Abstract

Forest dendromass is still the major raw material in the production of solid biofuels, which are still the most important feedstock in the structure of primary energy production from renewable energy sources. Because of the high species and type diversity of production residues generated at wood processing sites, as well as at logging sites, the quality of commercial solid biomass produced there has to be evaluated. The aim of this study was to assess the thermophysical characteristics and the elemental composition of ten types of commercial solid biofuels (pinewood sawdust; energy chips I, II, and III; veneer sheets; shavings; birch bark; pine bark; pulp chips; and veneer chips), depending on their acquisition time (August, October, December, February, April, and June). Pulp chips had the significantly lowest moisture content (mean 26.92%), ash content (mean 0.39% DM—dry matter), nitrogen (N) content (mean 0.11% DM), and sulfur (S) content (mean 0.011% DM) and the highest carbon (C) content (mean 56.09% DM), hydrogen (H) content (6.40% DM), and lower heating value (LHV) (mean 13.61 GJ Mg−1). The three types of energy chips (I, II, and III) had good energy parameters, especially regarding their satisfactory LHV and ash, S, and N content. On the other hand, pine and birch bark had the worst ash, S, and N contents, although they had beneficial higher heating values (HHVs) and C contents. Solid biofuels acquired in summer (June) had the lowest levels of moisture and ash and the highest LHV. The highest moisture content and the lowest LHV were found in winter (December).

1. Introduction

Forests occupy 9274.8 thousand ha of land, which accounted for 29.7% of the area in Poland at the end of 2022 []. Publicly owned forests dominated in terms of ownership structure, as they accounted for 80.8% of the total forest areas. Coniferous trees accounted for 68.6% of the forest area, and deciduous trees accounted for 31.4% []. Broken down into species, pine (Pinus sylvestris L.) accounted for nearly 58.6% of forest areas, and it was the dominant species. Oak trees occupied the largest area among deciduous trees (8.0%). Pine is a common species in Poland and in Europe [], and it is one of the most economically important species []. This species is widely used for timber production, in the furniture and construction industries, and for paper pulp production. Moreover, the production residue of this species is used for bioenergy generation []. Forests and wood resources provide the basis for the development of many branches of industry in Poland []. In 2022, 44,646.7 thousand cubic meters of wood were acquired in Poland, including 42,702.8 thousand cubic meters of large timber, 1943.8 thousand cubic meters of small timber, and 0.8 thousand cubic meters of stumpwood. Compared with 2021, the quantity of harvested wood grew by 5.7%, with that of large timber increasing by 4.9% and that of small timber increasing by as much as 25.2% []. This dendromass is acquired by the wood industry, which produces higher added-value products, and the process is accompanied by the generation of production waste, which can be (and is) used in energy generation.

Forest dendromass is still the major raw material in the production of solid biofuels, which are still the most important feedstock in the structure of primary energy production from renewable energy sources. Solid biofuels account for as much as 70%, with the average for the EU being about 40% []. Forests and the wood processing industry are sources of dendromass as production residues, e.g., twigs, edgings, shavings, sawdust, bark, etc. It is estimated that more than 63% of dendromass residue is derived at sawmills [,,], and sawmill residues can account for as much as approximately 55% of a log charge []. This residue is used for a variety of purposes, including the production of chipboard and fiberboard, paper pulp, boxes, cardboard, bedding for farm animals, and compost [,,]. They can be used as feedstock for power plants, combined heat and power plants, and heating plants [,]. This is the reason for the growing demand for these materials, including wood chips, especially for the generation of bioenergy [,]. Finding suitable sources of biomass to use as energy feedstock in commonly used conversion technologies is a current and important issue. It is critical to understand the energy equivalence of biomass for its effective use in bioenergy generation []. Dendromass consists mainly of bark, wood, and green material (small twigs and leaves), with wood accounting for 60–75% of deciduous dendromass, bark accounting for 5–20%, and green biomass accounting for 15–20%. As for coniferous dendromass, wood accounts for 70–80%, bark accounts for 5–15%, and green material accounts for 10–15% [].

Because of the high species and type diversity of production residue generated at wood processing sites, as well as at logging sites [], the quality of commercial solid biomass produced there has to be evaluated. There is a lack of precise information in this regard, and this is very important from the point of view of logistics companies, biomass producers, and end users of these solid biofuels. Therefore, the aim of this study was to assess the thermophysical and elemental composition of ten types of commercial solid biofuels (pinewood sawdust; energy chips I, II, and III; veneer sheets; shavings; birch bark; pine bark; pulp chips; and veneer chips), depending on the month of their acquisition (August, October, December, February, April, and June).

2. Materials and Methods

2.1. Study Object

This study dealt with ten types of dendromass marketed by Quercus Sp. z o.o. This company is one of the leading producers of dendromass transported by lorries and trains, both to large power plants and combined heat and power plants, as well as to small local heating plants [,]. Depending on the type of energy-generating installation and its technical equipment, as well as the contracts signed, the company supplies various biofuel types (dendromass) to different end customers. Therefore, it produces and offers different solid biofuels from raw materials obtained from wood processing plants and forest logging sites to suit end customers’ requirements. Ten solid biofuel types offered by the company were examined in this study (Figure 1): (1) pinewood sawdust; (2) energy chips I, which comprised sawmill edgings, shavings, bark, sawdust, and branches from forest logging sites; (3) veneer sheets generated in poplar and linden processing; (4) shavings from pinewood and fir processing; (5) energy chips II, which comprised sawmill edgings, shavings, bark, sawdust, post-handling waste, and so-called “fronts”; (6) birch bark; (7) pine bark; (8) pulp chips, which consisted of pure (no bark) deciduous and coniferous wood; (9) energy chips III, which comprised sawmill edgings, bark, sawdust, and post-handling waste; and (10) veneer chips, which consisted of pure (no bark) poplar, linden, and aspen.

Figure 1.

Types of tested commercial solid biofuels.

All of these solid biofuel types were prepared and stored in an open concrete-paved logistics yard at the company site. Samples of each solid biofuel type were collected for one year in two-month intervals, i.e., they were collected six times. The collection of representative samples started in early August 2018 and continued early into the following months: October 2018, December 2018, February 2019, April 2019, and June 2019. Heaps of each of the solid biofuels were collected from random places during these periods. The samples were packed into plastic bags, 3–5 kg in each, and transported to the laboratory for analyses.

2.2. Laboratory Analyses

The tests were started by separating the laboratory samples, which was followed by the determination of selected thermophysical characteristics and elemental composition. First, the moisture content (MC) of biomass was determined in an FD BINDER drier at 105 °C, in accordance with PN-EN ISO 18134-2 []. After being completely dried, dendromass was ground in a Retsch SM 200 laboratory mill equipped with a 1 mm mesh sieve. An Eltra Tga-Thermostep thermogravimetric oven was used to determine the ash content at 550 °C as well as the volatile matter (VM) and fixed carbon (FC) content at 650 °C, in accordance with PN-EN ISO 18122:2016-01 [] and PN-EN ISO 18123:2016-01 []. The nitrogen (N) content of the dendromass was determined using the Kjeldahl method with a K-435 mineralizer and a BUCHI B-324 distilling device. The carbon (C), hydrogen (H), and sulfur (S) contents were determined with an ELTRA CHS-500 automatic analyzer in accordance with PN-EN ISO 16948:2015-07 [] and PN-EN ISO 16994:2016-10 []. The higher heating value (HHV) was determined with the dynamic method in an IKA C2000 calorimeter. Subsequently, the HHV, moisture, and hydrogen content were used to calculate the lower heating value (LHV) in accordance with PN-EN ISO 18125:2017-07 [] (Equation (1)). All the laboratory analyses were performed at each biofuel acquisition time in triplicate. In consequence, 180 analyses were performed for each attribute.

where

LHV = (HHV − 206 × H) × (1 − 0.01 × MC) − 23.0 × MC

LHV—lower heating value (J g−1);

HHV—higher heating value (J g−1 DM);

H—hydrogen content (% DM);

MC—moisture content (%).

2.3. Statistical Analysis

The statistical analyses of all the data for the thermophysical characteristics and elemental composition were based on two-way ANOVA. Ten types of solid biofuels were the first factor in the analysis, and six acquisition times were the other. The arithmetic mean, the coefficient of variation, and the standard deviation were calculated for each of the analyzed attributes. Homogeneous groups were identified with Tukey’s honestly significant difference (HSD) test at the level of significance of p < 0.05. Moreover, descriptive statistics were determined for the whole data set: mean, median, minimum value, maximum value, lower quartile, upper quartile, standard deviation, and coefficient of variation. Moreover, an agglomerative hierarchical clustering analysis was performed for the biofuel types and their attributes. The input data were standardized in columns before the analyses. Ward’s method was applied for data agglomeration. Clusters were identified with Sneath’s criterion. Two cut-off lines were applied: the first at 2/3 Dmax and the second at 1/3 Dmax, where Dmax denoted the maximum measure of distance D. All the statistical analyses were performed with STATISTICA 13 software (TIBCO Software Inc., Palo Alto, CA, USA).

3. Results and Discussion

3.1. Thermophysical Characteristics

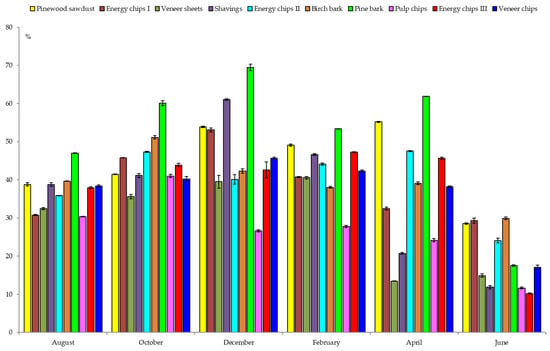

All of the thermophysical characteristics under study, i.e., MC, Ash, FC, VM, HHV, and LHV, were differentiated significantly by the primary factors (biomass type and acquisition time) as well as by interactions between them and were below 0.001 (p < 0.001). Among the solid biofuels under study, pulp chips had the significantly lowest moisture content (26.92%) and was considered homogeneous group “h” (Table 1). The moisture content of the veneer sheets was also below 30%, but it was in a different homogeneous group, “g”. There were another five biofuel types within the interval between 30 and 40% of mean moisture content, including three types of energy chips (I, II, and III). The moisture content of birch bark slightly exceeded 40%, and that of pinewood sawdust was higher (44.5%). The significantly highest moisture content (51.56%) was determined for pine bark, homogeneous group “a”. Higher moisture contents for consecutive solid biofuel acquisition times were determined in the winter and autumn months than in spring and summer. In consequence, the significantly highest value of this attribute was determined in December (47.43%), homogeneous group “a”. The moisture content exceeding 40% was also determined in solid biofuels obtained in October and February. The biofuel moisture content in August and April ranged from 37 to 38%. The lowest moisture content was determined in the biofuels obtained in June (19.51%), with the coefficient of variation in that month exceeding 38%. The moisture content of the solid biofuels under study ranged from 10% to nearly 70% for energy chips III obtained in June and pine bark obtained in December, respectively (Figure 2). This is not surprising because the moisture content of solid biofuels may be diverse and many depend mainly on the season of the year; the weather conditions; the methods of dendromass acquisition and processing; the period of storage, if any; and the plant species from which the dendromass was obtained. It is obvious that the moisture content of freshly harvested dendromass will be higher compared with periodical storage for natural drying. The maximum moisture content of raw wood or branches may reach 70% for bark []. Moreover, depending on the species and conditions, the moisture content of freshly felled wood can range from 35 to 60%. On the other hand, the moisture content of wood dried in the open can decrease to 20–25%, and that of wood dried under a roof can decrease to 15–20%. Therefore, the moisture content of sawdust from fresh pinewood was about 60%, and it was over 50% for sawmill residue []. An equally high moisture content (over 59%) was determined in sawdust from the industrial processing of pinewood, and the moisture content of chips produced from small logs and twigs was slightly lower (52.5%) []. The moisture content of wood slabs, as measured in other studies (55%), was higher than that of sawdust (43%) and was 49% in P. sylvestris []. A lower moisture content (38%) was determined in chips from pinewood edgings, which was a consequence of their several weeks of storage in summer and their drying under natural conditions []. This was confirmed in other studies, in which the wood chip moisture content ranged from 29 to 46%, depending on the acquisition time, with the mean being 38.3% []. The higher moisture content in the cited studies was determined in chips in winter (45.6%). The value of this attribute decreased significantly in spring and summer (by 8 and 17 percentage points (pp.), respectively). The moisture content of the chips reached 41% in autumn. The moisture content of chips obtained from logging residues in Sweden was higher and was 50.6% immediately after harvesting, and then, it decreased with the storage period []. The moisture content of logging residues from various tree species, when dried in summer, was definitely lower and ranged from 23 to 36% for Norway spruce and Black alder, respectively []. The moisture content of short-rotation woody crop (SRWC) dendromass was also diverse. Black locust biomass contained definitely less moisture (approx. 40%) compared with willow (approx. 50%) and poplar (approx. 60%) [,,,].

Table 1.

Solid biofuel thermophysical characteristics depending on the biomass type and its acquisition time.

Figure 2.

The moisture content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

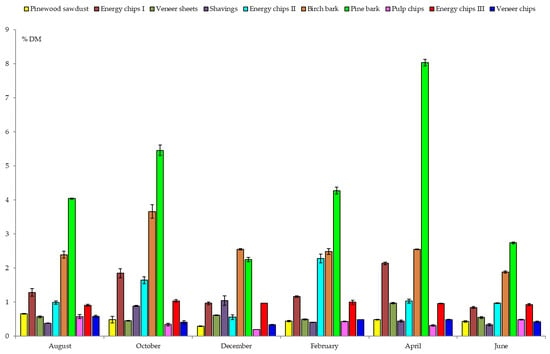

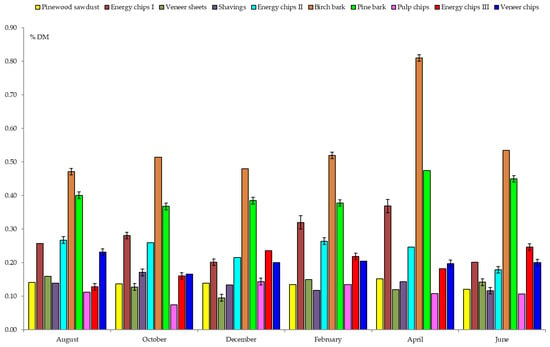

The pulp chips had the significantly lowest ash content—0.39% DM—and was considered homogeneous group “h” (Table 1). A low ash content—below 0.5% DM—was also determined in veneer chips and pinewood sawdust. The ash content of veneer sheets and shavings was 0.6% DM, homogeneous group “f”. The ash content of energy chips ranged from 0.97 to 1.37% DM for energy chips III and I, respectively. A definitely higher ash content was determined in birch and pine bark (2.59% and 4.46% DM, respectively). For the consecutive dates of solid biofuel acquisition, the lowest ash content (<1% DM) was determined in June and in December, homogeneous group “e”. The value of this attribute in August and February was higher by 30–40%, and that in October and April was higher by 69% and 81%, respectively. The ash content at the acquisition times under study had a very high coefficient of variance, ranging from 78 to 129%, in June and April, respectively. The ash content of the solid biofuels under study ranged throughout the experiment from 0.2% to nearly 8.0% for pulp chips obtained in December and pine bark obtained in April, respectively (Figure 3). Pine bark contained the highest ash levels at most of the acquisition times under study. Its higher content in birch bark compared with pine bark was determined only in December.

Figure 3.

The ash content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

In general, bark contains more ash than wood []. Therefore, sawmill residue contains less ash than forest residue because of the higher bark and mineral content []. The ash content of wood slabs was higher (0.5% DM) compared with sawdust, which was caused by the fact that wood slabs contained an admixture of bark whose ash content was higher []. The ash content of pinewood sawdust from a sawmill, as determined in a different study, was 0.36% DM [], and it was higher in sawdust from forest residues (0.50% DM) []. A very low ash content (0.26% DM) was determined in wood chips produced from P. sylvestris slabs []. The ash content, as measured in chips supplied over a period of two years, ranged from 2.05 to 4.75% DM []. The ash content determined in wood chips in Sweden was similar (2.88% DM) []. The ash content of dendromass was differentiated significantly by the species and part of the tree. It was found to be 0.24% DM in the pure wood of Norway spruce and 7.80% DM in the bark of European beech []. The ash contents of P. sylvestris stem wood (0.22% DM), branch base (0.48% DM), branch twigs (1.56% DM), and stem bark (1.78% DM) were also highly diverse []. The ash contents of Picea abies wood, bark, and needles were also diverse (0.28%, 2.32%, and 3.22% DM, respectively) []. Similar relationships between the ash content of wood and the bark of the species were demonstrated by Neiva et al. []. The ash content, as determined in the branches and bark of Greek spruce, was higher (3.2% and 9.5% DM, respectively) [].

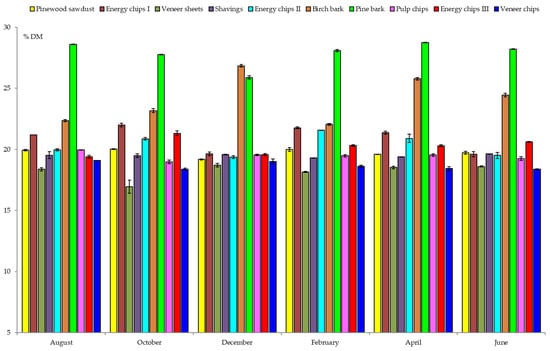

Pine bark contained the significantly highest FC levels (27.87% DM) and the significantly lowest VM levels (67.66% DM) (Table 1). The FC content of birch bark was lower by more than 3 pp., and the VM content was higher by more than 5 pp. Moreover, the FC content was over 20% DM in all three types of energy chips. It was less than 20% in the other five solid biofuel types. The highest FC content with respect to the consecutive harvest dates for the solid biofuels (21.26% DM) and the lowest VM content (77.00% DM) was determined in April. The FC content, as determined on other dates, ranged between 20.73 and 20.93% DM, and the VM content was between 77.49 and 78.28% DM. The FC content ranged between 16.9% DM and 28.7% DM throughout the experiment for veneer sheets acquired in October and pine bark acquired in April (Figure 4). The VM content ranged from 63.2% DM to 82.6% DM for pine bark acquired in April and veneer sheets acquired in October (Figure 5).

Figure 4.

The fixed carbon content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

Figure 5.

The volatile matter content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

The FC content of wood slabs, as determined in a different study (21.4% DM), was higher than that of sawdust (20.0% DM), and the mean for P. sylvestris biomass was 20.7% DM []. The significantly higher VM content was determined in sawdust (79.7% DM) than in wood slabs (78.1% DM) because of a strong negative correlation between FC and VM. The VM content of Picea sp. sawdust, as determined in a different study, was close (79.2% DM) [] or higher, at 80.7% DM [] and 82.1% DM [].

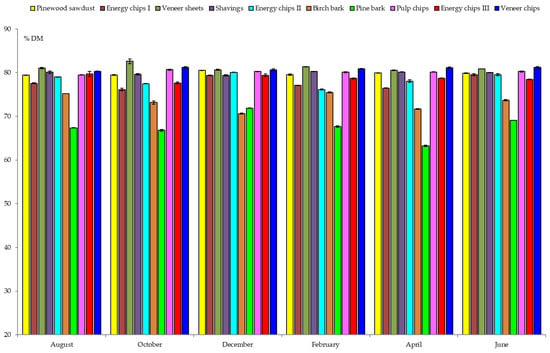

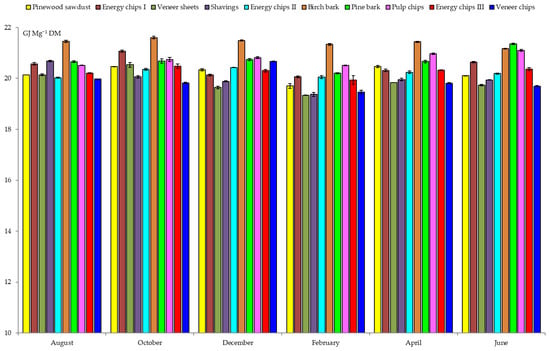

Birch bark had the significantly highest HHV (21.41 GJ Mg−1 DM, homogeneous group “a”) (Table 1). The value of this attribute for pulp chips and pine bark was lower by 3%, and it was higher than 20.7 GJ Mg−1 DM. The HHV of more than 20 GJ Mg−1 DM was also determined for pinewood sawdust and all three types of energy chips (I, II, and III). The HHV determined for the other three solid biofuels (veneer sheets, shavings, and veneer chips) did not exceed 20 GJ Mg−1 DM and was lower than the highest value by approx. 7%. Regarding consecutive dates of solid biofuel acquisition, the lowest HHV (19.99 GJ Mg−1 DM) was determined in February, homogeneous group “d”. The value of this attribute, as determined in the other months, ranged from 20.40 to 20.58 GJ Mg−1 DM in April and October, respectively. The HHV, as calculated for the solid biofuel types under study, ranged from 19.34 to 21.60 GJ Mg−1 DM throughout the experiment for veneer sheets obtained in February and for birch bark obtained in October, respectively (Figure 6). Birch bark had the highest HHV calculated at most of the dates under study. It was higher only for pine bark acquired in June. HHV was significantly correlated with the N, S, C, FC, and ash contents (Table 2). The HHV of P. sylvestris wood slabs, as determined in a different study (20.49 GJ Mg−1 DM), was close to that for sawdust (20.45 GJ Mg−1 DM) []. A similar HHV of coniferous biomass (20.4 GJ Mg−1 DM) was reported by Pretzsch [], and it was lower for deciduous trees (19.8 GJ Mg−1 DM). Further, Telmo [] determined the HHV of coniferous wood to be 20.5 GJ Mg−1 DM and 20.2 GJ Mg−1 DM for deciduous dendromass. According to literature reports, a higher HHV was determined for bark compared with other dendromass types [,], and this was also confirmed in this study.

Figure 6.

Higher heating value of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

Table 2.

Simple correlation coefficient between the solid biofuel attributes under study.

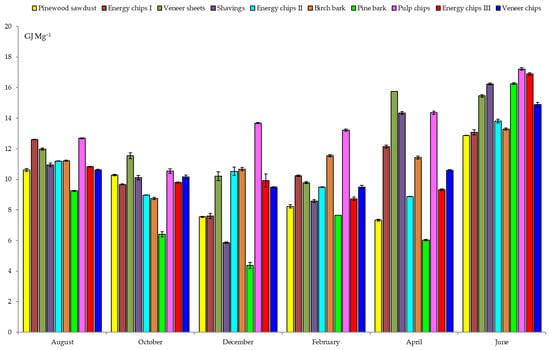

Obviously, the LHV was negatively correlated with the moisture content (−0.99) (Table 2). Therefore, pulp chips (with the significantly lowest moisture content) had the significantly highest LHV among the solid biofuels under study (13.61 GJ Mg−1, homogeneous group “a”) (Table 1). The second homogeneous group “b” included veneer sheets, with the LHV being lower by 9% (12.45 GJ Mg−1). Further, the LHV of birch bark and shavings was lower by 19%, and it was slightly over 11 GJ Mg−1. The LHV of the three types of energy chips and veneer chips was lower than the highest value by 20–23%, homogeneous groups “d, e”. The LHVs of pinewood sawdust (9.48 GJ Mg−1) and pine bark (8.33 GJ Mg−1) were lower by 30 and 39%, compared with pulp chips, which was a consequence of their high moisture content. The significantly highest LHV among the solid biofuel acquisition times was determined in June (14.99 GJ Mg−1) in the homogeneous group “a”. The LHV slightly exceeded 11 GJ Mg−1 in another summer month (August) and in the spring (April), and it was lower by 25–27%. The LHV was lower by 35–36% in autumn (October) and winter (February). The lowest value of this attribute (8.98 GJ Mg−1) was determined in December, and it was lower by 40%. The LHV of the solid biofuels under study ranged from 4.37 to nearly 17.21 GJ Mg−1 throughout the experiment for pine bark obtained in December and pulp chips obtained in June, respectively (Figure 7).

Figure 7.

The lower heating value of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

The LHV of wood chips determined in a different study was 10.46 GJ Mg–1 []. The value of this attribute was significantly affected by the period when they were acquired. The significantly highest LHV (12.35 GJ Mg–1) was determined for the chips in summer when their moisture content was the lowest. The value of this attribute decreased significantly in spring, autumn, and winter, by 14%, 19%, and 28%, respectively. In a study in Sweden, the LHV of fresh wood chips was lower (8.35 GJ Mg–1), and it increased to 9.00 GJ Mg–1 after four months of storage []. The LHV of fresh P. sylvestris biomass, as determined in a different study, did not exceed 9 GJ Mg–1, and it was 8.63 GJ Mg–1 []. This attribute for sawdust was significantly higher (9.91 GJ Mg–1) than for wood slabs (7.35 GJ Mg−1). These values lay within the same range as the results of the authors’ experiment for chips obtained in autumn and winter. The LHV for chips obtained in late autumn from naturally dried logging residues of Norway spruce and Scots pine was higher (14 GJ Mg–1) []. It was lower for black alder (12.5 GJ Mg–1) and silver birch (11.3 GJ Mg–1). The LHV of fresh SRWC dendromass varied depending on the plant species. The LHV calculated for black locust was significantly the highest (10.25 GJ Mg–1) []. The value of this attribute for willow and poplar was significantly lower by 21% and 34%, respectively, which was a consequence of a higher moisture content of willow and poplar compared with black locust.

3.2. Elemental Composition

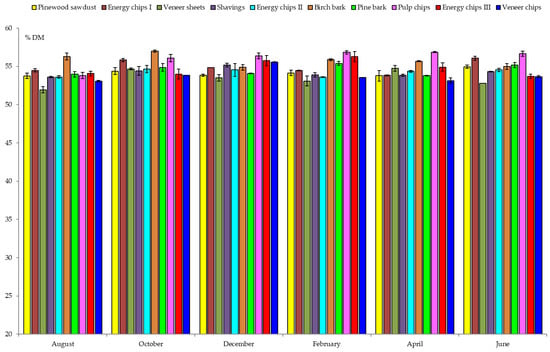

The C, H, S, and N contents were significantly differentiated by the primary factors and the interactions between them and were below 0.001 (p < 0.001). The pulp chips had the significantly highest C content (56.09% DM) in homogeneous group “a” (Table 3). The same homogeneous group included birch bark, and its C content was lower by 0.3 pp. The C content of the six solid biofuels ranged from 54 to 55% DM in homogeneous groups “b, c, d”. The lowest C content was determined in veneer sheets (53.44% DM). The C content for the five biofuel acquisition times ranged from 54 to 55% DM in homogeneous groups “a, b, c”. The lowest value of this attribute was determined in August (53.85% DM). The C content of the solid biofuels under study ranged from 51.9% DM to 56.7% DM throughout the experiment for veneer sheets obtained in June and pulp chips obtained in June, respectively (Figure 8). The C content was correlated positively with HHV and FC and negatively with VM (Table 2). The mean C content of P. sylvestris biomass, as determined in a different study, was 53.43% DM [], with sawdust (54.21% DM) containing more of this element by 2.4 pp. than wood slabs. A lower C content (48.4% DM) was determined in Pinus sp. sawdust in China [] and in Hevea brasiliensis sawdust (48.5% DM) obtained from a wood processing plant []. Betula pendula wood chips also contained less C (50.4% DM) []. A high C content was found in SRWC poplar and willow biomass (over 53.3% DM) compared with black locust (52.6% DM) []. This attribute was found to be lower in a different study []. Moreover, black locust and poplar (over 51.5% DM) contained more C than willow (48.8% DM).

Table 3.

The solid biofuel elemental composition depending on the biomass type and the acquisition time.

Figure 8.

The carbon content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

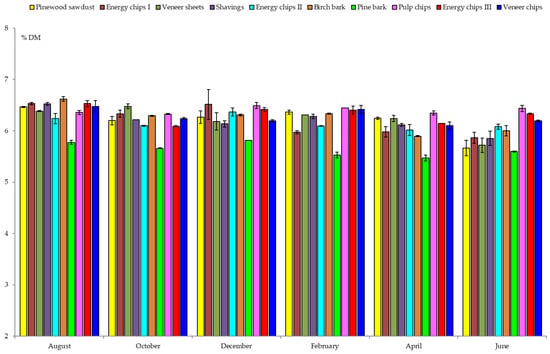

The H content of the nine solid biofuel types exceeded 6% DM, with the highest value being determined in pulp chips (6.40% DM) (Table 3). The lowest H content was determined in pine bark (5.64% DM). The H content for the five dates of the biofuel acquisition exceeded 6% DM, with the highest being determined in August (6.39% DM). The lowest value of the attribute was determined in June (5.97% DM). The H content throughout the experiment ranged between 5.53% DM and 6.66% DM for pine bark obtained in February and birch bark obtained in August (Figure 9). This attribute was correlated positively with VM and negatively with ash and FC content (Table 2).

Figure 9.

The hydrogen content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

The mean H content of P. sylvestris biomass, as determined in a different study, was 6.64% DM [], with sawdust (6.75% DM) containing more of this element by 0.22 pp. than wood slabs. A high H content was also determined in Pinus sp. wood chips (6.64% DM) [] and sawdust (6.72% DM) from China []. The element content of Populus sp. sawdust in that country was lower (5.91% DM) []. A similar H content (approx. 5.9% DM) was also determined in the biomass of poplar, willow, and black locust []. A higher H content of the species biomass (6.2–6.4% DM) was determined in a different study [].

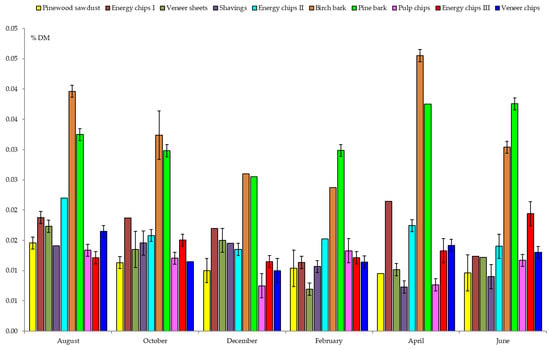

The pulp chips and pine sawdust had the significantly lowest S content (0.011% DM) in homogeneous group “e” (Table 3). The S content of the six solid biofuels did not exceed 0.017% DM in homogeneous groups “b, c, d”. The highest S content was determined in birch and pine bark (0.033 and 0.032% DM), respectively. Therefore, these values were higher by 300% compared with the lowest S content. The S content for the five dates of the biofuel acquisition was lower than 0.019% DM in homogeneous groups “b, c, d”. The highest value of this attribute was determined in August (0.020% DM). The S content of the solid biofuels under study ranged between 0.007% DM and 0.046% DM throughout the experiment for veneer sheets obtained in February and birch bark obtained in April (Figure 10). This attribute was significantly negatively correlated with VM, H, and LHV and positively with the other parameters under analysis (Table 2).

Figure 10.

The sulfur content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

The mean S content of P. sylvestris biomass determined in a different study was 0.009% DM [], with wood slabs (0.011% DM) containing more of this element than sawdust (0.007% DM). This may have been a consequence of the higher bark content of wood slabs, as bark contains more sulfur than wood [,]. The S content of the solid biofuels from forest dendromass, as demonstrated in the current study, lay within the range indicated for wood (0.01–0.05% DM), as well as for Pinus spp. wood (0.009–0.03% DM) []. A higher S content can be expected in dendromass from SRWC. Meanwhile, the element content of the SRWC willow and poplar did not exceed 0.026% DM, and it was 0.033% DM in black locust []. The S content of willow, poplar, and black locust in a study in Spain [] was higher (0.03, 0.04 and 0.05% DM), respectively. Therefore, the S content for black locust was similar to or higher than those for pine and birch bark in this study. This is important information as the sulfur dioxide emission from biomass combustion depends on the sulfur content, combustion temperature, and the amount of S retained in the ash [].

The pulp chips had the significantly lowest N content—0.11% DM—and was considered homogeneous group “g” (Table 3). The N content of the three solid biofuels (pinewood sawdust, veneer sheets, and shavings) did not exceed 0.15% DM in homogeneous group “f”. The element content of energy chips III and veneer chips was 0.20% DM. The N content of energy chips II and I was under 0.30% DM. It increased to 0.41% DM in pine bark and to 0.55% DM in birch bark. Therefore, these values were higher by 370% and 500% compared with the lowest N content of pulp chips. As for the dates of biofuel acquisition, the N content ranged from 0.22 to 0.28% DM in December and April, respectively. The N content of the solid biofuels under study ranged between 0.07% DM and 0.81% DM throughout the experiment for pulp chips obtained in October and birch bark obtained in April (Figure 11). The N content was significantly negatively correlated with VM, H, and LHV and positively correlated with S, FC, and ash (Table 2).

Figure 11.

The nitrogen content of the solid biofuel types under study depending on the acquisition time; error bars denote standard deviation.

The mean N content of P. sylvestris biomass determined in a different study was 0.12% DM [], with wood slabs (0.15% DM) containing more of this element than sawdust (0.08% DM), which could be a consequence of a higher bark content of wood slabs. As in this study, other authors also demonstrated a definitely higher N content of bark compared to wood [,]. Moreover, a higher N content of this solid biofuel results in higher NOx emissions []. A low and similar N content to the current results was determined in P. sylvestris sawdust (0.13% DM) obtained in Spain []. Further, the element content of SRWC biomass was higher, and it was 0.38 and 0.43% DM in willow and poplar, and it was 0.91% DM in black locust []. The N content of black locust determined in a different study [] was high (0.63% DM). Therefore, these N content values were even higher than in pine and birch bark in the current study.

3.3. General Characteristics of Dendromass Solid Biofuels

Table 4 shows the descriptive statistics for the whole data set for all the dendromass solid biofuels of forest origin, obtained at two-month intervals during one year. These results show that the strongest dispersion, expressed as a coefficient of variation, was determined for ash content (>107%). The span (minimum—maximum) of this important attribute was very wide, and it ranged from 0.19 to 8.13% DM, with a mean of 1.31% DM. A lower but also strong dispersion was found for the N and S contents (60.1% and 52.0%), respectively. The N content spanned from 0.07 to 0.82% DM, with a mean of 0.24% DM. The values ranged from 0.006 to 0.046% DM for sulfur content, and the mean was 0.017% DM. The average variability of 25–34% was determined for LHV and moisture content, and the mean values for these attributes were 10.91 MJ kg−1 and 38.25%, respectively. The moisture content lay within a broad range (minimum—maximum) from 10 to 70%, and LHV ranged from 4.18 to 17.28 GJ Mg−1. Low variability (coefficient of variation < 15%) was determined for FC, VM, HHV, and C and H contents. Moreover, the higher result uniformity (coefficient of variation <3%) was determined for the C content and HHV.

Table 4.

Selected statistical analysis indicators for the attributes under study (N Valid = 180).

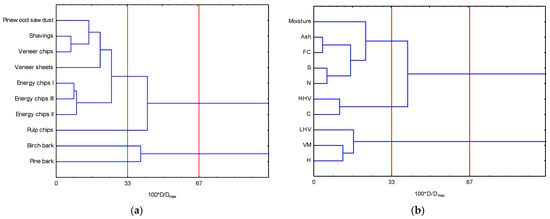

The cluster analysis based on the values of all the attributes of the ten solid biofuels from forest dendromass at the cut-off point of 2/3 Dmax allowed for grouping them into two main clusters (Figure 12a). Pine bark and birch bark made their own cluster. The other eight biofuel types (veneer sheets, pulp chips, veneer chips, shavings, pinewood sawdust, and three types of energy chips) made a second, separate cluster. When the analysis accuracy increased, four clusters were identified at the cut-off at 1/3 Dmax. Pine bark and birch bark made two separate clusters. Moreover, pulp chips formed a separate cluster. A fourth cluster included all the remaining seven types of solid biofuels, including three types of energy chips: pinewood sawdust, veneer sheets, shavings, and veneer chips. Two clusters were identified for the analyzed biofuel attributes at the cut-off at 2/3 Dmax (Figure 12b). One cluster included LHV, H content, and volatile matter content. The next cluster included the other seven analyzed parameters: moisture content; ash content; FC; HHV; and C, S, and N content. With an increase in the accuracy of the analysis, three clusters were identified at the cut-off at 1/3 Dmax. The first cluster remained unchanged. A second cluster was identified, containing HHV and C content. The third cluster included the remaining five analyzed parameters.

Figure 12.

The dendrogram of a hierarchical cluster analysis showing the similarities between solid biofuels from dendromass (a) and their thermophysical characteristics and elemental composition (b). The red vertical line marks the Sneath criterion (2/3 Dmax) and (1/3 Dmax). D—linage distance; Dmax—maximum linage distance.

4. Conclusions

This study characterized the thermophysical characteristics and the elemental composition of ten solid biofuel types produced over a period of one year from dendromass of forest origin, traded between producers and end customers. This is very important from both the scientific and practical perspectives as it will affect the further effectiveness and justifiability of solid biofuels used for heat and electricity generation. This study showed that the solid biofuel quality was significantly differentiated by the biomass type from which they were produced and the acquisition time, and the interactions of these two factors. Pulp chips proved to be the most valuable solid biofuel because of their beneficial thermophysical characteristics and elemental composition. However, this material is also known to have other potential applications. Therefore, its price and availability, depending on the demand for it from other branches of industry, may put some restrictions on the power generation sector. Consequently, attention should be drawn to the three types of energy chips (I, II, and III) produced from various production residues, which also had beneficial energy-related parameters. The other biofuels can be (and are) successfully used for energy generation, although the properties of pine and birch bark were the least beneficial. Obviously, the thermophysical characteristics of all of the solid biofuels obtained in the summer (June) were better. Nevertheless, they can be successfully used in the all-year supply chain for dendromass used for energy generation. Data on changes in the quality of various commercial solid biofuels are important both for companies dealing with the production and logistics of production residues of forest origin and also for end consumers of such biofuels who use them as energy feedstock. Obviously, various bioenergy installations can be dedicated to various biofuel types with respect to their thermophysical characteristics and elemental composition. Nevertheless, the knowledge of commercial solid biofuel characteristics can facilitate the organization of supply logistics and can provide a specific installation with the optimal fuel produced from production residues of forest origin.

Author Contributions

Conceptualization, M.J.S.; methodology, M.J.S. and M.K.; validation, M.J.S., M.K. and E.O.-Z.; formal analysis, M.J.S. and M.K.; investigation, M.J.S., M.K. and E.O.-Z.; resources, M.J.S.; data curation, M.J.S.; writing—original draft preparation, M.J.S.; writing—review and editing, M.J.S., M.K., E.O.-Z. and J.S.; visualization, J.S. and M.J.S.; supervision, M.J.S.; project administration, M.J.S.; funding acquisition, M.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

The results presented in this paper were obtained as part of a comprehensive study financed by the University of Warmia and Mazury in Olsztyn, Faculty of Agriculture and Forestry, Department of Genetics, Plant Breeding and Bioresource Engineering (grant No. 30.610.007-110) and co-financed by the National (Polish) Centre for Research and Development (NCBiR), titled “Environment, agriculture and forestry”, No. BIOSTRATEG3/344128/12/NCBR/2017.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to industrial confidentiality.

Acknowledgments

We thank the staff of the Department of Genetics, Plant Breeding and Bioresource Engineering and the Quercus Sp. z o.o., for their technical support during the experiment.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Statistics Poland. Forestry in 2022. Signal Information; Statistics Poland: Warsaw, Poland, 2023; p. 5.

- Statistics Poland. Statistical Yearbook of Forestry 2022. Statistical Publishing Establishment; Statistics Poland: Warsaw, Poland, 2022; p. 440.

- Kozakiewicz, P.; Jankowska, A.; Mamiński, M.; Marciszewska, K.; Ciurzycki, W.; Tulik, M. The Wood of Scots Pine (Pinus sylvestris L.) from Post-Agricultural Lands Has Suitable Properties for the Timber Industry. Forests 2020, 11, 1033. [Google Scholar] [CrossRef]

- Roszyk, E.; Mania, P.; Iwańska, E.; Kusiak, W.; Broda, M. Mechanical Performance of Scots Pine Wood from Northwestern Poland—A Case Study. BioResources 2020, 15, 6781–6794. [Google Scholar] [CrossRef]

- IPCC. Working group III contribution to the sixth assessment report of the intergovernmental panel on climate change. In Climate Change 2022 Mitigation of Climate Change Summary for Policymakers; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2022; p. 63. [Google Scholar]

- Gołos, P.; Hilszczański, J. Social and economic importance of the forestry and wood sector in Poland. In BSR Policy Briefing Series, The Forest Industry around the Baltic Sea Region: Future Challenges and Opportunities, 1st ed.; Liutho, K., Ed.; Centrum Balticum: Turku, Finland, 2020; pp. 36–48. [Google Scholar]

- Statistics Poland. Energy from Renewable Sources in 2021; Statistics Poland: Warsaw, Poland, 2022; p. 96.

- Wzorek, M. Characterization of the Properties of Alternative Fuels Containing Sewage Sludge. Fuel Process. Technol. 2012, 104, 80–89. [Google Scholar] [CrossRef]

- Loeffler, D.; Anderson, N.; Morgan, A.M.; Sorenson, C.B. On-Site Energy Consumption at Softwood Sawmills in Montana. For. Prod. J. 2016, 66, 155–163. [Google Scholar] [CrossRef]

- Mansoori, G.A.; Agyarko, L.B.; Estevez, L.A.; Fallahi, B.; Gladyshev, G.; dos Santos, R.G.; Niaki, S.; Perisic, O.; Sillanpaa, M.; Tumba, K.; et al. Fuels of the Future for Renewable Energy Sources (Ammonia, Biofuels, Hydrogen). arXiv 2021. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Acheampong, B. Strength Properties and Calorific Values of Sawdust-Briquettes as Wood-Residue Energy Generation Source from Tropical Hardwoods of Different Densities. Biomass Bioenergy 2016, 85, 144–152. [Google Scholar] [CrossRef]

- Krigstin, S.; Hayashi, K.; Tchórzewski, J.; Wetzel, S. Current Inventory and Modelling Of Sawmill Residues in Eastern Canada. For. Chron. 2012, 88, 626–635. [Google Scholar] [CrossRef]

- Islam, M.A.; Rahman, M.S.; Bosunia, A.K.M.A.; Lahiry, A.K. Present Status and Potentiality of the Economic Utilization of the Sawmill Residue and Wastage in Bangladesh. In IRG/WP 04-50211 the International Research Group on Wood Preservation, Proceedings of the 35th Annual Meeting, Ljubljana, Slovenia, 6–10 June 2004; IRG Secretariat: Stockholm, Sweden, 2004; pp. 1–13. [Google Scholar]

- Mirski, R.; Dukarska, D.; Derkowski, A.; Czarnecki, R.; Dziurka, D. By-products of Sawmill Industry as Raw Materials for the Manufacture of Chip-Sawdust Boards. J. Build. Eng. 2020, 32, 101460. [Google Scholar] [CrossRef]

- Pedišius, N.; Praspaliauskas, M.; Pedišius, J.; Dzenajavičienė, E.F. Analysis of Wood Chip Characteristics for Energy Production in Lithuania. Energies 2021, 14, 3931. [Google Scholar] [CrossRef]

- Demirbas, A. Reuse of Wood Wastes for Energy Generation. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 1687–1693. [Google Scholar] [CrossRef]

- Irdla, M.; Padari, A.; Kurvits, V.; Muiste, P. The Chipping Cost of Wood Raw Material for Fuel in Estonian Conditions. For. Stud. 2017, 66, 65–74. [Google Scholar] [CrossRef]

- Vusić, D.; Vujanić, F.; Pešić, K.; Šafran, B.; Jurišić, V.; Zečić, Ž. Variability of Normative Properties of Wood Chips and Implications to Quality Control. Energies 2021, 14, 3789. [Google Scholar] [CrossRef]

- Petráš, R.; Mecko, J.; Kukla, J.; Kuklová, M. Calorific Value of Basic Fractions of Above-Ground Biomass for Scots Pine. Acta Reg. Et Environ. 2019, 16, 34–37. [Google Scholar] [CrossRef]

- Nosek, R.; Holubcik, M.; Jandacka, J. The Impact of Bark Content of Wood Biomass on Biofuel Properties. BioResources 2016, 11, 44–53. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Dudziec, P.; Olba-Zięty, E.; Stachowicz, P.; Krzyżaniak, M. Forest Dendromass as Energy Feedstock: Diversity of Properties and Composition Depending on Systematic Genus and Organ. Energies 2022, 15, 1442. [Google Scholar] [CrossRef]

- Stolarski, J.; Wierzbicki, S.; Nitkiewicz, S.; Stolarski, M.J. Wood Chip Production Efficiency Depending on Chipper Type. Energies 2023, 16, 4894. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Sieniawski, W.; Krzyżaniak, M.; Olba-Zięty, E. Quality and Delivery Costs of Wood Chips by Railway vs. Road Transport. Energies 2021, 14, 6877. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-2; Solid Biofuels–Determination of Moisture Content–Dryer Method–Part 2: Total Moisture–Simplified Method. Polish Standardization Committee: Warsaw, Poland, 2014.

- PN-EN ISO 18122:2016-01; Solid Biofuels—Determination of Ash Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18123:2016-01; Solid Biofuels—Determination of Volatile Matter Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Polish Standardization Committee: Warsaw, Poland, 2015.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. Polish Standardization Committee: Warsaw, Poland, 2017.

- Kask, Ü.; Vares, V.; Saareoks, M. Wood Fuel User Manual, 1st ed.; Tartu Regional Energy Agency: Tartu, Estonia, 2020; pp. 14–43. [Google Scholar]

- Laurila, J.; Havimo, M.; Lauhanen, R. Compression Drying of Energy Wood. Fuel Process. Technol. 2014, 124, 286–289. [Google Scholar] [CrossRef]

- Deboni, T.; Simioni, F.; Brand, M.; Lopes, G. Evolution of the Quality of Forest Biomass for Energy Generation in a Cogeneration Plant. Renew. Energy 2019, 135, 1291–1302. [Google Scholar] [CrossRef]

- Dudziec, P.; Stachowicz, P.; Stolarski, M.J. Diversity of Properties of Sawmill Residues Used as Feedstock for Energy Generation. Renew. Energy 2023, 202, 822–833. [Google Scholar] [CrossRef]

- Anerud, E.; Jirjis, R.; Larsson, G.; Eliasson, L. Fuel Quality of Stored Wood Chips—Influence of Semi-Permeable Covering Material. Appl. Energy 2018, 231, 628–634. [Google Scholar] [CrossRef]

- Kurvits, V.; Ots, K.; Kangur, A.; Korjus, H.; Muiste, P. Assessment of Load and Quality of Logging Residues from Clear-Felling Areas in Järvselja: A Case Study from Southeast Estonia. Cent. Eur. For. J. 2020, 66, 3–11. [Google Scholar] [CrossRef]

- Gasol, C.M.; Brun, F.; Mosso, A.; Rieradevall, J.; Gabarrell, X. Economic Assessment and Comparison of Acacia Energy Crop with Annual Traditional Crops in Southern Europe. Energy Policy 2010, 38, 592–597. [Google Scholar] [CrossRef]

- Sabatti, M.; Fabbrini, F.; Harfouche, A.; Beritognolo, I.; Mareschi, L.; Carlini, M.; Paris, P.; Scarascia-Mugnozza, G. Evaluation of Biomass Production Potential and Heating Value of Hybrid Poplar Genotypes in a Short-Rotation Culture in Italy. Ind. Crops Prod. 2014, 61, 62–73. [Google Scholar] [CrossRef]

- Monedero, E.; Hernández, J.J.; Collado, R. Combustion-Related Properties of Poplar, Willow and Black Locust to be Used as Fuels in Power Plants. Energies 2017, 10, 997. [Google Scholar] [CrossRef]

- Mitsui, Y.; Seto, S.; Nishio, M.; Minato, K.; Ishizawa, K.; Satoh, S. Willow Clones with High Biomass Yield in Short Rotation Coppice in the Southern Region of Tohoku District (Japan). Biomass Bioenergy 2010, 34, 467–473. [Google Scholar] [CrossRef]

- Krutul, D.; Zielenkiewicz, T.; Radomski, A.; Zawadzki, J.; Antczak, A.; Drożdżek, M.; Makowski, T. Metals Accumulation in Scots Pine (Pinus Sylvestris L.) Wood and Bark Affected by Environmental Pollution. Wood Res. 2017, 62, 353–364. [Google Scholar]

- Gendek, A.; Malatak, J.; Velebil, J. Effect of Harvest Method and Composition of Wood Chips on Their Caloric Value and Ash Content. Sylwan 2018, 162, 248–257. [Google Scholar]

- Carrillo-Parra, A.; Contreras-Trejo, J.C.; Pompa-García, M.; Pulgarín-Gámiz, M.Á.; Rutiaga-Quiñones, J.G.; Pámanes-Carrasco, G.; Ngangyo-Heya, M. Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure. Appl. Sci. 2020, 10, 6383. [Google Scholar] [CrossRef]

- Cordero, T.; Marquez, F.; Rodriguez-Mirasol, J.; Rodriguez, J.J. Predicting Heating Values of Lignocellulosic and Carbonaceous Materials from Proximate Analysis. Fuel 2001, 80, 1567–1571. [Google Scholar] [CrossRef]

- Dibdiakova, J.; Wang, L.; Li, H. Characterization of Ashes from Pinus Sylvestris Forest Biomass. Energy Procedia 2015, 75, 186–191. [Google Scholar] [CrossRef][Green Version]

- Palacka, M.; Vician, P.; Holubčík, M.; Jandačka, J. The Energy Characteristics of Different Parts of the Tree. Procedia Eng. 2017, 192, 654–658. [Google Scholar] [CrossRef]

- Neiva, D.M.; Araújo, S.; Gominho, J.; de Carneiro, A.C.C.; Pereira, H. An Integrated Characterization of Picea Abies Industrial Bark Regarding Chemical Composition, Thermal Properties and Polar Extracts Activity. PLoS ONE 2018, 13, e0208270. [Google Scholar] [CrossRef] [PubMed]

- Ninikas, K.; Ntalos, G.; Mitani, A.; Koutsianitis, D. Calorific Values from Greek Spruce Residues and Bioenergy Potentials via Pellet Production. Pro Ligno 2019, 4, 300–305. [Google Scholar]

- Charis, G.; Danha, G.; Muzenda, E. Characterizations of Biomasses for Subsequent Thermochemical Conversion: A Comparative Study of Pine Sawdust and Acacia Tortilis. Processes 2020, 8, 546. [Google Scholar] [CrossRef]

- Marangwanda, G.T.; Madyira, D.M.; Ndungu, P.G.; Chihobo, C.H. Combustion Characterisation of Bituminous Coal and Pinus Sawdust Blends by Use of Thermo-Gravimetric Analysis. Energies 2021, 14, 7547. [Google Scholar] [CrossRef]

- Čajová Kantová, N.; Holubčík, M.; Čaja, A.; Trnka, J.; Jandačka, J. Analyses of Pellets Produced from Spruce Sawdust, Spruce Bark, and Pine Cones in Different Proportions. Energies 2022, 15, 2725. [Google Scholar] [CrossRef]

- Pretzsch, H. Forest Dynamics, Growth and Yield from Measurement to Model, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 90–93. [Google Scholar]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate Analysis, Backwards Stepwise Regression Between Gross Calorific Value, Ultimate and Chemical Analysis of Wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef]

- Feng, S.; Cheng, S.; Yuan, Z.; Leitch, M.; Xu, C.C. Valorization of Bark for Chemicals and Materials: A Review. Renew. Sustain. Energy Rev. 2013, 26, 560–578. [Google Scholar] [CrossRef]

- Stachowicz, P.; Stolarski, M.J. Thermophysical Properties and Elemental Composition of Black Locust, Poplar and Willow Biomass. Energies 2023, 16, 305. [Google Scholar] [CrossRef]

- Chen, T.; Deng, C.; Liu, R. Effect of Selective Condensation on the Characterization of Bio-oil from Pine Sawdust Fast Pyrolysis Using a Fluidized-Bed Reactor. Energy Fuels 2010, 24, 6616–6623. [Google Scholar] [CrossRef]

- Ali, L.; Ahmed Baloch, K.; Palamanit, A.; Raza, S.A.; Laohaprapanon, S.; Techato, K. Physicochemical Characterisation and the Prospects of Biofuel Production from Rubberwood Sawdust and Sewage Sludge. Sustainability 2021, 13, 5942. [Google Scholar] [CrossRef]

- Sarker, S.; Nielsen, H. Preliminary Fixed-Bed Downdraft Gasification of Birch Woodchips. Int. J. Environ. Sci. Technol. 2014, 12, 2119–2126. [Google Scholar] [CrossRef]

- Chew, J.; Doshi, V. Recent Advances in Biomass Pretreatment—Torrefaction Fundamentals and Technology. Renew. Sust. Energ. Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Jin, C.; Sun, J.; Chen, Y.; Guo, Y.; Han, D.; Wang, R.; Zhao, C. Sawdust Wastes-Derived Porous Carbons for CO2 Adsorption. Part 1. Optimization Preparation via Orthogonal Experiment. Sep. Purif. Technol. 2021, 276, 119270. [Google Scholar] [CrossRef]

- He, Y.; Zhao, Y.; Chai, M.; Zhou, Z.; Sarker, M.; Li, C.; Liu, R.; Cai, J.; Liu, X. Comparative Study of Fast Pyrolysis, Hydropyrolysis and Catalytic Hydropyrolysis of Poplar Sawdust and Rice Husk in a Modified Py-GC/MS Microreactor System: Insights into Product Distribution, Quantum Description and Reaction Mechanism. Renew. Sust. Energ. Rev. 2020, 119, 109604. [Google Scholar] [CrossRef]

- Kraszkiewicz, A. Chemical Composition and Selected Energy Properties of Black Locust Bark (Robinia pseudoacacia L.). Agric. Eng. 2016, 20, 117–124. [Google Scholar] [CrossRef]

- Han, K.; Gao, J.; Qi, J. The Study of Sulphur Retention Characteristics of Biomass Briquettes During Combustion. Energy 2019, 186, 115788. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.; Bueno, J. Spanish Biofuels Heating Value Estimation. Part I: Ultimate Analysis Data. Fuel 2014, 117, 1130–1138. [Google Scholar] [CrossRef]

- Filbakk, T.; Jirjis, R.; Nurmi, J.; Høibø, O. The Effect of Bark Content on Quality Parameters of Scots Pine (Pinus Sylvestris L.) Pellets. Biomass Bioenergy 2011, 35, 3342–3349. [Google Scholar] [CrossRef]

- Rosas, J.G.; Gómez, N.; Cara-Jiménez, J.; González-Arias, J.; Olego, M.Á.; Sánchez, M.E. Evaluation of Joint Management of Pine Wood Waste and Residual Microalgae for Agricultural Application. Sustainability 2021, 13, 53. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).