Physicochemical Characterization and Thermal Behavior of Different Wood Species from the Amazon Biome

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Extraction with 95% Ethanol

2.3. Analytical Methods

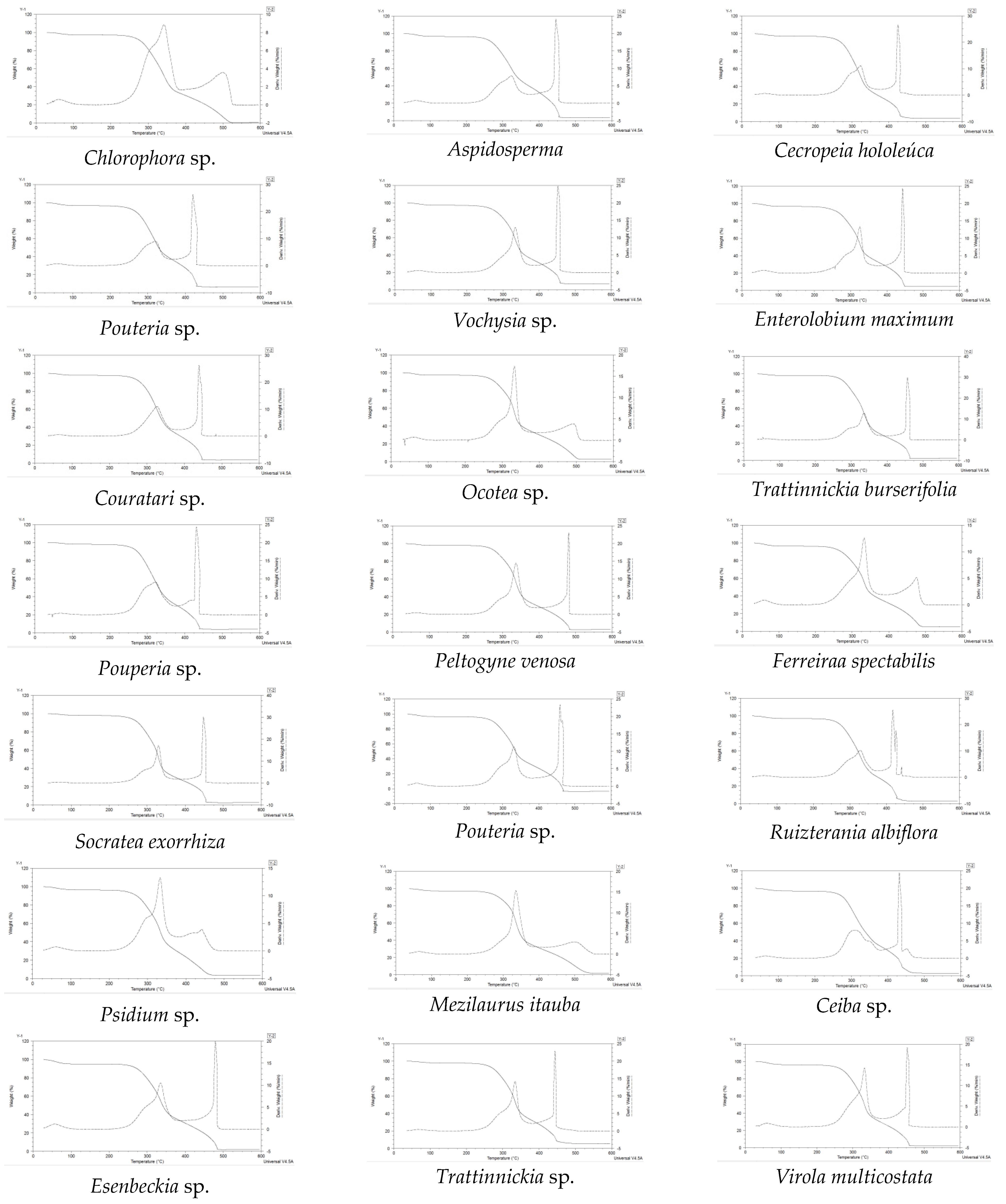

2.4. Thermal Behavior Study of the Woods

2.5. Higher Heating Value (HHV)

3. Results and Discussion

3.1. Analysis of Physicochemical Composition of the Biomasses

3.2. Thermal Behavior Analysis

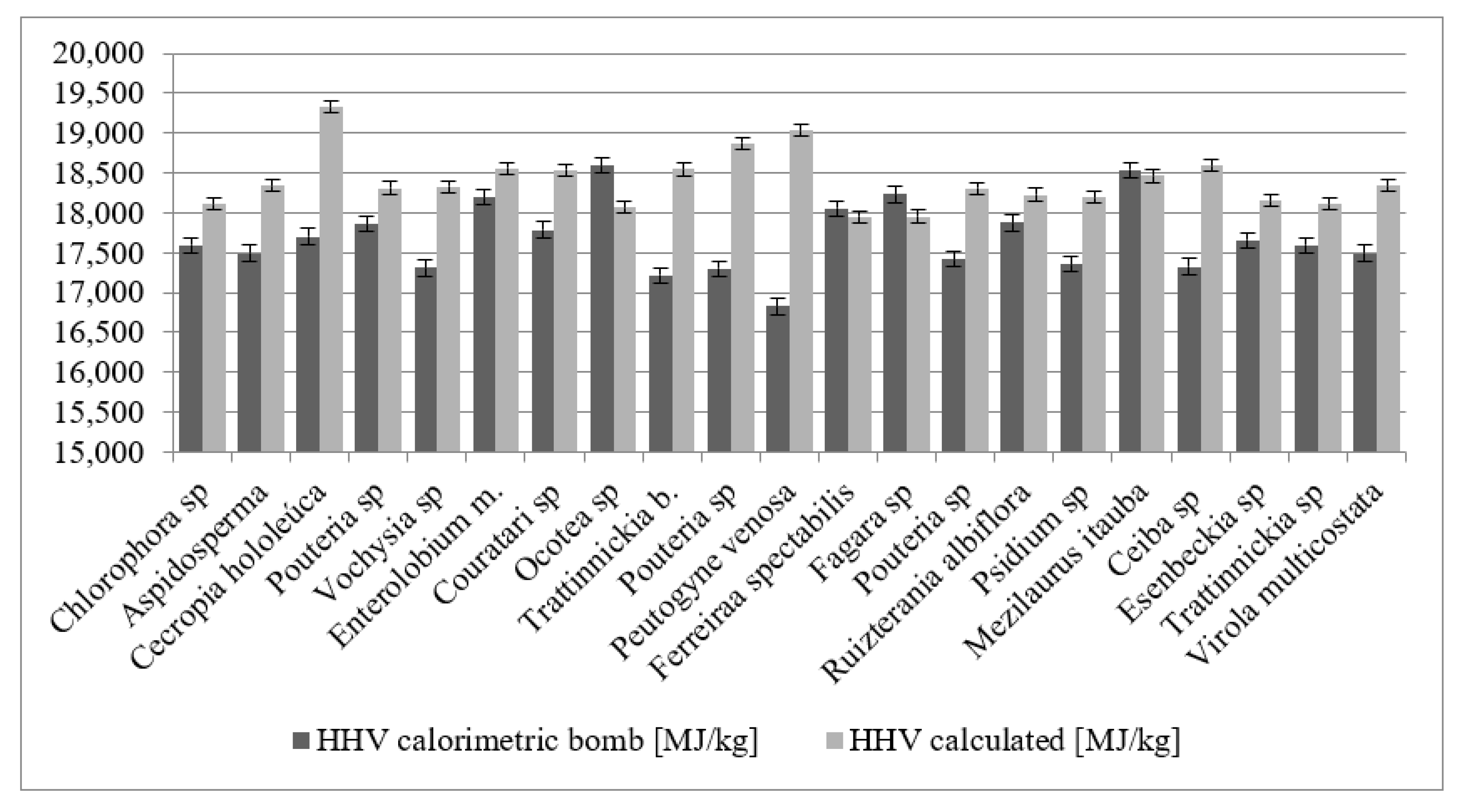

3.3. Higher Heating Value

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cruz, J.D.S.; Blanco, C.J.C.; Júnior, J.F.D.O. Modeling of land use and land cover change dynamics for future projection of the Amazon number curve. Sci. Total Environ. 2022, 811, 152348. [Google Scholar] [CrossRef]

- da Silva, R.M.; Lopes, A.G.; Santos, C.A.G. Deforestation and fires in the Brazilian Amazon from 2001 to 2020: Impacts on rainfall variability and land surface temperature. J. Environ. Manag. 2023, 326, 116664. [Google Scholar] [CrossRef]

- Trigueiro, W.R.; Nabout, J.C.; Tessarolo, G. Uncovering the spatial variability of recent deforestation drivers in the Brazilian Cerrado. J. Environ. Manag. 2020, 275, 111243. [Google Scholar] [CrossRef]

- Condé, T.M.; Higuchi, N.; Lima, A.J.N. Illegal Selective Logging and Forest Fires in the Northern Brazilian Amazon. Forests 2019, 10, 61. [Google Scholar] [CrossRef]

- Semper-Pascual, A.; Decarre, J.; Baumann, M.; Busso, J.M.; Camino, M.; Gómez-Valencia, B.; Kuemmerle, T. Biodiversity loss in deforestation frontiers: Linking occupancy modelling and physiological stress indicators to understand local extinctions. Biol. Conserv. 2019, 236, 281–288. [Google Scholar] [CrossRef]

- Betts, M.G.; Wolf, C.; Ripple, W.J.; Phalan, B.; Millers, K.A.; Duarte, A.; Butchart, S.H.M.; Levi, T. Global forest loss disproportionately erodes biodiversity in intact landscapes. Nature 2017, 547, 441–444. [Google Scholar] [CrossRef]

- Kalamandeen, M.; Gloor, E.; Mitchard, E.; Quincey, D.; Ziv, G.; Spracklen, D.; Spracklen, B.; Adami, M.; Aragão, L.E.O.C.; Galbraith, D. Pervasive Rise of Small-scale Deforestation in Amazonia. Sci. Rep. 2018, 8, 327–336. [Google Scholar] [CrossRef]

- Colodette, J.L.; Gomes, C.M.; Gomes, F.J.; Cabral, C.P. The Brazilian wood biomass supply and utilization focusing on eucalypt. Chem. Biol. Technol. Agric. 2014, 1, 25. [Google Scholar] [CrossRef]

- Rocha, S.M.G.; Vidaurre, G.B.; Pezzopane, J.E.M.; Almeida, M.N.F.; Carneiro, R.L.; Campoe, O.C.; Scolforo, H.F.; Alvares, C.A.; Neves, J.C.L.; Xavier, A.C.; et al. Influence of climatic variations on production, biomass and density of wood in eucalyptus clones of different species. For. Ecol. Manag. 2020, 473, 118–126. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Lukk, T.; Tuohy, M.G.; Gong, L.; Nguyen-Tri, P.; Goddard, A.D.; Bill, R.M.; Nayak, S.; et al. Lignocellulosic biorefineries: The current state of challenges and strategies for efficient commercialization. Renew. Sustain. Energy Rev. 2021, 148, 111–123. [Google Scholar] [CrossRef]

- Ashokkumar, V.; Venkatkarthick, R.; Jayashree, S.; Chuetor, S.; Dharmaraj, S.; Kumar, G.; Chen, W.-H.; Ngamcharussrivichai, C. Recent advances in lignocellulosic biomass for biofuels and value-added bioproducts-A critical review. Bioresour. Technol. 2022, 344, 126195. [Google Scholar] [CrossRef]

- Pinheiro, W.; Neto, J.P.; Botelho, A.; Dos Santos, K.; Da Silva, G.; Muribeca, A.; Pamplona, S.; Fonseca, S.; Silva, M.; Arruda, M. The use of Bagassa guianensis aubl. forestry waste as an alternative for obtaining bioproducts and bioactive compounds. Arab. J. Chem. 2022, 15, 103813. [Google Scholar] [CrossRef]

- Choiński, B.; Szatyłowicz, E.; Zgłobicka, I.; Ylidiz, M.J. A Critical Investigation of Certificated Industrial Wood Pellet Combustion: Influence of process conditions on CO/CO2 emission. Energies 2022, 16, 250. [Google Scholar] [CrossRef]

- Szatyłowicz, E.; Hawrylik, E. Assessment of Migration of PAHs Contained in Soot of Solid Fuel Combustion into the Aquatic Environment. Water 2022, 14, 3079. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef]

- Bimestre, T.A.; Júnior, J.A.M.; Botura, C.A.; Canettieri, E.; Tuna, C.E. Theoretical modeling and experimental validation of hydrodynamic cavitation reactor with a Venturi tube for sugarcane bagasse pretreatment. Bioresour. Technol. 2020, 311, 123540. [Google Scholar] [CrossRef]

- Hosseini Koupaie, E.; Dahadha, S.; Bazyar Lakeh, A.A.; Azizi, A.; Elbeshbishy, E. Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production:a review. J. Environ. Manag. 2019, 233, 774–784. [Google Scholar] [CrossRef]

- Bimestre, T.A.; Júnior, J.A.M.; Canettieri, E.V.; Tuna, C.E. Hydrodynamic cavitation for lignocellulosic biomass pretreatment: A review of recent developments and future perspectives. Bioresour. Bioprocess. 2022, 9, 231–239. [Google Scholar] [CrossRef]

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- de Medeiros, D.T.; de Melo, R.R.; de Cademartori, P.H.G.; Batista, F.G.; Mascarenhas, A.R.P. Caracterização da madeira de espécies da Amazônia. Madera Y Bosques 2021, 27, 272–279. [Google Scholar] [CrossRef]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. NREL/TP-510-42619; Determination of Extractives in Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Hyman, D.; Payne, C.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Wolfe, J. NREL/TP-510-42621; Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process Samples; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. NREL/TP-510-42622; Determination of Ash in Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. NREL/TP-510-42618; Determination of Structural Carbohydrates and Lignin in Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Demirbas, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Zheng, C.; Lee, D.H.; Liang, D.T. In-Depth Investigation of Biomass Pyrolysis Based on Three Major Components: Hemicellulose, cellulose and lignin. Energy Fuels 2015, 20, 388–393. [Google Scholar] [CrossRef]

- Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and characterization of lignin from different biomass resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

- Ebringerová, A.; Hromádková, Z.; Heinze, T. Hemicellulose. Polym. Phys. 2005, 186, 1–67. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.; Li, B.; Zhang, H.; Qi, B.; Wu, Y. An expeditious methodology for estimating the exergy of woody biomass by means of heating values. Fuel 2015, 159, 712–719. [Google Scholar] [CrossRef]

- Liu, Z.; Mi, Y.; Kan, Y.; Bai, Y.; Li, J.; Gao, Z. Evaluation of the interactions of typical wood extracts on the bonding performance of soybean-based adhesives. Polym. Test. 2022, 118, 107908. [Google Scholar] [CrossRef]

- Santos, M.B.; Sillero, L.; Gatto, D.A.; Labidi, J. Bioactive molecules in wood extractives: Methods of extraction and separation, a review. Ind. Crop. Prod. 2022, 186, 115231. [Google Scholar] [CrossRef]

- Miyauchi, T.; Mori, M.; Ito, K. Quantitative determination of benzalkonium chloride in treated wood by solid-phase extraction followed by liquid chromatography with ultraviolet detection. J. Chromatogr. A 2005, 1095, 74–80. [Google Scholar] [CrossRef]

- Babinszki, B.; Jakab, E.; Terjék, V.; Sebestyén, Z.; Várhegyi, G.; May, Z.; Mahakhant, A.; Attanatho, L.; Suemanotham, A.; Thanmongkhon, Y.; et al. Thermal decomposition of biomass wastes derived from palm oil production. J. Anal. Appl. Pyrolysis 2021, 155, 105069. [Google Scholar] [CrossRef]

- Raad, T.J.; Pinheiro, P.C.C.; Yoshida, M.I. Equação geral de mecanismos cinéticos da carbonização do Eucalyptus spp. Cerne 2006, 12, 93–106. [Google Scholar]

- Corradini, E.; Teixeira, E.M.; Paladin, P.D.; Agnelli, J.A.; Silva, O.R.R.F.; Mattoso, L.H.C. Thermal stability and degradation kinetic study of white and colored cotton fibers by thermogravimetric analysis. J. Therm. Anal. Calorim. 2009, 97, 415–419. [Google Scholar] [CrossRef]

- Rudnik, E. Thermal properties of biocomposites. J. Therm. Anal. Calorim. 2007, 88, 495–498. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors affecting the mechanics of carbonized wood: Literature review. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

| Samples | Scientific Name | Common Name * |

|---|---|---|

| 1 | Chlorophora sp. | Limoeiro |

| 2 | Aspidosperma | Quina |

| 3 | Cecropeia hololeúca | Embaúba Vermelha |

| 4 | Pouteria sp. | Leiteiro Branco |

| 5 | Vochysia sp. | Cambará |

| 6 | Enterolobium maximum | Timburí |

| 7 | Couratari sp. | Tauarí |

| 8 | Ocotea sp. | Canelão |

| 9 | Trattinnickia burserifolia | Amescla |

| 10 | Pouteria sp. | Leiteiro |

| 11 | Peltogyne venosa | Roxinho |

| 12 | Ferreiraa spectabilis | Sucupira Amarela |

| 13 | Fagara sp. | Mamica de Porca |

| 14 | Pouteria sp. | Pariri |

| 15 | Ruizterania albiflora | Mandioqueira |

| 16 | Psidium sp. | Araça |

| 17 | Mezilaurus itauba | Itaúba |

| 18 | Ceiba sp. | Samaúma |

| 19 | Esenbeckia sp. | Guarantã |

| 20 | Trattinnickia sp. | Morcegueira |

| 21 | Virola multicostata | Ucuúba |

| Samples | Moisture | Cellulose | Hemicellulose | Total Lignin * | Extractives | Ash |

|---|---|---|---|---|---|---|

| Chlorophora sp. | 8.60 | 44.36 ± 0.26 | 16.25 ± 1.15 | 28.86 ± 0.15 | 1.70 | 0.82 ± 0.04 |

| Aspidosperma | 9.30 | 31.26 ± 1.32 | 10.30 ± 0.59 | 31.24 ± 0.79 | 1.25 | 0.93 ± 0.11 |

| Cecropeia hololeúca | 8.61 | 37.88 ± 1.12 | 12.94 ± 0.31 | 29.83 ± 0.24 | 2.50 | 1.35 ± 0.07 |

| Pouteria sp. | 8.28 | 38.70 ± 0.85 | 14.21 ± 0.18 | 30.58 ± 0.82 | 1.61 | 2.80 ± 0.35 |

| Vochysia sp. | 8.45 | 49.50 ± 0.39 | 12.56 ± 0.35 | 32.28 ± 1.18 | 0.18 | 3.90 ± 0.49 |

| Enterolobium maximum | 7.96 | 33.01 ± 0.09 | 16.15 ± 0.84 | 26.83 ± 1.83 | 6.86 | 0.85 ± 0.01 |

| Couratari sp. | 7.94 | 49.45 ± 1.68 | 8.63 ± 0.54 | 30.69 ± 0.71 | 3.16 | 0.50 ± 0.34 |

| Ocotea sp. | 7.09 | 37.69 ± 0.13 | 10.90 ± 0.03 | 30.08 ± 0.58 | 0.29 | 0.75 ± 0.01 |

| Trattinnickia burserifolia | 5.78 | 49.77 ± 2.57 | 14.20 ± 0.83 | 30.10 ± 0.54 | 3.77 | 1.04 ± 0.08 |

| Pouteria sp. | 8.28 | 45.37 ± 0.97 | 12.66 ± 0.06 | 27.63 ± 0.78 | 1.65 | 1,50 ± 0.07 |

| Peltogyne venosa | 7.29 | 47.57 ± 2.29 | 9.76 ± 0.94 | 30.80 ± 0.26 | 6.76 | 1.55 ± 0.28 |

| Ferreiraa spectabilis | 8.26 | 33.36 ± 2.48 | 12.66 ± 0.61 | 29.82 ± 0.08 | 3.40 | 0.65 ± 0.21 |

| Fagara sp. | 7.94 | 41.56 ± 0.88 | 17.00 ± 0.34 | 30.71 ± 0.68 | 5.22 | 0.70 ± 0.07 |

| Pouteria sp. | 8.04 | 40.00 ± 0.90 | 11.16 ± 0.47 | 29.96 ± 0.27 | 6.29 | 0.72 ± 0.11 |

| Ruizterania albiflora | 6.00 | 55.90 ± 1.20 | 9.23 ± 0.19 | 28.71 ± 0.31 | 3.29 | 1.12 ± 0.04 |

| Psidium sp. | 8.07 | 41.24 ± 0.55 | 15.75 ± 0.30 | 30.06 ± 0.18 | 1.47 | 1.65 ± 0.01 |

| Mezilaurus itauba | 8.55 | 37.15 ± 6.86 | 13.70 ± 0.22 | 30.25 ± 0.09 | 2.39 | 0.62 ± 0.11 |

| Ceiba sp. | 9.11 | 45.56 ± 1.19 | 12.53 ± 0.77 | 32.18 ± 0.06 | 0.53 | 1.50 ± 0.07 |

| Esenbeckia sp. | 7.40 | 41.69 ± 0.57 | 12.09 ± 0.25 | 27.81 ± 0.14 | 1.46 | 0.55 ± 0.01 |

| Trattinnickia sp. | 9.71 | 45.18 ± 0.08 | 13.38 ± 0.52 | 33.86 ± 0.13 | 0.71 | 1.72 ± 0.04 |

| Virola multicostata | 8.49 | 41.07 ± 0.09 | 13.59 ± 0.20 | 28.13 ± 0.52 | 2.62 | 0.85 ± 0.07 |

| Average | 8.05 | 41.74 | 12.38 | 30.02 | 2.72 | 1.27 |

| Standard deviation | 0.95 | 7.31 | 2.62 | 1.66 | 2.06 | 0.83 |

| Samples | Experimental HHV [MJ kg−1] | Calculated HHV [MJ kg−1] | Difference (%) |

|---|---|---|---|

| Lignin—isolated | 20.02 ± 0.083 | ___ | ___ |

| Cellulose—Sigma | 15.27 ± 0.033 | ___ | ___ |

| Hemicellulose—commercial | 15.47 ± 0.005 | ___ | ___ |

| Chlorophora sp. | 17.59 ± 0.040 | 18.11 | 2.88 |

| Aspidosperma | 17.49 ± 0.427 | 18.34 | 4.63 |

| Cecropia hololeúca | 17.70 ± 0.293 | 19.32 | 8.37 |

| Pouteria sp. | 17.86 ± 0.077 | 18.31 | 2.49 |

| Vochysia sp. | 17.31 ± 0.195 | 18.33 | 5.56 |

| Enterolobium máximum | 18.19 ± 0.054 | 18.56 | 1.98 |

| Couratari sp. | 17.79 ± 0.027 | 18.53 | 4.04 |

| Ocotea sp. | 18.59 ± 0.082 | 18.07 | 2.86 |

| Trattinnickia burcerifolia | 17.21 ± 0.026 | 18.54 | 7.18 |

| Pouteria sp. | 17.30 ± 0.072 | 18.87 | 8.30 |

| Peutogyne venosa | 16.83 ± 0.413 | 19.04 | 11.61 |

| Ferreiraa spectabilis | 18.05 ± 0.157 | 17.95 | 0.56 |

| Fagara sp. | 18.23 ± 0.126 | 17.95 | 1.53 |

| Pouteria sp. | 17.42 ± 0.327 | 18.31 | 4.85 |

| Ruizterania albiflora | 17.87 ± 0.167 | 18.23 | 1.95 |

| Psidium sp. | 17.35 ± 0.320 | 18.19 | 4.62 |

| Mezilaurus itauba | 18.54 ± 0.140 | 18.46 | 0.41 |

| Ceiba sp. | 17.33 ± 0.043 | 18.59 | 6.81 |

| Esenbeckia sp. | 17.66 ± 0.033 | 18.15 | 2.71 |

| Trattinnickia sp. | 17.59 ± 0.040 | 18.11 | 2.88 |

| Virola multicostata | 17.49 ± 0.427 | 18.34 | 4.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bimestre, T.A.; Silva, F.S.; Tuna, C.E.; dos Santos, J.C.; de Carvalho, J.A., Jr.; Canettieri, E.V. Physicochemical Characterization and Thermal Behavior of Different Wood Species from the Amazon Biome. Energies 2023, 16, 2257. https://doi.org/10.3390/en16052257

Bimestre TA, Silva FS, Tuna CE, dos Santos JC, de Carvalho JA Jr., Canettieri EV. Physicochemical Characterization and Thermal Behavior of Different Wood Species from the Amazon Biome. Energies. 2023; 16(5):2257. https://doi.org/10.3390/en16052257

Chicago/Turabian StyleBimestre, Thiago Averaldo, Fellipe Sartori Silva, Celso Eduardo Tuna, José Carlos dos Santos, João Andrade de Carvalho, Jr., and Eliana Vieira Canettieri. 2023. "Physicochemical Characterization and Thermal Behavior of Different Wood Species from the Amazon Biome" Energies 16, no. 5: 2257. https://doi.org/10.3390/en16052257

APA StyleBimestre, T. A., Silva, F. S., Tuna, C. E., dos Santos, J. C., de Carvalho, J. A., Jr., & Canettieri, E. V. (2023). Physicochemical Characterization and Thermal Behavior of Different Wood Species from the Amazon Biome. Energies, 16(5), 2257. https://doi.org/10.3390/en16052257