Bacterial Foraging Algorithm for a Neural Network Learning Improvement in an Automatic Generation Controller

Abstract

:1. Introduction

2. Modelling of Hybrid Power System

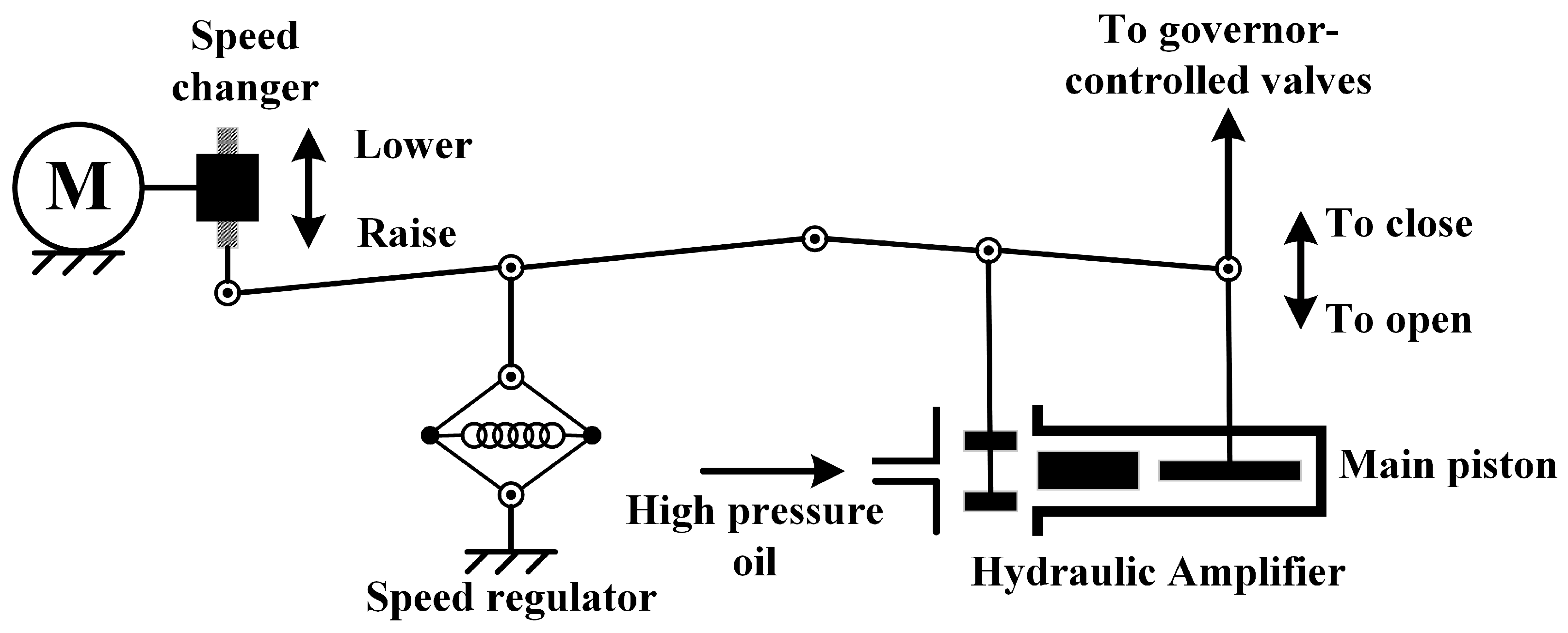

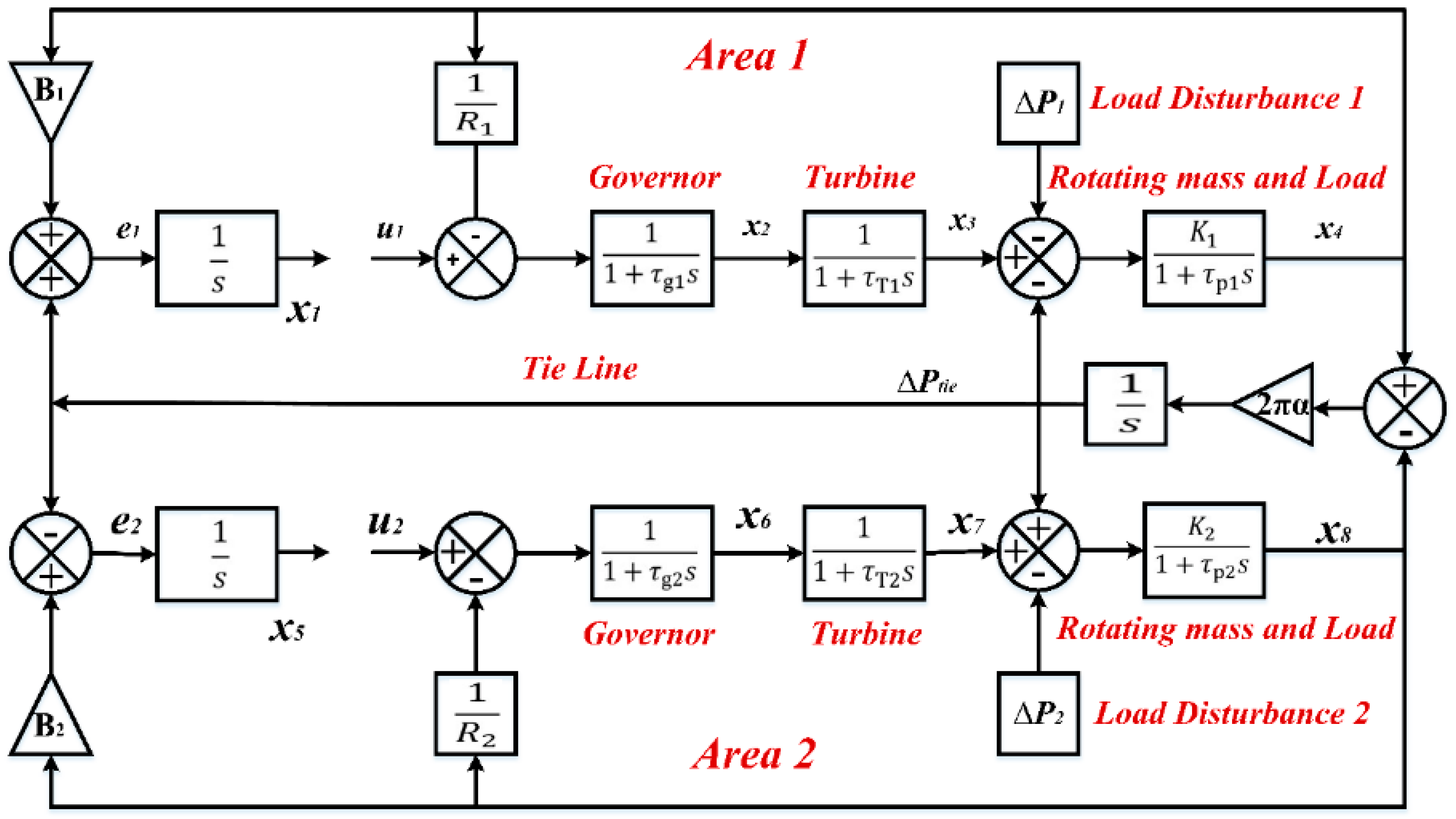

2.1. Modelling of Power System

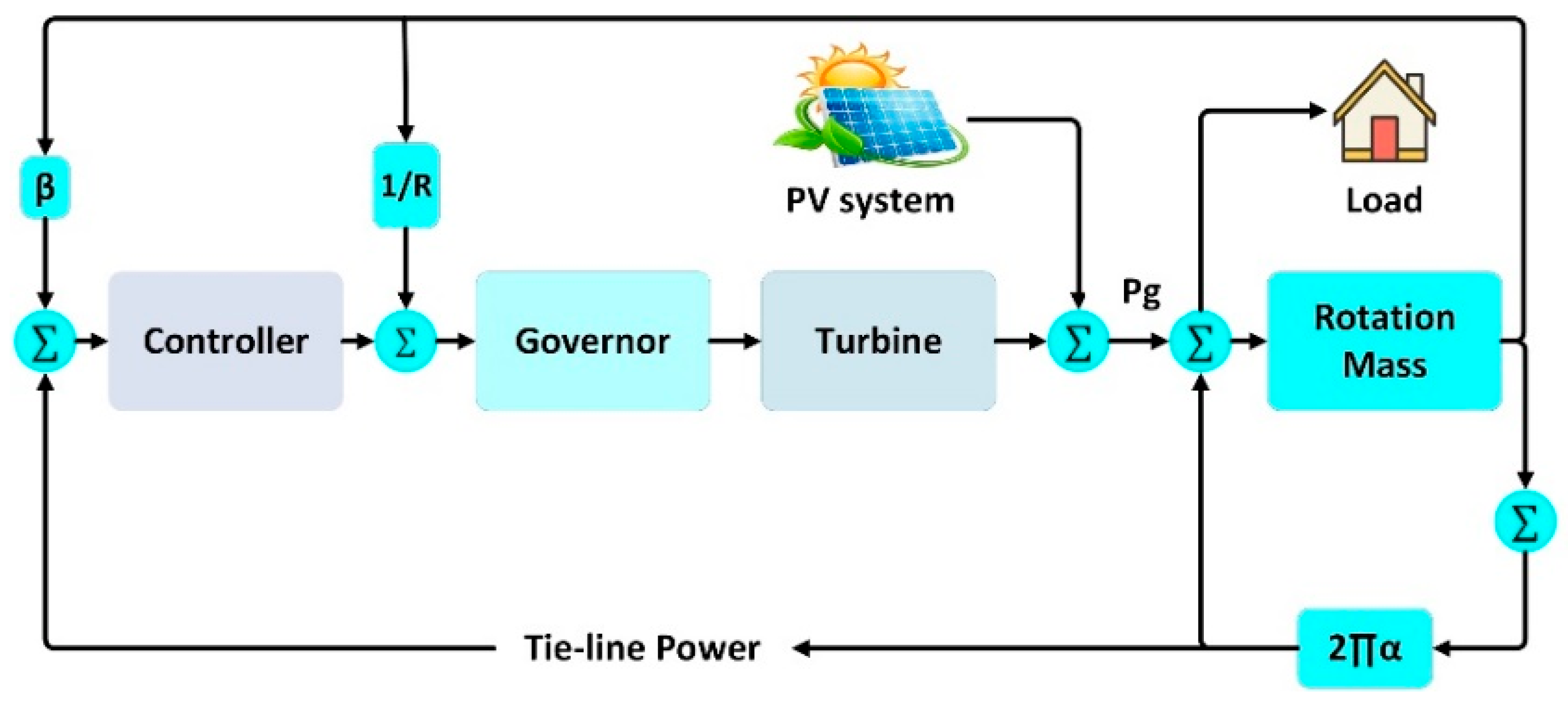

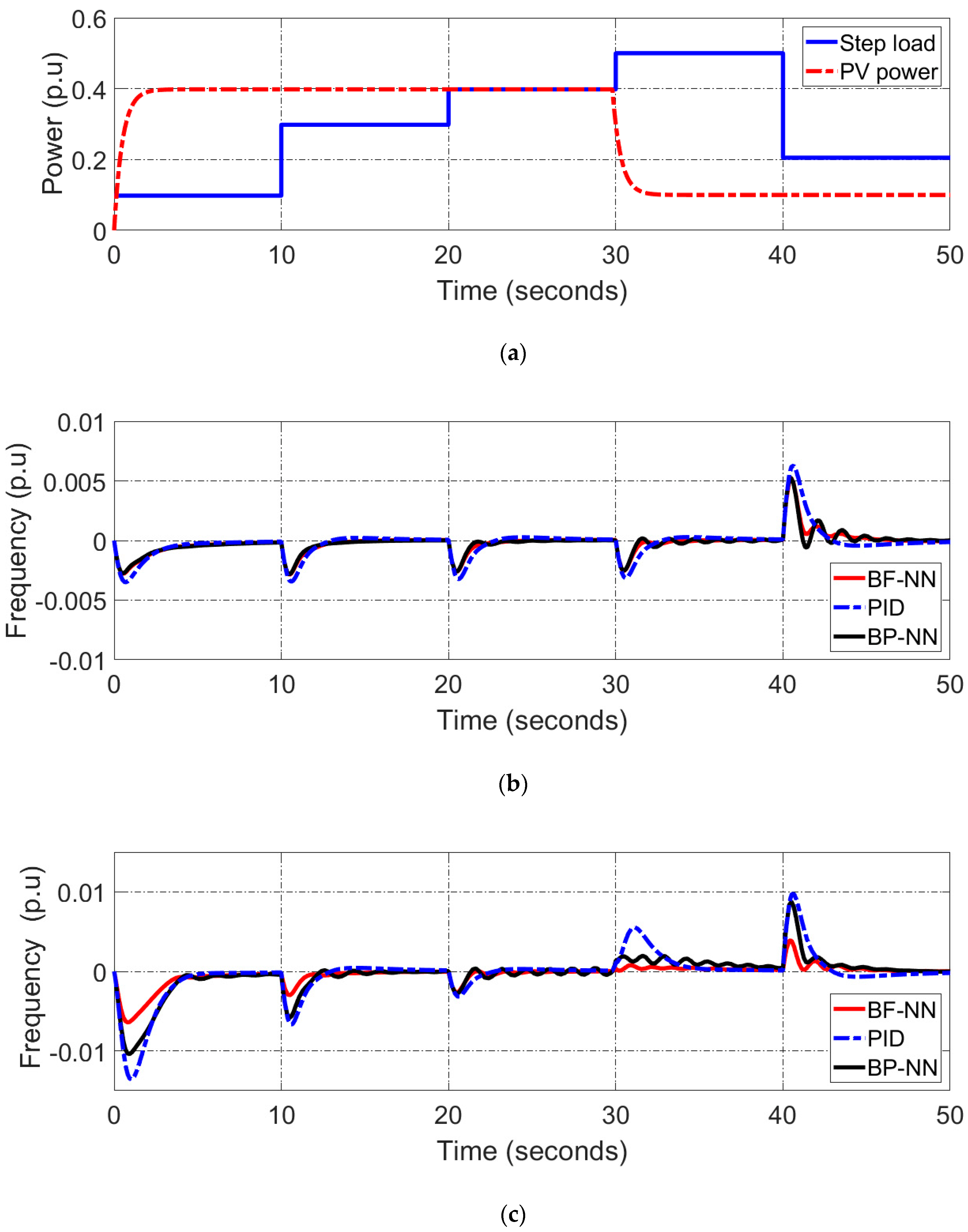

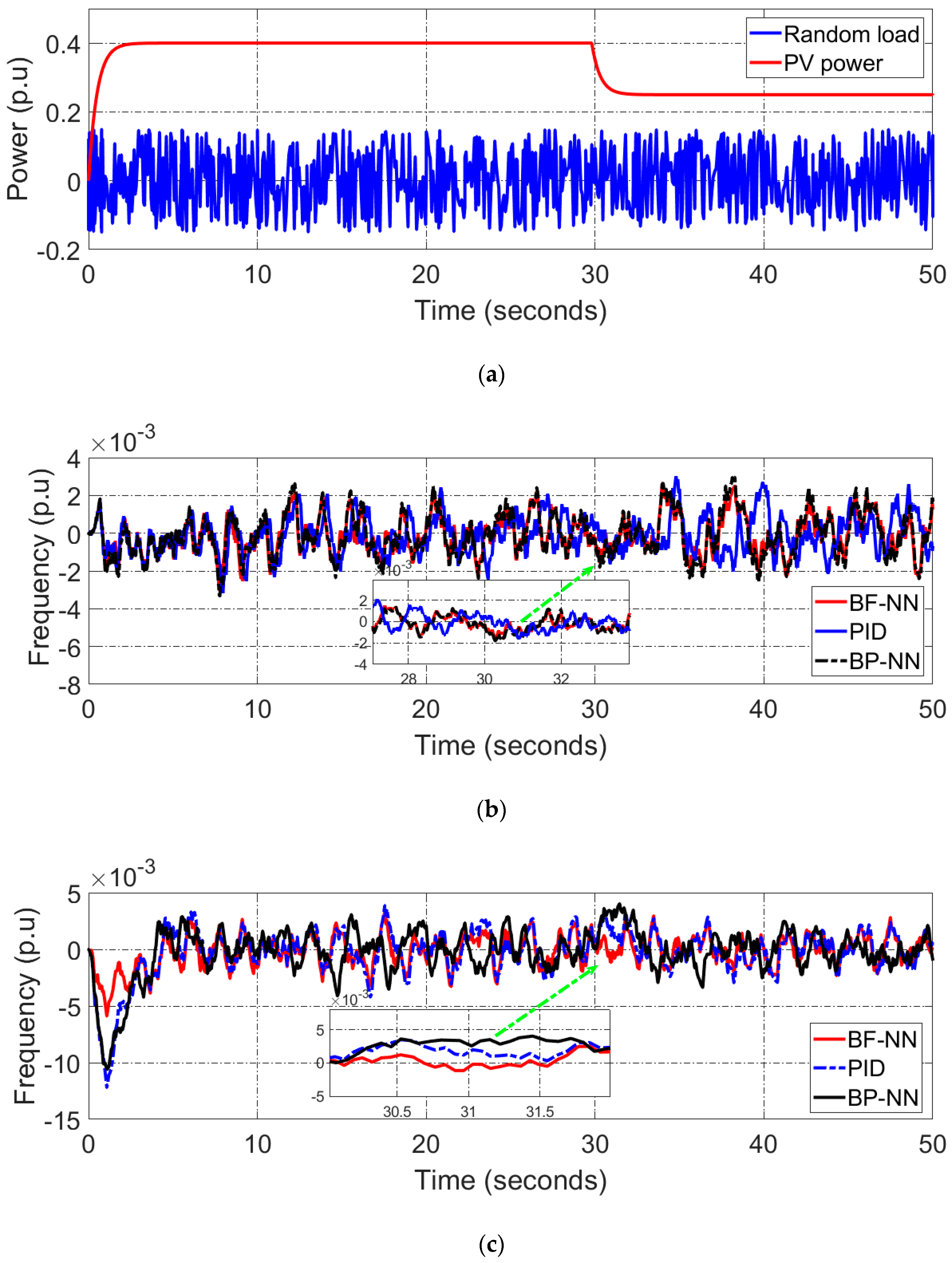

2.2. Modelling of PV Generation

3. Materials and Methods

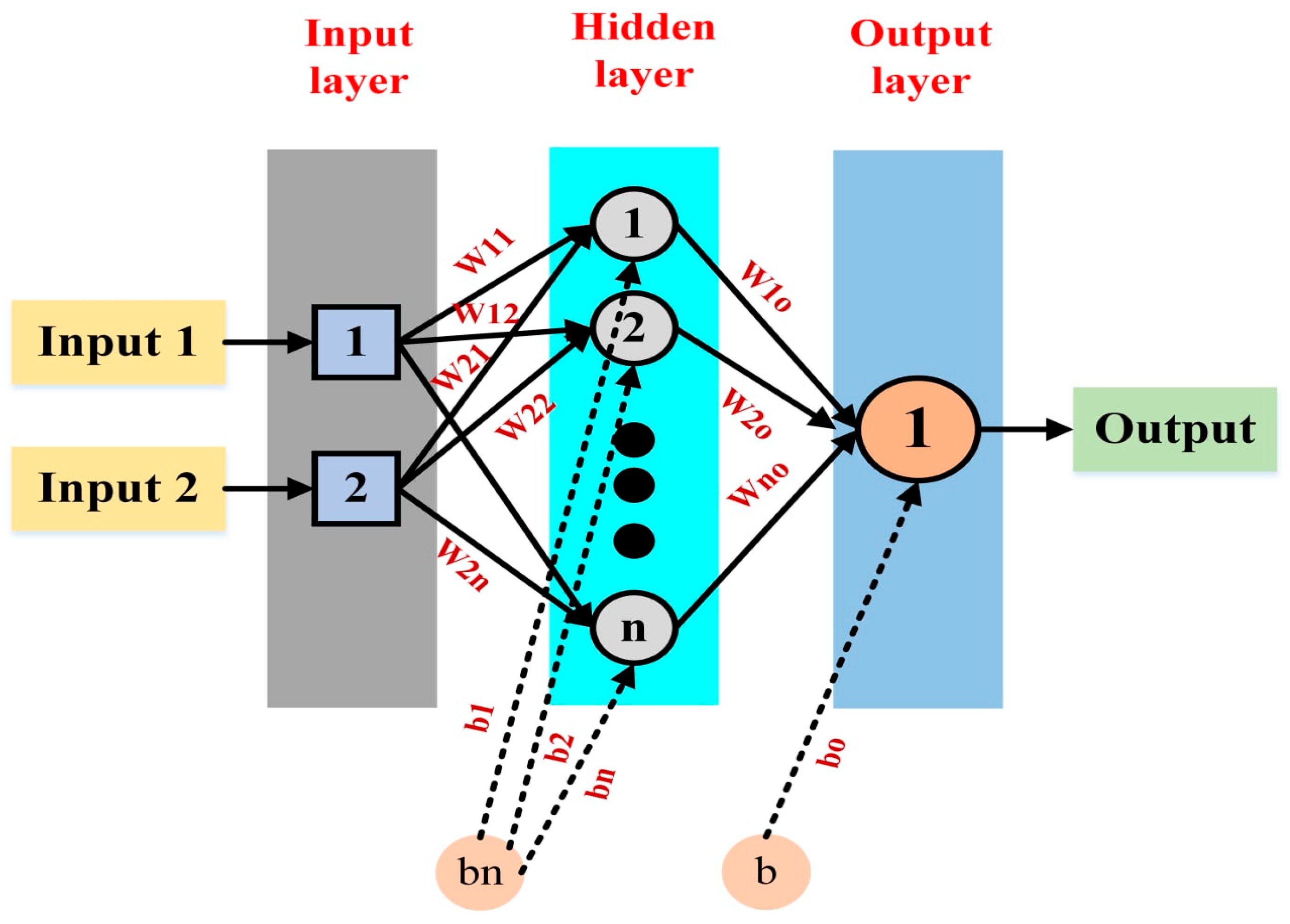

3.1. Neural Network Technique

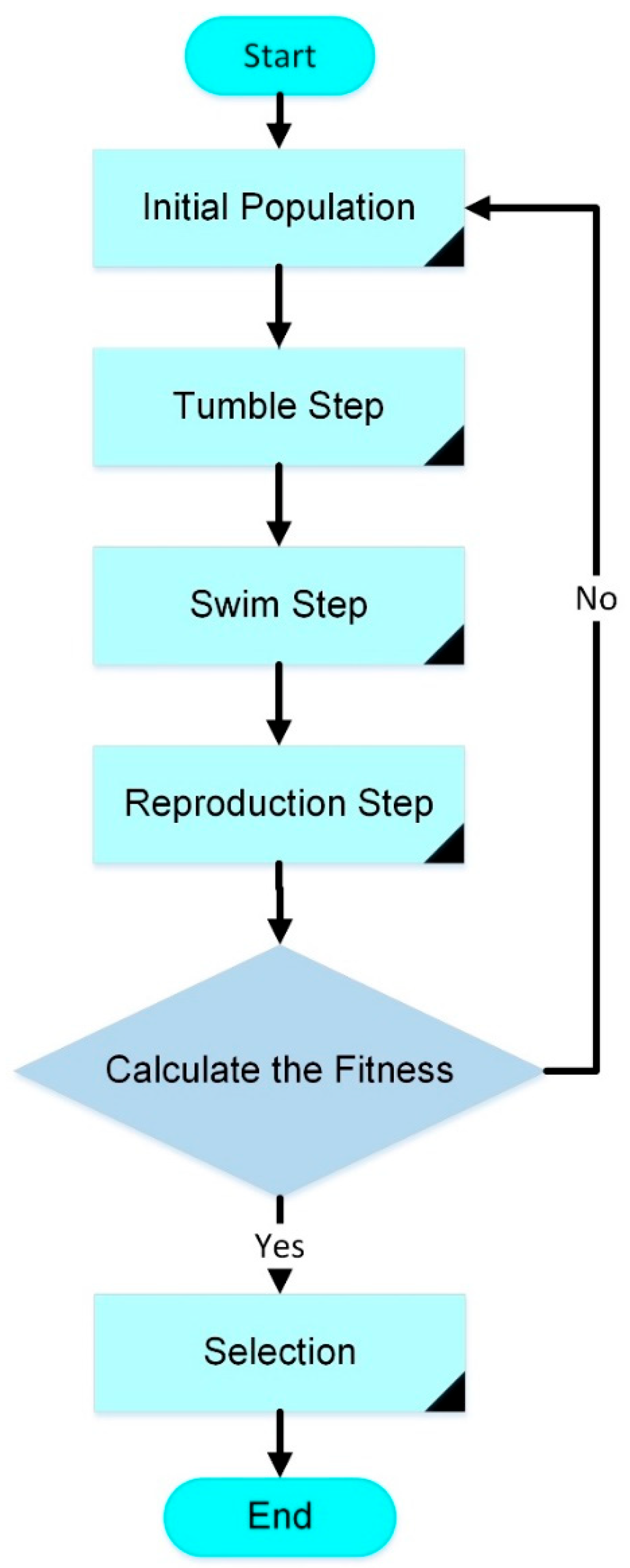

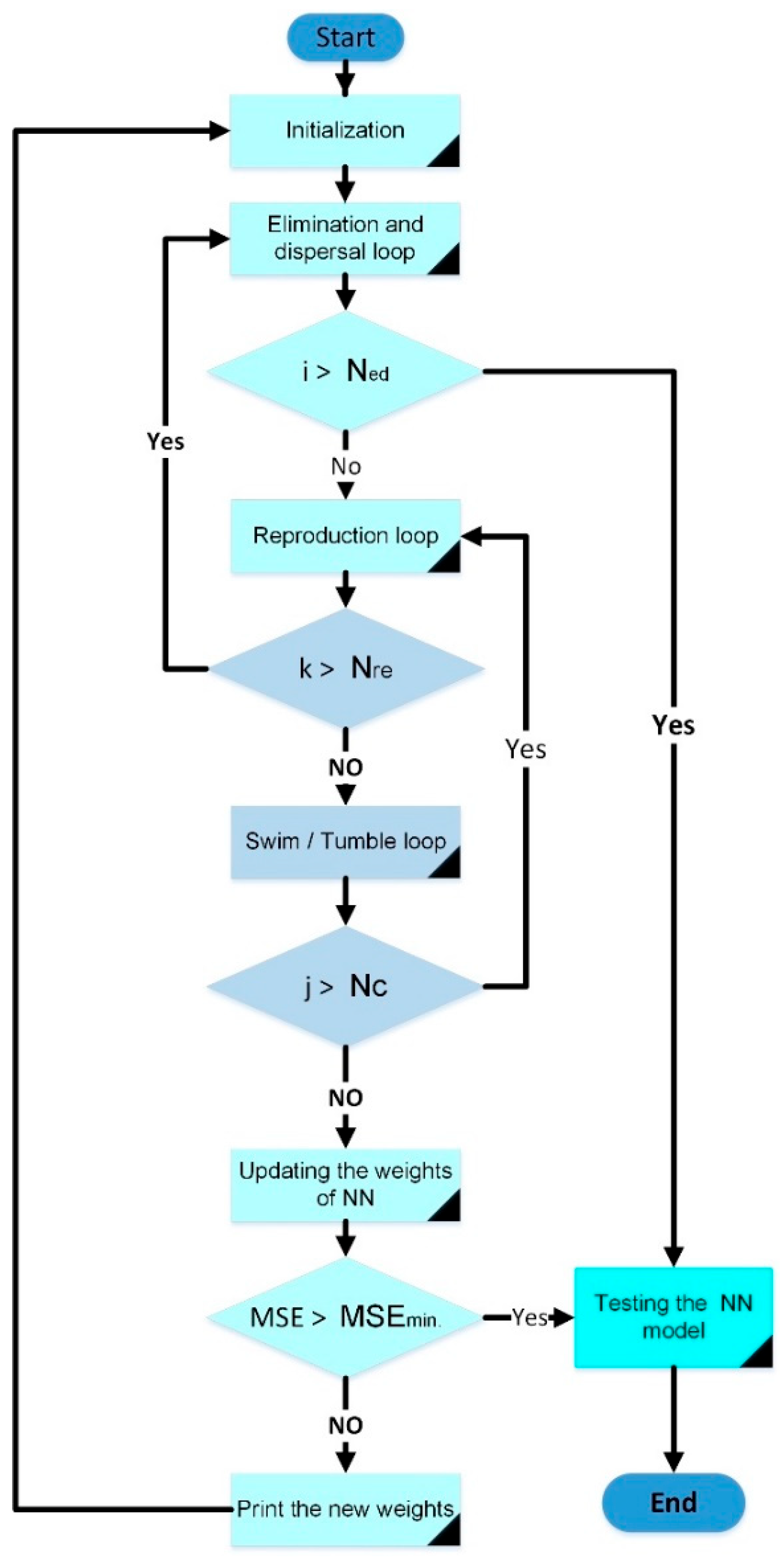

3.2. Bacterial Foraging Algorithm

- A.

- Chemotaxis Step

- B.

- Swarming Step

- C.

- Reproduction Step

- D.

- Elimination and Dispersal Step

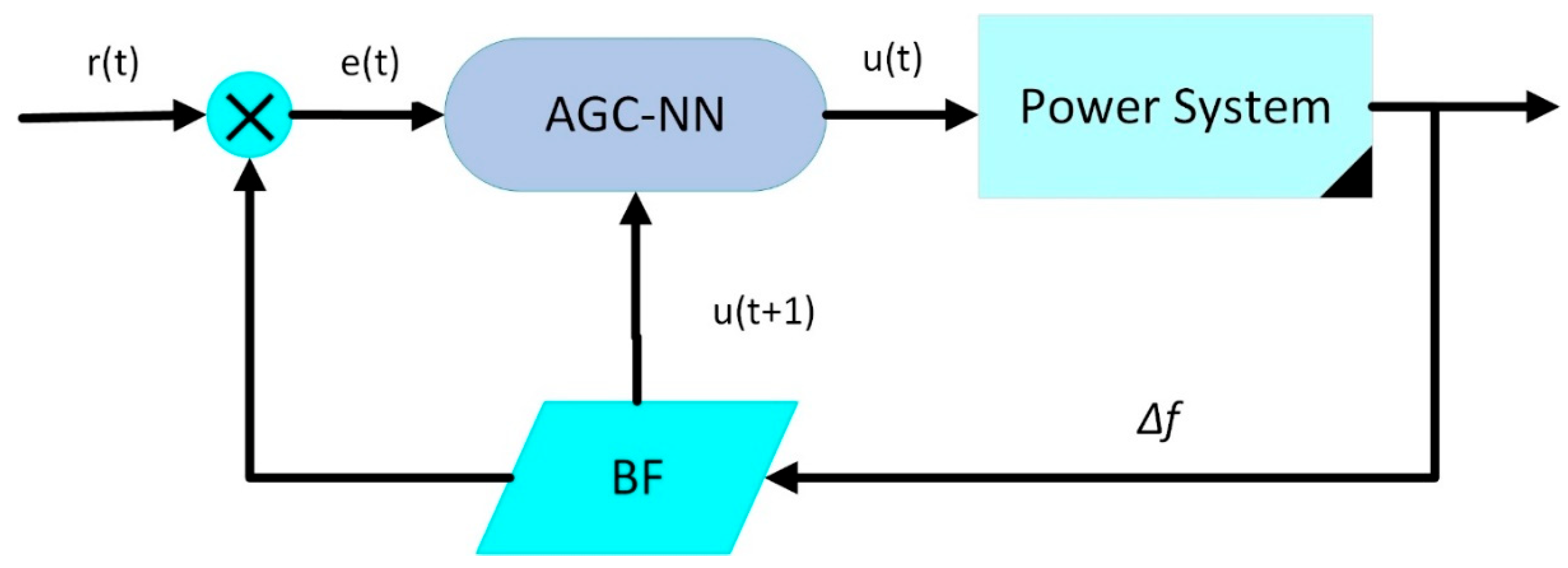

4. Proposed Method

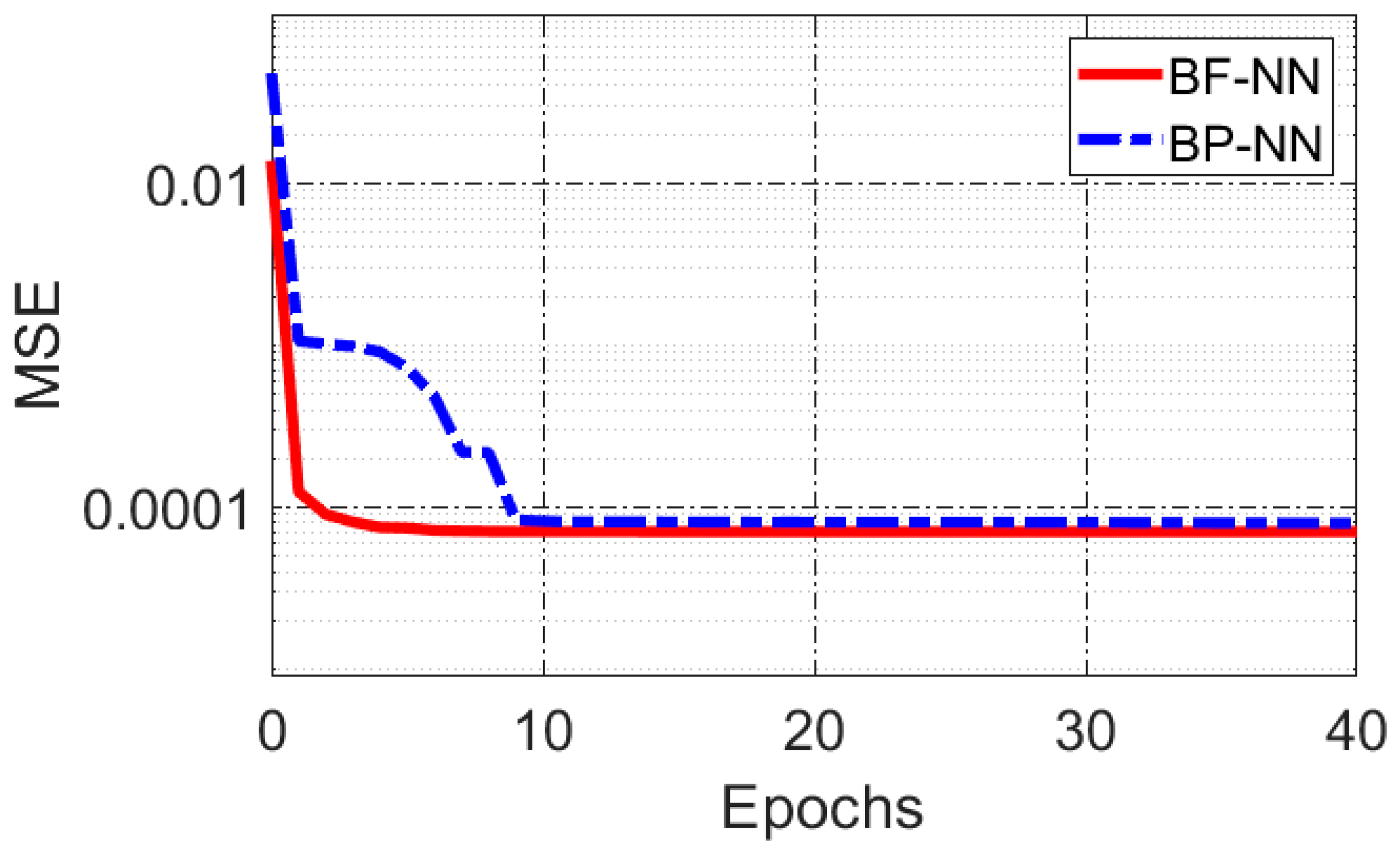

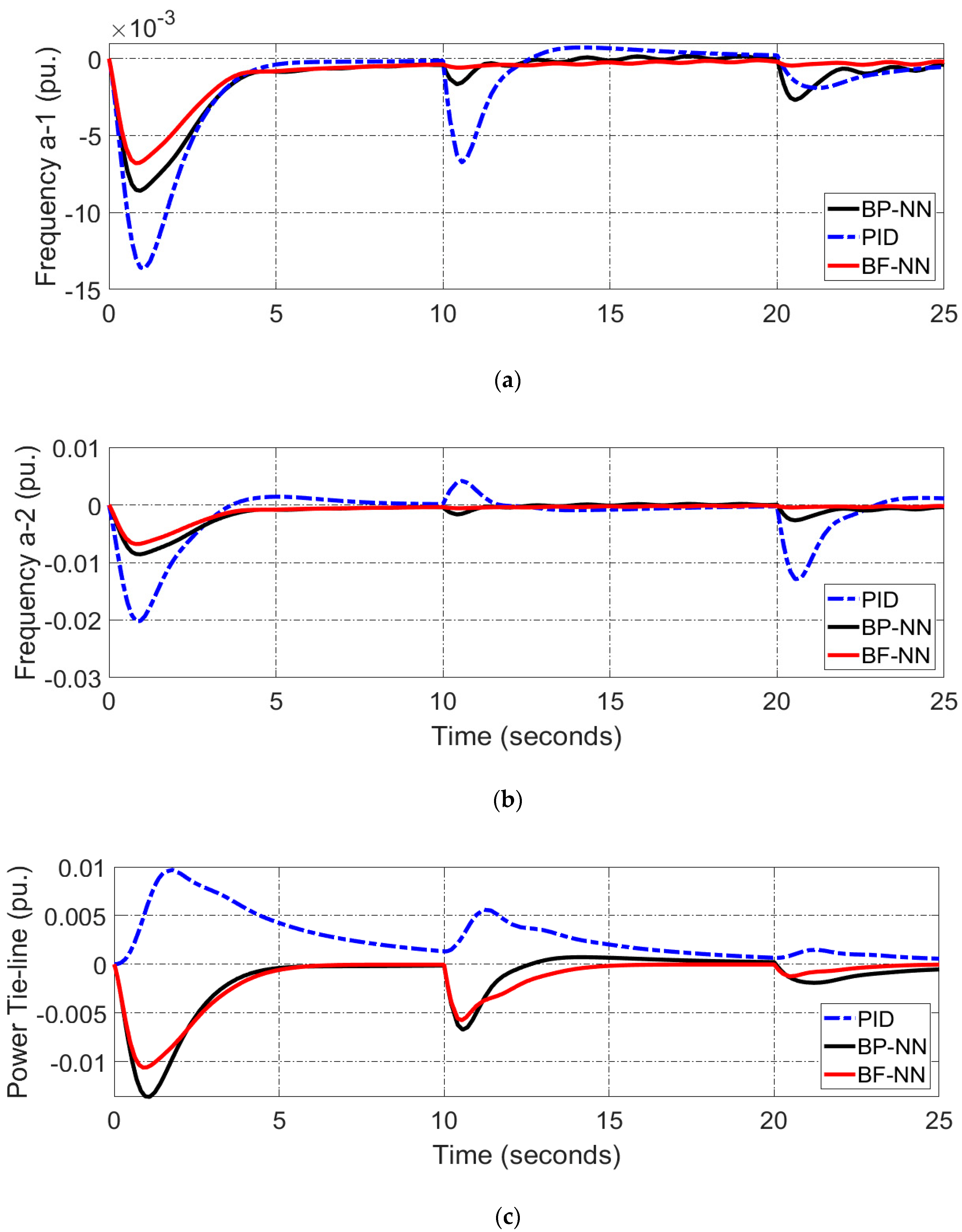

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Feng, W.; Xie, Y.; Luo, F.; Zhang, X.; Duan, W. Enhanced stability criteria of network-based load frequency control of power systems with time-varying delays. Energies 2021, 14, 5820. [Google Scholar] [CrossRef]

- Chen, B.Y.; Shangguan, X.C.; Jin, L.; Li, D.Y. An improved stability criterion for load frequency control of power systems with time-varying delays. Energies 2020, 13, 2101. [Google Scholar] [CrossRef] [Green Version]

- Ma, M.; Liu, X.; Zhang, C. LFC for multi-area interconnected power system concerning wind turbines based on DMPC. IET Gener. Transm. Distrib. 2017, 11, 2689–2696. [Google Scholar] [CrossRef]

- Al-Majidi, S.D.; Al-Nussairi, M.K.; Mohammed, A.J.; Abbod, M.F.; Al-raweshidy, H.S. Design of a Load Frequency Controller Based on an Optimal Neural Network. Energies 2022, 15, 6223. [Google Scholar] [CrossRef]

- Ranjan, M.; Shankar, R. A literature survey on load frequency control considering renewable energy integration in power system: Recent trends and future prospects. J. Energy Storage 2022, 45, 103717. [Google Scholar] [CrossRef]

- Tan, W.; Zhang, H.; Yu, M. Decentralized load frequency control in deregulated environments. Int. J. Electr. Power Energy Syst. 2012, 41, 16–26. [Google Scholar] [CrossRef]

- Pappachen, A.; Fathima, A.P. Critical research areas on load frequency control issues in a deregulated power system: A state-of-the-art-of-review. Renew. Sustain. Energy Rev. 2017, 72, 163–177. [Google Scholar] [CrossRef]

- Alhelou, H.H.; Hamedani-Golshan, M.E.; Zamani, R.; Heydarian-Forushani, E.; Siano, P. Challenges and opportunities of load frequency control in conventional, modern and future smart power systems: A comprehensive review. Energies 2018, 11, 2497. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Wang, C.; Hu, Y.; Liu, Z.; Yan, C.; He, S. Load frequency control of photovoltaic generation-integrated multi-area interconnected power systems based on double equivalent-input-disturbance controllers. Energies 2020, 13, 6103. [Google Scholar] [CrossRef]

- Sitharthan, R.; Karthikeyan, M.; Sundar, D.S.; Rajasekaran, S. Adaptive hybrid intelligent MPPT controller to approximate effectual wind speed and optimal rotor speed of variable speed wind turbine. ISA Trans. 2019, 96, 479–489. [Google Scholar] [CrossRef]

- Sitharthan, R.; Geethanjali, M. An adaptive Elman neural network with C-PSO learning algorithm-based pitch angle controller for DFIG based WECS. J. Vib. Control 2015, 23, 716–730. [Google Scholar] [CrossRef]

- Soundarya, G.; Sitharthan, R.; Sundarabalan, C.K.; Balasundar, C.; Karthikaikannan, D.; Sharma, J. Design and Modeling of Hybrid DC/AC Microgrid With Manifold Renewable Energy Sources. IEEE Can. J. Electr. Comput. Eng. 2021, 44, 130–135. [Google Scholar] [CrossRef]

- Pandey, S.K.; Kishor, N.; Mohanty, S.R. Frequency Regulation in Hybrid Power System Frequency Regulation in Hybrid Power System Using Iterative Proportional-Integral-Derivative H∞. Electr. Power Compon. Syst. 2014, 42, 132–148. [Google Scholar] [CrossRef]

- Bevrani, H.; Member, S.; Feizi, M.R.; Member, S. Robust Frequency Control in an Islanded Microgrid: H∞ and μ-Synthesis Approaches. IEEE Trans. Smart Grid 2016, 7, 706–717. [Google Scholar] [CrossRef] [Green Version]

- Shayeghi, H.; Shayanfar, H.A.; Jalili, A. Load frequency control strategies: A state-of-the-art survey for the researcher. Energy Convers. Manag. 2009, 50, 344–353. [Google Scholar] [CrossRef]

- Chen, G.; Li, Z.; Zhang, Z.; Li, S. An Improved ACO Algorithm Optimized Fuzzy PID Controller for Load Frequency Control in Multi Area Interconnected Power Systems. IEEE Access 2020, 8, 6429–6447. [Google Scholar] [CrossRef]

- Grigsby, L.L. Power System Stability and Control, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–450. [Google Scholar] [CrossRef]

- Zhong, Q.; Yang, J.; Shi, K.; Zhong, S.; Li, Z.; Sotelo, M.A. Event-Triggered Load Frequency Control for Multi-Area Nonlinear Power Systems Based on Non-Fragile Proportional Integral Control Strategy. IEEE Trans. Intell. Transp. Syst. 2022, 23, 12191–12201. [Google Scholar] [CrossRef]

- Al-Majidi, S.D.; Abbod, M.F.; Al-Raweshidy, H.S. Maximum Power Point Tracking Technique based on a Neural-Fuzzy Approach for Stand-alone Photovoltaic System. In Proceedings of the UPEC 2020-2020 55th International Universities Power Engineering Conference, Torino, Italy, 1–4 September 2020. [Google Scholar] [CrossRef]

- Al-Majidi, S.D.; Abbod, M.F.; Al-Raweshidy, H.S. Design of an Efficient Maximum Power Point Tracker Based on ANFIS Using an Experimental Photovoltaic System Data. Electronics 2019, 8, 858. [Google Scholar] [CrossRef] [Green Version]

- Sa-ngawong, N.; Ngamroo, I. Intelligent photovoltaic farms for robust frequency stabilization in multi-area interconnected power system based on PSO-based optimal Sugeno fuzzy logic control. Renew. Energy 2015, 74, 555–567. [Google Scholar] [CrossRef]

- Al-Nussairi, M.K.; Al-Majidi, S.D.; Hussein, A.R.; Bayindir, R. Design of a Load Frequency Control based on a Fuzzy logic for Single Area Networks. In Proceedings of the 10th IEEE International Conference on Renewable Energy Research and Application (ICRERA 2021), Ankara, Turkey, 26–29 September 2021; pp. 216–220. [Google Scholar] [CrossRef]

- Karimipouya, A.; Abdi, H. Microgrid frequency control using the virtual inertia and ANFIS-based Controller. Int. J. Ind. Electron. Control Optim. 2019, 2, 145–154. [Google Scholar] [CrossRef]

- Dash, K.S.R.S.S. Load frequency control of autonomous power system using adaptive fuzzy based PID controller optimized on improved sine cosine algorithm. J. Ambient Intell. Humaniz. Comput. 2018, 10, 2361–2373. [Google Scholar] [CrossRef]

- Nitisha, K.N.; Puneet, T.; Vineet, M.; Rana, K.K.P.S. Efficient control of integrated power system using self-tuned fractional-order fuzzy PID controller. Neural Comput. Appl. 2018, 31, 4137–4155. [Google Scholar] [CrossRef]

- Sharma, Y.; Saikia, L.C. Electrical Power and Energy Systems Automatic generation control of a multi-area ST—Thermal power system using Grey Wolf Optimizer algorithm based classical controllers. Int. J. Electr. Power Energy Syst. 2015, 73, 853–862. [Google Scholar] [CrossRef]

- Kant, S.; Mohanty, S.R.; Kishor, N.; Catalão, J.P.S. Electrical Power and Energy Systems Frequency regulation in hybrid power systems using particle swarm optimization and linear matrix inequalities based robust controller design. Int. J. Electr. Power Energy Syst. 2014, 63, 887–900. [Google Scholar] [CrossRef]

- Fan, W.; Hu, Z.; Veerasamy, V. PSO-Based Model Predictive Control for Load Frequency Regulation with Wind Turbines. Energies 2022, 15, 8219. [Google Scholar] [CrossRef]

- El-fergany, A.A.; El-hameed, M.A. Efficient frequency controllers for autonomous two-area hybrid microgrid system using social-spider optimiser. IET Gener. Transm. Distrib. 2017, 11, 637–648. [Google Scholar] [CrossRef]

- Al-dunainawi, Y.; Abbod, M.F.; Jizany, A. Engineering Applications of Arti fi cial Intelligence A new MIMO ANFIS-PSO based NARMA-L2 controller for nonlinear dynamic systems. Eng. Appl. Artif. Intell. 2017, 62, 265–275. [Google Scholar] [CrossRef] [Green Version]

- Abdolrasol, M.G.M.; Hussain, S.M.S.; Ustun, T.S.; Sarker, M.R.; Hannan, M.A.; Mohamed, R.; Ali, J.A.; Mekhilef, S.; Milad, A. Artificial neural networks based optimization techniques: A review. Electronics 2021, 10, 2689. [Google Scholar] [CrossRef]

- Rosa, J.P.S.; Guerra, D.J.D.; Horta, N.C.G.; Martins, R.M.F.; Lourenço, N.C.C. Overview of Artificial Neural Networks; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Jain, A.K.; Mao, J.; Mohiuddin, K.M. Artificial neural networks: A tutorial. Computer 1996, 29, 31–44. [Google Scholar] [CrossRef] [Green Version]

- Al-hadi, I.A.A.; Zaiton, S.; Hashim, M.; Mariyam, S.; Shamsuddin, H. Bacterial Foraging Optimization Algorithm For Neural Network Learning Enhancement. In Proceedings of the 2011 11th International Conference on Hybrid Intelligent Systems (HIS), Melacca, Malaysia, 5–8 December 2011; pp. 200–205. [Google Scholar] [CrossRef]

- Nanda, J.; Mishra, S.; Saikia, L.C. Maiden Application of Bacterial Foraging-Based Optimization Technique in Multiarea Automatic Generation Control. IEEE Trans. Power Syst. 2009, 24, 602–609. [Google Scholar] [CrossRef]

- Tang, J.; Liu, G.; Pan, Q. A Review on Representative Swarm Intelligence Algorithms for Solving Optimization Problems: Applications and Trends. IEEE/CAA J. Autom. Sin. 2021, 8, 1627–1643. [Google Scholar] [CrossRef]

- Eslami, M.; Shareef, H.; Mohamed, A.; Khajehzadeh, M. PSS and TCSC Damping Controller Coordinated Design Using GSA. Energy Procedia 2012, 14, 763–769. [Google Scholar] [CrossRef] [Green Version]

- Eslami, M.; Shareef, H.; Mohamed, A. Optimization and Coordination of Damping Controls for Optimal Oscillations Damping in Multi-Machine Power System. Int. Rev. Electr. Eng. 2011, 6, 1984–1993. [Google Scholar]

- Eslami, M.; Neshat, M. A Novel Hybrid Sine Cosine Algorithm and Pattern Search for Optimal Coordination of Power System Damping Controllers. Sustainability 2022, 14, 541. [Google Scholar] [CrossRef]

- Eslami, M.; Shareef, H.; Mohamed, A.; Khajehzadeh, M. Damping Controller Design for Power System Oscillations Using Hybrid GA-SQP y. Int. Rev. Electr. Eng 2010, 6, 888–896. [Google Scholar]

| Parameters | Definition |

|---|---|

| Δf | Historical change in frequency |

| ΔPtie | Historical change in tie-line power |

| R | Regulations of governor |

| G | Controller gain |

| Pg | Output power of generator |

| u1 and u2 | Control inputs in areas 1 and 2 |

| ΔPg1 and ΔPg2 | Historical change in output power of governor |

| ΔPt1 and ΔPt2 | Historical change in output power of turbine |

| ΔP1 = D1 | Load Disturbances in area 1 |

| ΔP2 = D2 | Load Disturbances in area 2 |

| K1 and K2 | Constants of areas 1 and 2 |

| 𝝉P1 and 𝝉P2 | Time constants of areas 1 and 2 |

| B1 and B2 | Tie-line frequency bias in areas 1 and 2 |

| 𝝉g1 and 𝝉g2 | Time constants of governor for areas 1 and 2 |

| 𝝉T1 and 𝝉T2 | Turbine time constants for areas 1 and 2 |

| Parameters | Definition |

|---|---|

| IPV | Output PV current |

| IL | Current generator |

| I0 | Saturation current |

| q | Electrical charge |

| n | PV diode factor |

| k | Boltzmann’s constant |

| T | Ambient temperature |

| VPV | Output PV voltage |

| Rs | Series resistance |

| Rsh | Shunt resistance |

| Parameters | Value |

|---|---|

| Dimension of search space | 93 |

| Bacterial size (S) | 50 |

| Number of chemotactic steps (Nc) | 5 |

| Number of reproduction steps (Nre) | 50 |

| Number of elimination/dispersal events (Ned) | 4 |

| Probability of eliminated/dispersed | 0.25 |

| Approaches | ITAE |

|---|---|

| BF-NN | 5.20 s |

| BP-NN | 8.79 s |

| PID | 13.25 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Majidi, S.D.; Altai, H.D.S.; Lazim, M.H.; Al-Nussairi, M.K.; Abbod, M.F.; Al-Raweshidy, H.S. Bacterial Foraging Algorithm for a Neural Network Learning Improvement in an Automatic Generation Controller. Energies 2023, 16, 2802. https://doi.org/10.3390/en16062802

Al-Majidi SD, Altai HDS, Lazim MH, Al-Nussairi MK, Abbod MF, Al-Raweshidy HS. Bacterial Foraging Algorithm for a Neural Network Learning Improvement in an Automatic Generation Controller. Energies. 2023; 16(6):2802. https://doi.org/10.3390/en16062802

Chicago/Turabian StyleAl-Majidi, Sadeq D., Hisham Dawood Salman Altai, Mohammed H. Lazim, Mohammed Kh. Al-Nussairi, Maysam F. Abbod, and Hamed S. Al-Raweshidy. 2023. "Bacterial Foraging Algorithm for a Neural Network Learning Improvement in an Automatic Generation Controller" Energies 16, no. 6: 2802. https://doi.org/10.3390/en16062802

APA StyleAl-Majidi, S. D., Altai, H. D. S., Lazim, M. H., Al-Nussairi, M. K., Abbod, M. F., & Al-Raweshidy, H. S. (2023). Bacterial Foraging Algorithm for a Neural Network Learning Improvement in an Automatic Generation Controller. Energies, 16(6), 2802. https://doi.org/10.3390/en16062802