 151748. [Google Scholar] [CrossRef]

- Li, X.; Deng, C.; Wang, H.; Si, J.; Zhang, S.; Huang, B. Iron Nitride@C Nanocubes inside Core–Shell Fibers to Realize High Air-Stability, Ultralong Life, and Superior Lithium/Sodium Storages. ACS Appl. Mater. Interfaces 2021, 13, 7297–7307. [Google Scholar] [CrossRef]

- He, H.; Sun, D.; Tang, Y.; Wang, H.; Shao, M. Understanding and Improving the Initial Coulombic Efficiency of High-Capacity Anode Materials for Practical Sodium Ion Batteries. Energy Storage Mater. 2019, 23, 233–251. [Google Scholar] [CrossRef]

- Rakhymbay, L.; Bazybek, N.; Kudaibergenov, K.; Myung, S.-T.; Bakenov, Z.; Konarov, A. Present Development and Future Perspectives on Biowaste-Derived Hard Carbon Anodes for Room Temperature Sodium-Ion Batteries. J. Power Sources 2024, 602, 234347. [Google Scholar] [CrossRef]

- Gabriel, E.; Ma, C.; Graff, K.; Conrado, A.; Hou, D.; Xiong, H. Heterostructure Engineering in Electrode Materials for Sodium-Ion Batteries: Recent Progress and Perspectives. eScience 2023, 3, 100139. [Google Scholar] [CrossRef]

| Parameters | Lithium | Sodium |

|---|---|---|

| Cation radius [Å] | 0.76 | 1.02 |

| Relative atomic mass | 6.94 | 22.98 |

| E0 (vs. SHE) [V] | −3.07 | −2.71 |

| Cost, carbonates | USD 5000 ton−1 | USD 150 ton−1 |

| Theoretical capacity [mAh g−1] | 3829 | 1165 |

| Coordination preference | Octahedral and tetrahedral | Octahedral and prismatic |

| Desolvation energy in polycarbonate [kJ mol−1] | 218.0 | 157.3 |

| Materials | Initial Reversible Capacity | ICE | Cycling Performance | Capacity Retention (%) | Ref. |

|---|---|---|---|---|---|

| CoP3@C | 238.1 mAh g−1 @ 100 mA g−1 | 87 | 212 mAh g−1 after 80 cycles @ 100 mA g−1 | 77.6 | [93] |

| CoP4/CF | 902 mAh g−1 @ 0.3 A g-−1 | 53.3 | 535 mAh g−1 after 1000 cycles @ 1 A g−1 | 90 | [94] |

| CrP4/C | 881 mAh g−1 @ 50 mA g−1 | 78.3 | 613 mAh g−1 after 50 cycles @ 50 mA g−1 | 86.4 | [95] |

| CuP2/C | 396 mAh g−1 @ 50 mA g−1 | 65 | 450 mAh g−1 after 100 cycles @ 200 mA g−1 | - | [96] |

| CuP2/C | 470 mAh g−1 @ 150 mA g−1 | 67.1 | 450 mAh g−1 after 30 cycles @ 150 mA g−1 | - | [97] |

| FeP4 | 1137 mAh g−1 @ 89 mA g−1 | 84.1 | 1023 mAh g−1 after 30 cycles @ 89 mA g−1 | 90 | [98] |

| FeP4/CF | 984 mAh g−1 @ 0.3 A g−1 | 58.8 | 711 mAh g−1 after 1000 cycles @ 1 A g−1 | 90 | [94] |

| GeP5/AB/p-rGO | 597.5 mAh g−1 @ 100 mA g−1 | 60 | 400 mAh g−1 after 50 cycles @ 500 mA g−1 | 81.6 | [99] |

| MnP4/Graphene | 718 mAh g−1 @ 50 mA g−1 | 66.5 | 627 mAh g−1 after 100 cycles @ 50 mA g−1 | 87.3 | [100] |

| NiP1.5S0.5 | 608 mAh g−1 @ 50 mA g−1 | 75.8 | 299 mAh g−1 after 200 cycles @ 500 mA g−1 | - | [101] |

| NiP2/C | 489 mAh g−1 @ 50 mA g−1 | 75 | 231 mAh g−1 after 250 cycles @ 500 mA g−1 | 93.6 | [102] |

| NiP3/CNT | 868.4 mAh g−1 @ 100 mA g−1 | - | 363.8 mAh g−1 after 200 cycles @ 1600 mA g−1 | 65 | [103] |

| SiP2/C | 501 mAh g−1 @ 50 mA g−1 | 76 | 410 mAh g−1 after 100 cycles @ 50 mA g−1 | - | [104] |

| SnP3/C | 805 mAh g−1 @ 150 mA g−1 | 71.2 | 810 mAh g−1 after 150 cycles @ 150 mA g−1 | - | [105] |

| Sn3P4-C | 721 mAh g−1 @ 200 mA g−1 | 60 | 420 mAh g−1 after 2000 cycles @ 2 A g−1 | - | [106] |

| ZnP2/C | 704 mAh g−1 @ 50 mA g−1 | 65.8 | 883 mAh g−1 after 130 cycles @ 50 mA g−1 | - | [107] |

| Material Group | Reaction Mechanism (Discharged to Na/Na+) | Advantages | Common Issues that Need to Be Addressed | Example |

|---|---|---|---|---|

| Oxides (TM-O) | Insertion | Cost-effective Excellent cycle retention | Low capacity Moderate working potential | Early TM oxides (e.g., TiO2, Li4Ti7O12, Na4Ti5O12, VO2, etc.) |

| Conversion | Cost-effective High capacity | Poor cycle retention Moderate working potential Moderate voltage hysteresis | Later TM oxides (e.g., Fe2O3, Fe3O4, Co3O4, NiO, etc.) | |

| Sulfides (TM-S) | Conversion | Moderate capacity | High working potential Large voltage hysteresis Moderate cycle retention | TM sulfides (e.g., TiS2, MoS2, FeS, FeS2, NiS2, etc.) |

| Selenides (TM-Se) | Conversion | High electrical conductivity | Low capacity High working potential High voltage hysteresis | TM selenides (e.g., TiSe2, MoSe2, FeSe, FeSe2, etc.) |

| Phosphides (TM-P) | Insertion | Low working potential Excellent cycle retention | Low capacity | Early TM phosphides (e.g., V4P7) |

| Conversion | Low working potential High capacity | Low voltage hysteresis Poor cycle retention | Middle and later TM phosphides (e.g., CrP4, MnP4, CoP4, FeP4, etc.) | |

| Nitrides (TM-N) | Insertion | Low working potential Excellent cycle retention | Moderate capacity Low ICE | Early TM nitrides (e.g., TiN, VN, etc.) |

| Conversion | Low working potential Feasible high capacity | Low voltage hysteresis Low ICE | Later TM nitrides (e.g., Ni3N, Cu3N, etc.) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, I.; Ha, S.; Kim, K.-H. Review and Recent Advances in Metal Compounds as Potential High-Performance Anodes for Sodium Ion Batteries. Energies 2024, 17, 2646. https://doi.org/10.3390/en17112646

Choi I, Ha S, Kim K-H. Review and Recent Advances in Metal Compounds as Potential High-Performance Anodes for Sodium Ion Batteries. Energies. 2024; 17(11):2646. https://doi.org/10.3390/en17112646

Chicago/Turabian StyleChoi, Inji, Sion Ha, and Kyeong-Ho Kim. 2024. "Review and Recent Advances in Metal Compounds as Potential High-Performance Anodes for Sodium Ion Batteries" Energies 17, no. 11: 2646. https://doi.org/10.3390/en17112646

APA StyleChoi, I., Ha, S., & Kim, K.-H. (2024). Review and Recent Advances in Metal Compounds as Potential High-Performance Anodes for Sodium Ion Batteries. Energies, 17(11), 2646. https://doi.org/10.3390/en17112646