Review of Recent Applications of Heat Pipe Heat Exchanger Use for Waste Heat Recovery

Abstract

1. Introduction

- Unidirectional heat transfer: In some applications, it is necessary to transfer heat from one medium to another in a unidirectional manner, and it is not desirable to have unnecessary heat transfer. Traditional heat exchangers transfer heat in the presence of a temperature difference, whereas HPHXs possess thermal diode characteristics, ensuring unidirectional heat conduction from a primary medium to a secondary medium [2].

- Complete separation of hot and cold media: In HPHXs, the hot and cold media are completely separated, with almost no cross-leakage for heat exchange. This means that no mixing of media occurs when the heat is transferred, ensuring the safety and reliability of the system. For instance, employing HPHXs in nuclear reactors can eliminate the need for secondary pumped heat exchange loops and reduce the possibility of tritium entering the process heat flow [3].

- Isothermal operations: HPs within HPHXs can achieve isothermal operations, meaning that the working fluid inside the HP maintains a stable temperature during the heat transfer process. For example, during waste heat recovery, if the temperature of acid gases is below the dew point, the gases would condense, leading to severe corrosion. Due to the isothermal operation characteristics of HPHX, this situation can be effectively prevented, improving the stability and reliability of the system [4,5,6].

- Modularization: Each HP in HPHX can be considered an independent entity, and the failure of a single HP will not lead to the entire system becoming inoperative. For example, applying HPHXs to heat sink systems can avoid the issue of single-point failure of the original radiators [7].

| HP Types | Principles | Advantages | Applications in References | Configurations |

|---|---|---|---|---|

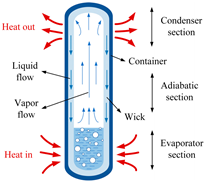

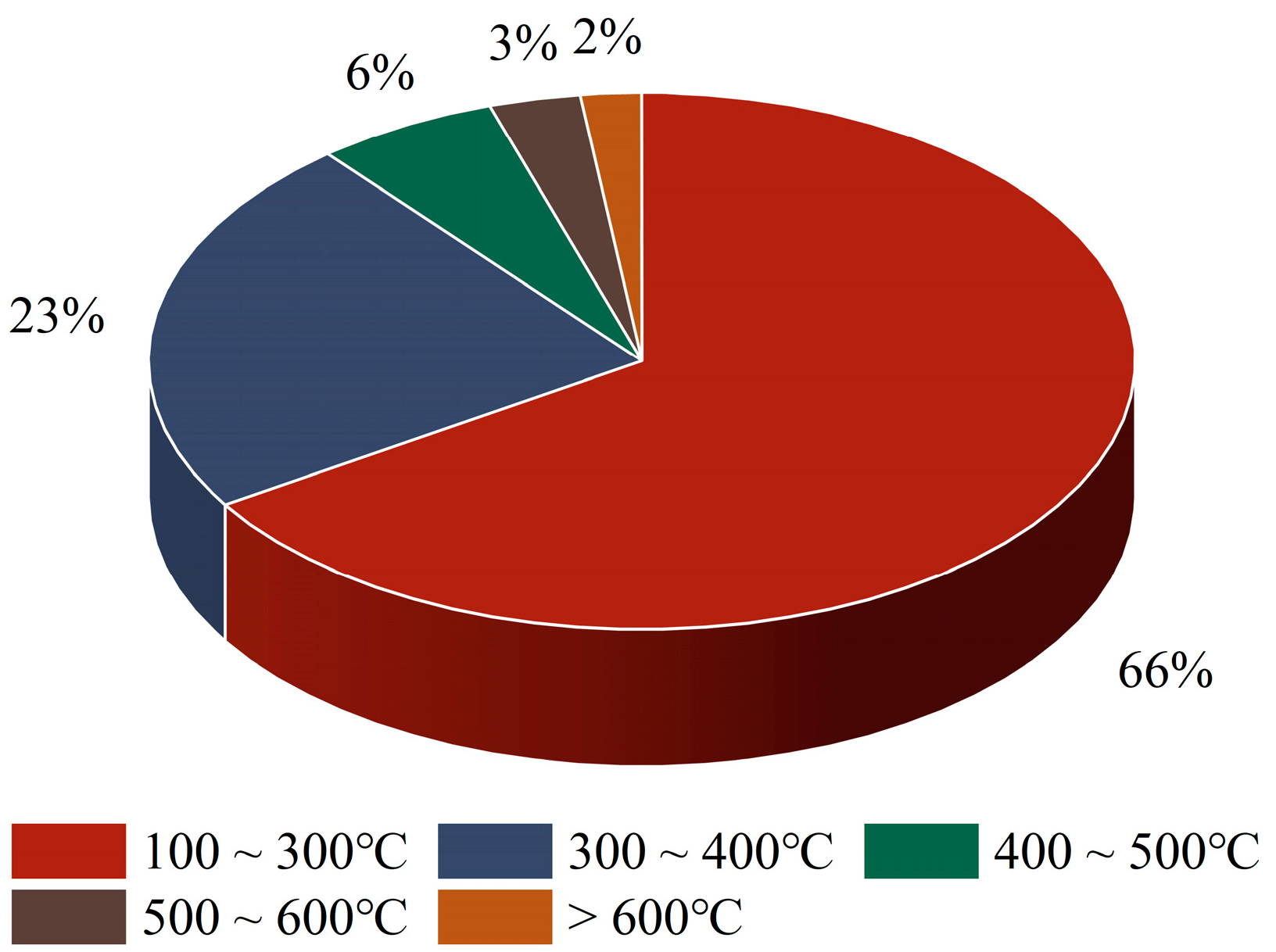

| Wick heat pipe | When the hot end is heated, the working fluid at the hot end evaporates, forming vapor. The vapor moves through the pipe to the cooling end, where it condenses into liquid and then returns to the hot end through wick structure, forming a closed heat cycle. | Simple, reliable, requiring no external power, and suitable for most heat conduction needs. | TOPAZ-II power system [7], nuclear power plant [8], withering of tea leaves [9], HVAC systems [10] |  |

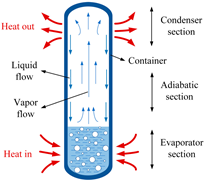

| Thermosyphon | The key distinction from wick heat pipes is that thermosyphons use natural convection and gravity to transfer heat, eliminating the need for a wick structure. Their dependence on gravity means that the condensing end must be positioned above the evaporating end. | They require no external power and are suitable for vertical heat transfer and microgravity environments. | nuclear reactor [3,11], the ceramic industry [4,5,6,12], solar collector [13,14], coal to liquid process [15,16], HVAC systems [17,18,19,20,21,22], heat recovery system [23,24,25,26,27,28,29], gas city gate station [30], steel industry [31,32], dyeing and printing industry [33], the pressure reduction stations [34], heat recovery of coal-fired flue gas [35], aluminum industry [36], combine harvester [37] |  |

| Flat-plate heat pipe | Flat-plate heat pipes typically have thinner cross-sections, making them suitable for heat conduction within limited spaces. | They are suitable for confined spaces and can achieve efficient heat conduction within thinner structures. | solar collector [38,39,40], photovoltaic panel [41], steel industry [42,43] |  |

| Concentric tube heat pipe | Concentric tube heat pipes consist of two concentric pipes, where the inner pipe serves as the evaporator section, and the outer pipe serves as the condenser section. The working fluid circulates within the inner pipe, facilitating heat transfer. | They can handle larger heat conduction distances and exhibit high heat transfer efficiency. | electronic component system [44,45] |  |

| Micro-structure heat pipe | Micro-heat pipes are similar to wick heat pipes but are smaller in size, making them suitable for efficient heat transfer in small-scale devices. | They are suitable for microdevices and can achieve efficient heat transfer within limited spaces. | HVAC systems [46,47], heat recovery in the cold regions [48], industrial equipment [49], oil fume heat recovery [50] | / |

2. HPHX Industrial Application

2.1. Solar Energy Systems

2.2. Nuclear Energy Systems

2.3. Geothermal Energy Systems

2.4. HVAC Systems

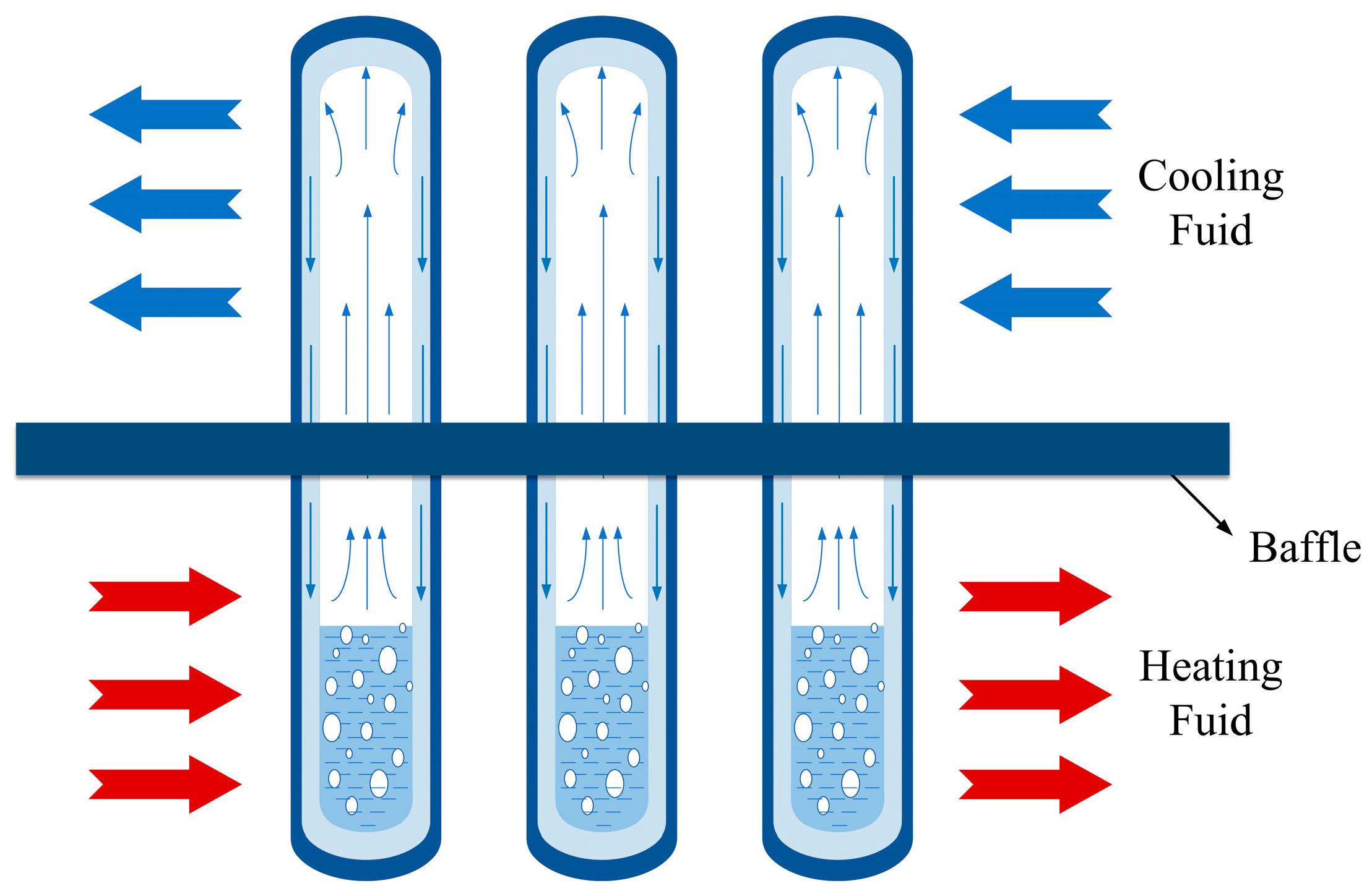

3. HPHX for Low-Temperature Waste Heat Recovery

3.1. HP Type and Dry-Out Analysis

3.2. HP Materials and Working Medium Compatibility

3.3. HPHX Performance Optimization

3.4. HPHX Performance Prediction

4. HPHX for Medium- and High-Temperature Waste Heat Recovery

5. Conclusions

- HPHXs have been applied in the fields of solar energy, nuclear energy, geothermal energy, HVAC systems, and waste heat recovery. However, they are more commonly applied in low-temperature fields because the operating temperatures of HPHXs fit the temperatures of most economic HPs. When HPHXs are applied in medium- and high-temperature fields, some special organic fluids or liquid metals are often used as working fluids, which are more costly. In addition, high-temperature HPs using liquid metals as the working fluid also have freezing start-up and heat transfer limitation problems, which may cause the HP to fail.

- The HP feature is crucial for the construction of the HPHX. The HP type, material, and working fluid should be compatible. Meanwhile, the thermosyphon but not wick-structure HP is more commonly used due to less flow resistance for condensation. Thermosyphon-based HPHXs are widely used in nuclear reactors, HVAC systems, and low-temperature waste heat recovery due to their simple and low-cost production. In addition, in low-temperature waste heat recovery, a concentric tube heat pipe heat exchanger has been proposed and applied in order to prevent the drying-out limit in thermosyphons. In solar energy systems and high-temperature waste heat recovery, flat-plate HPHXs are utilized more often to maximize the radiation absorption area in order to further improve the heat transfer efficiency.

- Copper and aluminum are also commonly used materials for HPs in HVAC systems, and refrigerants are regarded as ideal fluids. Alternative low GWP and near-zero GWP working fluids are being investigated in HVACs. On the other hand, the materials of HPHXs used in nuclear reactors and medium- and high-temperature waste heat recovery are usually high-temperature alloys with high-temperature resistance and corrosion resistance. The choice of working fluid should consider the saturation temperature, working pressure, and material compatibility. Different working fluids are used in different temperature regions in order to meet the demand for waste heat recovery and save costs.

- The addition of surfactants and nanoparticles to the working fluid shows a substantial impact on HPHX performance. In addition, the impact of the HP inclination angle, structure, length of HP evaporation sections, and operating conditions were also studied. Moreover, measures to prevent and reduce the formation of fouling are necessary. For low-temperature waste heat recovery, the impact of the number of passes and descaling devices on enhancing HPHX heat exchange has also been studied in the field of low-temperature waste heat recovery.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| IEA | International Energy Agency |

| HP | heat pipe |

| HPHX | heat pipe heat exchanger |

| CFD | computational fluid dynamics |

| VOF | volume of fluid |

| LMTD | log mean temperature difference |

| ε-NTU | effectiveness-number of transfer units |

| HVAC | heating, ventilation, and air conditioning |

| PV/T | photovoltaic/thermal |

| PV | photovoltaic |

| RSM | response surface methodology |

| PTC | parabolic trough collector |

| CTL | coal-to-liquid fuel |

| EPRHR | emergency passive residual heat removal system |

| CWT | cooling water tank |

| EGS | enhanced geothermal system |

| MHPA | micro-heat pipe array |

| LPH | liters per hour |

| HVAC | heating, ventilation, and air conditioning |

| AII | airborne infectionisolation |

| COP | coefficient of performance |

| vol% | volume percent |

| IWBH | indirect water bath heater |

References

- IEA. CO2 Emissions in 2022. 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2022 (accessed on 5 January 2024).

- Shabgard, H.; Allen, M.J.; Sharifi, N.; Benin, S.P.; Faghri, A.; Bergman, T.L. Heat pipe heat exchangers and heat sinks: Opportunities, challenges, applications, analysis, and state of the art. Int. J. Heat Mass Transf. 2015, 89, 138–158. [Google Scholar] [CrossRef]

- Dobson, R.; Laubscher, R. Heat pipe heat exchanger for high temperature nuclear reactor technology. Front. Heat Pipes 2013, 4, 023002. [Google Scholar] [CrossRef]

- Brough, D.; Mezquita, A.; Ferrer, S.; Segarra, C.; Chauhan, A.; Almahmoud, S.; Khordehgah, N.; Ahmad, L.; Middleton, D.; Sewell, H.I.; et al. An experimental study and computational validation of waste heat recovery from a lab scale ceramic kiln using a vertical multi-pass heat pipe heat exchanger. Energy 2020, 208, 118325. [Google Scholar] [CrossRef]

- Delpech, B.; Milani, M.; Montorsi, L.; Boscardin, D.; Chauhan, A.; Almahmoud, S.; Axcell, B.; Jouhara, H. Energy efficiency enhancement and waste heat recovery in industrial processes by means of the heat pipe technology: Case of the ceramic industry. Energy 2018, 158, 656–665. [Google Scholar] [CrossRef]

- Jouhara, H.; Bertrand, D.; Axcell, B.; Montorsi, L.; Venturelli, M.; Almahmoud, S.; Milani, M.; Ahmad, L.; Chauhan, A. Investigation on a full-scale heat pipe heat exchanger in the ceramics industry for waste heat recovery. Energy 2021, 223, 120037. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, C.; Chen, R.; Tian, W.; Qiu, S.; Su, G.H. Preliminary design and thermal analysis of a liquid metal heat pipe radiator for TOPAZ-II power system. Ann. Nucl. Energy 2016, 97, 208–220. [Google Scholar] [CrossRef]

- Xie, C.Y.; Tao, H.Z.; Li, W.; Cheng, J.J. Numerical simulation and experimental investigation of heat pipe heat exchanger applied in residual heat removal system. Ann. Nucl. Energy 2019, 133, 568–579. [Google Scholar] [CrossRef]

- Gunawan, Y.; Putra, N.; Hakim, I.I.; Agustina, D.; Mahlia, T.M.I. Withering of tea leaves using heat pipe heat exchanger by utilizing low-temperature geothermal energy. Int. J. Low-Carbon Technol. 2021, 16, 146–155. [Google Scholar]

- Sukarno, R.; Putra, N.; Hakim, I.I.; Rachman, F.F.; Mahlia, T.M.I. Utilizing heat pipe heat exchanger to reduce the energy consumption of airborne infection isolation hospital room HVAC system. J. Build. Eng. 2021, 35, 102116. [Google Scholar] [CrossRef]

- Laubscher, R.; Dobson, R.T. Theoretical and experimental modelling of a heat pipe heat exchanger for high temperature nuclear reactor technology. Appl. Therm. Eng. 2013, 61, 259–267. [Google Scholar] [CrossRef]

- Delpech, B.; Axcell, B.; Jouhara, H. Experimental investigation of a radiative heat pipe for waste heat recovery in a ceramics kiln. Energy 2019, 170, 636–651. [Google Scholar] [CrossRef]

- Sahu, S.; Pise, A.; Chougule, S. Performance enhancement of two phase thermosyphon flat-plate solar collectors by using surfactant and nanofluid. Front. Heat Pipes 2013, 4, 1–6. [Google Scholar]

- Sarafraz, M.M.; Tlili, I.; Tian, Z.; Bakouri, M.; Safaei, M.R. Smart optimization of a thermosyphon heat pipe for an evacuated tube solar collector using response surface methodology (RSM). Phys. A-Stat. Mech. Appl. 2019, 534, 122146. [Google Scholar]

- Tshamala, M.C.; Dobson, R.T. Simulation of a High-Temperature Modular Reactor (HTMR) for Power and Coal-to-Liquid Fuel-Cogeneration Plant. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Tshamala, M.C.; Dobson, R.T. Design of Heat-Pipe Heat Exchanger (Hphe) for a Coal-to-Liquid Fuel Process Using Nuclear Energy. In Proceedings of the 24th International Conference on Nuclear Engineering, Charlotte, NC, USA, 26–30 June 2016; Volume 1. [Google Scholar]

- Zhang, L.Y.; Liu, Y.Y.; Guo, X.; Meng, X.Z.; Jin, L.W.; Zhang, Q.L.; Hu, W.J. Experimental investigation and economic analysis of gravity heat pipe exchanger applied in communication base station. Appl. Energy 2017, 194, 499–507. [Google Scholar] [CrossRef]

- Ali, S.M.; Sarsam, W.S. Theoretical and experimental investigation of a heat pipe heat exchanger for energy recovery of exhaust air. Heat Transf. 2022, 51, 3600–3619. [Google Scholar] [CrossRef]

- Abedalh, A.S.; Yasin, N.J.; Ameen, H.A. Thermal performance of HAVC system using heat pipe heat exchanger. J. Mech. Eng. Res. Dev. 2021, 44, 1–9. [Google Scholar]

- Abdallah, A.S.; Yasin, N.J.; Ameen, H.A. Thermal Performance Enhancement of Heat Pipe Heat Exchanger in the Air-Conditioning System by Using Nanofluid. Front. Heat Mass Transf. 2022, 18, 1–7. [Google Scholar] [CrossRef]

- Monirimanesh, N.; Nowee, S.M.; Khayyami, S.; Abrishamchi, I. Performance enhancement of an experimental air conditioning system by using TiO2/methanol nanofluid in heat pipe heat exchangers. Heat Mass Transf. 2016, 52, 1025–1035. [Google Scholar] [CrossRef]

- Abdelaziz, G.B.; Abdelbaky, M.A.; Halim, M.A.; Omara, M.E.; Elkhaldy, I.A.; Abdullah, A.S.; Omara, Z.M.; Essa, F.A.; Ali, A.; Sharshir, S.W.; et al. Energy saving via Heat Pipe Heat Exchanger in air conditioning applications “experimental study and economic analysis”. J. Build. Eng. 2021, 35, 102053. [Google Scholar] [CrossRef]

- Gedik, E.; Yılmaz, M.; Kurt, H. Experimental investigation on the thermal performance of heat recovery system with gravity assisted heat pipe charged with R134a and R410A. Appl. Therm. Eng. 2016, 99, 334–342. [Google Scholar] [CrossRef]

- Ozturk, A.; Ozalp, M.; Sozen, A. Experimental Investigation of an Al2O3/Distilled Water Nanofluid Used In the Heat Pipes of Heat Exchangers. Gazi Univ. J. Sci. 2018, 31, 616–626. [Google Scholar]

- Ramos, J.B.; Chong, A.; Tan, C.; Matthews, J.; Boocock, M.A.; Jouhara, H. Experimental analysis of gas to water two phase closed thermosyphon based heat exchanger. In Proceedings of the 10th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Orlando, FL, USA, 14–16 July 2014. [Google Scholar]

- Ramos, J.; Chong, A.; Jouhara, H. Experimental and numerical investigation of a cross flow air-to-water heat pipe-based heat exchanger used in waste heat recovery. Int. J. Heat Mass Transf. 2016, 102, 1267–1281. [Google Scholar] [CrossRef]

- Mroue, H.; Ramos, J.B.; Wrobel, L.C.; Jouhara, H. Experimental and numerical investigation of an air-to-water heat pipe-based heat exchanger. Appl. Therm. Eng. 2015, 78, 339–350. [Google Scholar] [CrossRef]

- Mroue, H.; Ramos, J.B.; Wrobel, L.C.; Jouhara, H. Performance evaluation of a multi-pass air-to-water thermosyphon-based heat exchanger. Energy 2017, 139, 1243–1260. [Google Scholar] [CrossRef]

- Geum, G.; Kang, S.; Cho, S.; Kong, D.; Lee, S.; Seo, J.; Shin, D.H.; Lee, S.H.; Lee, J.; Lee, H. Thermal performance analysis of heat pipe heat exchanger for effective waste heat recovery. Int. Commun. Heat Mass Transf. 2024, 151, 107223. [Google Scholar] [CrossRef]

- Alizadeh, A.; Ghadamian, H.; Aminy, M.; Hoseinzadeh, S.; Sahebi, H.K.; Sohani, A. An experimental investigation on using heat pipe heat exchanger to improve energy performance in gas city gate station. Energy 2022, 252, 123959. [Google Scholar] [CrossRef]

- Ma, H.T.; Du, N.; Zhang, Z.Y.; Lyu, F.; Deng, N.; Li, C.; Ye, S.J. Assessment of the optimum operation conditions on a heat pipe heat exchanger for waste heat recovery in steel industry. Renew. Sustain. Energy Rev. 2017, 79, 50–60. [Google Scholar] [CrossRef]

- Ma, H.T.; Yin, L.H.; Shen, X.P.; Lu, W.Q.; Sun, Y.X.; Zhang, Y.F.; Deng, N. Experimental study on heat pipe assisted heat exchanger used for industrial waste heat recovery. Appl. Energy 2016, 169, 177–186. [Google Scholar] [CrossRef]

- Tian, E.; He, Y.L.; Tao, W.Q. Research on a new type waste heat recovery gravity heat pipe exchanger. Appl. Energy 2017, 188, 586–594. [Google Scholar] [CrossRef]

- Rastegar, S.; Kargarsharifabad, H.; Rahbar, N.; Shafii, M.B. Distilled water production with combination of solar still and thermosyphon heat pipe heat exchanger coupled with indirect water bath heater—Experimental study and thermoeconomic analysis. Appl. Therm. Eng. 2020, 176, 115437. [Google Scholar] [CrossRef]

- Zhang, S.W.; Song, G.H.; Xue, Z.H. Techno-Economic Assessment of Enamel Heat Pipe Exchanger in a Combined Heat and Power Plant With Back Pressure Turbine. J. Therm. Sci. Eng. Appl. 2021, 13, 044501. [Google Scholar] [CrossRef]

- Jouhara, H.; Nieto, N.; Egilegor, B.; Zuazua, J.; Gonz, E.; Yebra, I.; Igesias, A.; Delpech, B.; Almahmoud, S.; Brough, D.; et al. Waste heat recovery solution based on a heat pipe heat exchanger for the aluminium die casting industry. Energy 2023, 266, 126459. [Google Scholar] [CrossRef]

- Xu, J.; Wang, M.J.; Chen, P.L.; Liu, M.H. Recovering Exhaust Heat of Combine Harvester through Heat Pipe Exchanger for Drying Grain. INMATEH-Agric. Eng. 2019, 58, 187–194. [Google Scholar]

- Jouhara, H.; Milko, J.; Danielewicz, J.; Sayegh, M.A.; Szulgowska-Zgrzywa, M.; Ramos, J.B.; Lester, S.P. The performance of a novel flat heat pipe based thermal and PV/T (photovoltaic and thermal systems) solar collector that can be used as an energy-active building envelope material. Energy 2016, 108, 148–154. [Google Scholar] [CrossRef]

- Jouhara, H.; Szulgowska-Zgrzywa, M.; Sayegh, M.A.; Milko, J.; Danielewicz, J.; Nannou, T.K.; Lester, S.P. The performance of a heat pipe based solar PV/T roof collector and its potential contribution in district heating applications. Energy 2017, 136, 117–125. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Safaei, M.R. Diurnal thermal evaluation of an evacuated tube solar collector (ETSC) charged with graphene nanoplatelets-methanol nano-suspension. Renew. Energy 2019, 142, 364–372. [Google Scholar] [CrossRef]

- Al-Mabsali, S.A.; Candido, J.P.; Chaudhry, H.N.; Gul, M.S. Investigation of an Inclined Heat Pipe Heat Exchanger as a Passive Cooling Mechanism on a Photovoltaic Panel. Energies 2021, 14, 7828. [Google Scholar] [CrossRef]

- Jouhara, H.; Almahmoud, S.; Chauhan, A.; Delpech, B.; Bianchi, G.; Tassou, S.A.; Llera, R.; Lago, F.; Arribas, J.J. Experimental and theoretical investigation of a flat heat pipe heat exchanger for waste heat recovery in the steel industry. Energy 2017, 141, 1928–1939. [Google Scholar] [CrossRef]

- Almahmoud, S.; Jouhara, H. Experimental and theoretical investigation on a radiative flat heat pipe heat exchanger. Energy 2019, 174, 972–984. [Google Scholar] [CrossRef]

- Ramkumar, P.; Sivasubramanian, M.; Raveendiran, P.; Kanna, P.R. An experimental inquisition of waste heat recovery in electronic component system using concentric tube heat pipe heat exchanger with different working fluids under gravity assistance. Microprocess. Microsyst. 2021, 83, 104033. [Google Scholar] [CrossRef]

- Ramkumar, P.; Vivek, C.M.; Ramasamy, S.; Kajavali, A.; Sivasubramanian, M. Experimental and numerical study using ANFIS-neuro fuzzy model on heat pipe heat exchanger. Mater. Today-Proc. 2022, 62, 2152–2162. [Google Scholar] [CrossRef]

- Diao, Y.H.; Liang, L.; Kang, Y.M.; Zhao, Y.H.; Wang, Z.Y.; Zhu, T.T. Experimental study on the heat recovery characteristic of a heat exchanger based on a flat micro-heat pipe array for the ventilation of residential buildings. Energy Build. 2017, 152, 448–457. [Google Scholar] [CrossRef]

- Jing, H.R.; Quan, Z.H.; Zhao, Y.H.; Wang, L.C.; Ren, R.Y.; Liu, Z.C. Thermal Performance and Energy Saving Analysis of Indoor Air-Water Heat Exchanger Based on Micro Heat Pipe Array for Data Center. Energies 2020, 13, 393. [Google Scholar] [CrossRef]

- Yang, J.G.; Zhao, Y.H.; Chen, A.X.; Quan, Z.H. Thermal Performance of a Low-Temperature Heat Exchanger Using a Micro Heat Pipe Array. Energies 2019, 12, 675. [Google Scholar] [CrossRef]

- Yang, J.G.; Hao, W.; Lv, J.L. Assessing the performance of a gas-water heat exchanger based on micro-heat pipe technology. Exp. Heat Transf. 2022, 36, 892–917. [Google Scholar]

- Yang, J.A.; Feng, Z.T.; Liu, Z.H.; Song, D.Y. Study on the performance of oil fume heat recovery heat exchanger based on micro heat pipe array. Energy Rep. 2024, 11, 240–248. [Google Scholar] [CrossRef]

- Tiwatane, T.; Barve, S. Experimental Study of Waste Heat Recovery Using Heat Pipe Heat Exchanger with Hybrid Nano fluid: A Review. Int. J. Mech. Ind. Technol 2015, 3, 40–47. [Google Scholar]

- Ong, K.S. Review of heat pipe heat exchangers for enhanced dehumidification and cooling in air conditioning systems. Int. J. Low-Carbon Technol. 2016, 11, 416–423. [Google Scholar] [CrossRef]

- Zohuri, B.; Lam, S.; Forsberg, C. Heat-Pipe Heat Exchangers for Salt-Cooled Fission and Fusion Reactors to Avoid Salt Freezing and Control Tritium: A Review. Nucl. Technol. 2020, 206, 1642–1658. [Google Scholar] [CrossRef]

- Parab, S.; ProfM, G.; Chavan, O. Heat pipe heat exchangers and HVAC system–A review. Int. J. Trendy Res. Eng. Technol. 2023, 7, 6–10. [Google Scholar] [CrossRef]

- Nithin, V.K. Opportunities, challenges, and state of the art of flexible heat-pipe heat exchangers: A comprehensive review. Heat Transf. 2024, 53, 893–938. [Google Scholar]

- Qiao, K.; Tao, H.Z.; Li, Y.N.; Zhao, B.M.; Song, C.; Li, W.; Cheng, J.J. Numerical study on long-term passive heat removal of EPRHR cooling water tank (CWT) using heat pipe heat exchanger. Ann. Nucl. Energy 2022, 175, 109212. [Google Scholar] [CrossRef]

- Zorn, R.; Steger, H.; Kolbel, T. De-Icing and Snow Melting System with Innovative Heat Pipe Technology. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Hakim, I.I.; Sukarno, R.; Putra, N. Utilization of U-shaped finned heat pipe heat exchanger in energy-efficient HVAC systems. Therm. Sci. Eng. Prog. 2021, 25, 100984. [Google Scholar] [CrossRef]

- Longo, G.A.; Righetti, G.; Zilio, C.; Bertolo, F. Experimental and theoretical analysis of a heat pipe heat exchanger operating with a low global warming potential refrigerant. Appl. Therm. Eng. 2014, 65, 361–368. [Google Scholar] [CrossRef]

- Jouhara, H.; Meskimmon, R. An investigation into the use of water as a working fluid in wraparound loop heat pipe heat exchanger for applications in energy efficient HVAC systems. Energy 2018, 156, 597–605. [Google Scholar] [CrossRef]

- Tian, Z.X.; Wang, C.L.; Guo, K.; Zhang, D.L.; Su, G.H.; Tian, W.X.; Qiu, S.Z. A review of liquid metal high temperature heat pipes: Theoretical model, design, and application. Int. J. Heat Mass Transf. 2023, 214, 124434. [Google Scholar] [CrossRef]

- Rassamakin, B.; Khairnasov, S.; Zaripov, V.; Rassamakin, A.; Alforova, O. Aluminum heat pipes applied in solar collectors. Sol. Energy 2013, 94, 145–154. [Google Scholar] [CrossRef]

- Faghri, A. Heat Pipe Science and Technology; Global Digital Press: Oxford, UK, 1995. [Google Scholar]

- Franco, A.; Vaccaro, M. On the use of heat pipe principle for the exploitation of medium–low temperature geothermal resources. Appl. Therm. Eng. 2013, 59, 189–199. [Google Scholar] [CrossRef]

- Pambudi, N.A.; Itoi, R.; Yamashiro, R.; Alam, B.Y.C.S.; Tusara, L.; Jalilinasrabady, S.; Khasani, J. The behavior of silica in geothermal brine from Dieng geothermal power plant, Indonesia. Geothermics 2015, 54, 109–114. [Google Scholar] [CrossRef]

- Zender–Świercz, E. A review of heat recovery in ventilation. Energies 2021, 14, 1759. [Google Scholar] [CrossRef]

- Eidan, A.A.; Najim, S.E.; Jalil, J.M. An experimental and a numerical investigation of HVAC system using thermosyphon heat exchangers for sub-tropical climates. Appl. Therm. Eng. 2017, 114, 693–703. [Google Scholar] [CrossRef]

- Kakkar, A. Potential of U-shaped heat pipe heat exchanger in tropical climates for low sensible heat ratio applications. ASHRAE Trans. 2017, 123, 263. [Google Scholar]

- Aprea, C.; Greco, A.; Maiorino, A.; Masselli, C.; Metallo, A. HFO1234ze as drop-in replacement for R134a in domestic refrigerators: An environmental impact analysis. Energy Procedia 2016, 101, 964–971. [Google Scholar] [CrossRef]

- Sánchez, D.; Cabello, R.; Llopis, R.; Arauzo, I.; Catalán-Gil, J.; Torrella, E. Energy performance evaluation of R1234yf, R1234ze (E), R600a, R290 and R152a as low-GWP R134a alternatives. Int. J. Refrig. 2017, 74, 269–282. [Google Scholar] [CrossRef]

- Babu, N.N.; Kamath, H.C. Materials used in Heat Pipe. Mater. Today Proc. 2015, 2, 1469–1478. [Google Scholar] [CrossRef]

- Haddad, C.; Périlhon, C.; Danlos, A.; François, M.-X.; Descombes, G. Some Efficient Solutions to Recover Low and Medium Waste Heat: Competitiveness of the Thermoacoustic Technology. Energy Procedia 2014, 50, 1056–1069. [Google Scholar] [CrossRef]

- Jouhara, H.; Almahmoud, S.; Brough, D.; Guichet, V.; Delpech, B.; Chauhan, A.; Ahmad, L.; Serey, N. Experimental and theoretical investigation of the performance of an air to water multi-pass heat pipe-based heat exchanger. Energy 2021, 219, 119624. [Google Scholar] [CrossRef]

- Danielewicz, J.; Sayegh, M.A.; Śniechowska, B.; Szulgowska-Zgrzywa, M.; Jouhara, H. Experimental and analytical performance investigation of air to air two phase closed thermosyphon based heat exchangers. Energy 2014, 77, 82–87. [Google Scholar] [CrossRef]

- Wang, Y.; Han, X.; Liang, Q.; He, W.; Lang, Z. Experimental investigation of the thermal performance of a novel concentric condenser heat pipe array. Int. J. Heat Mass Transf. 2015, 82, 170–178. [Google Scholar] [CrossRef]

- Han, X.X.; Wang, Y.X. Experimental investigation of the thermal performance of a novel concentric tube heat pipe heat exchanger. Int. J. Heat Mass Transf. 2018, 127, 1338–1342. [Google Scholar] [CrossRef]

- Zhang, J.; Diao, Y.H.; Zhao, Y.H.; Tang, X.; Yu, W.J.; Wang, S. Experimental study on the heat recovery characteristics of a new-type flat micro-heat pipe array heat exchanger using nanofluid. Energy Convers. Manag. 2013, 75, 609–616. [Google Scholar] [CrossRef]

- Yang, X.; Yan, Y.Y.; Mullen, D. Recent developments of lightweight, high performance heat pipes. Appl. Therm. Eng. 2012, 33–34, 1–14. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 2000, 21, 58–64. [Google Scholar] [CrossRef]

- Gakkhar, N.; Soni, M.S.; Jakhar, S. Second law thermodynamic study of solar assisted distillation system: A review. Renew. Sustain. Energy Rev. 2016, 56, 519–535. [Google Scholar] [CrossRef]

- Thulukkanam, K. Heat Exchanger Design Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Han, C.L.; Zou, L.J. Study on the heat transfer characteristics of a moderate-temperature heat pipe heat exchanger. Int. J. Heat Mass Transf. 2015, 91, 302–310. [Google Scholar] [CrossRef]

| Reference | Main Contents | Major Contributions and Conclusions |

|---|---|---|

| Shabgard et al. in 2015 [2] | (1) Thermal network modeling (2) Classification and application of HPHXs and heat pipe heat sinks (HPHSs) (3) Three case studies | The applications, general design procedures, and analytical tools for HPHX, based on the thermal network approach, were summarized. It included three practical case studies where the predicted outcomes revealed the potential advantages of HPHXs. Various HPHX and HPHS systems, including a potential thermal energy storage solution utilizing a phase change material, were detailed accompanied by their corresponding thermal networks. |

| Tiwatane et al. in 2015 [51] | (1) A comprehensive investigation of heat transfer capacity limits of HPs (2) Applications of HPs in energy conservation and renewable energy-based systems (3) Energy savings in air conditioning system by heat recovering using HPHX (4) Nanoparticles application in enhancing thermal conductivity of fluids with nanoparticles (5) The impact of the filling ratio on the thermal characteristics of wire-mesh HPs utilizing copper oxide nanofluid | The theory, design and construction of waste heat recovery using HPHXs with nanofluids, especially their use in waste heat recovery for energy recovery in automobiles, were summarized. The characteristic design and heat transfer limitations of single HPs without wick and working with Hybrid Nanofluids were investigated. |

| Ong in 2016 [52] | (1) HPHXs for enhanced dehumidification and cooling in air conditioning systems (2) HPs for cooling (3) HPs for cooling and dehumidification (4) Wrap-around HPHX (5) Testing of HPHXs | Several studies on the cooling and dehumidification aspects of different air conditioning systems were summarized. |

| Zohuri et al. in 2020 [53] | (1) Reactor systems and HP design requirements (2) HP design and start-up temperatures (3) HP heat transfer analysis (4) Tritium control | Examining the use of heat exchangers with multiple HPs for salt-cooled fission and fusion systems that serve four functions: (1) transfer heat from primary coolant to power cycle, secondary loop, or environment; (2) enhance the safety of the secondary circuit by ensuring the reactor’s salt coolant is isolated from the high-pressure power cycle; (3) cease heat transfer if the reactor coolant nears its freezing point, averting primary loop obstruction; and (4) prevent tritium release into the environment while enabling tritium recovery. The status of HP technology and the limits of HP technology were summarized. |

| Parab et al. in 2023 [54] | (1) Application of HP (2) Literature review: HPs, HPHXs, pulsating heat pipe & factors affecting its performance | The performance, components, and applications of the most current HP devices were analyzed. The study on HPs that has been performed in terms of design and analysis were summarized. |

| Nithin in 2024 [55] | (1) Types of HPs (2) Heat pipe recuperative heat exchanger for air preheating (3) Heat pipe regenerative heat exchanger for air preheating | Research progress on flexible HP systems based on heat exchangers is summarized. |

| Reference | Application | External Fluid | HP Type | HP Material Wick Material | Working Fluid |

|---|---|---|---|---|---|

| Jouhara et al. in 2016 [38] | solar collector | radiation–water/glycol | flat heat pipe | N/A | N/A |

| Jouhara et al. in 2017 [39] | solar collector | radiation–water | flat heat pipe | aluminum | ammonia |

| Al-Mabsali et al. in 2021 [41] | photovoltaic panel | radiation–air | flat heat pipe | copper wick: fiber mesh | water |

| Sahu et al. in 2013 [13] | solar collector | radiation–water | thermosyphon | copper | pure water, water surfactant, CNT–water nanofluid |

| Sarafraz et al. in 2019 [40] | solar collector | radiation–water | flat heat pipe | N/A | graphene–methanol nanofluid |

| Sarafraz et al. in 2019 [14] | solar collector | radiation–water | thermosyphon | copper | acetone, nanofluids |

| Dobson et al. in 2013 [3] | nuclear reactor | gas–water | thermosyphon | steel | sodium |

| Dobson et al. in 2013 [11] | nuclear reactor | gas–water | thermosyphon | N/A | Dowtherm-A |

| Tshamala and Dobson in 2014 [15] | coal to liquid process | helium–water | thermosyphon | N/A | sodium |

| Tshamala and Dobson in 2016 [16] | coal to liquid process | helium–water | thermosyphon | N/A | sodium |

| Zhang et al. in 2016 [7] | TOPAZ-II power system | radiation–air | wick heat pipe | Inconel wick: stainless steel | potassium |

| Qiao et al. in 2022 [56] | cooling water tank | air–water | separated heat pipe | carbon steel | water |

| Xie et al. in 2019 [8] | nuclear power plant | water–water | wick heat pipe | N/A wick: N/A | water |

| Zorn et al. in 2014 [57] | de-Icing and snow melting system | geothermal energy–solid | N/A | copper | CO2 |

| Gunawan et al. in 2021 [9] | withering of tea leaves | air–water | wick heat pipe | copper wick: copper | water |

| Diao et al. in 2017 [46] | HVAC systems | air–air | micro-heat pipe | aluminum alloy | N/A |

| Jing et al. in 2020 [47] | HVAC systems | air–water | micro-heat pipe | aluminum alloy | R141b |

| Zhang et al. in 2017 [17] | HVAC systems | air–air | thermosyphon | aluminum | R134a |

| Sukarno et al. in 2021 [10] | HVAC systems | air–air | wick heat pipe | copper wick: sintered copper | water |

| Sharma et al. in 2022 [18] | HVAC systems | air–air | thermosyphon | copper | R22, R407c |

| Abedalh et al. in 2021 [19] | HVAC systems | air–air | thermosyphon | copper | distilled water |

| Abdallah et al. in 2022 [20] | HVAC systems | air–air | thermosyphon | copper | copper oxide nanofluid |

| Monirimanesh et al. in 2016 [21] | HVAC systems | air–air | thermosyphon | copper | TiO2/methanol nanofluids |

| Abdelaziz et al. in 2021 [22] | HVAC systems | air–air | thermosyphon | copper | R123 |

| Hakim et al. in 2021 [58] | HVAC systems | air–air | loop heat pipe | copper wick: sintered copper | water |

| Longo et al. in 2014 [59] | HVAC systems | air–air | N/A | copper | HFC134a, HFO1234ze(E) |

| Jouhara et al. in 2018 [60] | HVAC systems | air–air | loop heat pipe | copper | water |

| Reference | Waste Heat Temperature/°C | Application | External Fluid | HP Type | HP Material Wick Material | Working Fluid |

|---|---|---|---|---|---|---|

| Gedik et al. in 2016 [23] | 75~175 | heat recovery system | flue gas–water | thermosyphon | copper | R134a, R410a |

| Alizadeh et al. in 2022 [30] | ~32 | gas city gate station | flue gas–natural gas | thermosyphon | copper | R134a |

| Ozturk et al. in 2018 [24] | ~90 | heat recovery system | air–air | thermosyphon | copper | distilled water, Al2O3 nanofluid |

| Ramos et al. in 2014 [25] | 50~300 | waste heat recovery | air–water | thermosyphon | carbon steel | distilled water |

| Ramos et al. in 2016 [26] | 50~300 | waste heat recovery | air–water | thermosyphon | carbon steel | distilled water |

| Mroue et al. in 2015 [27] | 100~300 | waste heat recovery | air–water | thermosyphon | carbon steel | distilled water |

| Mroue et al. in 2017 [28] | 100~250 | waste heat recovery | air–water | thermosyphon | carbon steel | water |

| Jouhara et al. in 2021 [73] | 102 ± 1 | N/A | air–water | thermosyphon | copper | distilled water |

| Brough et al. in 2020 [4] | 135~270 | ceramic kiln | exhaust gas–water | thermosyphon | N/A | distilled water |

| Geum et al. in 2024 [29] | 200 | waste heat recovery | air–water | thermosyphon | copper | water |

| Ma et al. in 2017 [31,32] | 70~85 | steel industry | waste liquid–water | thermosyphon | carbon steel | distilled water |

| Tian et al. in 2017 [33] | 173~192 | dyeing and printing industry | exhaust gas–air | thermosyphon | steel | water |

| Delpech et al. in 2018 [5] | 204 | the ceramic industry | air–air | thermosyphon | N/A | N/A |

| Jouhara et al. in 2021 [6] | 204 | the ceramics industry | flue gas–air | thermosyphon | carbon steel | water |

| Danielewicz et al. in 2014 [74] | 120 | N/A | air–air | thermosyphon | carbon steel | methanol |

| Rastegar et al. in 2020 [34] | 100~105 | the pressure reduction stations | exhaust gas– water | thermosyphon | copper | water |

| Zhang et al. in 2021 [35] | 50~70 | heat recovery of coal-fired flue gas | flue gas–water | thermosyphon | enamel | N/A |

| Wang et al. in 2015 [75] | 40~80 | N/A | electric heating units–water | concentric tube heat pipe | aluminum | acetone |

| Han et al. in 2018 [76] | N/A | N/A | electric heating units–water | concentric tube heat pipe | aluminum | acetone |

| Ramkumar et al. in 2021 [44] | 55~70 | electronic component system | water–water | concentric tube heat pipe | copper wick: stainless steel | methanol, acetone |

| Ramkumar et al. in 2022 [45] | 50~70 | electronic component system | water–water | concentric tube heat pipe | copper wick: stainless steel | methanol, acetone |

| Yang et al. in 2019 [48] | ~36.6 | heat recovery in the cold regions | flue gas–air | micro-heat pipe | aluminum | N/A |

| Yang et al. in 2022 [49] | 50~210 | Industrial equipment | flue gas–water | micro-heat pipe | aluminum | acetone |

| Yang et al. in 2024 [50] | ~44 °C | oil fume heat recovery | air–air | micro-heat pipe | N/A | acetone |

| Zhang et al. in 2013 [77] | ~40 | N/A | air–air | micro-heat pipe | aluminum | δ-Al2O3-R141b nanofluids, R141b |

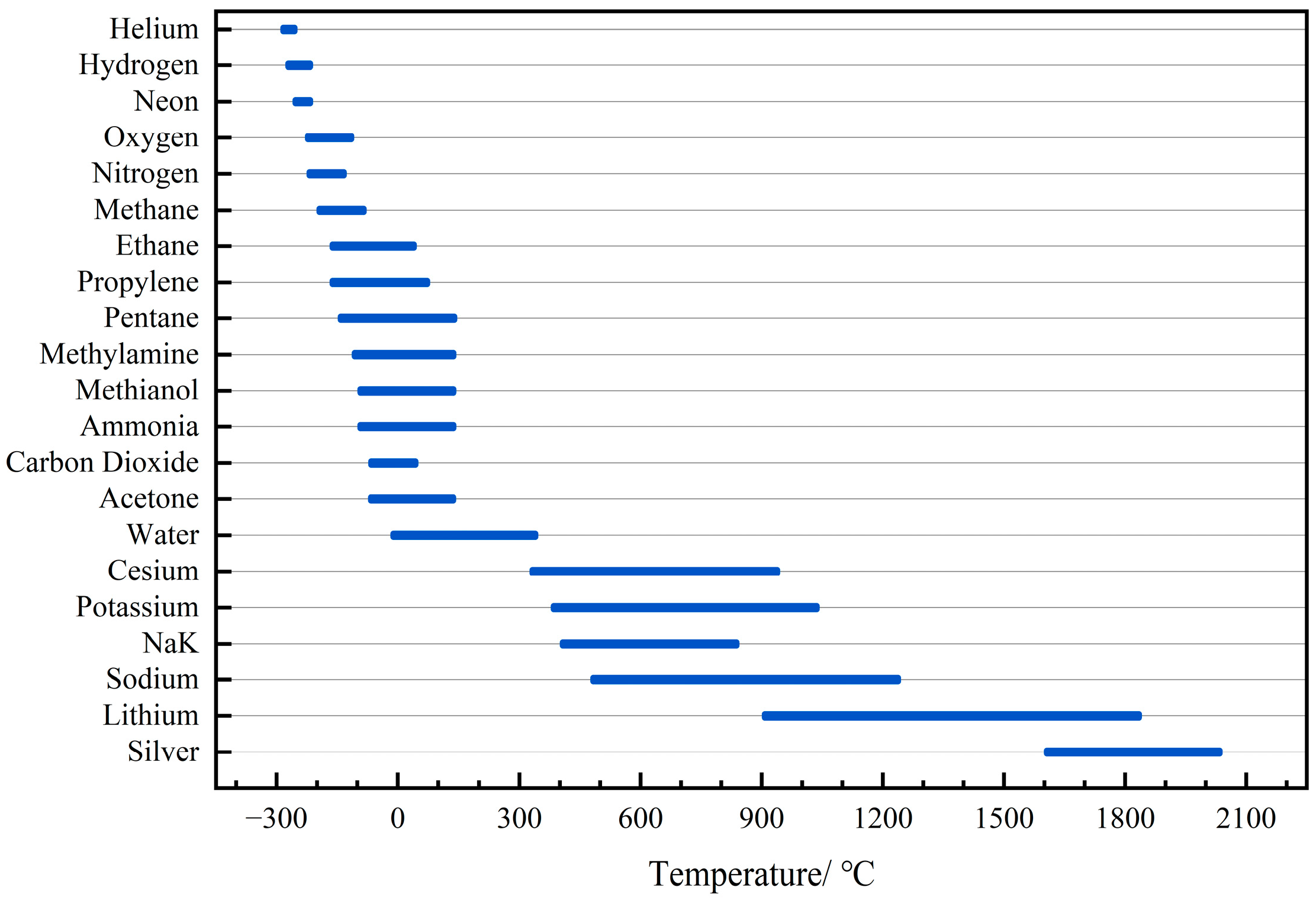

| Temperature Type | Temperature Range | Working Fluid |

|---|---|---|

| Low temperature | <277 °C | Commonly used working fluids include methanol, ethanol, ammonia, acetone, and water. |

| Medium temperature | 277~427 °C | Special organic fluids like naphthalene and biphenyl can be used for medium-temperature applications. |

| High temperature | >427 °C | Liquid metals, such as potassium, sodium, and silver, are used to achieve very high heat fluxes due to their large surface tensions and high latent heats of vaporization. |

| Reference | Waste Heat Temperature/°C | Application | External Fluid | HP Type | HP Material Wick Material | Working Fluid |

|---|---|---|---|---|---|---|

| Xu et al. in 2019 [37] | 434 | combine harvester | exhaust gas–air | thermosyphon | carbon steel | water |

| Jouhara et al. in 2017 [42] | >500 | steel industry | radiation–water | flat heat pipe | stainless steel | water |

| Almahmoud et al. in 2019 [43] | 400~580 | steel industry | radiation–water | flat heat pipe | stainless steel | water |

| Han et al. in 2015 [82] | 450 | N/A | air–air | thermosyphon | carbon steel | low temperature: water; transition temperature: naphthalene, water; medium temperature: naphthalene |

| Jouhara et al. in 2023 [36] | 400 | aluminum industry | air–air | thermosyphon | N/A | distilled water, Dowtherm |

| Delpech et al. in 2019 [12] | 500~580 | ceramics industry | radiation–water | thermosyphon | stainless steel | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Guo, Q.; Guo, W.; Chu, W.; Wang, Q. Review of Recent Applications of Heat Pipe Heat Exchanger Use for Waste Heat Recovery. Energies 2024, 17, 2504. https://doi.org/10.3390/en17112504

Ding Y, Guo Q, Guo W, Chu W, Wang Q. Review of Recent Applications of Heat Pipe Heat Exchanger Use for Waste Heat Recovery. Energies. 2024; 17(11):2504. https://doi.org/10.3390/en17112504

Chicago/Turabian StyleDing, Yi, Qiang Guo, Wenyuan Guo, Wenxiao Chu, and Qiuwang Wang. 2024. "Review of Recent Applications of Heat Pipe Heat Exchanger Use for Waste Heat Recovery" Energies 17, no. 11: 2504. https://doi.org/10.3390/en17112504

APA StyleDing, Y., Guo, Q., Guo, W., Chu, W., & Wang, Q. (2024). Review of Recent Applications of Heat Pipe Heat Exchanger Use for Waste Heat Recovery. Energies, 17(11), 2504. https://doi.org/10.3390/en17112504