1. Introduction

The development of hydrogen energy has been listed in the 14th Five-Year Plan in China, and the development of hydrogen energy has risen to the level of national strategy [

1]. Major developed countries, such as Japan, South Korea, the United States, and the European Union, also regard the development of hydrogen energy as a significant strategic direction for new energy technology innovation in the future [

2,

3,

4]. The transportation industry is regarded as an important application demonstration field for hydrogen energy worldwide, and many countries are focusing on promoting the application of hydrogen fuel cell vehicles owing to their high energy density, zero pollution, and low noise [

5,

6,

7]. Fully understanding the dangers of hydrogen and safely using hydrogen energy are necessary for the rapid and healthy development of the hydrogen fuel cell vehicle industry. On-board hydrogen systems are important guarantees of the safety of hydrogen fuel cell vehicles. Currently, the main problems related to the hydrogen safety of on-board hydrogen systems are unclear risk points of hydrogen leakage, imperfect safety prevention and control strategies, and incomplete standard systems. In particular, research on safety problems in the transportation process of fuel cell vehicles is still lacking. This study focuses on the analysis of safety risk points and corresponding safety measures for the on-board hydrogen system in the two processes of the use and transportation of hydrogen fuel cell vehicles.

This study aimed to identify the key risk factors that induce the hydrogen leakage, combustion, and explosion when the hydrogen fuel cell vehicles are used and transported. Then, the corresponding strategy was given to avoid or reduce the risk.

This paper is divided into four sections. This section introduced the state of hydrogen development and safety to date. The following section describes the materials and methods of the study. The third is the results section, which includes the analysis on safety risks and measures of on-board hydrogen systems during the operation and transportation of the HFCV. The last section discusses the problems that emerge during the process for resolving the risk and gives suggestions on making strategies, standards, and policies.

2. Materials and Methods

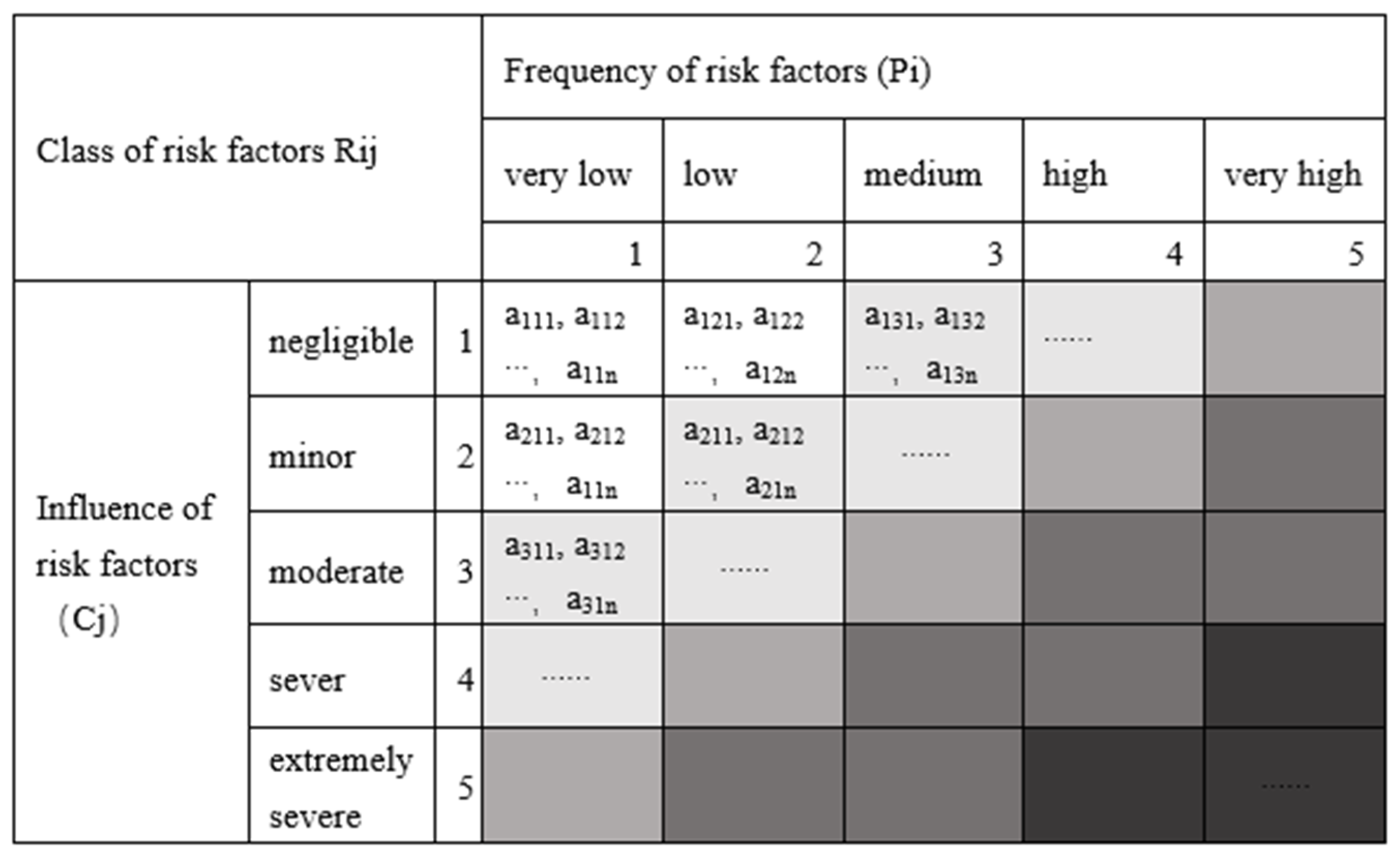

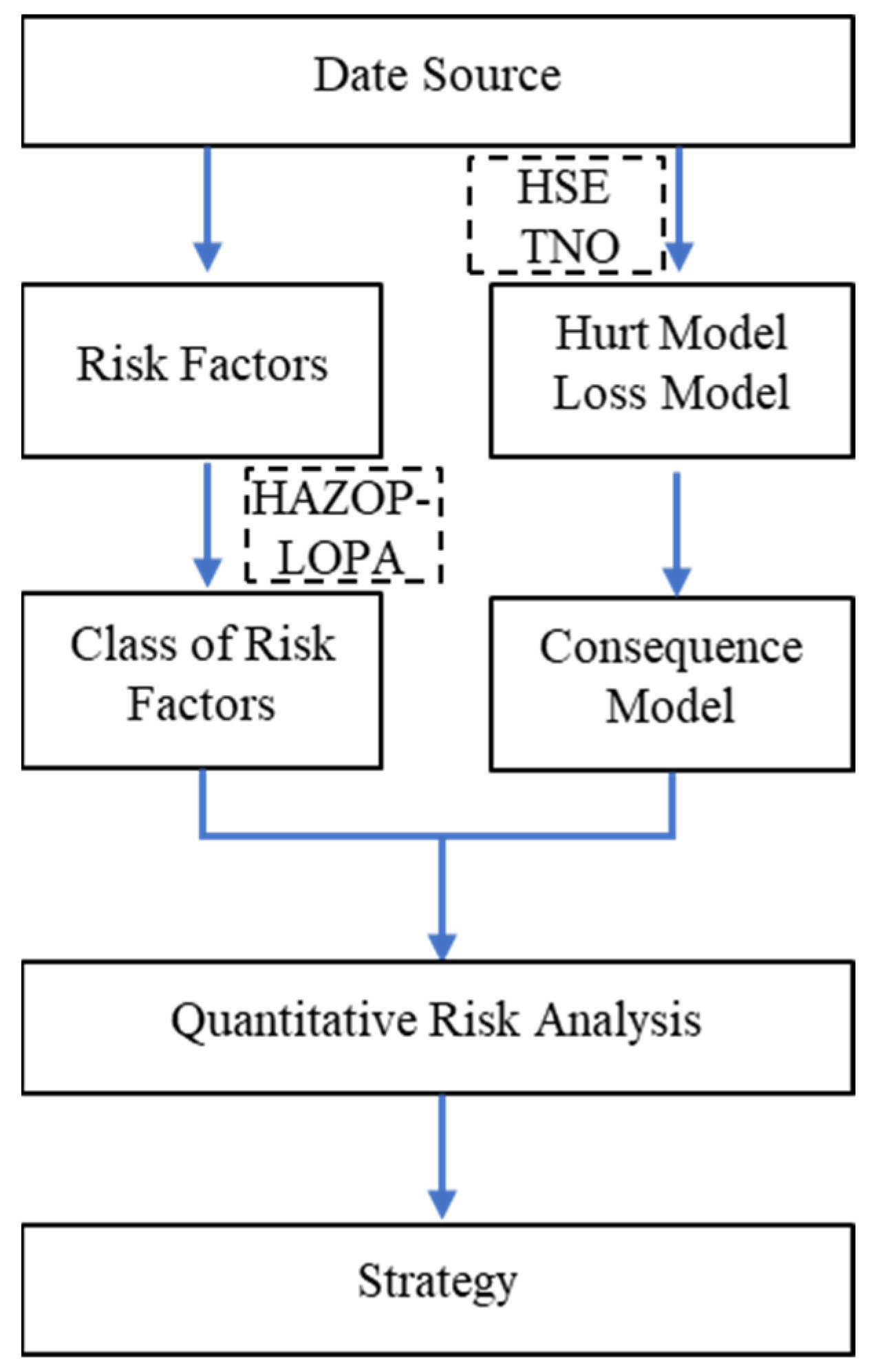

The main sources of data for the study risk factors were identified in on-board hydrogen systems and transport processes by investigating major databases. The HAZOP-LOPA risk matrix joint analysis method was used for establishing the risk factor class model, as shown in

Figure 1. At the same time, the consequences model caused by risk factors was set up based on data source and loss model. The risk is quantitatively evaluated by combining the risk factor class model and the consequence model, and then the strategy to avoid or reduce the risk was given. The analysis procedure is shown in

Figure 2.

The main sources of data for the study were Hydrogen Tools (H2Tools), Hydrogen Accidents and Incidents Database (HIAD), Japanese High Pressure Gas Safety Act (HPGSA), Composite Data Products (CDPs) of National Renewable Energy Laboratory, White Papers of China Hydrogen and Fuel Cell Industry (WPCHFCI), and experiments. H2Tools is developed by the Pacific Northwest National Laboratory, which is supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy. HIAD was developed by the Joint Research Centre (JRC) of the European Commission and worked as the repository of systematic data describing in detail hydrogen-related undesired events. HPGSA aims to regulate the production, storage, transportation, and other related aspects of the handling of high-pressure gases, including hydrogen. CDPs aggregate the analysis results of the status and progress of the technology and the laboratory publishes them online. Since 2015, CDPs have focused on the fuel cell electric vehicle evaluations hydrogen station. WPCHFCI is developed by National Energy Administration of and Ministry of Transport in China and aims to describe the status of the hydrogen industry and direct its development. The experimental data include the results from the reference and authors’ laboratory.

Hazard and Operability Analysis (HAZOP) is a systematic and structured technique used to identify, assess, and mitigate potential risks and hazards in complex processes. The resulting data from the HAZOP analysis are used as inputs to the Protective Layer Analysis (LOPA) to simulate the accident site in a variety of scenarios. Then, the risk factors are graded according to the frequency and impact of the risk in the accident. Combined with the probability of risk occurrence, experimental data, and loss model, the consequences model caused by risk factors is established. The experimental data include hydrogen diffusion concentration distribution data, combustion explosion temperature data, pressure data, etc. The loss models include thermal damage model, overpressure model, asphyxiation model, and so on.

Thermal damage usually refers to the level of injury caused by thermal radiation, which is a function of the intensity of heat flux and the duration of exposure. Expressed in thermal dose units:

where

i is the heat radiation flux,

t is the exposure time.

The overpressure model includes the overpressure model in open space:

where

I is the pulse,

Eflam is the combustible energy,

Pambient is ambient pressure and the overpressure model in confined space.

where

p0 is the initial pressure,

VT is the total volume of the enclosed space,

VCnH2n+2 is the volume of the pure fuel expanded after release,

Vstoich is the fuel volume of the stoichiometric fuel-air mixture,

σ is the expansion ratio of the stoichiometric fuel-air mixture, and

γ is the specific heat ratio of the air.

where

t is the exposure time,

CO2 is the concentration of oxygen.

3. Results

3.1. Analysis on Safety Risks and Measures of On-Board Hydrogen System during the HFCV Operation

Currently, it is generally believed that the hydrogen safety of HFCV refers to the overall safety of the on-board hydrogen system during vehicle operation and transfer. Hydrogen filling, storage, and supply systems are the three main components of the on-board hydrogen systems of fuel cell vehicles. This section introduces the safety risks and measures for these three components during the HFCV operation.

3.1.1. Safety Risks and Measures of Hydrogen Filling System

The main components of the hydrogen filling system include the hydrogen fuel cell electric vehicle refueling receptacle (hereinafter referred to as the receptacle), filters, hydrogen transportation pipelines, pipeline solenoid valves, and one-way valve [

8,

9,

10]. The pipeline solenoid valve can effectively prevent the gas from entering the battery when the cylinder is inflated, and the one-way valve can prevent the gas from leaking when the receptacle is damaged.

The main risks of a hydrogen filling system arising from the aforementioned critical components include the hydrogen embrittlement leakage, over-temperature filling, static electricity in the pipeline, leakage, and combustion at the receptacle [

10,

11,

12,

13]. To avoid risks and reduce consequences, the following measures are proposed to be taken.

First, it is about the materials. The metal materials used for all accessories in the hydrogen filling system (such as the 316 L stainless steel for valves and high-pressure hydrogen filter, aluminum alloy and titanium alloy for low pressure hydrogen filter, and Monel alloy for hydrogen transportation pipeline) must pass a material safety performance test to prevent hydrogen embrittlement. At the same time, checking the nonmetallic accessories is also important. In March 2022, the 2019 Hyundai Nexo caught fire at a hydrogen refueling station in South Korea. Through the deep investigation, it was found that the fire was caused by material falling from the receptacle that resulted in a hydrogen leak and subsequent blaze. Therefore, a long-term service performance test is required for nonmetallic pipe-fitting gaskets and hydrogen transmission hoses. The hose used in the hydrogen filling gun can withstand cyclic tests from a low temperature (233 K) to a high temperature (358 K) repeatedly under high pressure [

11,

12,

14]. Additionally, the reliability and stability of the sensors must be tested.

Second, it is about the over-temperature. The pressure in the vehicle-mounted hydrogen storage cylinder rapidly reaches 10 MPa (usually within a few minutes) when the high-pressure hydrogen storage tank fills the on-board hydrogen storage cylinder. The rapid increase in the pressure in the cylinder and rapid compression of hydrogen result in a significant increase in the temperature of the vehicle-mounted hydrogen storage cylinder, which corresponds to a security threat. To inject hydrogen quickly and safely, a combination of hydrogen precooling, temperature control, and hierarchically optimized filling is often used in engineering practice [

15,

16,

17]. Specifically, hydrogen precooling is the process of cooling the hydrogen to a temperature of 233.15 K before low-temperature filling. Temperature control refers to controlling the pressure increase rate and hydrogen filling flow to the cylinder to prevent reaching an excessively high cylinder temperature when hydrogen precooling cannot ensure that the cylinder temperature is below the safety limit. Hierarchical optimized filling refers to a hydrogen filling method that classifies the hydrogen storage tank pressure into low, medium, and high grades and enables the hydrogen filling machine to operate in an orderly manner. To prevent the temperature from increasing further, a temperature sensor was installed to monitor the hydrogen temperature of the hydrogen filling gun in real time. When the temperature is higher than 358 K, hydrogen filling must be stopped immediately [

18]. Additionally, the hydrogen flow rate is easy to ignore when considering the safety of the filling process. In the process of hydrogen filling, the flow velocity in the pipeline inevitably increases, and the friction between the hydrogen in the pipeline and pipe wall increases. In particular, when the pipeline contains other impurities, such as microcracks and rust, electrostatic sparks can easily form, which may lead to accidents. Therefore, the flow rate in a pipe should not be excessively high.

The receptacle, which also functions as a one-way valve and particle filter, is one of the key components of the hydrogen filling system. The receptacle and charging inlet cannot be set on the same side of the vehicle body. They are not located in the same compartment and should be at least 20 cm apart. GB/T 26779-2021 [

19] is currently the main standard for the detection of receptacles in China and has made relevant provisions on the marks, types, test methods, and requirements of receptacles for fuel cell vehicles. Relevant provisions were also made regarding the durability, airtightness, compatibility, and environmental adaptability of the receptacle. Another standard related to the filling equipment is the International Standard ISO 17268:2020 [

20]. Unlike GB/T 26779-2021, ISO 17268:2020 focuses on the connection equipment for compressed hydrogen vehicle filling, which defines the design, safety, and operational characteristics of hydrogen vehicle filling connectors.

3.1.2. Safety Risks and Measures for Hydrogen Storage Systems

The most common on-board hydrogen storage systems are high-pressure hydrogen storage cylinder systems. A typical high-pressure compressed hydrogen storage system comprises a hydrogen cylinder, solenoid valve, one-way valve, globe valve, and temperature-driven pressure relief device (TPRD).

The risks usually arise from the above components and include [

12,

15,

21,

22,

23,

24]:

- (1)

High-pressure hydrogen leakage owing to hydrogen embrittlement of the cylinder;

- (2)

Hydrogen leaks and containers being destroyed because of the pressure mismatch between the hydrogen filler at the hydrogen station and hydrogen storage tank;

- (3)

Hydrogen leakage due to faults in key components such as cylinder valves and pressure relief valves;

- (4)

Hydrogen leakage at the joint between the unloading valve and connecting pipeline.

To address the aforementioned risks, the measures considered are as follows:

For hydrogen cylinders, it’s essential to mitigate the risk of hydrogen embrittlement through two aspects: appropriate material selection and processing technology. Additionally, proper installation methods of hydrogen cylinders should be employed to prevent the accumulation of leaked hydrogen. Hydrogen storage cylinders and pipelines should not be installed in passenger compartments, luggage compartments, or other places with poor ventilation. Ventilation systems or other measures for discharging hydrogen must be considered. A hydrogen storage bottle should be installed away from the heat source, the ambient temperature should not exceed 323 K, and insulation measures should be taken when necessary [

25]. Currently, the specifications of a single-bottle group, 2-bottle group, 4-bottle group, 6-bottle group, and 8-bottle group are used for hydrogen fuel cell buses according to the requirements of vehicle quality, rated power, and driving mileage. The arrangement of the bottle groups is very important, and the arrangement method usually includes the top and underfloor layouts of the roof. In the rooftop layout, the roof is regarded as isolating the hydrogen storage bottle compartment from the crew compartment, and a shielded cylinder cover is necessary to avoid direct sunlight. In the underfloor layout, effective isolation measures are required between the hydrogen storage bottle and crew compartments. When the hydrogen storage bottle is placed under the frame, effective protective measures under the hydrogen storage bottle should be taken to avoid splashing and the collision of the hydrogen storage container. The minimum distance between the cylinder and ground is approximately 20 cm. For both layouts, the effectiveness of the isolation must be verified by smoking testing. In fuel cell cars, hydrogen storage bottles are usually mounted in the middle of the chassis, under the rear seat, and in an open space between the suitcase and the rear wheel.

The cylinder valve is generally integrated with a one-way valve, solenoid valve, TPRD, and other accessories, and it is installed on the hydrogen cylinder as one part. The connections between the cylinder valves and pipes must satisfy the installation specifications. Relevant tests of the cylinder valve, such as performance and fire tests, were conducted together with the hydrogen cylinder. The TPRD is currently essential for the timely and quick release of the hydrogen. It is in the bottle and connected to the inside of the hydrogen storage bottle. When the temperature of the hydrogen storage bottle reached the set value, the TPRD opened and hydrogen in the bottle was released. The solenoid valve in the cylinder primarily cooperates with the hydrogen leakage alarm system. When the hydrogen leakage concentration reached a set value, the solenoid valve cut off the hydrogen supply. Manual shut-off valves are typically open and can be manually cut off when the solenoid valve fails. The solenoid and manual shut-off valves functioned together to effectively cut off the hydrogen supply as a dangerous situation occurred.

Promptly detecting and measuring the hydrogen concentration is the primary step before valves can cut off the hydrogen supply. Therefore, having hydrogen leakage detectors with reasonable layouts is necessary. Currently, hydrogen sensors are mainly divided into electrochemical, optical, and catalyst sensors based on various working principles. Owing to the aging of sensors, changes in environmental conditions, or physical or chemical changes inside the sensor, hydrogen sensors may exhibit drift. The recovery time, response time, and compensation after drift are important research directions in current sensor research. The electrochemical hydrogen-sensing technology has matured and is the most widely used in making a hydrogen sensor with a response time of 20–50 s [

26,

27]. The response time is a bit longer for a hydrogen leakage accident. To design a sensor with good performance, so that the hydrogen released due to part failure and pipe joint leakage can be detected in real time, is inevitable. An effective signal processing system is necessary to ensure that the signal is accurately transmitted to the alarm device.

3.1.3. Safety Risks and Measures of Hydrogen Supply System

The hydrogen supply system is the most important part of a hydrogen fuel cell vehicle. The function of the hydrogen supply system is to decompress hydrogen in an automotive high-pressure compressed hydrogen storage cylinder through a decompression valve before the hydrogen enters the fuel cell stack. The system guarantees the feeding of the fuel cell stack hydrogen at an appropriate pressure and temperature. In general, a hydrogen supply system consists of one-way valves, safety valves, high-pressure cylinder fuse valves, solenoids, flow control valves, manual shut-off valves, flow sensors, temperature sensors, and various connection pipes [

28,

29,

30].

The main risks of the hydrogen supply system include the following: (1) hydrogen leakage due to hydrogen fragility in the pipes and valve bodies; (2) fires caused by static electricity; (3) leakages at pipeline connections; (4) the failure of electrical components, including disturbed solenoid valves and short circuits [

31,

32,

33]. The measures taken were as follows:

First, the hydrogen supply system should be installed in a relatively open space. In a closed or semi-closed space, the hydrogen supply system should be safely isolated from the cabin, cab, or cargo box [

34]. According to the installation specifications for the gas systems of gas vehicles, the direction of the exhaust gas should not exceed 45° from the ground to allow the leaked hydrogen to be discharged in time. The distance between the ventilation connector and exhaust pipe and other heat sources should not be less than 25 cm, and the total area of ventilation should not be less than 4.5 cm

2 [

35]. Similar requirements exist for hydrogen supply systems. For most vehicle factories, the angle of the TPRD for releasing the hydrogen is set to 45° and direction is to the back of the vehicle. The ventilation scheme has been examined for various spaces in many studies and has varied from space to space [

36,

37].

The areas where static electricity may occur in the hydrogen supply system should be reliably grounded to avoid static electricity generation. Measures should also be taken to control the leaking hydrogen accumulation to avoid combustion due to static electricity. To eliminate static electricity, the metal parts of the supporting and fixing pipelines should not be in direct contact with the pipeline, and nonmetallic padding should be added. The parts should also be properly arranged to exclude friction between adjacent parts to the maximum possible extent. Before hydrogen supply, the connections and airtightness of all parts should be checked. Bubble detection and soap bubble tests are commonly used methods. Additionally, the halogen flame method, helium mass spectrometry leak detector, and ultrasonography are sensitive detection methods [

38].

To address this risk, the following principles have been proposed: avoiding leakages, detecting leakages, and responding to leakages. The most important and primary step in dealing with leakage is to avoid it. If leakage is unavoidable, it is necessary to have effective measures to ensure its timely detection and a quick response after detection. Therefore, the pipes joining the spare parts should be firmly fixed, and the spacing between the fixing points should not be too large. If necessary, the hydrogen storage and supply assembly should be connected to a hose for the fuel cell system to reduce leakage. The hydrogen concentration sensor should be installed in the area of the higher point where hydrogen is easily accumulated in the car. The number of sensors should be increased in spaces with scattered clusters. To detect hydrogen leakage quickly and effectively, reasonable locations and quantities of hydrogen sensors should be examined. Once a leak is detected, measures to solve it are necessary. A solenoid valve and pressure sensor were installed in the hydrogen supply system. When a pressure change occurs due to leakage, the pipeline pressure monitoring controller will detect any abnormalities in the hydrogen supply system’s pressure. Upon detection, the solenoid valve will immediately close, halting the pipeline system’s operation. In addition to closing the solenoid valve, doors and windows should be promptly opened, and ventilation systems should be activated to enhance air circulation. This will aid in dispersing the hydrogen and swiftly reducing its concentration to below the explosive limit.

To minimize the failure of electrical components, all parts of the electrical system are required to meet environmental requirements, including temperature, flame retardancy, salt fog resistance, electrical insulation, electromagnetic interference, and water and dust protection requirements. The power interface should not be set near the hydrogen inlet, and the hydrogen pipeline should be relatively isolated from the charging high-voltage line. The electrical components of the hydrogen supply system should be tested for water and dust resistance, and the protection level should not be lower than IP67 (refer to GB/T 4208-2017) [

39].

Accidents involving joint leakage, failure of pressure-reducing valves, and bottle-mouth valves have also occurred. However, no standards have been set for the pipeline system components of on-board hydrogen systems. China’s GB/T 29126-2012 [

40] and GB/T 26990-2011 [

41] standards have only partial provisions regarding the test methods and technical conditions of high-pressure compression hydrogen storage systems, hydrogen supply systems, and on-board hydrogen refueling systems for HFCV. The installation and test methods for unloading valves, pressure-reducing valves, pipe joints, pressure sensors, and other components used in the hydrogen supply system are specified in EU Nos. 406/2010 and EC No79/2009 of the European Union.

3.2. Analysis of Safety Risks and Measures of Fuel Cell Vehicles in the Process of Transfer and Centralized Storage

The safety issues related to HFCV storage and transfer from factories to consumers are crucial for the development of the hydrogen industry. Several typical scenarios are often involved in the transfer of HFCV, including ro-ro ships, containers, highways, parking lots, and tunnels. The causes of leakage and explosions include environmental factors (such as wind speed and temperature) and mixed traffic (such as hydrogen–hydrogen vehicles, hydrogen–electric vehicles, hydrogen–oil vehicles, and hydrogen–oil–electric vehicles) [

42,

43,

44]. During the transfer process of HFCV, a certain amount of electric energy and hydrogen are required in storage batteries and hydrogen storage bottles, which pose certain safety risks for transportation.

The primary safety concerns during hydrogen fuel cell vehicle transfer and storage include: (1) both periodic and sporadic jolts during sea and land transportation can cause hydrogen bottles to loosen, plug components to detach, and hydrogen or electrolyte leakage to occur; (2) collisions during transportation, especially on land, pose unforeseen risks; and (3) when oil, electric, and hydrogen vehicles are transported or stored together, the associated risk of explosions increases. To address these risks, the following measures have been implemented.

The stability of the on-board hydrogen system frame structure is very important for the stability of the whole system. The vibration of the vehicle operation should be studied, and the fixed method of the hydrogen storage system should be analyzed according to the vibration frequency. A hydrogen storage system with a hydrogen cylinder group, valve body, and high-pressure pipeline must be firmly fixed to the car to avoid movement or rotation induced by vibrations or impacts. In general, the performance of the hydrogen cylinder is inevitably affected during the installation process. The proper installation method must ensure that the stiffness of the cylinder cannot be decreased and that the structure of the vehicle cannot be weakened after installation. The reliability of the electrical connector must be considered to avoid it falling off or touching the wire of the electrical parts and short circuiting due to vibration. It is recommended to regularly check the tightness of the fixed structure of the on-board hydrogen system and observe whether the hydrogen cylinder exhibits displacement and rotation.

The on-board hydrogen system of an HFCV requires a certain shock resistance performance to avoid damage to the hydrogen supply system caused by vibration and shock during transportation and storage. When hydrogen storage cylinders are installed in the exposed spaces of vehicles, effective protective measures must be taken (such as avoiding angular, sharp structures around the hydrogen storage cylinders). A safe anti-collision design is necessary to automatically shut off the hydrogen supply when a collision occurs. Owing to the complexity of the collision process, hydrogen leakage is possible, even if each component is designed to be very strong. To mitigate the consequences of leakage, an inertial switch with a redundant design should be installed in at least two locations on the HFCV. This switch activates upon collision, converting the collision signal into an electrical signal and transmitting it to the hydrogen system control system, which then shuts off the hydrogen supply. Concurrently, a hydrogen discharge port should be designed for the hydrogen leakage area to guarantee the prompt release of any escaping hydrogen.

In multivehicle transportation and storage scenarios, including various vehicle fuel types, combustion or explosion caused by single-vehicle accidents may lead to a chain reaction of the surrounding HFCV. To reduce the scope of accidents and degree of destruction, an arrangement of vehicles is required. A reasonable spacing between vehicles can decrease the accident scope and reduce accident consequences, as the diffusion distance of hydrogen gas is influenced by factors such as the on-board hydrogen pressure space size and vehicle speed [

45,

46]. Currently, no relevant documents stipulate the arrangement and layout of vehicles during transport and storage. To monitor accidents, a temperature sensor is essential to detect the external temperature. If the temperature increases suddenly and rapidly, a fire may occur around the gas cylinder, which one can immediately be alerted to by a hydrogen system controller. In addition to the external sensor, a hot-melt plug was placed in the hydrogen cylinder. Once the surrounding vehicles are on fire during transport and storage, the high temperature around the hydrogen storage cylinder causes the plug to melt, decreasing the hydrogen release velocity.

In terms of standards, the status monitoring and safety requirements of the on-board hydrogen system during transfer are still in the laboratory stage, and no technical specifications have been established. For HFCV transportation and storage, it is essential to establish technical safety requirements in alignment with standards such as the “International Regulations on Hazards”, “Classification Code for Steel Seagoing Vessels”, and the “General Technical Conditions for Vehicle Carriers”.

4. Summary and Outlook

During the usage, transfer, and storage of HFCVs, the safety measures for on-board hydrogen systems focus on prevention and monitoring. The safety strategy operates based on four key principles. The first is the avoidance of leakage, emphasizing the need to minimize hydrogen leaks. This can be achieved by selecting hydrogen-compatible materials to reduce embrittlement risks, enhancing the resistance of parts and systems to vibration and impact, bolstering the stability and strength of system structures to enhance the reliability of storage bottles, valve bodies, and joints, and installing collision protection equipment to decrease collision-induced leakages. The second principle is to prevent accumulation. The system should feature efficient ventilation facilities and a layout that promotes hydrogen dispersion. During sea or land transportation, forced ventilation measures should be designed and vehicle layouts optimized to diminish the chance of hydrogen pooling. The third principle is timely detection, involving the installation of highly sensitive hydrogen sensors and alarms. Optimizing the layout of these sensors ensures the swift detection of potential leaks. The fourth principle is rapid control, where, upon detecting a hydrogen leak, immediate actions, such as cutting off the hydrogen supply and activating forced ventilation equipment, are implemented.

Currently, a hydrogen energy standard system is lacking in China. At present, the standards related to HFCV, mainly involving the general foundation, vehicle standards, infrastructure, and fuel system, have been established by several standards and technical committees under the Standardization Administration. The major standards that have been published are: GB/T 26779-2021 [

19] “Hydrogen fuel cell electric vehicle refueling receptacle”, GB/T 24549-2020 [

47] “Fuel cell electric vehicle Safety requirements”, GB/T 29126-2012 [

40] “Fuel cell electric vehicle on-board hydrogen system test method”, GB/T 26990-2011 [

41] “Fuel cell electric vehicle on-board hydrogen system specifications”, GB/T 34584-2017 [

48] “Safety technical regulations for hydrogen refueling station”, and GB/T 35544-2017 [

49] “Fully-wrapped carbon fiber reinforced cylinders with an aluminum liner for the on-board storage of compressed hydrogen as a fuel for land vehicles”. These standards are mainly based on references and lack sufficient experimental data and the necessary research support. For example, the installation position of the sensor mentioned in GB/T 24549-2020 [

47] corresponds to the “appropriate position”. However, this position has not yet been specified. In particular, the standards for on-board hydrogen systems in the transfer process are still lacking. The formulation of standards must be considered in terms of three aspects: space dimension, time length, and interaction breadth. Standards vary by space; for example, hydrogen leakage in a confined space is more likely to occur than that in an open space. Therefore, the standard content for sea transport (confined spaces) differs from that for land transport (open spaces). In terms of time, the formulation of standards is based on the full lifecycle of an on-board hydrogen system. It is necessary to consider not only safety in use but also safety in the processes of production, transportation, and storage, as well as the service life of the components. Interaction breadth refers to the vehicle–vehicle networking and monitoring linkage between multiple-fuel vehicles (hydrogen, electric, and oil). With the further promotion of HFCVs, the safety requirements for on-board hydrogen systems will inevitably increase. Therefore, several standards are not enough to direct the safety of HFCVs, and a serial of standards should be worked out. The standards of a hydrogen storage cylinder, for instance, may include the standard of producing, the standard of refilling, the standard of accessories, and so on. The standard not only involves system safety itself, but also guidance for users and emergency management strategies.

In conclusion, establishing scientific, systematic, and integrated safety standards for hydrogen energy is a strong guarantee for the safe application of hydrogen energy.

Author Contributions

Conceptualization, Z.Y. and Y.L.; methodology, Z.Y.; investigation, W.Q.; resources, J.W. and Z.D.; data curation, W.Q.; writing—original draft preparation, X.J. and Y.H.; writing—review and editing, Y.L.; supervision, J.W. and Y.L.; project administration, Z.Y. and Y.L.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China [grant number: 2021YFB4001001].

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

A.Y. and J.W. were employed by the China Automotive Technology & Research Center Co., Ltd. W.Q. was employed by China Automotive Engineering Research Institute Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Li, Y.; Zhao, Z.; Yao, Z.; Zhang, X.; Li, J.; Wang, J. Hydrogen energy industry and economic analysis for vehicles in representative regions of China. J. Beijing Univ. Technol. 2022, 48, 331–344. [Google Scholar]

- Yap, J.; McLellan, B. Evaluating the attitudes of Japanese society towards the hydrogen economy: A comparative study of recent and past community surveys. Int. J. Hydrogen Energy, 2023; in press. [Google Scholar] [CrossRef]

- Neumann, F.; Zeyen, E.; Victoria, M.; Brown, T. The potential role of a hydrogen network in Europe. Joule 2023, 7, 1793–1817. [Google Scholar] [CrossRef]

- Okunlola, A.; Giwa, T.; Di Lullo, G.; Davis, M.; Gemechu, E.; Kumar, A. Techno-economic assessment of low-carbon hydrogen export from Western Canada to Eastern Canada, the USA, the Asia-Pacific, and Europe. Int. J. Hydrogen Energy 2022, 47, 6453–6477. [Google Scholar] [CrossRef]

- Yan, S.; Yang, M.; Sun, C.; Xu, S. Liquid Water Characteristics in the Compressed Gradient Porosity Gas Diffusion Layer of Proton Exchange Membrane Fuel Cells Using the Lattice Boltzmann Method. Energies 2023, 16, 6010. [Google Scholar] [CrossRef]

- Haider, R.; Wen, Y.; Ma, Z.-F.; Wilkinson, D.P.; Zhang, L.; Yuan, X.; Song, S.; Zhang, J. High temperature proton exchange membrane fuel cells: Progress in advanced materials and key technologies. Chem. Soc. Rev. 2020, 50, 1138–1187. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Zhang, Y.; Xu, S. Temperature sensitivity characteristics of PEM fuel cell and output performance improvement based on optimal active temperature control. Int. J. Heat Mass Transf. 2023, 203, 123966. [Google Scholar] [CrossRef]

- Li, J.; Ramteke, A.; Youn, E.; Hansen, E.; Kratschmar, K.; Prakash, A.; Stager, J.; Ku, A.Y. Liquid pump-enabled hydrogen refueling system for heavy duty fuel cell vehicles: Pump performance and J2601-compliant fills with precooling. Int. J. Hydrogen Energy 2021, 46, 22018–22029. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, C.; Duan, H.; Jiang, S.; Zhou, Z.; Grouset, D.; Zhang, M.; Ye, X. Modeling and optimal control of fast filling process of hydrogen to fuel cell vehicle. J. Energy Storage 2021, 35, 102306. [Google Scholar] [CrossRef]

- Genovese, M.; Fragiacomo, P. Hydrogen refueling station: Overview of the technological status and research enhancement. J. Energy Storage 2023, 61, 106758. [Google Scholar] [CrossRef]

- Tsiklios, C.; Hermesmann, M.; Müller, T. Hydrogen transport in large-scale transmission pipeline networks: Thermodynamic and environmental assessment of repurposed and new pipeline configurations. Appl. Energy 2022, 327, 120097. [Google Scholar] [CrossRef]

- Wang, X.; Fu, J.; Liu, Z.; Liu, J. Review of researches on important components of hydrogen supply systems and rapid hydrogen refueling processes. Int. J. Hydrogen Energy 2023, 48, 1904–1929. [Google Scholar] [CrossRef]

- Macadre, A.; Yano, H.; Matsuoka, S.; Furtado, J. The effect of hydrogen on the fatigue life of Ni–Cr–Mo steel envisaged for use as a storage cylinder for a 70MPa hydrogen station. Int. J. Fatigue 2011, 33, 1608–1619. [Google Scholar] [CrossRef]

- Xiao, J.; Bénard, P.; Chahine, R. Estimation of final hydrogen temperature from refueling parameters. Int. J. Hydrogen Energy 2017, 42, 7521–7528. [Google Scholar] [CrossRef]

- Wang, X.; Gao, W. Hydrogen leakage risk assessment for hydrogen refueling stations. Int. J. Hydrogen Energy 2023, 48, 35795–35808. [Google Scholar] [CrossRef]

- Handa, K.; Oshima, S.; Rembutsu, T. Precooling temperature relaxation technology in hydrogen refueling for fuel-cell vehicles. Int. J. Hydrogen Energy 2021, 46, 33511–33522. [Google Scholar] [CrossRef]

- Yu, Y.; Lu, C.; Ye, S.; Hua, Z.; Gu, C. Optimization on volume ratio of three-stage cascade storage system in hydrogen refueling stations. Int. J. Hydrogen Energy 2022, 27, 13430–13441. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, X.; Bujlo, P.; Chen, B.; Zhang, X.; Sheng, X.; Liang, C. Review on the safety analysis and protection strategies of fast filling hydrogen storage system for fuel cell vehicle application. J. Energy Storage 2021, 45, 103451. [Google Scholar] [CrossRef]

- GB 26779-2021; Hydrogen Fuel Cell Electric Vehicle Refueling Receptacle. Chinese Standard Institution: Beijing, China, 2021.

- ISO 17268:2020; Gaseous Hydrogen Land Vehicle Refueling Connection Devices. International Organization for Standardization: Geneva, Switzerland, 2020.

- Ye, J.; Zhao, Z.; Cui, J.; Hua, Z.; Peng, W.; Jiang, P. Transient flow behaviors of the check valve with different spool-head angle in high-pressure hydrogen storage systems. J. Energy Storage 2022, 46, 103761. [Google Scholar] [CrossRef]

- Genovese, M.; Blekhman, D.; Dray, M.; Fragiacomo, P. Hydrogen station in situ back-to-back fueling data for design and modeling. J. Clean. Prod. 2021, 329, 129737. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Barhoumi, E.M.; Ben Belgacem, I.; Mansir, I.B.; Aliyu, M.; Emori, W.; Uzoma, P.C.; Beitelmal, W.H.; Akyüz, E.; Radwan, A.B.; et al. A focused review of the hydrogen storage tank embrittlement mechanism process. Int. J. Hydrogen Energy 2023, 48, 12935–12948. [Google Scholar] [CrossRef]

- Chen, L.; Xu, K.; Yang, Z.; Yan, Z.; Zhai, C.; Dong, Z. Optimal design of a novel nested-nozzle ejector for PEMFC’s hydrogen supply and recirculation system. Int. J. Hydrogen Energy 2023, 48, 27330–27343. [Google Scholar] [CrossRef]

- Li, M.; Yang, Q.; Zhang, C.; Huang, S.; Zhang, M.; Zhang, G.; Zhao, L.; Jiang, S. Experimental and numerical study of the temperature evolution in hydrogen cylinder under fast-refueling process. Int. J. Heat Mass Transf. 2023, 211, 124220. [Google Scholar] [CrossRef]

- Zhang, Y.; Su, Y.; Chen, J.; Zhang, Y.; He, M. Progress and prospects of research on hydrogen sensors. Chin. Sci. Bull. 2023, 68, 204–219. [Google Scholar] [CrossRef]

- Hübert, T.; Boon-Brett, L.; Black, G.; Banach, U. Hydrogen sensors—A review. Sens. Actuators B Chem. 2011, 157, 329–352. [Google Scholar] [CrossRef]

- Xu, Z.; Yan, Y.; Wei, W.; Sun, D.; Ni, Z. Supply system of cryo-compressed hydrogen for fuel cell stacks on heavy duty trucks. Int. J. Hydrogen Energy 2020, 45, 12921–12931. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; She, X.; Luo, Y.; Sun, Q.; Teng, L. Numerical study on the behavior and design of a novel multistage hydrogen pressure-reducing valve. Int. J. Hydrogen Energy 2022, 47, 14646–14657. [Google Scholar] [CrossRef]

- Chen, F.-Q.; Ren, X.-D.; Hu, B.; Li, X.-S.; Gu, C.-W.; Jin, Z.-J. Parametric analysis on multi-stage high pressure reducing valve for hydrogen decompression. Int. J. Hydrogen Energy 2019, 44, 31263–31274. [Google Scholar] [CrossRef]

- Abohamzeh, E.; Salehi, F.; Sheikholeslami, M.; Abbassi, R.; Khan, F. Review of hydrogen safety during storage, transmission, and applications processes. J. Loss Prev. Process Ind. 2021, 72, 104569. [Google Scholar] [CrossRef]

- Sánchez-Squella, A.; Fernández, D.; Benavides, R.; Saldias, J. Risk analysis, regulation proposal and technical guide for pilot tests of hydrogen vehicles in underground mining. Int. J. Hydrogen Energy 2022, 47, 18799–18809. [Google Scholar] [CrossRef]

- Groth, K.M.; Al-Douri, A.; West, M.; Hartmann, K.; Saur, G.; Buttner, W. Design and requirements of a hydrogen component reliability database (HyCReD). Int. J. Hydrogen Energy, 2023; in press. [Google Scholar] [CrossRef]

- Li, H.; Welsh, R.; Morris, A. Emergency responders’ perceptions of Hydrogen Fuel Cell Vehicle: A qualitative study on the U.K. fire and rescue services. Int. J. Hydrogen Energy 2021, 46, 32750–32761. [Google Scholar] [CrossRef]

- GB 19239-2022; Installation Specification for Gas System of Gas Vehicles. Chinese Standard Institution: Beijing, China, 2022.

- Zhang, X.; Wang, Q.; Hou, X.; Li, Y.; Miao, Y.; Li, K.; Zhang, L. Numerical Analysis of the Hydrogen Dispersion Behavior in Different Directions in a Naturally Ventilated Space. Appl. Sci. 2021, 11, 615. [Google Scholar] [CrossRef]

- Prasad, K. High-pressure release and dispersion of hydrogen in a partially enclosed compartment: Effect of natural and forced ventilation. Int. J. Hydrogen Energy 2014, 39, 6518–6532. [Google Scholar] [CrossRef]

- Fursenko, R.V.; Odintsov, E.S. A novel concept of automatic soap flowmeter with bubble detection by closing an electrical circuit. Flow Meas. Instrum. 2022, 85, 102165. [Google Scholar] [CrossRef]

- GB 4208-2013; Degrees of Protection Provided by Enclosure. Chinese Standard Institution: Beijing, China, 2013.

- GB/T 29126-2012; Fuel Cell Electric Vehicle On-Board Hydrogen System Test Method. Chinese Standard Institution: Beijing, China, 2012.

- GB/T 26990-2011; Fuel Cell Electric Vehicle On-Board Hydrogen System Specifications. Chinese Standard Institution: Beijing, China, 2011.

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrogen Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Hou, X.; Lan, H.; Zhao, Z.; Li, J.; Hu, C.; Li, Y. Effect of obstacle location on hydrogen dispersion in a hydrogen fuel cell bus with natural and mechanical ventilation. Process. Saf. Environ. Prot. 2023, 171, 995–1008. [Google Scholar] [CrossRef]

- Shibani; Salehi, F.; Baalisampang, T.; Abbassi, R. Numerical modeling towards the safety assessment of multiple hydrogen fires in confined areas. Process. Saf. Environ. Prot. 2022, 160, 594–609. [Google Scholar] [CrossRef]

- Chen, G.; Qi, B.; Hu, W.; Zhang, Y.; Wei, J. A fast POD prediction method for hydrogen leakage at different pressures. Int. J. Hydrogen Energy, 2023; in press. [Google Scholar] [CrossRef]

- Sun, R.; Pu, L.; Yu, H.; Dai, M.; Li, Y. Modeling the diffusion of flammable hydrogen cloud under different liquid hydrogen leakage conditions in a hydrogen refueling station. Int. J. Hydrogen Energy 2022, 47, 25849–25863. [Google Scholar] [CrossRef]

- GB/T 24549-2020; Fuel Cell Electric Vehicle Safety Requirements. Chinese Standard Institution: Beijing, China, 2020.

- GB/T 34584-2017; Safety Technical Regulations for Hydrogen Refueling Station. Chinese Standard Institution: Beijing, China, 2017.

- GB/T35544-2017; Fully-Wrapped Carbon Fiber Reinforced Cylinders with an Aluminum Liner for the On-Board Storage of Compressed Hydrogen as a Fuel for Land Vehicles. Chinese Standard Institution: Beijing, China, 2017.

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).