1. Introduction

Wind and water power systems have emerged as two of the dominant renewable sources of energy with immense growth potential across the globe, including in Poland [

1,

2,

3]. In particular, the use of wind energy has become a very popular solution in recent years. According to the Global Wind Energy Council [

4], in 2015, the wind turbine industry reached the milestone of 60 GW in new installations per year. Moreover, the previous annual record was set at the level of over 51 GW of new capacity. In total, by the end of 2015, the wind power capacity was 432 GW—17% of the growth in a market. Eight years later, on 15 June 2023, the global wind industry reached the 1 TW milestone. Recently completed wind power projects in China, the USA, Morocco, and Europe have pushed the capacity across that level threshold as the industry has delivered on the ever-growing ambitions of governments around the world [

5].

The main types of generators used in renewable sources of energy (RESs) that cooperate with wind or water turbines are AC poly-phase machines. There are two main major types: induction and synchronous. In this article, a special type of synchronous generator with permanent magnets (PMSG) is analyzed. These machines are known for being the most efficient choice amidst the current generator designs on the market [

6,

7,

8,

9]. Furthermore, their great performance and low cost of conservation during their long lifespan make them the best choice in the cost-efficiency sense.

An unconventional type of synchronous generator, named the PMSG generator with magnetic flux modulation (PMSGFM), was used in the presented energy conversion system. Its main structure and principle of working are described in the next chapter. A dedicated special power electronics circuit, which is used to convert the electric energy produced by a generator, had to be applied.

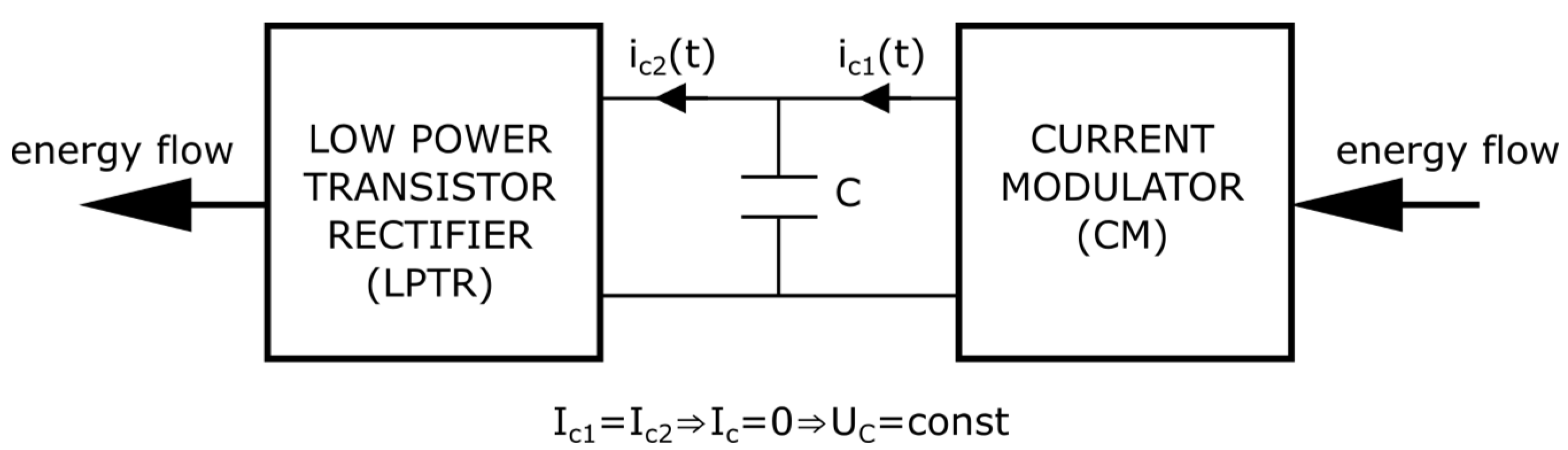

Additionally, to improve the efficiency, it was proposed to use a low-power transistor rectifier (LPTR). With the help of this converter, it became possible to transfer electric energy to the AC grid. In this way, the voltage stabilization in the DC bus of the current modulator was also achieved. The elaborated control algorithms of this active rectifier are also discussed.

The last part of this article describes chosen simulation and experimental results of this research.

2. The Unconventional PMSG Generator with Magnetic Flux Modulation

The essential part of the power conversion system is the generator (G). It is especially useful when cooperating with wind or water turbines. It is possible, thanks to the dedicated power electronics converter, to return the produced energy to the grid (on-grid mode) or to use it locally (off-grid mode). In addition, cooperation with chemical energy stores can be also considered.

The high efficiency of the whole system is the main goal to be achieved. The effectiveness of the conversion of mechanical energy into electrical energy must be achieved via the simple means of the electrical structure. As a consequence of this, agenerator, with notably designed stator windings and a distinctive power electronics converter, is proposed. It is able to enforce a sinusoidal magnetomotive force (mmf). A consequence of this is that the resultant magnetic flux is relatively similar to a sine wave. Hence, it limits the power loss in “iron”, which, in addition to the loss in “copper”, is one of the dominant power losses in the generator.

The power electronics converter connects the generator to the load (L). It has a simplified design, which mostly uses the uncontrolled rectifiers. The reason for this is that it provides a high energy conversion efficiency. The main spheres of application are medium and large power systems, where the advantages are notably evident.

The simplified block diagram of the main part of the system is shown in

Figure 1. The source of the electrical energy is a synchronous generator with an unconventional construction when it comes to the stator windings. It consists of a pair of three-phase windings in the stator. The first of the windings is connected in the star and the second one in the delta connection. The voltages at the power terminals of the generator (windings) should be the same in terms of the values, but the voltages are shifted relative to each other by an angle of π/6.

Both windings feed two independent six-pulse diode rectifiers (RCT1, RCT2). The power electronics-controlled current source—in other words, the current modulator (CM)—is located at the outputs of both rectifiers, shaping their output currents (

,

). The CM generates the output current (

). The current runs through the primary winding of the pulse transformer (PT). This transformer has divided the secondary winding. It interconnects the outputs of both rectifiers, which means that influencing the shapes of the rectifiers’ output currents is possible by applying the

flowing through the pulse transformer (PT) [

11,

12,

13]. The interrelation between the rectifier’s output currents, the modulator’s current, and the system’s output (

) is presented in Formulas (1)–(3):

where

,

are PT winding turns and

.

The main goal of the current modulator with the pulse transformer is to provide the suitable shape of each phase current of the generator (G). Thus, as a result, the

mmf associated with a given pair of windings (star–delta) is a sine wave. This reduces power loss in its magnetic circuit to a minimum value. This phenomenon has been called “the modulation of the magnetic flux”. It refers directly to the principles of the CM operation. So, the generator can be named, in this case, as a synchronous generator with a permanent magnet with magnetic flux modulation (PMSGMF). In order to ensure the sine shape of the

mmf, the MFM output current must comply with Equation (4) [

14]:

where

is the frequency of the generators’ output voltage.

However, if the modulator generates the signal, which is described by this equation, it should be noted that the sine wave of the resultant

mmf associated with only one given pair of windings (star–delta) will be obtained. In the remaining given pair of windings, the resultant

mmf will be additionally deformed. This is not a preferred solution. For this reason, the current modulator should generate a signal characterized by the same phase shift in relation to each of the individual resultant

mmf values of the presented generator. As a consequence, the modulator should generate a signal described by Equation (5).

The current given by (5) has a triangular shape, and its fundamental frequency is six times higher than the current value of

. Taking into account (5), the expected shapes of the phase currents of the generator will look like those shown in

Figure 2.

As a consequence, the

mmf associated with each pair of stator windings is quasi-sinusoidal (

Figure 3).

By shaping the phase currents of the star–delta windings (

Figure 2), it is possible to influence the resultant

mmf associated with given pairs of windings.

From the perspective of the intricacy of the system’s construction, a very important detail is that the power of the current modulator with the pulse transformer is really low, theoretically about 2.35% [

13], in comparison to the system’s nominal output power.

5. Selected Results of Simulation and Experimental Research

The results presented in this chapter were obtained via both simulation and experimentation. The flux modulation concept for the generator was verified on the basis of simulation tests. At this stage of research, the construction of a new physical model of the generator was still in progress. The power electronic system was built physically. For this purpose, instead of the generator, a transformer with appropriate connection groups was used (

Figure 13).

In order to check the effectiveness of the proposed unconventional PMSGFM with star–delta winding, a comparative analysis of the finite element method (FEM) was carried out. The torque constant and core losses were compared with a standard designed PMSG. The Ansys Maxwell environment was used, and in this, two FEM PMSG models were developed. The geometries of the magnetic circuits of both models were identical. The only difference was related to the design of the stator windings [

10]. The individual coils were placed in the same slots, and the numbers of turns in the star and delta coils were set to produce the same value of electromotive force between the lines. For comparison purposes, the simulation parameters, including mesh density, time step size, and Newton Raphson procedure tolerance, were retained during model testing [

10]. Due to the different numbers of turns in the star and delta winding coils, the slot current eq

i was determined. The value of this equivalent signal was referenced to the total

mmf in the slot generated by particular phase windings according to the equation below:

The results of the finite element analysis provide the conclusion that if a machine with star–delta winding is compared to a machine with a standard-designed magnetic circuit, there is practically no observable decrease in performance. Both of the machines present the same torque vs. current characteristics. Moreover, the calculated core losses are the same (

Figure 14).

The determined back

emf waveforms from line to line (

) for the star winding, and also the phase (

) for the delta winding, are presented in

Figure 15a, while the line-to-line signals of a model with a classic design are shown in

Figure 15b.

Since the core losses in the cases of both described generators (standard and with star–delta winding groups) were at the same level, it may seem that the proposed generator solution is not justified. However, it should be remembered that the efficiency of the entire system is also greatly influenced by the converters cooperating with the generator. Therefore, in the following part, a comparative analysis of the efficiency of the power electronic circuit is conducted. Two structures are considered, namely:

- -

The described structure based on diode rectifiers with a current modulator, which is dedicated to PMSGFM with star–delta windings;

- -

A fully controlled classical transistor rectifier, which is supplied by a standard PMSG generator.

For the evaluation of the loss in the power-electronic circuits of the elaborated systems, simulation models of these sections were built in the OrCAD environment [

10]. Models of IGBT IPMs were based on components produced by MITSUBISHI ELECTRIC. For calculations of power losses in the used modules, this company provides its own software, which is called Melcosim ver. 5.4.2.

In the first case, for the system based on current modulation, a replacement model of the generator was used. This structure consisted of the three-winding transformer with a secondary side winding connected in star and delta. The primary side was connected to a three-phase voltage source with an output signal that varied in the range of 80 ÷ 400 V. The output frequency varied in the range of 10 ÷ 50 Hz. The model of the proposed power electronics circiuit consists of the following blocks:

The diode rectifiers—this model is based on twothree-phase bridge diode rectifier modulesof type 26MT120 (25 A/1200 V), produced by VISHAY [

16];

The current modulator—the main utilized elements were the IGBT-based H-bridge, output inductive low-pass filter, and pulse transformer; the used model of the semiconductor device was based on the IPM/IGBT module type PM25CL1A120 (25 A/1200 V); the models of the coil and impulsive transformer were based on physical devices [

17]; the additional transistor rectifier was build in the same way as the current modulator.

Other basic parameters of this system were as follows:

- -

Nominal output values for generator: fGN = 50 Hz, UGoutN = 535 V, IGoutN = 10 A;

- -

Nominal output values for current modulator: LCM = 350 ÷ 450 μH (the coil inductance value depended on the value of the coil current), frequency of carrier signal: 10 kHz.

The schematic diagram of the power circuit of the elaborated system that was used during the tests is presented in

Figure 13.

In the second case, for the system without current modulation, the generator was replaced by a three-phase energetic transformer, which wasutilized in the star configuration. The active transistor rectifier also used PM25CL1A120. The rated output voltage was equal to 600 V and the rated current was 9 A. The schematic diagram of the power circuit of the used model is shown in

Figure 16.

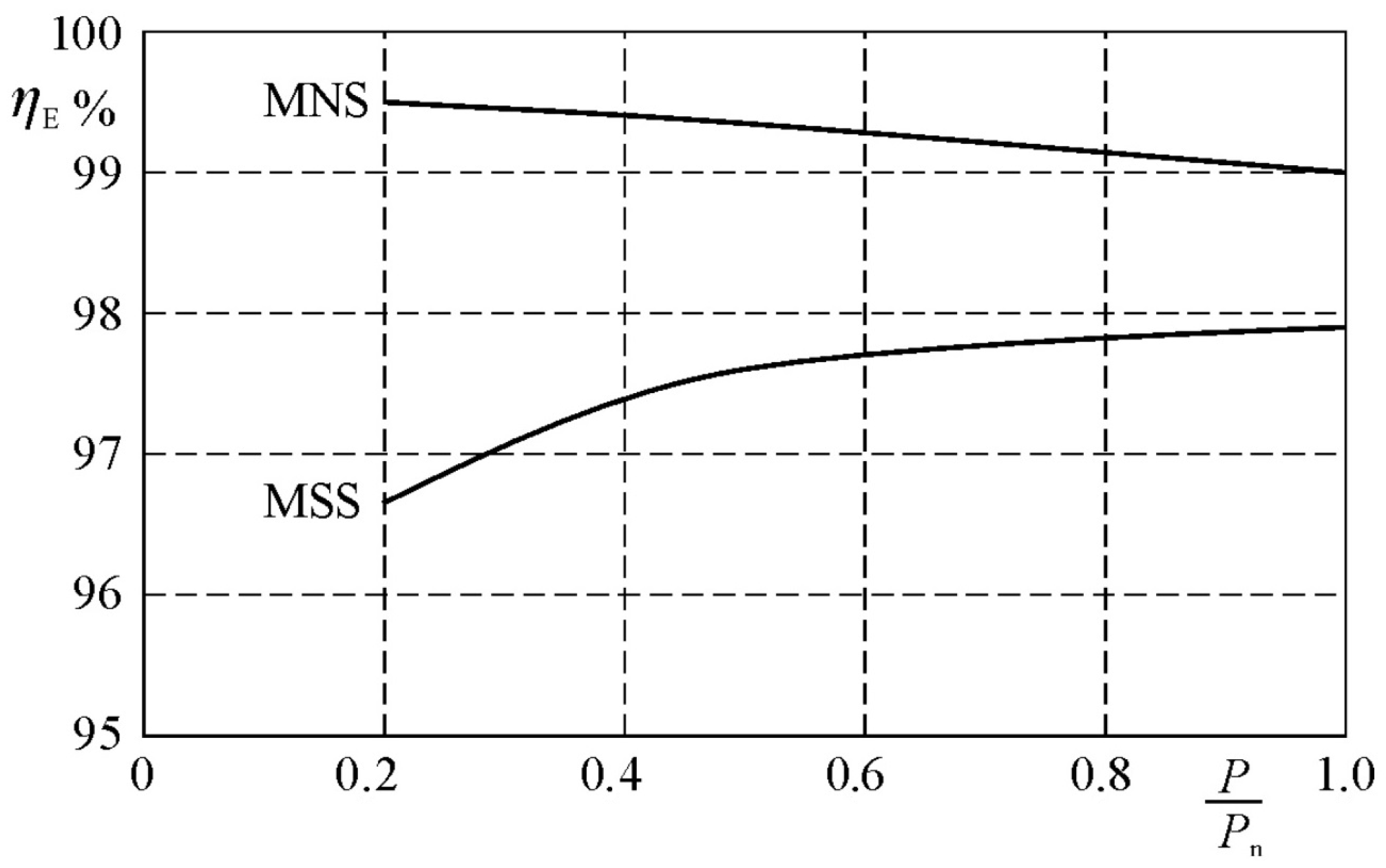

Figure 17 presents the curves of the simulation model efficiency (

ηE) for both the MSS (Model of the Standard System) and the MNS (Model of the Novelty System based on current modulation) vs. the relative output power of a power electronics system.

The efficiency of the elaborated system was higher than in the case of a classic model by 1.1 ÷ 2.9% depending on the output power.

During the works, the construction and preliminary tests of the power-electronic part of the described system were carried out (the generator with the star–delta winding group is currently under construction). The main circuits of the current modulator (CM) and the additional low-power transistor rectifier (LPTR) were built on the basis of two modules (PM50RSA120 from Mitsubishi) [

18]. Current- and voltage-measuring transducers were implemented using LA 55-P/SP1 and LV 25-P elements from LEM [

19,

20]. These converters are also equipped with an optoelectronic galvanic isolation system enabling the separation of the power circuits from the control part.

The control system of the power-electronic current modulator and the transistor rectifier was built with the help of the ALS-G3-1369 system. It is based on a floating-point signal processor of the SHARC 3 family—the ADSP-21369 generation from Analog Devices. As a result of using an efficient signal processor equipped with an extensive, 16-channel PWM generator module, it is possible to implement complex control algorithms for power-electronic converters [

21].

The analog-to-digital interface based on AD7656BST chips is responsible for processing analog signals [

22]. It is equipped with two 16-bit 6-channel analog-to-digital converters with simultaneous sampling. During the experimental tests, the impulse frequency (PWM frequency) was assumed to be 12 kHz and the signal sampling frequency to be 240 kHz.

In the source code, a control system based on unconventional structures of elaborated current regulators was implemented. For this purpose, digital filters with infinite impulse response (IIR) were used. This allowed to increase the gain of the regulators while maintaining a stable closed-loop system. In

Figure 18 are shown the output signals for both variants of the current regulator (with only a low-pass filter structure and with an additional high-pass filter), which were utilized in the control path of the current modulator. In this case, it works as a controlled power-electronics current source. As a reference signal, the square waveform was used.

The amplification k values were chosen in such a way as to enable the excitation of the system. The values of k for both variants of the regulator differed by 30%. Based on the obtained results, it was found that the oscillation frequency of the output signal was higher in the case of the implemented additional high-pass structure. This proves a wider usable frequency response and, consequently, the better dynamics of the entire system. As a consequence, the quality of mapping the reference signals for the current modulator and the low-power transistor rectifier was improved.

The elaborated-during-research algorithm for controlling the additional rectifier, which works in inverter mode, was also implemented. In this case, the structure of the current regulator was the same as in the case of the control path of the current modulator.

Figure 19 presents the output signals of diode rectifiers and the signal generated by the current modulator for the physical model. The resultant grid current for the selected phase is shown in

Figure 20. However, based on the earlier results, it can be concluded that this current corresponds to the resultant magnetomotive force (

mmf) of the synchronous generator PMSGFM associated with a given pair of windings with a star–delta connection group.

The voltage waveform on the primary side of the transformer coupling the transistor rectifier (LPTR) with the AC grid and the current generated by this subsystem are presented in

Figure 21.

It can be observed that these signals are shifted by 180 electrical degrees. This is due to the work of the transistor rectifier in the inverter mode. It is estimated that the use of this additional converter will increase the efficiency of the whole system by about 2%, which is not without significance at high power. The signal of the DC bus of the LPTR and CM is shown in

Figure 22.

The described experimental results confirm the correct functioning of the implemented control algorithm for the additional transistor rectifier. The stabilization of the voltage on the DC bus was ensured, with the return of energy to the AC grid. Visible pulsations in the DC bus (

Figure 22) resulted from the twelve-pulse nature of the diode rectifier, which was used in the main power circuit.