A Review of Compensation Topologies and Control Techniques of Bidirectional Wireless Power Transfer Systems for Electric Vehicle Applications

Abstract

:1. Introduction

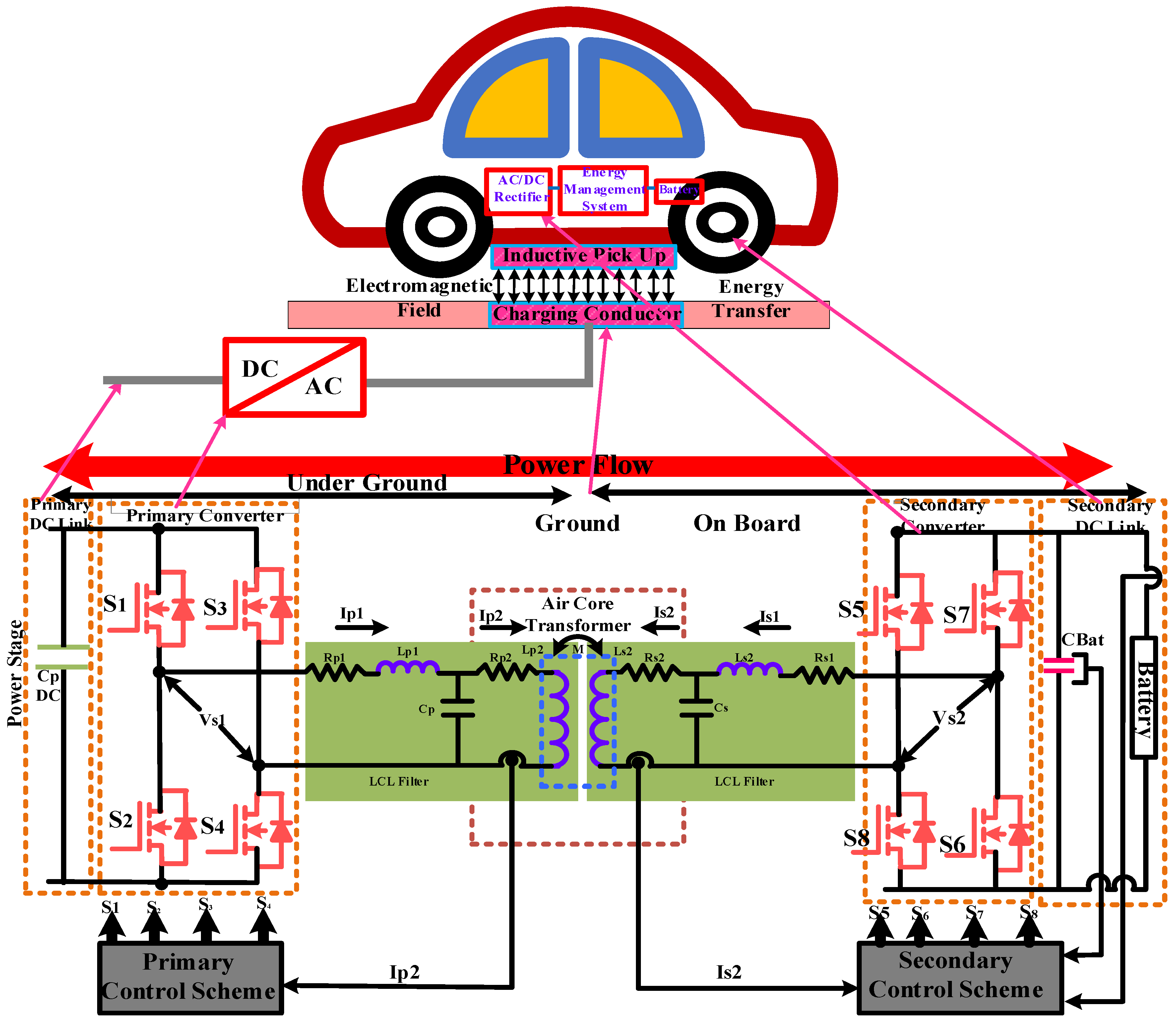

2. General Description of BWPT

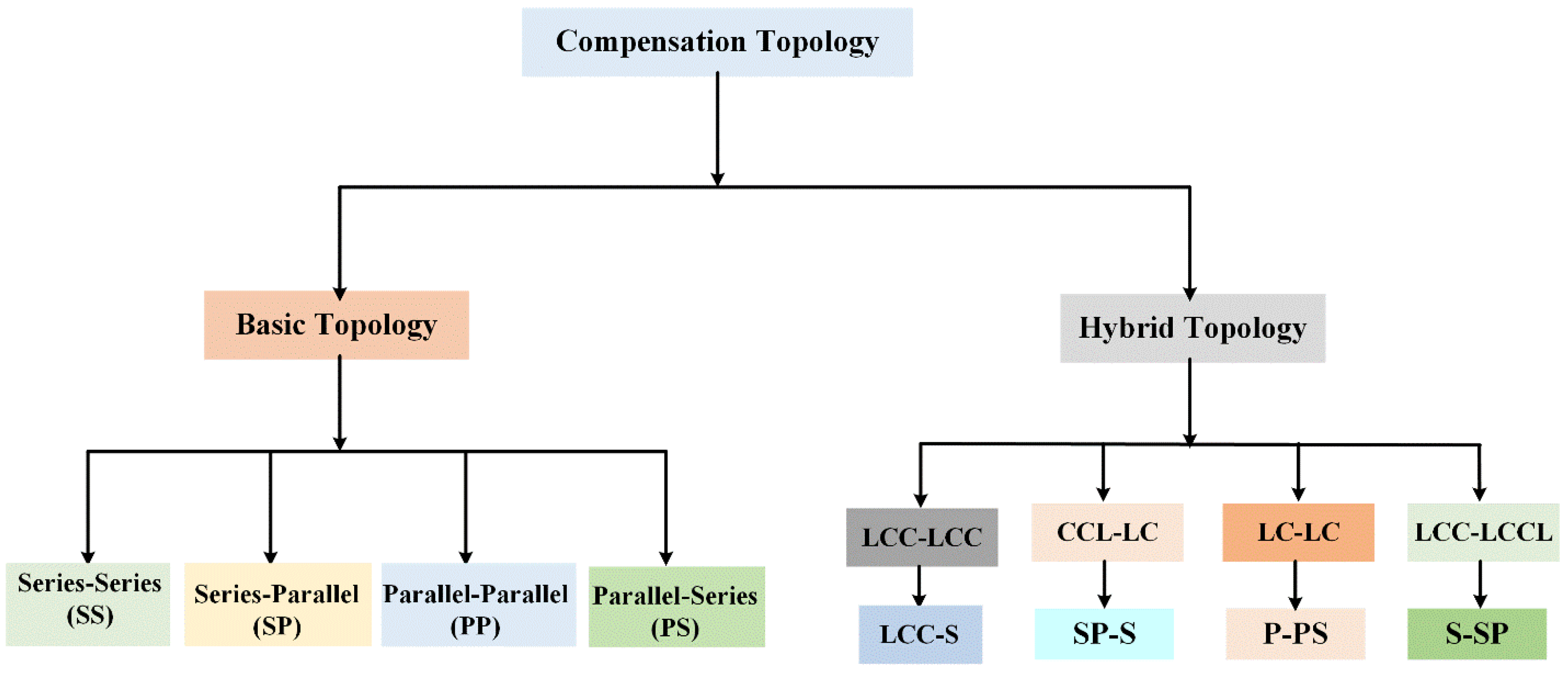

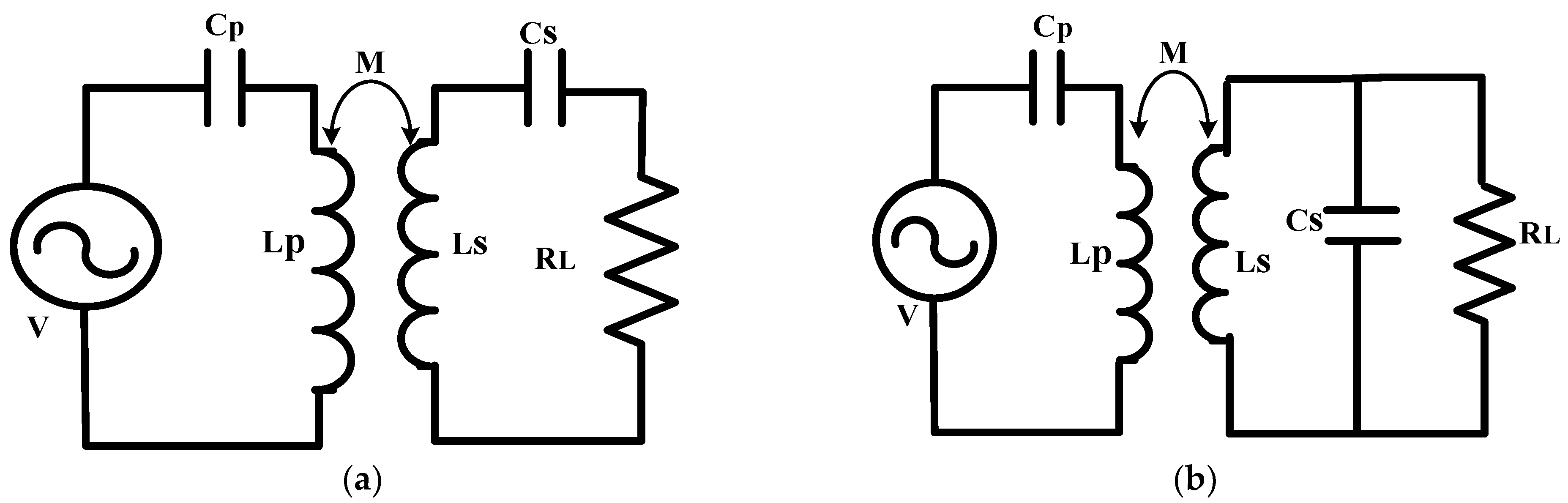

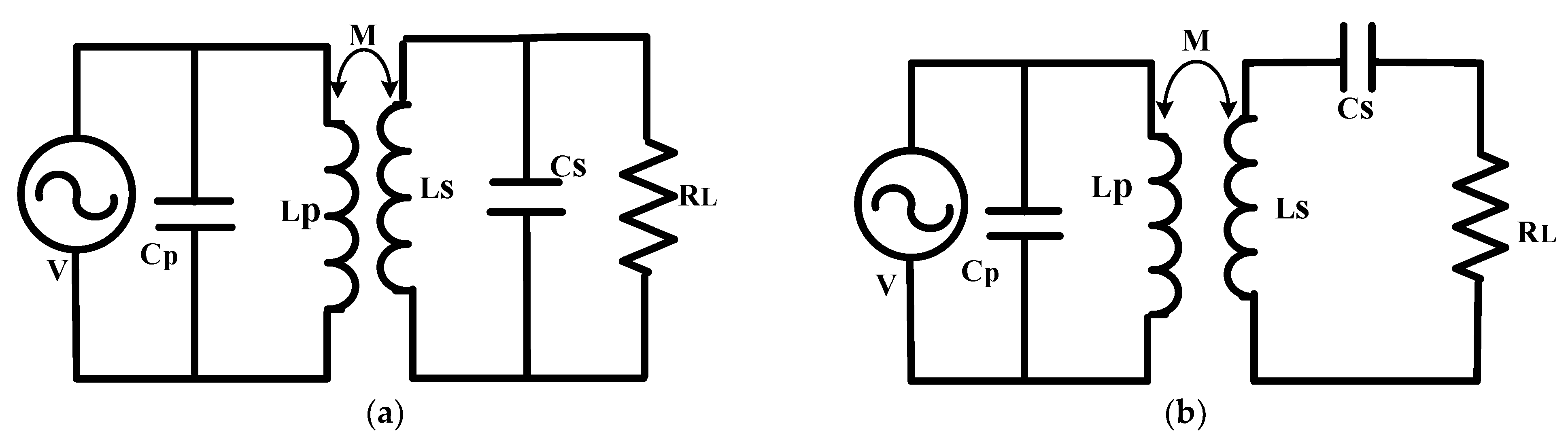

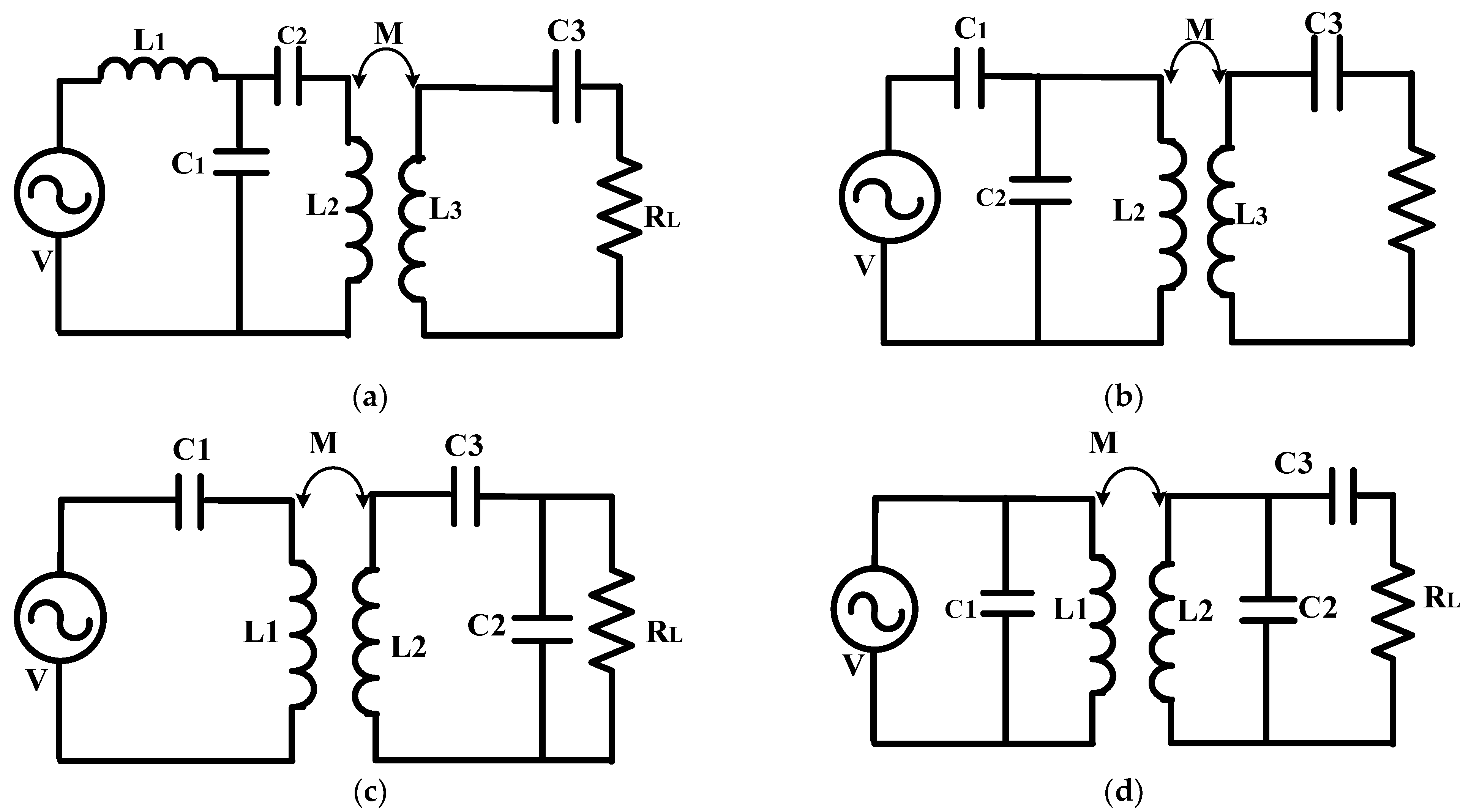

2.1. Classifications of the Compensation Topologies

2.2. Parallel–Parallel/Parallel–Series Compensation

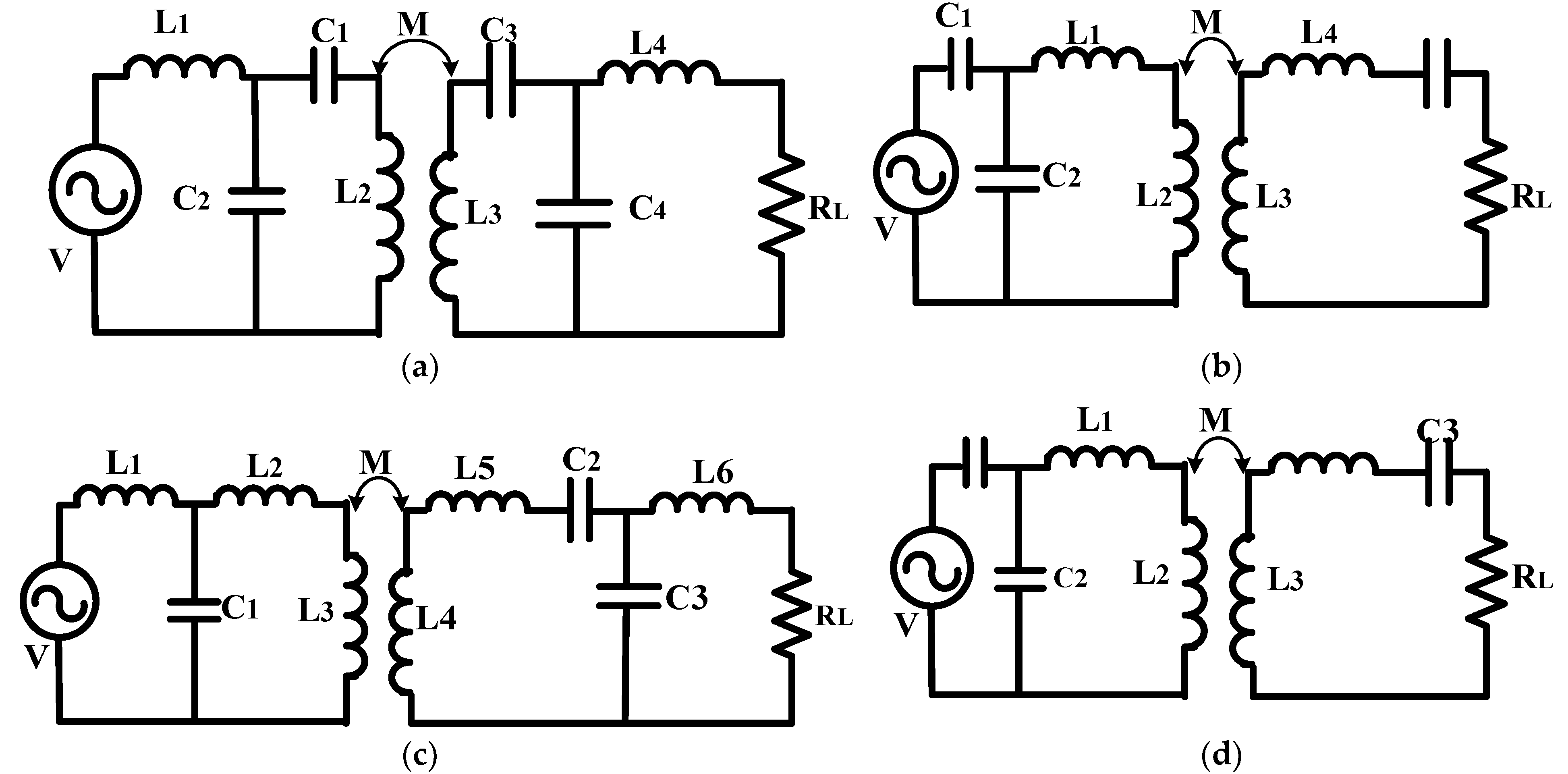

2.3. Hybrid Compensation Topology

2.4. Theoretical Analysis of Bidirectional LCL Compensation for an IPT System

3. Control Strategies for Isolated and Non-Isolated Bidirectional DC-DC Converters

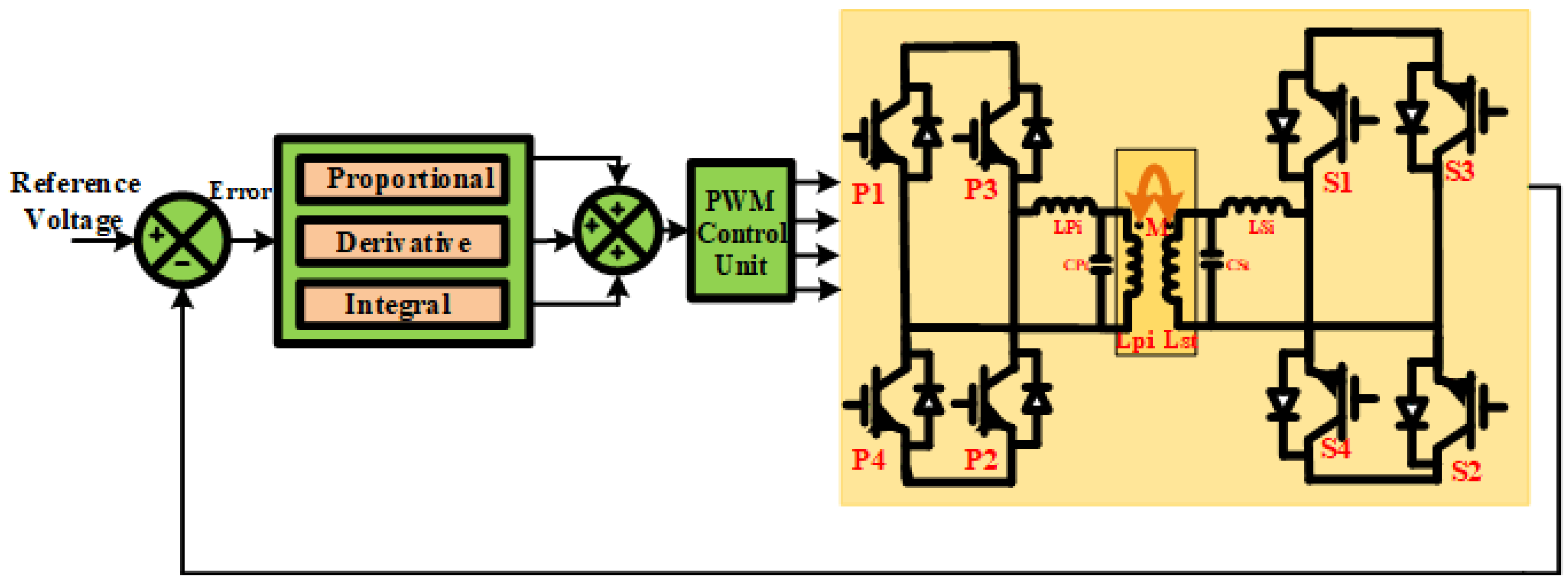

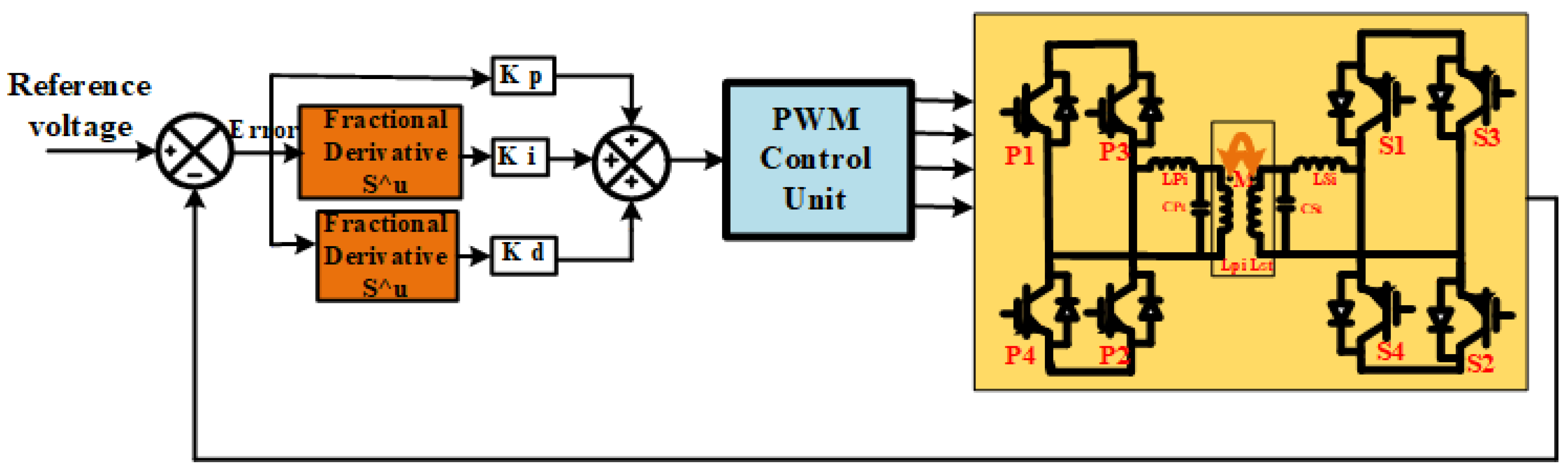

3.1. Proportional–Integral–Derivative (PID) Control

3.2. Sliding-Mode Control

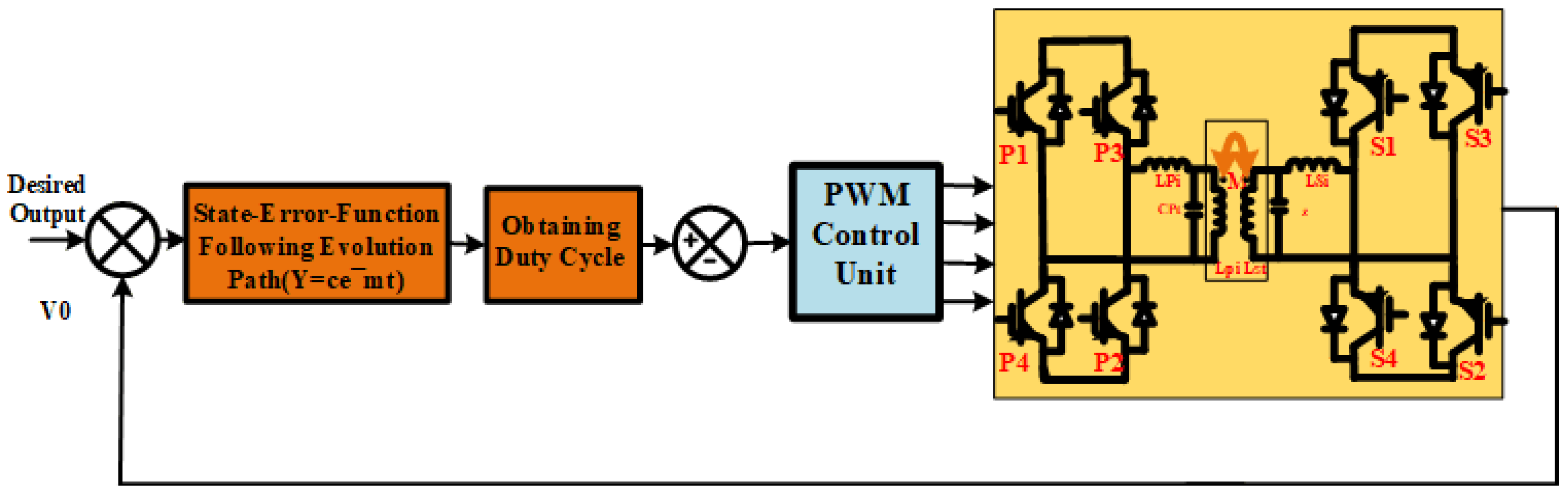

3.3. Dynamic Evolution Control

3.4. Model-Predictive Control

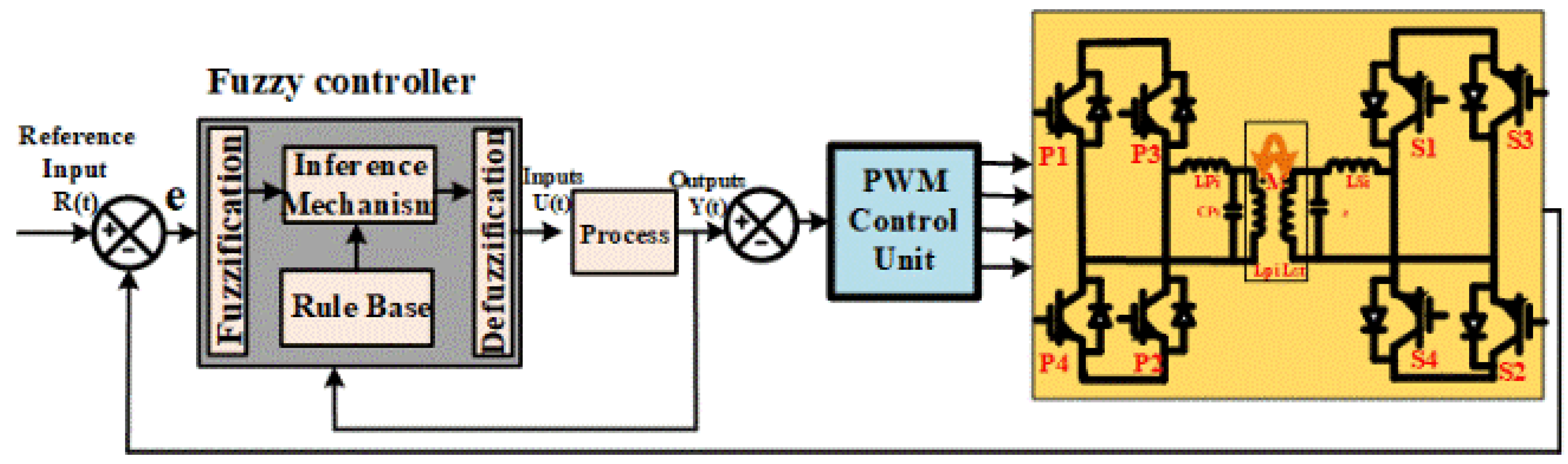

3.5. Fuzzy-Logic Control

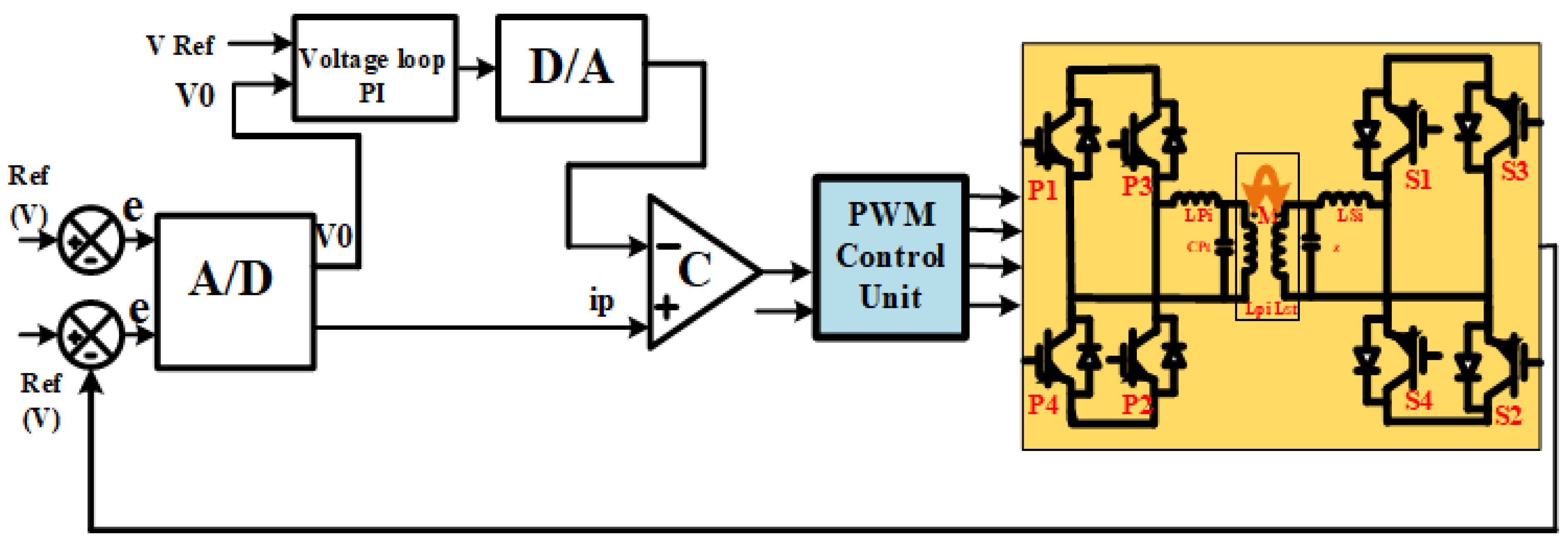

3.6. Digital Control

3.7. Boundary Control

4. Techniques for Switching Modulation Strategies of Bidirectional Dc-Dc Converters

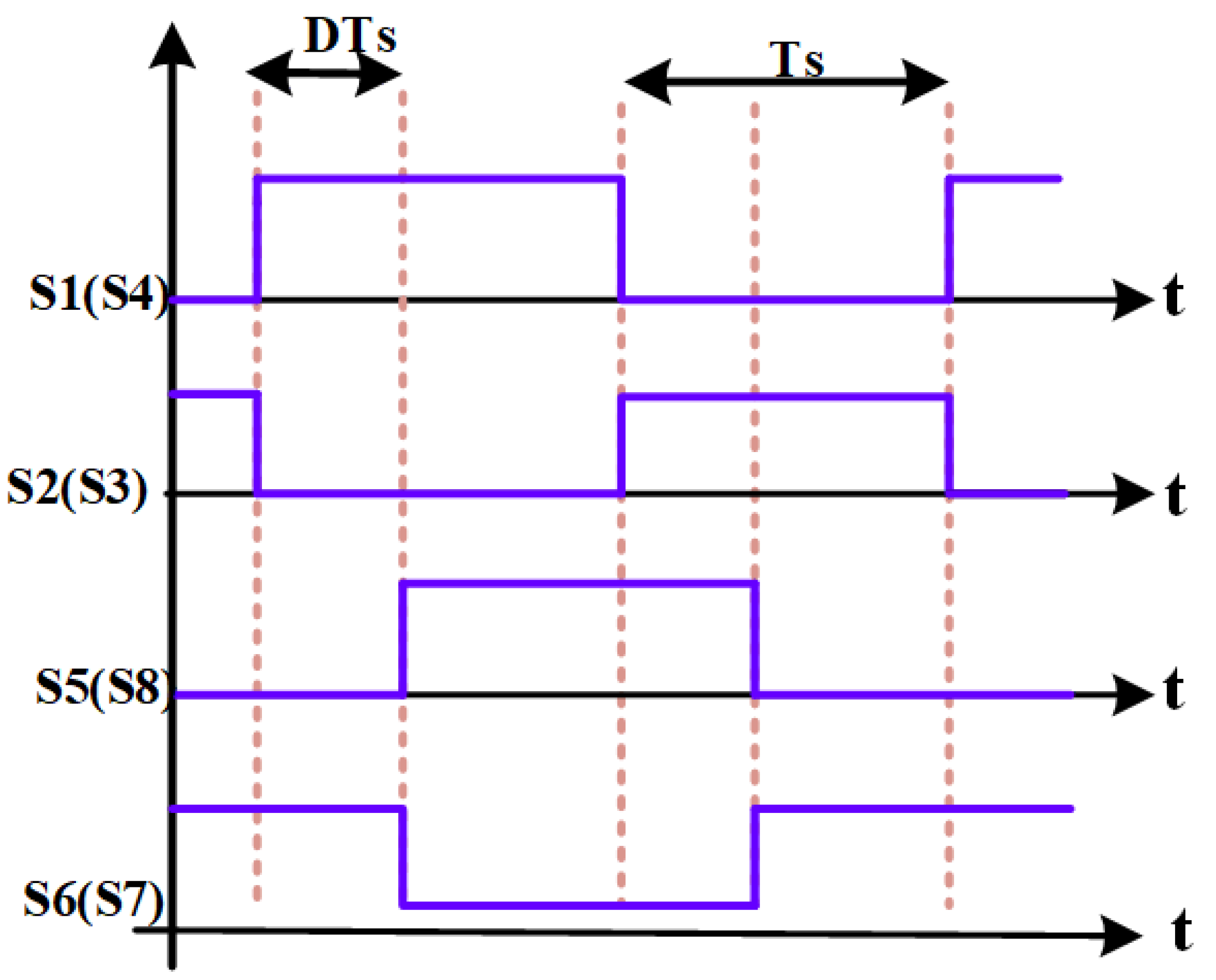

4.1. PWM Control

4.2. Single-Phase Shift Control

4.3. PWM and Phase-Shift Control

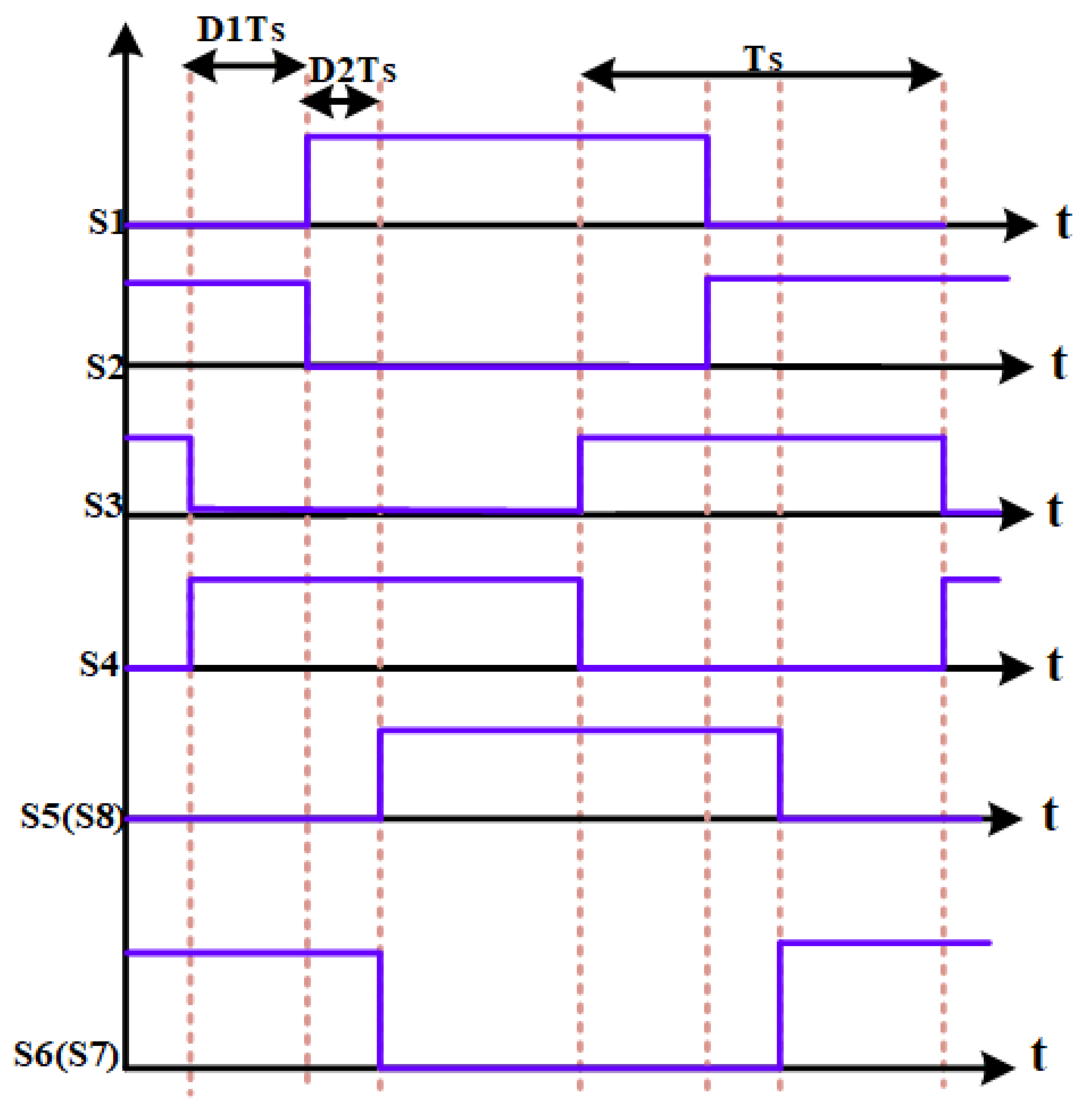

4.4. Dual-Phase Shift Modulation

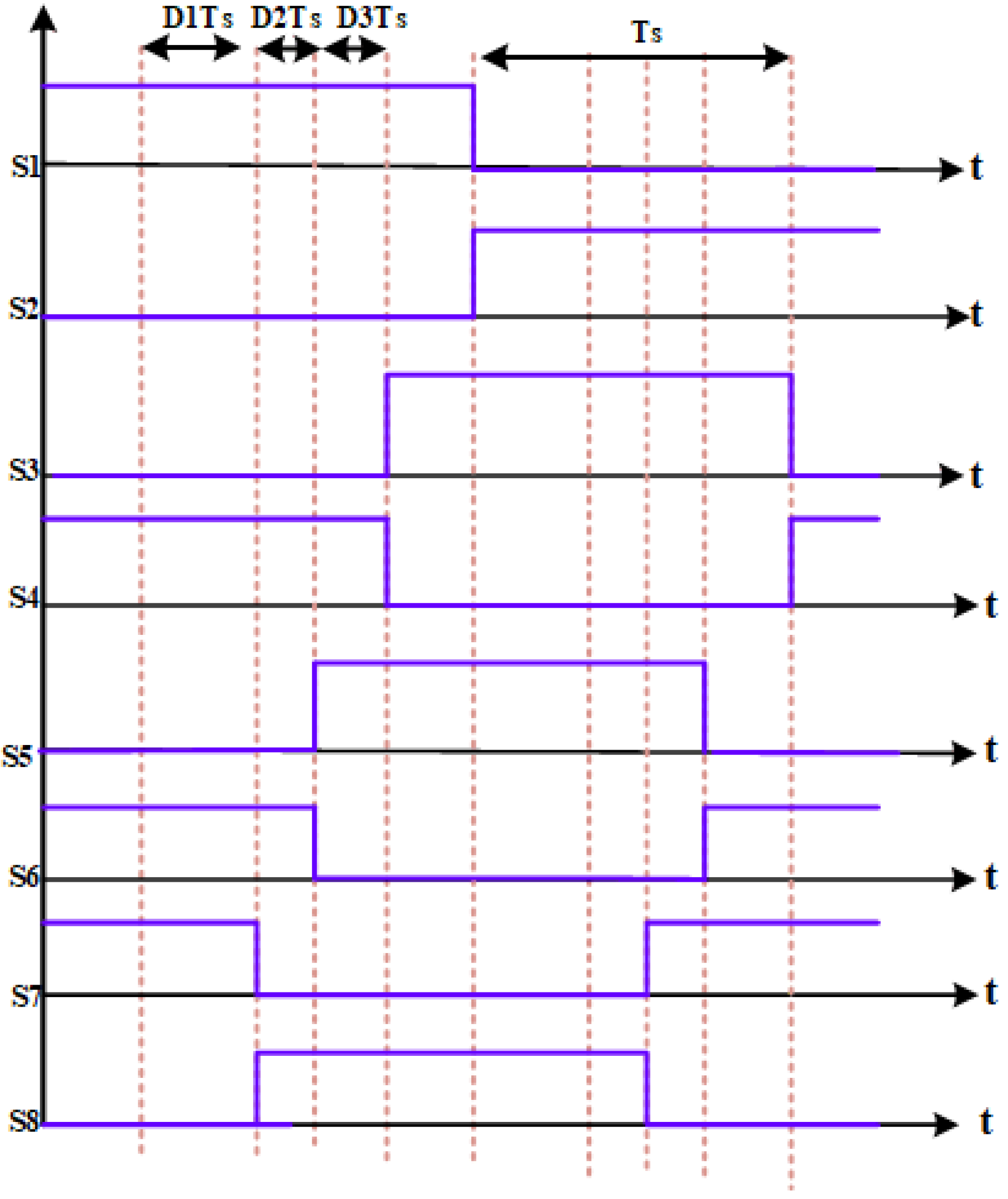

4.5. Triple-Phase Shift

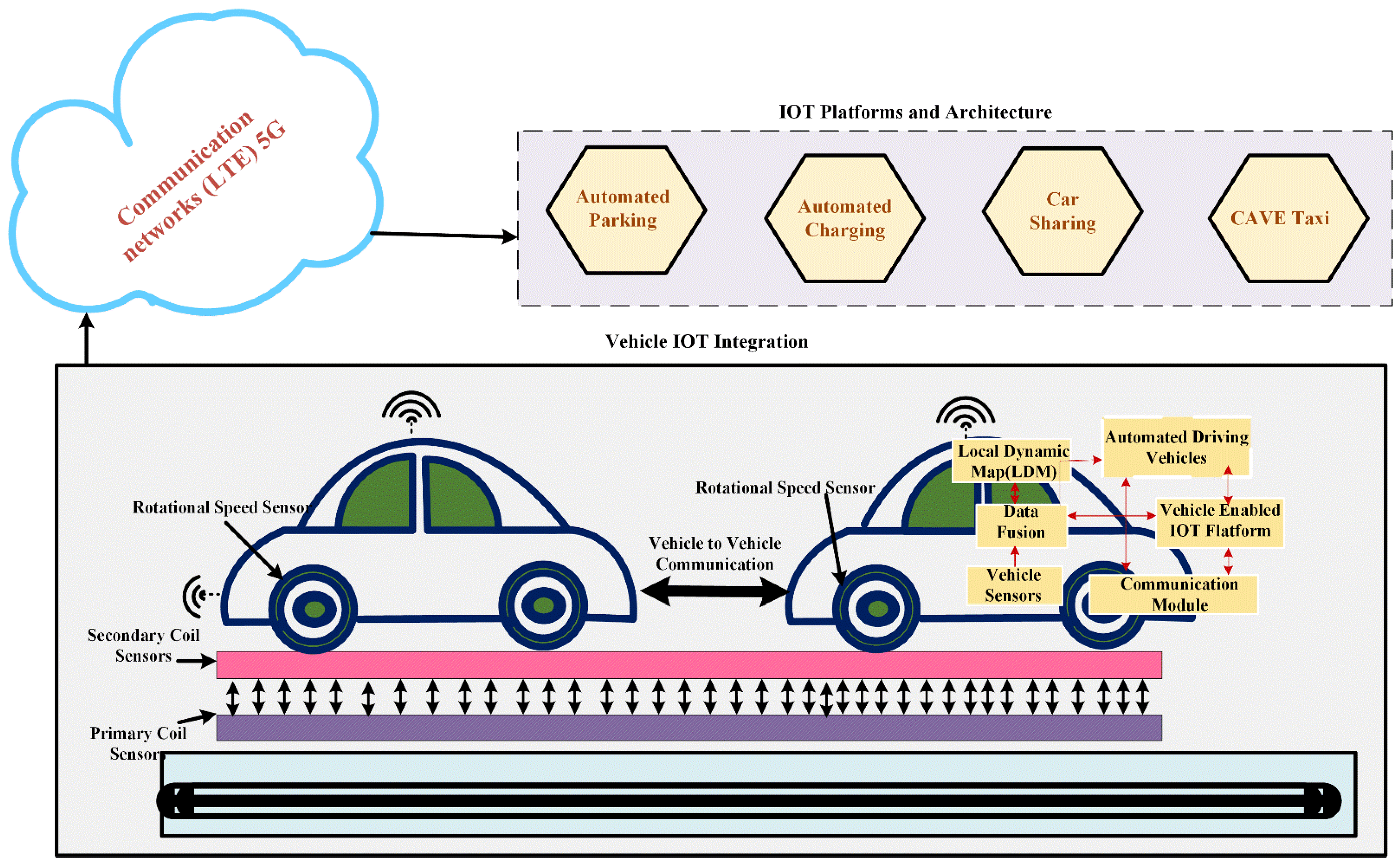

5. Internet of Things Interface in Bidirectional Wireless Power Transfer

5.1. V2G on Bidirectional Wireless Power Transfer

5.2. Strengths of V2G Technologies

5.3. Weakness of V2G Technologies

5.4. Opportunities of V2G Technologies

5.5. Benefits of V2G Technologies

5.6. Threats of V2G Technologies

6. Future Scope and Challenges of Bidirectional Wireless Power Transfer

- The design and implementation of the BDWPT system for Vehicle-To-Home applications to meet domestic power-sharing requirements.

- Using machine learning approaches to design a practical and cost-effective wireless charging pad structure with an improved power transfer rate.

- The efficient high-frequency switching converter design uses wide bandgap devices to minimise conversion losses.

- The WPT system will be used in autonomous vehicle applications so that people do not have to be involved in recharging.

- The design of a tuned/auto-tuned compensation circuit is capable of avoiding problems caused by misalignment and load variations [76].

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skouras, T.A.; Gkonis, P.K.; Llias, C.N.; Trakadas, P.T.; Tsampasis, E.G.; Zahariadis, T.V. Electrical Vehicles: Current State of the Art, Future Challenges, and Perspectives. Clean Technol. 2020, 2, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Patil, D.; McDonough, M.K.; Miller, J.M.; Fahimi, B.; Balsara, P.T. Wireless Power Transfer for Vehicular Applications: Overview and Challenges. IEEE Trans. Transp. Electrif. 2017, 4, 3–37. [Google Scholar] [CrossRef]

- Baguley, C.A.; Jayasinghe, S.G.; Madawala, U.K. Theory and Control of Wireless Power Transfer Systems. In Control of Power Electronic Converters and Systems; Elsevier: Amsterdam, The Netherlands, 2018; Volume 2, pp. 291–307. ISBN 9780128161364. [Google Scholar]

- Tang, Y.; Chen, Y.; Madawala, U.K.; Thrimawithana, D.J.; Ma, H. A New Controller for Bidirectional Wireless Power Transfer Systems. IEEE Trans Power Electron 2018, 33, 9076–9087. [Google Scholar] [CrossRef]

- The University of Buner; Institute of Electrical and Electronics Engineers. Proceedings of the 1st International Conference on Electrical, Communication and Computer Engineering (ICECCE 2019), Swat, Pakistan, 24–25 July 2019; ISBN 9781728138251.

- Mohamed, A.A.S.; BerzoyBerlin, A.; de Almeida, F.G.N.; Mohammed, O. Modeling and Assessment Analysis of Various Compensation Topologies in Bidirectional IWPT System for EV Applications. IEEE Trans. Ind. Appl. 2017, 53, 4973–4984. [Google Scholar] [CrossRef]

- Wen, F.; Chu, X.; Li, Q.; Gu, W. Compensation Parameters Optimization of Wireless Power Transfer for Electric Vehicles. Electronics 2020, 9, 789. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A Double-Sided LCC Compensation Network and Its Tuning Method for Wireless Power Transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Nayak, P.S.R.; Kishan, D. Performance Analysis of Series/Parallel and Dual Side LCC Compensation Topologies of Inductive Power Transfer for EV Battery Charging System. Front. Energy 2020, 14, 166–179. [Google Scholar] [CrossRef]

- Gorji, S.A.; Sahebi, H.G.; Ektesabi, M.; Rad, A.B. Topologies and Control Schemes of Bidirectional DC–DCDC-DC Power Converters: An Overview. IEEE Access 2019, 7, 117997–118019. [Google Scholar] [CrossRef]

- González-González, J.M.; Triviño-Cabrera, A.; Aguado, J.A. Design and Validation of a Control Algorithm for a SAE J2954-Compliant Wireless Charger to Guarantee the Operational Electrical Constraints. Energies 2018, 11, 604. [Google Scholar] [CrossRef] [Green Version]

- Ahire, D.B.; Gond, V.J.; Chopade, J.J. Compensation topologies for wireless power transmission system in medical implant applications: A review. Biosens. Bioelectron. X 2022, 11, 100180. [Google Scholar] [CrossRef]

- Aydin, E.; Aydemir, M.T.; Aksoz, A.; el Baghdadi, M.; Hegazy, O. Inductive Power Transfer for Electric Vehicle Charging Applications: A Comprehensive Review. Energies 2022, 15, 4962. [Google Scholar] [CrossRef]

- Niu, S.; Xu, H.; Sun, Z.; Shao, Z.Y.; Jian, L. The State-of-the-Arts of Wireless Electric Vehicle Charging via Magnetic Resonance: Principles, Standards, and Core Technologies. Renew. Sustain. Energy Rev. 2019, 114, 109302. [Google Scholar] [CrossRef]

- Zhang, W.; Mi, C.C. Compensation Topologies of High-Power Wireless Power Transfer Systems. IEEE Trans. Veh. Technol. 2016, 65, 4768–4778. [Google Scholar] [CrossRef]

- Ota, R.; Hoshi, N.; Haruna, J. Design of Compensation Capacitor in S/P Topology of Inductive Power Transfer System with Buck or Boost Converter on Secondary Side. IEEJ J. Ind. Appl. 2015, 4, 476–485. [Google Scholar] [CrossRef] [Green Version]

- Sohn, Y.H.; Choi, B.H.; Lee, E.S.; Lim, G.C.; Cho, G.H.; Rim, C.T. General Unified Analyses of Two-Capacitor Inductive Power Transfer Systems: Equivalence of Current-Source SS and SP Compensations. IEEE Trans. Power Electron. 2015, 30, 6030–6045. [Google Scholar] [CrossRef]

- Shevchenko, V.; HusevGusev, O.; Strzelecki, R.; Pakhaliuk, B.; Poliakov, N.; Strzelecka, N. Compensation Topologies in IPT Systems: Standards, Requirements, Classification, Analysis, Comparison, and Application. IEEE Access 2019, 7, 120559–120580. [Google Scholar] [CrossRef]

- Houran, M.A.; Yang, X.; Chen, W. Magnetically Coupled Resonance Wpt: Review of Compensation Topologies, Resonator Structures with Misalignment, and Emi Diagnostics. Electronics 2018, 7, 296. [Google Scholar] [CrossRef] [Green Version]

- Fu, M.; Tang, Z.; Ma, C. Analysis and Optimized Design of Compensation Capacitors for a Megahertz WPT System Using Full-Bridge Rectifier. IEEE Trans. Ind. Inf. 2019, 15, 95–104. [Google Scholar] [CrossRef]

- Zou, X.; He, X.; Lan, J. Analysis of Compensation Topology of Magnetically Coupled Wireless Energy. In Proceedings of the 2020 IEEE 1st China International Youth Conference on Electrical Engineering, CIYCEE 2020, Wuhan, China, 1 November 2020. [Google Scholar]

- Alam, M.M.; Mekhilef, S.; Bassi, H.; Rawa, M.J.H. Analysis of LC-LC2 Compensated Inductive Power Transfer for High Efficiency and Load Independent Voltage Gain. Energies 2018, 11, 2883. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Zhao, H.; Li, S.; Deng, J.; Kan, T.; Mi, C.C. Integrated LCC Compensation Topology for Wireless Charger in Electric and Plug-in Electric Vehicles. IEEE Trans. Ind. Electron. 2015, 62, 4215–4225. [Google Scholar] [CrossRef]

- Mohamed, A.A.S.; ShaierShazier, A.A.; Metwally, H.; Selem, S.I. An Overview of Dynamic Inductive Charging for Electric Vehicles. Energies 2022, 15, 5613. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.; Liu, X.; Xu, D. S/CLC Compensation Topology Analysis and Circular Coil Design for Wireless Power Transfer. IEEE Trans. Transp. Electrif. 2017, 3, 496–507. [Google Scholar] [CrossRef]

- Hou, J.; Chen, Q.; Ren, X.; Ruan, X.; Wong, S.C.; Tse, C.K. Precise Characteristics Analysis of Series/Series-Parallel Compensated Contactless Resonant Converter. IEEE J. Emerg. Sel. Top Power Electron. 2015, 3, 101–110. [Google Scholar] [CrossRef]

- Hossain, A.; Darvish, P.; Mekhilef, S.; Tey, K.S.; Tong, C.W. A New Coil Structure of Dual Transmitters and Dual Receivers with Integrated Decoupling Coils for Increasing Power Transfer and Misalignment Tolerance of Wireless EV Charging System. IEEE Trans. Ind. Electron. 2022, 69, 7869–7878. [Google Scholar] [CrossRef]

- Farias Martins, L. Modelling and Analysis of DC-DC Converters for Bidirectional EV Charging Applications; University of Sheffield: Sheffield, UK, 2019. [Google Scholar]

- Alhurayyis, I.; Elkhateb, A.; Morrow, J. Isolated and Non-isolated DC-to-DC Converters for Medium-Voltage DC Networks: A Review. IEEE J. Emerg. Sel. Top Power Electron. 2021, 9, 7486–7500. [Google Scholar] [CrossRef]

- Neath, M.J.; Swain, A.K.; Madawala, U.K.; Thrimawithana, D.J. An Optimal PID Controller for a Bidirectional Inductive Power Transfer System Using Multiobjective Genetic Algorithm. IEEE Trans. Power Electron. 2014, 29, 1523–1531. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Y.; Park, S.J.; Kim, D.H. A Family of Bidirectional DC-DC Converters for Battery Storage System with High Voltage Gain. Energies 2019, 12, 1289. [Google Scholar] [CrossRef] [Green Version]

- Araiza, A.T.; Medina, J.L.M. Variable Structure with Sliding Mode Controls for DC Motors. In Proceedings of the International Power Electronics Congress—CIEP, San Luis Potosi, Mexico, 16–19 October 1995; pp. 26–29. [Google Scholar]

- MartmezMartinez-Salamero, L.; Calvente, J.; Giral, R.; Poveda, A.; Fossas, E. Analysis of a Bidirectional Coupled-Inductor Cuk Converter Operating in Sliding Mode. IEEE Trans. Circuits Syst. Fundam. Theory Appl. 1998, 45, 355–363. [Google Scholar] [CrossRef]

- Morel, C.; Guignard, J.-C.; Guillet, M. Sliding Mode Control of DC-to-DC Power Converters. In Proceedings of the 9th International Conference on Electronics, Circuits and Systems, Dubrovnik, Croatia, 15–18 September 2002. [Google Scholar]

- Romero, A.; Martinez-Salamero, L.; Valderrama, H.; Pallas, O.; Alarcon, E. General Purpose Sliding-Mode Controller for Bidirectional Switching Converters. In Proceedings of the 1998 IEEE International Symposium on Circuits and Systems (ISCAS), Monterey, CA, USA, 31 May–3 June 1998; Volume 6, pp. 466–469. [Google Scholar]

- Agarwal, A.; Deekshitha, K.; Singh, S.; Fulwani, D. Sliding Mode Control of a Bidirectional DC/DC Converter with Constant Power Load. In Proceedings of the 2015 IEEE First International Conference on DC Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 287–292. [Google Scholar]

- Samosir, A.S.; Yatim, A.H.M. Implementation of Dynamic Evolution Control of Bidirectional DC-DC Converter for Interfacing Ultracapacitor Energy Storage to Fuel-Cell System. IEEE Trans. Ind. Electron. 2010, 57, 3468–3473. [Google Scholar] [CrossRef]

- Pirooz, A.; Noroozian, R. Model Predictive Control of Classic Bidirectional DC-DC Converter for Battery Applications. In Proceedings of the 2016 7th Power Electronics and Drive Systems Technologies Conference (PEDSTC), Tehran, Iran, 16–18 February 2016; pp. 517–522. [Google Scholar]

- Ebad, M.; Song, B.M. Accurate Model Predictive Control of Bidirectional DC-DC Converters for DC Distributed Power Systems. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012. [Google Scholar]

- Tsai-Fu, W.; Chang, C.H.; Chen, Y.K. A Fuzzy-Logic-Controlled Single-Stage Converter for Pv-Powered Lighting System Applications. IEEE Trans. Ind. Electron. 2000, 47, 287–296. [Google Scholar] [CrossRef]

- Jabbour, N.; Mademlis, C.; Kioskeridis, I. Improved Performance in a Supercapacitor-Based Energy Storage Control System with Bidirectional DC-DC Converter for Elevator Motor Drives. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014. [Google Scholar]

- Ferreira, A.A.; Pomilio, J.A.; Spiazzi, G.; de Araujo Silva, L. Energy Management Fuzzy Logic Supervisory for Electric Vehicle Power Supplies System. IEEE Trans. Power Electron. 2008, 23, 107–115. [Google Scholar] [CrossRef]

- Adam, K.B.; Ashari, M. Design of Bidirectional Converter Using Fuzzy Logic Controller to Optimise Battery Performance in Electric Vehicle. In Proceedings of the 2015 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 20–21 May 2015; pp. 201–205. [Google Scholar]

- Lakshmi Narayana, R.; Sreeramulu Mahesh, G.; Cheepati, K.R.; Yuvaraj, T. A Fuzzy Logic Based Controller for the Bidirectional Converter in an Electric Vehicle. Int. J. Eng. Adv. Technol. 2019, 9, 58–62. [Google Scholar] [CrossRef]

- Thummala, P.; Maksimovic, D.; Zhang, Z.; Andersen, M.A.E. Digital Control of a High-Voltage (2.5 KVVK) Bidirectional DC-DC Flyback Converter for Driving a Capacitive Incremental Actuator. IEEE Trans. Power Electron. 2016, 31, 8500–8516. [Google Scholar] [CrossRef] [Green Version]

- Jung, J.H.; Kim, H.S.; Ryu, M.H.; Baek, J.W. Design Methodology of Bidirectional CLLC Resonant Converter for High-Frequency Isolation of DC Distribution Systems. IEEE Trans. Power Electron. 2013, 28, 1741–1755. [Google Scholar] [CrossRef]

- Babazadeh, A.; Maksimović, D. Hybrid Digital Adaptive Control for Fast Transient Response in Synchronous Buck DC-DC Converters. IEEE Trans. Power Electron. 2009, 24, 2625–2638. [Google Scholar] [CrossRef]

- Krismer, F.; Kolar, J.W. Accurate Small-Signal Model for the Digital Control of an Automotive Bidirectional Dual Active Bridge. IEEE Trans. Power Electron. 2009, 24, 2756–2768. [Google Scholar] [CrossRef]

- Leung, K.K.S.; Chung, H.S.H. Derivation of a Second-Order Switching Surface in the Boundary Control of Buck Converters. IEEE Power Electron. Lett. 2004, 2, 63–67. [Google Scholar] [CrossRef]

- Galvez, J.M.; Ordonez, M.; Luchino, F.; Quaicoe, J.E. Improvements in Boundary Control of Boost Converters Using the Natural Switching Surface. IEEE Trans. Power Electron. 2011, 26, 3367–3376. [Google Scholar] [CrossRef]

- Onwuchekwa, C.N.; Kwasinski, A. Analysis of Boundary Control for Buck Converters with Instantaneous Constant-Power Loads. IEEE Trans. Power Electron. 2010, 25, 2018–2032. [Google Scholar] [CrossRef]

- Mumtaz, F.; Zaihar Yahaya, N.; Tanzim Meraj, S.; Singh, B.; Kannan, R.; Ibrahim, O. Review on Non-Isolated DC-DC Converters and Their Control Techniques for Renewable Energy Applications. Ain Shams Eng. J. 2021, 12, 3747–3763. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Faisal, M.; Ansari, S.; Hannan, M.A.; Karim, T.F.; Ayob, A.; Hussain, A.; Miah, M.S.; Saad, M.H.M. Review of Electric Vehicle Converter Configurations, Control Schemes and Optimisations: Challenges and Suggestions. Electronics 2021, 10, 477. [Google Scholar] [CrossRef]

- Anbazhagan, L.; Ramiah, J.; Krishnaswamy, V.; Jayachandran, D.N. A Comprehensive Review on Bidirectional Traction Converter for Electric Vehicles. Int. J. Electron. Telecommun. 2019, 65, 635–649. [Google Scholar]

- Xu, D.; Zhao, C.; Fan, H. A PWM plus Phase-Shift Control Bidirectional Dc-Dc Converter. IEEE Trans. Power Electron. 2004, 19, 666–675. [Google Scholar] [CrossRef]

- Xiao, H.; Xie, S. A ZVS Bidirectional DC-DC Converter with Phase-Shift plus PWM Control Scheme. IEEE Trans. Power Electron. 2008, 23, 813–823. [Google Scholar] [CrossRef]

- Li, S.; Xiangli, K.; Smedley, K.M. A Control Map for a Bidirectional PWM Plus Phase-Shift-Modulated Push-Pull DC-DC Converter. IEEE Trans. Ind. Electron. 2017, 64, 8514–8524. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Li, H. Asymmetrical Duty Cycle Control and Decoupled Power Flow Design of a Three-Port Bidirectional DC-DC Converter for Fuel Cell Vehicle Application. IEEE Trans. Power Electron. 2012, 27, 891–904. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, Q.; Sun, W. Extended-Phase-Shift Control of Isolated Bidirectional DC-DC Converter for Power Distribution in Microgrid. IEEE Trans. Power Electron. 2012, 27, 4667–4680. [Google Scholar] [CrossRef]

- Zhao, B.; Song, Q.; Liu, W. Power Characterization of Isolated Bidirectional Dual-Active-Bridge Dc-Dc Converter with Dual-Phase-Shift Control. IEEE Trans. Power Electron. 2012, 27, 4172–4176. [Google Scholar] [CrossRef]

- Wu, K.; de Silva, C.W.; Dunford, W.G. Stability Analysis of Isolated Bidirectional Dual Active Full-Bridge DC-DC Converter with Triple Phase-Shift Control. IEEE Trans. Power Electron. 2012, 27, 2007–2017. [Google Scholar] [CrossRef]

- Harrye Harry, Y.A.; Ahmed, K.H.; Adam, G.P.; Aboushady, A.A. Comprehensive Steady State Analysis of Bidirectional Dual Active Bridge DC/DC Converter Using Triple Phase Shift Control. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014; pp. 437–442. [Google Scholar]

- Rana, M.M.; Xiang, W.; Wang, E.; Li, X.; Choi, B.J. Internet of Things Infrastructure for Wireless Power Transfer Systems. IEEE Access 2018, 6, 19295–19303. [Google Scholar] [CrossRef]

- Reka, S.S.; Dragicevic, T. Future Effectual Role of Energy Delivery: A Comprehensive Review of Internet of Things and Smart Grid. Renew. Sustain. Energy Rev. 2018, 91, 90–108. [Google Scholar] [CrossRef]

- Taiebat, M.; Xu, M. Synergies of Four Emerging Technologies for Accelerated Adoption of Electric Vehicles: Shared Mobility, Wireless Charging, Vehicle-to-Grid, and Vehicle Automation. J. Clean. Prod. 2019, 230, 794–797. [Google Scholar] [CrossRef]

- Sassi, H.B.; Errahimi, F.; Essbai, N.; Alaoui, C. V2G and Wireless V2G concepts: State ofthe Art and Current Challenges. In Proceedings of the IEEE Staff 2019 International Conference on Wireless Technologies, Embedded, and Intelligent Systems (WITS), Fez, Morocco, 3–4 April 2019; ISBN 9781538678503. [Google Scholar]

- Yilmaz, M.; Krein, P.T. Review of the Impact of Vehicle-to-Grid Technologies on Distribution Systems and Utility Interfaces. IEEE Trans. Power Electron. 2013, 28, 5673–5689. [Google Scholar] [CrossRef]

- Goel, S.; Sharma, R.; Rathore, A.K. A Review on Barrier and Challenges of Electric Vehicle in India and Vehicle to Grid Optimisation. Transp. Eng. 2021, 4, 100057. [Google Scholar] [CrossRef]

- Vadi, S.; Bayindir, R.; Colak, A.M.; Hossain, E. A Review on Communication Standards and Charging Topologies of V2G and V2H Operation Strategies. Energies 2019, 12, 3748. [Google Scholar] [CrossRef] [Green Version]

- Tuttle, D.P.; Baldick, R. The Evolution of Plug-in Electric Vehicle-Grid Interactions. IEEE Trans. Smart Grid. 2012, 3, 500–505. [Google Scholar] [CrossRef] [Green Version]

- Ravi, S.S.; Aziz, M. Utilization of Electric Vehicles for Vehicle-to-Grid Services: Progress and Perspectives. Energies 2022, 15, 589. [Google Scholar] [CrossRef]

- Noel, L.; Zarazua, G.; Rubens, D.E.; Kester, J.; Sovacool, B.K. Vehicle-to-Grid A Sociotechnical Transition Beyond Electric Mobility; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Vehicle-to-Grid (V2G): Everything You Need to Know. Available online: https://www.virta.global/vehicle-to-grid-v2g (accessed on 30 June 2022).

- Park, L.; Jeong, S.; Lakew, D.S.; Kim, J.; Cho, S. New Challenges of Wireless Power Transfer and Secured Billing for Internet of Electric Vehicles. IEEE Commun. Mag. 2019, 57, 118–124. [Google Scholar] [CrossRef]

- Zhang, B.; Carlson, R.B.; Smart, J.G.; Dufek, E.J.; Liaw, B. Challenges of Future High Power Wireless Power Transfer for Light-Duty Electric Vehicles—Technology and Risk Management. eTransportation 2019, 2, 100012. [Google Scholar] [CrossRef]

- Mayordomo, I.; Drager, T.; Spies, P.; Bernhard, J.; Pflaum, A. An Overview of Technical Challenges and Advances of Inductive Wireless Power Transmission. Proc. IEEE 2013, 101, 1302–1311. [Google Scholar] [CrossRef]

| Topology | The Total Impedance on the Primary Side | Output Characteristics |

|---|---|---|

| SS [6] | ||

| SP [7] | ||

| PS [6,12] | ||

| PP [12] |

| Topologies | SS. [12,20] | SP [14,18] | PS. [12,18] | PP. [12,14,18] | |

|---|---|---|---|---|---|

| Parameter | |||||

| Impedance affects the R load and the coupling coefficient. | Primary | Yes | Yes | No | No |

| Secondary | Yes | No | Yes | No | |

| Allowance for no coupling | Not Permitted | Permitted | Permitted | Permitted | |

| Total impedance | Reductions through misalignment | Decreases with misalignment | Rises with misalignment | Misalignment increases | |

| Responsiveness to imbalance of coils | Small | Slightly higher than SS | Rise | High | |

| Voltage ratings of inverter devices | DC link voltage is less (but less than SP) | Reduce the DC link voltage | In comparison to SS and SP, considerably higher power is required | In comparison to SS and SP, considerably higher power is required | |

| Purpose of low-power applications | Inferior to Parallel | Superior to Series | Inferior to Parallel | Superior to Series | |

| Regardless of load output | Voltage and current | Voltage and current | Only voltage | Only current | |

| Disadvantages | The load and resonance frequency has no impact on the output current. At frequencies greater than 1 MHz, efficiency and transmitted power are higher than in SP. | It necessitates a much lower self-inductance receiver coil than SS. The constant current is applied via the simultaneous secondary resonance circuit. | No data | No data | |

| Limitations | Load dependence of the voltage transfer ratio during the partial load state. Self-inductances of receiver coils must be higher than SP. | Due to a lack of a DC component, there is a blockage. | To avoid sudden voltage shifts, continuous input current is required. | They decreased the power factor. On the Parallel secondary, there is a high load voltage. The Parallel primary has a lot of current source requirements. | |

| Applications for consideration | WPT stationary and dynamic charger for EVs | Applications involving biomedical and low-power transportation | It requires a significant amount of power, such as buses and EVs. | High-power applications such as EVs and buses. | |

| Configuration | LCL Adjustment [15,18] | SP/ [15,18] | S/SP [15,18] | LCC and Modifications [15,18] | |

|---|---|---|---|---|---|

| Parameter | |||||

| Integrating supplementary components | Dual inductances | Single capacitor | One capacitor is used. | One inductor and one capacitor are used. | |

| Valuation and dimensions | Higher | Not great at all | Not extremely high | Smaller in size and cost | |

| Advantage | They are achieving exceptional performance throughout the pairing and load-in processes. The Quality Factor (Q) and Volt Ampere (VA) are decreased due to high efficiency at short voltage. | Regarding high misalignment, the output power could be maintained. It has a much greater positive tolerance than the traditional SS strategy. | The parameter remains independent of load changes or coupling coefficients. Under a broad range of parameter adjustments, there is a lower circuiting loss than SP. | The operation can be accomplished by both ZCA and ZPA, simultaneously, irrespective of the loading conditions and the coupling ratio. Tolerances for high misalignment. | |

| Drawbacks | The load’s genuine and fictitious components are included in the primary side impedance. | Recompenses for secondary series disadvantages are integrated. | No data | More composite fine-tuning | |

| Recommended applications | The WPT charger is used for Electric Vehicle applications. | Techniques involving charging mobile phone batteries | Numerous applications for high-power applications | EV high-frequency WPT applications Configuration for inter-load WPT LCC SP compensation | |

| Control Systems | Control Difficulties | Benefits | Limitations | Recommended Applications |

|---|---|---|---|---|

| PID Control [30] | Power flow controls the transition times between dual directions of the element against excessive current, minimising switching dead time. | Low cost, high dependability, high efficiency. | Low efficiency. In the event of conflicts, there is uncertainty and a lack of stability. Having difficulty avoiding a significant directional transitory between directions. | Micro-grid systems, Electric Vehicle, Fuel Cell, satellite applications. |

| Sliding-Mode Control [34] | Controlling the extreme load fluctuations and load line while seeing outside in large signal. | The ability to represent systems on both small and large scales through reference monitoring and limited time responsiveness. | Precise parameter and condition data are required. | Controlling DC motors: autonomous DC systems and DC smart grid applications for energy storage and hybrids for Electric Vehicles. |

| Dynamic-Evolution Control [10,37] | Minimising the potential difference even if there is a fluctuation in the load current. | Monitoring reference is practical. No requirement for accurate model, variable information is capable of making up for differences. | Because the switching frequency includes a dividing element, designing an antilog circuit is challenging. | Connecting ultra-capacitor energy storage to a Fuel-Cell system. |

| Model Predictive Control [10,38] | Power flow management variables, the DC voltage, and the current. | Fast dynamic response to reference tracking. | Constrained by the use of a sequential converter model within the algorithms. | DC distributed power systems, battery application. |

| Fuzzy-Logic Control [44] | Reducing energy consumption affects the grid. The supercapacitor operates smoothly during both charge and discharge. They are reducing the amount of time control. | Quick response. These properties provide a strong reaction. Appropriateness for non-linear and imprecise systems with variable fluctuation, unpredictability, and load current. | Responsive to professional information. | Energy storage devices, hybrid Electric Vehicles, and PV-powered lighting systems require power administration. |

| Boundary Control [10,49] | Time-optimal transient performance switching surface that does not include current sensing. For any boost converter, creating a standard switching surface. | World stability, reliable functioning of large signals. A quick dynamic response. | The transient response is unimproved. Ideal time-optimum control and model accuracy affect ideal time-optimum control. | Buck and boost converters. |

| Digital Control [48] | Achieving valley switching in the bidirectional converter accurate DAB short signal models. Using effective power flow direction changes at launch while providing input current protection, rapid transient responses. | Instead of recognising the HV side, minimising the capacitance switching losses. High EMI district. Enhance the effectiveness and charging/discharging rate. Fault detection, ease of use, higher reliability. | Implementing non-standard electronic configurations is challenging. Linear control law. A great effort is necessary. Analog/digital processing commitment. | Influencing a capacitor incremental controller. Energy storage systems. DC power distribution systems. Power management. |

| Switching Perspectives | Control Difficulties | Benefits | Limitations | Recommended Applications |

|---|---|---|---|---|

| PWM [10] | Considering the different converter performance characteristics | Easy to implement | Inadequate non-linear capability | High power applications, rural electric generator, power machine |

| Single-Phase Shift (SPS) [10] | Regulating the flow of energy. Reducing the power loss of the circulating current while it is being circulated in the multi-port. The converter’s power generated must be increased. | Incredible dynamic performances. Simple to use. Control of soft switching. Capability ZVS. | Reversible power. Low efficiency across a wide range of operations. ZVS operating range restrictions and significant current stress in quasi-voltage conserving ratios. Excessive RMS-inductor current and difficult switching with light loads. | Management system for hybrid Electric Vehicles. An EV powered by Fuel Cells. Applications for photovoltaics. |

| PWM + Single-Phase Shift (SPS) [10,55] | Reducing circulation conduction loss and increasing the voltage increase in current-fed switches. Reduction in size or weight. EMI interruption solution. Determining the proper duty cycle and associated Phase-Shift value. | It minimises the stress generated by the circulating current. Conduction losses are minimised. Widen the ZVS range. Increase effectiveness. Improve dependability. Increase flexibility with soft switching. | When the input and output voltage are square waves with a 50% duty ratio, a high current and reactive power are made. | In both low- and high-power applications, application of electric aviation. Coordinated energy storage. Applications of photovoltaic power batteries. |

| Dual-Phase Shift (DPS) [10,60] | Enhancing Performance Characteristics (EPC). Removing reactive power. Improving the efficiency across the entire load range. Implementing current stress has improved the switching strategy. | Reduction of peak current minimises conduction losses. Increased power capability. Improved efficiency. Greater flexibility in regulation. Improved performance in both the static and dynamic conditions. | It contains operational modes that are less than ideal. It is difficult to determine the worldwide efficiency level that is ideal. | Microgrids are used to distribute power when the power demand is low and the voltage conversion ratio is high. Practical use of power conversion. |

| Triple-Phase shift (TPS) [10,61] | Taking into account all operational modes. Changes to the stability analysis of any conceivable random constraints. Extending the range of the smooth-switching operation. | Increasing the ZVS dynamic range for enhanced performance. This increases the number of control variables, which in turn lowers the overall losses. Due to the three degrees of freedom, DPS is more flexible than SPS. | No shuttered solution is found to get the best parameter at the medium power level. | Battery backup systems. The utilisation of rapid charging technology. A propulsion transformer can be found in an electrical railroad locomotive. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkatesan, M.; Rajamanickam, N.; Vishnuram, P.; Bajaj, M.; Blazek, V.; Prokop, L.; Misak, S. A Review of Compensation Topologies and Control Techniques of Bidirectional Wireless Power Transfer Systems for Electric Vehicle Applications. Energies 2022, 15, 7816. https://doi.org/10.3390/en15207816

Venkatesan M, Rajamanickam N, Vishnuram P, Bajaj M, Blazek V, Prokop L, Misak S. A Review of Compensation Topologies and Control Techniques of Bidirectional Wireless Power Transfer Systems for Electric Vehicle Applications. Energies. 2022; 15(20):7816. https://doi.org/10.3390/en15207816

Chicago/Turabian StyleVenkatesan, Murugan, Narayanamoorthi Rajamanickam, Pradeep Vishnuram, Mohit Bajaj, Vojtech Blazek, Lukas Prokop, and Stanislav Misak. 2022. "A Review of Compensation Topologies and Control Techniques of Bidirectional Wireless Power Transfer Systems for Electric Vehicle Applications" Energies 15, no. 20: 7816. https://doi.org/10.3390/en15207816

APA StyleVenkatesan, M., Rajamanickam, N., Vishnuram, P., Bajaj, M., Blazek, V., Prokop, L., & Misak, S. (2022). A Review of Compensation Topologies and Control Techniques of Bidirectional Wireless Power Transfer Systems for Electric Vehicle Applications. Energies, 15(20), 7816. https://doi.org/10.3390/en15207816