Abstract

In recent years, the prominence of conformance control technology in heavy oil steam flooding has significantly increased in oilfield development. However, the high-temperature demands of heavy oil steam flooding require more resilient plugging agents. Resin-based plugging agents, known for their exceptional temperature resistance and strength, have emerged as a viable solution within this domain. Yet, they face issues like rapid curing at high temperatures and limited sealing reach. Thus, we introduce a novel approach: epoxy resin gel (EHRB), consisting of epoxy resin (ER) as the curing agent, urotropine (HMTA) and pyrocatechol (RO) as cross-linking agents, and n-butyl glycidyl ether (BGE) as a diluent. EHRB gels at 130 °C in 5.4 h, with curing commencing at 160 °C, extending resin curing time and expanding the sealing radius. This study assessed EHRB’s performance and high-temperature stability through displacement experiments, TGA, and DSC analysis. The results indicate that the EHRB has low viscosity, high compressive strength, and minimal mass loss at high temperatures. At 260 °C, the mass loss is less than 15%. The plugging rate exceeds 90%, and it can withstand steam flushing for over 6 PV. Additionally, it demonstrates a 17% improvement in EOR. EHRB demonstrates outstanding capabilities in proficient channel control for heavy oil steam flooding, offering vital technical support for conformance control in this challenging environment.

1. Introduction

With the depletion of conventional oil resources, the exploration and development focus has shifted predominantly toward unconventional oil and gas resources. Heavy oil, as a significant component of unconventional oil and gas resources, is abundant and widely distributed, making it a primary driver of future petroleum development [1,2,3,4,5,6]. Steam flooding is a common method for thermal recovery of heavy oil. High-temperature steam can reduce the viscosity of heavy oil, making it an effective approach for heavy oil development, which is widely applied worldwide [7,8,9,10]. However, long-term steam injection during the later stages of development can lead to the formation of dominant channels, resulting in steam override and low oil production rates with high water cuts. Nevertheless, substantial reserves of remaining oil are distributed in areas unaffected by steam flooding. Therefore, the conformance control of dominant channels becomes a crucial research direction to improve heavy oil recovery and enhance the overall sweep efficiency [11,12,13,14,15,16].

Controlling dominant channels is a prerequisite for enhancing oil recovery through steam injection [17]. In contrast to conventional plugging methods, steam flooding involves higher temperatures and greater erosive forces, presenting challenges to the temperature resistance and erosion resistance of plugging agents [18,19]. Plugging agents need to withstand high temperatures and resist flushing [20,21]. Gels, foams, and resins are the most commonly used dominant channel plugging agents [22]. Gels may dehydrate at high temperatures, causing a rapid decrease in blocking strength. Additionally, gel solutions are diluted by formation water during the injection process and weakened by screen pipes, perforations, and formation pore shear, thus compromising gel performance [23]. Although sulfonated phenolic resins can endure temperatures up to 180 °C and have been applied in some oilfields, their high cost limits widespread use [15,24]. Foam systems not only enhance sweep efficiency but also improve oil displacement efficiency and have been successfully used for steam control [25,26,27,28]. However, foams encounter limitations in plugging capabilities and stability issues, thus serving as a technical bottleneck that hinders their widespread application [29,30,31]. Resin systems, known for their high curing strength and stability, have been applied for years in oilfield steam control. However, their fast curing at high temperatures results in a small sealing radius, and the rapid curing introduces operational risks [32,33,34]. Hence, there is an urgent need to develop steam control agents that are high-temperature resistant, have controllable gelation time, possess strong plugging capabilities, and carry low operational risks.

This study aimed to address the technical challenges in the context of the Fengcheng heavy oil reservoir, Well No. 18, characterized by a reservoir depth of less than 500 m, an average porosity of 30.2%, an average permeability of 1536 mD, and a sustained subsurface temperature of 130–134 °C after steam injection, with the original oil having a viscosity of 35,200 mPa·s. To tackle the problem of rapid resin curing, we developed an epoxy resin plugging agent system (EHRB) that primarily utilizes ER as the main agent, BGE as the diluent, and substitutes HMTA and RO for curing agents, forming a gel before curing. Furthermore, we investigated the impact of different additives on gelation performance and stability as well as the effects of diluents on system viscosity and post-curing compressive strength. The study included displacement experiments to assess plugging performance, erosion resistance, and enhanced oil recovery (EOR) efficiency. Finally, through thermal analysis using TGA and DSC, we analyzed the temperature resistance mechanism of the developed system. This research introduces a novel approach to address challenges in heavy oil steam control, providing valuable insights and potential solutions for the industry.

2. Materials and Methods

2.1. Materials

The main agent, ER (bisphenol A epoxy resins) average molecular weight of 6000 g/mol, epoxy value 0.54, was purchased from Babang Petrochemical Co., Ltd. (Chongqing, China). The diluent, BGE, was sourced from Tianjin Zhonghe Shengtai Chemical Co., Ltd. (Tianjin, China). The cross-linking agents, HMTA and RO, were provided by Weifang Xingjia Chemical Co., Ltd. (Weifang, China). The simulated formation water used in the experiment in this paper was prepared according to the ionic composition of formation water from Fengcheng Oilfield. The total salinity of the simulated water was 5832.5 mg/L, and the ionic composition is shown in Table 1.

Table 1.

Ionic composition of simulated formation water.

2.2. Preparation of EHRB

To prepare the gel solution, measure and combine the required amounts of ER, BGE, HMTA, and RO. Mix them thoroughly in a beaker and then transfer the mixture into vials. Seal the vials using a spray gun. Place the vials in an aging chamber and position them inside a high-temperature oven with the internal temperature set at 130 °C.

2.3. Determination of Gel Time and Gel Strength

In this study, the strength of EHRB was determined using the GSC strength code method. Letters A to I were used to represent different levels of gel strength, with grade “I” indicating the highest strength, as shown in Table 2. Initially, the EHRB solution was prepared according to the method described in Section 2.2. Subsequently, samples were taken from the oven every hour to record the time and strength code. Upon stabilization of the strength code, the current code reflected the strength level of the EHRB, and the corresponding gelation time was documented. Each group had three parallel samples, and the gelation time was the average of the sample data [35,36].

Table 2.

Gel strength code.

2.4. Effect of BGE Addition on Viscosity and Curing Strength

Tests were carried out to evaluate the influence of diluent addition on the system’s viscosity along with its impact on post-gelation curing time and compressive strength. The experimental procedure is as follows: We employed a rotational viscometer (Brookfield TC-150, Middleborough, MA, USA) to measure the viscosity of different BGE content EHRB samples at 30 °C, 50 °C, 70 °C, and 130 °C. Utilizing a compression strength testing machine (Chandler 4207D CHANDLER Industrial Instruments Co., Ltd., Tulsa, OK, USA), we studied the compressive strength of cured EHRB, using a 50% deformation rate as the criterion, to determine the compressive strength under varying BGE content levels.

2.5. Core Plugging Experiment

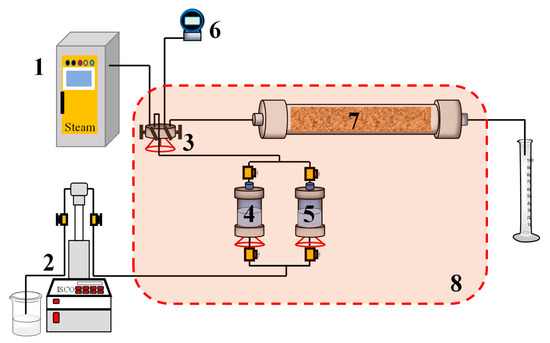

In the study, a simulated core flow apparatus, as shown in Figure 1, was used to prepare a series of sand packs with varying permeabilities using quartz sand [37]. The experimental procedure was as follows:

Figure 1.

Flow chart of sandpack model: 1—steam generator, 2—ISCO pump, 3—six-port valve, 4—water container, 5—EHRB container, 6—pressure gauge, 7—sand-filled pipe, 8—oven.

- (1)

- Connect the appropriate pipelines and check the airtightness of the setup.

- (2)

- Adjust the six-way valves 2 and 5 to connect the middle container 6 with the sand packing tube entrance. Control the ISCO pump in constant flow mode to inject water at a flow rate of 0.5 mL/min. The pressure acquisition system 4 records the injection pressure at the sand packing tube entrance, and the stabilized pressure is noted as P1. Use the following formula to calculate the sand packing tube’s permeability.

- (3)

- Adjust the six-way valves 2 and 5 to connect the middle container 7 with the sand packing tube entrance. Inject the epoxy resin gel into the sand packing tube at the same flow rate for 1 pore volume (1 PV), maintaining the oven temperature at 130 °C for 6 h to allow gelation. Subsequently, increase the temperature to 260 °C for aging over 3 h to ensure complete curing of the resin gel.

- (4)

- Adjust the six-way valves 2 and 5 to connect the middle container 6 with the sand packing tube entrance. Continue to displace with water at a flow rate of 0.5 mL/min, recording the breakthrough pressure at the time of stable pressure and the permeability at the point of breakthrough. Calculate the plugging efficiency and breakthrough pressure gradient.

2.6. EHRB Erosion Experiment

The durability of the plugging agent in providing long-lasting effectiveness is a critical factor in steam control, analogous to the equipment utilized in Section 2.4. Prepare different sand packs. Inject 1 pore volume (1 PV) of EHRB, allow gelation at 130 °C for 6 h, and subsequently increase the temperature to 260 °C for aging over 3 h to ensure complete curing. Adjust the steam generator temperature to 260 °C and inject steam at a rate of 3 mL/min, continuously flushing for 6 pore volumes (6 PV). Record the inlet pressure to investigate the erosion resistance capability of EHRB.

2.7. Oil Displacement Experiment

The purpose of blocking steam channels is to increase the steam sweep efficiency, which is ultimately aimed at enhancing oil recovery [38]. The potential for EHRB to improve oil recovery was studied through oil displacement experiments. We used the experimental apparatus shown in Figure 1. First, sand packs with varying permeabilities were prepared. Next, heavy oil was injected until there was no water at the outlet of the sand pack, and the sand packing tube was aged at 130 °C for 3 days. Steam flooding was conducted at a flow rate of 3 mL/min at 260 °C, until the water content at the outlet of the sand-filled tube reached 100%, and the oil recovery was calculated. Subsequently, an injection of 1 pore volume (1 PV) of EHRB into the sand pack was carried out. The mixture was allowed to gel at 130 °C for 6 h and subsequently aged at 260 °C for 3 h to ensure thorough curing. Steam injection was continued until the water content reached 100%, and the final oil recovery was recorded to calculate the incremental recovery.

2.8. Research on Heat Resistance Mechanism

To study the thermal resistance mechanism of EHRB, we used TGA and DSC to conducted experimental research on the weight change and heat change in the plugging agent at high temperatures. The experimental procedure was as follows: Place the plugging agent in a freeze dryer and freeze dry it for 24 h. The resulting solid is the sample. Conduct thermal loss analysis on the synthesized anti-blocking agent sample using a TGA 8000 (PerkinElmer Instruments Co., Ltd., Waltham, MA, USA) thermogravimetric analyzer in a nitrogen environment. The temperature range is from 30 to 600 °C with a heating rate of 10 °C/min. Use DSC to measure the DSC curve of the sample in the same nitrogen environment.

3. Results and Discussion

3.1. Preparation of EHRB

3.1.1. Cross-Linking Process

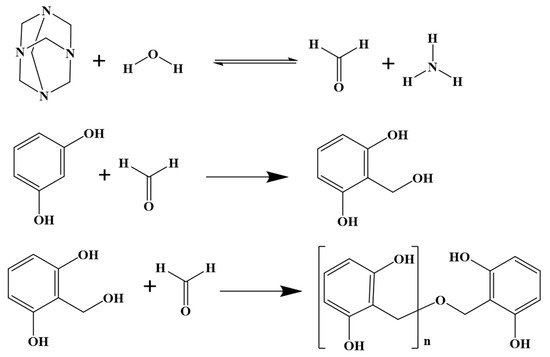

EHRB’s cross-linking reaction involves a condensation reaction between ER, HMTA, and RO. The reaction mechanism is as follows: HMTA undergoes hydrolysis to produce formaldehyde, which reacts with RO to generate polyhydroxymethyl phenols and phenolic aldehyde resins. Polyhydroxymethyl phenols and phenolic aldehyde resins cross-link with ER at high temperatures. The formation of cross-linking agents is illustrated in Figure 2 [39,40].

Figure 2.

Process of cross-linking.

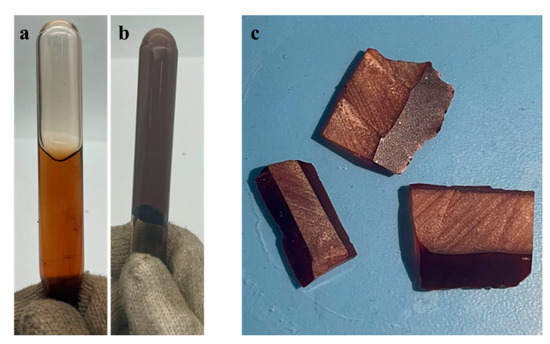

3.1.2. EHRB Shape

The macroscopic morphology of the EHRB system in the gelation-curing process is depicted in Figure 3. Figure 3a represents the base liquid before gelation, with a viscosity of 352 mPa·s at 50 °C, demonstrating good injectability. Figure 3b shows the gel formed at 130 °C, which appears dark brown, achieving a strength level of ‘H’. At this stage, it possesses plugging capabilities. Figure 3c illustrates the morphology of the system after curing at 260 °C, which is characterized by high strength. It exhibits excellent plugging performance and resistance to high-temperature steam in the reservoir.

Figure 3.

(a) The morphology of EHRB before gelation, (b) the morphology of EHRB after gelation, (c) the morphology of EHRB after curing.

3.2. Effect of Additive Concentration on EHRB Gel Performance

The gelation time, gelation strength, and dehydration rate of different concentrations of ER, BGE, HMTA, and RO were measured at an experimental temperature of 130 °C.

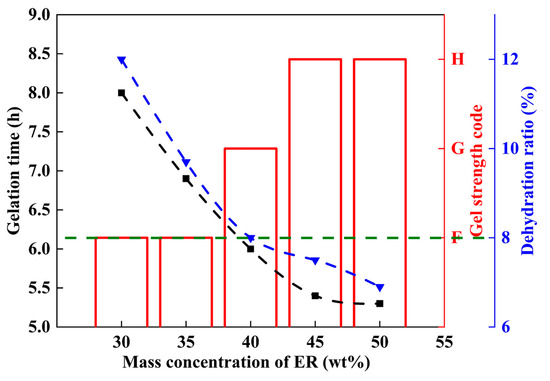

3.2.1. Effect of ER Concentration on Gel Properties

While maintaining constant concentrations of BGE, HMTA, and RO, the study systematically measured the impact of various ER concentrations (ranging from 30 to 50 wt%) on the gelation time, gelation strength, and dehydration rate of EHRB. The results are shown in Figure 4. As the ER concentration increases, the gelation strength increases from level ‘F’ to ‘H’. The gelation time reduces from 8 to 5.3 h, which is a decrease of 33.75%. The dehydration rate decreases by 5.1%, going from 12.0% to 6.9%.

Figure 4.

The gelation properties of different concentrations of ER (2.5 wt% HMTA + 3.0 wt% RO + 20 wt% BGE).

The results indicate that an increase in ER concentration is beneficial for enhancing the gelation rate and stability. This is because the ‘epoxy groups’ involved in the cross-linking groups increase with the higher concentration of epoxy resin, resulting in a faster reaction rate and a higher cross-linking density. Using a standard of dehydration rate <8.0% and gelation strength ‘H’, the optimal ER concentration is ≥45 wt%.

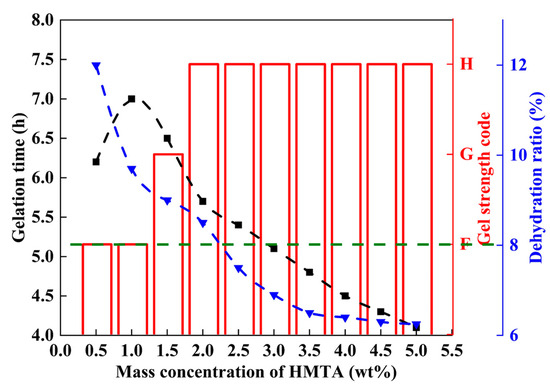

3.2.2. Effect of HMTA Concentration on Gel Properties

With ER, RO, and BGE concentrations held constant, the effect of different HMTA concentrations (ranging from 0.5% to 5%) on the gelation time, gelation strength, and dehydration rate of EHRB was measured. The results are presented in Figure 5. When the HMTA concentration is ≤1.5%, the gelation strength increases from level ‘E’ to ‘G’. The gelation time increases from 6.2 to 6.5 h, and the dehydration rate decreases from 12.0% to 9.0%. When the urotropine concentration is >1.5%, the gelation strength increases from ‘G’ to ‘H’, the gelation time decreases from 6.5 to 6.2 h, and the dehydration rate decreases from 9.0% to 6.2%.

Figure 5.

The gelation properties of different concentrations of HMTA (45 wt% ER + 3.0 wt% RO + 20 wt% BGE).

The results suggest that low concentrations of HMTA are unable to prepare high-strength gels. An increase in the HMTA concentration is beneficial for enhancing gelation rate and stability. This is because when the HMTA concentration is low, there are fewer ‘-OH’ groups participating in cross-linking, resulting in a lower cross-linking density and weaker gelation strength. As the HMTA concentration increases, the number of ‘-OH’ groups increases, accelerating the cross-linking reaction and increasing the cross-linking density. Using a standard of dehydration rate <8.0%, the optimal HMTA dosage is ≥2.5%.

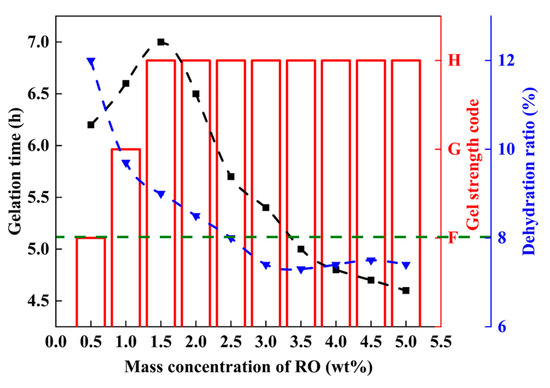

3.2.3. Effect of RO Concentration on Gel Properties

With ER, HMTA, and BGE concentrations held constant, the effect of different RO concentrations (ranging from 0.5% to 5%) on the gelation time, gelation strength, and dehydration rate of EHRB was measured. The results are shown in Figure 6. When the RO concentration is ≤1.5%, the gelation strength increases from level ‘E’ to ‘H’. The gelation time increases from 6.2 to 7 h, and the dehydration rate decreases from 12.0% to 9.0%. When the RO concentration is >1.5%, the gelation strength remains at the ‘H’ level, the gelation time decreases from 7 to 4.6 h, and the dehydration rate decreases from 9.0% to 7.4%.

Figure 6.

The gelation properties of different concentrations of RO (45 wt% ER + 2.5 wt% HMTA + 20 wt% BGE).

The results indicate that low concentrations of RO cannot prepare high-strength gels. Increasing the concentration of RO is beneficial for enhancing gelation rate and stability. This is because as the concentration of RO increases, the content of polyhydroxymethyl phenols and phenolic aldehyde resins also increases, meaning the number of cross-linking sites increases. Consequently, a low concentration of RO results in a diminished cross-linking density and weakened gelation strength, whereas a high concentration of RO yields an elevated cross-linking density and increased gelation strength. The optimal dosage of RO is deemed to be ≥3.0%.

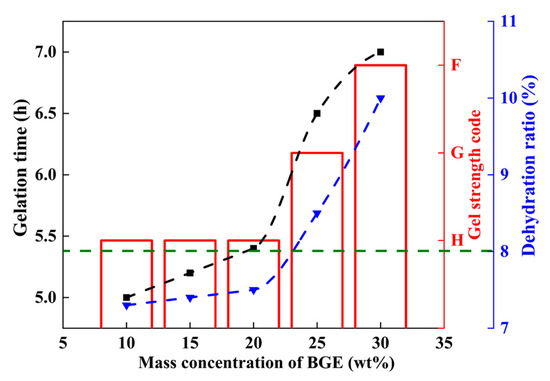

3.2.4. Effect of BGE Concentration on Gel Properties

With ER, HMTA, and RO concentrations held constant, the effect of different BGE concentrations (ranging from 10% to 30%) on the gelation time, gelation strength, and dehydration rate of EHRB was measured. The results are depicted in Figure 7. When the BGE concentration is ≤20%, the gelation strength remains at the ‘H’ level. The gelation time increases from 5 to 5.4 h, and the dehydration rate increases from 7.3% to 7.5%. When the diluent concentration is >20%, the gelation strength decreases from the ‘H’ to ‘F’ level, the gelation time increases from 5.4 to 7 h, and the dehydration rate increases from 7.5% to 10%.

Figure 7.

The gelation properties of different concentrations of BGE (45 wt% ER + 2.5 wt% HMTA + 3.0 wt% RO).

3.3. Effect of BGE Addition on Viscosity and Curing Strength

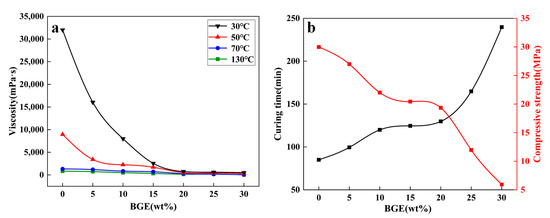

Due to the high initial viscosity of the resin (greater than 30,000 mPa·s at room temperature), it is difficult to pump it into the field. Therefore, it needs to be diluted to reduce viscosity. However, increasing the diluent can affect the system’s compressive strength. Therefore, we systematically assessed the impact of diluent addition on system viscosity, gelation time, and compressive strength post-gelation.

As the concentration of BGE increases, the viscosity of EHRB significantly decreases. At a BGE concentration of 20%, it remains relatively stable, with a viscosity of 352 mPa·s at 50 °C, meeting the requirements for field construction.

The increase in the density of BGE reduces the system’s viscosity and compressive strength while also increasing the curing time, as shown in Figure 8. With an increase in BGE content, the curing time increases from 85 to 240 min. This is due to the increased BGE content, which relatively reduces the concentration of the main agent and cross-linking agent, thus suppressing the cross-linking rate. At the same time, the compressive strength decreases from 30 to 6 MPa. BGE’s molecular structure contains flexible chains with ether bonds, giving EHRB some flexibility after curing. However, excessive BGE will significantly reduce the strength after curing. Therefore, at a BGE concentration of 20%, the compressive strength is greater than 20 MPa, and the curing time is approximately 2 h.

Figure 8.

(a) The effect of BGE concentration on viscosity, (b) the effect of BGE concentration on curing time and compressive strength.

3.4. EHRB Sealing Performance

The plugging performance is a crucial indicator for steam channel control. In this section, the experimental method outlined in Section 2.4 was used to measure the permeation characteristics of the sand pack before and after EHRB injection, calculate the plugging efficiency, and determine the breakthrough pressure. The results are shown in Table 3.

Table 3.

Core parameters before and after plugging.

It can be observed that EHRB exhibits excellent plugging performance exceeding 90% in sand packs with different permeabilities. EHRB solidifies within the preferential pathways, effectively blocking these channels. After solidification, EHRB gains a certain level of strength, allowing it to easily plug or bridge larger pore throats, thereby increasing the breakthrough pressure of the resin gel. The solidification of EHRB has a remarkable effect on regulating steam channels.

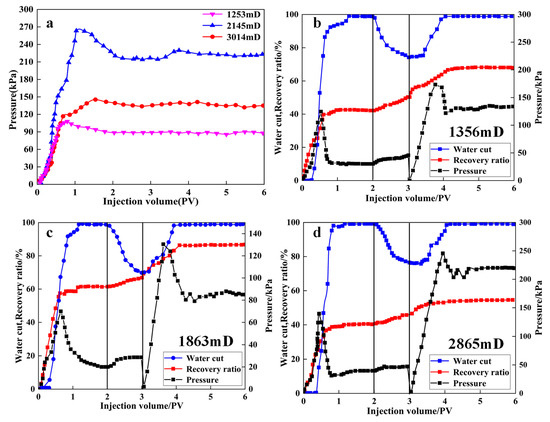

3.5. EHRB Erosion Resistance

The resistance to flushing performance is a crucial indicator for determining the long-term plugging ability. Figure 9a shows the pressure changes during steam flushing in sand packs with different permeabilities after EHRB injection. The pressure curve can be divided into three stages: rapid increase, slight decrease, and stabilization. The rapid increase and slight decrease stages are attributed to the phenomenon of steam injection filling the sand pack before the pressure rises to the outlet. In the stabilization stage, EHRB, based on its excellent heat resistance and plugging strength, effectively stabilizes the blockage of the steam channels. The injected steam has a minimal impact on EHRB, resulting in gentle pressure fluctuations. Even after injecting 6 PV of steam, the pressure remains at a relatively high level, indicating that EHRB has excellent resistance to flushing and can block the steam channels for an extended period.

Figure 9.

(a) EHRB’s erosion resistance, (b–d) different permeability sand-filled pipe EHRB’s performance in improving oil recovery.

3.6. EOR Performance of EHRB

The purpose of blocking the steam channels is to enhance oil recovery. The results of the oil displacement tests in sand packs with different permeabilities are shown in Figure 9b–d. In the initial stage of steam flooding, the steam generated by the steam generator is compressed at the pipeline and the inlet of the sand pack, leading to a gradual increase in pressure. At this point, there is no liquid at the outlet of the sand pack. When the pressure reaches a certain level, fluids start to flow out of the sand pack. As the heavy oil is progressively heated, the flow resistance of heavy oil and injection pressure gradually decrease. Due to the higher mobility of steam compared to heavy oil, when water breakthrough occurs, the produced liquid’s water cut sharply increases, resulting in a slower oil recovery rate, indicating the characteristics of steam channeling. When the injected volume reaches approximately 1.3 PV, the water cut approaches 100%. However, there is still a significant amount of remaining oil in the sand pack. Subsequently, 1 pore volume (1 PV) of gel resin is injected into the sand pack. The elevated viscosity of the gel resin, upon injection, serves to modulate the oil–water mobility, resulting in an increase in injection pressure and a gradual reduction in water cut. This process leads to a marginal enhancement in oil recovery. After aging, steam flooding continues, and the displacement pressure is significantly higher than the final pressure after gel resin injection, indicating that the gel resin enhances the plugging ability. The plugging causes steam diversion, resulting in an average 17% increase in heavy oil recovery among the three sand packs.

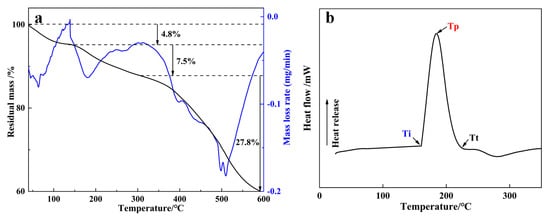

3.7. Research on Heat Resistance Mechanism

EHRB’s thermal decomposition is primarily divided into three stages, as shown in Figure 10: In the range of 40–135 °C, there is a slow decomposition rate with a mass loss of 4.8%. This is due to the loss of polymer weight caused by the heating and volatilization of the free water adsorbed by the hydrophilic groups in EHRB as the temperature rises. In the range of 135–302 °C, there is a faster decomposition rate with a mass loss of 7.5%. Mass loss in this stage is primarily due to the partial breakage of the ether bonds in the cross-linking sites. In the range of 302–600 °C, there is a mass loss of 27.8%. This stage is attributed to the degradation of the main chain’s C-C bonds and the breakdown of the main chain. The thermal decomposition stages provide insights into the high-temperature resistance mechanisms of EHRB. The first stage involves the loss of absorbed water, the second stage relates to the breakdown of ether bonds in the cross-linking sites, and the final stage involves the degradation of the main chain. These processes collectively contribute to the material’s high-temperature performance.

Figure 10.

(a) TAG curve of EHRB, (b) DSC curve of EHRB.

Additionally, the DSC heating curve in Figure 10b reveals a single exothermic peak with EHRB exhibiting specific curing temperature parameters as follows: initial curing temperature (Ti): 160 °C; peak curing temperature (Tp): 184 °C; final curing temperature (Tt): 224 °C. These temperatures are higher than the reservoir temperature. The relatively narrow curing peak suggests that EHRB cures rapidly at elevated temperatures, reducing the risk of steam erosion due to the curing rate during steam injection. The resulting cured material effectively plugs dominant pathways, thus enhancing the efficiency of steam-assisted oil recovery.

4. Conclusions

This study prepared EHRB suitable for consistency control in high-temperature heavy oil steam reservoirs and investigated the effects of various component concentrations on gel performance. The study also examined the impact of diluents on EHRB viscosity and curing strength. Furthermore, the sealing performance, erosion resistance, and enhanced oil recovery (EOR) capabilities of EHRB were evaluated. Thermal analysis using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) provided insights into EHRB’s thermal stability mechanisms. The following conclusions can be drawn:

- (1)

- EHRB can form high-strength and stable gels at 130 °C. The optimal concentrations of different additives are as follows: ER ≥ 45 wt%, HMTA ≥ 2.5 wt%, RO ≥ 3.0 wt%, and BGE ≤ 20%. The gel strength can reach the “H” level with gelation times ranging from 4.6 to 8 h, and dehydration rates between 12% and 6.2%.

- (2)

- Adding 20 wt% of BGE to EHRB can effectively reduce the system’s viscosity to meet on-site injection requirements while maintaining the system’s compressive strength.

- (3)

- EHRB exhibits a sealing efficiency of over 90% at 260 °C and demonstrates excellent resistance to steam flushing and enhanced oil recovery (EOR) performance. It is well suited for controlling dominant pathways in heavy oil steam flooding applications.

- (4)

- The high-temperature resistance of EHRB is attributed to the enhanced network structure resulting from the cross-linking reactions between phenolic–aldehyde resin and epoxy groups as well as self-polymerization of epoxy groups. EHRB features a narrow curing temperature window, allowing for rapid solidification to reduce steam erosion. EHRB is a promising solution for consistent control in heavy oil steam flooding with broad application prospects.

Author Contributions

Investigation, Y.S.; data curation, F.D.; writing—original draft preparation, Y.S.; writing—review and editing, Y.L. and Z.Z.; supervision, N.X.; project administration, N.X.; funding acquisition, H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

Author Yu Li was employed by the Exploration and Development Research Institute of PetroChina Qinghai Oilfield Company, Zhuo Zhou was employed by the Petroleum Engineering Technology Research Institute of Jianghan Oilfield Administration Bureau of Sinopec Group, Nuolin Xiong was employed by the Sinopec Jianghan Oilfield Fuling Shale Gas Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ding, M.; Liu, P.; Wang, Y.; Zhang, Z.; Dong, J.; Duan, Y. Adaptability to Enhance Heavy Oil Recovery by Combination and Foam Systems with Fine-Emulsification Properties. Energies 2023, 16, 7303. [Google Scholar] [CrossRef]

- Luo, C.; Wu, Y.; He, W.; Gao, Y.; Liu, J. Mechanisms and Operational Strategies of Multi-Lateral Steam-Assisted Gravity Drainage (SAGD) for Heterogeneous Reservoirs. Energies 2023, 16, 7351. [Google Scholar] [CrossRef]

- Lv, B.; Sun, P.; Wu, Y.; Yang, Z.; Liu, P.; Wang, C.; Liu, Q. Study and Application of Oily Sludge Profile Control Technology in Heavy Oil Reservoir. Energies 2023, 16, 5064. [Google Scholar] [CrossRef]

- Minakov, A.V.; Meshkova, V.D.; Guzey, D.V.; Pryazhnikov, M.I. Recent Advances in the Study of In Situ Combustion for Enhanced Oil Recovery. Energies 2023, 16, 4266. [Google Scholar] [CrossRef]

- Xie, Q.; Liang, G.; Liu, S.; Wang, R.; Feng, M.; Liao, C. Physical and Numerical Simulations of Steam Drive and Gravity Drainage Using the Confined Bottom Oil–Water Transition Zone to Develop Super Heavy Oil. Energies 2023, 16, 6302. [Google Scholar] [CrossRef]

- Fathy, D.; El-Balkiemy, A.F.; Makled, W.A.; Hosny, A.M. Organic geochemical signals of Paleozoic rocks in the southern Tethys, Siwa basin, Egypt: Implications for source rock characterization and petroleum system. Phys. Chem. Earth Parts A/B/C 2023, 130, 103393. [Google Scholar] [CrossRef]

- Willman, B.; Valleroy, V.; Runberg, G.; Cornelius, A.; Powers, L. Laboratory studies of oil recovery by steam injection. J. Pet. Technol. 1961, 13, 681–690. [Google Scholar] [CrossRef]

- Volek, C.; Pryor, J. Steam Distillation Drive-Brea Field, California. J. Pet. Technol. 1972, 24, 899–906. [Google Scholar] [CrossRef]

- Belghache, A.; Holyoak, S.; Alwazeer, A.; Choudhury, S.; Shibli, A.; Mahrazy, K.; Amri, Z.; Yazidi, R.; D’Amours, K. Designing a Cross Top Down Steam Drive Pilot to Unlock a Complex Ultra Heavy Oil Field in the Sultanate of Oman. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018; p. D022S005R002. [Google Scholar]

- Fan, J.; Yang, J.; Fan, X.; Wu, L. Experimental study on the mechanism of enhanced oil recovery by non-condensable gas-assisted steam flooding process in extra-heavy oil reservoir. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 444–460. [Google Scholar] [CrossRef]

- Liu, C.; Liao, X.; Zhang, Y.; Chang, M.-M.; Mu, C.; Li, T.; Qin, R.; Fu, R.; Bie, X.; Zheng, J. Field application of polymer microspheres flooding: A pilot test in offshore heavy oil reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012; p. SPE-158293-MS. [Google Scholar]

- Cao, W.; Xie, K.; Lu, X.; Liu, Y.; Zhang, Y. Effect of profile-control oil-displacement agent on increasing oil recovery and its mechanism. Fuel 2019, 237, 1151–1160. [Google Scholar] [CrossRef]

- Caili, D.; Qing, Y.; Fulin, Z. In-depth profile control technologies in China—A review of the state of the art. Pet. Sci. Technol. 2010, 28, 1307–1315. [Google Scholar] [CrossRef]

- Yanbin, C.; Dongqing, L.; Zhang, Z.; Shantang, W.; Quan, W.; Daohong, X. Steam channeling control in the steam flooding of super heavy oil reservoirs, Shengli Oilfield. Pet. Explor. Dev. 2012, 39, 785–790. [Google Scholar]

- Wang, C.; Liu, H.; Zheng, Q.; Liu, Y.; Dong, X.; Hong, C. A new high-temperature gel for profile control in heavy oil reservoirs. J. Energy Resour. Technol. 2016, 138, 022901. [Google Scholar] [CrossRef]

- Lu, C.; Liu, H.; Pang, Z.; Dong, X.; Xiu, W. A new profile control design based on quantitative identification of steam breakthrough channel in heavy oil reservoirs. J. Pet. Explor. Prod. Technol. 2014, 4, 17–35. [Google Scholar] [CrossRef][Green Version]

- Zhu, D.; Bai, B.; Hou, J. Polymer gel systems for water management in high-temperature petroleum reservoirs: A chemical review. Energy Fuels 2017, 31, 13063–13087. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Pang, Z.; Gao, M. Visualization study on plugging characteristics of temperature-resistant gel during steam flooding. Energy Fuels 2016, 30, 6968–6976. [Google Scholar] [CrossRef]

- Wei, B.; Li, Q.; Jin, F.; Li, H.; Wang, C. The potential of a novel nanofluid in enhancing oil recovery. Energy Fuels 2016, 30, 2882–2891. [Google Scholar] [CrossRef]

- Liu, D.; Shi, X.; Zhong, X.; Zhao, H.; Pei, C.; Zhu, T.; Zhang, F.; Shao, M.; Huo, G. Properties and plugging behaviors of smectite-superfine cement dispersion using as water shutoff in heavy oil reservoir. Appl. Clay Sci. 2017, 147, 160–167. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Li, B. Experimental study and application of tannin foam for profile modification in cyclic steam stimulated well. J. Pet. Sci. Eng. 2014, 118, 88–98. [Google Scholar] [CrossRef]

- Baojun, B.; Ming, H.; Yuxiang, L. Influence factor analysis on the plugging performance of gel plugging agent. Oil Gas Recovery Technol. 1997, 4, 22–29. [Google Scholar]

- Dai, C.; Gu, C.; Liu, B.; Lyu, Y.; Yao, X.; He, H.; Fang, J.; Zhao, G. Preparation of low-temperature expandable graphite as a novel steam plugging agent in heavy oil reservoirs. J. Mol. Liq. 2019, 293, 111535. [Google Scholar] [CrossRef]

- Jie, W.; Meilong, F.; Ruokun, X.; Zhiyuan, Z.; Lifeng, C. Study and Application of High-temperature Channeling Blocking System Based on Multi-group Cross Linked Gel for Heavy Oil Reservoirs. Spec. Oil Gas Reserv. 2021, 28, 151–157. [Google Scholar]

- Liu, P.; Zhang, X.; Wu, Y.; Li, X. Enhanced oil recovery by air-foam flooding system in tight oil reservoirs: Study on the profile-controlling mechanisms. J. Pet. Sci. Eng. 2017, 150, 208–216. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Liu, R.; Liu, H.; Li, X.; Fan, Z. The reservoir suitability studies of nitrogen foam flooding in Shengli Oilfield. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 20–22 October 2008; p. SPE-114800-MS. [Google Scholar]

- HUANG, X. High Temperature Foam Profile Control System for Heavy Oil Reservoir in Lab Experiment. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2007, 29, 116. [Google Scholar]

- Sun, C.; Hou, J.; Pan, G.; Xia, Z. Optimized polymer enhanced foam flooding for ordinary heavy oil reservoir after cross-linked polymer flooding. J. Pet. Explor. Prod. Technol. 2016, 6, 777–785. [Google Scholar] [CrossRef] [PubMed]

- Pang, Z.; Liu, H.; Zhu, L. A laboratory study of enhancing heavy oil recovery with steam flooding by adding nitrogen foams. J. Pet. Sci. Eng. 2015, 128, 184–193. [Google Scholar] [CrossRef]

- Pang, Z.; Wu, Y.; Zhao, M. Novel evaluation method of foam agents for thermal recovery in heavy oil reservoirs. Energy Fuels 2016, 30, 2948–2957. [Google Scholar] [CrossRef]

- Sun, L.; Li, D.; Pu, W.; Li, L.; Bai, B.; Han, Q.; Zhang, Y.; Tang, X. Combining preformed particle gel and curable resin-coated particles to control water production from high-temperature and high-salinity fractured producers. SPE J. 2020, 25, 938–950. [Google Scholar] [CrossRef]

- Liu, Q.; Mu, H.; Wang, J.; Fan, Z. The synthesize and property evaluation of high temperature resistant phenolic resin-type profile control agent. Open J. Compos. Mater. 2014, 4, 173–176. [Google Scholar] [CrossRef]

- Li, W.; Lee, L.J. Shrinkage control of low-profile unsaturated polyester resins cured at low temperature. Polymer 1998, 39, 5677–5687. [Google Scholar] [CrossRef]

- Tokar, E.; Tutov, M.; Kozlov, P.; Slobodyuk, A.; Egorin, A. Effect of the resorcinol/formaldehyde ratio and the temperature of the Resorcinol–Formaldehyde gel solidification on the chemical stability and sorption characteristics of ion-exchange resins. Gels 2021, 7, 239. [Google Scholar] [CrossRef] [PubMed]

- Jia, H.; Pu, W.-F.; Zhao, J.-Z.; Liao, R. Experimental investigation of the novel phenol− formaldehyde cross-linking HPAM gel system: Based on the secondary cross-linking method of organic cross-linkers and its gelation performance study after flowing through porous media. Energy Fuels 2011, 25, 727–736. [Google Scholar] [CrossRef]

- Xu, B.; Zhao, G.; Gu, C.; Dai, C.; Zhao, W.; Ma, T. Research and Application Progress of Wet-Phase Modified Expandable Graphite as a Steam Plugging Agent in Heavy Oil Reservoirs. Energy Fuels 2022, 37, 1081–1091. [Google Scholar] [CrossRef]

- Zhao, G.; Dai, C.; Gu, C.; You, Q.; Sun, Y. Expandable graphite particles as a novel in-depth steam channeling control agent in heavy oil reservoirs. Chem. Eng. J. 2019, 368, 668–677. [Google Scholar] [CrossRef]

- Sydansk, R.D. Delayed in situ crosslinking of acrylamide polymers for oil recovery applications in high-temperature formations. US Patent No 4844168, 4 July 1989. [Google Scholar]

- Ding, F.; Dai, C.; Sun, Y.; Zhao, G.; You, Q.; Liu, Y. Gelling behavior of PAM/phenolic crosslinked gel and its profile control in a low-temperature and high-salinity reservoir. Gels 2022, 8, 433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).