Pore-Scale Analysis of the Permeability Damage and Recovery during Cyclic Freshwater and Brine Injection in Porous Media Containing Non-Swelling Clays

Abstract

:1. Introduction

2. Materials and Methods

2.1. Immersed Boundary Method

2.2. DLVO Interactions

2.3. Problem Setup and Cyclic Injection

3. Results and Discussion

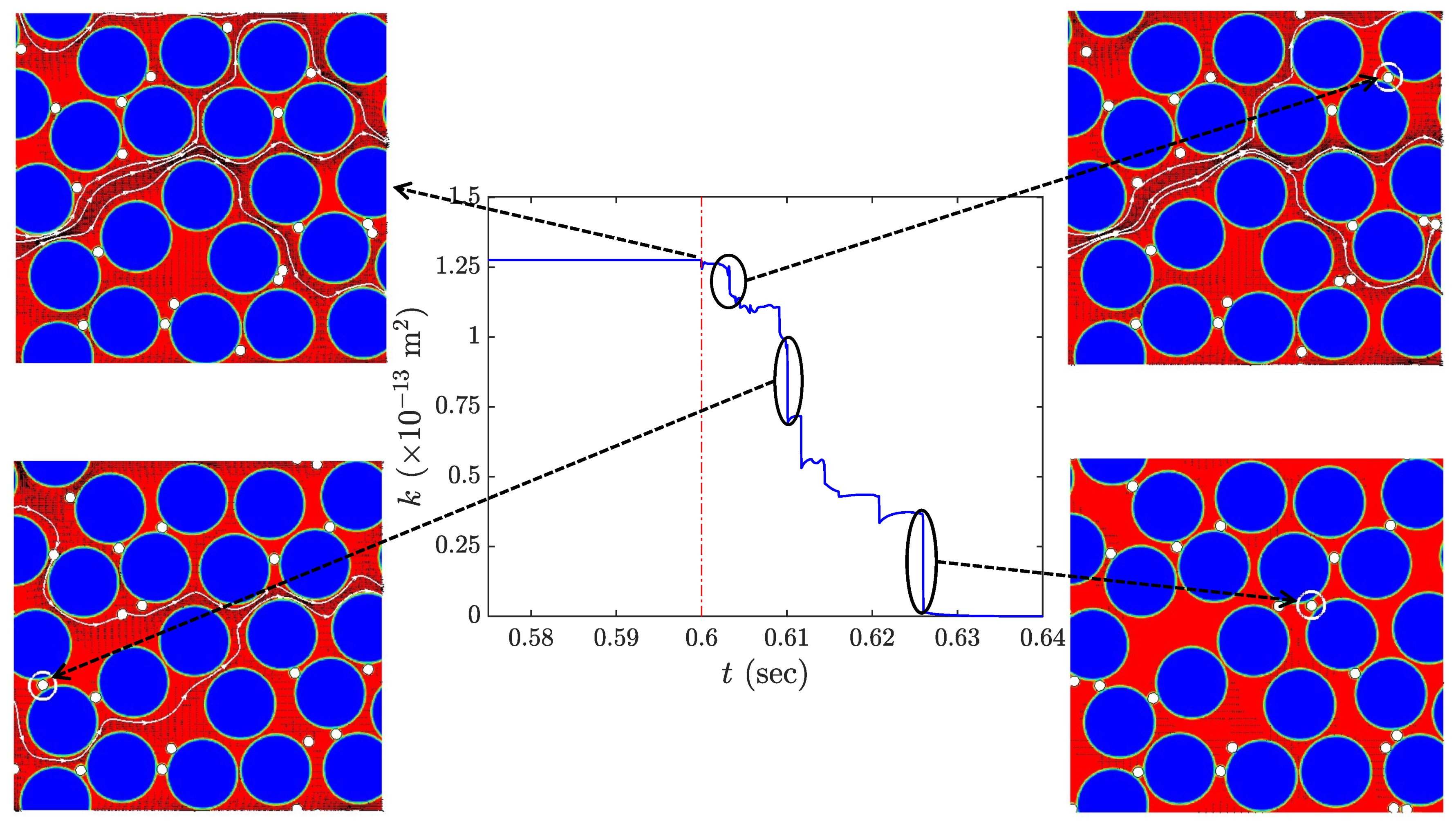

3.1. Permeability Damage Due to Pore Clogging

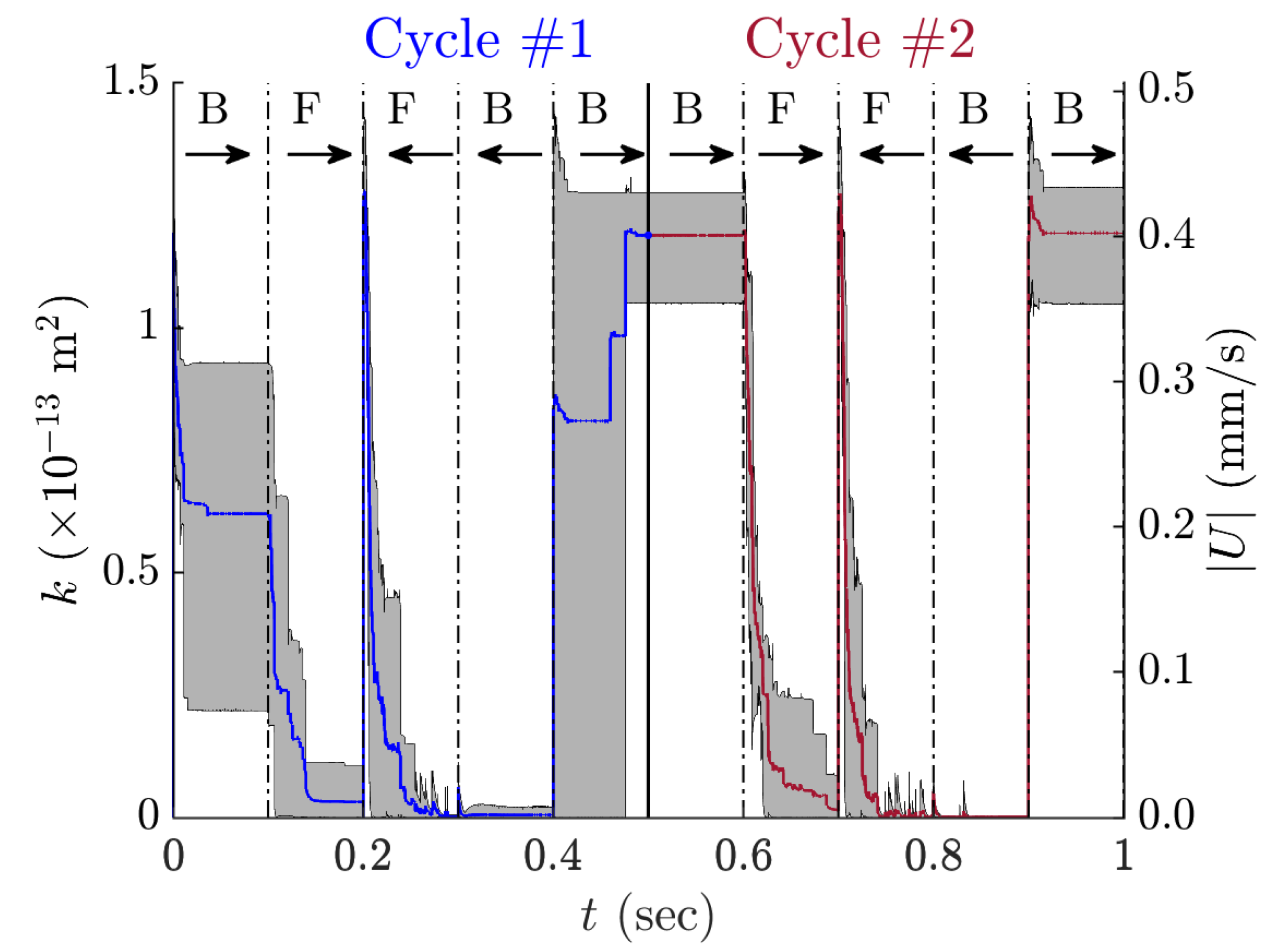

3.2. Cyclic Injection with Uniform Clay Size

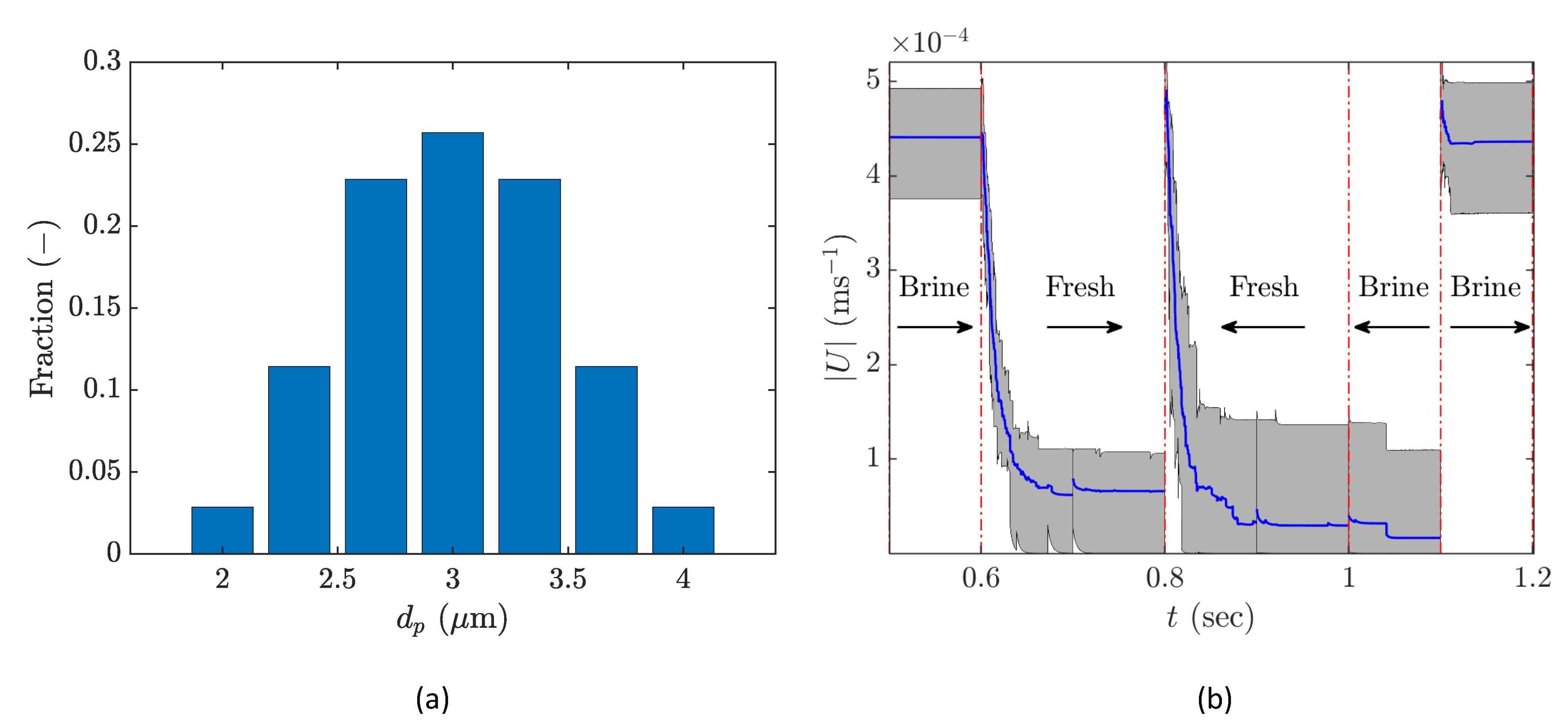

3.3. Clay Fine Distribution at Different Phases of Injection

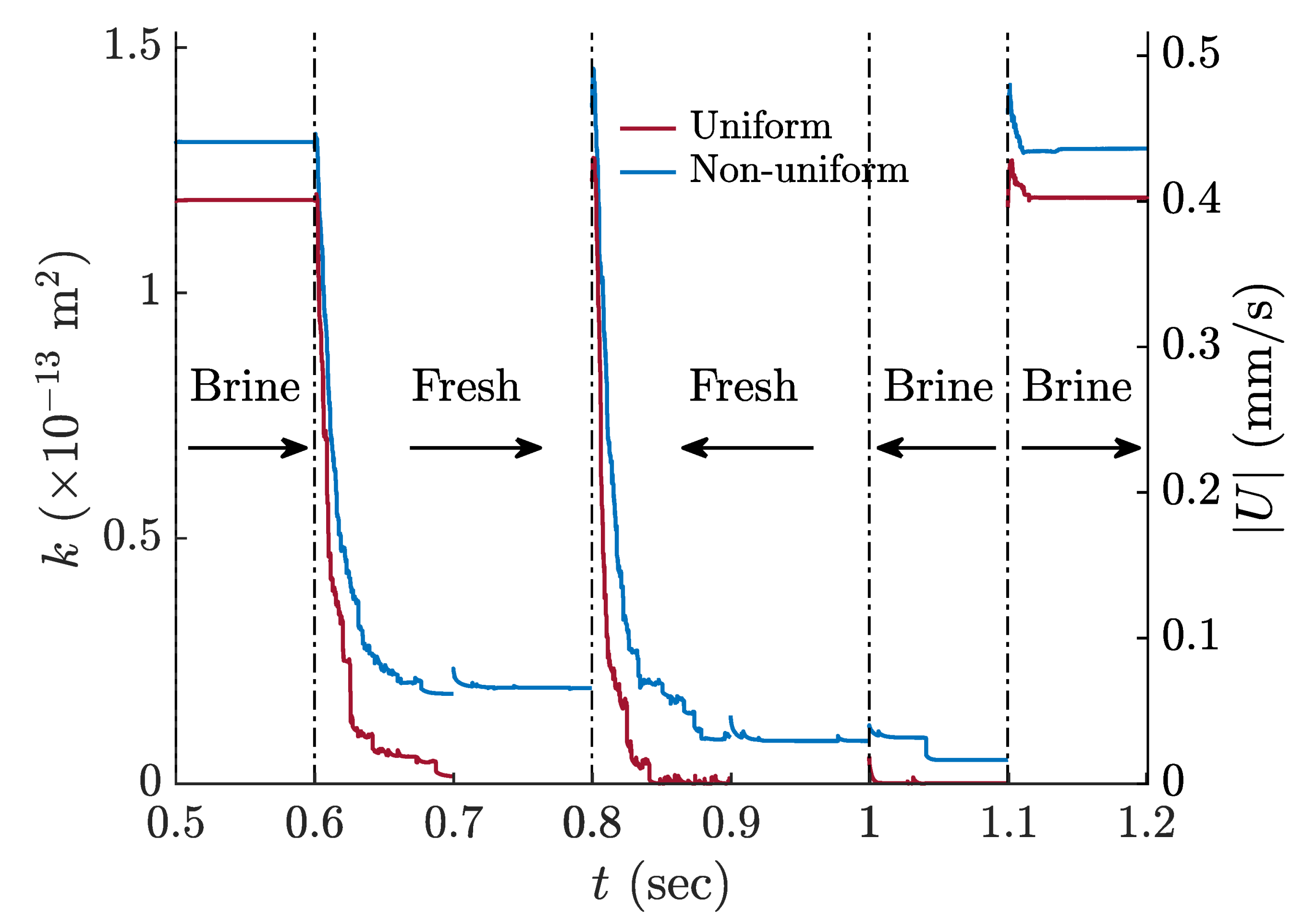

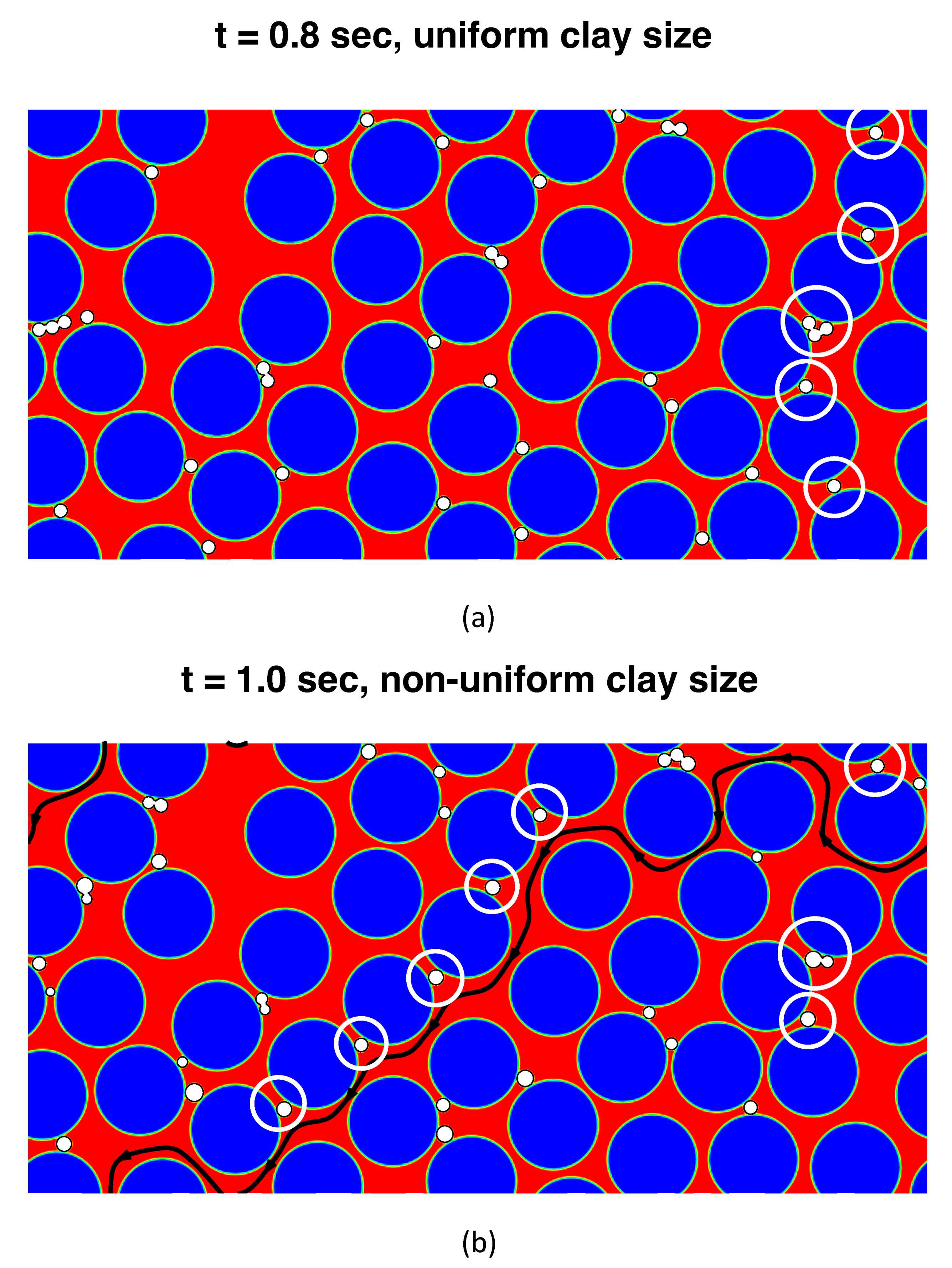

3.4. Impact of Non-Uniform Clay Size Distribution

4. Conclusions

- A clear relationship was established between the phenomenon of pore throat clogging by mobile clay fines and the permeability damage under low salinity conditions in the porous medium.

- In addition to being a function of the instantaneous salinity in the medium, the permeability damage is a function of the immediate history of the flow through it, and also depends on the direction of the flow. This was demonstrated by the repeated observation from our simulations that brine flow after freshwater flow along the same direction does not restore any of the permeability damage.

- In contrast, the permeability damage observed during injection in a fixed direction is recovered when followed by injection of brine in the opposite direction. This can be attributed to the process of the unclogged clay fines staying bound to the grains by strong net attractive DLVO force under high salinity, and moving along the grain surface to allow brine flow in the reverse direction.

- With the clay mass fraction and mean clay size kept constant, a non-uniform clay diameter distribution resulted in a less severe damage in permeability compared to a uniform clay size, in the freshwater injection phase. However, in both cases the permeability was completely restored when followed by freshwater-backward and brine-forward injection, in that order.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DLVO | Derjaguin–Landau–Verwey–Overbeek force |

| vdW | Van der Waals force |

| EDL | Electric double layer force |

Appendix A. Supplementary Analyses

Appendix A.1. Grid Independence Analysis

Appendix A.2. Implementation of the Immersed Boundary Method

References

- Civan, F. Reservoir Formation Damage: Fundamentals, Modeling, Assessment, and Mitigation, 3rd ed.; Gulf Professional Publishing: Houston, TX, USA, 2015; pp. 1–1012. [Google Scholar]

- Corapcioglu, M.; Abboud, N.; Haridas, A. Governing Equations for Particle Transport in Porous Media. In Advances in Transport Phenomena in Porous Media; Springer: Dordrecht, The Netherlands, 1987; pp. 269–342. [Google Scholar]

- De Silva, D.; Ranjith, P.G.; Perera, S.; Dai, Z.; Yang, S. An experimental evaluation of unique CO2 flow behaviour in loosely held fine particles rich sandstone under deep reservoir conditions and influencing factors. Energy 2017, 119, 121–137. [Google Scholar] [CrossRef]

- Goldenberg, L.; Magaritz, M.; Mandel, S. Experimental investigation on irreversible changes of hydraulic conductivity on the seawater-freshwater interface in coastal aquifers. Water Resour. Res. 1983, 19, 77–85. [Google Scholar] [CrossRef]

- Khilar, K.; Fogler, H. Migrations of Fines in Porous Media; Springer: Dordrecht, The Netherlands, 1998. [Google Scholar]

- Xie, Q.; Saeedi, A.; Delle Piane, C.; Esteban, L.; Brady, P. Fines migration during CO2 injection: Experimental results interpreted using surface forces. Int. J. Greenh. Gas Control. 2017, 65, 32–39. [Google Scholar] [CrossRef]

- You, Z.; Yang, Y.; Badalyan, A.; Bedrikovetsky, P.; Hand, M. Mathematical modelling of fines migration in geothermal reservoirs. Geothermics 2016, 59, 123–133. [Google Scholar] [CrossRef]

- Brown, D.L.; Silvey, W.D. Artificial recharge to a freshwater-sensitive brackish-water sand aquifer, Norfolk, Virginia. U.S. Geol. Surv. Prof. Paper 1977, 53, 939. [Google Scholar]

- Cihan, A.; Petrusak, R.; Bhuvankar, P.; Alumbaugh, D.; Trautz, R.; Birkholzer, J. Permeability Decline by Clay Fines Migration around a Low-Salinity Fluid Injection Well. Groundwater 2022, 60, 87–98. [Google Scholar] [CrossRef]

- Jones, J. Influence of Chemical Composition of Water on Clay Blocking of Permeability. J. Pet. Technol. 1964, 16, 441–446. [Google Scholar] [CrossRef]

- Khilar, K.; Fogler, H. Water Sensitivity of Sandstones. Soc. Pet. Eng. J. 1983, 23, 55–64. [Google Scholar] [CrossRef]

- Konikow, L.; August, L.; Voss, C. Effects of Clay Dispersion on Aquifer Storage and Recovery in Coastal Aquifers. Transp. Porous Media 2001, 43, 45–64. [Google Scholar] [CrossRef]

- Mohan, K.; Fogler, H. Colloidally induced smectitic fines migration: Existence of microquakes. Aiche J. 1997, 43, 565–576. [Google Scholar] [CrossRef]

- Shenglai, Y.; Sheng, Z.; Liu, W.; Song, Z.; Wu, M.; Zhang, J. Evaluation and prevention of formation damage in offshore sandstone reservoirs in China. Pet. Sci. 2008, 5, 340–347. [Google Scholar]

- Song, W.; Kovscek, A. Direct visualization of pore-scale fines migration and formation damage during low-salinity waterflooding. J. Nat. Gas Sci. Eng. 2016, 34, 8. [Google Scholar] [CrossRef]

- Torkzaban, S.; Bradford, S.; Vanderzalm, J.; Patterson, B.; Harris, B.; Prommer, H. Colloid release and clogging in porous media: Effects of solution ionic strength and flow velocity. J. Contam. Hydrol. 2015, 181, 161–171. [Google Scholar] [CrossRef] [PubMed]

- Wilson, M.; Wilson, L.; Patey, I. The influence of individual clay minerals on formation damage of reservoir sandstones: A critical review with some new insights. Clay Miner. 2014, 49, 147–164. [Google Scholar] [CrossRef]

- Israelachvili, J. Intermolecular and Surface Forces, 3rd ed.; Academic Press: Cambridge, UK, 2011. [Google Scholar]

- Churaev, N.; Lyklema, J.; Churaeva, M. Liquid and Vapor Flows in Porous Bodies: Surface Phenomena; Routledge: London, UK, 2018. [Google Scholar]

- Chequer, L.; Vaz, A.; Bedrikovetsky, P. Injectivity decline during low-salinity waterflooding due to fines migration. J. Pet. Sci. Eng. 2018, 165, 1054–1072. [Google Scholar] [CrossRef]

- Russell, T.; Pham, D.; Neishaboor, M.; Badalyan, A.; Behr, A.; Genolet, L.; Kowollik, P.; Zeinijahromi, A.; Bedrikovetsky, P. Effects of kaolinite in rocks on fines migration. J. Nat. Gas Sci. Eng. 2017, 45, 243–255. [Google Scholar] [CrossRef]

- Brady, P.; Morrow, N.; Fogden, A.; Deniz, V.; Loahardjo, N.; Winoto, W. Electrostatics and the Low Salinity Effect in Sandstone Reservoirs. Energy Fuels 2015, 29, 150126112424008. [Google Scholar] [CrossRef]

- Blume, T.; Weisbrod, N.; Selker, J. Permeability Changes in Layered Sediments: Impact of Particle Release. Groundwater 2002, 40, 466–474. [Google Scholar] [CrossRef]

- Khilar, K.; Fogler, H. Permeability Reduction in Water Sensitivity of Sandstones. In Surface Phenomena in Enhanced oil Recovery; Springer: Boston, MA, USA, 1981; pp. 721–740. [Google Scholar]

- Bhuvankar, P.; Cihan, A.; Birkholzer, J. Pore-scale CFD simulations of clay mobilization in natural porous media due to fresh water injection. Chem. Eng. Sci. 2022, 247, 117046. [Google Scholar] [CrossRef]

- Mittal, R.; Iaccarino, G. Immersed Boundary Methods. Annu. Rev. Fluid Mech. 2005, 37, 239–261. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Elimelech, M. Surface Element Integration: A Novel Technique for Evaluation of DLVO Interaction between a Particle and a Flat Plate. J. Colloid Interface Sci. 1997, 193, 273–285. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Moin, P. Application of a fractional-step method to incompressible Navier-Stokes equations. J. Comput. Phys. 1985, 59, 308–323. [Google Scholar] [CrossRef]

- Bedrikovetsky, P.; Siquera, F.D.; Furtado, C.A.; Souza, A.L.S. Modified particle detachment model for colloidal transport in porous media. Transp Porous Med. 2010, 86, 353–383. [Google Scholar] [CrossRef]

- Sefrioui, N.; Ahmadi-Sénichault, A.; Omari, A.; Bertin, H. Numerical simulation of retention and release of colloids in porous media at the pore scale. Colloids Surfaces Physicochem. Eng. Asp. 2013, 427, 33–40. [Google Scholar] [CrossRef]

- Sethian, J.; Smereka, P. Level Set Methods For Fluid Interfaces. Annu. Rev. Fluid Mech. 2003, 35, 341–372. [Google Scholar] [CrossRef]

- Bigot, B.; Bonometti, T.; Lacaze, L.; Thual, O. A simple immersed-boundary method for solid-fluid interaction in constant and stratified-density flows. Comput. Fluids 2014, 97, 126–142. [Google Scholar] [CrossRef]

- Ardekani, A.; Dabiri, S.; Rangel, R. Collision of multi-particle and general shape objects in a viscous fluid. J. Comput. Phys. 2008, 227, 10094–10107. [Google Scholar] [CrossRef]

- Vincent, S.; Motta, J.; Sarthou, A.; Estivalèzes, J.; Simonin, O.; Climent, E. A Lagrangian VOF tensorial penalty method for the DNS of resolved particle-laden flows. J. Comput. Phys. 2013, 256, 582–614. [Google Scholar] [CrossRef]

- Andrade, J.; Lim, K.; Avila, C.; Vlahinić, I. Granular element method for computational particle mechanics. Comput. Methods Appl. Mech. Eng. 2012, 241–244, 262–274. [Google Scholar] [CrossRef]

- Zeinijahromi, A.; Vaz, A. Well impairment by fines migration in gas fields. J. Pet. Sci. Eng. 2012, 88–89, 125–135. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Elimelech, M.; Borkovec, M. DLVO Interaction between Colloidal Particles: Beyond Derjaguin’s Approximation. Croat. Chem. Acta 1998, 71, 883–903. [Google Scholar]

- Wang, L.; Yin, Z. Fluid flow and mass transport in fractured media with curved fractures and varying apertures: A 3D modeling approach. Int. J. Numer. Methods Eng. 2023, 124, 4311–4338. [Google Scholar] [CrossRef]

- Bodin, J. From analytical solutions of solute transport equations to multidimensional time-domain random walk (TDRW) algorithms. Water Resour. Res. 2015, 51, 1860–1871. [Google Scholar] [CrossRef]

- Zou, L.; Cvetkovic, V. Impact of normal stress-induced closure on laboratory-scale solute transport in a natural rock fracture. J. Rock Mech. Geotech. Eng. 2020, 12, 732–741. [Google Scholar] [CrossRef]

- Gray, D.; Rex, R. Formation Damage in Sandstones Caused by Clay Dispersion and Migration. Clays Clay Miner. 1966, 14, 355–366. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhuvankar, P.; Cihan, A.; Birkholzer, J.T. Pore-Scale Analysis of the Permeability Damage and Recovery during Cyclic Freshwater and Brine Injection in Porous Media Containing Non-Swelling Clays. Energies 2023, 16, 7568. https://doi.org/10.3390/en16227568

Bhuvankar P, Cihan A, Birkholzer JT. Pore-Scale Analysis of the Permeability Damage and Recovery during Cyclic Freshwater and Brine Injection in Porous Media Containing Non-Swelling Clays. Energies. 2023; 16(22):7568. https://doi.org/10.3390/en16227568

Chicago/Turabian StyleBhuvankar, Pramod, Abdullah Cihan, and Jen T. Birkholzer. 2023. "Pore-Scale Analysis of the Permeability Damage and Recovery during Cyclic Freshwater and Brine Injection in Porous Media Containing Non-Swelling Clays" Energies 16, no. 22: 7568. https://doi.org/10.3390/en16227568

APA StyleBhuvankar, P., Cihan, A., & Birkholzer, J. T. (2023). Pore-Scale Analysis of the Permeability Damage and Recovery during Cyclic Freshwater and Brine Injection in Porous Media Containing Non-Swelling Clays. Energies, 16(22), 7568. https://doi.org/10.3390/en16227568