A Decade Review of the Art of Inspection and Monitoring Technologies for Long-Distance Oil and Gas Pipelines in Permafrost Areas

Abstract

:1. Introduction

2. Defects and Risks of Pipelines in Permafrost Areas

3. In-Line Inspection Technologies

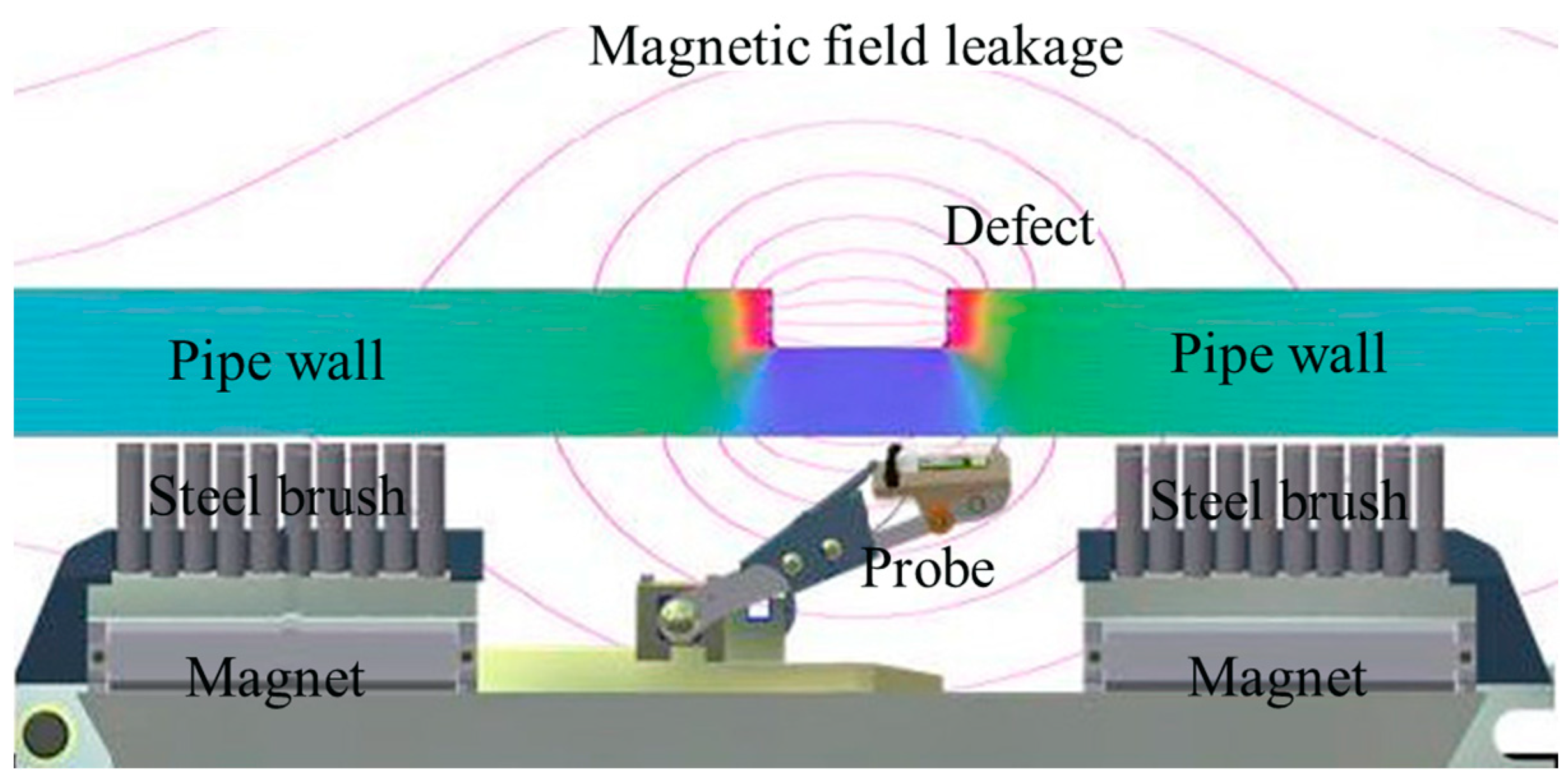

3.1. High-Resolution Pipeline Magnetic Flux Leakage Inspection

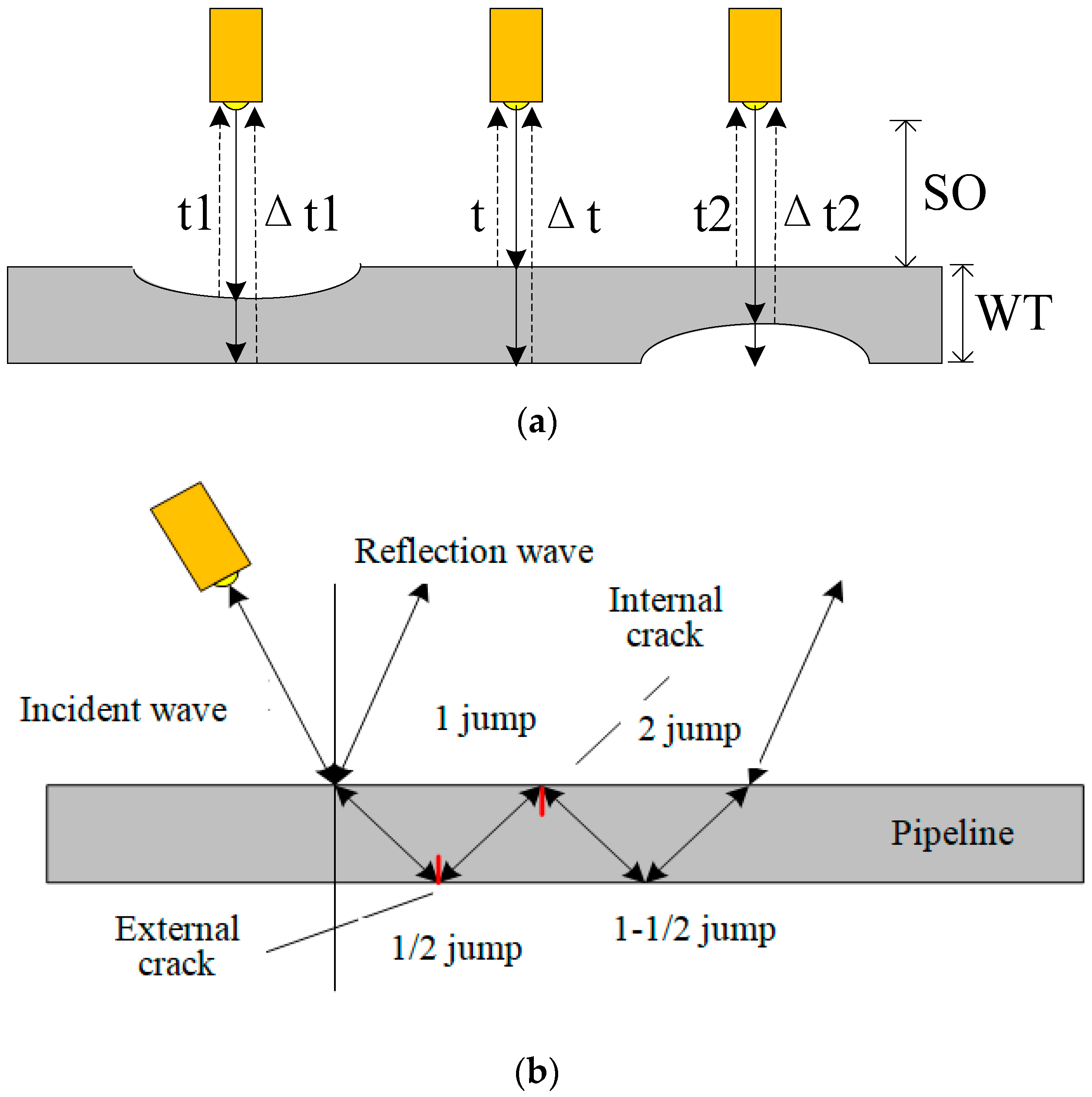

3.2. Ultrasonic In-Line Inspection

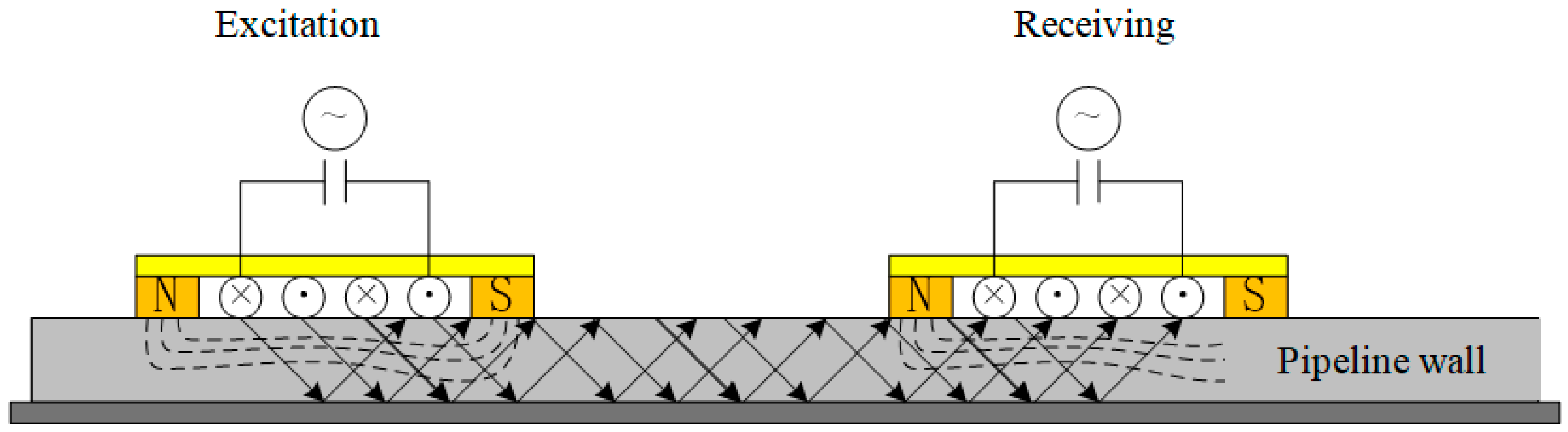

3.3. Electromagnetic Acoustic Transducer Inspection

3.4. Electromagnetic Eddy Current Inspection

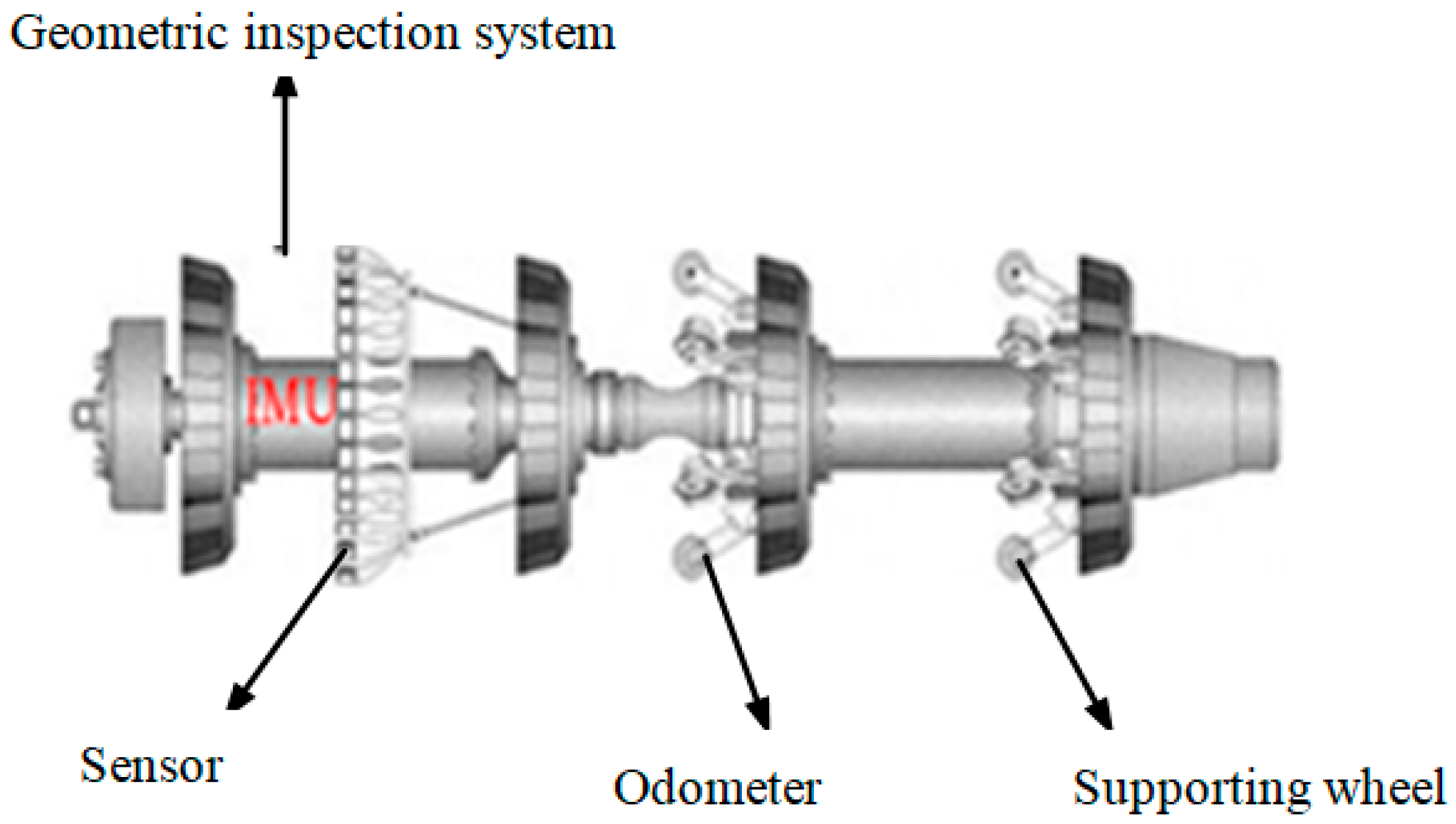

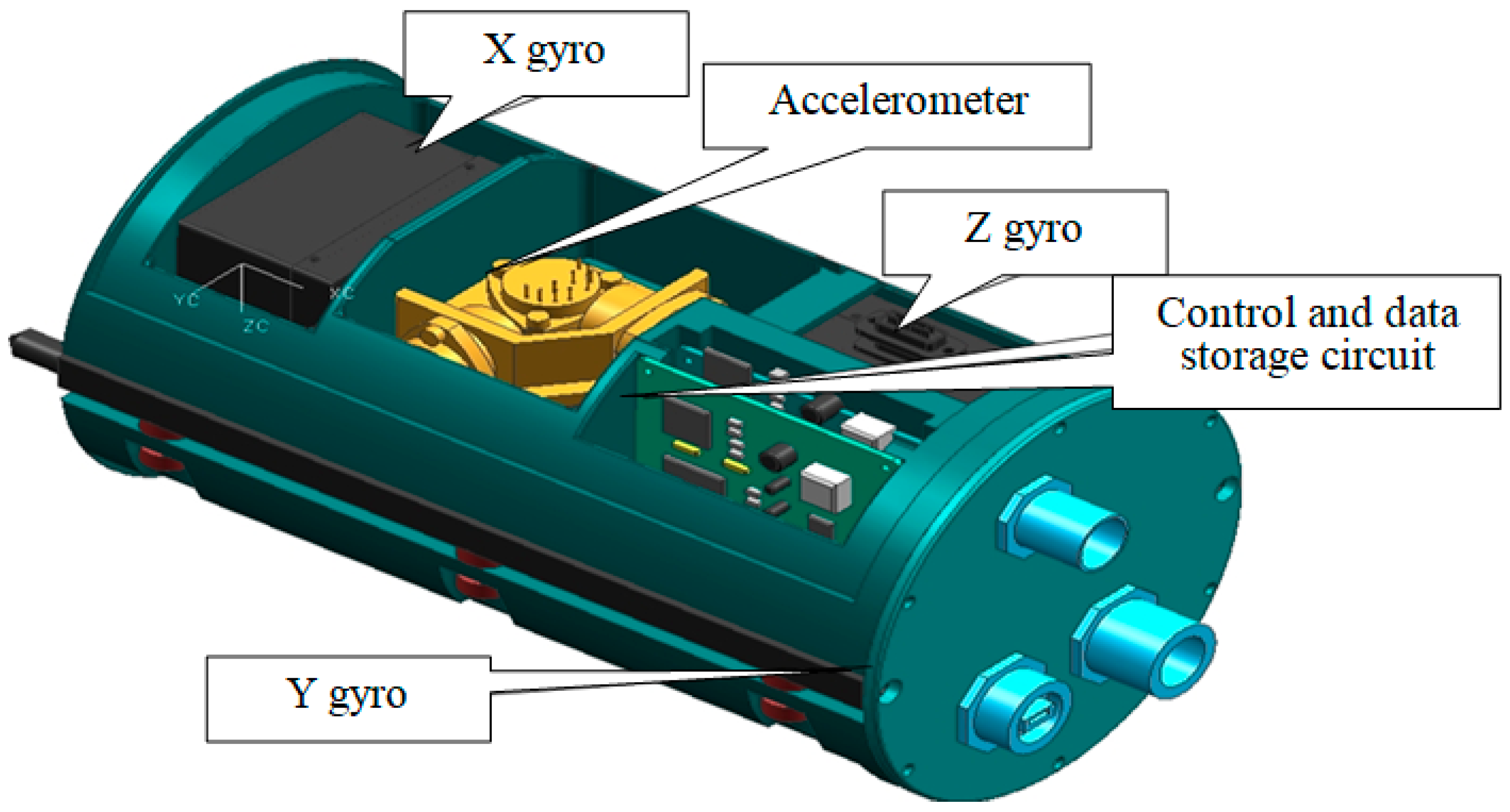

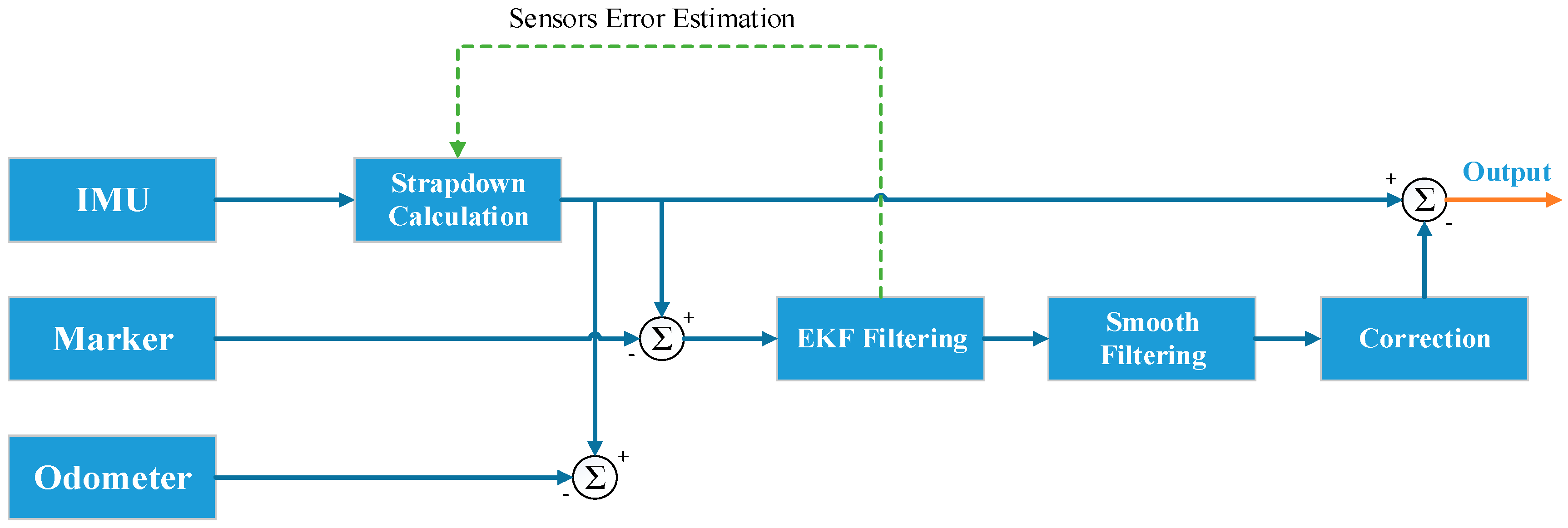

3.5. IMU Centerline and Bending Strain Inspection

- The gyroscopes and accelerometers in the inspection tool obtain the angular velocity of rotation and the displacement acceleration of the inspection tool. These data are processed to gather the information on the position attitude of the inspection tool at any time;

- The drifting of inertial components may cause an increase in the measurement error as time goes by. Inspection data can be rectified by using the GPS coordinates of the aboveground marker, odometer, pipeline characteristics (weld and bend), and other parameters;

- After pipeline inspection, the data stored in the inspection tool are imported into computer. They are then processed in a specialized software to obtain the distribution track and position parameters of the pipeline centerline.

3.6. Geometry Deformation In-Line Inspection

- Mechanical inspection technology employs mechanical tensioning arms; it is therefore not suitable for 360° pipeline-wall inspection;

- Mechanical inspection technology is, in principle, tension inspection. The pulley at the top of each tensioning arm is in contact with the impurities on pipeline wall (e.g., salt crystals), so the undulating surface of the pipeline wall caused by such impurities cannot be identified;

- Electromagnetic inspection technology can overcome the influence of nonmetallic impurities on the pipeline wall to realize a satisfactory inspection.

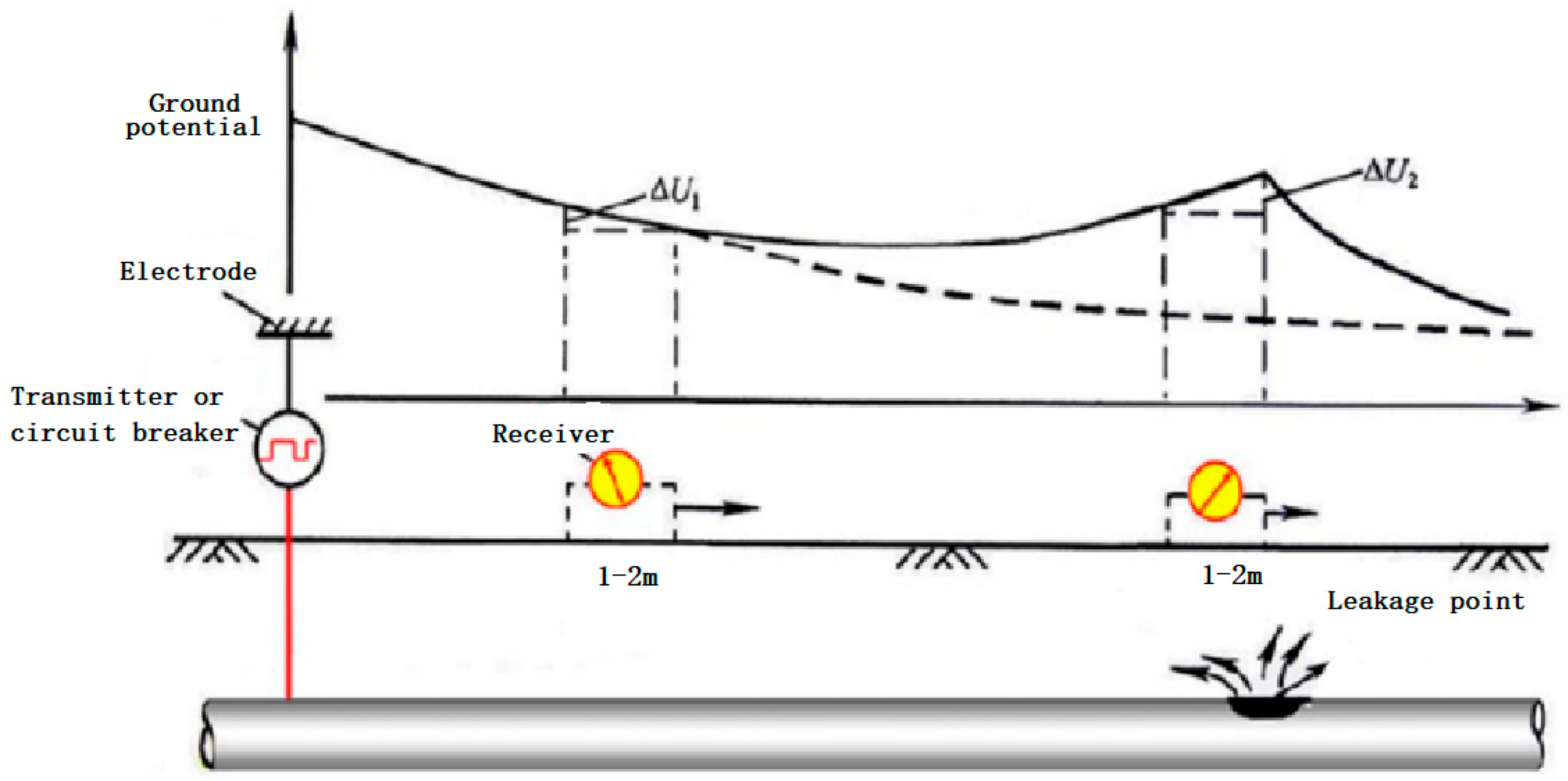

4. External Corrosion Direct Assessment Technologies

4.1. Direct Current Voltage Gradient

4.2. Alternating Current Voltage Gradient

4.3. Pipeline Current Mapper

- If the coating of a pipeline is in good condition, the reading of the current often decreases slightly [86];

- If the coating of a pipeline is entirely aged, the reading of the current drops dramatically [87];

- If the coating of a pipeline has some sections in poor condition, the current at the aged sections decreases significantly;

- The pipeline is overlapped with other metal structures;

- The sleeve of pipeline has a poor coating which overlaps the pipeline;

- On the buried route of the pipeline, the pipeline outer coating is in good condition, but there are dry or sandy areas [88].

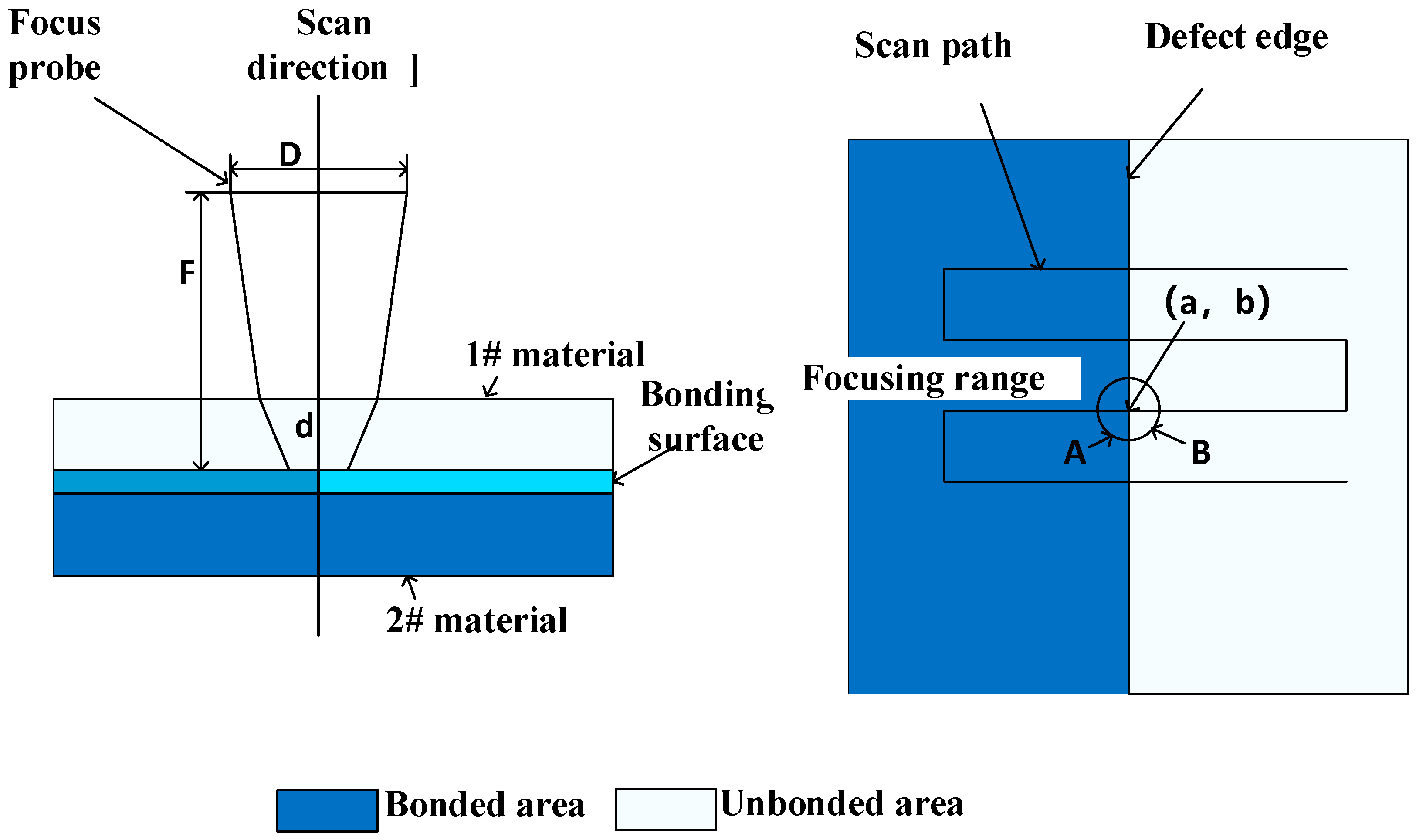

4.4. Direct Inspection: Ultrasonic Testing

4.5. Direct Inspection: Soil Resistivity

5. Integrated Monitoring Systems for Pipelines in Permafrost Areas

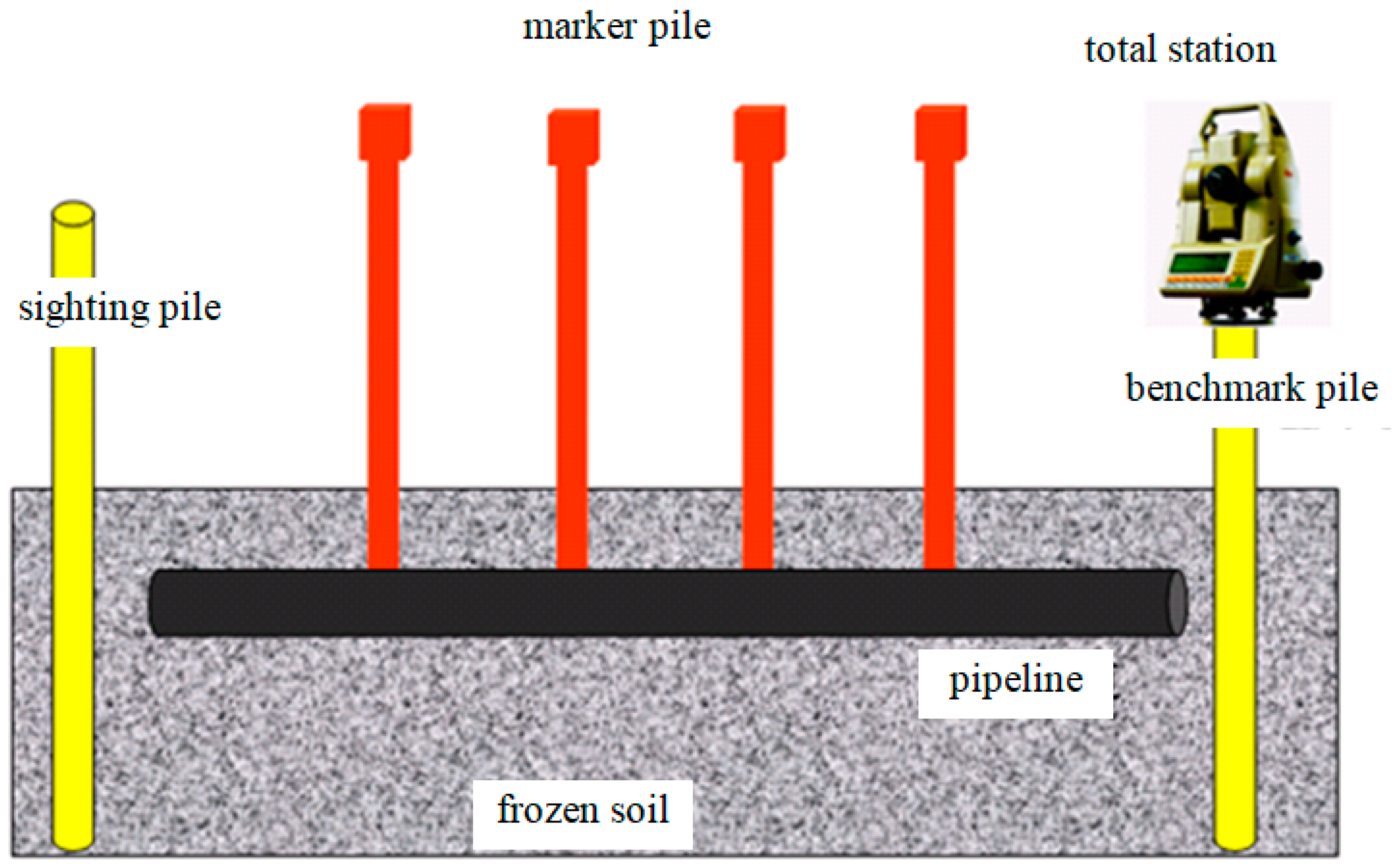

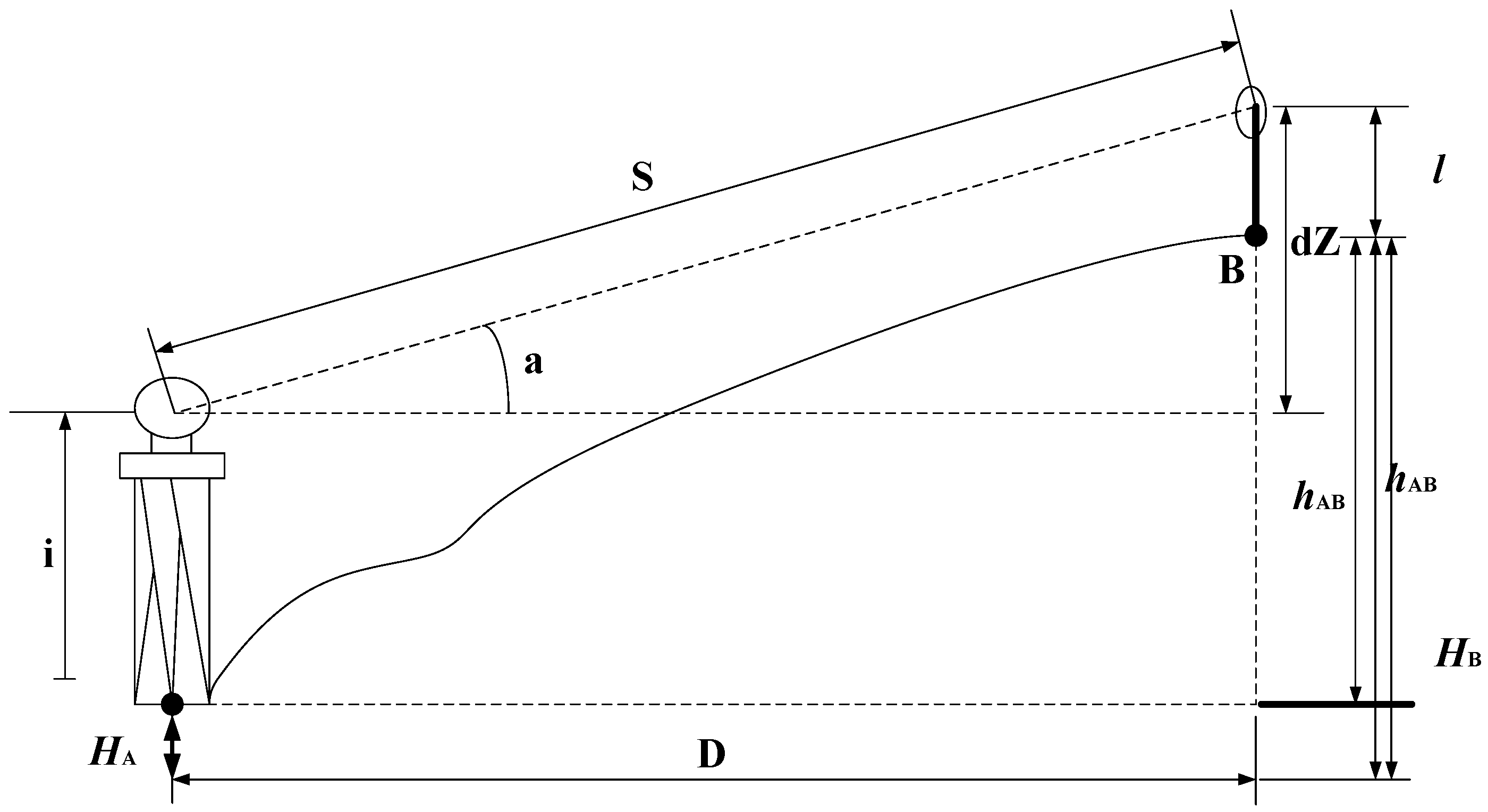

5.1. Displacement Monitoring of the Pipeline and Soil

5.1.1. Mechanical Displacement Monitoring Technology

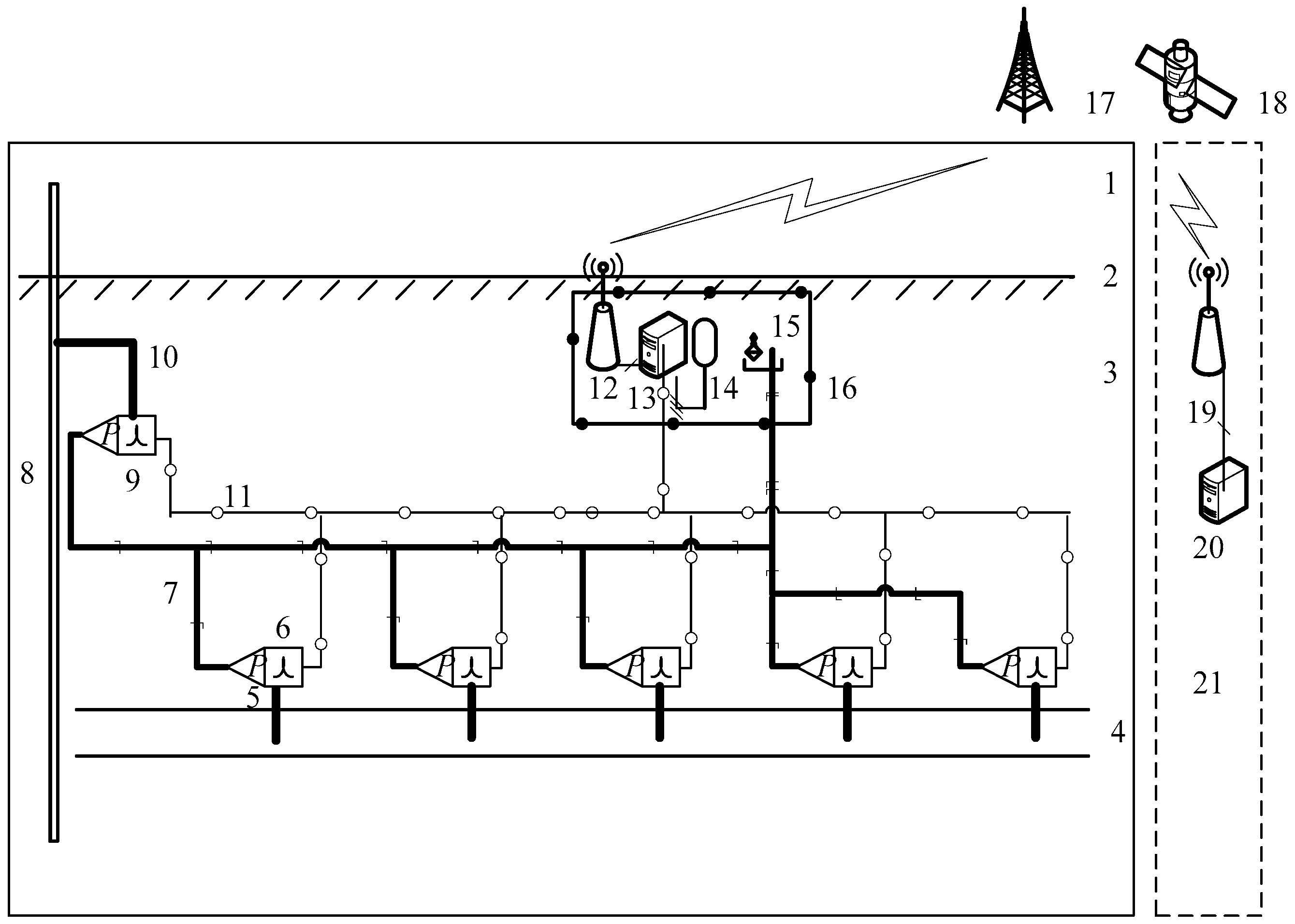

5.1.2. Automatic Monitoring System

- Characteristics of Monitoring System

- An automatic monitoring system for the vertical displacement of a pipeline based on liquid pressure is put forward The system can automatically monitor the vertical displacement of a pipeline in a permafrost area;

- The vertical displacement monitoring equipment for a pipeline is different from the common liquid pressure monitoring method with a static-level settlement measurement device. It places piezometers at reference points and monitoring points to measure the liquid pressure of the hydraulic system at these points to calculate the elevation difference between these points. Piezometers have a larger measuring range (70 kPa); therefore, this method can be used for monitoring with a large measuring range (2 m) in regions with a large elevation difference (3–5 m). Meanwhile, it is not affected by a variation in atmospheric pressure or a variation in the level of a liquid tank (which is caused by liquid leakage and container expansion or shrinkage). Hence, monitoring accuracy is guaranteed (better than 7 mm);

- All devices at the site are buried underground to guarantee their normal operation in the harsh climate environment of alpine regions (which are covered by snow and ice in the winter, with an extreme ambient temperature of −50 °C, and turn into marsh and wetlands due to thawing in the summer).

5.2. Soil Temperature Monitoring

5.2.1. Principles of Monitoring System

5.2.2. Characteristics of Monitoring System

- The temperature measurement accuracy is 0.1 °C, and the error of vertical distance between temperature sensors is <1 cm, measured at the site prior to burial;

- The signal cable of sensors is protected by a plastic tube and buried at a depth of 30 cm;

- The temperature collection secondary meter (the data collection and storage system) meets the “GB3836.1-2000 General Requirements for Electrical Equipment”, and can operate normally under a temperature of −30 °C;

- The concrete well is provided with thermal insulation and protection against frost heave, groundwater penetration, and rainwater. The cable holes are sealed after cabling. The upper edge of the well is 20 cm above the ground surface;

- The battery (dedicated power supply) has a capacity ≥ 100 AH and can withstand low temperatures (offering normal service under −30 °C);

- The data collected for 10 consecutive days are taken as the basis to judge whether the temperature monitoring system functions normally.

5.3. Stress and Strain Monitoring

5.3.1. Fiber Bragg Grating (FBG)

5.3.2. Vibrating Wire Sensor Monitoring

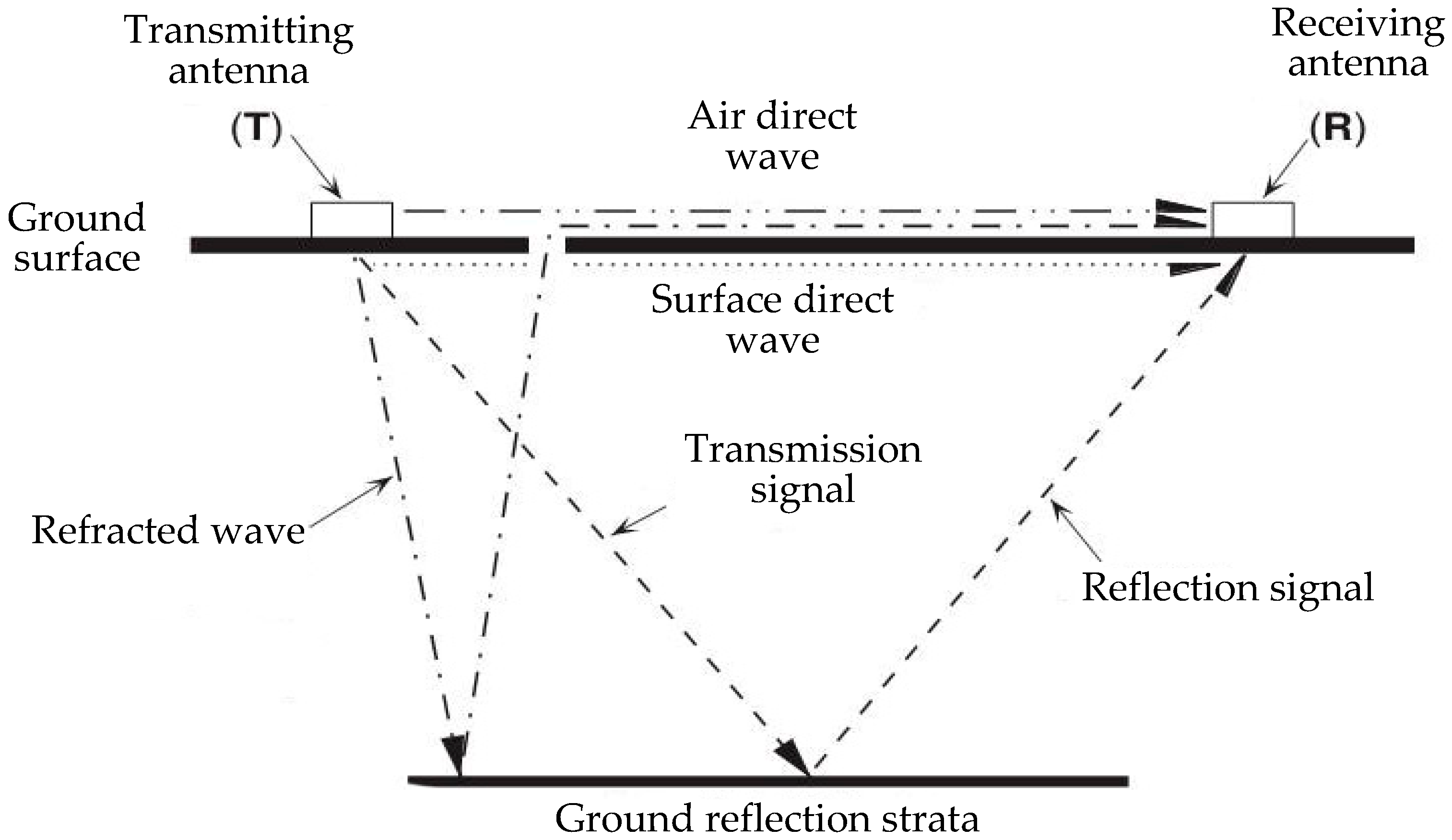

5.4. Ground-Penetrating Radar Measurement

5.4.1. Principles of Monitoring System

5.4.2. Characteristics of Monitoring System

5.5. Slope Monitoring

5.5.1. Time-Domain Reflectometry

5.5.2. Borehole Inclinometer

6. New Technologies for Pipeline Defect In-Line Inspection

7. Conclusions

- Regarding defects, including the metal loss of a pipeline in a permafrost area, in-line inspection methods may be employed. These include magnetic flux leakage, electromagnetic eddy current, ultrasonic, and electromagnetic acoustic transducer inspections. Regarding geometry deformations such as pit, a high-accuracy geometry inspection tool can be used for inspection. The IMU in-line inspection technology can be employed to indicate bending and variation in a pipeline along the entire route. It features a high inspection accuracy, accurate positioning, and comprehensive data, etc., so it is applicable to the bending strain and displacement inspection of a pipeline in a permafrost area. Different inspection technologies are combined and analyzed comprehensively to fully understand and learn about the state of pipelines in permafrost areas;

- Off-line inspection is another important way to inspect a pipeline in a permafrost area. Indirect inspection is combined with verification by direct inspection to check and evaluate the integrity of the anticorrosive coating and the effectiveness of the cathodic protection for the pipeline. In the end, a pipeline external corrosion control rectification scheme is put forward based on inspection and evaluation;

- Regarding the external environment of a pipeline in a permafrost area, a monitoring system should be developed and established. For instance, a temperature-sensing system can effectively detect the influence of surrounding permafrost and the development trend of the thaw cycle after a pipeline is put into operation, providing a technical guarantee for the dynamic observation of the soil temperature field around the buried pipeline. The pipeline-displacement monitoring system, based on the measurement by electronic total station, can monitor the pipeline displacement in a convenient, vivid, and effective way. A grating fiber stress inspection system can provide the absolute and relative load conditions for a pipeline in the monitored area. Due to its high accuracy and confidence level, the system can be taken as an important method for the early warning of pipeline displacement and load safety in the key areas.

Funding

Data Availability Statement

Conflicts of Interest

References

- Rui, Z.; Li, C.; Peng, F.; Ling, K.; Chen, G.; Zhou, X.; Chang, H. Development of industry performance metrics for offshore oil and gas project. J. Nat. Gas Sci. Eng. 2017, 39, 44–53. [Google Scholar] [CrossRef]

- Ting, W.; Hui, Y.; Feng, Q.S.; Zhou, L.J.; Wang, F.X.; Xu, X.Q. Current status and prospect of inline inspection technologies for defects in girth weld of oil and gas pipeline. Oil Gas Storage Transp. 2015, 34, 694–698. [Google Scholar]

- Kim, K.; Zhou, W.; Huang, S.L. Frost heave predictions of buried chilled gas pipelines with the effect of permafrost. Cold Reg. Sci. Technol. 2008, 53, 384–396. [Google Scholar] [CrossRef]

- Feng, S.G.; Zhang, X.; Ma, T. Thaw settlement prevention and temperature monitor of Mohe-Daqing Crude Oil Pipeline in permafrost. Oil Gas Storage Transp. 2014, 33, 478–483. [Google Scholar]

- Oswell, J.M.; Skibinsky, D. Discussion of Frost heave and pipeline upheaval buckling. Can. Geotech. J. 2005, 42, 321–322. [Google Scholar] [CrossRef]

- Vladimirov, A.I.; Kershenbaum, V.Y. Industrial Safety and Reliability of Main Pipelines; Vladimirov, I., Kershenbaum, V., Eds.; National Institute of Oil and Gas: Moscow, Russia, 2009. [Google Scholar]

- Ivantsov, O.M.; Kharionovskiy, V.I. Main Pipeline Reliability; Nedra: Moscow, Russia, 1978. [Google Scholar]

- Naumov, O.V. Simulation of Main pipeline SSS in permafrost soil condition. In Proceedings of the MIKMUS 30: Collected Papers, Moscow, Russia, 4–6 December 2019; pp. 153–155. [Google Scholar]

- Naumov, O.V.; Moskvitin, G.V.; Polyakov, A.N.; Pugachev, M.S. Particularities in operation of pipelines of underground routing in kryolith (permafrost soil) conditions. In Proceedings of the MIKMUS 29 Conference: Collected Papers, Moscow, Russia, 7–9 December 2016; pp. 97–99. [Google Scholar]

- Zonn, I.S.; Kostianoy, A.G.; Semenov, A.V.; Joksimović, A.; Đurović, M. Friendship-Adria Oil Pipeline. In The Adriatic Sea Encyclopedia. Encyclopedia of Seas; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Khrenov, N.N. Reliability of chilled gas pipelines in permafrost. Soil Mech. Found. Eng. 2010, 47, 26–31. [Google Scholar] [CrossRef]

- Ma, Y.B.; Tan, D.J.; Jing, H.; Xue, Q.; Zhang, Z.C. Permafrost Hazard of Mohe-Daqing Crude Oil Pipeline. Adv. Mater. Res. 2013, 13, 2659–2663. [Google Scholar] [CrossRef]

- Dong, P.; Zheng, D.H.; Hang, J.Z.; Lu, J.J. Monitoring of temperature field around buried oil pipeline in Mo-Da permafrost region. Oil Gas Storage Transp. 2018, 37, 58–65. [Google Scholar]

- Yu, X.F.; Wang, G.P.; Zou, Y.C.; Wang, Q.; Zhao, H.M.; Lu, X.G. Effects of Pipeline Construction on Wetland Ecosystems: Russia–China Oil Pipeline Project (Mohe-Daqing Section). AMBIO 2010, 39, 447–450. [Google Scholar] [CrossRef]

- Li, Y.G.; Jing, H.J.; Sheng, Y. Recent Advances in Frozen Ground Engineering Geology Survey along the China-Russia Crude Oil Pipeline Route (Mohe-Daqing Section). J. Glaciol. Geocryol. 2008, 30, 170–175. [Google Scholar]

- Chen, P.C.; Yang, B.L.; Wang, M. Geological hazard risk of moda pipeline and its permafrost region. Oil Gas Storage Transp. 2011, 30, 621–623. [Google Scholar]

- Fan, S.Z.; Li, G.Y.; Mu, Y.H. Study on Thermal Hazards Assessment at a Typical Site along MoHe-Daqing Section of China-Russia Crude Oil Pipeline. J. Disaste Prev. Mitig. Eng. 2017, 37, 456–461. [Google Scholar]

- Oswell, J.M. Pipelines in permafrost: Geotechnical issues and lessons. Can. Geotech. J. 2011, 48, 1412–1431. [Google Scholar] [CrossRef]

- Wang, F.; Li, G.Y.; Ma, W.; Wu, Q.B.; Jiang, N.S.; Wang, P. Pipeline–permafrost interaction monitoring system along the China–Russia crude oil pipeline. Eng. Geol. 2019, 254, 113–125. [Google Scholar] [CrossRef]

- Dadfar, B.; El Naggar, M.H.; Nastev, M. Vulnerability of buried energy pipelines subject to earthquake-triggered transverse landslides in permafrost thawing slopes. J. Pipeline Syst. Eng. Pract. 2018, 9, 04018015. [Google Scholar] [CrossRef]

- Wang, F.; Li, G.Y.; Ma, W.; Mu, Y.H.; Mao, Y.C.; Wang, B. Influence of Warm Oil Pipeline on Underlying Permafrost and Cooling Effect of Thermosyphon Based on Field Observations. In Proceedings of the China-Europe Conference on Geotechnical Engineering, Vienna, Austria, 13–16 August 2016; Springer: Cham, Switzerland, 2018; pp. 1424–1428. [Google Scholar]

- An, Y. Application of EPC Management Model in Construction of Long-distance Pipeline Project. In Proceedings of the Advances in Materials, Machinery, Electrical Engineering (AMMEE 2017), Tianjin, China, 10–11 June 2017; Atlantis Press: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Vanaei, H.R.; Eslami, A.; Egbewande, A. A review on pipeline corrosion, in-line inspection (ILI), and corrosion growth rate models. Int. J. Press. Vessels Pip. 2017, 149, 43–54. [Google Scholar] [CrossRef]

- Feng, Q.; Li, R.; Nie, B.; Liu, S.; Zhao, L.; Zhang, H. Literature review: Theory and application of in-line inspection technologies for oil and gas pipeline girth weld defection. Sensors 2017, 17, 50. [Google Scholar] [CrossRef]

- Xie, M.; Tian, Z. A review on pipeline integrity management utilizing in-line inspection data. Eng. Fail. Anal. 2018, 92, 222–239. [Google Scholar] [CrossRef]

- Siraj, T.; Zhou, W. Quantification of Measurement Errors in the Lengths of Metal-Loss Corrosion Defects Reported by Inline Inspection Tools. J. Press. Vessels Technol. 2019, 141, 061402. [Google Scholar] [CrossRef]

- Desjardins, G.; Nickle, R.; Skibinsky, D.; Yip, J. Comparison of In-Line Inspection Service Provider Magnetic Flux Leakage (MFL) Technology and Analytical Performance Based on Multiple Runs on Pipeline Segments. In Proceedings of the 2012 9th International Pipeline Conference, IPC2012-90251, Calgary, AB, Canada, 24–28 September 2012. [Google Scholar]

- Ding, Z.W.; He, R.Y.; Liu, Z. The simulation analysis and quantity model of pipeline defect signals in magnetic flux leakage testing. Nondestruct. Test. 2013, 35, 30–33. [Google Scholar]

- Amineh, R.K.; Natalia, K.; Nikolova, J.; Reilly, P. Characterization of Surface-Br-eaking Cracks Using One Tangential Component of Magnetic Leakage Field Measurements. IEEE Trans. Magn. 2008, 44, 516–524. [Google Scholar] [CrossRef]

- Feng, Q.S. Three-axis high-resolution MFL internal inspection technology for in-service pipeline. Oil Gas Storage Transp. 2009, 28, 72–75. [Google Scholar]

- Wang, F.X.; Feng, Q.S.; Wang, X.L.; Yan, B.C.; Chu, W.W. Signal analysis and application of tri-axial MFL sensors for pipeline in-line inspection. Oil Gas Storage Transp. 2010, 29, 815–817. [Google Scholar]

- Co, V.; Ironside, S.; Ellis, C.; Wilkie, G. Characterization of Mechanical Damage Through Use of the Tri-Axial Magnetic Flux Leakage Technology. In Proceedings of the 2006 6th International Pipeline Conference, IPC2006-10454, Calgary, AB, Canada, 25–29 September 2006. [Google Scholar]

- Azizzadeh, T.; Safizadeh, M.S. Identification and Sizing of Neighboring Pits Using Three-Axis Magnetic Flux Leakage Technique. J. Test. Eval. 2019, 49, 1837–1852. [Google Scholar] [CrossRef]

- Pham, H.Q.; Trinh, Q.T.; Doan, D.T.; Tran, Q.H. Importance of magnetizing field on magnetic flux leakage signal of defects. IEEE Trans. Magn. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Song, Q.; Ding, W.; Peng, H.; Shuai, J.; Wang, B. A new magnetic testing technology based on magnetic gradient tensor theory. Insight Non-Destr. Test. Cond. Monit. 2017, 59, 325–329. [Google Scholar] [CrossRef]

- Azizzadeh, T.; Safizadeh, M.S. Estimation of the diameters, depths and separation distances of the closely-spaced pitting defects using combination of three axial MFL components. Measurement 2019, 138, 341–349. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, C.; Anyaoha, U.; Siggers, K.; Liu, Z. Parameterizing Magnetic Flux Leakage Data for Pipeline Corrosion Defect Retrieval. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; IEEE: New York, NY, USA, 2019; pp. 2665–2670. [Google Scholar]

- Chen, J. Three-axial MFL inspection in pipelines for defect imaging using a hybrid inversion procedure. Insight Non-Destr. Test. Cond. Monit. 2016, 58, 302–307. [Google Scholar] [CrossRef]

- Nikolova, N.K.; Cronin, D.; Pasha, S.M.; Amineh, R.K.; Smith, I.; Thompson, R.; Hare, J.R. Electric Resistance Welded Seam Inspection Using Circumferential Flux. In Proceedings of the 2008 7th International Pipeline Conference, IPC2008-64376, Calgary, AB, Canada, 29 September–3 October 2008. [Google Scholar]

- Ireland, R.C.; Torres, C.R. Challenges in Circumferential Magnetisation II: A FEA Point of View. In Proceedings of the 2006 6th International Pipeline Conference, IPC2006-10093, Calgary, AB, Canada, 25–29 September 2006. [Google Scholar]

- Willems, H. Advanced Ultrasonic In-Line Inspection for the Assessment of Pipelines Affected by Pitting and Pinhole Corrosion. In Proceedings of the ASME 2017 India Oil and Gas Pipeline Conference, Mumbai, India, 20–22 April 2017; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2017. [Google Scholar]

- Sha, S.; Xiang, X.; Wu, X.; Wang, Q.; Feng, Q.; Zhao, G.; Zhang, H. Signal identification technology of oil transmission pipeline girth weld based on Ultrasonic ILI. Oil Gas Storage Transp. 2018, 37, 022053. [Google Scholar]

- Peter, T.; Wang, X.J. A new method based on ultrasonic guided wave inspection and matching pursuit for evaluating the axial severity of pipeline defect. In Proceedings of the Meetings on Acoustics 2014, Indianapolis, IN, USA, 27–31 October 2014; Volume 15, pp. 1–6. [Google Scholar]

- Slaughter, M.; Huss, M.; Zakharov, Y. A pipeline inspection case study: Design improvements on a new generation ut in-line inspection crack tool. Pipeline Gas J. 2013, 240, 100–101. [Google Scholar]

- Steinhubl, S.M.; Mann, D.R. Engineering and ultrasonic tool run in a natural gas pipeline to detect SCC. In Proceedings of the 2006 6th International Pipeline Conference, IPC2008-64510, Calgary, AB, Canada, 29 September–3 October 2008; Volume 7, pp. 100–103. [Google Scholar]

- Miao, C.; Guo, W.; Du, X.; Ling, Z. Ultrasonic Inspection Technique for Inside Pressurized Pipeline Elbows. In Proceedings of the ASME 2017 Pressure Vessels and Piping Conference, Waikoloa, HI, USA, 16–20 July 2017; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2017. [Google Scholar]

- Sampath, S.; Bhattacharya, B.; Aryan, P.; Sohn, H. A Real-Time, Non-Contact Method for In-Line Inspection of Oil and Gas Pipelines Using Optical Sensor Array. Sensors 2019, 19, 3615. [Google Scholar] [CrossRef]

- Amaya-Gomez, R.; Sánchez-Silva, M.; Muñoz, F. Pattern recognition techniques implementation on data from In-Line Inspection (ILI). J. Loss Prev. Process Ind. 2016, 44, 735–747. [Google Scholar] [CrossRef]

- Ren, B.; Xin, J. In-line inspection of unpiggable buried live gas pipelines using circumferential EMAT guided waves. AIP Conf. Proc. 2018, 1949, 020019. [Google Scholar]

- Palmer, M.; Davies, C.; Ginten, M.; Palmer-Jones, R. Detection of Crack Initiation Based on Repeat In-Line Inspection. In Proceedings of the 2016 11th International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2016; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2016. [Google Scholar]

- Huang, S.; Ye, C.; Wang, K.; Zhao, W. and Dong, J. Development of Oil and Gas Pipeline Crack Detector Based on EMAT. Nondestruct. Test. 2009, 31, 827–829. [Google Scholar]

- Li, Z. Development and Application of Electromagnetic Ultrasonic (EMAT) Technology. NDT 2006, 30, 13–14. [Google Scholar]

- Hilvert, M.; Beuker, T. High-Resolution EMAT as a Diagnostic Tool for Analysis of SCC and Crack-Like Pipelines Defects. In Proceedings of the 2015 India International Oil and Gas Pipeline Conference, IOGPC2015-7940, New Delhi, India, 17–18 April 2015. [Google Scholar]

- Kania, R.; Weber, R.; Klein, S. Investigation and Assessment of Low-Frequency ERW Seam Imperfections by EMAT and CMFL ILI. In Proceedings of the 2014 10th International Pipeline Conference, IPC2014-33294, Calgary, AB, Canada, 29 September–3 October 2014. [Google Scholar]

- García-Gómez, J.; Gil-Pita, R.; Rosa-Zurera, M.; Romero-Camacho, A.; Jiménez-Garrido, J.A.; García-Benavides, V. Smart sound processing for defect sizing in pipelines using EMAT actuator based multi-frequency lamb waves. Sensors 2018, 18, 802. [Google Scholar] [CrossRef] [PubMed]

- Piao, G.; Guo, J.; Hu, T.; Deng, Y.; Leung, H. A novel pulsed eddy current method for high-speed pipeline inline inspection. Sens. Actuators A Phys. 2019, 295, 244–258. [Google Scholar] [CrossRef]

- Camerini, C.; Rebello, J.M.A.; Braga, L.; Santos, R.; Chady, T.; Psuj, G.; Pereira, G. Eddy Current System for Complex Geometry Inspection in High Speed Application. Bad. Nieniszcz. Diagn. 2018, 2, 6–10. [Google Scholar]

- Camerini, C.; Rebello, J.M.A.; Braga, L.; Santos, R.; Chady, T.; Psuj, G.; Pereira, G. In-Line Inspection Tool with Eddy Current Instrumentation for Fatigue Crack Detection. Sensors 2018, 18, 2161. [Google Scholar] [CrossRef]

- Piao, G.; Guo, J.; Hu, T.; Deng, Y. High-Speed Inspection Method Fusing Pulsed Eddy Current and Magnetic Flux Leakage. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; IEEE: New York, NY, USA, 2019; pp. 1–6. [Google Scholar]

- Song, H.; Yang, L.; Liu, G.; Tian, G.; Ona, D.; Song, Y.; Li, S. Comparative Analysis of In-line Inspection Equipments and Technologies. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 032021. [Google Scholar] [CrossRef]

- Xie, L.; Gao, B.; Yun Tian, G.; Xiao, X.; Wu, S.; Yin, Y.; Mao, D. Investigation of Remote Field Eddy Current Defect Detection for Pipeline Welds. In Proceedings of the 2018 IEEE Far East NDT New Technology & Application Forum (FENDT), Xiamen, China, 6–8 July 2018; IEEE: New York, NY, USA, 2018; pp. 137–141. [Google Scholar]

- Kosasih, A.S.; Bakri, F.; Sujatmiko, M. Low Cost-Low Risk Intelligent Pig: Sharing Experience of Running Eddy Current Pig for Subsea Pipeline Inspection. In Proceedings of the Indonesian Petroleum Association, Jakarta, Indonesia, 4–6 September 2019. [Google Scholar]

- Xue, Z.; Fan, M.; Cao, B.; Wen, D. A fast numerical method for the analytical model of pulsed eddy current for pipelines. Insight Non-Destr. Test. Cond. Monit. 2020, 62, 27–33. [Google Scholar] [CrossRef]

- Li, R.; Zhang, L.; Zhang, X.L. Long-term Strain and Displacement Monitoring of Long-distance Oil-gas Pipeline. China Pet. Mach. 2016, 44, 118–122. [Google Scholar]

- Li, R.; Liu, H.Z.; Cheng, P.C. Bending strain and displacement monitoring method for pipelines in permafrost zones. Oil Gas Storage Transp. 2017, 36, 393–408. [Google Scholar]

- Li, R.; Cai, M.; Shi, Y.; Feng, Q.; Liu, S.; Zhao, X. Pipeline bending strain measurement and compensation technology based on wavelet neural network. J. Sens. 2016, 2016, 8363242. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, D.; Dai, M.; Chen, P. A Compensation Method for Spiral Error of Pipeline Bending Strain In-Line Inspection. J. Test. Eval. 2018, 47, 3372–3386. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, D.; Wang, T.; Dai, M.; Li, R.; Feng, Q. A novel algorithm for pipeline displacement and bending strain of in-line inspection based on inertia measurement technology. Adv. Mech. Eng. 2018, 10, 1687814018816755. [Google Scholar] [CrossRef]

- Feng, Q.; Li, R.; Zhang, H. Modeling and calculation of dent based on pipeline bending strain. J. Sens. 2016, 2016, 8126214. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, D.; Li, R. Compensation Method for Pipeline Centerline Measurement of in-Line Inspection during Odometer Slips Based on Multi-Sensor Fusion and LSTM Network. Sensors 2019, 19, 3740. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Cai, M.; Shi, Y.; Feng, Q.; Chen, P. Technologies and application of pipeline centerline and bending strain of In-line inspection based on inertial navigation. Trans. Inst. Meas. Control 2018, 40, 1554–1567. [Google Scholar] [CrossRef]

- Ameh, E.S.; Lawal, L.S. Dent and gouge defects assessment: A case study of gas pipeline. Eur. J. Eng. Technol. 2018, 6, 26–35. [Google Scholar]

- Westwood, S.; Jungwirth, D.; Nickle, R.; Dewar, D.; Martens, M. In Line Inspection of Geotechnical Hazards. In Proceedings of the 2014 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2014. [Google Scholar]

- Wang, R.Y.; Kania, R.; Arumugam, U.; Gao, M. A Combined Approach to Characterization of Dent with Metal Loss. In Proceedings of the 2012 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2012; pp. 209–216. [Google Scholar]

- Warman, D.J.; Johnston, D.; Mackenzie, J.D.; Rapp, S.; Travers, B. Management of pipeline dents and mechanical damage in gas pipelines. In Proceedings of the 2006 International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2006; pp. 551–560. [Google Scholar]

- Kishawy, H.A.; Gabbar, H.A. Review of pipeline integrity management practices. Int. J. Press. Vessels Pip. 2010, 87, 373–380. [Google Scholar] [CrossRef]

- Segall, S.M.; Reid, R.G.; Gummow, R. Use of an Integrated CIPS/DCVG Survey in the ECDA Process. In Proceedings of the NACE International. Corrosion 2006, San Diego, CA, USA, 12–16 March 2006; pp. 12–16. [Google Scholar]

- Lin, R.; Li, H. Combinational Application of ACVG and CIPS to Anti-Corrosion Assessment of Buried Pipeline. Corros. Prot. 2010, 6, 475–477. [Google Scholar]

- Shawki, S. Above ground coating integrity assessment: Experience with SUMED pipelines. In Integrity of Pipelines Transporting Hydrocarbons; Springer: Berlin/Heidelberg, Germany, 2011; pp. 311–322. [Google Scholar]

- Yu, K. Making use of external corrosion defect assessment (ECDA) data to predict DCVG% IR drop and coating defect area. Mater. Corros. 2018, 69, 1237–1256. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, P.; He, S.; Wang, W. PCM inspection technology study for external anticorrosive coatings of oil and gas pipelines. China Meas. Test. Technol. 2008, 7, 1–3. [Google Scholar]

- He, H. Analysis on Influence Factors of PCM and ACVG Coating Detection Technology. Gas Heat 2016, 36, 5. [Google Scholar]

- Liu, Z.; Zhang, P.; Peng, X.; Sun, D. PCM Technology Application to the Lan-Cheng-Yu Oil Pipeline. Pipeline Tech. Equip. 2009, 5, 47–48. [Google Scholar]

- Teng, Y.; Han, S.; Jiang, G.; Cai, P.; Kong, C. Application of PCM on Buried Steel Pipelines. Pipeline Tech. Equip. 2010, 4, 18–20. [Google Scholar]

- Qiu, H.Y.; Yang, X. The Application of PCM Measurement Technique in Gas Pipeline Anticorrosive Coating. Total Corros. Control. 2009, 23, 1–13. [Google Scholar]

- Luo, H.; Zhang, Z.; Sun, F. Inspection and analysis of anticorrosion coatings of surface transport pipeline in Changqing gas field. Chem. Eng. Oil Gas 2012, 41, 325–326. [Google Scholar]

- Wu, C.; Li, R.; Xue, Z.; Liu, L. The Cathodic Protection System Testing and Evaluation of Renqiu Pipeline Station. In Proceedings of the ICPTT 2009: Advances and Experiences with Pipelines and Trenchless Technology for Water, Sewer, Gas, and Oil Applications, Shanghai, China, 18–21 October 2009; pp. 1689–1693. [Google Scholar]

- Bo, G.; Yu, Y. PCM System for Testing the Protection Coating of Buried Pipelines. Petrochem. Corros. Prot. 2001, 4. [Google Scholar]

- Huang, J.; Que, P. The Application of Wavelet Analysis in Ultrasonic Testing of Pipeline Defect. J. Transcluction Technol. 2003, 3, 130–132. [Google Scholar]

- Ryou, Y.D.; Lee, J.H.; Jung, S.W.; Park, K.W. A Study on the Development and the Verification Experiment of ECDA Equipment. J. Korean Inst. Gas 2016, 20, 72–81. [Google Scholar] [CrossRef]

- Abels, T.; Bich, N. ICDA Case Study: 43 Year Old Sour Gas Pipeline. In Proceedings of the 2006 International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2006; pp. 597–611. [Google Scholar]

- Alobaidi, W.M.; Alkuam, E.A.; Al-Rizzo, H.M.; Sandgren, E. Applications of ultrasonic techniques in oil and gas pipeline industries: A review. Am. J. Oper. Res. 2015, 5, 274. [Google Scholar] [CrossRef]

- Su, J.; Long, Y. Status quo of External Inspection Technique for Pipeline Wall Thickness and Defects. Oil Gas Storage Transp. 2009, 28, 56–58. [Google Scholar]

- Moles, M.; Ginzel, E. Pipeline girth weld inspections using ultrasonic phased arrays. In Proceedings of the 2002 4th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2002; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2002; pp. 629–636. [Google Scholar]

- Wang, Z.; Cao, Q.; Luan, N.; Zhang, L. Development of new pipeline maintenance system for repairing early-built offshore oil pipelines. In Proceedings of the 2008 IEEE International Conference on Industrial Technology, Chengdu, China, 21–24 April 2008; IEEE: New York, NY, USA, 2008; pp. 1–6. [Google Scholar]

- Willems, H.H.; Barbian, O.A.; Uzelac, N.I. Internal Inspection Device for Detection of Longitudinal Cracks in Oil and Gas Pipelines: Results from an Operational Experience. In Proceedings of the 1996 1st International Pipeline Conference, Calgary, AB, Canada, 9–13 June 1996; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 1996; pp. 345–352. [Google Scholar]

- Dobmann, G.; Barbian, O.A.; Willems, H. State of the art of in-line nondestructive weld inspection of pipelines by ultrasonics. Russ. J. Nondestruct. Test. 2007, 43, 755–761. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, Z. Applications of Finish Construction Surveying to Underground Pipelines by RIS-K2 Ground Penetrating Radar. Chin. J. Eng. Geophys. 2007, 4, 395–399. [Google Scholar]

- Ashworth, B.; Uzelac, N.; Willems, H.; Barbian, O.A. Detection and Verification of SCC in a Gas Transmission Pipeline. In Proceedings of the 2000 3rd International Pipeline Conference, Calgary, AB, Canada, 1–5 October 2000; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2000. [Google Scholar]

- Vargas-Arista, B.; Balvantin, A.; Baltazar, A.; García-Vázquez, F. On the use of ultrasonic spectral analysis for the characterization of artificially degraded API 5L X52 steel pipeline welded joints. Mater. Sci. Eng. A 2012, 550, 227–234. [Google Scholar] [CrossRef]

- Palmer, J.D. Soil resistivity-measurement and analysis. Mater. Prot. Perform. 1974, 13, 41–46. [Google Scholar]

- Cosentino, P.F.; Rio, S.N. Electromagnetic Ground Conductivity Survey Technique in pipeline Integrity.

- Marušić, K.; Kekez, K.; Martinez, S. Comparison of soil properties measurements in pipeline corrosion estimation. Mater. Corros. 2019, 70, 1700–1707. [Google Scholar] [CrossRef]

- Wilmott, M.J.; Jack, T.R.; Geerligs, J.; Dupuis, B.; Sutherby, R.L.; Diakow, D. Soil probe measures several properties to predict corrosion. Oil Gas J. 1995, 93, 28038. [Google Scholar]

- Shamsuri, S.R. The Effect of Soil Resistivity on Corrosion Behaviour of Coated and Uncoated Low Carbon Steel. Master’s Thesis, Universiti Teknologi Malaysia, Johor Bahru, Malaysia, 2010. [Google Scholar]

- Sawma, E.; Zeitoun, B.; Harmouche, N.; Georges, S.; Hamad, M.; Slaoui, F.H. Electromagnetic induction in pipelines due to overhead high voltage power lines. In Proceedings of the 2010 International Conference on Power System Technology, Zhejiang, China, 24–28 October 2010; IEEE: New York, NY, USA, 2010; pp. 1–6. [Google Scholar]

- Scott, G.N. Process and Means for Measuring Soil Resistivity and Certain Electrical Characteristics Associated with a Buried Pipeline Line. U.S. Patent 2,378,440, 19 June 1945. [Google Scholar]

- Ayako, Y.; Wang, H.; Liang, R.Y.; Castaneda, H. A clustering based method to evaluate soil corrosivity for pipeline external integrity management. Int. J. Press. Vessels Pip. 2015, 126, 37–47. [Google Scholar]

- Osella, A.; Favetto, A. Effects of soil resistivity on currents induced on pipelines. J. Appl. Geophys. 2000, 44, 303–312. [Google Scholar] [CrossRef]

- Liu, D.R.; Wang, P.F.; Wang, X.; Hu, Y. The mechanism of pipe-trench thaw collapse of buried oil and gas pipelines in permafrost regions. Oil Gas Storage Transp. 2019, 38, 788–792. [Google Scholar]

- Hu, Y.; Xu, Z.; Wang, P.F.; Wang, X.; Shi, R.; Zhao, J.; Zhang, D. Field monitoring for frost heaving and thawing-settlement of soil around gas pipelines in permafrost region. J. Eng. Geol. 2018, 26, 1035–1042. [Google Scholar]

- Jin, H.; Yu, W.; Chen, Y.; Gao, X.; Li, F.; Yao, Z. (Differential) Frost heave and thaw settlement in the engineering design and construction of oil pipelines in permafrost regions: A review. J. Glaciol. Geocryol. 2005, 27, 454–464. [Google Scholar]

- Lyu, L.Z.; Jin, H.J.; Chang, X.L. Interannual variations of the air temperature, surface temperature and shallow ground temperature along the China-Russia crude oil pipeline. J. Glaciol. Geocryol. 2010, 32, 794–802. [Google Scholar]

- Zhang, S.; Wang, X.; Sha, S.; Zhang, A.G.; Wu, G.S.; Ma, Y.B.; Wang, Q. Monitoring of frost heaving and thaw settlement of Mohe-Daqing Crude Oil Pipeline. Oil Gas Storage Transp. 2014, 33, 488–491. [Google Scholar]

- Jing, H.; Ma, Y.; Han, B.; Li, L.; Tan, D.; Feng, Q.; Chen, P.; Wu, Z.; Hao, J.; Liu, J. Automatic Monitoring Method and System for Vertical Displacement of Oil and Gas Pipeline in Frozen Soil Area: Beijing. CN 2011104554614, 16 October 2013. [Google Scholar]

- Qian, Z. Numerical Simulation and Application of Soil Temperature Field around Buried Thermal Pipeline; Xi’an Shiyou University: Xi’an, China, 2017; pp. 15–19. [Google Scholar]

- Gao, S.H.; Jin, H.J.; He, R.X. Influence factors on the groundtemperature recovery process of an open-pit coal mine backfillin the permafrost area of northeastern China. Hydrogeol. Eng. Geol. 2017, 44, 137–143. [Google Scholar]

- Lyu, H.Q.; Li, J.F.; Tang, Y.L. Several key technical issues of permafrost pipeline. Nat. Gas Oil 2009, 27, 1–4. [Google Scholar]

- Dai, H.Y.; Chen, S.H.; Wu, Y.J. Analysis of the warm andcool season’s climate variations in the ecological function sites inthe Great Khingan, Inner Mongolia. J. Glaciol. Geocryol. 2016, 38, 645–652. [Google Scholar]

- Wang, Y.P. Formation Mechanisms and Mitigative Measures for Frost Hazards of Foundation Soils in Permafrost Areas along the China-Russia Crude Oil Pipeline Route; Cold and Arid Regions Environmental and Engineering Research Institute: Lanzhou, China; Chinese Academy of Sciences: Beijing, China, 2016; pp. 1–13. [Google Scholar]

- Ma, Y.B.; Hu, Z.X.; Yang, J. Oil pipeline security monitoring system based on fiber Bragg grating sensor. J. Appl. Opt. 2009, 30, 505–509. [Google Scholar]

- Zhang, Y.; Chen, L.; Kang, R.; Li, J. Fiber bragg grating sensing technology in landside monitoring. Opt. Commun. Technol. 2010, 2, 39–41. [Google Scholar]

- Chen, L. Fiber Bragg Grating Sensing Technology in Landside Monitoring; Yan Shan University: Qin Huangdao, China, 2010; pp. 7–12. [Google Scholar]

- Jiang, T. Pipeline Leakage Monitoring Research Based on Fiber Bragg Grating Sensing Technology; Dalian University of Technology: Dalian, China, 2013; pp. 19–20. [Google Scholar]

- Lin, L.; Chen, W.M.; Zhang, P.; Xie, Y.Y. Distributed optic fiber sensor with a sub-ring. Acta Photonica Sin. 2009, 38, 1118–1121. [Google Scholar]

- Zhang, Z.W. Design of Sagnac Optic-Fiber Pipeline Prealarm System; Tianjin University: Tianjin, China, 2010; pp. 7–13. [Google Scholar]

- Xu, X.; Shuai, J.; Xiao, W. The Installation Method of Strain Gage Used to Monitor Pipeline Strain in Landslide-prone Areas. Oil Gas Storage Transp. 2010, 29, 780–782. [Google Scholar]

- Du, J.; Chen, C.; Jian, W. Stress-strain Monitoring Technique for Relaying Pipe Section over Lanzhou-Chengdu-Chongqing Oil Product Pipeline. Oil Gas Storage Transp. 2009, 28, 69–71. [Google Scholar]

- Wang, X.; Liu, X.; Wang, B.; Tian, S.; Lin, C.; Sha, S.; Wang, B. PCP Company GPR technology for Mohe-Daqing Crude Oil Pipeline. Oil Gas Storage Transp. 2014, 33, 829–833. [Google Scholar]

- Wu, X.-P.; Wei, Y.L.; Zhang, J.P. Study on the application effect of ground-penetrating radar in permafrost engineering geological investigation. China Earthq. Eng. J. 2013, 35, 23–25. [Google Scholar]

- Fan, Z.; Zhang, L.; Lu, X. Application study on ground penetrating radar for highway engineering exploration in permafrost region. Geotech. Investig. Surv. 2010, 38, 46–50. [Google Scholar]

- Bing, B.; Jian, Z. Advanced and Applications of ground penetrating radar measuring technology. Chin. J. Rock Mech. Eng. 2001, 20, 26–30. [Google Scholar]

- Chen, L.; Yu, W.B.; Yi, X.; Wu, Y.; Ma, Y. Application of ground penetration radar to permafrost survey in Mohe County, Heilongjiang Province. J. Glaciol. Geocryol. 2015, 37, 723–730. [Google Scholar]

- Shi, Y.; Zhang, Q. Application of TDR technique in yaan xiakou landslide monitoring. Site Investig. Sci. Technol. 2005, 1, 55–57. [Google Scholar]

- Sun, J.; Li, S.; Liu, K.; Xu, M. Current status of security pre-warning technologies for oil and gas pipelines. Oil Gas Storage Transp. 2016, 35, 1023. [Google Scholar]

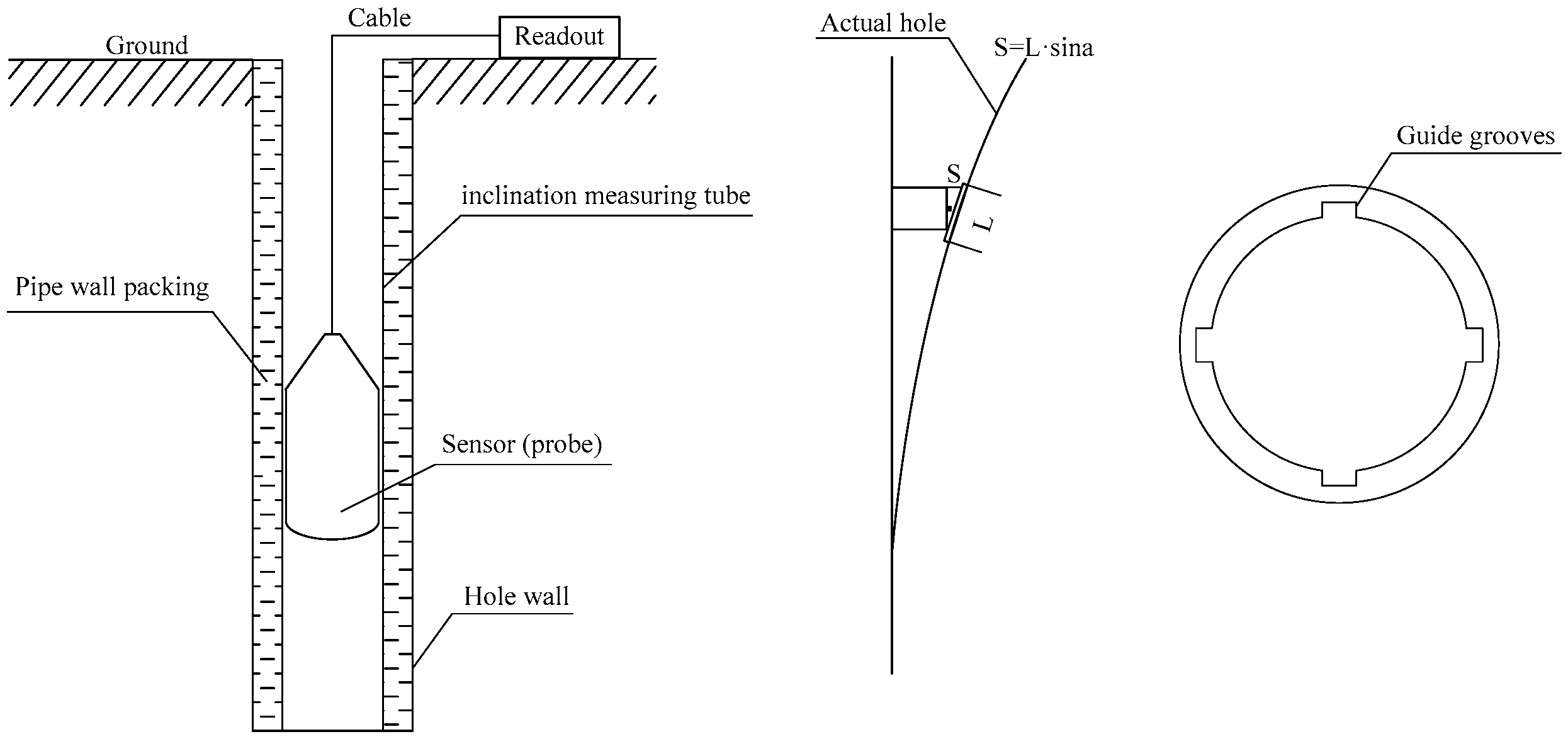

- Ma, Q.; Zhang, B. Theory and application of borehole inclinometer in slope monitoring. GuiZhou Sci. 2008, 26, 84–86. [Google Scholar]

- Wei, S.W. New technologies and development trends of geological disaster monitoring in linear engineering. Railw. Eng. 2019, 59, 57–63. [Google Scholar]

| General | Pitting | Axial Grooving | Axial Slotting | |

|---|---|---|---|---|

| Depth at POD = 90% | 0.1 t | 0.12 t | 0.2 t | ±0.12 t |

| Depth sizing accuracy at 80% certainty | ±0.1 t | ±0.1 t | ±0.15 t | ±0.1 t |

| Length sizing accuracy at 80% certainty | ±15 mm | ±10 mm | ±10 mm | ±10 mm |

| Width sizing accuracy at 80% certainty | ±15 mm | ±12 mm | ±12 mm | ±12 mm |

| General | Pitting | Axial Grooving | Axial Slotting | |

|---|---|---|---|---|

| Depth at POD = 90% | 0.15 t | 0.15 t | 0.1 t | ±0.20 t |

| Depth sizing accuracy at 80% certainty | ±0.15 t | ±0.19 t | ±0.15 t | ±0.15 t |

| Length sizing accuracy at 80% certainty | ±15 mm | ±12 mm | ±15 mm | ±15 mm |

| Width sizing accuracy at 80% certainty | ±15 mm | ±15 mm | ±15 mm | ±15 mm |

| POD for Axial Cracks, Crack-Like Anomalies and Liner Indications ≥ 90% Min. Depth of Crack with L ≥ 20 mm (0.79 in) | ||

|---|---|---|

| Base material and at weld | 1 mm | 0.04 in |

| In weld | 2 mm | 0.08 in |

| Depth sizing accuracy at 80% certainty | ||

| 1…<4 mm (0.04…<0.16 in) | ±1 mm | ±0.04 in |

| ≥4 mm (0.16 in) | ±1.3 mm | ±0.05 in |

| Length sizing accuracy at 90% certainty | ±10 mm | ±0.39 in |

| Location in pipeline wall | ||

| Internal/external | Yes | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.; Li, R.; Jia, G.; Lan, H.; Fu, K.; Liu, X. A Decade Review of the Art of Inspection and Monitoring Technologies for Long-Distance Oil and Gas Pipelines in Permafrost Areas. Energies 2023, 16, 1751. https://doi.org/10.3390/en16041751

Chen P, Li R, Jia G, Lan H, Fu K, Liu X. A Decade Review of the Art of Inspection and Monitoring Technologies for Long-Distance Oil and Gas Pipelines in Permafrost Areas. Energies. 2023; 16(4):1751. https://doi.org/10.3390/en16041751

Chicago/Turabian StyleChen, Pengchao, Rui Li, Guangming Jia, Hao Lan, Kuan Fu, and Xiaoben Liu. 2023. "A Decade Review of the Art of Inspection and Monitoring Technologies for Long-Distance Oil and Gas Pipelines in Permafrost Areas" Energies 16, no. 4: 1751. https://doi.org/10.3390/en16041751

APA StyleChen, P., Li, R., Jia, G., Lan, H., Fu, K., & Liu, X. (2023). A Decade Review of the Art of Inspection and Monitoring Technologies for Long-Distance Oil and Gas Pipelines in Permafrost Areas. Energies, 16(4), 1751. https://doi.org/10.3390/en16041751