Coupling Mechanism of Multiple-Thermal-Fluid Multi-Cycle Stimulation in Ultra-Heavy-Oil Reservoirs

Abstract

1. Introduction

2. MTF Stimulation Production Law

2.1. Variation Law of Daily Oil Production

2.2. Variation Law of Water Content

2.3. Formation Pressure Variation Law

3. Multi-Cycle MTF Stimulation Multi-Media Coupling Mechanism

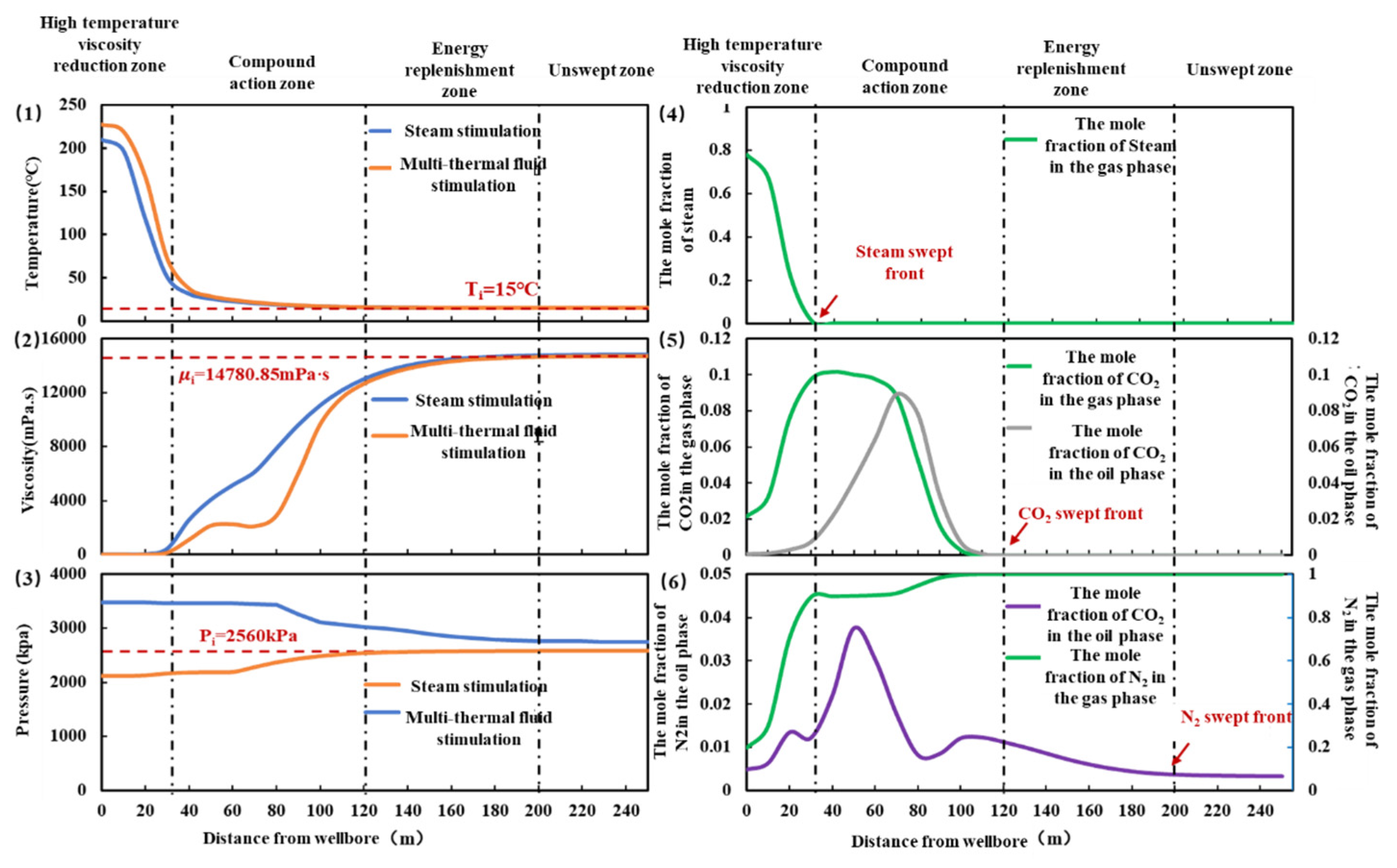

3.1. Zonal Division in the MTF Stimulation Mechanism

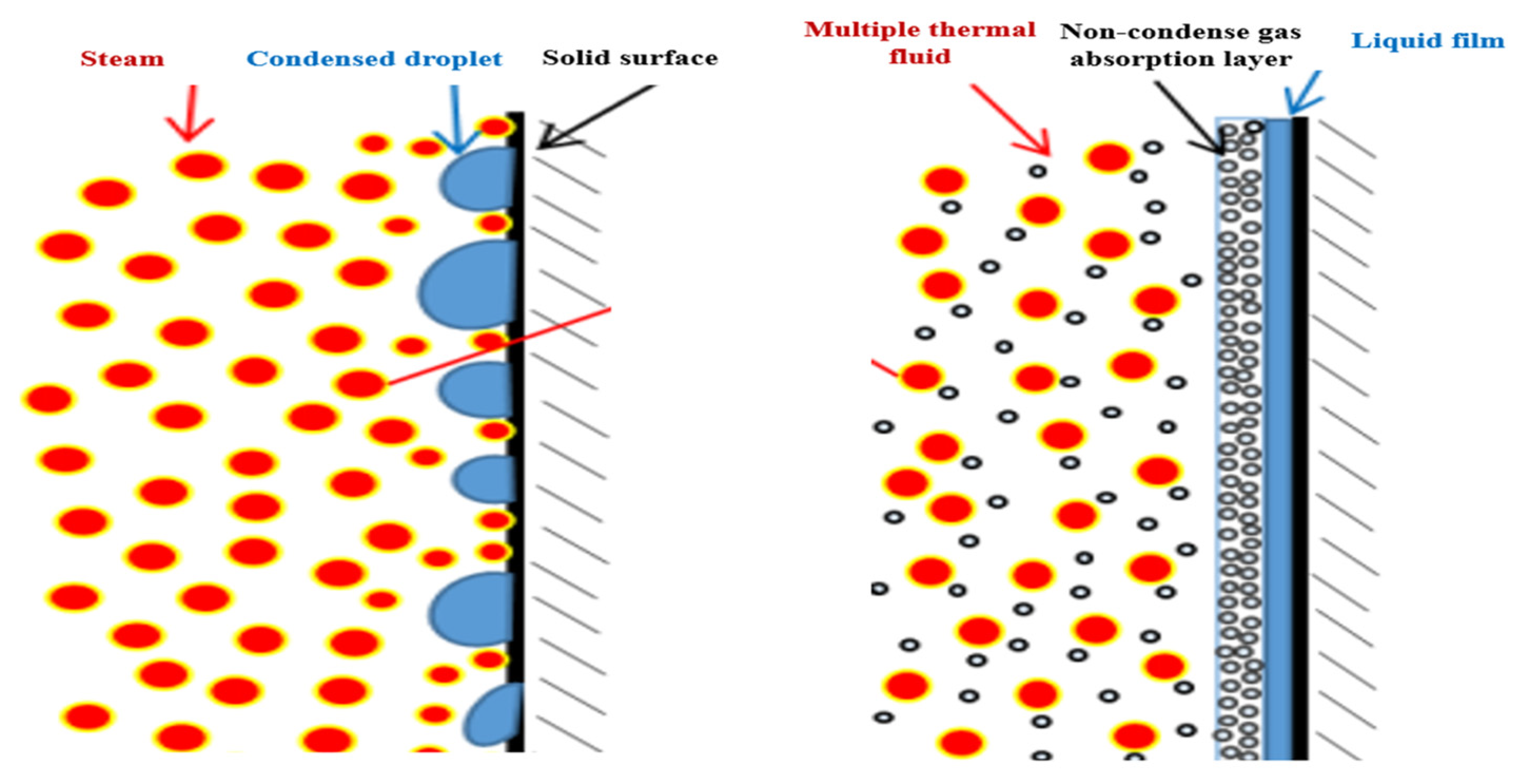

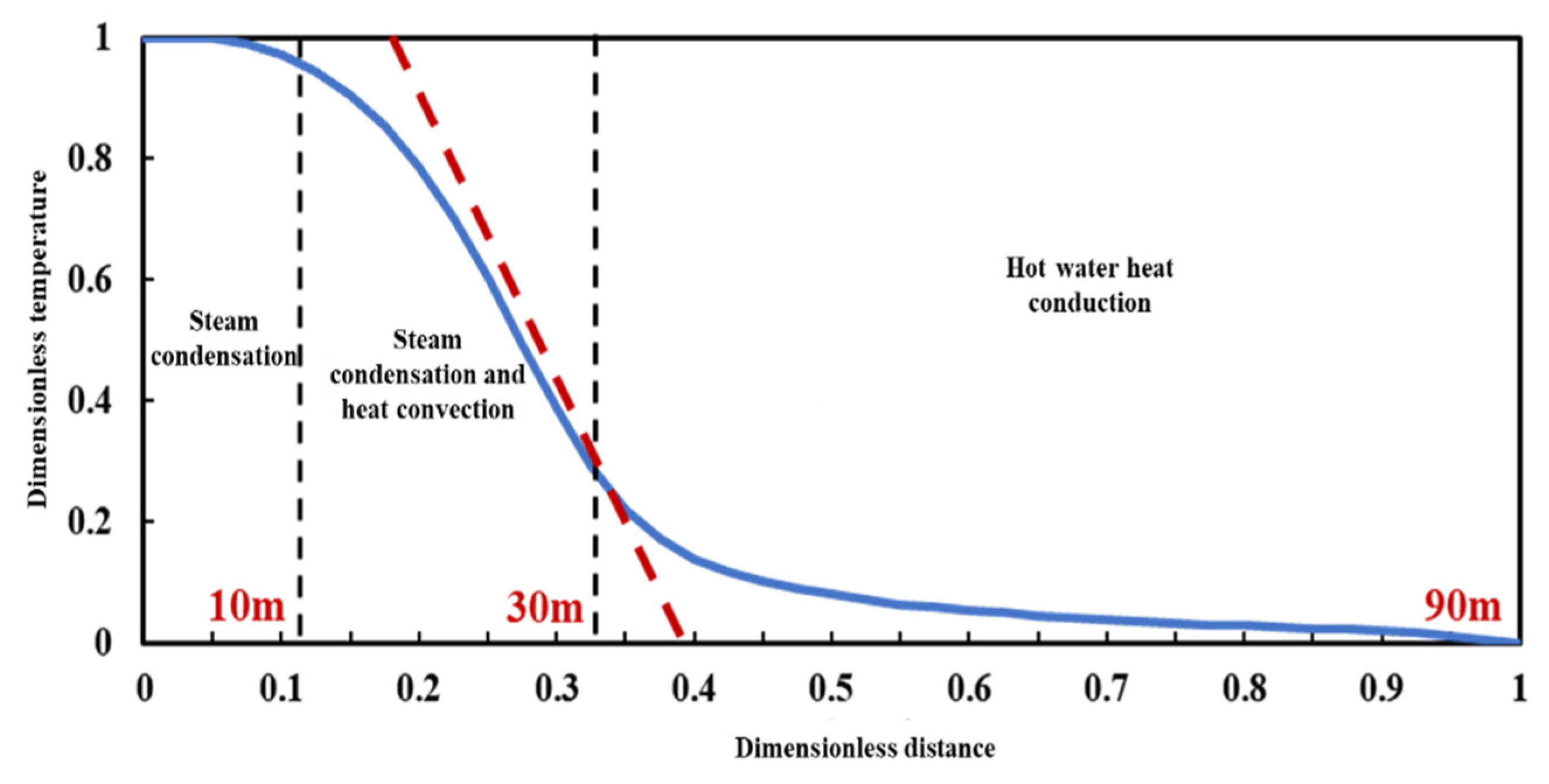

3.2. High-Temperature Viscosity-Reduction Zone

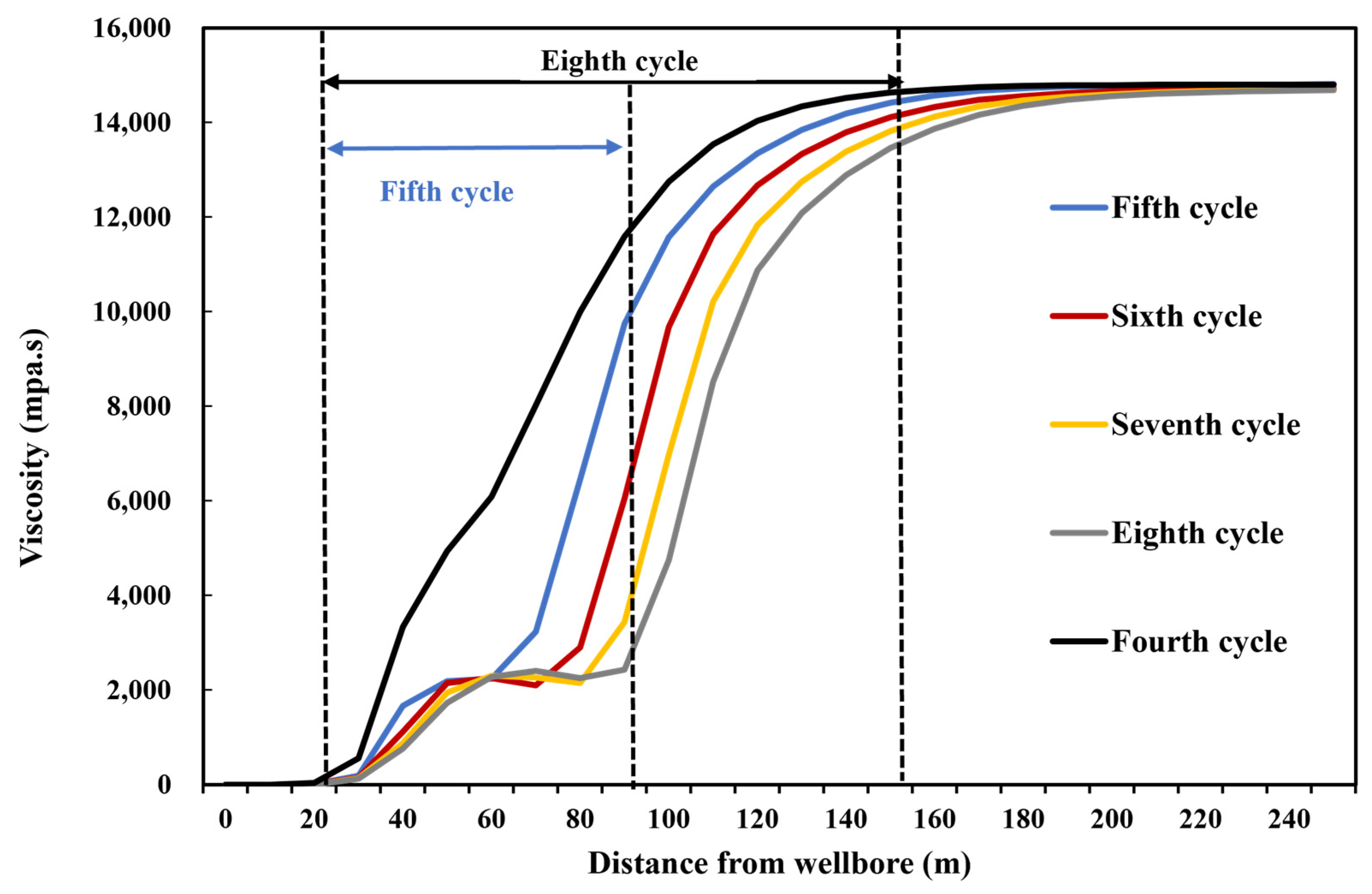

3.3. Compound Action Zone

3.4. Energy-Replenishment Zone

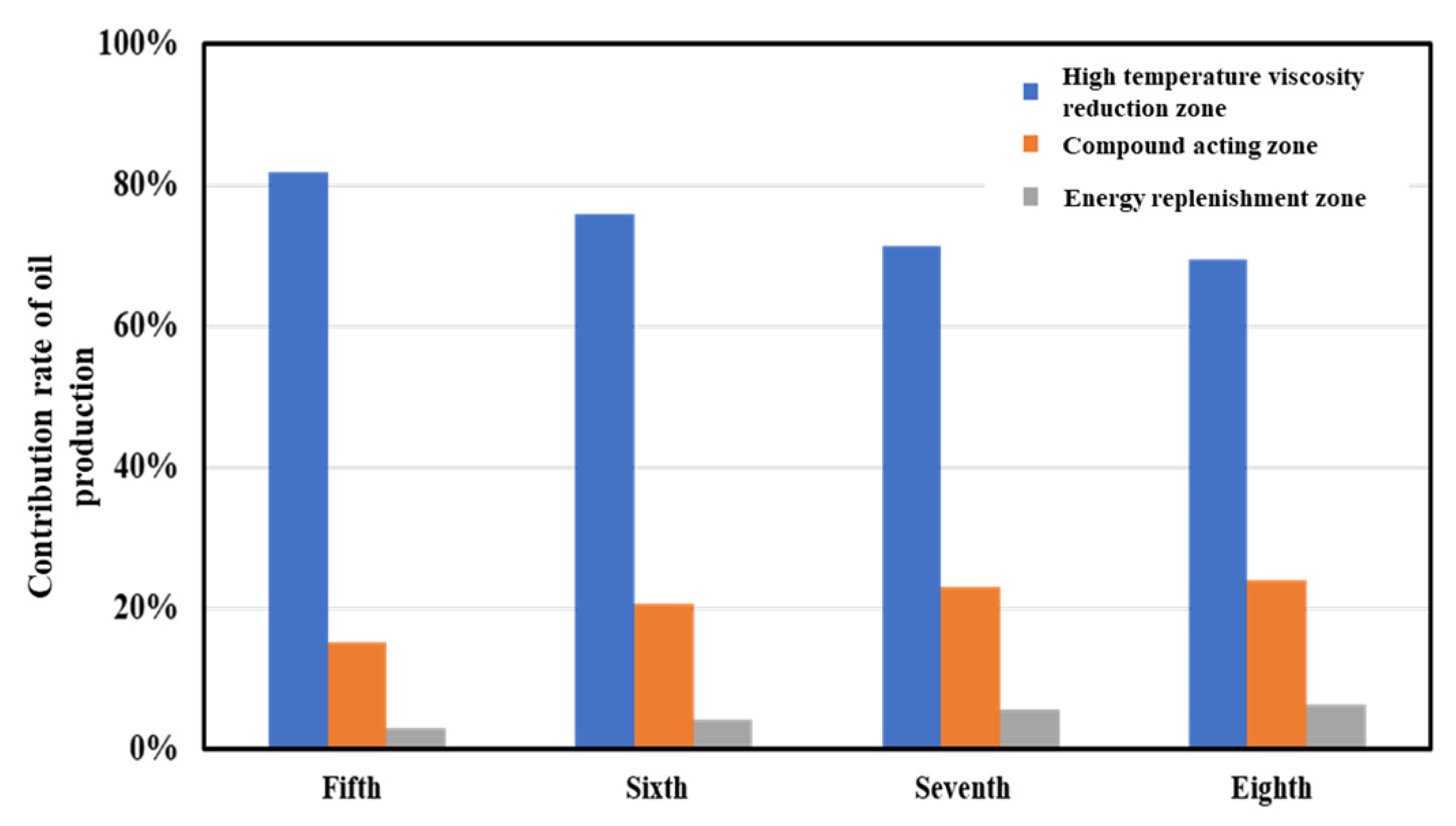

3.5. Analysis of Contribution Rate of Oil Production in Different Zones

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F.; Xu, W.; Wu, T.; Ge, T.; Wang, H.; Wu, C.; Wang, D. Research on the mechanism of MTFs on enhanced oil recovery and reservoir adaptability. Pet. Geol. Recovery Effic. 2014, 21, 75–78. [Google Scholar]

- Liu, D.; Hu, T.; Pan, G.; Wu, J.; Zhang, J. Comparison of Production Results between MTF Stimulation and Steam Stimulation in Offshore Application. Spec. Oil Gas Reserv. 2015, 22, 118–120. [Google Scholar]

- Feng, X.; Li, J.; Yang, B.; Shi, H. Research on Optimization Design for Increasing Production of Offshore Heavy Oil Multi-thermal Fluid Handling Components. J. Chongqing Univ. Sci. Technol. (Nat. Sci. Ed.) 2018, 20, 28–32. [Google Scholar]

- Chen, J. Multiple thermal fluid huff-puff in offshore deep thin heavy oil reservoir. Spec. Oil Gas Reserv. 2016, 23, 97–100+155–156. [Google Scholar]

- Zhang, W.; Sun, Y.; Lin, T.; Ma, Z.; Sun, Y.; Liu, H. Experimental study on mechanisms of the Multi-fluid thermal recovery on offshore heavy oil. Petrochem. Ind. Appl. 2013, 32, 34–36. [Google Scholar]

- Ge, T.; Pang, Z.; Luo, C.; Gao, Z.; Du, C. Experimental study on MTF flooding by using horizontal wells in offshore heavy oil reservoirs. Pet. Geol. Recovery Effic. 2019, 26, 62–69. [Google Scholar]

- Yang, B.; Li, J.; Qi, C.; Shi, H.; Zhu, W. Research on optimized MTFs stimulation of offshore heavy oil reservoirs. Pet. Geol. Eng. 2012, 26, 54–56. [Google Scholar]

- Lu, T.; Ban, X.; Li, Z.; Gao, Y.; Guo, E.; Yang, J.; Ma, H.; Wang, H.; Wei, Y. Mechanisms on expansion of SAGD steam chamber assisted by flue gas. Acta Pet. Sin. 2021, 42, 1072–1080. [Google Scholar]

- Wang, Z. Study of Steam Heat Transfer Law in Development of Flue Gas Assisted SAGD; China University of Petroleum (East China): Dongying, China, 2019. [Google Scholar]

- Huang, Z.; Zhao, Q.; Chen, L.; Miao, Y.; Wang, Y.; Jin, H.; Guo, L. Fundamentals of Enhanced Heavy Oil Recovery by Supercritical MTF Flooding. J. Eng. Thermophys. 2022, 43, 974–981. [Google Scholar]

- Huang, S.; Cao, M.; Cheng, L. Experimental study on the mechanism of enhanced oil recovery by MTF in offshore heavy oil. Int. J. Heat Mass Transf. 2018, 122, 1074–1084. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, Q.; Chen, L.; Guo, L.; Miao, Y.; Wang, Y.; Jin, H. Experimental investigation of enhanced oil recovery and in-situ upgrading of heavy oil via CO2-and N2-assisted supercritical water flooding. Chem. Eng. Sci. 2023, 268, 118378. [Google Scholar] [CrossRef]

- Zhang, N.; Zhu, R.; Zhu, Y. MTF Huff-Puff Mechanism Based on Discrete Wellbore Model. Xinjiang Pet. Geol. 2020, 9, 332–336. [Google Scholar]

- Liu, Y.; Wang, C.; Li, X.; Xu, H. Development mechanism of multivariate thermal fluid of deep super-heavy oil. Fault-Block Oil Gas Field 2019, 26, 638–643. [Google Scholar]

- Zhang, T.; Li, Y.; Sun, S.; Bai, H. Accelerating flash calculations in unconventional reservoirs considering capillary pressure using an optimized deep learning algorithm. J. Pet. Sci. Eng. 2020, 195, 107886. [Google Scholar] [CrossRef]

- Zhou, Y. Studies and practices on the steam injection EOR of water drived heavy oil reservoirs in Shengli petroliferous province. Pet. Explor. Dev. 2006, 33, 479–483. [Google Scholar]

- Lawal, K.A.; Vesovic, V. Analytic investigation of convection during conduction heating of a heavy-oil reservoir. In SPE Annual Technical Conference and Exhibition; OnePetro: Richardson, TX, USA, 2009. [Google Scholar]

- Wang, F.; Mou, Z.; Liu, P.; Zhang, S.; Wang, C.; Li, X. Experiment and numerical simulation on mechanism of CO2 assisted mining in ultra heavy oil reservoirs. Pet. Geol. Recovery Effic. 2017, 24, 86–91. [Google Scholar]

- Zhou, W.; Kou, G.; Zhang, Z.; An, K.; Liu, S.; Liu, Y. Steam-CO2 Flooding for Heavy Oil in District 9-6, Karamay Oilfield: Experiment and Evaluation. Xinjiang Pet. Geol. 2019, 40, 204–207. [Google Scholar]

- Leng, G. Laboratory Study on Air and CO2 Assisted Steam Stimulation. Oil Chem. 2018, 35, 447–450. [Google Scholar]

| Stimulation Cycles | Steam (t) | Carbon Dioxide (t) | Nitrogen (t) | Cumulative Oil Production (t) | Oil–Steam Ratio (t/t) |

|---|---|---|---|---|---|

| First cycle | 2206 | / | / | 298.1 | 0.135 |

| Second cycle | 5460 | / | / | 400.8 | 0.073 |

| Third cycle | 4324 | / | / | 828.9 | 0.192 |

| Fourth cycle | 4468 | / | / | 501.9 | 0.112 |

| Fifth cycle | 4037 | / | / | 475.1 | 0.118 |

| Sixth cycle | 1506 | 370.08 | 1765.92 | 3434.7 | 2.281 |

| Seventh cycle | 3531 | 1454.43 | 6940.17 | 4727.6 | 1.339 |

| Eighth cycle | 4025 | 1614.55 | 7704.21 | 4513.0 | 1.121 |

| Reservoir Parameters | Number of Grids | Mesh Size (m) | Porosity | Horizontal Permeability (mD) | Vertical Permeability (mD) |

|---|---|---|---|---|---|

| Numerical value | 50 × 50 × 15 | 10 × 10 × 2 | 28.1 | 2656 | 796.8 |

| Reservoir parameters | Sag ratio | Original formation viscosity (mPa.s) | Original oil Saturation (%) | Original formation temperature (°C) | Original formation pressure (MPa) |

| Numerical value | 0.3 | 14,780.85 | 75 | 15 | 2.56 |

| Production parameters | Daily water injection (m3/d) | Daily steam injection volume | N2 to CO2 volume ratio | Injection duration (d) | Soaking time (d) |

| Numerical value | 200 | 79,800 | 9:1 | 20 | 5 |

| Production parameters | Production time (d) | Throughput cycle | CSS cycles | MTF cycles | |

| Numerical value | 300 | 8 | 4 | 4 |

| The Fifth Cycle | The Sixth Cycle | The Seventh Cycle | The Eighth Cycle | |

|---|---|---|---|---|

| High-temperature oil-viscosity-reduction zone | 0~30 m | 0~30 m | 0~30 m | 0~30 m |

| Compound action zone | 30~120 m | 30~135 m | 30~148 m | 30~160 m |

| Energy-replenishment zone | 120~170 m | 135~200 m | 148~200 m | 160~200 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Bo, B.; Xu, A.; Wang, S.; Wang, C.; Liu, M.; Shan, F.; Zhao, L.; Ma, G. Coupling Mechanism of Multiple-Thermal-Fluid Multi-Cycle Stimulation in Ultra-Heavy-Oil Reservoirs. Energies 2024, 17, 2129. https://doi.org/10.3390/en17092129

Ma H, Bo B, Xu A, Wang S, Wang C, Liu M, Shan F, Zhao L, Ma G. Coupling Mechanism of Multiple-Thermal-Fluid Multi-Cycle Stimulation in Ultra-Heavy-Oil Reservoirs. Energies. 2024; 17(9):2129. https://doi.org/10.3390/en17092129

Chicago/Turabian StyleMa, Hongfei, Bing Bo, Anzhu Xu, Shuqin Wang, Chenggang Wang, Minghui Liu, Fachao Shan, Lun Zhao, and Gang Ma. 2024. "Coupling Mechanism of Multiple-Thermal-Fluid Multi-Cycle Stimulation in Ultra-Heavy-Oil Reservoirs" Energies 17, no. 9: 2129. https://doi.org/10.3390/en17092129

APA StyleMa, H., Bo, B., Xu, A., Wang, S., Wang, C., Liu, M., Shan, F., Zhao, L., & Ma, G. (2024). Coupling Mechanism of Multiple-Thermal-Fluid Multi-Cycle Stimulation in Ultra-Heavy-Oil Reservoirs. Energies, 17(9), 2129. https://doi.org/10.3390/en17092129