1. Introduction

Nature presents several multi-objective design problems in the real world. Even for scientists and engineers with a wide range of specialties, multi-objective optimization problems have become quite important. Nonetheless, despite significant progress, the robustness and effectiveness of existing techniques for addressing multi-objective optimization issues remained largely insufficient [

1]. As a result, there is constant space for improvement. This is required for multi-objective optimization problems to continue to be an interesting study topic.

Swarm intelligence, evolutionary algorithms, physics-based techniques, and human-based algorithms make up the four fundamental categories of meta-heuristic methods. At first, swarm intelligence approaches, such as particle swarm optimization (PSO) [

1], jellyfish search technique [

2,

3], Aquila optimization algorithm [

4,

5], hunter prey-based optimization [

6,

7], gorilla troops algorithm [

8], and honey badger algorithm [

9,

10], have been inspired by swarming and animal group behaviors. Second, evolutionary computer algorithms have been developed based on the representation of biological evolutionary aspects, such as crossovers, mutations, and selections [

11,

12,

13]. Additionally, physics-based techniques are motivated by physical laws, such as Archimedes optimization algorithm [

14,

15], electromagnetism-like algorithm [

16], big bang-big crunch algorithm [

17], and gravitational search algorithm [

18], Henry gas solubility method [

19], and motivate physics-based strategies. Finally, human behavior and evolution provide people the ability to become quite familiar with their environments, leading to the development of human-inspired optimizers, such as heap-based optimizers [

20], teaching learning-based optimization [

21], imperialist competitive algorithms [

22], and social network search techniques [

23].

In recent years, multi-objective optimization techniques have evolved dramatically. They attempt to provide a range of benefits, including the capacity to identify multiple solving options inside a single test, non-reliance on derivatives, quick convergence, precise Pareto-optimal set, and exhibiting the flexibility in managing both continuous and combinational parameters simultaneously with ease [

24]. They also aim to make people less vulnerable to the form or continuity of the Pareto front [

25]. To solve the multi-objective optimization challenges, several evolutionary strategies have been investigated [

26,

27,

28,

29,

30]. Rizk-Allah et al. [

31] presented a multi-objective fruit fly technique to solve the TLSM optimizing design. The fruit fly algorithm is initially started using a swarm of randomly selected fruit flies. During the early stages, the nearest non-dominated fruit fly assumes the role of the dominated individual. The fruit flies eventually engage in an evolutionary process by arbitrarily moving around the non-dominant alternative for each target. After that, either from the prior non-dominated position or the reference point, the fruit flies are upgraded to the closest place. The reference point is utilized to emphasize the convergence of the non-dominated alternatives, and the weighted sum approach has been included to modify the prior optimal positions of fruit flies. Despite its significant application in acquiring diversified Pareto solutions, its ability to meet design restrictions was called into doubt. The JAYA optimization algorithm has been utilized by Rao et al. in [

32] to optimize several design constraints where its strategy combines the global optimal solution attraction of swarm intelligent techniques with the strongest survival concept of evolutionary algorithms. To solve three mechanical design issues and come up with the optimum gear train design, WBD, and tension/compression spring, a butterfly method was created and enhanced by Arora et al. in [

33]. This algorithm includes an exploitation phase of advancement, which delivers solutions that give extra opportunities to enhance themselves. On the other side, both studies [

32,

33] were dealing with the WBD in a single-objective minimization model.

Yang et al. [

34] introduced a Multi-objective Flower Pollination Algorithm (MFPA), which was inspired by the pollination process of flowering species. Pereira et al. [

35] presented a Multi-objective Lichtenberg Algorithm (MOLA), which draws inspiration from Lichtenberg patterns and the spread of radial intra-cloud lightning. Since it dispenses the locations to be assessed in the fitness function under a Lichtenberg graph, which is snapped in dimensions and distinct rotations at every iteration, the technique calculates in its optimization workout a combination system relying on both the population and the trajectory, exhibiting a remarkable ability for exploitation and exploration. Mirjalili et al. [

36] introduced a Multi-objective Grasshopper Optimization Algorithm (MGOA) inspired by grasshopper swarm navigation in nature. Inside the swarm, the interaction between grasshoppers comprises forces of repulsion and attraction, and safe zones. Additionally, the Pareto optimum front for multi-objective problems is therefore estimated using an archiving and target-choosing strategy included in the algorithm.

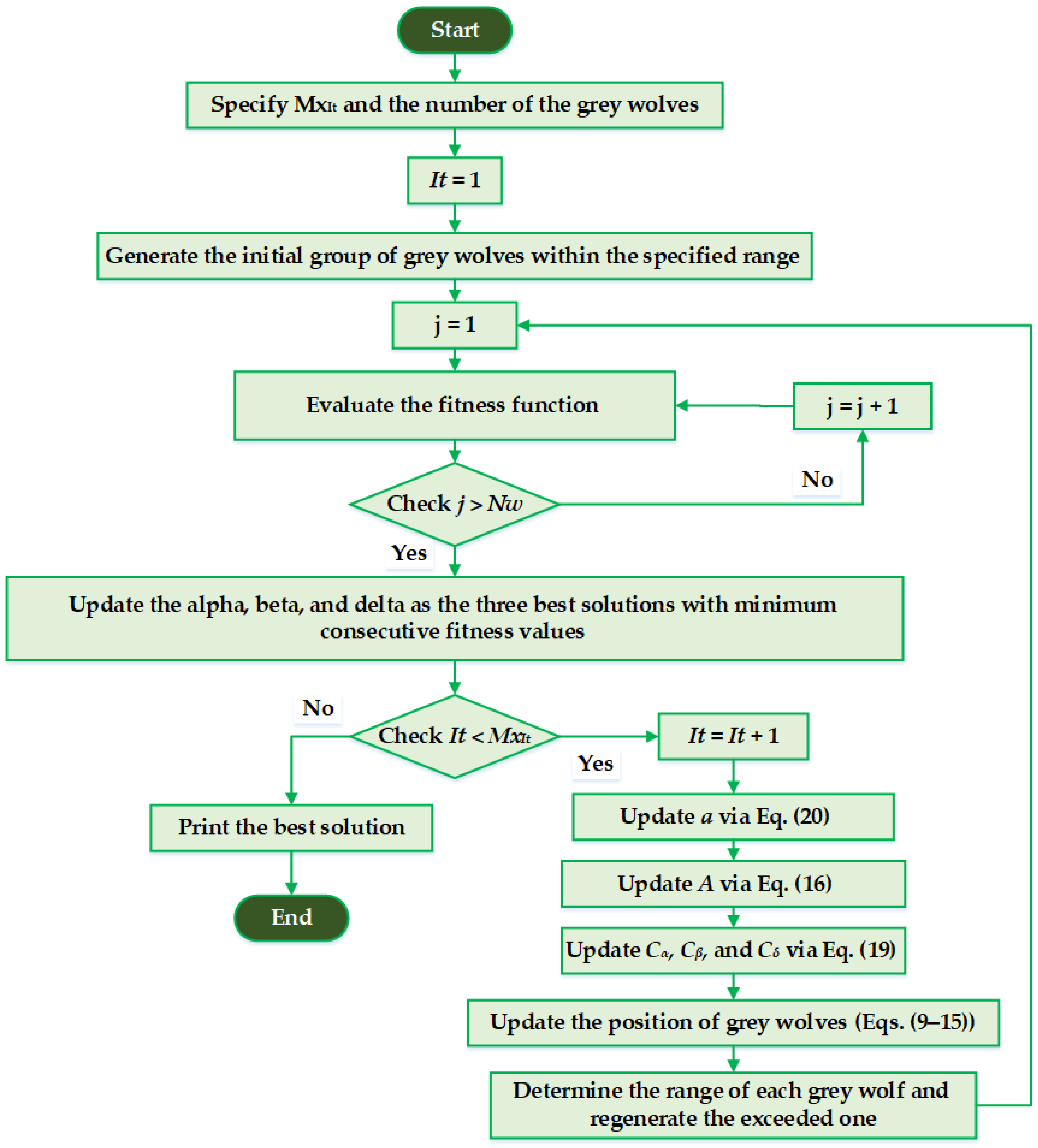

The grey wolf social structure and hunting methods are simulated by GWA. Grey wolves’ primary hunting techniques include searching for their target, encircling, and attacking their prey. GWA has several unique features of simplicity, convergence speed, and effectiveness, which makes it an application tool for several engineering problems, such as transport network optimization [

37], solid oxide fuel cell representation model [

38], forecasting the carbon price [

39], localization stability improvement and error minimization of wireless sensor networks [

40], energy consumption estimation of electric buses [

41], and coordination of static reactive power devices in distribution networks [

42].

The metaheuristic optimization problem is an interesting research topic, which has been widely utilized in mechanical engineering and smart materials. Ding et al. [

43] suggested a harmony search algorithm searching for the optimum design of flexure-based mechanism for non-circular diamond turning operation. Additionally, Yang et al. [

44] provides an efficient application of PSO in order to optimally identify the Preisach model parameters for piezoelectric actuators. To design a MGWO, an exterior repository with a predefined size, as a non-dominated Pareto set, is added [

45]. The exterior repository is a straightforward storage mechanism that could store or recover existing Pareto non-dominated solutions. A controlling approach that manages the repository whenever a solution wishes to access the archiving or when it is completed is its primary module. The exterior repository can only have a certain number of members. The current non-dominated alternatives are contrasted to the repository population throughout the repetition process.

1.1. Proposed Novelty of This Research

In this study, a Multi-Objective Grey Wolf Optimization (MGWO) for the Multi-Objective Shape Design of Tubular Linear Synchronous Motors is developed. For storing and retrieving Pareto optimal solutions, the MGWO includes an outside archive with a predetermined size built in. The social structure of grey wolves would then be established using this data, and multi-objective search settings would be used to model grey wolf hunting behavior. By maximizing the operating force and limiting the flux saturation, TLSMs can manage the multi-objective form design. The developed MGWO is compared to several recent algorithms of MFPA, MOLA, and MGOA. The superiority and effectiveness of the developed MGWO, compared to MFPA, MOLA and MGOA, is demonstrated in terms of their single-objective and multi-objective optimization frameworks for TLSM engineering problem. The results clearly indicate how efficient the proposed MGWO is at locating non-dominated solutions. When compared to MFPA, MOLA, and MGOA, the developed MGWO retains an average improvement of 73.46%, 19.07%, and 15.15%, respectively. The validation of the proposed MGWO is expanded to a multi-objective form of welded beam design (WBD) by minimizing deflection and manufacturing costs at the same time. Similar outcomes have been achieved with different reference points; the proposed MGWO yields an average improvement of 2.8%, 0.7%, and 3.04%, when compared to MFPA, MOLA, and MGOA, respectively.

1.2. Key Contribution of the Paper

The key contribution points in this paper can be classified into two categories:

From engineering point of view:

From mathematical point of view:

When comparing GWA to FPA, LA, and GOA for both design problems, single-objective optimization frameworks, GWA offers higher superiority, better convergence, and greater robustness;

Higher hypervolume indications show that the created MGWO outperforms the MFPA, MOLA, and MGOA when different reference points are taken into account for both design problems;

Furthermore, the proposed MGWO demonstrates greater efficiency and superiority versus true fronts of NSGA II, MFPA, MOLA, and MGOA for WBD based on different metrics presented in the literature, such as hypervolume, generational distance, inverted generational distance, spread, generalized-spread, and additive epsilon.

4. Simulation Results

In this section, the developed MGWO technique is applied for the multi-objective form design of TLSMs by maximizing the operating force and minimizing the flux saturation. The developed MGWO is compared to several recent algorithms of MFPA [

34], MOLA [

35], and MGOA [

36]. Three different cases are investigated.

In addition, the application of the developed MGWO technique is extended for one of the practical benchmark design problems to optimize the multi-objective form of welded beam design (WBD) by simultaneously minimizing the deflection and the manufacturing costs.

4.1. Applications for TLSM Design

For the TLSM design, three different cases are investigated. In the first and second cases, the assessments of GWA, FPA, LA and GOA are performed in terms of their single-objective optimization frameworks for the TLSM problem. The first case is dedicated to minimizing the flux saturation described in Equation (1), while the second case is dedicated to maximizing the operating force by minimizing its negative model described in Equation (3). GWA, FPA, LA, and GOA are performed 50 separate times with 100 search agents and 500 repetitions. These circumstances guarantee fair comparisons between them with 50,000 function evaluations. In the third case, the developed MGWO, MFPA, MOLA, and MGOA are performed for the multi-objective optimization framework of the TLSM design by simultaneously minimizing the fitness functions of Equations (1) and (3). The permitted ranges for the control variables are as follows: slot current (ins) [0,∞] A, the height of the slot (hs) [0, 0.08] m, the height of the magnet (hm) [0, 0.08] m, and slot thickness (ts) [0,0.009] m.

4.1.1. First Case: Minimizing the Flux Saturation

Only minimizing the flux saturation described in Equation (1) is treated as a single-objective target in this case. GWA, FPA, LA, and GOA are applied 50 times in this case, and their best results in terms of control variables and outcome fitness values are listed in

Table 1.

As can be seen, the FPA, LA, and GOA attain values of flux saturation of 1.4398, 1.4329, and 1.440899, respectively, while the GWA achieves the lowest value of 1.4312 for the flux saturation. This indicates the high effectiveness of the GWA in locating the region of the spectrum with the least flux saturation, which was discovered with slot current of 723.3687 A, slot height of 2.314 mm, magnet height of 34.709 mm, and slot thickness of 3.49 mm. Additionally,

Figure 6 shows the GWA, FPA, LA, and GOA’s best convergence curves.

From

Figure 6, GWA, FPA, LA, and GOA are beginning the search from an extremely high value, which illustrates that all the design constraints are violated. With the progress of the iterations, the GWA shows high speed in maintaining the inequality limitations at 115 iterations. GOA, FPA, and LA are then successfully tackling the inequality constraints after 257, 307, and 380 iterations, respectively.

Figure 7 shows the box and whisker’s plot of GWA, FPA, LA, and GOA for TLSM design under the first case to evaluate the robustness of the GWA, FPA, LA, and GOA over the distinct runs. As demonstrated, the GWA performs best across all runs with the lowest values of the evaluated objective.

Table 2 presents the robustness indices of the acquired fitness values of GWA, FPA, LA, and GOA to further demonstrate its success. With the smallest indices of 1.431472 as the minimum, 1.43206 as the mean, 1.432432 as the maximum, and 0.000278 as the standard deviation, the GWA in

Table 2 exhibits the most resilient behavior.

In comparison to the reported fruit fly algorithm in [

31],

Table 3 verifies the constraints justification based on the presented GWA for the TLSM design under the first case. For that, all the constraints are guaranteed using the presented GWA, while two constraints are highly violated due to the reported fruit fly algorithm.

4.1.2. Second Case: Maximizing the Operating Force

Only the maximization of the operating force, as described in Equation (3), is considered a single- objective target. GWA, FPA, LA, and GOA are employed here, and their best control variables and outcome fitness values are displayed in

Table 4. Simultaneously, the best convergence curves for the GWA, FPA, LA, and GOA are depicted in

Figure 8.

As shown, the GWA reaches the lowest value of 16,217.9 N for the flux saturation, while the FPA, LA, and GOA achieve levels of the force of 16,126.3 N, 16,217.8 N, and 16,161.23 N, respectively. With slot current of 781.77 A, slot height of 2.209 mm, magnet height of 36.195 mm, and slot thickness of 3.93 mm, the GWA was highly effective in locating the area of the spectrum with the least flux saturation.

To assess the robustness of the GWA, FPA, LA, and GOA over the various runs,

Figure 9 displays the box and whisker’s plot of the GWA, FPA, LA, and GOA for the TLSM design under the second case. As shown, the GWA consistently outperforms all other runs with the lowest values of the evaluated objective. To further illustrate its effectiveness,

Table 5 provides the robustness indices of the obtained fitness values of GWA, FPA, LA, and GOA. The minimum, mean, and maximum indices are all the smallest, measuring 16217.888 N, 16206.98 N, and 16199.74 N, respectively. For the standard deviation, the GWA provides the least value of 4.3, while FPA, GOA, and LA deliver counterparts of 92.96, 346.04, and 380.81, respectively. Therefore, the improvement in the standard deviation based on GWA records 96.31%, 98.74%, and 98.85% versus FPA, LA, and GOA, respectively.

Table 6 demonstrates the constraints justification based on the presented GWA for the TLSM design under the second case in comparison to the reported fruit fly algorithm in [

31]. As a result, the presented GWA guarantees all of the constraints, while the second constraint is slightly violated due to the reported fruit fly algorithm.

4.1.3. Third Case: Simultaneous Maximizing the Force and Minimizing the Flux Saturation

In the third case, the multi-objective optimization framework of the TLSM design is addressed by simultaneously minimizing the fitness functions of Equations (1) and (3). The developed MGWO, MFPA, MOLA, and MGOA are performed considering 100 search agents in the exterior repository. The corresponding Pareto fronts are depicted in

Figure 10, which illustrates the significant superiority of the developed MGWO in finding better solutions with lower saturations and higher forces in a simultaneous manner compared to the others. To quantify the hypervolume indicator for all the compared methods, a transfer mapping is carried out to the

x-axis by adding a positive value of 16,500, and so,

Figure 10 will be converted into

Figure 11 considering a reference point of (16,000,1.5).

Table 7 displays the hypervolume indicators of the developed MGWO, MFPA, MOLA, and MGOA for the TLSM design in the third case, considering various reference points. As demonstrated, the developed MGWO provides the best performance. In comparison to the MFPA, the developed MGWO provides improvement by 69.49%, 78.41%, and 72.5%, when compared to the reference points (16,000,1.5), (16,500,1.6), and (17,000,1.75), respectively. In comparison to the MOLA, the developed MGWO provides improvement by 25.08%, 17.17%, and 14.98%, respectively, with respect to the reference points. In comparison to the MGOA, the developed MGWO provides improvement by 19.05%, 13.97%, and 12.44%, respectively, with the reference points.

In addition to that, Non-dominated Sorting Genetic Algorithm II (NSGA II) is one of the most applied and successful algorithms in multi-objective optimization in engineering issues [

53,

54,

55]. It is a genetic algorithm that uses non-dominated sorting and crowding distance to find the Pareto optimal set of solutions for a multi-objective optimization problem. Therefore, a comparative assessment is extended between the proposed MGWO and NSGA II.

Figure 12 displays the regarding obtained Pareto set by both the proposed MGWO and the NSGA II.

As shown, the proposed MGWO shows higher outperformance compared to the well-known NSGA II since all their obtained solutions show significant dominance compared to their counterparts related to the NSGA II. As can be seen from

Figure 12, NSGA II is not always worse than the proposed MGWO, whereas NSGAII always provides better coverage of the PARETO front, as opposed to the gaps observed for the proposed algorithm; however, the proposed MGWO shows higher capability in finding better solutions on the basis of both objectives. The proposed MGWO shows higher capability over NSGA II in finding better solutions that are dominating the counterparts obtained by NSGA II.

Table 8 summarizes the corresponding metrics in terms of the minimum, maximum, range, mean, and standard deviation for each objective.

From this table, the proposed MGWA derives higher performance in all metric terms. For the first objective of saturation, the minimum, maximum, range, mean, and standard deviation are improved by 0.56%, 0.06%, 20.56%, 0.27%, and 13.71%, respectively. Additionally, for the second objective, the minimum, maximum, range, mean, and standard deviation are improved by 4.32%, 0.94%, 1.07%, 2.81%, and 23.91%, respectively.

4.2. Applications for Welded Beam Design

The welded beam problem formulation has four design constraints. In this problem, the manufacturing cost of the welding beam (

f1) and its deflection (

f2) should be maintained to a minimum. The four design variables are the weld thickness (

x1), clamping bar length (

x2), bar height (

x3), and bar thickness (

x4).

Figure 13 displays a WBD on a substrate [

56].

where,

The permitted ranges for the control variables are as follows: weld thickness (x1) [0.125,5] inches, clamping bar length (x2) [0.1, 10] inches, bar height (x3) [0.1, 10] inches, and bar thickness (x4) [0.125,5] inches. For the WBD problem, three different cases are investigated.

In the first and second cases, the assessment of GWA, FPA, LA, and GOA is performed considering single-objective targets for individually minimizing the manufacturing cost (f1) and the deflection (f2), respectively. In the third case, the developed MGWO, MFPA, MOLA, and MGOA are performed for the multi-objective WBD optimization.

4.2.1. First Case: Minimizing the Manufacturing Cost

In this case, GWA, FPA, LA, and GOA are applied to this case for minimizing the manufacturing cost, and their best regarding control variables and outcome fitness values are given in

Table 9. The GWA achieves the least expensive value of 1.725. This demonstrates the GWA’s superior effectiveness in locating the most cost-effective option, which is attained at a welding thickness of 0.2057 inches, clamping bar length of 3.4715 inches, bar height of 9.035 inches, and bar thickness of 0.20579 inches.

Figure 14 also depicts the best convergence curves for the GWA, FPA, LA, and GOA. GWA, FPA, LA, and GOA are starting their searches from quite high values, showing that all of the design limits have been broken. The GWA exhibits impressive speed in maintaining the inequality constraints at only 10 iterations as the iterations progress. The inequality restrictions are then successfully being addressed by GOA, FPA, and LA after 90, 160, and 185 iterations, correspondingly.

Figure 15 shows a statistical assessment of GWA, FPA, LA, and GOA for the WBD problem under the first case. In the first part, the box and whisker’s plot are plotted, which indicates that the GWA performs best across all runs with the lowest values of the evaluated objective. In the second part, the robustness indices are displayed, which declares the high resilience of the GWA since it obtains the smallest indices of 1.7252 as the minimum, 1.7258 as the mean, 1.7263 as the maximum, and 0.000299 as the standard deviation.

4.2.2. Second Case: Minimizing the Deflection

GWA, FPA, LA, and GOA are implemented in this case to reduce manufacturing costs, and their optimum control variables and outcome fitness values are provided in

Table 10. All of the strategies used successfully determine the optimal solution with a deflection value of 4.991 × 10

−7. The obtained values for bar height and bar thickness for all techniques are 10 inches and 5 inches, respectively. The differences in welding thickness and clamping bar length have no influence on the deflection target as they are functions of the other two variables as specified in Equation (25).

Figure 16 shows a statistical assessment of GWA, FPA, LA, and GOA for WBD problem under the first case. All compared techniques provide similar effective performance where the minimum, mean, and maximum are equivalent with 4.991E−07.

4.2.3. Third Case: Simultaneous Minimization of the Manufacturing Cost and Deflection

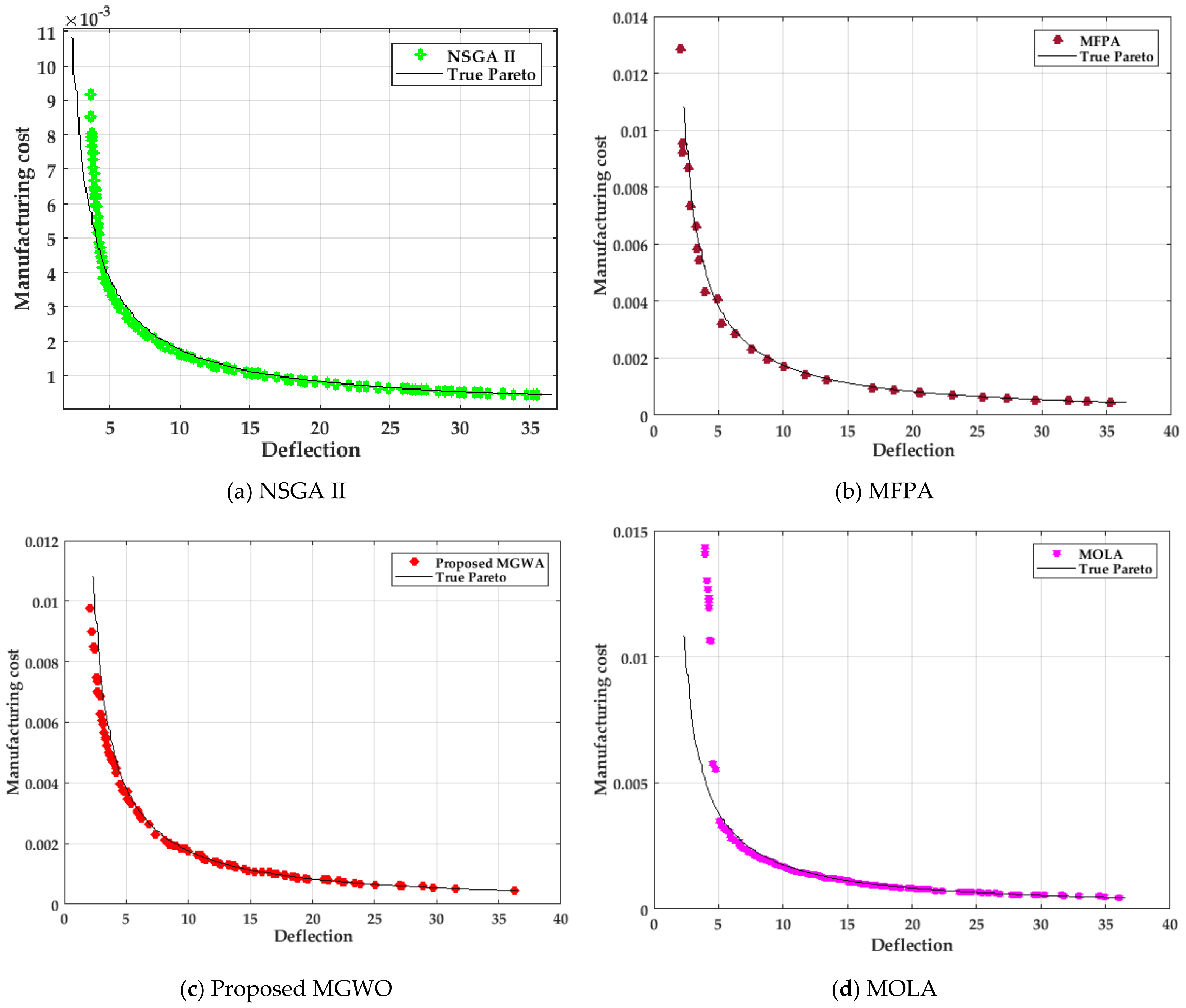

The multi-objective WBD optimization problem is studied in the third case.

Figure 17 depicts the relevant Pareto fronts for the developed MGWO, MFPA, MOLA, and MGOA using four distinct reference points.

Table 11 illustrates the hypervolume indicators of the produced MGWO, MFPA, MOLA, and MGOA for the WBD problem under the third scenario using the four reference points shown in

Figure 17. As demonstrated, the developed MGWO provides the best performance. In comparison to the MFPA, the developed MGWO improves by 2.92%, 3.969%, 1.81%, and 2.51% with reference points (40,0.01), (60,0.015), and (60,0.015), respectively. In comparison to the MGOA, the developed MGWO improves by 4.55%, 2.88%, 2.87%, and 1.85%, respectively, with the reference points. When compared to the MOLA, the developed MGWO improves by 0.983%, 0.714%, 0.615%, and 0.48%, respectively.

4.2.4. Comparative Assessment Considering Different Metrics

In this sub-section, a detailed comparative assessment considering different metrics presented in the literature, such as hypervolume, generational distance, inverted generational distance, spread, generalized-spread, and additive epsilon, considering the well-known bi-objective optimization problem of WBD, taking into account the true-Pareto front [

57].

Figure 18 displays the obtained Pareto fronts versus true fronts of the developed MGWO, NSGA II, MFPA, MOLA, and MGOA for WBD under third case whilst

Table 12 records the previous stated metrics. As shown, the proposed MGWO demonstrates greater efficiency where:

The proposed MGWO provides the greatest hypervolume indicator of 0.326 while MFPA comes second with hypervolume indicator of 0.3227;

The proposed MGWO achieves the least generational distance indicator of 0.0008, while NSGA II comes second with generational distance indicator of 0.0034;

The proposed MGWO achieves the least inverted generational distance indicator of 0.00095, while MFPA comes second with generational distance indicator of 0.00121;

In terms of the spread metric, the proposed MGWO achieves the least indicator value of 0.779, while MOLA and NSGA II come consecutively with 0.933 and 0.939, respectively;

In terms of the additive epsilon metric, the proposed MGWO achieves the least indicator value of 0.000132.

A closer accord to the comparison between the developed MGWO and NSGA II is shown in

Figure 19. As shown in the sub-plot, the developed MGWO shows higher superiority, not only in finding better solutions in dominating solutions obtained by the well-known NSGA II, but also the true pareto front.

5. Conclusions

This article suggests a developed the MGWO for the multi-objective shape design of tubular linear synchronous motors (TLSM). The multi-objective design of TLSM is handled by maximizing the operating force and minimizing the flux saturation. The developed MGWO is compared to several recent algorithms of MFPA, MOLA, and MGOA. Additionally, the validation of the developed MGWO is extended for a multi-objective form of welded beam design (WBD) by simultaneously minimizing the deflection and manufacturing costs. Moreover, considering single-objective optimization models for TLSM and WBD engineering problems, GWA, FPA, LA, and GOA are applied with a comparative assessment. The simulation results declare the superiority and effectiveness of the developed GWA over the others in achieving the single-objective minimization target. The satisfaction of all design constraints is guaranteed within their permissible limitations. A higher speed of convergence related to the employed GWA is also accompanied compared to the others. Moreover, considering the multi-objective optimization frameworks, the developed MGWO provides higher capability in acquiring non-dominated solutions with higher hypervolume indicators based on different reference points. Therefore, the developed MGWO demonstrates significant outperformance over MFPA, MOLA, and MGOA. As a result, the developed MGWO has shown promise in problem-solving capabilities when designing the TLSM and WBD. Furthermore, the proposed MGWO demonstrates greater efficiency and superiority versus true fronts of NSGA II, MFPA, MOLA, and MGOA for WBD based on different metrics presented in the literature, such as hypervolume, generational distance, inverted generational distance, spread, generalized-spread, and additive epsilon.