Abstract

In the evolving landscape of sustainable energy, efficient management of the hydrogen supply chain is paramount. This study addressed the critical need for decision-making support in this sector, highlighting the development and potential impact of a comprehensive hydrogen supply chain decision database. Utilizing a combination of qualitative and quantitative research methods, the study involved the collection and analysis of data across various stages of the hydrogen supply chain. Emphasis was placed on identifying key decision-making factors, integrating diverse data sources, and employing advanced analytical techniques to enhance the database’s utility. The findings revealed significant insights into the hydrogen supply chain, including bottlenecks, efficiency parameters, and potential areas for optimization. The developed database demonstrated its capability to aid in strategic decision making, offering a tool for stakeholders to navigate the complexities of hydrogen supply and distribution. The creation of the hydrogen supply chain decision database marks a step forward in the field, providing a valuable resource for researchers, policymakers, and industry professionals. It underscores the necessity of data-driven approaches in optimizing the hydrogen supply chain, potentially contributing to the acceleration of sustainable energy initiatives.

1. Introduction

Hydrogen is positioned to play a vital role in future energy systems, offering numerous benefits and addressing key challenges. Its versatility enables it to fulfill crucial roles in the low-carbon economy, complementing electricity by providing services related to heat, transportation, and power systems [1]. In 2021, global hydrogen demand reached 94 million metric tonnes, accounting for approximately 2.5% of global final energy consumption [2]. Projections indicate that hydrogen demand is expected to surge to over 500 million metric tons by 2070 [3]. Recognizing hydrogen’s potential, the International Energy Agency (IEA) emphasizes the opportune time to harness its benefits for a clean, secure, and affordable energy future [4]. Over 20 major economies, including China, the United States, Japan, and Europe, have elevated the development of hydrogen energy to their national strategic agendas. These countries have formulated development plans, roadmaps, and supportive policies to accelerate industrialization and foster the growth of hydrogen [5,6,7,8]. The significance of hydrogen’s potential is reflected in the global industry’s unveiling of 680 proposals for large-scale hydrogen projects as of the end of May 2022. Among these proposals, 534 projects aim to achieve full or partial commissioning by 2030, with an estimated total investment of approximately USD 240 billion [9].

Despite the massive potential that hydrogen energy holds in several sectors, the largest consumers of hydrogen today are refineries and chemical plants. They consume 38 million metric tons every year. In contrast, the transportation sector accounts for less than 0.73 million metric tons [3]. The widespread adoption of hydrogen, particularly outside industrial applications, is met with substantial challenges. These hurdles range from technological limitations and economic viability to lack of infrastructure and low public acceptance. For instance, in the transportation sector, the sales growth of fuel cell electric vehicles (FCEVs) has been relatively slow despite the impressive progress in technology. For instance, in the first quarter of 2023, only 725 new FCEVs were sold in the US, which was almost 30% less than the sales during the same period a year ago [10]. Although significant strides have been made since the first mass-market FCEV—the Toyota Mirai—was launched in 2014, the market share of FCEVs in the global automotive industry remains small compared to those of conventional internal combustion engine vehicles and battery electric vehicles (BEVs) [11]. Another key application of hydrogen energy—residential and commercial heating and power—has also been slower to take off. Fuel cell systems powered directly by hydrogen promise a high-efficiency, low-emission solution for heating and power, yet most of these systems are still in the pilot demonstration phase or limited to niche markets [12,13]. Barriers such as high upfront costs, limited awareness and understanding of the technology, and the need for extensive supporting infrastructure are common obstacles hindering their broad adoption [14]. Moreover, there are emerging applications of hydrogen in sectors previously thought to be difficult to decarbonize. For instance, in aviation, hydrogen-fueled or hydrogen-electric aircrafts are being explored as a solution to reduce the sector’s substantial carbon footprint [15]. However, such applications are still in the early stages of research and development, indicating the broad spectrum of challenges that need to be overcome to realize the full potential of hydrogen economy.

The complexity and challenge of developing a hydrogen economy can be attributed, in part, to the need for synchronizing the diverse interests and concerns of the primary stakeholders involved. These stakeholders include government agencies, investors, manufacturers, end users, hydrogen providers, and many others. Perhaps this intricate web of stakeholders partly explains why, despite significant enthusiasm and willingness, many regional governments and other stakeholders are hesitant to implement substantive measures to incorporate hydrogen into their regional energy systems.

The academic community has been diligently working to provide robust analytical support for decision makers navigating these complexities. A myriad of quantitative and qualitative methods have been applied to probe the multifaceted aspects of a potential hydrogen economy [16,17,18]. Among these methods, multi-objective evaluation of hydrogen supply chains (HSCs) based on operations research methodologies has emerged as a particularly promising approach [19,20,21,22,23]. These operations research methods provide an insightful lens to view the entirety of a HSC. They allow for an exploration of the interactions between the various components, from production to end use. This broad perspective is crucial to achieving a holistic understanding of the HSC, which can inform and shape strategic decision making. By leveraging these methods, we can identify comprehensive, viable strategies for the development of a hydrogen economy at various stages—from small-scale pilots to full-scale regional or national implementations. Additionally, the approach can help discern optimal paths towards achieving not only economic objectives but also environmental and societal goals. In this way, multi-objective evaluation becomes a potent tool in the arsenal of any decision maker aiming to facilitate the transition towards a more sustainable, hydrogen-based economy.

Over the past several decades, academics and practitioners in the field of operations research have developed a diverse arsenal of models and methods with enormous potential. However, to fully utilize these models and extract the valuable insights they can provide, the correct and comprehensive data must first be prepared. The concept of the supply chain decision database (SCDD) was initially introduced by modeling practitioners, supply chain managers, and analysts in the commercial sector. An SCDD encapsulates activities, resources, costs, and demands across a firm’s supply chain. It serves as a foundation to construct optimization models that can holistically analyze strategic or tactical decisions faced by the firm [24].

Drawing inspiration from this idea, we propose the creation of a hydrogen supply chain decision database (HSCDD). This specialized database would be the basis for building hydrogen supply chain-related optimization models. We posit that a standard HSCDD would not only assist numerous local governments in their analytical endeavors, but would also make the results of these analyses comparable by providing a consistent calculation base. Moreover, the introduction of an HSCDD could significantly streamline the pre-optimization process by enhancing data efficiency and reducing repetitive data processing tasks. The time saved through the use of such an organized and systematic approach can then be redirected to performance of more analytical tasks, thus improving the overall efficiency of research and decision-making processes.

The hydrogen economy is poised to be a cornerstone of sustainable energy transition, yet its potential is hampered by the absence of a unified decision support framework that can fully encapsulate the complexity of hydrogen supply chain (HSC) networks. Existing models within the HSC domain have advanced our understanding of cost and logistic optimization but tend to isolate economic factors from the broader spectrum of sustainability metrics. As a result, there is a significant gap in the literature and practice: a comprehensive decision-making tool that integrates the multi-dimensional facets of environmental impact, safety, economic viability, and social responsibility.

Our manuscript introduces the hydrogen supply chain decision database (HSCDD), an innovative construct that bridges this gap. We seek to address a pivotal question: “How can the creation of a hydrogen supply chain decision database (HSCDD) facilitate the optimization and strategic planning of hydrogen infrastructure networks, while considering the multi-dimensional aspects of cost, environmental impact, and safety?” The novelty of the HSCDD lies in its integrative approach, which coalesces disparate data sources—from financial parameters to environmental impact assessments—into a cohesive analytical platform. Unlike its predecessors, the HSCDD is not confined to a singular aspect of the supply chain; instead, it offers a panoramic view that considers the interdependencies of diverse factors influencing HSC viability and sustainability.

The contributions of our work are threefold:

- First, the HSCDD provides a pioneering framework for multi-criteria decision analysis in the context of HSCs, enabling stakeholders to evaluate and prioritize options with a comprehensive understanding of their implications.

- Second, our methodology advances the analytical rigor of HSC planning by incorporating life cycle assessment (LCA) and safety metrics into the economic analysis, facilitating a more balanced and sustainable approach to HSC optimization.

- Third, the HSCDD serves as a crucial stepping stone for future research, offering a versatile foundation for exploring the dynamic and complex nature of HSC networks under various scenarios and assumptions.

In essence, our work not only fills a discernible void in the current literature, but also equips practitioners and policymakers with a pragmatic tool poised to transform HSC design and management into a more holistic, efficient, and environmentally responsible endeavor.

2. From a Supply Chain Decision Database (SCDD) to a Hydrogen Supply Chain Decision Database (HSCDD)

Approximately three decades ago, supply chain managers started to understand that the vast transactional data collected by enterprise resource planning (ERP) systems and other similar data repositories did not automatically translate into effective supply chain decision making [24]. Specifically, raw transactional data, despite their volume and detail, cannot be directly input into optimization models, which are vital tools for strategic decision making.

This realization gave rise to the need for descriptive models. These models act as translators or bridges, transforming raw data into a format that optimization models can readily utilize. As pointed out by Shapiro [24], descriptive models span across a wide array of disciplines, including managerial accounting, forecasting methodologies, operations management, marketing science, and transportation science. Each of these disciplines contributes unique models and methods that help to interpret, contextualize, and prepare the raw data for further analysis. Table 1 provides a detailed breakdown of the functions of these descriptive models. Together, the raw data and the multitude of formulations, methods, and models from these various domains compose the SCDD.

Table 1.

The function of descriptive models employed in SCDD.

The SCDD, as a comprehensive and structured data warehouse, enables efficient data handling and model preparation, thereby facilitating more robust and insightful optimization analyses. The development and application of SCDDs have proven to be an effective strategy for improving supply chain decision making in various industries, and we propose a similar approach for the hydrogen economy in the form of an HSCDD.

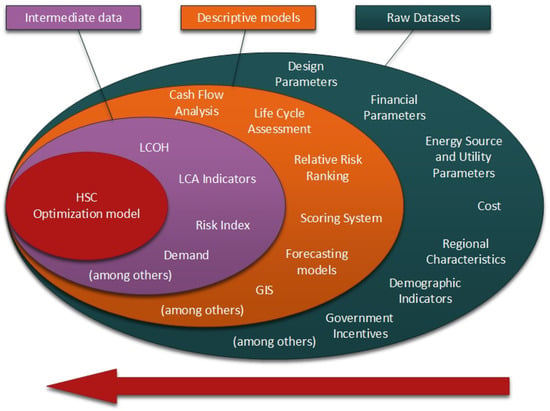

Figure 1 elucidates the structure of an SCDD (or HSCDD in our case) and its relationship with the optimization model. The raw data encompass collected information from a plethora of sources such as design parameters, costs, regional characteristics, and estimated or selected data like financial parameters. These raw data serve as the initial inputs for descriptive models. The outputs produced by these descriptive models, which we refer to as intermediate data, act as the essential inputs or optimization criteria for the creation of various optimization models. Additionally, raw data may also feed directly into these optimization models, acting as model parameters or decision variables, depending on the specific analysis needs.

Figure 1.

The structure of SCDD (HSCDD) and its relationship with the optimization model (LCOH: levelized cost of hydrogen; LCA: life cycle assessment).

As depicted in Figure 1, successful application of an optimization model largely hinges on effective organization and processing of raw data and descriptive models. This effective orchestration of data and models is precisely why SCDDs are increasingly employed by companies across industries. SCDDs have proven to be invaluable tools in aiding managers in utilizing operations research methods in their decision-making processes. By facilitating the smooth transition of data from raw forms to actionable insights, SCDDs play an instrumental role in enhancing the quality and effectiveness of strategic and tactical decision making [24]. In the context of design and planning of regional hydrogen infrastructures, an HSCDD serves a similar function. It provides a structured, comprehensive framework for the efficient organization and processing of relevant data, thereby enabling more effective application of optimization models to address the unique complexities and challenges of the hydrogen economy.

To leverage the numerous sophisticated models developed by operations research, we believe there is a compelling need to establish an HSCDD that can play a role in the emerging hydrogen energy market analogous to the role SCDDs play in the business world. Much like an SCDD, an HSCDD also comprises raw data and descriptive models. However, key differences distinguish the two.

Unlike the SCDD, which typically serves the business strategies of a single firm or a cooperative venture, the HSCDD we propose in this paper is envisioned to support the design, construction, and development of a regional hydrogen infrastructure network. This expands the scope of the HSCDD beyond a single firm’s boundaries to encompass a broader regional perspective, thus involving a wider range of stakeholders and considerations. Moreover, while an SCDD often focuses primarily on cost considerations, reflecting the profit-seeking nature of businesses, an HSCDD needs to take into account a broader set of evaluation criteria. These include not only economic feasibility and efficiency but also environmental impact, safety issues, and other societal considerations. The complex, multifaceted nature of a hydrogen economy necessitates this broader perspective and holistic approach. Therefore, the creation and utilization of an HSCDD must integrate these additional aspects to effectively support decision making in the context of a hydrogen supply chain.

In the sections to follow, we begin by presenting a concrete representation of a specific HSC network, following by a section that details the methodologies employed in the creation of the HSCDD. We then break down the HSC network into its two principal components: hydrogen supply and hydrogen demand. For each of these components, we introduce the representative descriptive models that play a critical role in interpreting and processing raw data. For the sake of simplicity and to maintain focus on the main concepts and mechanisms, we do not delve into the minute details of the various raw data types. Instead, we use several datasets as representative examples of groups of raw data. Towards the end of the paper, we explore how optimization modeling can be conducted based on the HSCDD that we propose and develop throughout the paper. We aim to demonstrate the practical applications and potential benefits of an HSCDD in facilitating more robust and effective decision making in the context of regional hydrogen infrastructure network planning and development.

3. The Hydrogen Supply Chain Network Representation

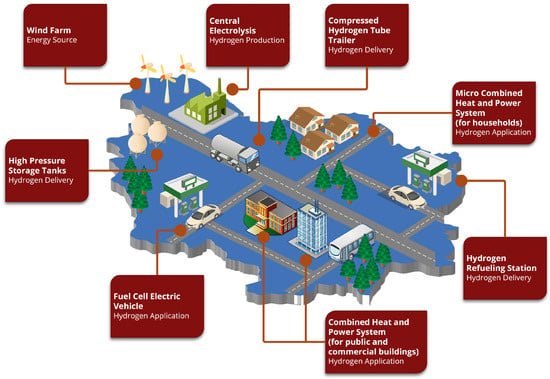

Figure 2 delineates network representation of a typical HSC. A comprehensive HSC encompasses multiple stages, ranging from the initial energy source to the final point of consumption. Broadly speaking, an HSC can be segmented into three primary components: hydrogen production, hydrogen delivery, and hydrogen application [25]. It is important to note that hydrogen has long-standing applications in various industries, including refining, metal treatment, and food processing [26]. However, these industrial uses of hydrogen are not the focus of our study. This is because the hydrogen utilized in these industries is predominantly “captive”, meaning it is used directly at the site of production, such as at a refinery or chemical plant [27]. This “captive” use of hydrogen presents a different set of dynamics and considerations, which are distinct from the broader hydrogen supply chain context we are exploring in this paper. Our focus in this paper is on the development of an HSCDD to support decision making related to the broader, regional hydrogen infrastructure network. This entails a focus on the HSC from production through to end-use applications that involve distribution and transportation, such as FCEVs and combined heat and power (CHP) systems. Therefore, our proposed HSC network representation and the subsequent development of the HSCDD are oriented towards these broader HSC applications.

Figure 2.

Network representation of a typical HSC (adapted from Li et al. [28]).

Hydrogen as an energy carrier must be derived from compounds that contain hydrogen. There are a plethora of methods to produce hydrogen, each leveraging different energy resources. These resources can include fossil fuels, such as natural gas, coal, and biomass; nuclear energy; and renewable energy sources like wind, solar, geothermal, and hydroelectric power, which can be used to split water into hydrogen and oxygen [29]. As of today, a substantial share of hydrogen is generated using natural gas through a process known as steam methane reforming (SMR). This method is presently the most economical way of hydrogen production [3]. However, as we transition towards a hydrogen economy, the objective is to significantly enhance the sustainability of our energy system, primarily by substantially reducing environmental impact.

In light of this goal, there is a growing interest in hydrogen production methods that leverage renewable energy sources [30]. These methods have the potential to deliver hydrogen with a minimal carbon footprint. Fossil fuel-based production methods could also play an essential role if combined with carbon capture and storage (CCS) technologies to yield low-carbon or even carbon-neutral hydrogen. It is crucial that our proposed HSCDD account for these different production methods and their respective economic, environmental, and safety considerations.

One of the unique characteristics of hydrogen is its low volumetric energy density, which makes it more expensive to deliver compared to other fuels like natural gas and gasoline. Consequently, this poses significant challenges and necessitates innovative solutions to improve the efficiency of hydrogen delivery [31]. Currently, researchers are exploring potential alternative hydrogen carriers, including metal hydrides and chemical hydrides, as potential solutions to this challenge [32]. These carriers have the potential to significantly enhance the efficiency of hydrogen delivery, while practical applications of these alternative carriers are still in their infancy.

Another promising avenue for hydrogen transportation involves integrating it into existing gas pipelines or establishing a dedicated pipeline network. This approach is gaining traction as it leverages the extensive infrastructure already in place for natural gas distribution. By introducing hydrogen into existing pipelines, we can utilize their established pathways, reducing the need for entirely new infrastructure. However, there are challenges associated with this method, primarily related to the compatibility of materials and the need for upgrades to ensure safety and efficiency. Researchers and engineers are actively working on addressing these issues to make hydrogen transportation via pipelines a viable and environmentally sustainable option. Additionally, this method has the potential to play a crucial role in facilitating the transition to clean energy future by enabling the distribution of green hydrogen produced from renewable sources to various industries and consumers.

In the interim, we must rely on the two traditional methods of hydrogen delivery: compressed gas supply and liquid hydrogen distribution. While these methods are well-established, they present their own set of challenges and considerations in terms of cost, environmental impact, and safety. As we develop our proposed HSCDD, it is important to account for these different delivery methods and their associated considerations. This will ensure that our HSCDD provides a comprehensive and realistic representation of the hydrogen delivery segment of the HSC.

Despite its importance, the analysis of hydrogen demand has often been paid little attention in many HSC-related studies. This oversight is typically manifested in assumptions of an exogenous trajectory for the number of FCEVs, which are used to estimate hydrogen demand. Additionally, many of these studies are limited in their scope, as they primarily focus on hydrogen applications in the transport sector, particularly FCEVs, while overlooking another promising area for non-industrial use—building heat and power. In our view, a comprehensive understanding of hydrogen demand is crucial for capturing the intricacies of an HSC network, including the variety of options and trade-offs involved. A detailed analysis of hydrogen demand, integrated into our proposed HSCDD, could shed light on potential applications and inform strategic decisions related to hydrogen infrastructure development.

Therefore, the creation of the HSCDD is divided into two major components: hydrogen supply, encompassing production and delivery, and hydrogen demand. By considering these two aspects separately, we aim to construct a robust HSCDD that accurately represents the multifaceted nature of a regional hydrogen infrastructure network. This approach also facilitates in-depth investigations into both supply and demand aspects of the hydrogen economy, yielding insights that can support strategic planning and decision making in this burgeoning sector.

4. Methodology in the Creation of the Hydrogen Supply Chain Decision Database

In this section, we detail the methodologies employed in the creation of the HSCDD. From the initial stages of data collection and preparation, through the application of descriptive modeling, to the final development of the decision-making database, we outline the comprehensive approach that underpins our research. This section provides a clear understanding of the processes and techniques used to ensure the HSCDD is both robust and effective in facilitating informed decisions in the hydrogen supply chain sector.

4.1. Data Collection and Preparation

In developing the HSCDD, our initial step was the meticulous collection and preparation of data, a foundational aspect crucial for the accuracy and relevance of the database.

- Sources and Types of Data: Our data gathering process involved sourcing information from a diverse array of channels. This included industry-specific data such as hydrogen production rates and distribution metrics, academic research providing insights into emerging hydrogen technologies, and governmental reports detailing regulatory frameworks and environmental impacts. We focused on collecting both quantitative data, such as production volumes and cost figures, and qualitative data, including expert opinions and regulatory guidelines.

- Data Validation and Verification: To ensure the reliability and accuracy of our data, we implemented a stringent validation and verification process. This process included cross-referencing data points with multiple sources, consulting industry experts to confirm the veracity of technical information, and employing statistical methods to identify and rectify any anomalies or inconsistencies. This rigorous approach was pivotal in establishing a solid foundation of trustworthy data for the HSCDD.

- Data Preprocessing: Given the diverse nature of our data sources, preprocessing was essential to standardize and harmonize the data. This step involved normalizing data formats, categorizing information into coherent groups (e.g., by technology type or geographic region), and converting qualitative descriptions into quantifiable metrics where possible. These preprocessing efforts were key to ensuring that the data were not only consistent but also structured in a way that facilitates effective analysis and integration into the HSCDD.

4.2. Descriptive Modeling

The development of the HSCDD was significantly enhanced by the incorporation of descriptive modeling. This stage was critical in transforming the collected raw data into a format that is both analyzable and meaningful for decision-making processes.

- Role in Data Transformation: Descriptive modeling played a pivotal role in our methodology, enabling us to interpret and understand the vast array of collected data. By applying these models, we were able to summarize and describe various aspects of the hydrogen supply chain, such as production trends, distribution patterns, and market dynamics. This process was crucial in identifying underlying patterns and relationships within the data, which are essential for informed decision making.

- Types of Models Used: Our approach involved the use of several descriptive models, each tailored to specific types of data and analysis requirements. For instance, we employed cash flow analysis models to evaluate the financial aspects of different hydrogen supply chain scenarios. Scoring systems were used to assess and compare the fueling needs of different residential areas.

4.3. Development of the Decision Database

The culmination of our efforts in data collection, validation, and the application of descriptive modeling was the creation of the HSCDD, a comprehensive tool designed to facilitate informed decision making in the hydrogen supply chain sector.

- Database Structure and Integration: The architecture of the HSCDD was meticulously crafted to ensure both robustness and user friendliness. At its core, the database integrates the rich dataset we compiled with the descriptive models, such as cash flow analyses and scoring systems, to provide a multifaceted view of the hydrogen supply chain. This integration allows for the seamless interaction between raw data and analytical models, enabling users to not only access extensive information, but also apply these models directly to the data within the database. The structure of the database is designed to support various types of queries, from simple data retrieval to complex analytical computations, catering to a wide range of user needs.

- Decision-Making Features: One of the key attributes of the HSCDD is its capability to assist in decision-making processes. The database includes features that allow for users to conduct scenario analyses, compare different supply chain options, and evaluate potential outcomes based on varying parameters. These functionalities are bolstered by the descriptive models integrated into the database, which provide the necessary framework to interpret data and make predictions or recommendations. This aspect of the HSCDD is particularly valuable for stakeholders who require a deep understanding of the hydrogen supply chain to make strategic decisions.

5. The Creation of Hydrogen Supply Chain Decision Database—Hydrogen Supply

In this section, we first describe the structure of the HSCDD based on the analysis of its service object optimization models. Next, we discuss the main components of the HSCDD separately.

5.1. The “Three Dimension”

Optimization models serve a crucial role in identifying optimal solutions by either maximizing or minimizing an “objective function”, a particular metric indicative of system performance. Traditionally, in the realm of infrastructure construction, analysts and decision makers typically select the minimization of total cost as the optimization objective. However, an exclusive focus on a single objective such as cost may inadvertently neglect other critical aspects of system performance. For instance, if cost is the sole consideration, steam methane reforming (SMR), which is currently the most cost-effective method, is likely to dominate approaches for hydrogen production. However, if environmental impacts are also considered, renewable energy-based water electrolysis becomes an equally valid and necessary approach, given its potential for low- or zero carbon emissions.

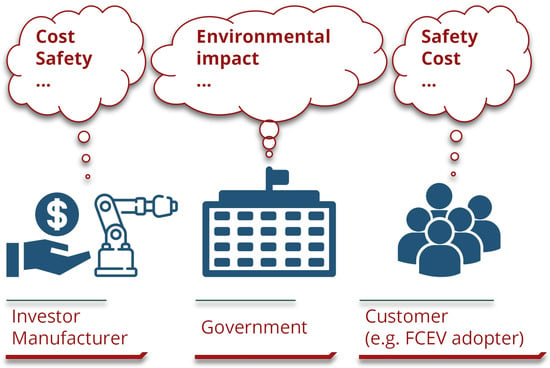

Similarly, considerations about safety could shift the preference from a centralized to a decentralized supply chain, in contrast to a network designed exclusively around cost minimization [33,33]. As depicted in Figure 3, different stakeholders possess different primary concerns regarding the HSC network, which stem from diverse considerations of interest. In this light, it is crucial to acknowledge the multidimensionality of the HSC optimization problem, which spans not just cost but also environmental and safety considerations. Recognizing the “three dimensions”—cost, environmental impact, and safety—and integrating them into the HSCDD lays the groundwork for a more balanced and holistic approach to hydrogen infrastructure network construction and optimization, one that aligns with the complex nature of real-world decision-making scenarios.

Figure 3.

The primary concerns of different groups of stakeholders.

Consequently, it becomes evident that the design of the HSC network should be governed by multi-objective optimization models. These models need to incorporate three critical performance metrics: cost, environmental impact, and safety. Collectively, these factors determine the direction and process of optimization, ensuring a more comprehensive and balanced solution. The primary purpose of constructing the HSCDD is to feed these multi-objective optimization models with relevant data and descriptive models. In alignment with this, the HSCDD for hydrogen supply is organized into three main sections, each of which corresponds to one of the critical performance metrics. These sections consist of an assortment of datasets and descriptive models, designed to represent the various elements and factors influencing each performance metric.

In the subsequent subsections, we delve into the composition of these three sections of the HSCDD. We elaborate on the kinds of datasets and descriptive models that form each section, explain how they capture the nuances of cost, environmental impact, and safety in the context of hydrogen supply, and illustrate their relevance to the multi-objective optimization of the HSC network. This provides a roadmap for the practical establishment and utilization of the HSCDD in the analysis and decision-making processes related to hydrogen infrastructure network construction.

5.2. Datasets and Descriptive Models

5.2.1. Cost

Upon reviewing the relevant literature, it is evident that most optimization models related to HSCs adopt a basic combination of capital and operating costs as the cost objective function [34]. In doing so, significant considerations such as the anticipated lifespan of infrastructures, different financing approaches, and the time value of money are often underrepresented. To address these concerns, we suggest the adoption of the levelized cost of hydrogen (LCOH) as a more encompassing representative of the cost issue.

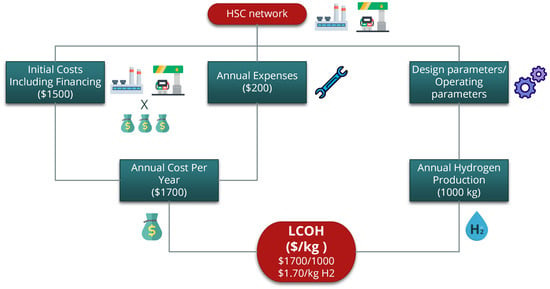

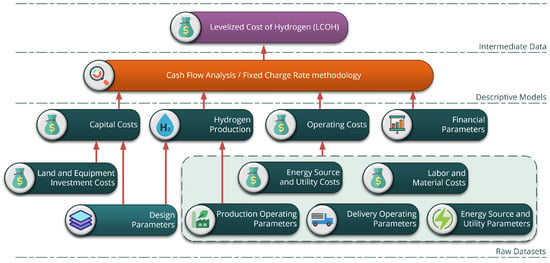

The concept of LCOH is derived from the levelized cost of electricity (LCOE), a measure commonly used in the economic assessment of energy projects [35]. The LCOE represents the net present value of the unit cost of electricity over the lifetime of a generating asset. Similarly, the LCOH reflects the average cost of producing one unit of hydrogen, factoring in all the costs over the life of the hydrogen production facility. This calculation process of LCOH is visualized in Figure 4.

Figure 4.

The concept of levelized cost of hydrogen (LCOH) (adapted from Li et al. [34]).

Utilizing LCOH as the metric allows for a more nuanced comparison of different hydrogen production and delivery technologies. It takes into account variations in lifespan, project size, capital cost, and capacity, making it a more comprehensive cost metric. By integrating LCOH into the HSCDD, we can provide a robust foundation for decision-making processes in the HSC that accounts for the full spectrum of costs over the long term. This approach can facilitate the selection of the most economically viable production and delivery technologies and strategies for different scenarios and requirements.

The discounted cash flow (DCF) model is a useful tool for calculating the LCOH to yield a prescribed internal rate of return (IRR). This model encapsulates various financial aspects, including revenue from hydrogen sales, capital costs, operating costs, replacement costs, and considerations related to depreciation and tax. By offering a comprehensive and detailed analysis of all future cash inflows and outflows, the DCF model can deliver a reasonable estimation of LCOH. Another methodology that can be employed is the fixed charge rate (FCR) analysis. While this approach might be less rigorous than the DCF model, it serves a similar purpose. FCR methodology determines the annual revenue necessary to cover investments. In mathematical terms, FCR is defined as the amount of revenue per dollar of investment required each year to cover the carrying charges (i.e., return on equity and book depreciation) on a specific investment [36]. This approach is particularly suitable for quickly determining the contribution of a particular component (an infrastructure or critical equipment) to the final LCOH.

It is important to note that regardless of the financial modeling method used, the key is to accurately capture all costs associated with hydrogen production and delivery over the asset’s lifecycle. The adoption of LCOH as a primary cost metric in HSCDD, combined with sound financial modeling, can help to ensure that decision-making processes in the HSC are grounded in comprehensive, long-term economic analysis.

The two methods discussed above serve as descriptive models and require to be fed with various raw datasets, as shown in Figure 5.

Figure 5.

Superstructure of the HSCDD: Hydrogen supply—Cost.

- Design Parameters: This refers to the design capacities of hydrogen infrastructures, such as plant life, land usage, site locations, and the technical parameters of primary components;

- Production/Delivery Operating Parameters: These parameters include capacity factors, labor force, material use for maintenance and repairs, and parameters used to describe operating conditions of primary components;

- Energy Source and Utility Parameters: This dataset encompasses the consumption of energy sources as feedstock for hydrogen production, as well as the use of utilities for hydrogen production and delivery;

- Site and Equipment Investment Costs: These are the costs incurred at the beginning of construction, also known as capital costs. They include land cost, site preparation, project contingency, one-time licensing fees, upfront permitting costs, and equipment costs. We note that land cost is considered a non-depreciable capital cost;

- Labor and Material Costs: These costs correspond mainly to the fixed operating cost and include labor, insurance, maintenance, and repair costs;

- Energy Source and Utility Costs: This dataset contains not only the current prices for all energy sources and utilities but also future price projections to satisfy the needs of cash flow analysis;

- Financial Parameters: These parameters refer to the financial input values required for cash flow analysis and FCR analysis. This includes parameters related to depreciation, financing issues (equity and debt), decommissioning cost, salvage value, inflation rate, after-tax IRR, and tax-related parameters.

Each of these data categories provides critical inputs for modeling the cost component of the HSCDD, reflecting the full breadth of financial considerations necessary for the effective planning and optimization of HSCs.

5.2.2. Environmental Impact

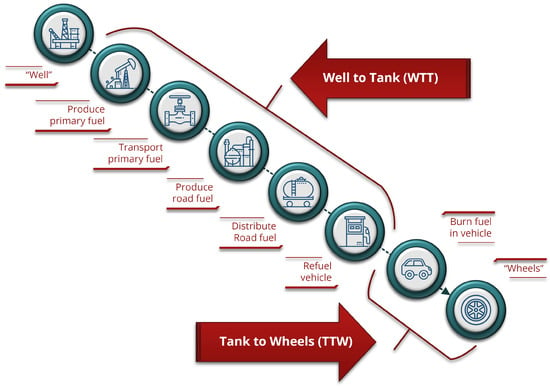

For a comprehensive and unbiased evaluation of the environmental impacts associated with a HSC network, a life cycle assessment (LCA) should be performed. This assessment must encompass all stages, including the recovery of the energy source, the production and delivery of hydrogen, and its ultimate consumption. A particular form of LCA used for transport fuels and vehicles is the “Well-to-Wheels” (WtW) analysis. As shown in Figure 6, this analysis is often divided into two primary stages: “Well-to-Tank” and “Tank-to-Wheels”.

Figure 6.

Well-to-Wheels analysis.

The “Well-to-Tank” stage comprises the production of the primary fuel (or energy source), its transportation, and the production and distribution of the fuel (in this case, hydrogen). Conversely, the “Tank-to-Wheels” stage deals solely with vehicle operation. WtW analysis is beneficial as it provides insights into the varying environmental impacts of different production, delivery technologies, and HSC network configurations at both stages. This holistic approach ultimately offers a comprehensive view of the real environmental impacts, which is essential for designing environmentally friendly HSC networks and making informed decisions regarding their deployment.

Several studies related to the HSC express the environmental impact through global warming potential (GWP). This metric signifies the overall impact of a process on the heat-absorbing capacity of the atmosphere, owing to the emissions of greenhouse gases, typically expressed as a CO-equivalent [33]. However, relying on a single environmental metric may be insufficient, as it could exclude other pertinent environmental factors from the analysis.

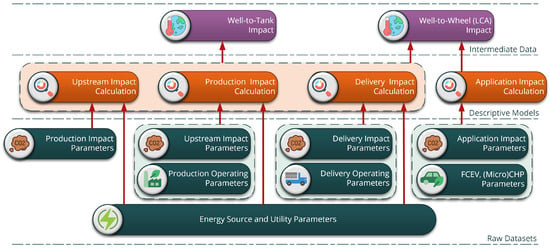

Hence, a broader array of environmental indicators should be considered when employing LCA or WtW approaches. This methodology can evaluate the environmental impact from various perspectives, offering a more comprehensive understanding of the ecological footprint of the HSC network. As depicted in Figure 7, we break down the “Well-to-Tank” stage into “Upstream Impact Calculation”, encompassing the recovery and transportation of the energy source, “Production Impact Calculation”, and “Delivery Impact Calculation”, which correspond to hydrogen production and delivery, respectively. We extend the “Application Impact Calculation” to take into account not only FCEVs but also the CHP and Micro-CHP systems. This diversified approach can offer a more accurate and inclusive picture of the environmental effects of hydrogen production, distribution, and use across multiple applications.

Figure 7.

Superstructure of the HSCDD: Hydrogen supply—Environmental impact.

- Upstream, Production, Delivery, and Application Impact Parameters: Each of these datasets includes different impact metrics that are relevant to the respective stages of the HSC. They provide critical data for understanding the environmental impact of each part of the process, from hydrogen production to final consumption;

- FCEV, (Micro) CHP Parameters: This dataset contains parameters related to the devices and systems that utilize hydrogen as an energy source. This primarily involves properties and operational characteristics of FCEVs, CHP systems, and micro-CHP systems.

The environmental component of the HSCDD therefore captures a wide range of information that can support multi-criteria optimization.

5.2.3. Safety

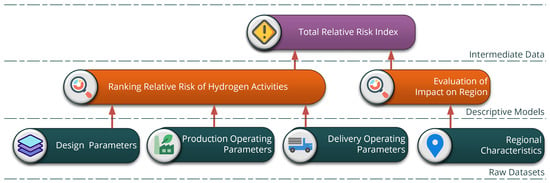

When it comes to safety, the aim of the HSCDD is to establish a quantitative evaluation system founded on risk analysis. Traditional methods such as quantitative risk analysis (QRA) and hazard and operability study (HAZOP) may not be perfectly suited for this task during the preliminary design stages of an HSC network. This is mainly because the level of detail available at this stage is not sufficient for an exhaustive analysis. As a result, we suggest the use of simpler techniques like rapid risk ranking (RRR).

The RRR method is often implemented as a collaborative session with experts. The group carries out several tasks including hazard identification (HAZID), consequence and frequency estimation, and risk ranking. Risk is determined by the combination of severity and probability of a potential hazard [37,38]. Severity of impact is divided into five distinct levels: “Catastrophic”, “Severe loss”, “Major damage”, “Damage”, and “Minor damage”. Each level is indicative of the potential impact magnitude, with “Catastrophic” implying significant irreversible consequences and “Minor damage” representing manageable and reversible impacts. Probability of occurrence is also stratified into five categories, labeled “A” through “E”. These range from events with a probability of less than 0.001 per year (Category A) to those with a probability between 1 and 10 per year (Category E), with the former being extremely unlikely and the latter relatively expected within any given year. The intersection of severity and probability determines the risk rating, which is denoted as “High” (H), “Medium” (M), or “Low” (L). For example, a catastrophic event even with the least probability (Category A) is considered to be high risk, highlighting the critical nature of such events. Conversely, an event categorized as “Minor damage” coupled with the same low probability is deemed to be low risk, suggesting that simpler control measures may be adequate.

It is important to note that the overall risk associated with a hydrogen infrastructure is determined not only by the potential hazards of hydrogen activities but also by their locations. For instance, a hydrogen production plant located in a densely populated city poses a higher risk than the same plant in a rural area [39]. Therefore, it is crucial to evaluate the potential impact on a region based on its unique characteristics such as population density. In conclusion, the HSCDD’s approach to safety is represented by the total relative risk index. This index is derived from the ranking of the relative risk of hydrogen activities and an evaluation of their potential impact on the region in which they take place.

The structure of the HSCDD for the safety design is depicted in Figure 8. Only one dataset is first shown here:

- Regional Characteristics: This dataset contains parameters (e.g., population density) used to evaluate the safety impact of hydrogen activities on a specific region.

Figure 8.

Superstructure of the HSCDD: Hydrogen supply—Safety.

6. The Creation of HSCDD—Hydrogen Demand

A key task of HSC modeling is to guide the development of strategies concerning hydrogen infrastructure investment schemes. In essence, these strategies provide answers to the “4W questions”, which pertain to the timing, location, size, and technology choices for building hydrogen infrastructures. Hydrogen infrastructures are designed to meet the specific hydrogen demand within a certain region. Therefore, in the context of the HSCDD, the goal for hydrogen demand estimation is to supply optimization models with intermediate data. These data pertain to the timing, location, and scale at which hydrogen demand occurs in the given region. In this section, we introduce several raw datasets and descriptive models, and we discuss two kinds of non-industrial hydrogen applications—FCEV and Micro-CHP systems, respectively.

6.1. The Estimation of Hydrogen Demand of FCEVs

Transitioning the transport sector from reliance on unsustainable fossil fuels to more sustainable sources is crucial for significantly reducing greenhouse gas emissions. FCEVs, along with other environmentally friendly vehicles such as plug-in hybrid electric vehicles (PHEVs) and battery electric vehicles (BEVs), are gradually supplanting traditional internal combustion engine vehicles (ICEVs). China, the world’s largest automobile market, has joined an expanding roster of nations setting timelines for the phase-out of fossil fuel-powered vehicles. Concurrently, numerous countries are accelerating the construction of the necessary supporting infrastructures, especially charging points or refuelling stations, for these environmentally friendly vehicles. These initiatives serve to encourage the adoption of FCEVs and other eco-friendly transport options, making the estimation of future hydrogen demand for these vehicles a critical factor in developing an effective HSC strategy.

Unlike PHEVs and other bi-fuel vehicles, most FCEVs are designed to run solely on hydrogen. This dependency places the availability of hydrogen fueling stations (HFSs) as a critical factor influencing the uptake of FCEVs in the consumer market [40]. Consequently, determining the optimal locations for HFSs becomes a crucial consideration in the regional design of an HSC network, particularly during its initial development stages. On the one hand, the presence of HFSs is necessary to cater to the fueling requirements of FCEVs on the road. On the other hand, a strategically planned network of fueling stations can stimulate the adoption of FCEVs by satisfying the “potential needs" of prospective consumers. Thus, maximizing the capability to meet these demands is a core objective of optimization models. The HSCDD, in this context, shoulders the responsibility of identifying and quantifying these needs, which it accomplishes by collating and structuring relevant raw datasets and descriptive models. By doing so, it aids in the design and implementation of a functional and efficient HSC.

Based on a thorough analysis of the refueling habits of conventional ICEV owners as well as surveys of FCEV users, it is observed that refueling demands typically arise near the vehicle owner’s residence (home fueling) or along their commuting routes (commute fueling) [41]. As such, for home fueling, it becomes imperative to identify regions where residents are most likely to be the “early adopters” of FCEVs, in essence determining and ranking the potential of different regions in terms of their propensity for FCEV ownership. For commute fueling, it is necessary to measure the density of commuting traffic through each region. Consequently, a comprehensive descriptive model is required, capable of evaluating the relative size of fueling demands raised in each region. A scoring system is adept for this task as it can account for the impact of diverse factors and output a quantified indicator. Melendez and Milbrandt [42] applied such a scoring system, coupled with geographic information system (GIS) methods, to differentiate hydrogen demand across the U.S., taking into account both consumer attributes (like income and education level) and policy attributes (like government incentives). The California Air Resources Board (ARB) similarly used a scoring system in their planning tool named CHIT (California Hydrogen Infrastructure Tool). The goal of CHIT is to provide general direction indicating regions where hydrogen fueling stations are most needed [41].

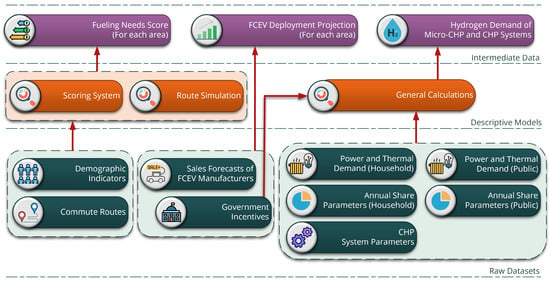

While a scoring system can effectively distinguish areas with relatively higher refueling needs, providing critical input for the placement of HFSs, a quantitative estimate of absolute fueling demand for specific regions, is also essential to determine the capacities of these HFSs. If we maintain an assumption of uniform average annual mileage for all FCEV adopters, the task of estimating fueling demand essentially translates to forecasting the number of FCEVs. In this context, two primary factors come into play: the deployment projections of FCEV manufacturers and the impact of government incentives. The participation of FCEV manufacturers is critical for kickstarting regional FCEV markets. On the one hand, sales plans of these manufacturers provide a reference point for determining fueling capacities. On the other hand, manufacturers may modify their deployment projections based on the existing state or planned development of HFSs. Additionally, government incentives and other related policies play a significant role in early-stage development of hydrogen-based transportation. Governments may either directly set developmental goals for the total number of registered FCEVs or provide other policy support. All these factors need to be considered when estimating the number of FCEVs. The raw datasets and descriptive models pertinent to this subsection are depicted in Figure 9.

Figure 9.

Superstructure of the HSCDD: Hydrogen demand.

- Demographic Indicators: This dataset describes the attributes affecting hydrogen vehicle adoption by consumers. The selection of attributes is based on researchers’ assumptions as well as market studies and analyses. For instance, the number of households with two or more vehicles is selected because it is assumed that households with multiple vehicles are more likely to adopt hydrogen vehicles. Household income acts in the same way. Education level is also included based on the assumption that higher education leads to earlier adoption.

- Commute Routes: Ideally, this dataset should include the fully detailed origin–destination data for commutes and the commute route between each origin–destination pair. Unfortunately, the observed, actual routes of commuters are hard to obtain. Instead, route simulation is applied to obtain approximate results.

6.2. The Estimation of Hydrogen Demand of Micro-CHP and CHP Systems

Combined heat and power (CHP) systems are energy conversion devices that utilize a single fuel source to simultaneously generate electricity and heat. CHP systems can be deployed at various scales, from public buildings to residential setups, the latter being referred to as micro-CHP systems with typical electrical output ranging between 0.1 and 10 kW. In 2009, micro-CHP systems were introduced in Japan under the name “ENE · FARM” and have since seen a growing adoption, exceeding 433,200 installations by the end of 2021 [43]. These systems utilize built-in reformers to produce hydrogen from fuels like natural gas, liquefied petroleum gas, or kerosene. However, using hydrogen directly as a fuel not only eliminates the need for reforming, but also significantly reduces the environmental impact if hydrogen is sourced from low-carbon energy sources [44]. Hydrogen is mostly considered as an alternative fuel in remote areas, where establishing a natural gas grid is challenging. In public and commercial buildings, CHP systems, fueled by either fossil fuels or hydrogen, can co-generate with electrically powered HVAC (Heating, Ventilation, and Air Conditioning) systems, providing power and heat loads as well as serving as a backup for uninterruptible power supply systems and/or diesel generators [44]. The supply chain for hydrogen for CHP and micro-CHP systems closely resembles that of liquefied petroleum gas, involving transportation to various distribution centers and subsequent distribution to end users. The hydrogen demand of a single CHP system mainly depends on the power and heat demand of the customer, the contributing share of the CHP system, and system efficiency. While estimating the number of future installations is challenging, factors such as government policy and system capital price forecasts could provide useful references. The raw datasets and descriptive models used in this subsection are depicted in Figure 9.

7. Optimization Modeling Based on HSCDD

In the preceding sections, we explored the architecture of the hydrogen supply chain decision database (HSCDD), various descriptive models, and an array of raw datasets. With the foundation laid by HSCDD, it is possible to establish optimization models for the HSC that meet diverse research requirements. Studies on the regional HSC network can be categorized into two key types: near-term and long-term analysis. Each developmental stage has different focal points. In this section, we delve into the main problems to be addressed in optimization models and demonstrate how the HSCDD can assist in establishing these models for both near- and long-term analyses.

7.1. Near-Term Analysis of Regional HSC Network

The term “near-term” pertains to the initial phase of development, with the emphasis on the question of “how to start”. More specifically, the aim is to discern how to foster a small-scale hydrogen energy market with a modest investment. Due to the investment size, which is deliberately kept small to mitigate financial risks, only small-scale infrastructure can be constructed. As such, we need to focus resources on catering to the most promising users. In the near term, FCEVs are the main consumers of hydrogen; hence, the design of the HSC network should be aimed primarily at meeting the fueling needs of these hydrogen-powered vehicles.

In the near term, distributed (forecourt/on-site) production is an apt approach for hydrogen production. This method involves constructing HFSs where hydrogen is produced on site and then stored for transfer to in-vehicle hydrogen storage. On-site hydrogen production facilitates the use of various hydrogen production methods depending on the available energy source. Some of these methods leverage renewable energy systems such as wind or solar, while others employ a fossil fuel source. The two primary on-site hydrogen production techniques are water electrolysis and steam methane reforming (SMR) [45]. If all hydrogen is produced on site, there is no requirement for hydrogen delivery, resulting in considerable investment savings. Where feasible, on-site hydrogen production, storage, and fueling apparatus can be installed within an existing gas station to further minimize the investment by sparing the cost of land. However, the drawback of on-site production is that it can entail relatively high manufacturing costs and environmental impacts due to small production scale.

In near term, the HSC network is designed to satisfy some potential fueling needs at a certain level of investment and environmental impact. To this end, the HSC optimization model chooses the following three objectives: maximizing the capability to meet the fueling needs, minimizing the LCOH, and minimizing the environmental impact. The questions that the optimization model is expected to answer include the following: How many HFS are needed for each station? Where can it be placed? What production technology will it adopt? What is its fueling capacity?

In near-term analyses, the primary descriptive models utilized are life cycle environmental impact calculations, cash flow analyses, and the fueling demand scoring system. Government incentive policies are crucial during this period. The government’s support for the development of the hydrogen market primarily stems from the fact that the use of hydrogen as an alternative to fossil fuels can help meet its emission reduction targets. Thus, an accurate assessment of the potential emission reduction effect is a critical basis for the formulation of incentive policies. The life cycle assessment (LCA) model, specifically Well-to-Wheels (WtW) analysis, can fulfill this requirement. Additionally, determining the lowest selling price is essential as it can assist in establishing the amount of subsidies needed to make hydrogen fuel economically competitive. Cash flow analysis can provide LCOH calculation, which is an excellent benchmark for this purpose. Finally, the fueling demand scoring system aids in identifying optimal locations for HFSs.

7.2. Long-Term Analysis of Regional HSC Network

In long-term analyses, the primary objective is to decrease the LCOH by leveraging economies of scale. This strategy improves the competitiveness of hydrogen energy and reduces dependency on governmental support. Besides FCEVs, CHP systems become another major application. Centralized production is implemented to produce a large amount of hydrogen at a lower cost. This production method can be either fossil fuel-based, using large-scale techniques like SMR or coal gasification combined with carbon capture and storage (CCS), or based on renewable energy, using centralized electrolysis powered by solar or wind energy. With the introduction of centralized production, a hydrogen delivery system becomes essential. Tube trailers and pipelines can be utilized for transporting gaseous hydrogen, while liquid tanks are suitable for networks based on liquid hydrogen. This dual focus on increasing production and enhancing delivery systems provides a holistic approach to scaling hydrogen infrastructure in the long term.

In the long term, the issue of HFS location becomes less critical due to the maturation of the fueling network. With the involvement of centralized production and hydrogen delivery, risk management becomes an important factor in the modeling process. Therefore, the HSC optimization model incorporates the following three objectives: minimizing the LCOH, environmental impact, and total relative risk. The optimization model is expected to provide decision support concerning the quantity of central production plants, as well as their location, technology, and capacity, and also the preferred delivery approach. This multifaceted strategy helps stakeholders make well-informed decisions while enhancing the overall efficiency and sustainability of the hydrogen supply chain.

The primary descriptive models adopted in the long-term analysis are life cycle environmental impact calculation, cash flow analysis, and relative risk ranking method.

7.3. The Transition Phase between the Near-Term and Long-Term Stages

The evolution of the HSC demands a seamless transition from its nascent stages of development, termed the near term, to its eventual maturity in the long term. This bridging phase, often referred to as the “mid-term” or the “adaptive phase”, is of paramount importance in ensuring that the investments made during the early stages remain resilient and adaptable in the face of growing and potentially shifting demand patterns.

Ensuring the sustainability of initial investments is a cornerstone of our approach. Our strategies in the near term, though crafted to address immediate fueling needs, are infused with foresight, anticipating the future landscape of the hydrogen economy. Distributed production methods chosen for the near term, for instance, are envisioned not just for their immediate relevance, but as foundational elements. These can either be scaled or integrated into a more extensive network as the sector matures.

Scalability and evolution of the supply chain to meet burgeoning demands form another crucial aspect of the transition. Recognizing the inherent differences in how demand might evolve across regions, our transition strategies emphasize infrastructure flexibility. Decisions about persisting with on-site stations or shifting focus to smaller, scalable production units are largely informed by the projected hydrogen demand in specific areas. Tools such as the fueling demand scoring system and the relative risk ranking method are pivotal in guiding these decisions. The goal is to ensure that the infrastructural choices of today remain in harmony with the long-term growth trajectories of tomorrow.

Several mechanisms underpin this transitional phase. Modular infrastructure development is central to our approach, allowing for infrastructural components to expand, reduce, or adapt based on the ebb and flow of demand and the advent of technological advancements. Furthermore, forging strategic partnerships with other energy providers and stakeholders in the supply chain can prove invaluable. Such collaborations offer opportunities for shared investments, diversifying risks, and leveraging complementary expertise. Last but not least, the importance of continuous monitoring cannot be overstated. A dynamic feedback mechanism will be put in place, employing real-time data analytics and periodic reviews. This will ensure that the HSC network remains nimble, responding adeptly to both anticipated and unforeseen shifts in the landscape.

In all, by delineating and actively managing this transition phase, the aim is to chart a path that is not only attuned to immediate demands, but also anticipates the future, thus laying the groundwork for a sustainable, efficient, and resilient hydrogen economy.

8. Conclusions

The four primary participants involved in the development of the hydrogen energy market—investors, manufacturers, governments, and customers—each have their unique interests. These can overlap, creating common ground, but can also conflict, leading to complex dynamics. Consequently, design of a regional HSC must take these intricate relationships into account. Contrary to the conventional supply chain studies that cater to a single company, the design and optimization of an HSC demand a broader perspective. They should explore and balance the trade-offs among various interests, considering a multitude of influencing factors, and must be grounded in universally accepted analysis methods. This comprehensive and multidimensional approach paves the way for a more efficient, sustainable, and equitable hydrogen energy market.

This paper centered around the pivotal question: “How can the creation of a HSCDD facilitate the optimization and strategic planning of hydrogen infrastructure networks, while considering the multi-dimensional aspects of cost, environmental impact, and safety?”. We first articulated the imperative of establishing a regional HSCDD as the foundation for optimization models. We then proposed a methodology for constructing the HSCDD by integrating raw datasets with descriptive models. For the hydrogen supply side, we presented descriptive models such as cash flow analysis, life cycle assessment, and risk ranking approach, along with relevant datasets. These aim to assess the primary system performance criteria: cost, environmental impact, and safety. Furthermore, we discussed the structuring of the HSCDD for hydrogen demand, analyzing two non-industrial hydrogen applications—FCEV and CHP systems. We presented descriptive models and datasets that aid in estimating hydrogen demand. Additionally, we explored how to carry out hydrogen energy-related optimization research utilizing this decision database, with distinct approaches for near-term and long-term analysis. We demonstrated that the HSCDD can facilitate the construction of various optimization models to satisfy diverse research requirements. By incorporating more descriptive models and datasets into the HSCDD, we can fortify its capability to support HSC optimization modeling. This will enhance our understanding of the transition process towards a hydrogen economy, helping to strategize and implement sustainable energy solutions effectively.

Author Contributions

Conceptualization, L.L.; validation, H.M.; writing—original draft preparation, L.L.; writing—review and editing, S.M.; supervision, M.-A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Shaanxi Provincial Natural Science Research Foundation (grant number 2023-JC-YB-628), and the Shaanxi Provincial Department of Education’s Annual Key Scientific Research Foundation (grant number 23JZ026).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HSC | Hydrogen supply chain |

| HSCDD | Hydrogen supply chain decision database |

| FCEV | Fuel cell electric vehicle |

| SCDD | Supply chain decision database |

| CHP | Combined heat and power |

| CCS | Carbon capture and storage |

| LCOH | Levelized cost of hydrogen |

| DCF | Discounted cash flow |

| FCR | Fixed charge rate |

| LCA | Life cycle assessment |

| WtW | Well to wheels |

References

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- IEA. Global Hydrogen Review 2022; Technical Report; IEA: Paris, France, 2022. [Google Scholar]

- Sönnichsen, N. Hydrogen: Fuel of the Future? A Statista Dossierplus on Hydrogen’s Relevance in the Net Zero Economy of Tomorrow; Technical Report; Statista: Hamburg, Germany, 2021. [Google Scholar]

- IEA. The Future of Hydrogen Seizing Today’s Opportunities; Technical Report; IEA: Paris, France, 2019. [Google Scholar]

- European Commission. A Hydrogen Strategy for a Climate-Neutral Europe; Technical Report; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Fuel Cell and Hydrogen Energy Association. Road Map to a US Hydrogen Economy; Technical Report; Fuel Cell and Hydrogen Energy Association: Washington, DC, USA, 2020. [Google Scholar]

- Hydrogen and Fuel Cell Strategy Council. The Strategic Road Map for Hydrogen and Fuel Cells—Industry-Academia-Government Action Plan to Realize a “Hydrogen Society”; Technical Report; Hydrogen and Fuel Cell Strategy Council: Tokyo, Japan, 2019. [Google Scholar]

- China’s National Development and Reform Commission. Medium and Long-Term Planning for the Development of Hydrogen Energy Industry; Technical Report; China’s National Development and Reform Commission: Beijing, China, 2022.

- Hydrogen Council. Hydrogen Insights 2022—An Updated Perspective on Hydrogen Market Development and Actions Required to Unlock Hydrogen at Scale; Technical Report; Hydrogen Council: Belgium, Belgium, 2022. [Google Scholar]

- Mark Kane. US: Hydrogen Fuel Cell Car Sales Fell by 30% in Q1 2023. 2023. Available online: https://insideevs.com/news/668706/us-hydrogen-fuel-cell-car-sales-2023q1/ (accessed on 31 May 2023).

- AFC TCP. 2019 Survey on the Number of Fuel Cell Vehicles, Hydrogen Refueling Stations and Targets; Technical Report; AFC TCP: Paris, France, 2019. [Google Scholar]

- Hy4Heat. Hy4Heat: Hydrogen for Heating Demonstration Programme. 2023. Available online: https://www.gov.uk/government/publications/hydrogen-for-heating-project (accessed on 31 May 2023).

- Rosenow, J. Is heating homes with hydrogen all but a pipe dream? An evidence review. Joule 2022, 6, 2225–2228. [Google Scholar] [CrossRef]

- Emodi, N.V.; Lovell, H.; Levitt, C.; Franklin, E. A systematic literature review of societal acceptance and stakeholders’ perception of hydrogen technologies. Int. J. Hydrogen Energy 2021, 46, 30669–30697. [Google Scholar] [CrossRef]

- Casey Crownhart. The 11th Breakthrough Technology of 2023 Takes Flight. 2023. Available online: https://www.technologyreview.com/2023/03/01/1069264/the-11th-breakthrough-technology-of-2023-takes-flight/ (accessed on 31 May 2023).

- Li, L.; Manier, H.; Manier, M.A. Hydrogen supply chain network design: An optimization-oriented review. Renew. Sustain. Energy Rev. 2019, 103, 342–360. [Google Scholar] [CrossRef]

- Riera, J.A.; Lima, R.M.; Knio, O.M. A review of hydrogen production and supply chain modeling and optimization. Int. J. Hydrogen Energy 2023, 48, 13731–13755. [Google Scholar] [CrossRef]

- Maryam, S. Review of modelling approaches used in the HSC context for the UK. Int. J. Hydrogen Energy 2017, 42, 24927–24938. [Google Scholar] [CrossRef]

- Reyes-Barquet, L.M.; Rico-Contreras, J.O.; Azzaro-Pantel, C.; Moras-Sánchez, C.G.; González-Huerta, M.A.; Villanueva-Vásquez, D.; Aguilar-Lasserre, A.A. Multi-objective optimal design of a hydrogen supply chain powered with agro-industrial wastes from the sugarcane industry: A Mexican case study. Mathematics 2022, 10, 437. [Google Scholar] [CrossRef]

- Cantú, V.H.; Azzaro-Pantel, C.; Ponsich, A. A Novel Matheuristic based on bi-level optimization for the multi-Objective design of hydrogen supply chains. Comput. Chem. Eng. 2021, 152, 107370. [Google Scholar] [CrossRef]

- Robles, J.O.; Azzaro-Pantel, C.; Aguilar-Lasserre, A. Optimization of a hydrogen supply chain network design under demand uncertainty by multi-objective genetic algorithms. Comput. Chem. Eng. 2020, 140, 106853. [Google Scholar] [CrossRef]

- Kuvvetli, Y. Multi-objective and multi-period hydrogen refueling station location problem. Int. J. Hydrogen Energy 2020, 45, 30845–30858. [Google Scholar] [CrossRef]

- Ogumerem, G.S.; Kim, C.; Kesisoglou, I.; Diangelakis, N.A.; Pistikopoulos, E.N. A multi-objective optimization for the design and operation of a hydrogen network for transportation fuel. Chem. Eng. Res. Des. 2018, 131, 279–292. [Google Scholar] [CrossRef]

- Shapiro, J. Modeling the Supply Chain; Nelson Education: Toronto, ON, Canada, 2006. [Google Scholar]

- Azzaro-Pantel, C. Hydrogen Supply Chain: Design, Deployment and Operation; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Abdin, Z.; Zafaranloo, A.; Rafiee, A.; Mérida, W.; Lipiński, W.; Khalilpour, K.R. Hydrogen as an energy vector. Renew. Sustain. Energy Rev. 2020, 120, 109620. [Google Scholar] [CrossRef]

- S&P Global. Hydrogen Market Research Hydrogen Market Outlook, Supply & Demand, Forecast and Analysis; Technical Report; S&P Global: New York, NY, USA, 2023. [Google Scholar]

- Li, L.; Manier, H.; Manier, M.A. Integrated optimization model for hydrogen supply chain network design and hydrogen fueling station planning. Comput. Chem. Eng. 2020, 134, 106683. [Google Scholar] [CrossRef]

- Sharma, S.; Ghoshal, S.K. Hydrogen the future transportation fuel: From production to applications. Renew. Sustain. Energy Rev. 2015, 43, 1151–1158. [Google Scholar] [CrossRef]

- Goldman Sachs Research. Carbonomics: The Clean Hydrogen Revolution; Technical Report; Goldman Sachs Research, 2022. [Google Scholar]

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrogen Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Reuß, M.; Grube, T.; Robinius, M.; Preuster, P.; Wasserscheid, P.; Stolten, D. Seasonal storage and alternative carriers: A flexible hydrogen supply chain model. Appl. Energy 2017, 200, 290–302. [Google Scholar] [CrossRef]

- Almaraz, S.D.L.; Azzaro-Pantel, C.; Montastruc, L.; Domenech, S. Hydrogen supply chain optimization for deployment scenarios in the Midi-Pyrénées region, France. Int. J. Hydrogen Energy 2014, 39, 11831–11845. [Google Scholar] [CrossRef]

- Li, L.; Feng, L.; Manier, H.; Manier, M.A. Life cycle optimization for hydrogen supply chain network design. Int. J. Hydrogen Energy 2022, in press. [Google Scholar] [CrossRef]

- Lazard. 2023 Levelized Cost of Energy+. 2023. Available online: https://www.lazard.com/research-insights/2023-levelized-cost-of-energyplus/ (accessed on 31 May 2023).

- National Renewable Energy Laboratory. LCOE Calculator. n.d. Available online: https://www.nrel.gov/analysis/tech-lcoe.html (accessed on 31 May 2023).

- Grist Project Management. Rapid Risk Ranking. 2022. Available online: https://www.gristprojectmanagement.us/ (accessed on 31 May 2023).

- Norsk Hydro ASA and DNV. Methodology for Rapid Risk Ranking of H2 Refueling Station Concepts; Technical Report; European Integrated Hydrogen Project, 2002. [Google Scholar]

- Kim, J.; Lee, Y.; Moon, I. An index-based risk assessment model for hydrogen infrastructure. Int. J. Hydrogen Energy 2011, 36, 6387–6398. [Google Scholar] [CrossRef]

- Low, J.M.; Haszeldine, R.S.; Mouli-Castillo, J. Refuelling infrastructure requirements for renewable hydrogen road fuel through the energy transition. Energy Policy 2023, 172, 113300. [Google Scholar] [CrossRef]

- Timothy Lipman. Fuel Cell Electric Vehicle and Hydrogen Fueling Station Development for San Francisco; Technical Report; California Energy Commission: Sacramento, CA, USA, 2022.

- Melendez, M.; Milbrandt, A. Regional Consumer Hydrogen Demand and Optimal Hydrogen Refueling Station Siting; Technical Report; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008. [CrossRef][Green Version]

- Klein, C. Japan: Installed ENE-FARM Systems Number 2021. 2022. Available online: https://www.statista.com/statistics/1248727/japan-installed-ene-farm-system-number/ (accessed on 31 May 2023).

- Dodds, P.E.; Staffell, I.; Hawkes, A.D.; Li, F.; Grünewald, P.; McDowall, W.; Ekins, P. Hydrogen and fuel cell technologies for heating: A review. Int. J. Hydrogen Energy 2015, 40, 2065–2083. [Google Scholar] [CrossRef]

- Alazemi, J.; Andrews, J. Automotive hydrogen fuelling stations: An international review. Renew. Sustain. Energy Rev. 2015, 48, 483–499. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).