Development of Carbon Nanotubes–Graphene–Polydimethylsiloxane Composite Film with Excellent Electrothermal Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. The CNT–Graphene–PDMS Composite Film’s Preparation and Electric Field Orientation

2.2. Performance Testing

3. Results and Discussion

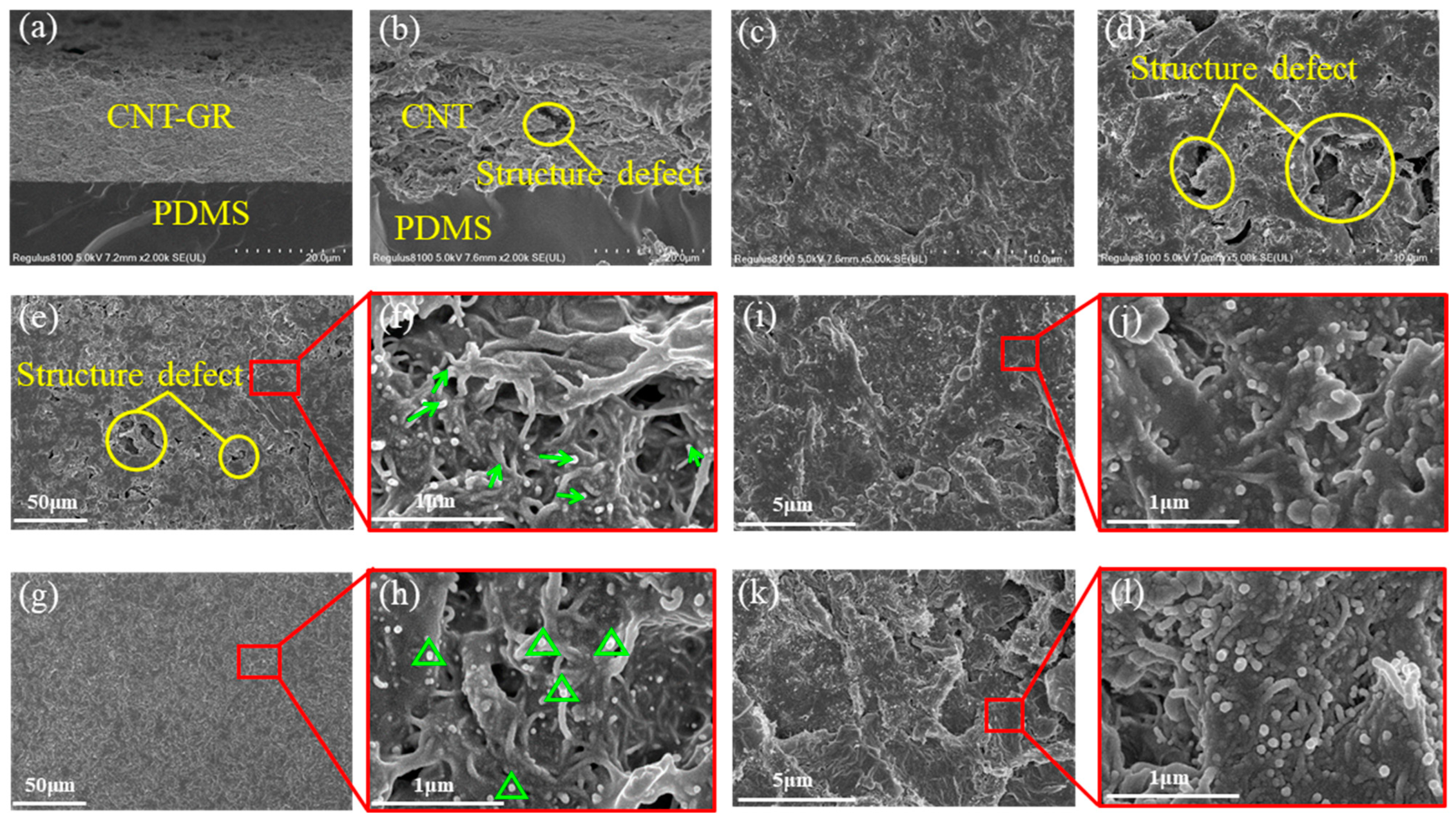

3.1. Microscopic Performance Characterization

3.2. Chemical Structure Analysis

3.3. Electrothermal Performance

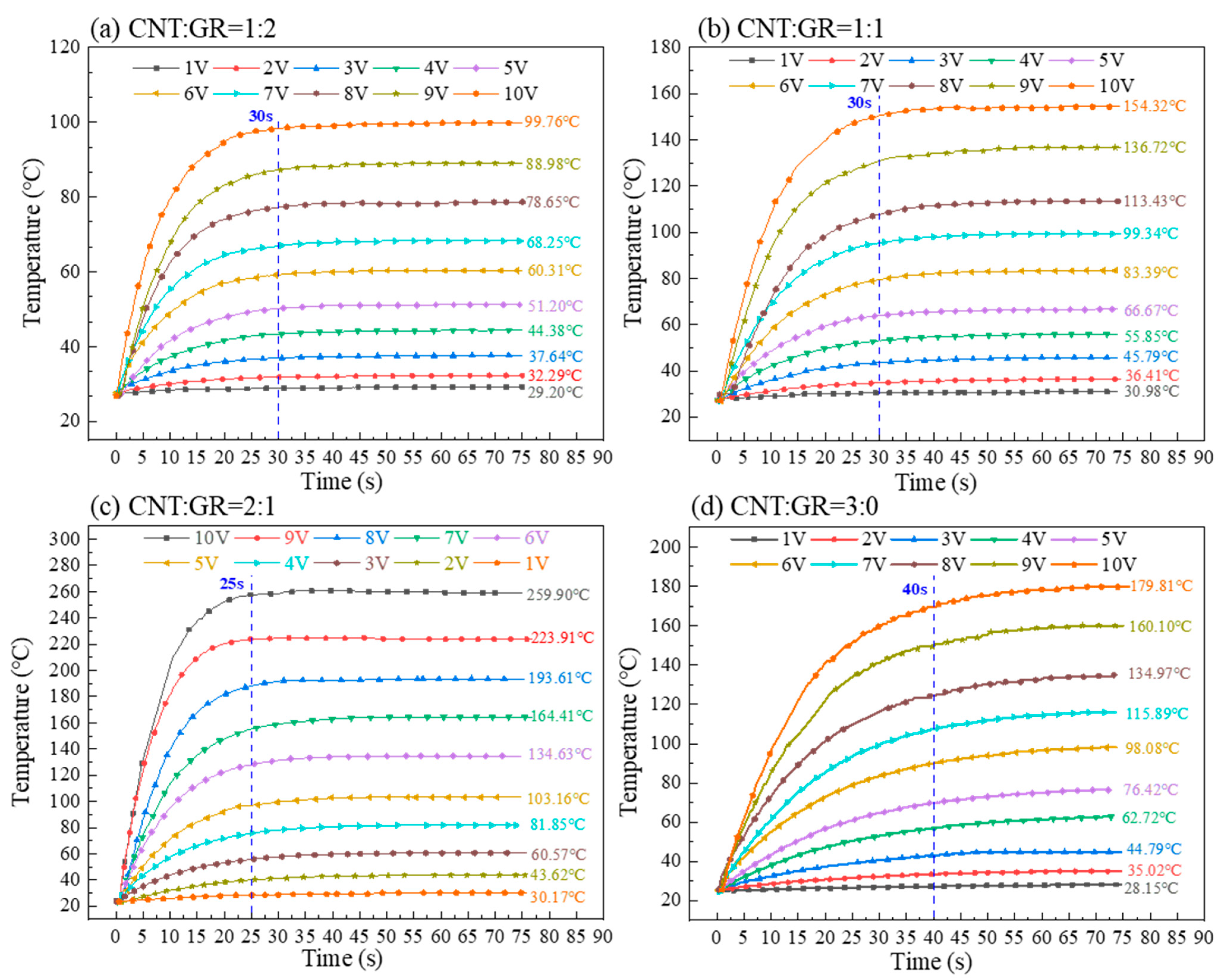

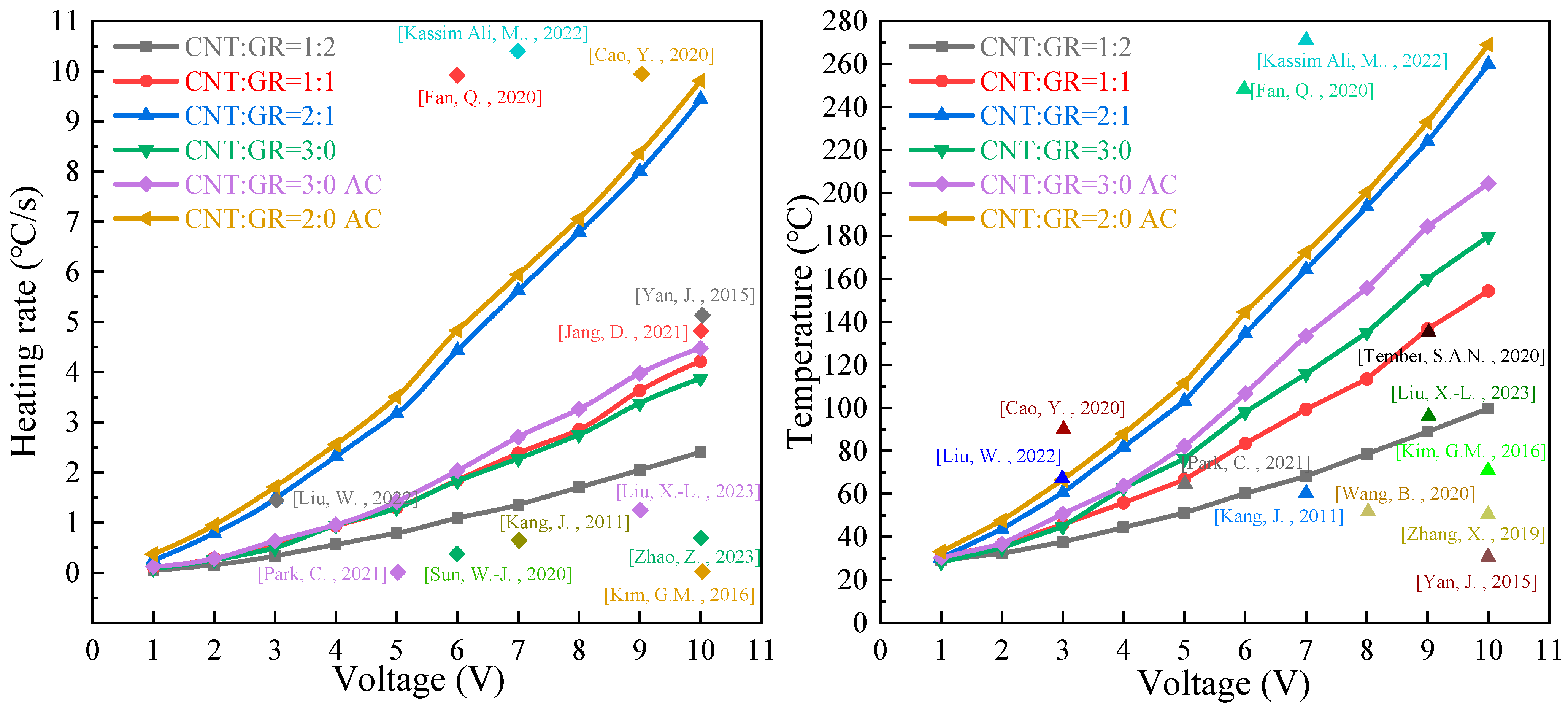

3.3.1. Effect of Voltage on Electrothermal Performance of the Composite Film

3.3.2. Effects of the Ratio of CNT to GR on the Electrothermal Performance and Cycle Temperature Stability Test

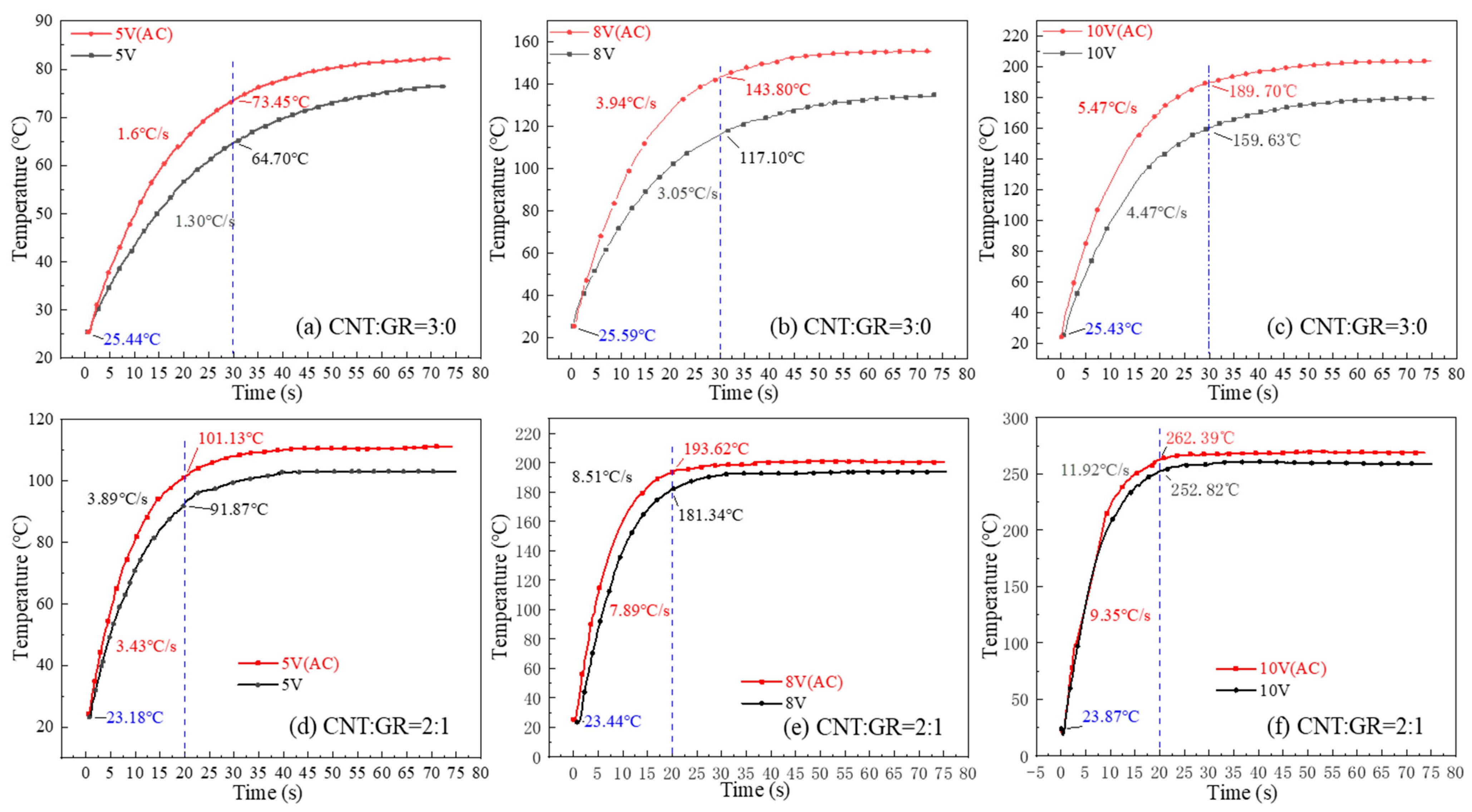

3.3.3. Influence of Electric Field Orientation on the Performance of Electrothermal

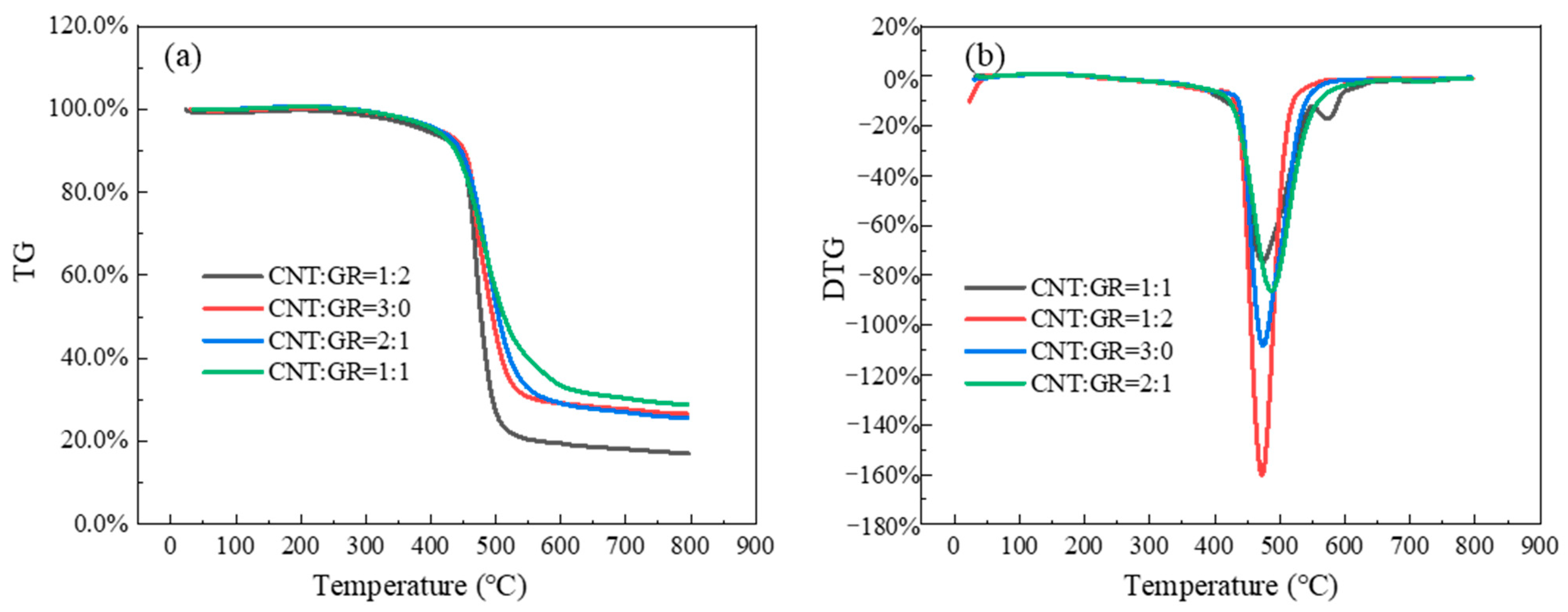

3.4. Thermal Stability Analysis

3.5. Thermal Conductivity Analysis

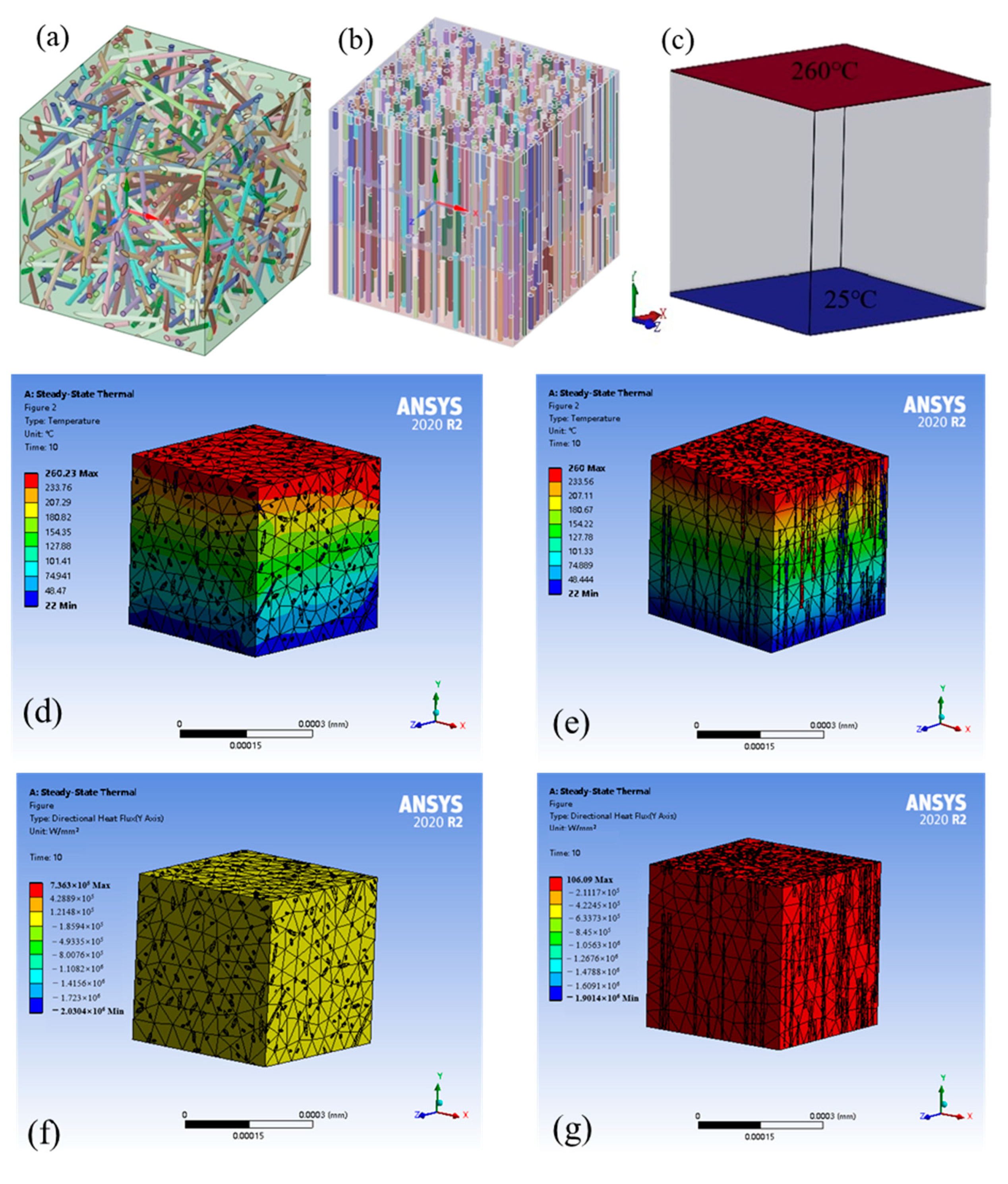

3.5.1. Simulations

3.5.2. Experiment

3.6. Application Prospect Analysis

4. Conclusions

- (1)

- The stable temperature of the composite film is proportional to U2. By adjusting the applied voltage, the stable temperature of the composite film can be controlled well. The temperature response time of the composite film is rapid, and it can rise to a stable temperature within 30 s and exhibit long-term running stability;

- (2)

- With the continuous adjustment of the ratio of carbon nanotubes to graphene, when the ratio of carbon nanotubes to graphene is 2:1, it has the lowest percolation threshold and its electrothermal performance is the best. The resistance of the composite film is 15 Ω, the power density is 13,333.3 W/m2, and the stable temperature is 260 °C at 10 V;

- (3)

- The electric field can improve the regular arrangement of carbon nanotubes. The heating rate of the oriented composite film increases by 1 °C/s, and the thermal conductivity of the oriented composite film is greater;

- (4)

- The decomposition temperature of the composite film in a nitrogen atmosphere is about 450 °C. The three-dimensional structure formed by the blending of graphene and carbon nanotubes makes the PDMS film have more excellent thermal stability. And the synergistic effect of graphene and carbon nanotubes can improve the thermal conductivity of the composite film.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, W.-J.; Zhou, C.-G.; Jia, L.-C.; Wang, Y.-Y.; Zhang, Y.-P.; Wang, T.; Yan, D.-X.; Li, Z.-M. A reliable and highly conductive carbon nanotube/thermoplastic polyurethane composite with an enhanced segregated structure for electrically driven heater applications. J. Mater. Chem. C 2020, 8, 8814–8822. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, Y.; Liu, X.; Zhao, Z.; Chen, J.; Jing, X.; Chen, H. Temperature self-regulating electrothermal pseudo-slippery surface for anti-icing. Chem. Eng. J. 2021, 422, 130110. [Google Scholar] [CrossRef]

- Chu, H.; Zhang, Z.; Liu, Y.; Leng, J. Self-heating fiber reinforced polymer composite using meso/macropore carbon nanotube paper and its application in deicing. Carbon 2014, 66, 154–163. [Google Scholar] [CrossRef]

- Park, C.; Kim, T.; Samuel, E.P.; Kim, Y.-I.; An, S.; Yoon, S.S. Superhydrophobic antibacterial wearable metallized fabric as supercapacitor, multifunctional sensors, and heater. J. Power Sources 2021, 506, 230142. [Google Scholar] [CrossRef]

- Feng, T.; Zhang, H.; Chen, G.; Hu, J.; Ning, C.; Yuan, T. Economic research on application of electric heating system based on game theory. Glob. Energy Interconnect. 2021, 4, 315–323. [Google Scholar] [CrossRef]

- Vertuccio, L.; De Santis, F.; Pantani, R.; Lafdi, K.; Guadagno, L. Effective de-icing skin using graphene-based flexible heater. Compos. Part B Eng. 2019, 162, 600–610. [Google Scholar] [CrossRef]

- Zhang, Q.; He, Z.; Fang, X.; Zhang, X.; Zhang, Z. Experimental and numerical investigations on a flexible paraffin/fiber composite phase change material for thermal therapy mask. Energy Storage Mater. 2017, 6, 36–45. [Google Scholar] [CrossRef]

- Wang, C.; Xia, K.; Wang, H.; Liang, X.; Yin, Z.; Zhang, Y. Advanced carbon for flexible and wearable electronics. Adv. Mater. 2019, 31, 1801072. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and heat-dependent mechanical characteristics of CNT-embedded cementitious composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Jang, D.; Yoon, H.N.; Seo, J.; Park, S.; Kil, T.; Lee, H.K. Improved electric heating characteristics of CNT-embedded polymeric composites with an addition of silica aerogel. Compos. Sci. Technol. 2021, 212, 108866. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, H.; Liu, X.; Wang, Z.; Zhu, Y.; Zhou, Y. The development of electric heating coating with temperature controlling capability for anti-icing/de-icing. Cold Reg. Sci. Technol. 2021, 184, 103234. [Google Scholar] [CrossRef]

- Kang, T.J.; Kim, T.; Seo, S.M.; Park, Y.J.; Kim, Y.H. Thickness-dependent thermal resistance of a transparent glass heater with a single-walled carbon nanotube coating. Carbon 2011, 49, 1087–1093. [Google Scholar] [CrossRef]

- Urper, O.; Çakmak, İ.; Karatepe, N. Fabrication of carbon nanotube transparent conductive films by vacuum filtration method. Mater. Lett. 2018, 223, 210–214. [Google Scholar] [CrossRef]

- Kang, J.; Kim, H.; Kim, K.S.; Lee, S.K.; Bae, S.; Ahn, J.H.; Kim, Y.J.; Choi, J.B.; Hong, B.H. High-performance graphene-based transparent flexible heaters. Nano Lett. 2011, 11, 5154–5158. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Wang, L.; Yao, Y.; Jiang, Y.; Xu, R.; Wang, H.; Wu, X.; Yu, Y. Integrating Conductivity, Captivity, and Immobility Ability into N/O Dual-Doped Porous Carbon Nanocage Anchored with CNT as an Effective Se Host for Advanced K-Se Battery. Adv. Funct. Mater. 2020, 30, 2003871. [Google Scholar] [CrossRef]

- Yao, X.; Hawkins, S.C.; Falzon, B.G. An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs. Carbon 2018, 136, 130–138. [Google Scholar] [CrossRef]

- Haibat, J.; Ceneviva, S.; Spencer, M.P.; Kwok, F.; Trivedi, S.; Mohney, S.E.; Yamamoto, N. Preliminary demonstration of energy-efficient fabrication of aligned CNT-polymer nanocomposites using magnetic fields. Compos. Sci. Technol. 2017, 152, 27–35. [Google Scholar] [CrossRef]

- Nie, Y.; Yang, J.; Liu, Z.; Zhou, Z.; Ming, Y.; Hao, T. Precursor formation and crystal nucleation in stretched polyethylene/carbon nanotube nanocomposites. Polymer 2022, 239, 124438. [Google Scholar] [CrossRef]

- Pothnis, J.R.; Kalyanasundaram, D.; Gururaja, S. Enhancement of open hole tensile strength via alignment of carbon nanotubes infused in glass fiber-epoxy-CNT multi-scale composites. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106155. [Google Scholar] [CrossRef]

- Sharma, A.; Tripathi, B.; Vijay, Y.K. Dramatic Improvement in properties of magnetically aligned CNT/polymer nanocomposites. J. Membr. Sci. 2010, 361, 89–95. [Google Scholar] [CrossRef]

- Martin, C.A.; Sandler, J.K.W.; Windle, A.H.; Schwarz, M.K.; Bauhofer, W.; Schulte, K.; Shaffer, M.S.P. Electric field-induced aligned multi-wall carbon nanotube networks in epoxy composites. Polymer 2005, 46, 877–886. [Google Scholar] [CrossRef]

- Oliva-Avilés, A.I.; Avilés, F.; Sosa, V.; Seidel, G.D. Dielectrophoretic modeling of the dynamic carbon nanotube network formation in viscous media under alternating current electric fields. Carbon 2014, 69, 342–354. [Google Scholar] [CrossRef]

- Zhang, R.P.; Zhu, Y.F.; Ma, C.; Liang, J. Alignment of carbon nanotubes in poly(methyl methacrylate) composites induced by electric field. J. Nanosci. Nanotechnol. 2009, 9, 2887–2893. [Google Scholar] [CrossRef] [PubMed]

- Mikhalchan, A.; Madrona, C.; Arévalo, L.; Malfois, M.; Vilatela, J.J. Improved alignment and stress transfer in CNT fibre fabrics studied by in situ X-ray and Raman during wet-drawing. Carbon 2022, 197, 368–377. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, Y.; Zhao, Y.; Sun, S.; Tan, H.J.F. Mechanism of in-situ dynamic catalysis and selective deactivation of H2O-activated biochar for biomass tar reforming. Fuel 2020, 279, 118450. [Google Scholar] [CrossRef]

- Dasbach, M.; Hampp, N.A. Enhanced light absorption and through-thickness heat conduction of vertically aligned transferable carbon nanotube/silicone rubber composite films. Mater. Chem. Phys. 2021, 267, 124690. [Google Scholar] [CrossRef]

- Maultzsch, J.; Telg, H.; Reich, S.; Thomsen, C. Radial breathing mode of single-walled carbon nanotubes: Optical transition energies and chiral-index assignment. Phys. Rev. B 2005, 72, 205438. [Google Scholar] [CrossRef]

- Farhat, H.; Sasaki, K.; Kalbac, M.; Hofmann, M.; Saito, R.; Dresselhaus, M.S.; Kong, J. Softening of the radial breathing mode in metallic carbon nanotubes. Phys. Rev. Lett. 2009, 102, 126804. [Google Scholar] [CrossRef]

- Kim, H.-J.; Kim, D.; Jung, S.; Yi, S.N.; Yun, Y.J.; Chang, S.K.; Ha, D.H. Charge Transport in Thick Reduced Graphene Oxide Film. J. Phys. Chem. C 2015, 119, 28685–28690. [Google Scholar] [CrossRef]

- Vollebregt, S.; Ishihara, R.; Tichelaar, F.D.; Hou, Y.; Beenakker, C.I.M. Influence of the growth temperature on the first and second-order Raman band ratios and widths of carbon nanotubes and fibers. Carbon 2012, 50, 3542–3554. [Google Scholar] [CrossRef]

- Ma, B.; Rodriguez, R.D.; Ruban, A.; Pavlov, S.; Sheremet, E. The correlation between electrical conductivity and second-order Raman modes of laser-reduced graphene oxide. Phys. Chem. Chem. Phys. 2019, 21, 10125–10134. [Google Scholar] [CrossRef]

- Krishnamoorthy, K.; Veerapandian, M.; Yun, K.; Kim, S.J. The chemical and structural analysis of graphene oxide with different degrees of oxidation. Carbon 2013, 53, 38–49. [Google Scholar] [CrossRef]

- Bokobza, L.; Zhang, J. Raman spectroscopic characterization of multiwall carbon nanotubes and of composites. Express Polym. Lett. 2012, 6, 601–608. [Google Scholar] [CrossRef]

- Sakamoto, H.; Fujiwara, I.; Takamura, E.; Suye, S.-I. Nanofiber-guided orientation of electrospun carbon nanotubes and fabrication of aligned CNT electrodes for biodevice applications. Mater. Chem. Phys. 2020, 245, 122745. [Google Scholar] [CrossRef]

- Bodik, M.; Maxian, O.; Hagara, J.; Nadazdy, P.; Jergel, M.; Majkova, E.; Siffalovic, P. Langmuir-Scheaffer Technique as a Method for Controlled Alignment of 1D Materials. Langmuir 2020, 36, 4540–4547. [Google Scholar] [CrossRef] [PubMed]

- Cao, Q.; Han, S.J.; Tulevski, G.S.; Zhu, Y.; Lu, D.D.; Haensch, W. Arrays of single-walled carbon nanotubes with full surface coverage for high-performance electronics. Nat. Nanotechnol. 2013, 8, 180–186. [Google Scholar] [CrossRef] [PubMed]

- Lancastre, J.J.H.; Fernandes, N.; Margaça, F.M.A.; Miranda Salvado, I.M.; Ferreira, L.M.; Falcão, A.N.; Casimiro, M.H. Study of PDMS conformation in PDMS-based hybrid materials prepared by gamma irradiation. Radiat. Phys. Chem. 2012, 81, 1336–1340. [Google Scholar] [CrossRef]

- Sulym, I.; Cetinkaya, A.; Yence, M.; Çorman, M.E.; Uzun, L.; Ozkan, S.A. Novel electrochemical sensor based on molecularly imprinted polymer combined with L-His-MWCNTs@PDMS-5 nanocomposite for selective and sensitive assay of tetracycline. Electrochim. Acta 2022, 430, 141102. [Google Scholar] [CrossRef]

- Krishna, A.; Aravinda, L.S.; Murugan, A.; Kumar, N.S.; Sankar, M.R.; Nagahanumaiah; Reddy, K.N.; Balashanmugam, N. A study on wafer scalable, industrially applicable CNT based nanocomposites of Al-CNT, Cu-CNT, Ti-CNT, and Ni-CNT as thermal interface materials synthesised by thin film techniques. Surf. Coat. Technol. 2022, 429, 127926. [Google Scholar] [CrossRef]

- Aqel, A.; El-Nour, K.M.M.A.; Ammar, R.A.A.; Al-Warthan, A. Carbon nanotubes, science and technology part (I) structure, synthesis and characterisation. Arab. J. Chem. 2012, 5, 1–23. [Google Scholar] [CrossRef]

- Cao, A.; Xu, C.; Liang, J.; Wu, D.; Wei, B.J.C.p.l. X-ray diffraction characterization on the alignment degree of carbon nanotubes. Chem. Phys. Lett. 2001, 344, 13–17. [Google Scholar] [CrossRef]

- Chu, K.; Yun, D.-J.; Kim, D.; Park, H.; Park, S.-H. Study of electric heating effects on carbon nanotube polymer composites. Org. Electron. 2014, 15, 2734–2741. [Google Scholar] [CrossRef]

- Wang, J.; Yu, S.; Luo, S.; Chu, B.; Sun, R.; Wong, C.-P. Investigation of nonlinear I–V behavior of CNTs filled polymer composites. Mater. Sci. Eng. B 2016, 206, 55–60. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, D.; Zhang, Y.; Huang, Y.; Sun, S.J.F.P.T. Effect of pyrolysis temperature on char structure and chemical speciation of alkali and alkaline earth metallic species in biochar. Fuel Process. Technol. 2016, 141, 54–60. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, Y.; Wang, Z.; Zhang, Y.; Zhang, K.; Chen, J.; Liu, X.; Chen, H. A biaxial stretchable, flexible electric heating composite film for de-icing. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107124. [Google Scholar] [CrossRef]

- Sierra-Chi, C.A.; López-Manchado, M.A.; Cauich-Rodríguez, J.V.; Gamboa, F.; Oliva, A.I.; Avilés, F. Functionalization of few-layer graphene sheets and carbon nanotubes for generation of hybrids and their effect on the piezoresistive properties of polymeric nanocomposites. Synth. Met. 2022, 289, 117121. [Google Scholar] [CrossRef]

- Yu, X.; Kwon, E. A carbon nanotube/cement composite with piezoresistive properties. Smart Mater. Struct. 2009, 18, 055010. [Google Scholar] [CrossRef]

- Shit, G.C.; Mondal, A.; Sinha, A.; Kundu, P.K. Electro-osmotic flow of power-law fluid and heat transfer in a micro-channel with effects of Joule heating and thermal radiation. Phys. A Stat. Mech. Its Appl. 2016, 462, 1040–1057. [Google Scholar] [CrossRef]

- Feng, D.; Guo, D.; Zhang, Y.; Sun, S.; Zhao, Y.; Shang, Q.; Sun, H.; Wu, J.; Tan, H.J.C.E.J. Functionalized construction of biochar with hierarchical pore structures and surface O-/N-containing groups for phenol adsorption. Chem. Eng. J. 2021, 410, 127707. [Google Scholar] [CrossRef]

- Wang, T.; Jing, L.C.; Zhu, Q.; Sagadevan Ethiraj, A.; Fan, X.; Liu, H.; Tian, Y.; Zhu, Z.; Meng, Z.; Geng, H.Z. Tannic acid modified graphene/CNT three-dimensional conductive network for preparing high-performance transparent flexible heaters. J. Colloid Interface Sci. 2020, 577, 300–310. [Google Scholar] [CrossRef]

- Shan, X.; Zhang, H.; Liu, C.; Yu, L.; Di, Y.; Zhang, X.; Dong, L.; Gan, Z. Reusable Self-Sterilization Masks Based on Electrothermal Graphene Filters. ACS Appl. Mater. Interfaces 2020, 12, 56579–56586. [Google Scholar] [CrossRef]

- Ren, C.; Si, Z.; Qu, Y.; Li, S.; Wu, H.; Meng, F.; Zhang, X.; Wang, Y.; Liu, C.; Qin, P. CF3-MOF enhanced pervaporation selectivity of PDMS membranes for butanol separation. Sep. Purif. Technol. 2022, 284, 120255. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, H.; Yu, F.; Zhao, X.; Wang, Y. Enhanced ethanol recovery of PDMS mixed matrix membranes with hydrophobically modified ZIF-90. Sep. Purif. Technol. 2018, 206, 80–89. [Google Scholar] [CrossRef]

- Fang, M.; Wu, C.; Yang, Z.; Wang, T.; Xia, Y.; Li, J. ZIF-8/PDMS mixed matrix membranes for propane/nitrogen mixture separation: Experimental result and permeation model validation. J. Membr. Sci. 2015, 474, 103–113. [Google Scholar] [CrossRef]

- Klonos, P.; Panagopoulou, A.; Bokobza, L.; Kyritsis, A.; Peoglos, V.; Pissis, P. Comparative studies on effects of silica and titania nanoparticles on crystallization and complex segmental dynamics in poly(dimethylsiloxane). Polymer 2010, 51, 5490–5499. [Google Scholar] [CrossRef]

- Jiang, B.; Huang, H.; Gong, W.; Gu, X.; Liu, T.; Zhang, J.; Qin, W.; Chen, H.; Jin, Y.; Liang, Z.J.A.F.M. Wood-Inspired Binder Enabled Vertical 3D Printing of g-C3N4/CNT Arrays for Highly Efficient Photoelectrochemical Hydrogen Evolution. Adv. Funct. Mater. 2021, 31, 2105045. [Google Scholar] [CrossRef]

- Shahzad, M.I.; Giorcelli, M.; Shahzad, N.; Guastella, S.; Castellino, M.; Jagdale, P.; Tagliaferro, A. Study of carbon nanotubes based Polydimethylsiloxane composite films. J. Phys. Conf. Ser. 2013, 439, 012010. [Google Scholar] [CrossRef]

- Pourasghar, A.; Chen, Z. Dual-phase-lag heat conduction in FG carbon nanotube reinforced polymer composites. Phys. B Condens. Matter 2019, 564, 147–156. [Google Scholar] [CrossRef]

- Yang, X.; Chen, D.; Han, Z.; Ma, X.; To, A.C. Effects of welding on thermal conductivity of randomly oriented carbon nanotube networks. Int. J. Heat Mass Transf. 2014, 70, 803–810. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Grimaldi, C.; With, G.; Friedrich, H. A Unified View on Nanoscale Packing, Connectivity, and Conductivity of CNT Networks. Adv. Funct. Mater. 2019, 29, 1807901. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Cao, Y.; Dong, J.J.P.M. Fabrication and self-sensing control of soft electrothermal actuator. Procedia Manuf. 2020, 48, 43–48. [Google Scholar] [CrossRef]

- Fan, Q.; Miao, J.; Tian, M.; Zhao, H.; Zhu, S.; Liu, X.; Ma, Y.; Qu, L. Low-voltage driven flexible double-layer electrothermal actuator for smart human-machine interactions. Sens. Actuators A Phys. 2020, 315, 112352. [Google Scholar] [CrossRef]

- Liu, W.; Sun, Y.; Cui, A.; Xia, Y.; Yan, Q.; Song, Y.; Wang, L.; Shan, G.; Wang, X. Electrothermal sterilization and self-powered real-time respiratory monitoring of reusable mask based on Ag micro-mesh films. Nano Energy 2023, 105, 107987. [Google Scholar] [CrossRef]

- Liu, X.-L.; Li, M.; Geng, W.-H.; Cao, W.; Tian, Y.-H.; Li, T.-Y.; Bin, P.-S.; Qian, P.-F.; Geng, H.-Z. Modified carbon nanotubes/polyvinyl alcohol composite electrothermal films. Surf. Interfaces 2023, 36, 102540. [Google Scholar] [CrossRef]

- Tembei, S.A.N.; Hessein, A.; Fath El-Bab, A.M.R.; El-Moneim, A.A. A low voltage, flexible, graphene-based electrothermal heater for wearable electronics and localized heating applications. Mater. Today Proc. 2020, 33, 1840–1844. [Google Scholar] [CrossRef]

- Tembei, S.A.N.; Kassim Ali, M.; Hessein, A.; Fath El-Bab, A.M.R.; Abd El-Moneim, A. High-performance flexible electrothermal Joule heaters from laser reduced F-N Co-doped graphene oxide with extended Sp2 networks. FlatChem 2022, 36, 100437. [Google Scholar] [CrossRef]

- Wang, B.; Cheng, H.; Zhu, J.; Yuan, Y.; Wang, C. A flexible and stretchable polypyrrole/knitted cotton for electrothermal heater. Org. Electron. 2020, 85, 105819. [Google Scholar] [CrossRef]

- Zhang, X.; Li, D.; Liu, K.; Tong, J.; Yi, X. Flexible graphene-coated carbon fiber veil/polydimethylsiloxane mats as electrothermal materials with rapid responsiveness. Int. J. Lightweight Mater. Manuf. 2019, 2, 241–249. [Google Scholar] [CrossRef]

- Zhao, Z.; Yan, C.; Li, D.; Tang, X.; Ran, J.; Bi, S.; Cheng, D.; Cai, G.; Wang, X. Fabrication of rGO/Cu NPs on knitted fabrics for action sensing and electrothermal applications. Surf. Interfaces 2023, 36, 102600. [Google Scholar] [CrossRef]

- Wu, J.; Wang, H.; Qiu, J.; Shao, J.; Zhang, K.; Yan, L. Electrochemical exfoliation for few-layer graphene in molybdate aqueous solution and its application for fast electrothermal film. Prog. Nat. Sci. Mater. Int. 2020, 30, 312–320. [Google Scholar] [CrossRef]

- Yan, J.; Jeong, Y.G. Highly elastic and transparent multiwalled carbon nanotube/polydimethylsiloxane bilayer films as electric heating materials. Mater. Des. 2015, 86, 72–79. [Google Scholar] [CrossRef]

| Name | CNT:GR = 3:0 | CNT:GR = 2:1 | ||

|---|---|---|---|---|

| Type | unoriented | oriented | unoriented | oriented |

| α | 0.714 | 0.823 | 0.785 | 1.266 |

| Λ (W/m·K) | 1.02 | 1.18 | 1.13 | 1.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Da, Y.; Wang, Y.; Dong, H.; Shang, Q.; Zhang, Y.; Wang, H.; Du, Q.; Gao, J. Development of Carbon Nanotubes–Graphene–Polydimethylsiloxane Composite Film with Excellent Electrothermal Performance. Energies 2024, 17, 46. https://doi.org/10.3390/en17010046

Da Y, Wang Y, Dong H, Shang Q, Zhang Y, Wang H, Du Q, Gao J. Development of Carbon Nanotubes–Graphene–Polydimethylsiloxane Composite Film with Excellent Electrothermal Performance. Energies. 2024; 17(1):46. https://doi.org/10.3390/en17010046

Chicago/Turabian StyleDa, Yaodong, Youxin Wang, Heming Dong, Qi Shang, Yu Zhang, Huashan Wang, Qian Du, and Jianmin Gao. 2024. "Development of Carbon Nanotubes–Graphene–Polydimethylsiloxane Composite Film with Excellent Electrothermal Performance" Energies 17, no. 1: 46. https://doi.org/10.3390/en17010046

APA StyleDa, Y., Wang, Y., Dong, H., Shang, Q., Zhang, Y., Wang, H., Du, Q., & Gao, J. (2024). Development of Carbon Nanotubes–Graphene–Polydimethylsiloxane Composite Film with Excellent Electrothermal Performance. Energies, 17(1), 46. https://doi.org/10.3390/en17010046