Abstract

Methanol as marine fuel represents one of the most cost-effective and practical solutions towards low-carbon shipping. Methanol fueled internal combustion engines have a high level of technological readiness and are already available on the market; however, technical data in terms of fuel consumption and emissions are not yet easily accessible. For this reason, the present study deals with the simulation of a virtual spark-ignition methanol engine, carried out in a Matlab-Simulink© R2023a environment to assess the CO2 emissions in several working conditions of a possible ship power system. The thermodynamic model of the methanol fueled engine is derived from a marine gas engine simulator, already validated by the authors in a previous work. This article presents the relevant modifications necessary to adapt the engine to the methanol fuel mode with regard to the different fuel characteristics. The simulation analysis compares the results of the virtual methanol engine with available data from a similar, existing gas engine, highlighting the differences in efficiency and carbon dioxide emissions.

1. Introduction

The transport sector is facing massive changes due to the need to reduce climate-altering emissions. For the shipping sector this challenge is still complex as ships’ size and ships’ high energy and power demand make the current commercially available solutions unsuitable. Moreover, the ship decarbonization process not only covers carbon dioxide (CO2) but also a reduction in other harmful emissions, such as nitrous oxide (N2O) and methane (CH4), as they present a Global Warming Potential (GWP) higher than CO2. To this end, the Annex VI of the MARPOL Convention [1], by the International Maritime Organization (IMO), reports increasingly stringent limits on some main air pollutants, such as NOx and SOx, as well as requiring yearly improvements in ship efficiency. In terms of greenhouse gas (GHG) emission and carbon intensity (CO2 emissions per transport work of a ship) reduction, IMO aims to reach net-zero GHG emissions from international shipping by 2050, a reduction of at least 40% in carbon intensity by 2030, and a 70% reduction in total annual GHG emissions by 2040. Meanwhile, the European Union, aiming towards climate neutrality by 2050, has included the shipping sector in the Emission Trading Scheme (ETS) and set a new regulation on alternative fuels (FuelEU Maritime) pushing for the adoption of alternative fuels and basing its strategy on the “polluter pays” principle. There are currently various technologies that aim to reduce emissions and increase the efficiency of ships, but they are not long-term solutions. Energy saving solutions such as more efficient hull forms, air lubrication systems [2], waste heat recovery systems from internal combustion engines (ICEs) [3,4,5,6,7], more powerful batteries and hybrid energy devices [8,9,10] can reduce air pollutants but cannot reach net-zero emissions while ship propulsion systems are based on fossil fuels. Therefore, further technological progress is crucial in the development of marine engines powered by green alternative fuels (i.e., produced from renewable sources to guarantee zero emissions in the life cycle).

In this scenario, methanol seems to be a viable proposal to reduce emissions and it is also suitable for both ICEs and fuel cells. (FC) [11,12]. In particular, FC systems with onboard methanol reformers are being deployed in pilot projects in the United States, Europe, and China [13,14]. However, in applications where a higher power density is required, ICEs still represent the most suitable solution.

Although research on methanol is going fast and there are already many methanol ICEs in the order books of the most important marine engine manufacturers [13], in the scientific literature, there are few publications concerning marine ICEs running on methanol (most of which refer to technical and economic analyses concerning the conversion of diesel engines to methanol [15]). Nonetheless, for naval architects, it is very important to know the fuel consumption map of the engine to evaluate its economic and environmental efficiency, as ships’ operating conditions vary. The present study provides a contribution to cover this lack of information by a simulation analysis of a virtual SI methanol internal combustion engine, based on a model of a four-stroke natural gas engine model, developed by the authors in [16]. Both NG and methanol engines operate according to thermodynamic cycles that are quite similar (Otto–Miller cycle), so the choice can be considered reasonable.

The approach adopted for the simulation of the combustion process of the engine is rather simplified; therefore, it allows for a reliable prediction of fuel consumption only, without being able to calculate all the polluting emissions (e.g., NOx and particulate matter). However, the development of the proposed simulator is useful for testing engines powered by alternative fuels not yet marketed, mainly in terms of decarbonization effects on the ship. In fact, the simulation analysis shows that a reliable prediction of fuel consumption also easily allows for an estimate of equivalent CO2 emissions by an appropriate carbon emission factor. Furthermore, the simulation code allows for this analysis to be extended to any operating point of the engine, making it particularly useful in mechanical propulsion applications, where the required power can significantly differ from the traditional load of the propeller (i.e., the cubic relationship between power and revolutions), as can usually happen in fast craft such as planing and semi-planing boats [17]. The same consideration can also be made in the case of using the engine as an electric energy generator, which can traditionally be used at constant rpm, but also at variable rpm as seen in some recent applications [18].

1.1. Marine Alternative Fuels

Several alternative fuels are going to power ships in the near future, each one being characterized by different chemical and physical properties. The most promising are natural gas (NG or LNG), methanol, ammonia, and hydrogen.

NG is by far the most widely used alternative fuel with application onboard cruise ships, bulkers, and ferries. Although providing a small reduction in GHG emissions, NG manages to reduce PM and SOx which are also critical for ships to enter emission-controlled areas. NG is commonly stored liquified at cryogenic temperatures in pressurized and insulated tanks, i.e., space- and weight-demanding solutions which result in less space for cargo or passengers.

Ammonia as a fuel is suitable for spark-ignition (SI) ICEs and compression ignition (CI) engines in Dual Fuel (DF) configurations, with the injection of a pilot fuel (diesel oil) or it can be also directly fed into fuel cells. Unfortunately, the main drawback of ammonia is its toxicity for human beings, resulting in a very challenging integration onboard passenger ships [19]. Regarding the storage, ammonia is also commonly stored in insulated and pressurized tanks at a temperature of −33 °C.

Hydrogen is generally stored as compressed gas at pressures ranging from 350 to 700 bar as its liquefaction at minus 253 °C is still very challenging. As a fuel, studies on marine ICE fueled by hydrogen are still ongoing both for SI and CI ICEs and no commercial applications are yet available. Nevertheless, hydrogen represents the long-term solution as its combustion process does not produce harmful compounds.

Methanol is a liquid alcohol (CH3OH) at room temperature and can be stored in common fuel tanks, thus representing a crucial advantage against other alternative fuels in the definition of the general arrangement plan of a vessel. However, some special precautions must be taken to avoid the unwanted release of methanol which is flammable and toxic to humans. Some of these precautions consist of using of cofferdams, double-walled pipes, and inert gas to avoid explosions. Methanol, for humans, is irritating to the eyes, skin, and respiratory tract and causes dryness and cracking of the skin. As reported in [20], the quantity of liquid methanol necessary to be ingested to cause the death of an adult man is approximately 10–30 mL, while the exposure limit to methanol vapors (Permissible Exposure Limit—PEL) is 200 ppm, for eight hours, for forty hours per week.

As a fuel, methanol combustion produces CO2, but in a broader perspective, its life cycle emissions are highly dependent on the production process. In fact, green methanol can be obtained from biomass or renewable energy, allowing for net-zero emission, since the CO2 emissions resulting from combustion are offset by the CO2 absorption of growing crops or carbon capture systems. In particular, bio-methanol is produced through the gasification of biomass and from the synthesis of the resulting syngas (CO + H2) into methanol. During the synthesis, the syngas is pressurized and converted to methanol in the presence of a catalyst, followed by its purification, removing water and other impurities. The methanol conversion is carried out at high pressure and low temperatures (50–100 bar and 220–275 °C, using the catalyst of copper and zinc oxides on alumina) [21]. The other cleaner pathway to produce methanol is the synthesis of methanol from the CO2 captured from a fossil fuel-powered engine and hydrogen from green electricity (i.e., from the hydrolysis of water powered by wind or solar power). An extensive review of the different Well-to-Wake greenhouse gas emission factors is available in [22], where it is shown how green methanol has an emission factor equal to 13.6 gCO2e/MJ, versus the 94.4 gCO2e/MJ of grey methanol (i.e., methanol produced from natural gas as feedstock).

For these reasons, green methanol is considered by shipowners as a suitable fuel for use in the near future, which may allow for the needed reduction in GHG emissions.

1.2. Marine Methanol ICEs: State of the Art

In this paragraph, a state-of-the-art marine methanol fueled engine is presented. Although there are several studies ongoing and some already commercially available methanol engines, there is still a lack of available information regarding meaningful parameters for the on-board integration of these engines such as fuel consumption maps, efficiency in different working points, and exhaust gasses’ temperature and flow.

From a commercial point of view, marine engine manufacturers such as MAN Energy Solutions are already commercializing methanol-ready two-stroke engines, some of which have been in operation since 2016. For these DF engines, no modifications in methanol fuel mode are required inside the engine, since the changes only affect the injectors, cylinder heads and fuel delivery system. Starting in 2024, MAN Energy Solutions will also begin offering methanol retrofit solutions for four-stroke engines. Table 1 summarizes the upcoming development programs of other major marine engine manufacturers regarding their strategies for developing methanol technologies [13].

Table 1.

Methanol development programs of the main marine engines manufacturers [13].

In the scientific literature, numerous solutions for utilizing methanol in internal combustion engines (ICEs) have been studied and tested. However, most of the available literature focuses on automotive engines [23], which are typically smaller than marine engines. As a result, the findings may not be entirely relevant to marine engines.

Methanol, as a consequence of its characteristics as a fuel, is well suited for use in spark-ignition (SI) engines given its high octane number and high latent heat of vaporization [23]. There are few scientific and experimental publications in the literature regarding single-fuel methanol fueled engines. In [24], the use of methanol as a mono-fuel in a 320 mm bored marine engine is simulated via CFD code and validated, as far as possible, through available experimental data. The lean methanol–air mixtures appeared to ignite reliably, and high thermal efficiencies and low NOx were found. In [25], two automotive SI engines are tested, running on methanol (M100). The experimental results showed an increase in efficiency and a reduction in NOx resulting from the reduction in temperature, due to the high latent heat and higher volumetric efficiency. In [26], a single-cylinder large-bore high-speed diesel engine with about 5 L cylinder displacement and 1800 rpm was converted to a port fuel injected (PFI) spark-ignited (SI) methanol combustion system. The effect of the air to fuel ratio on emission and performance was studied in the range of 1.4 to 1.75. Preignitions were not found to be an issue and engine knock was the limiting factor for the achievable engine load. The results show brake thermal efficiencies superior to the state of the art of natural gas engines. These preliminary tests highlight the good potential for a single-fueled methanol engine as a future marine power solution due to its low emissions and efficiency.

2. Materials and Methods

The numerical simulation was performed in Matlab-Simulink® environment; therefore, no commercial software specifically dedicated to engine simulation [27,28] was adopted. Each mechanical component and physical phenomenon is modeled through mathematical approaches developed by authors. The simulation process is based on the resolution of the thermodynamic cycle of the engine, where the fuel combustion is modeled by Wiebe equation [16,17]. By this approach, it is not possible to achieve a reliable estimation of the main polluting emissions; however, this method allows for better management of the code computation, as well as its easier integration into a complete simulation of the ship’s motions [29].

2.1. General Modeling of the SI Engine

The development of the simulation approach refers to a four-stroke NG marine engine (C26:33L8PG, 2430 kW@1000 rpm) developed by Rolls-Royce Bergen [30].

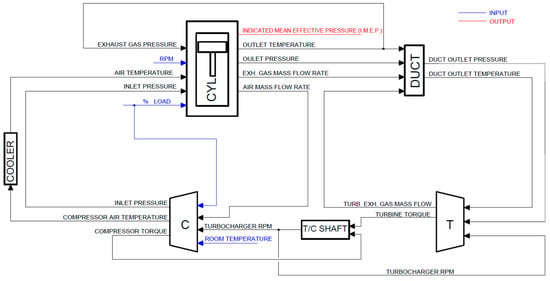

For a brief reminder on the modeling, Figure 1 shows the simulation flow of the cylinder model, including turbocharger dynamics. Load fraction (i.e., % LOAD) and engine speed in revolutions per minute (i.e., RPM) represent the main input variables, while the indicated mean effective pressure (IMEP), obtained from the numerical integration over time of the thermodynamic cycle, is the main output from which it is possible to calculate the engine brake power.

Figure 1.

SI engine simulation flow with main input (blue color) and output data (red color).

The throttle valve position (and associated losses) is not simulated as the load fraction (i.e., % LOAD in Figure 1) value is simulated through the volumetric efficiency (λv) which is input directly into the simulator. The volumetric efficiency was calculated so that the engine power was the same as the natural gas engine simulator. In other words, through the volumetric efficiency, different positions of the throttle valve were simulated.

The cylinder actual Otto–Miller cycle is determined at each crank angle value, by a single-zone zero-dimensional approach. Then, once the friction mean effective pressure FMEP has been estimated as a function of IMEP and engine speed [31], the brake mean effective pressure BMEP can be found as follows:

Finally, the brake power is obtained with the following equation:

where V is the cylinder displaced volume, n is the rotational speed of engine and ε is the number of revolutions required to complete one engine cycle (ε = 1 for two-stroke engine; ε = 2 for four-stroke engine).

The turbocharger dynamics are solved through the evaluation of the turbine torque:

and compressor torque:

where mexh and mair are the mass flow of air and exhaust gas, cp,exh and cp,air are the isobaric specific heat of air and exhaust gas, and n are the revolutions of the TC group. TIN,t is the temperature at the turbine inlet, TOUT,t and TOUT,c are the temperature at the outlet of the turbine and compressor and TAMB is room temperature.

The problem solution needs important input data such as engine geometric data, fuel properties, and exhaust valves characteristics, together with their opening/closing timing, and compressor and turbine performance maps. For the sake of greater clarity, further information on the engine simulator is given in previous articles by the authors [16,17].

2.2. Methanol SI Engine Simulation

In the present study, the NG marine engine (C26:33L8PG by Rolls Royce) is also simulated in methanol fuel mode. Table 2 reports the main data of the two fuels, necessary for the comparative simulation analysis.

Table 2.

NG and methanol fuel characteristics [18].

Both engine simulators are based on the Otto–Miller thermodynamic cycle type, have the same maximum continuous rating (MCR) speed and power, as well as geometrical data and turbocharge characteristics, such as compressor and turbine maps. The methanol engine model is optimized to achieve maximum efficiency in all operating conditions and generate the same MCR power as the NG engine. The modifications made to the original model to make it suitable for running on methanol are described in the following.

2.2.1. Air/Fuel Ratio

As regards the equivalence ratio (φ = αs/α, where α is the air/fuel ratio and αs the stoichiometric one), in the NG engine φ is equal to 0.5 [16], as well as in the methanol fuel mode [24] (i.e., excess air ratio equal to 2). In both fuel modes, the respective equivalence ratio values are kept constant in each operating condition.

In [24], where a CFD model of a mono-fuel marine SI engine fueled by methanol is simulated and validated, the authors tested different excess air ratios, aiming to find the best compromise between engine efficiency and delivered power. The excess air ratios ranged from 2 to 2.8. An excess air ratio equal to 2.4 showed the highest values in combustion efficiency and lowest emissions. Nevertheless, the power density (i.e., BMEP) was found to be too low. To find the best compromise between efficiency, power density and emission, the authors considered a value of 2.1 acceptable.

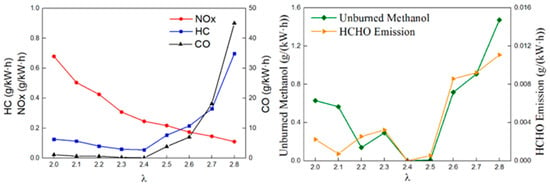

A further reduction in excess air ratios was applied to the engine simulation of the present article, taking into account the high power density required from marine engines, especially in fast craft [17]. No critical issues in emission were found applying this slight reduction in λ, as shown in Figure 2, where the increase in NOx emissions does not affect the compliance of the engine with NOx IMO Tier III limits.

Figure 2.

Emissions at different excess air ratios (λ) from [24].

2.2.2. Ignition and Combustion

After ignition, since the flame propagation speed of methanol is greater than that of NG [23], the duration of combustion, in terms of crank angle values, is reduced by 15% compared to the NG application.

The Wiebe equation simulates the heat release (xb) for each value of the crank angle θ:

where a and m are numerical constants; θign is the combustion start crank angle and Δθ is the overall combustion crank angle.

In the methanol simulator, the volumetric efficiency of the engine was reduced to obtain the same MCR power, achieved by increasing the inlet valve closing delay after the bottom dead center. In addition, a new ignition start crank angle setting θign has been defined to maximize the cylinder IMEP in all engine working conditions. The combustion start crank angle advance has been reduced by 1 ÷ 1.5 degrees, when compared to the NG engine model.

3. Results

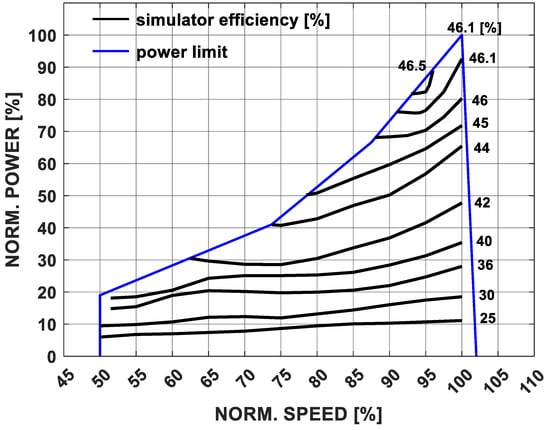

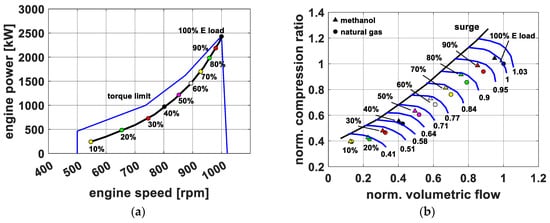

The simulation analysis aims to estimate the specific methanol fuel consumption (i.e., the inverse of the engine efficiency) in the entire ICE working area, as illustrated in Figure 3 in dimensionless form. However, for a more effective presentation of the simulation results, the comparison between the two fuel modes refers to only ten engine operating conditions, corresponding to the theoretical propeller load in a possible marine propulsion application. In particular, Figure 4a shows the ICE load diagram, defining the ten working conditions in a power range between 10% and 100% of MCR, with steps equal to 10%. Since the methanol engine modeling is derived from the NG model, the torque limit curve is also considered to be common to the two fuel modes.

Figure 3.

ICE methanol fuel consumption map [17].

Figure 4.

NG and methanol engines working conditions in the load diagram (a) and compressor maps (b).

Figure 4b reports the ten engines’ working conditions in the turbocharger (TC) compressor maps, normalized by dividing each characteristic by the correspondent value referring to the MCR working condition in the NG mode. The figure shows that in the methanol fuel mode, at the same engine load, the compressor works at a greater pressure ratio and a lower volumetric flow compared to NG condition. Obviously, the higher air-supply pressure involves also a higher maximum pressure inside the cylinders.

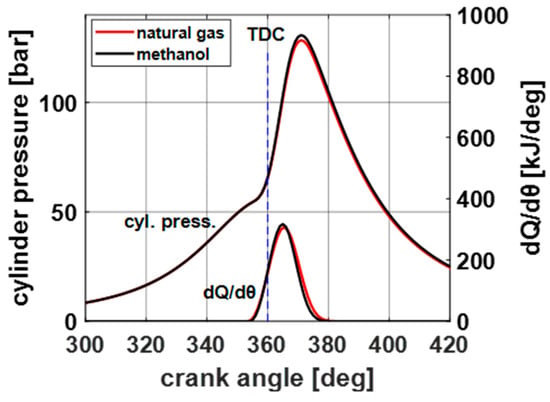

The different tuning of the combustion process simulated through the Weibe Equation (5) is shown in Figure 5, where the combustion duration is reduced as well as the ignition start crank angle. A steeper increase in heat release and cylinder pressure is visible, as also reported in [24].

Figure 5.

NG and methanol engines in-cylinder pressure and heat release rates at 80% engine load.

The engines efficiency (ηE) and its engine percentage difference (Δx/x) are expressed by the following equation:

where PE is the engine brake power; Mf and Hi are the fuel mass flow rate and its lower heating value, respectively; Δx represents the change in the generic variable x and xNG is the generic variable referred to the NG fuel at the same engine load of the variable x.

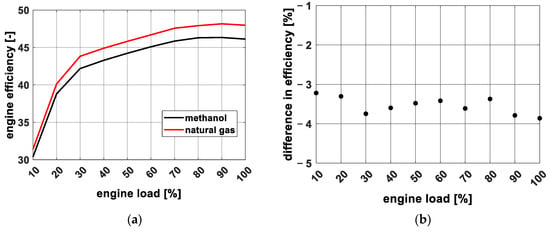

Figure 6a shows the engine efficiency in the two fuel modes, while Figure 6b reports the percentage difference on the propeller curve.

Figure 6.

Engines’ efficiency (a) and percentage difference in fuel modes (b).

Figure 6a highlights a greater efficiency of the NG engine; this difference decreases from about 4% down to slightly greater than 3% as the engine load decreases (Figure 6b).

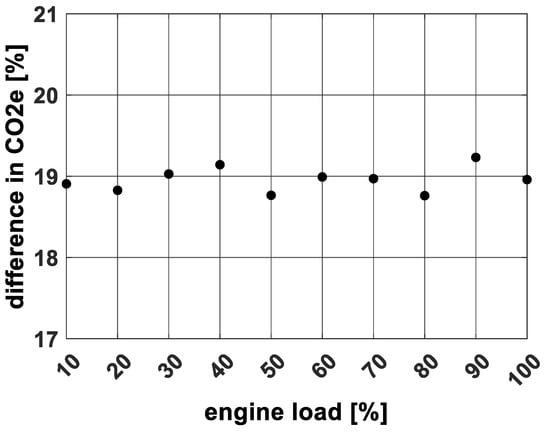

To assess the difference in equivalent carbon dioxide (CO2e) emissions from methanol and NG, both Well-to-Tank (WtT) emissions and Tank-to-Wake (TtW) emissions are considered. The sum of the emissions from WtT and TtW represents the emissions from the fuel over its whole lifecycle, also known as Well-to-Wake (WtW) emissions. Thus, to evaluate the WtT specific emissions, the WtT carbon emission factors (CFe) [32] of each fuel (NG and methanol) are considered and divided by the respective engine efficiency for the several engine loads. The carbon emission factors resulting from a biological production process are applied for both fuels. The TtW emission contribution is calculated by again considering the efficiency of the simulated engines, but no emissions due to NOx and methane slip are considered as they are not predictable by the current simulation model. Figure 7 shows the percentage difference in CO2e emissions per MJ at the engine shaft between the two fuel modes. Results highlight greater CO2e emissions in the WtW perspective of the methanol mode in comparison with NG, ranging between 18.7% and 19.3%, depending on the engine load.

Figure 7.

Well-to-Wake CO2e emissions comparison.

Although there is a slight reduction in engine efficiency between the methanol and NG engine simulators, the different production pathways of the two fuels may allow for a reduction in emissions on a lifecycle basis. As per [30], bio-methanol from farmed wood, bio-methanol from black liquor, and E-methanol present different WtT carbon emission factors (CFe), but for each one of these production processes the TtW emissions are considered equal to zero. In this perspective, the simulated methanol engine can be assumed as CO2 neutral if a green production pathway is adopted.

4. Discussion

The previous section presented the results of a study that demonstrated how a methanol engine could be a viable solution to reduce emissions from ships, despite its slightly lower efficiency compared to a natural gas engine (between 3 and 4%). This study also showed that the use of green fuels resulted in a much greater reduction in emissions than the reduction in efficiency. In comparison, natural gas engines have a higher lower heating value (LHV) and efficiency, making them a popular choice for use on-board ships. However, it is important to consider the challenge of storing natural gas, which requires cryogenic temperatures. This difficulty is even more pronounced in small boats, such as those used for passenger transport or small cabotage.

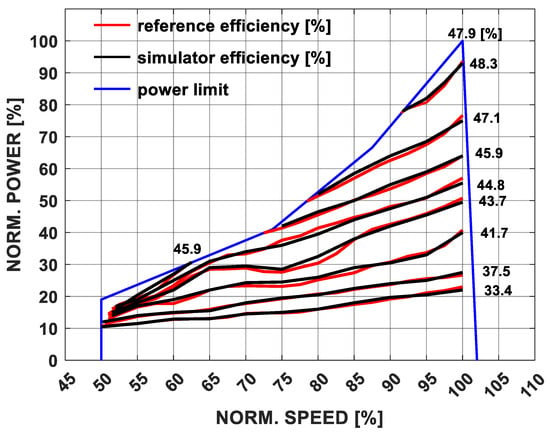

We remember that simulation refers only to a virtual engine fueled by methanol, while NG powers the real existing engine. For this reason, the current simulation model can be validated only in NG fuel mode, as shown in Figure 8 where the engine data sheet and simulation results are compared. In detail, average errors of less than 2%, with peak values lower than 4%, can be declared [16].

Figure 8.

Specific NG fuel consumption map: comparison between engine manufacturer data and simulation.

Instead, as regards the virtual engine running on methanol, simulation validation had to be based on the data available in [33], which is the only useful work found by the authors on this subject. Specifically, [33] presents data of a two-stroke engine (MAN 9S90 ME-C, 37.62 MW @ 72 rpm), converted to operate by NG (using 1.5% MDO as pilot fuel) or methanol (5% MDO pilot fuel), showing higher values of CO2 emission in the methanol mode than NG fuel. To this regard, Figure 7 shows a difference in CO2e emission between the two fuels of less than 20%. This difference is rather similar to the value reported in [33]. On this basis, the simulation results seem to provide a first positive indication on the reliability of the methanol engine simulator. On the other hand, considering the significant differences in power and working principles between the two engine types (i.e., the two-stroke engine in [33] versus the four-stroke engine in the present paper), there is an urgent need for more reliable feedback through the availability of experimental data as soon as possible.

5. Conclusions

This article presents a simulation study on the behavior of a marine engine fueled by methanol, as a possible response to the decarbonization process through alternative shipping fuels. The engine does not actually exist; however, the geometric and power output data used for the simulation refer to a real four-stroke marine engine running on natural gas. This choice of data is due to the same working thermodynamic cycle in the two combustion modes and to the unavailability of methanol engine manufacturer’s data for the modeling validation, while gas engines are now still widely studied and widespread onboard ships. Therefore, the engine simulation approach is validated on the natural gas fuel mode, while the running conditions by methanol are only extrapolated on the basis of some considerations about the different thermodynamic properties of methanol fuel (e.g., lower heating value, flame propagation speed during combustion, equivalence ratio, …), compared to natural gas characteristics. This is why the main results in terms of fuel consumption, efficiency, and decarbonization effects are shown through a comparative analysis between the two engine operating modes. Among the most interesting results for a naval architect, there is the availability, by simulation, of the methanol consumption map in the entire working area of the engine, to be used for a proper matching between engine and propeller in the design stage of a ship propulsion system. Although the analysis was carried out on a virtual methanol engine and therefore an accurate experimental validation is still necessary, the extrapolated simulation data can give a useful indication of the emissions produced, depending on the type of methanol, fossil or green.

Author Contributions

Conceptualization, U.C.; methodology, M.A. and U.C.; formal analysis, M.A., F.B. and F.S.; validation, U.C.; investigation, F.B. and F.S.; data curation, F.S.; writing—original draft preparation, M.A.; writing—review and editing, F.B., E.F. and F.S.; visualization, F.S.; supervision, M.A.; funding acquisition, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was performed as part of the “CN-MOST—Spoke 3 (Waterways)” research activity and funded under the National Recovery and Resilience Plan (NRRP) of Italian Ministry of University and Research, funded by the European Union—NextGenerationEU- CUP E63C22000930007.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

| BMEP | Brake Mean Effective Pressure |

| CFD | Computational Fluid Dynamics |

| CFe | Carbon emission Factors |

| CI | Compression ignition |

| CO2e | equivalent CO2 |

| DF | Dual Fuel |

| ETS | Emission Trading Scheme |

| FC | Fuel cell |

| FMEP | Friction Mean Effective Pressure |

| GHG | Greenhouse Gas |

| GT | Gross Tonnage |

| GWP | Global Warming Potential |

| ICE | Internal Combustion Engine |

| IMEP | Indicated Mean Effective Pressure |

| IMO | International Maritime Organization |

| LNG | Liquified Natural Gas |

| MARPOL | International Convention for the Prevention of Pollution from Ships |

| MCR | Maximum Continuous Rating |

| MDO | Marine Diesel Oil |

| NG | Natural Gas |

| PEL | Permissible Exposure Limit |

| PFI | Port Fuel Injection |

| PM | Particulate Matter |

| SI | Spark Ignition |

| TC | Turbocharger |

| TDC | Top Dead Center |

| TtW | Tank-to-Wake |

| WtT | Well-to-Tank |

| WtW | Well-to-Wake |

References

- International Maritime Organization (IMO). Amendments to the Annex of the Protocol of 1997 to Amend the International Convention International Convention for the Prevention of Pollution from Ships, 1973, as Modified by the Protocol of 1978 Relating Thereto (Revised MARPOL Annex VI), MPEC 58/23/Add.1, Annex 13, 1:45; International Maritime Organization: London, UK, 2008. [Google Scholar]

- Lee, J.; Kim, J.; Kim, B.; Jang, J.; McStay, P.; Raptakis, G.; Fitzpatrick, P. Full scale applications of air lubrication for reduction of ship frictional resistance. In Proceedings of the SNAME Maritime Convention, SMC 2017, Houston, TX, USA, 24–28 October 2017. [Google Scholar]

- Altosole, M.; Laviola, M.; Trucco, A.; Sabattini, A. Waste heat recovery systems from marine diesel engines: Comparison between new design and retrofitting solutions. In Proceedings of the 2nd International Conference on Maritime Technology and Engineering, MARTECH 2014, Lisbon, Portugal, 15–17 October 2014; Soares, C.G., Santos, T.A., Eds.; CRC Press: Boca Raton, FL, USA, 2015; pp. 735–742. [Google Scholar] [CrossRef]

- Altosole, M.; Campora, U.; Donnarumma, S.; Zaccone, R. Simulation techniques for design and control of a waste heat recovery system in marine natural gas propulsion applications. J. Mar. Sci. Eng. 2019, 7, 397. [Google Scholar] [CrossRef]

- Altosole, M.; Benvenuto, G.; Zaccone, R.; Campora, U. Comparison of saturated and superheated steam plants for waste-heat recovery of dual-fuel marine engines. Energies 2020, 13, 985. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Palombo, A.; Vicidomini, M. Sustainable energy design of cruise ships through dynamic simulations: Multi-objective optimization for waste heat recovery. Energy Convers. Manag. 2020, 221, 113166. [Google Scholar] [CrossRef]

- Altosole, M.; Campora, U.; Mocerino, L.; Zaccone, R. An Innovative variable layout steam plant for waste heat recovery from marine dual-fuel engines. Ships Offshore Struct. 2023, 18, 429–437. [Google Scholar] [CrossRef]

- Ono, Y.; Shiraishi, K.; Sakamoto, K.; Ito, Y. Development of new turbocharger technologies for energy efficiency and low emissions. In Proceedings of the 10th International Conference on Turbochargers and Turbocharging, London, UK, 15–16 May 2012; pp. 365–374. [Google Scholar] [CrossRef]

- Altosole, M.; Benvenuto, G.; Campora, U.; Silvestro, F.; Terlizzi, G. Efficiency improvement of a natural gas marine engine using a hybrid turbocharger. Energies 2018, 11, 1924. [Google Scholar] [CrossRef]

- Altosole, M.; Balsamo, F.; Campora, U.; Mocerino, L. Marine dual-fuel engines power smart management by hybrid turbocharging systems. J. Mar. Sci. Eng. 2021, 9, 663. [Google Scholar] [CrossRef]

- Balsamo, F.; Capasso, C.; Coppola, T.; Micoli, L.; Russo, R.; Veneri, O. A case study on High-Temperature Fuel Cells for Hybrid electric Ship Propulsion. In Proceedings of the 2023 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles and International Transportation Electrification Conference, ESARS-ITEC 2023, Venice, Italy, 29–31 March 2023. [Google Scholar] [CrossRef]

- Altosole, M.; Balsamo, F.; Mocerino, L.; Scamardella, F. Methanol fuelled hybrid propulsion system for a charter yacht. In Proceedings of the 8th International Conference on Clean Electrical Power Renewable Energy Resources Impact, Sicily, Italy, 27–29 June 2023; pp. 810–817. [Google Scholar] [CrossRef]

- Methanol Institute. Marine Methanol: Future-Proof Shipping Fuel; Technical Report; Methanol Institute: Washington, DC, USA, 2023. [Google Scholar]

- Lee, H.; Jung, I.; Roh, G.; Na, Y.; Kang, H. Comparative analysis of on-board methane and methanol reforming systems combined with HT-PEM fuel cell and CO2 capture/liquefaction system for hydrogen fueled ship application. Energies 2020, 13, 224. [Google Scholar] [CrossRef]

- Ammar, N.R. An environmental and economic analysis of methanol fuel for a cellular container ship. Transp. Res. Part D 2019, 69, 66–76. [Google Scholar] [CrossRef]

- Altosole, M.; Benvenuto, G.; Campora, U.; Laviola, M.; Zaccone, R. Simulation and Performance Comparison Between Diesel and Natural Gas Engines for Marine Applications. Proc. IMechE Part M J. Eng. Marit. Environ. 2017, 231, 690–704. [Google Scholar] [CrossRef]

- Acanfora, M.; Altosole, M.; Balsamo, F.; Campora, U.; Scamardella, F. A Methanol Fueled Marine Engine Simulator for Fast Craft Applications. Progress in Marine Science and Technology. In Proceedings of the 13th Symposium on High Speed Marine Vehicles, HSMV 2023, Naples, Italy, 23–25 October 2023; Volume 7, pp. 117–125. [Google Scholar] [CrossRef]

- Mobarra, M.; Rezkallah, M.; Ilinca, A. Variable Speed Diesel Generators: Performance and Characteristic Comparison. Energies 2022, 15, 592. [Google Scholar] [CrossRef]

- Scamardella, F.; Zamboni, G.; Canepa, E.; Gualeni, P.; Macocco, A. Ammonia as an alternative fuel for large passenger ships: Benefits and challenges. In Proceedings of the 20th International Conference on Ship and Maritime Research, NAV 2022, La Spezia, Italy, 15–17 June 2022; Rizzuto, E., Ruggiero, V., Eds.; IOS Press: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Methanol Institute. Methanol Safe Handling Manual, 4th ed.; Methanol Institute: Washington, DC, USA, 2017. [Google Scholar]

- European Maritime Safety Agency. Update on Potential of Biofuels in Shipping; EMSA: Lisbon, Portugal, 2022. [Google Scholar]

- Zamboni, G.; Scamardella, F.; Gualeni, P.; Canepa, E. Comparative analysis among different alternative fuels for ship propulsion in a well-to-wake perspective. Heliyon 2024, 10, e26016. [Google Scholar] [CrossRef] [PubMed]

- Verhelst, S.; Turner, J.W.G.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Leng, X.; Deng, Y.; He, D.; Wei, S.; He, Z.; Wang, Q.; Long, W.; Zhu, S. A preliminary numerical study on the use of methanol as a Mono-Fuel for a large bore marine engine. Fuel 2022, 310, 122309. [Google Scholar] [CrossRef]

- Vancoillie, J.; Demuynck, J.; Sileghem, L.; Van De Ginste, M.; Verhelst, S.; Brabant, L.V.H.L.; Van Hoorebeke, L. The potential of methanol as a fuel for flex-fuel and dedicated spark-ignition engines. Appl. Energy 2013, 102, 140–149. [Google Scholar] [CrossRef]

- Güdden, A.; Pischinger, S.; Geiger, J.; Heuser, B.; Müther, M. An experimental study on methanol as a fuel in large bore high speed engine applications–Port fuel injected spark ignited combustion. Fuel 2021, 303, 121292. [Google Scholar] [CrossRef]

- Tadros, M.; Ventura, M.; Guedes Soares, C. Optimization of the Performance of Marine Diesel Engines to Minimize the Formation of SOx Emissions. J. Mar. Sci. Appl. 2020, 19, 473–484. [Google Scholar] [CrossRef]

- Mocerino, L.; Soares, C.G.; Rizzuto, E.; Balsamo, F.; Quaranta, F. Validation of an Emission Model for a Marine Diesel Engine with Data from Sea Operations. J. Mar. Sci. Appl. 2021, 20, 534–545. [Google Scholar] [CrossRef]

- Acanfora, M.; Altosole, M.; Balsamo, F.; Micoli, L.; Campora, U. Simulation Modeling of a Ship Propulsion System in Waves for Control Purposes. J. Mar. Sci. Eng. 2022, 10, 36. [Google Scholar] [CrossRef]

- Rolls-Royce. Diesel and Gas Engines Generator Set and Propulsion Systems. Report; Bergen Engines AS: Bergen, Norway, 2015. [Google Scholar]

- Benvenuto, G.; Campora, U. A computer model for the dynamic simulation of turbocharged diesel engine. In Proceedings of the 1st International Conference on Control and Diagnostics in Automotive Applications, Genoa, Italy, 3–4 October 1996. [Google Scholar]

- Nelissen, D.; Kleijn, A.; Faber, J. FuelEU Maritime and EU ETS Sound Incentives for the Fuel Choice? CE Delft: Delft, The Netherlands, February 2022; Available online: www.cedelft.eu (accessed on 10 January 2024).

- Elkafas, A.G.; Shouman, M.R. Assessment of Technical and Environmental Performance of Marine Alternative fuels for Container Ships. Arab Academy for Science Technology and Maritime Transport College of Maritime Transport and Technology. Res. Sq. 2021, preprint. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).