Research on Optimization of Profile Parameters in Screw Compressor Based on BP Neural Network and Genetic Algorithm

Abstract

1. Introduction

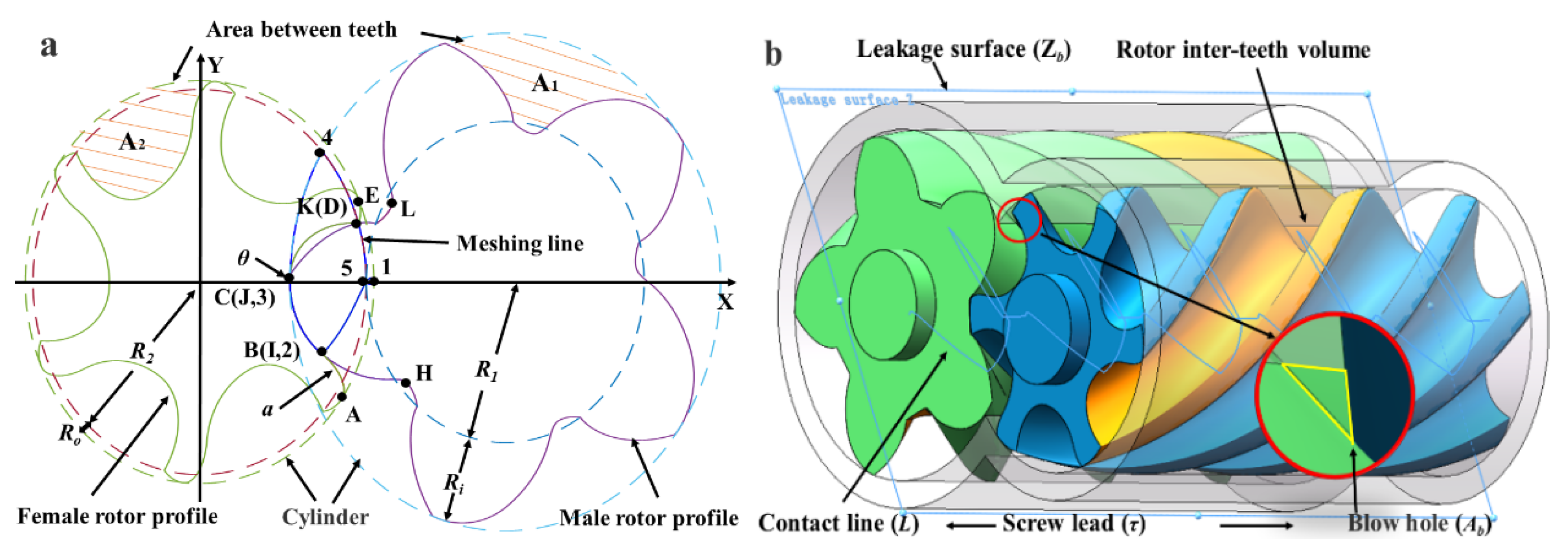

2. Two-Screw Compressor Geometric Characteristics

2.1. Profile Parameters

2.2. Calculation Method of Geometric Characteristics

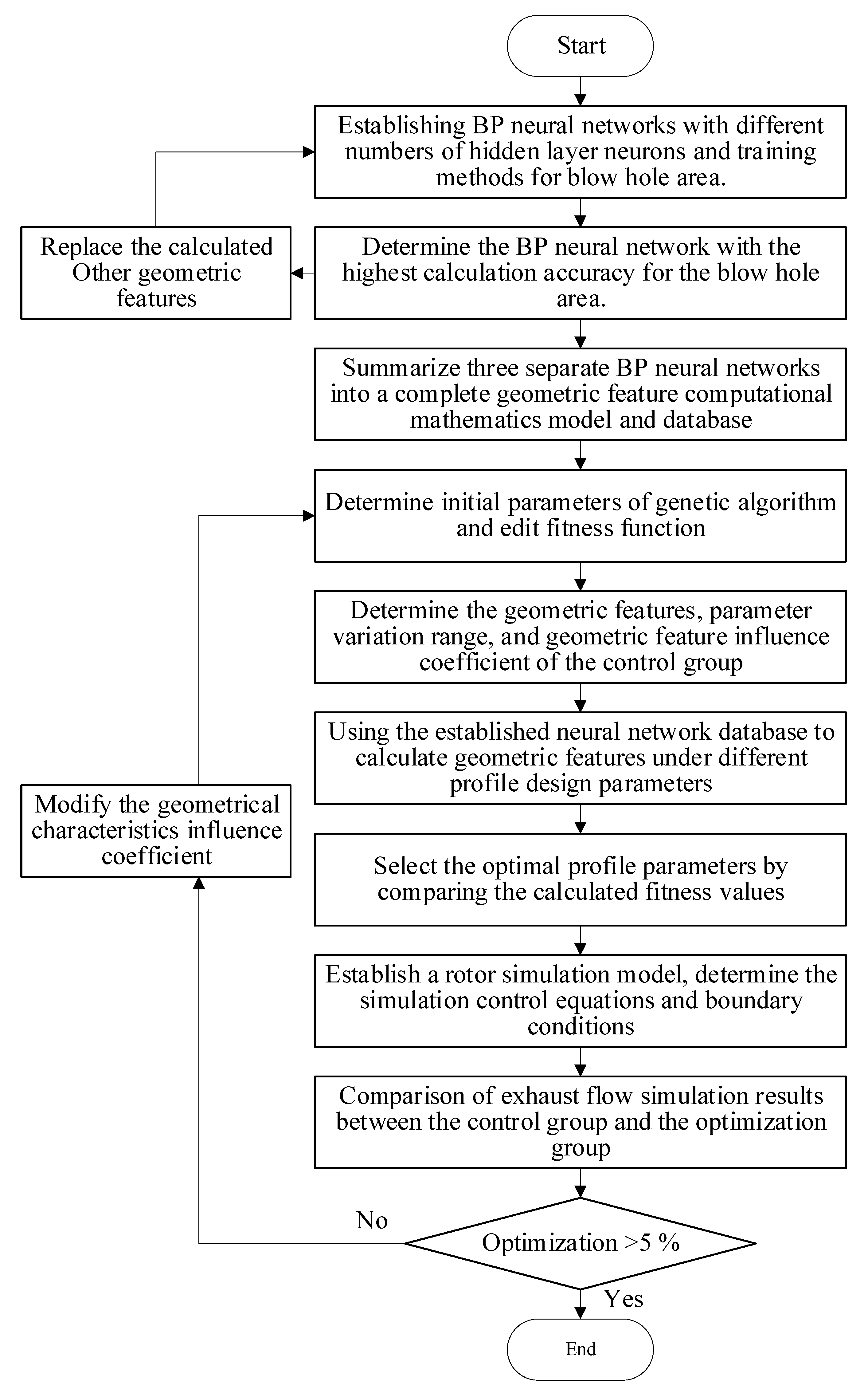

2.3. Optimization Procedure

3. Discrete Point Number Independence Verification

4. BP Neural Network

4.1. Parameter Definition of BP Neural Network

4.2. Effects of Number of Hidden Neurons and Training Method on the Prediction Accuracy

5. Configuration Optimization

5.1. Parameter Definition of Genetic Algorithm

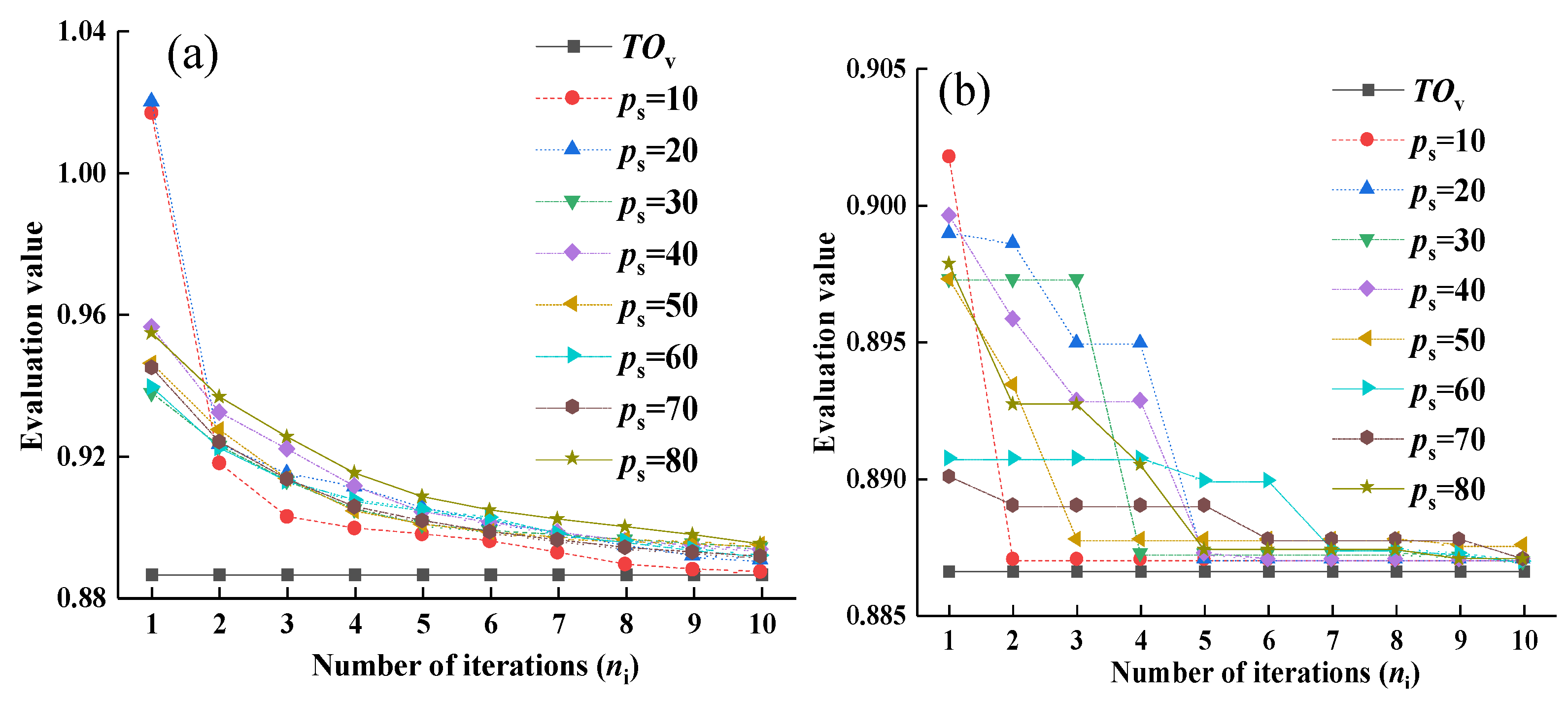

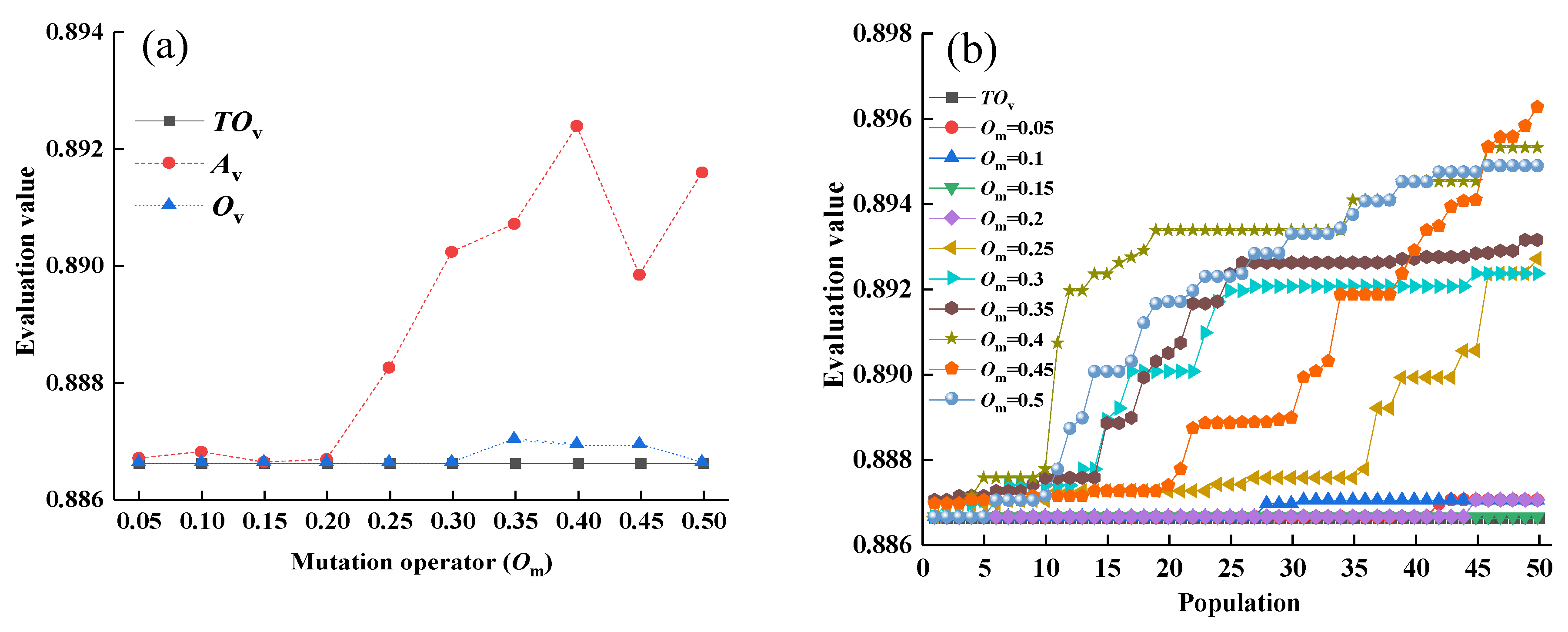

5.2. Effects of Population Size and Number of Iterations on the Population

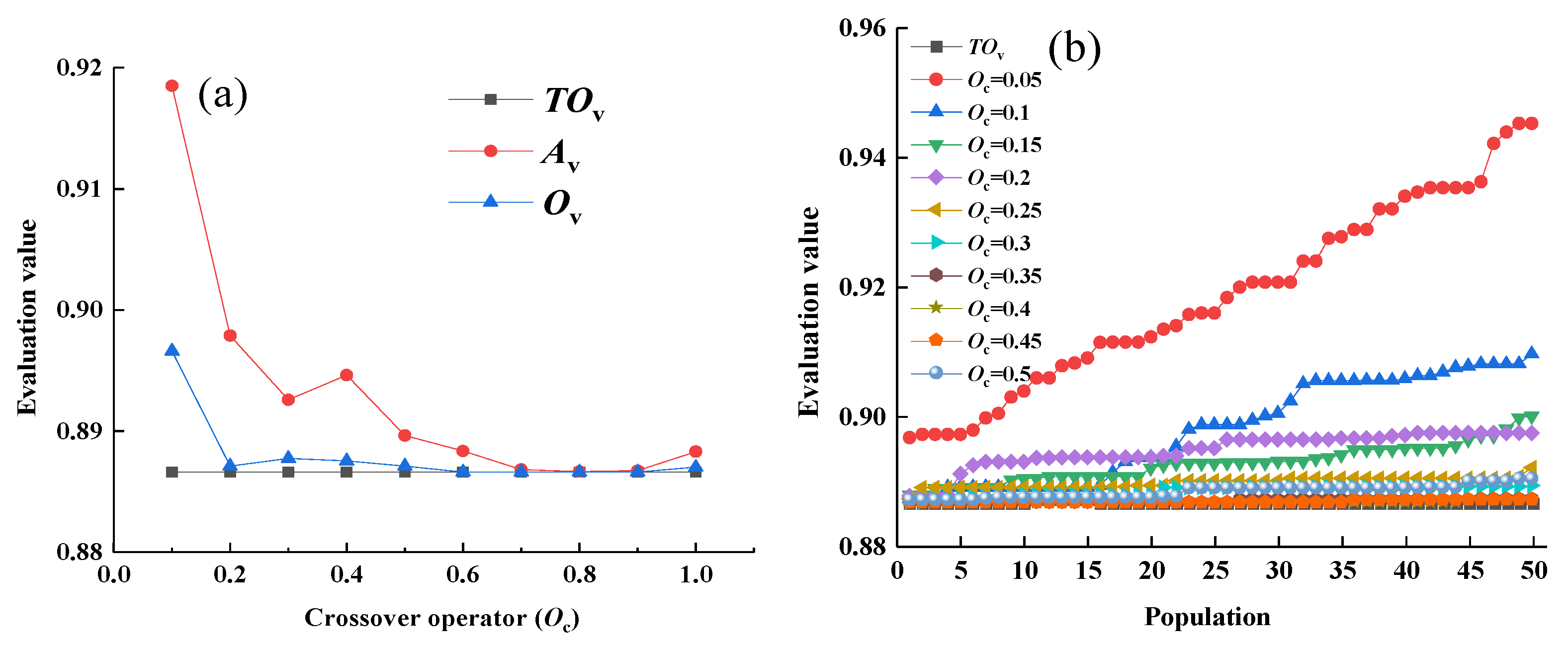

5.3. Effects of Crossover Operator and Mutation Operator on Population

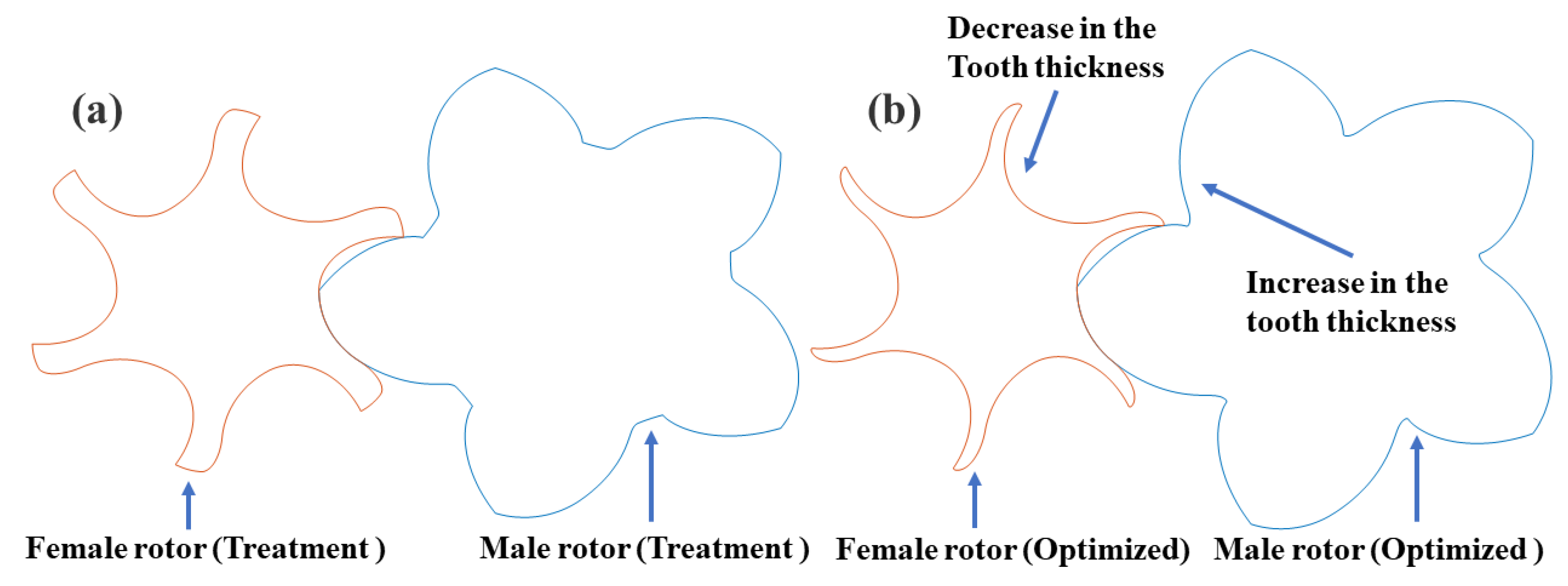

5.4. Optimization Result

6. CFD Simulation Results

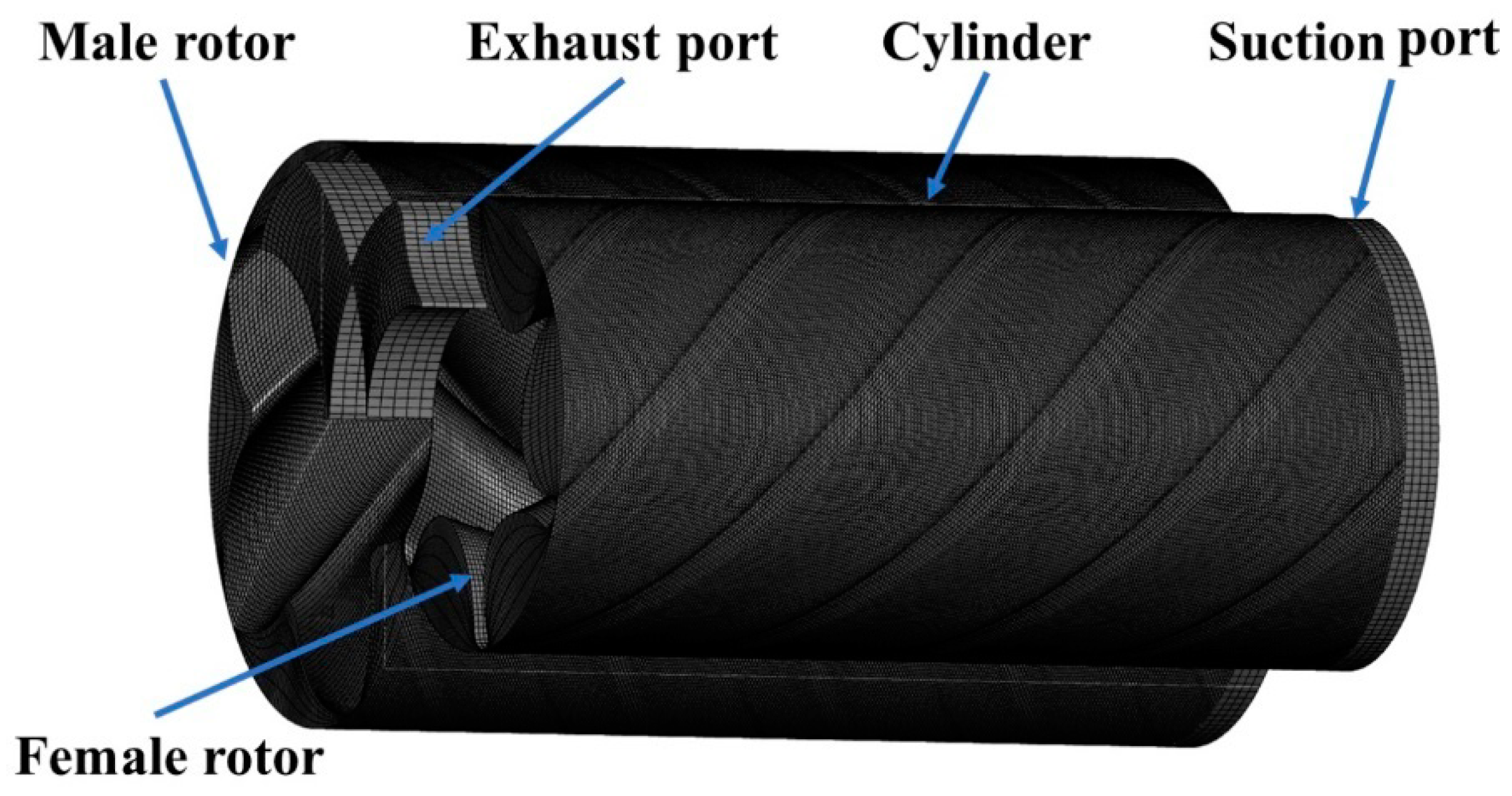

6.1. Model and Control Method

6.2. Mesh Independent Verification and Time Independent Verification

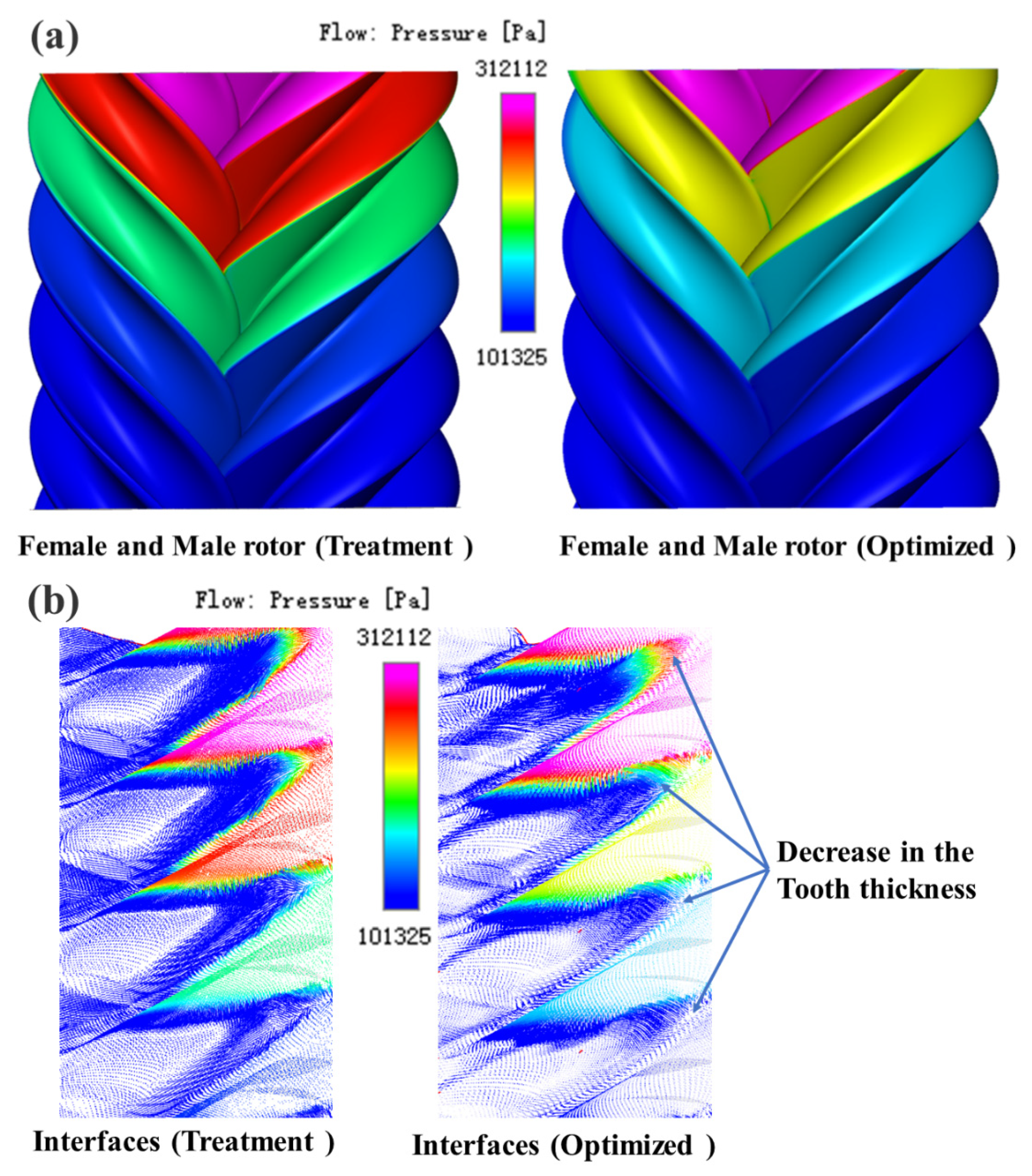

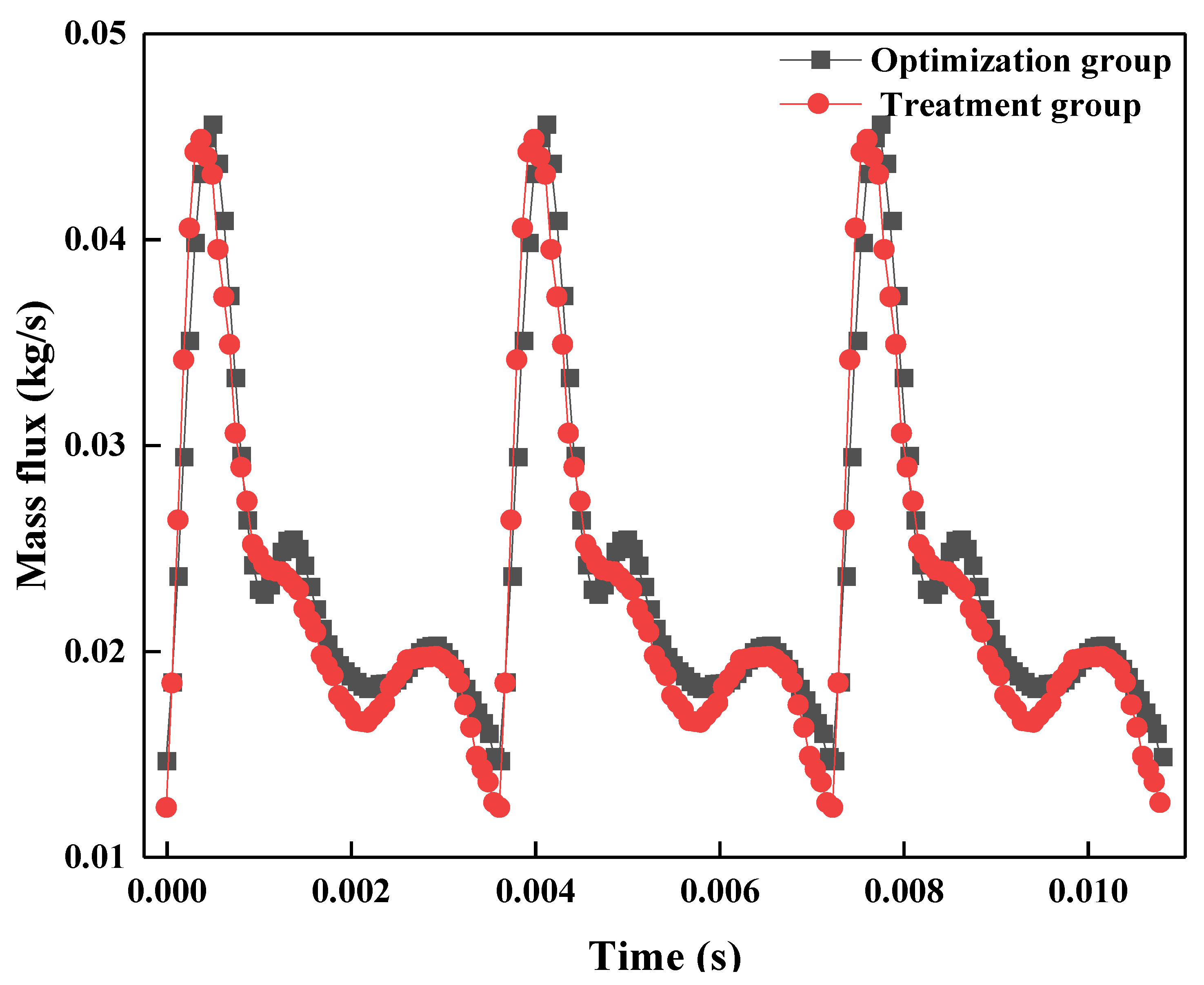

6.3. Optimization Comparison

7. Conclusions

8. Prospect

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | radius of the elliptic arc (mm) |

| A | area between teeth (mm2) |

| A1 | cross-sectional area of the single male groove (mm2) |

| A2 | cross-sectional area of the single female groove (mm2) |

| Ab | blow hole area (mm2) |

| Abt | blow hole area of treatment group (mm2) |

| Abo | blow hole area of optimization group (mm2) |

| Av | average value |

| BP | back-propagation |

| c | step length |

| Cn | area utilization rate |

| Cnt | area utilization rate treatment group |

| Cno | area utilization rate optimization group |

| D1 | diameter of the positive rotor (mm) |

| f | body force |

| H | number of hidden neurons |

| I | effects coefficient |

| IC | effects coefficient of area utilization rate |

| IL | effects coefficient of contact line |

| IA | effects coefficient of blow hole area |

| k | sample value |

| ki’ | average value of the sample |

| ki’’ | predicted sample value |

| L | length of the contact line (mm) |

| Lt | length of the contact line of treatment group (mm) |

| Lo | length of the contact line of optimization group (mm) |

| M | number of input neurons |

| Mv | minimum value |

| MSE | mean square error |

| N | number of output neurons |

| n | surface normal |

| ni | number of iterations |

| Ov | optimal value |

| Oc | crossover operator |

| Om | mutation operator |

| p | static pressure (Pa) |

| ps | population size |

| R | goodness-of-fitting index |

| Ri | inner radiuses of the male rotor (mm) |

| Ro | outer radius of the female rotor (mm) |

| R1 | pitch radius of male rotor (mm) |

| R2 | pitch radius of female rotor (mm) |

| s | sample size |

| t | time |

| ti, ti+1 | starting point and end point parameters of the curve |

| TOv | theoretical optimal value |

| Vmax | maximum geometric characteristics |

| Vmin | minimum geometric characteristics |

| xi, yi, zi | curve parameter equation |

| xi’, yi’ | derivative of the curve equation to the parameter |

| Z1 | number of male rotor teeth |

| Zb | the leakage surface |

| θ | protection angle (°) |

| ρ | average local fluid density (kg/m3) |

| υ | fluid velocity |

| υσ | mesh velocity |

| σ | surface of control volume |

| Ω(t) | control volume as a function of time |

| τ | screw lead (mm) |

| τij | effective shear stress |

| μ | dynamic viscosity (Pa/s) |

| μt | turbulent dynamic viscosity (Pa/s) |

| δij | Kronecker delta |

References

- Guo, Y.; Wang, T.; Liu, X.; Zhang, M.; Peng, X. Mathematical modelling and design of the ionic liquid compressor for the hydrogen refuelling station. Int. J. Energy Res. 2022, 46, 19123–19137. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiu, H.; Li, D.; He, Z.; Xing, Z.; Wu, L. Development of ultra-high-efficiency medium-capacity chillers with two-stage compression and interstage vapor injection technologies. Energies 2022, 15, 9562. [Google Scholar] [CrossRef]

- Rey Martínez, F.J.; San José Alonso, J.F.; Velasco Gómez, E.; Tejero González, A.; Esquivias, P.M.; Rey Hernández, J.M. Energy consumption reduction of a chiller plant by adding evaporative pads to decrease condensation temperature. Energies 2020, 13, 2218. [Google Scholar] [CrossRef]

- Tao, W.; Guo, Y.; He, Z.; Peng, X. Investigation on the delayed closure of the suction valve in the refrigerator compressor by FSI modeling. Int. J. Refrig. 2018, 91, 111–121. [Google Scholar] [CrossRef]

- Wu, H.; Liu, J.; Shen, Y.; Liang, M.; Zhang, B. Research on performance of variable-lead rotor twin screw compressor. Energies 2021, 14, 6970. [Google Scholar] [CrossRef]

- Wu, H.; Huang, H.; Zhang, B.; Xiong, B.; Lin, K. CFD simulation and experimental study of working process of screw refrigeration compressor with R134a. Energies 2019, 12, 2054. [Google Scholar] [CrossRef]

- Gan, R.; Li, B.; Tang, T.; Liu, S.; Chu, J.; Yang, G. Noise optimization of multi-stage orifice plates based on RBF neural network response surface and adaptive NSGA-II. Ann. Nucl. Energy 2022, 178, 109372. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Li, C.; Yu, Y.; Zhou, G.; Wang, C.; Zhao, W. Temperature prediction of lithium-ion battery based on artificial neural network model. Appl. Therm. Eng. 2023, 228, 120482. [Google Scholar] [CrossRef]

- Sirignano, J.; MacArt, J.; Spiliopoulos, K. PDE-constrained models with neural network terms: Optimization and global convergence. J. Comput. Phys. 2023, 481, 112016. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Hernandez, C.; Lara, J.; Arjona, M.A.; Melgoza-Vazquez, E. Multi-objective electromagnetic design optimization of a power transformer using 3d finite element analysis, response surface methodology, and the third generation non-sorting genetic algorithm. Energies 2023, 16, 2248. [Google Scholar] [CrossRef]

- Ahmed, F.; Zhu, S.; Yu, G.; Luo, E. A potent numerical model coupled with multi-objective NSGA-II algorithm for the optimal design of stirling engine. Energy 2022, 247, 123468. [Google Scholar] [CrossRef]

- Wu, X.; Wang, L.; Chen, B.; Feng, Z.; Qin, Y.; Liu, Q.; Liu, Y. Multi-objective optimization of shield construction parameters based on random forests and NSGA-II. Adv. Eng. Inform. 2022, 54, 101751. [Google Scholar] [CrossRef]

- Fazlinezhad, A.; Fattahi, M.; Tavakoli-Chaleshtori, R.; Rezaveisi, H. Sensitivity analysis and multi-objective optimization of oxidative dehydrogenation of propane in a fixed-bed reactor over vanadium/graphene for propylene production. Chem. Eng. Technol. 2022, 45, 309–318. [Google Scholar] [CrossRef]

- Cornwell, E.Y.; Waite, L.J. Social disconnectedness, perceived isolation, and health among older adults. J. Health Soc. Behav. 2009, 50, 31–48. [Google Scholar] [CrossRef]

- Ma, S.-B.; Kim, S.; Kim, J.-H. Optimization Design of a Two-Vane Pump for Wastewater Treatment Using Machine-Learning-Based Surrogate Modeling. Processes 2020, 8, 1170. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, F.; Shi, L.; Liu, H. Multi-conditional optimization of a high-specific-speed axial flow pump impeller based on machine learning. Machines 2022, 10, 1037. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, S.; Liu, J.; Tong, J.; Dang, J.; Yang, F.; Ouyang, M. Multi-objective optimization of the Atkinson cycle gasoline engine using NSGA III coupled with support vector machine and back-propagation algorithm. Energy 2023, 262, 125262. [Google Scholar] [CrossRef]

- Byeon, S.-S.; Lee, J.-Y.; Kim, Y.-J. Performance characteristics of a 4 × 6 oil-free twin-screw compressor. Energies 2017, 10, 945. [Google Scholar] [CrossRef]

- Tian, Y.; Geng, Y.; Yuan, H.; Zhao, Z. Investigation on water injection characteristics and its influence on the performance of twin-screw steam compressor. Energy 2022, 259, 124886. [Google Scholar] [CrossRef]

- He, Z.; Wang, T.; Wang, X.; Peng, X.; Xing, Z. Experimental investigation into the effect of oil injection on the performance of a variable speed twin-screw compressor. Energies 2018, 11, 1342. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, X.; Zhao, L.; Pan, S.; Wang, Z.; Cui, D.; Geng, M. Clearance distribution design and thermal deformation analysis of variable-pitch screw rotors for twin-screw vacuum pumps. Vacuum 2023, 211, 111936. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, L.; Zhao, X.; Pan, S.; Wang, Z.; Cui, D.; Geng, M. Optimal design and development of two-segment variable-pitch screw rotors for twin-screw vacuum pumps. Vacuum 2022, 203, 111254. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Ding, H.; Visser, F.C.; Jiang, Y.; Furmanczyk, M. Demonstration and validation of a 3d CFD simulation tool predicting pump performance and cavitation for industrial applications. J. Fluids Eng. 2011, 131, 011101. [Google Scholar] [CrossRef]

| Parameter. | Z2 | Z1 | R2 (mm) | Ri(mm) | θ (°) | Ro (mm) | a (mm) | τ (mm) |

|---|---|---|---|---|---|---|---|---|

| Value | 6 | 5 | 50 | 24 | 0 | 1 | 12 | 300 |

| Profile Parameter | Calculation Specification | Value | Deviation (%) | ||

|---|---|---|---|---|---|

| L (mm) | Discrete point number | 600 | 176.64 | 0.56 | |

| 1200 | 175.65 | 0.00 | |||

| 2400 | 175.65 | 0.00 | |||

| 3600 | 175.65 | 0.00 | |||

| Results from SolidWorks | 175.65 | / | |||

| Ab (mm2) | Discrete point number | 600 | 2.9124 | −5.72 | |

| 1200 | 3.0213 | −2.19 | |||

| 2400 | 3.0698 | −0.62 | |||

| 3600 | 3.0851 | 0.002 | |||

| Results from SolidWorks | 3.089 | / | |||

| Cn | Discrete point number | 600 | 0.45679 | 0.02 | |

| 1200 | 0.45674 | 0.00 | |||

| 2400 | 0.45673 | 0.00 | |||

| 3600 | 0.45672 | 0.00 | |||

| Results from SolidWorks | 0.45672 | / | |||

| Calculation time (s) | Discrete pointnumber | 600 | 95.91 | / | |

| 1200 | 110.11 | / | |||

| 2400 | 349.86 | / | |||

| 3600 | 1079.34 | / | |||

| Parameter | H = 8 | H = 12 | H = 16 | |||||

|---|---|---|---|---|---|---|---|---|

| MSE | R | MSE | R | MSE | R | |||

| Ab/mm2 | L-m | Training | 1.3 × 10−3 | 0.67 | 1.9 × 10−3 | 0.60 | 1.1 × 10−3 | 0.71 |

| Interpolation | 4.1 × 10−3 | 0.46 | 3.0 × 10−4 | 0.87 | 3.0 × 10−4 | 0.89 | ||

| Extrapolation | 5.0 × 10−4 | 0.83 | 6.0 × 10−4 | 0.78 | 5.0 × 10−3 | 0.47 | ||

| B-r | Training | 2.0 × 10−4 | 0.95 | 2.0 × 10−4 | 0.96 | 5.9 × 10−4 | 0.98 | |

| Interpolation | 1.5 × 10−3 | 0.85 | 1.0 × 10−3 | 0.96 | 8.7 × 10−4 | 0.93 | ||

| Extrapolation | 4.3 × 10−2 | 0.19 | 5.2 × 10−3 | 0.26 | 3.6 × 10−3 | 0.84 | ||

| Q-c-g | Training | 1.6 × 10−3 | 0.53 | 2.1 × 10−3 | 0.56 | 1.4 × 10−3 | 0.63 | |

| Interpolation | 5.3 × 10−3 | 0.48 | 4.0 × 10−4 | 0.79 | 5.0 × 10−4 | 0.81 | ||

| Extrapolation | 7.0 × 10−3 | 0.70 | 4.0 × 10−4 | 0.80 | 4.7 × 10−3 | 0.43 | ||

| L/mm | L-m | Training | 1.4 × 10−3 | 0.64 | 1.8 × 10−3 | 0.62 | 1.4 × 10−3 | 0.66 |

| Interpolation | 1.0 × 10−4 | 0.93 | 1.0 × 10−4 | 0.95 | 4.2 × 10−3 | 0.52 | ||

| Extrapolation | 4.8 × 10−3 | 0.46 | 7.0 × 10−4 | 0.79 | 1.0 × 10−4 | 0.93 | ||

| B-r | Training | 1.1 × 10−3 | 0.70 | 1.4 × 10−3 | 0.69 | 1.0 × 10−4 | 0.99 | |

| Interpolation | 9.0 × 10−4 | 0.83 | 2.2 × 10−3 | 0.75 | 6.0 × 10−4 | 0.88 | ||

| Extrapolation | 4.7 × 10−3 | 0.50 | 1.0 × 10−3 | 0.71 | 1.3 × 10−3 | 0.66 | ||

| Q-c-g | Training | 1.6 × 10−3 | 0.58 | 1.5 × 10−3 | 0.60 | 2.0 × 10−3 | 0.56 | |

| Interpolation | 2.0 × 10−4 | 0.89 | 5.5 × 10−3 | 0.38 | 7.0 × 10−4 | 0.72 | ||

| Extrapolation | 5.5 × 10−3 | 0.40 | 2.0 × 10−4 | 0.90 | 4.0 × 10−4 | 0.81 | ||

| Cn | L-m | Training | 7.6 × 10−3 | 0.69 | 1.2 × 10−2 | 0.56 | 1.8 × 10−3 | 0.93 |

| Interpolation | 1.2 × 10−3 | 0.85 | 1.4 × 10−3 | 0.60 | 1.0 × 10−4 | 0.98 | ||

| Extrapolation | 1.1 × 10−2 | 0.60 | 2.1 × 10−3 | 0.54 | 2.0 × 10−4 | 0.99 | ||

| B-r | Training | 1.1 × 10−3 | 0.96 | 4.0 × 10−4 | 0.98 | 1.0 × 10−3 | 0.96 | |

| Interpolation | 2.4 × 10−3 | 0.87 | 1.5 × 10−3 | 0.91 | 3.3 × 10−3 | 0.85 | ||

| Extrapolation | 5.3 × 10−3 | 0.38 | 6.9 × 10−3 | 0.90 | 5.4 × 10−3 | 0.64 | ||

| Q-c-g | Training | 1.1 × 10−2 | 0.24 | 1.3 × 10−2 | 0.32 | 1.3 × 10−2 | 0.29 | |

| Interpolation | 3.5 × 10−3 | 0.32 | 1.2 × 10−2 | 0.41 | 6.7 × 10−3 | 0.43 | ||

| Extrapolation | 4.2 × 10−2 | 0.22 | 1.3 × 10−2 | 0.08 | 1.2 × 10−2 | 0.25 | ||

| Parameters | Upper | Lower | Step |

|---|---|---|---|

| Ri (mm) | 26 | 20 | 1 |

| Ro (mm) | 0.2 | 1 | 0.2 |

| θ (°) | 0 | 2 | 0.1 |

| a (mm) | 8 | 12 | 1 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Rotor speed (r/m) | 4800 | Wrap angle (°) | 250 |

| Suction pressure (MPa) | 0.1 | Rotor clearance (mm) | 0.03 |

| Exhaust pressure (MPa) | 0.3 | Axial clearance (mm) | 0.04 |

| Center of rotor (mm) | 91.67 | Radial clearance (mm) | 0.06 |

| Mesh Sizes (mm) | Mass Flow (kg/s) | |

|---|---|---|

| Value | Error | |

| 2 | 0.0350 | 8.8% |

| 1 | 0.0368 | 4.2% |

| 0.5 | 0.0375 | 1.5% |

| 0.25 | 0.0381 | / |

| Time Step (s) | Mass Flow (kg/s) | |

|---|---|---|

| Value | Error | |

| 1 × 10−4 | 680.0368 | 3% |

| 8 × 10−5 | 0.0375 | 1.2% |

| 4 × 10−5 | 0.0379 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Qi, Q.; Zhang, W.; Zhan, D. Research on Optimization of Profile Parameters in Screw Compressor Based on BP Neural Network and Genetic Algorithm. Energies 2023, 16, 3632. https://doi.org/10.3390/en16093632

Wang T, Qi Q, Zhang W, Zhan D. Research on Optimization of Profile Parameters in Screw Compressor Based on BP Neural Network and Genetic Algorithm. Energies. 2023; 16(9):3632. https://doi.org/10.3390/en16093632

Chicago/Turabian StyleWang, Tao, Qiang Qi, Wei Zhang, and Dengyi Zhan. 2023. "Research on Optimization of Profile Parameters in Screw Compressor Based on BP Neural Network and Genetic Algorithm" Energies 16, no. 9: 3632. https://doi.org/10.3390/en16093632

APA StyleWang, T., Qi, Q., Zhang, W., & Zhan, D. (2023). Research on Optimization of Profile Parameters in Screw Compressor Based on BP Neural Network and Genetic Algorithm. Energies, 16(9), 3632. https://doi.org/10.3390/en16093632