Electrification of Biorefinery Concepts for Improved Productivity—Yield, Economic and GHG Performances

Abstract

:1. Introduction

- Biomass typically exhibits a hydrogen-to-carbon atomic ratio ranging from 1 to 1.5, whereas hydrocarbon-based fuels typically possess a ratio 2. This discrepancy implies that carbon atoms are inevitably lost unless an alternative balancing method is employed, such as the addition of hydrogen.

- Biomass inherently contains a substantial amount of oxygen, which must be eliminated to varying degrees depending on the desired product. This elimination often occurs in the form of CO2 or H2O. The removal of oxygen as CO2 results in carbon losses, while its removal as water exacerbates the hydrogen-carbon imbalance mentioned in the previous point. In many conversion technologies, hydrogen is utilized, either directly or indirectly, to facilitate the removal of oxygen.

- Several conversion technologies, including gasification and steam reforming, operate at high temperatures, with energy supplied through the combustion of the biogenic feedstock itself or intermediary substances. This high-temperature operation can lead to energy losses.

- the feasibility of integrating electrification within diverse lignocellulosic biofuel value chains, assessing both their technical and commercial relevance in the present and in the short to medium term.

- the potential consequences of integrating electrification on production capabilities, carbon efficiency and resource utilization within various biofuel value chains.

- the possible effects of integrating electrification on production expenses and greenhouse gas performance across different biofuel value chains. Additionally, it aims to analyze which electrification strategies yield the greatest benefits, including improved resource efficiency.

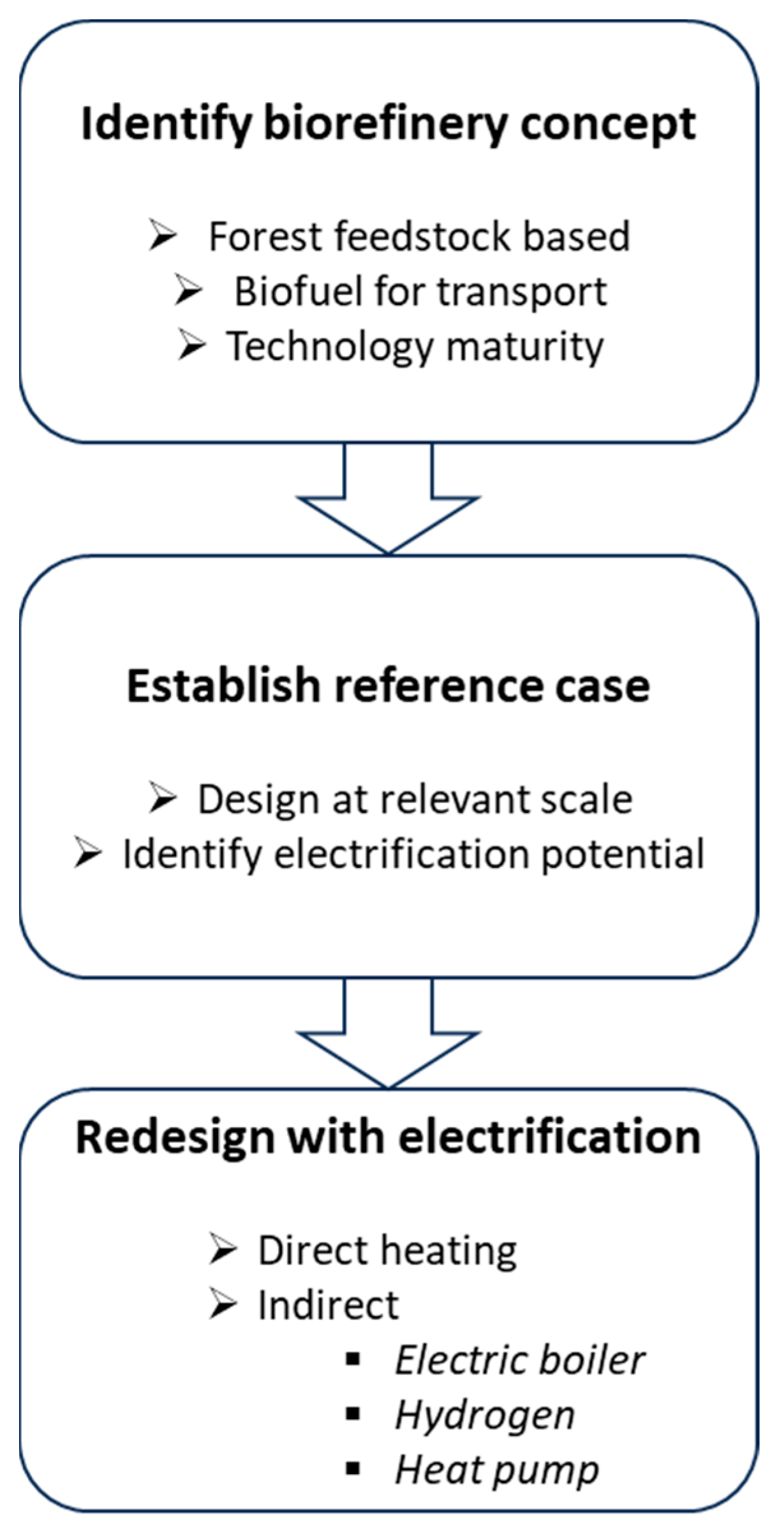

2. Material and Methods

- Feedstock is primarily lignocellulosic forest residue but also agricultural residue;

- Nordic region production potential and the corresponding suitable technologies;

- Biofuel as the primary product, primarily for road transport but also aviation fuel;

- Technologies considered should be available at the commercial level or have the potential to be commercially deployed at scale at the latest by 2030.

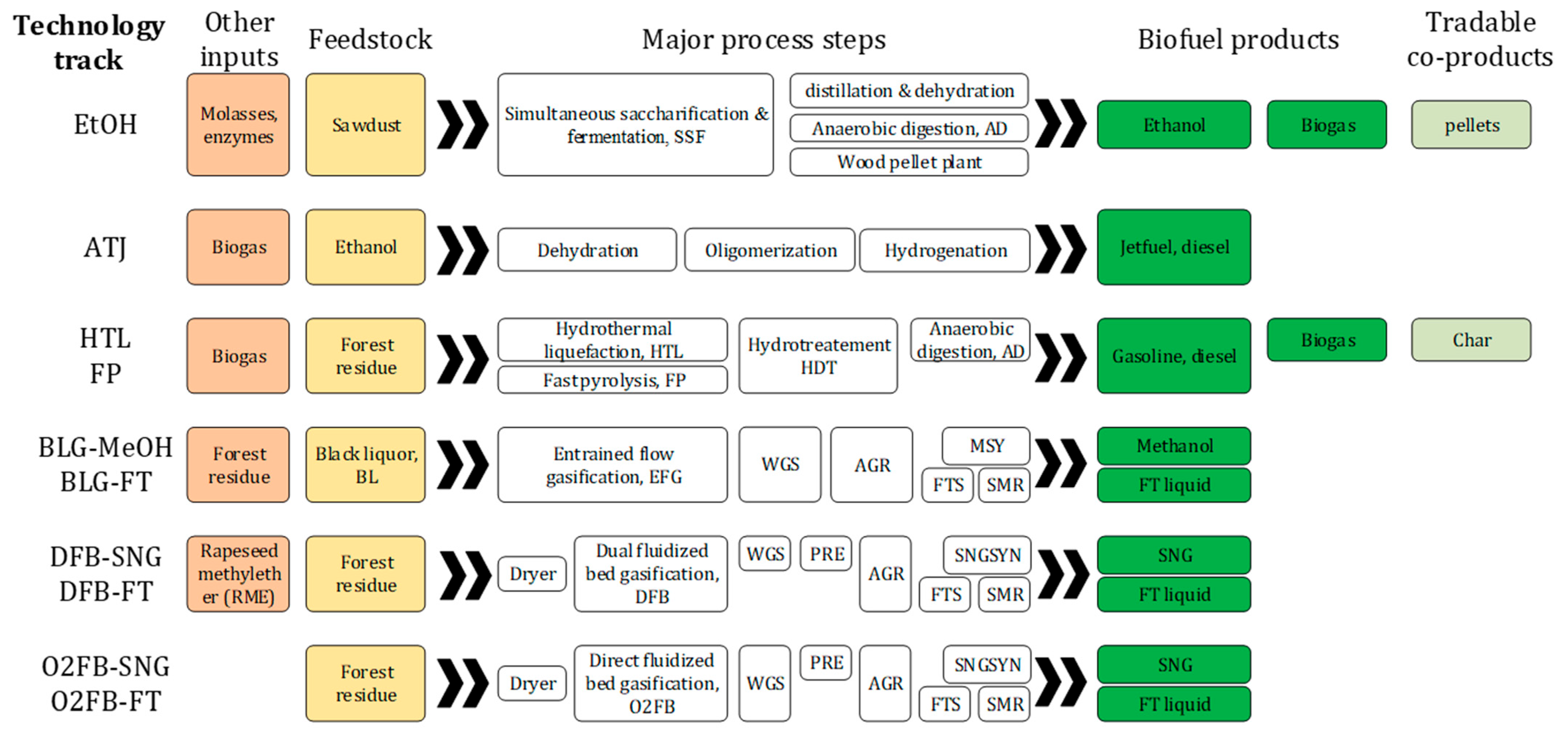

2.1. Biofuel Production Tracks

2.2. Electrification Options

2.3. Performance Evalaution Methodology

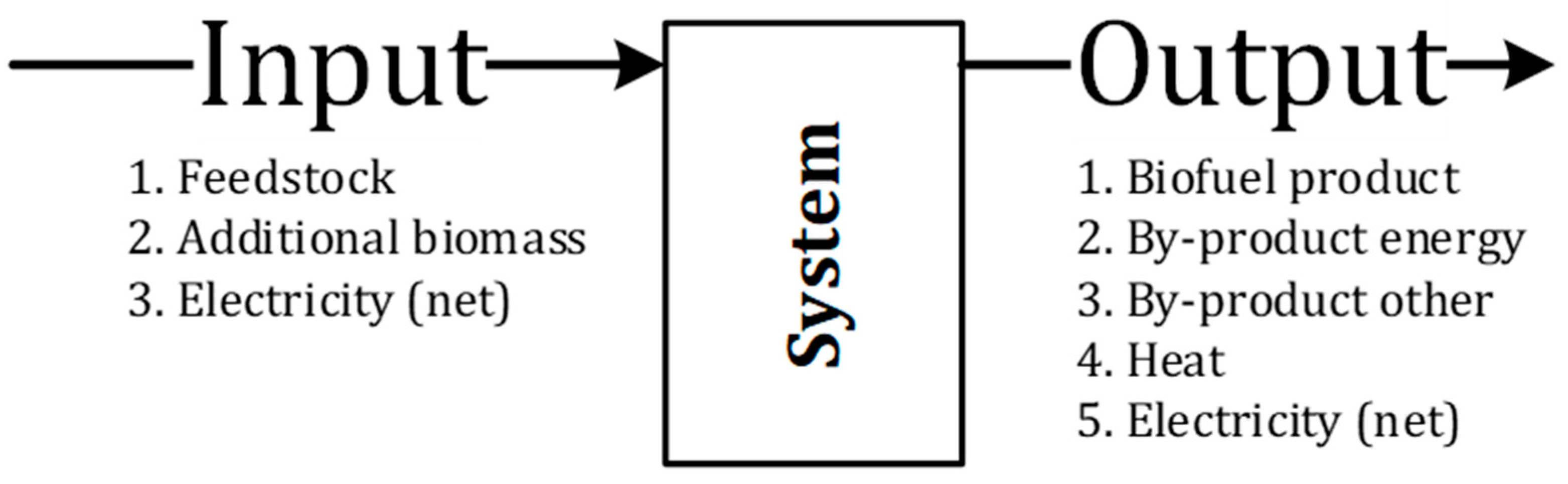

2.3.1. Process Performance

2.3.2. Economic Performance

2.3.3. Greenhouse Gas Performance

3. Results and Discussion

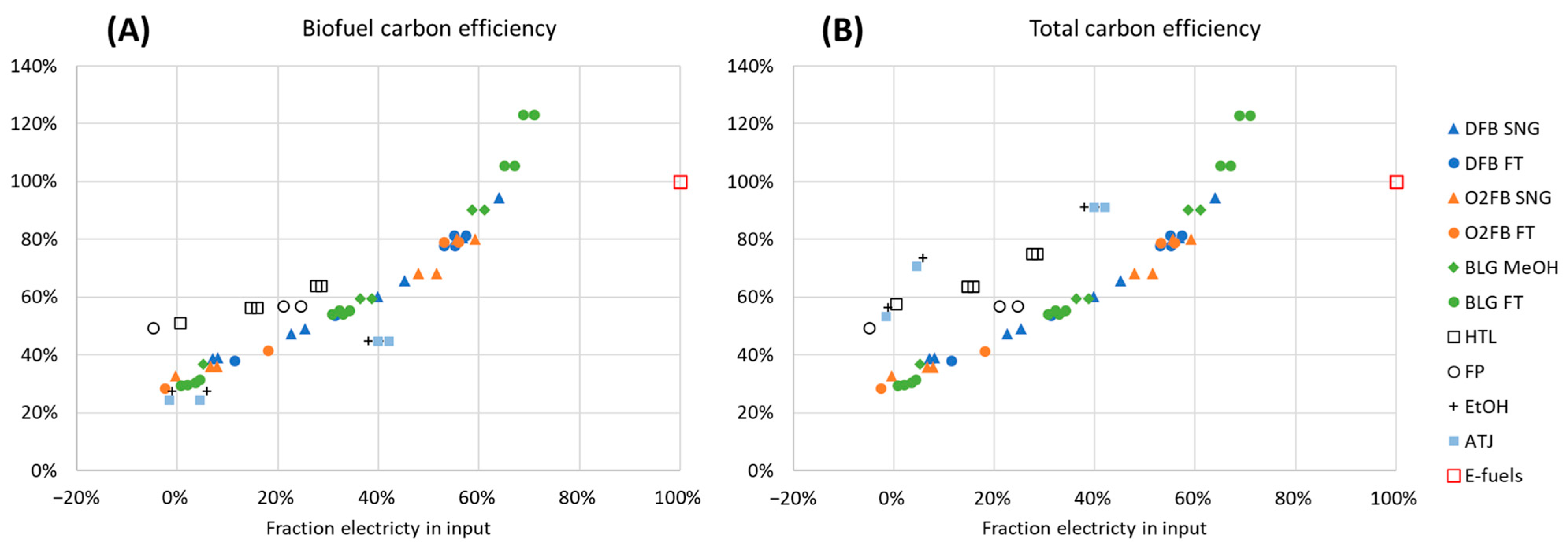

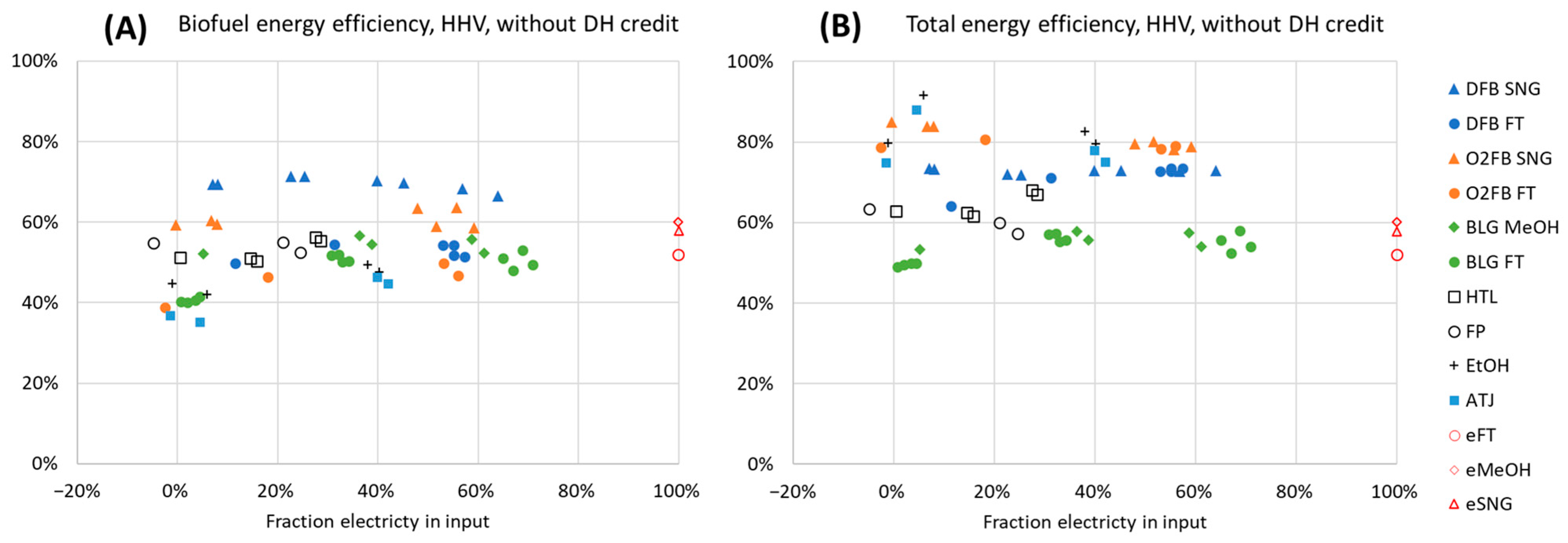

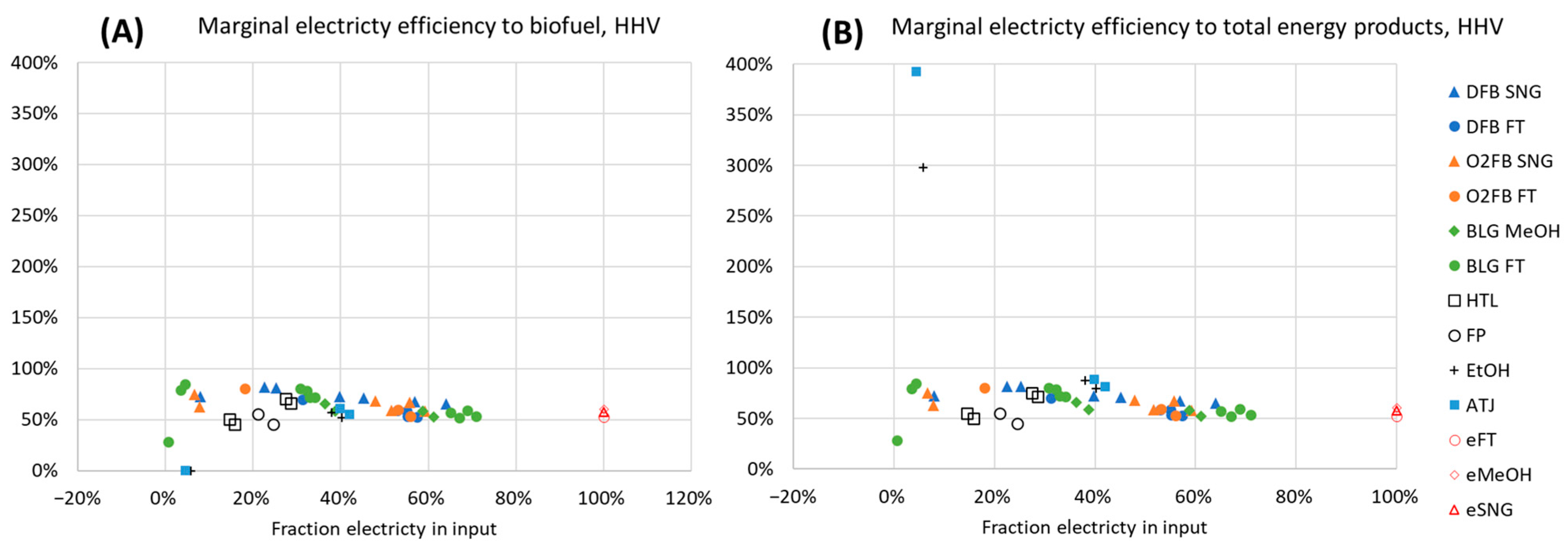

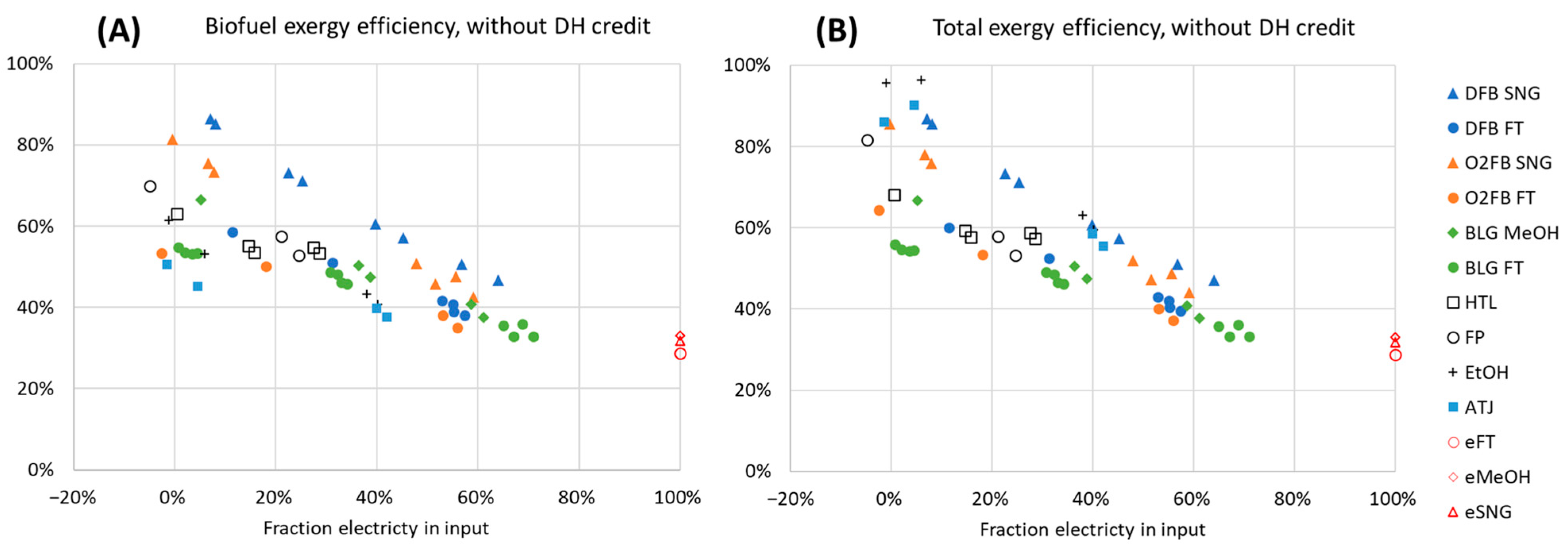

3.1. Process Performance

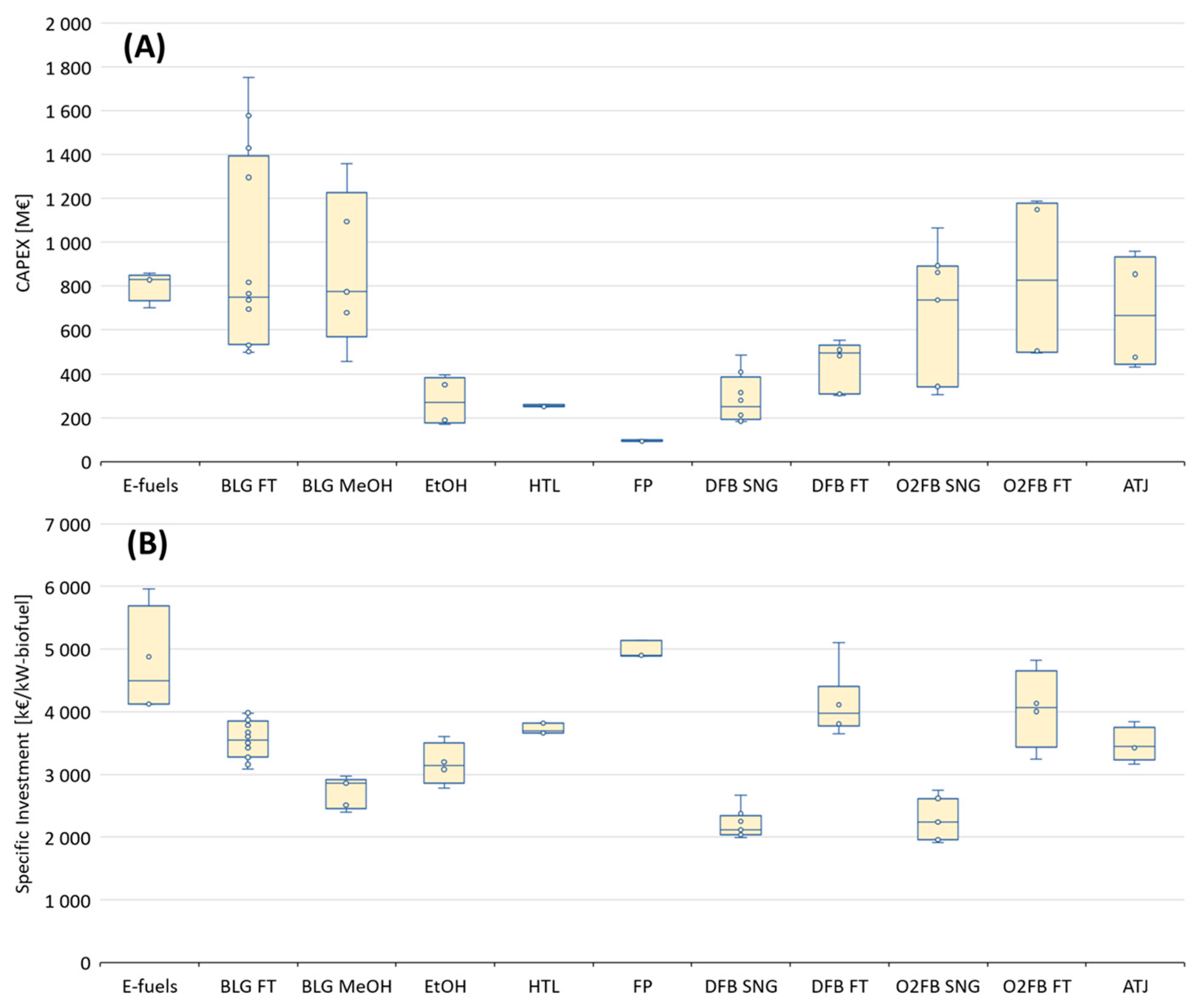

3.2. Economic Performance

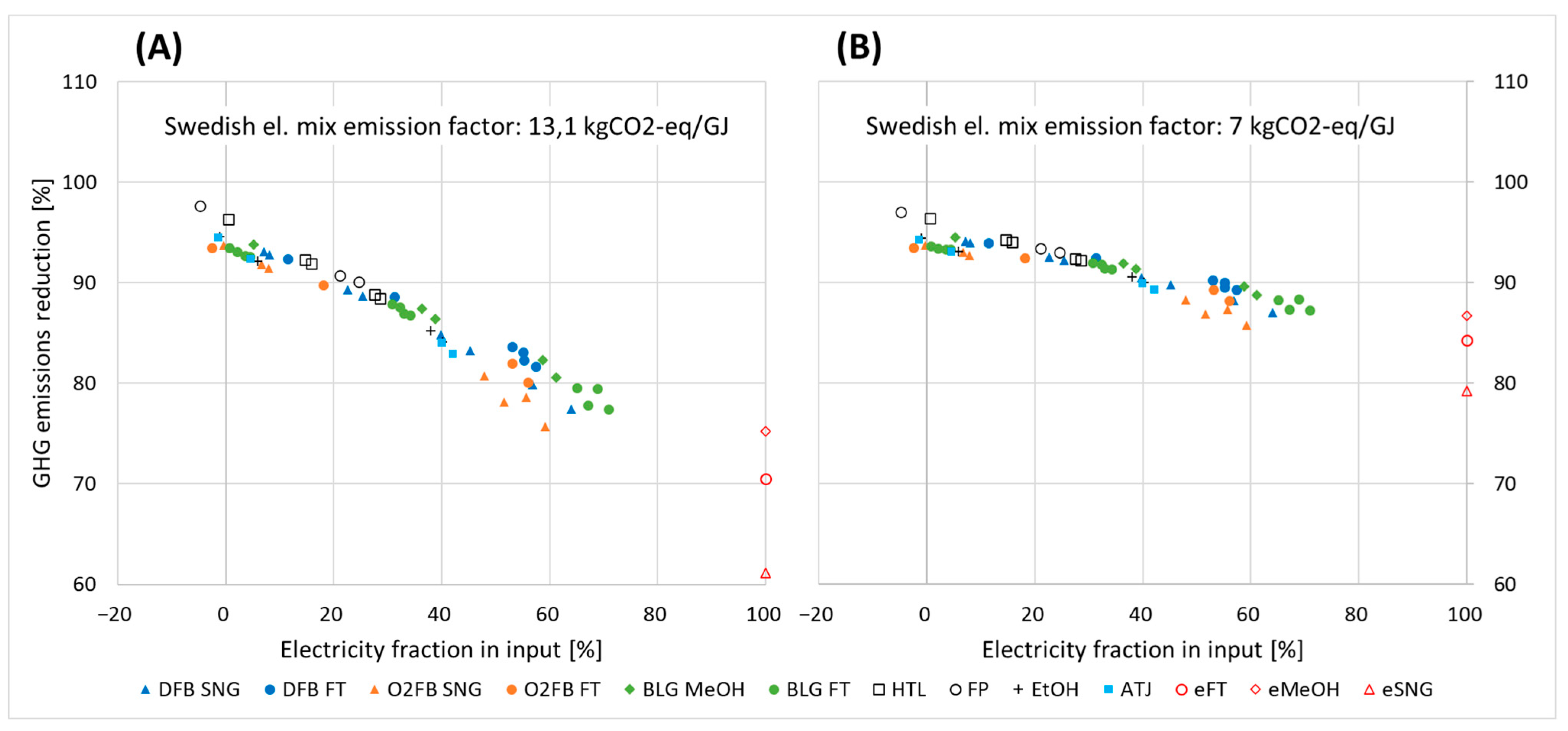

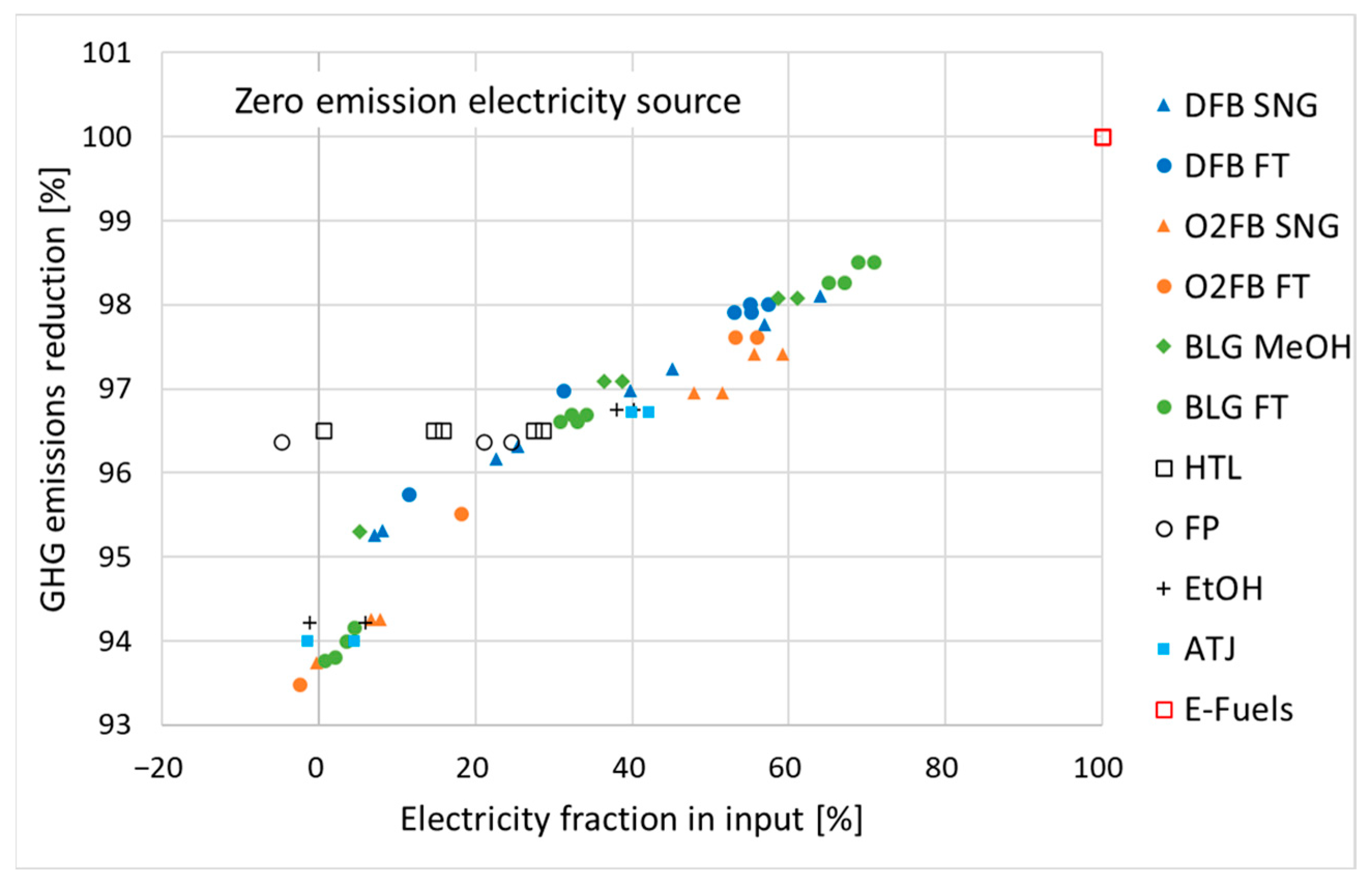

3.3. Greenhouse Gas Performance

4. Conclusions

- Improved biorefinery performance: These concepts utilize electrical energy to enhance the performance of biorefineries, resulting in increased biofuel yield and carbon efficiency.

- Efficient use of forest feedstock: by maximizing the utilization of limited forest feedstock, these concepts contribute to the efficient transition of sectors like transportation and chemicals toward sustainable practices.

- Resource efficiency: bio-electrofuel tracks offer resource-efficient options, ensuring maximum utilization of biogenic carbon.

- Key electrification technologies: electrification technologies such as electrolysis, high-temperature direct electric heating and MVR heat pumps are identified as crucial for achieving performance improvements.

- High carbon conversion in gasification tracks: gasification tracks, especially when electrified with technologies like electrolysis-based H2 addition, rWGS and eSMR, achieve carbon conversion efficiencies nearing 100%. Crediting excess heat to replace biomass use further increases efficiency.

- Increased transportation fuel production: many gasification tracks can double or even triple the production of transportation fuels from the same amount of feedstock.

- Improved carbon efficiency in liquefaction tracks: electrified configurations in liquefaction tracks result in significantly improved carbon efficiency, particularly for EtOH/ATJ, HTL and FP.

- Marginal energy performance gains: overall energy performance shows marginal improvements with increased electrification in most tracks, with minor percentage point gains.

- Economic viability: the production cost (PC) of gasification-based bio-electrofuels is in a competitive range, making it an economically viable option. Indirect electrification can enhance overall economic performance, especially when there is high fuel demand.

- High GHG reduction performance: The investigated plant designs generally achieve high greenhouse gas (GHG) reduction performance across all options. Electricity consumption is a significant driver of GHG emissions, but most tracks achieve substantial GHG emissions savings, with the most electrified options surpassing 97%.

- Carbon footprint sensitivity: The performance of bio-electrofuel configurations may outperform pure biofuel tracks, especially when considering the carbon footprint of the electricity source and the feedstock supply chain.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Hansson, J.; Hagberg, M.; Hennlock, M.; Karlsson, K.B.; Salvucci, R.; Andersson, M.; Sarasini, S.; Piriya Uteng, T.; Wråke, M. Sustainable Horizons in Future Transport—With a Nordic Focus Project Summary 2015–2019; Nordic Energy Research: Oslo, Norway, 2019. [Google Scholar]

- Alamia, A.; Larsson, A.; Breitholtz, C.; Thunman, H. Performance of Large-Scale Biomass Gasifiers in a Biorefinery, a State-of-the-Art Reference. Int. J. Energy Res. 2017, 41, 2001–2019. [Google Scholar] [CrossRef]

- Jafri, Y.; Furusjö, E.; Kirtania, K.; Gebart, R. Performance of a Pilot-Scale Entrained-Flow Black Liquor Gasifier. Energy Fuels 2016, 30, 3175–3185. [Google Scholar] [CrossRef]

- Pettersson, K.; Harvey, S. CO2 Emission Balances for Different Black Liquor Gasification Biorefinery Concepts for Production of Electricity or Second-Generation Liquid Biofuels. Energy 2010, 35, 1101–1106. [Google Scholar] [CrossRef]

- Motta, I.L.; Miranda, N.T.; Maciel Filho, R.; Wolf Maciel, M.R. Biomass Gasification in Fluidized Beds: A Review of Biomass Moisture Content and Operating Pressure Effects. Renew. Sustain. Energy Rev. 2018, 94, 998–1023. [Google Scholar] [CrossRef]

- Frankó, B.; Galbe, M.; Wallberg, O. Bioethanol Production from Forestry Residues: A Comparative Techno-Economic Analysis. Appl. Energy 2016, 184, 727–736. [Google Scholar] [CrossRef]

- Frankó, B.; Galbe, M.; Wallberg, O. Influence of Bark on Fuel Ethanol Production from Steam-Pretreated Spruce. Biotechnol. Biofuels 2015, 8, 15. [Google Scholar] [CrossRef]

- Sassner, P.; Galbe, M.; Zacchi, G. Techno-Economic Evaluation of Bioethanol Production from Three Different Lignocellulosic Materials. Biomass Bioenergy 2008, 32, 422–430. [Google Scholar] [CrossRef]

- Jafri, Y.; Ahlström, J.M.; Furusjö, E.; Harvey, S.; Pettersson, K.; Svensson, E.; Wetterlund, E. Double Yields and Negative Emissions? Resource, Climate and Cost Efficiencies in Biofuels with Carbon Capture, Storage and Utilization. Front. Energy Res. 2021, 10, 797529. [Google Scholar] [CrossRef]

- Tews, I.J.; Zhu, Y.; Drennan, C.; Elliott, D.C.; Snowden-Swan, L.J.; Onarheim, K.; Solantausta, Y.; Beckman, D. Biomass Direct Liquefaction Options. TechnoEconomic and Life Cycle Assessment; Pacific Northwest National Lab.: Richland, WA, USA, 2014. [Google Scholar] [CrossRef]

- Funkenbusch, L.T.; Mullins, M.E.; Vamling, L.; Belkhieri, T. Technoeconomic Assessment of Hydrothermal Liquefaction Oil from Lignin with Catalytic Upgrading for Renewable Fuel and Chemical Production. WIREs Energy Environ. 2019, 8, e319. [Google Scholar] [CrossRef]

- Carrasco, J.L.; Gunukula, S.; Boateng, A.A.; Mullen, C.A.; Desisto, W.J.; Wheeler, M.C. Pyrolysis of Forest Residues: An Approach to Techno-Economics for Bio-Fuel Production q. Fuel 2017, 193, 477–484. [Google Scholar] [CrossRef]

- Hannula, I. Hydrogen Enhancement Potential of Synthetic Biofuels Manufacture in the European Context: A Techno-Economic Assessment. Energy 2016, 104, 199–212. [Google Scholar] [CrossRef]

- Karl, J.; Pröll, T. Steam Gasification of Biomass in Dual Fluidized Bed Gasifiers: A Review. Renew. Sustain. Energy Rev. 2018, 98, 64–78. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; van den Oever, A.E.M.; Grosso, M. A Review on Biofuels for Light-Duty Vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C.; Pinto, P.C.R. Gasification-Based Biorefinery Integration in the Pulp and Paper Industry: A Critical Review. Renew. Sustain. Energy Rev. 2020, 133, 110210. [Google Scholar] [CrossRef]

- Dossow, M.; Dieterich, V.; Hanel, A.; Spliethoff, H.; Fendt, S. Improving Carbon Efficiency for an Advanced Biomass-to-Liquid Process Using Hydrogen and Oxygen from Electrolysis. Renew. Sustain. Energy Rev. 2021, 152, 111670. [Google Scholar] [CrossRef]

- Mesfun, S.; Engvall, K.; Toffolo, A. Electrolysis Assisted Biomass Gasification for Liquid Fuels Production. Front. Energy Res. 2022, 10, 799553. [Google Scholar] [CrossRef]

- Onarheim, K.; Hannula, I.; Solantausta, Y. Hydrogen Enhanced Biofuels for Transport via Fast Pyrolysis of Biomass: A Conceptual Assessment. Energy 2020, 199, 117337. [Google Scholar] [CrossRef]

- Hillestad, M.; Ostadi, M.; Alamo Serrano, G.D.; Rytter, E.; Austbø, B.; Pharoah, J.G.; Burheim, O.S. Improving Carbon Efficiency and Profitability of the Biomass to Liquid Process with Hydrogen from Renewable Power. Fuel 2018, 234, 1431–1451. [Google Scholar] [CrossRef]

- Albrecht, F.G.; Nguyen, T. Van Prospects of Electrofuels to Defossilize Transportation in Denmark—A Techno-Economic and Ecological Analysis. Energy 2020, 192, 116511. [Google Scholar] [CrossRef]

- Brynolf, S.; Taljegard, M.; Grahn, M.; Hansson, J. Electrofuels for the Transport Sector: A Review of Production Costs. Renew. Sustain. Energy Rev. 2018, 81, 1887–1905. [Google Scholar] [CrossRef]

- Poluzzi, A.; Guandalini, G.; Guffanti, S.; Martinelli, M.; Moioli, S.; Huttenhuis, P.; Rexwinkel, G.; Palonen, J.; Martelli, E.; Groppi, G.; et al. Flexible Power and Biomass-To-Methanol Plants With Different Gasification Technologies. Front. Energy Res. 2022, 9, 795673. [Google Scholar] [CrossRef]

- Habermeyer, F.; Kurkela, E.; Maier, S.; Dietrich, R.U. Techno-Economic Analysis of a Flexible Process Concept for the Production of Transport Fuels and Heat from Biomass and Renewable Electricity. Front. Energy Res. 2021, 9, 723774. [Google Scholar] [CrossRef]

- Wismann, S.T.; Engbæk, J.S.; Vendelbo, S.B.; Bendixen, F.B.; Eriksen, W.L.; Aasberg-Petersen, K.; Frandsen, C.; Chorkendorff, I.; Mortensen, P.M. Electrified Methane Reforming: A Compact Approach to Greener Industrial Hydrogen Production. Science 2019, 364, 756–759. [Google Scholar] [CrossRef] [PubMed]

- Fornell, R. Process Integration Studies on Kraft Pulp-Mill-Based Biorefineries Producing Ethanol. Ph.D. Thesis, Chalmers University of Technology, Heat and Power Technology, Department of Energy and Environment, Gothenburg, Sweden, 2012. [Google Scholar]

- Geleynse, S.; Brandt, K.; Garcia-Perez, M.; Wolcott, M.; Zhang, X. The Alcohol-to-Jet Conversion Pathway for Drop-In Biofuels: Techno-Economic Evaluation. ChemSusChem 2018, 11, 3728–3741. [Google Scholar] [CrossRef]

- van Dyk, S.; Saddler, J. Progress in the Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies, Potential and Challenges; IEA Bioenergy: Paris, France, 2021; ISBN 9781910154878. [Google Scholar]

- Naqvi, M.; Yan, J.; Dahlquist, E. Black Liquor Gasification Integrated in Pulp and Paper Mills: A Critical Review. Bioresour. Technol. 2010, 101, 8001–8015. [Google Scholar] [CrossRef]

- Carvalho, L.; Lundgren, J.; Wetterlund, E.; Wolf, J.; Furusjö, E. Methanol Production via Black Liquor Co-Gasification with Expanded Raw Material Base—Techno-Economic Assessment. Appl. Energy 2018, 225, 570–584. [Google Scholar] [CrossRef]

- Berglin, N.; Lovell, A.; Delin, L.; Törmälä, J. The 2010 Reference Mill for Kraft Market Pulp. In Proceedings of the Tappi PEERS Conference, Portland, OR, USA, 2–5 October 2011; pp. 191–197. [Google Scholar]

- Stora Källor för Biogen CO2 Lista. Available online: https://bioenergitidningen.se/app/uploads/sites/2/2019/04/Stora-kallor-för-biogen-CO2-lista.pdf (accessed on 21 February 2022).

- Brandberg, A.; Hjortsberg, H.; Sävbark, B.; Ekbom, T.; Hjerpe, C.J.; Landälv, I. BioMeeT. Planning of Biomass-Based Methanol Energy Combine—Trollhättan Region; Nykomb Synergetics AB: Stockholm, Sweden, 2000. [Google Scholar]

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future Cost and Performance of Water Electrolysis: An Expert Elicitation Study. Int. J. Hydrogen Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

- Energymyndigheten Wood Fuel and Peat Prices. Available online: https://pxexternal.energimyndigheten.se/pxweb/sv/Trädbränsle-ochtorvpriser/?rxid=79e3c147-398b-4bb3-9b08-517ec64c39d1 (accessed on 23 August 2022).

- Svenska Kraftnät. Långsiktig Marknadsanalys; Svenska Kraftnät: Stockholm, Sweden, 2021. [Google Scholar]

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic Assessment of Advanced Biofuel Production via Gasification Using Cost Data from the GoBiGas Plant. Energy Sci. Eng. 2019, 7, 217–229. [Google Scholar] [CrossRef]

- de la Fuente, T.; González-García, S.; Athanassiadis, D.; Nordfjell, T. Fuel Consumption and GHG Emissions of Forest Biomass Supply Chains in Northern Sweden: A Comparison Analysis between Integrated and Conventional Supply Chains. Scand. J. For. Res. 2017, 32, 568–581. [Google Scholar] [CrossRef]

- Jafri, Y.; Wetterlund, E.; Mesfun, S.; Rådberg, H.; Mossberg, J.; Hulteberg, C.; Furusjö, E. Combining Expansion in Pulp Capacity with Production of Sustainable Biofuels—Techno-Economic and Greenhouse Gas Emissions Assessment of Drop-in Fuels from Black Liquor Part-Streams. Appl. Energy 2020, 279, 115879. [Google Scholar] [CrossRef]

- Brown, A.; Waldheim, L.; Landälv, I.; Saddler, J.; Ebadian, M.; McMillan James, D.; Bonomi, A.; Klein, B. Advanced Biofuels—Potential for Cost Reduction, IEA Bioenergy: Task 41: 2020:01; IEA Bioenergy: Paris, France, 2020. [Google Scholar]

- Fuel Cell Technology—Elcogen. Available online: https://elcogen.com/ (accessed on 22 August 2022).

- HIAT-Hydrogen and Informatics Institute of Applied Technolgies. Available online: https://www.hiat.de/ (accessed on 22 August 2022).

- Klop, E. Steaming Ahead with MVR. Available online: https://blueterra.nl/wp-content/uploads/2018/03/Steaming-ahead-with-MVR-COSPP.pdf (accessed on 22 August 2022).

- Liang, Z.; Rongwong, W.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.; et al. Recent Progress and New Developments in Post-Combustion Carbon-Capture Technology with Amine Based Solvents. Int. J. Greenh. Gas Control. 2015, 40, 26–54. [Google Scholar] [CrossRef]

- Xie, N.; Chen, B.; Tan, C.; Liu, Z. Energy Consumption and Exergy Analysis of MEA-Based and Hydrate-Based CO2 Separation. Ind. Eng. Chem. Res. 2017, 56, 15094–15101. [Google Scholar] [CrossRef]

- Baltrusaitis, J.; Luyben, W.L. Methane Conversion to Syngas for Gas-to-Liquids (GTL): Is Sustainable CO2 Reuse via Dry Methane Reforming (DMR) Cost Competitive with SMR and ATR Processes? ACS Sustain. Chem. Eng. 2015, 3, 2100–2111. [Google Scholar] [CrossRef]

- Arvidsson, M.; Morandin, M.; Harvey, S. Biomass Gasi Fi Cation-Based Syngas Production for a Conventional Oxo Synthesis Plant—Process Modeling, Integration Opportunities, and Thermodynamic Performance. Energy Fuels 2014, 28, 4075–4087. [Google Scholar] [CrossRef]

- Glenk, G.; Reichelstein, S. Economics of Converting Renewable Power to Hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- Marsidi, M. Industrial Mechanical Vapour Recompression (MVR). Available online: https://energy.nl/wp-content/uploads/industrial-mechanical-vapour-recompression-1-7.pdf (accessed on 30 October 2023).

- Liu, G.; Larson, E.D.; Williams, R.H.; Kreutz, T.G.; Guo, X. Making Fischer-Tropsch Fuels and Electricity from Coal and Biomass: Performance and Cost Analysis. Energy Fuels 2011, 25, 415–437. [Google Scholar] [CrossRef]

| Technology Tracks | Acronym |

|---|---|

| Lignocellulosic ethanol | EtOH |

| Alcohol to jet (lignocellulosic ethanol including ethanol to jet) | ATJ |

| Hydrothermal liquefaction and upgrading | HTL |

| Fast pyrolysis and upgrading | FP |

| Black liquor gasification and upgrading to methanol | BLG-MeOH |

| Black liquor gasification and upgrading to Fischer–Tropsch (FT) liquid | BLG-FT |

| Dual fluidized bed gasification and upgrading to Synthetic Natural Gas (SNG) | DFB-SNG |

| Dual fluidized bed gasification and upgrading to FT liquid | DFB-FT |

| Direct fluidized bed gasification and upgrading to SNG | O2FB-SNG |

| Direct fluidized bed gasification and upgrading to FT liquid | O2FB-FT |

| Technology Track | Pathway Acronym | Description with Emphasis on Configuration Changes Introduced to Enable Electrification | Reference Technologies | Technologies for Enabling Electrification | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CHP | SMR | WGS | SOEC | PEM | rWGS | eSMR | MVR | eRea | |||

| EtOH | EtOH_ref | Self-sufficient in heat and electricity, distillation and pellet drying steam satisfied from CHP system that combusts fermentation stillage and part of lignin, excess lignin utilized for pellet production, organic derivatives utilized for biogas production via anaerobic digestion | X | ||||||||

| EtOH_1 | distillation and pellet drying heat requirements satisfied with MVR heat pump | X | X | ||||||||

| EtOH_2 | distillation and pellet drying heat requirements satisfied with MVR heat pump, fermentation CO2 utilized for biogas synthesis using H2 from SOEC electrolysis | X | X | X | X | ||||||

| EtOH_3 | distillation and pellet drying heat requirements satisfied with MVR heat pump, fermentation CO2 utilized for biogas synthesis using H2 from PEM electrolysis | X | X | X | X | ||||||

| ATJ | ATJ_ref | EtOH_ref, Dehydration and Oligomerization heat supplied from biogas, H2 for upgrading from biogas reforming | X | ||||||||

| ATJ_1 | EtOH_1, Dehydration and Oligomerization heat supplied from biogas, H2 for upgrading from biogas reforming | X | |||||||||

| ATJ_2 | EtOH_2, Dehydration and Oligomerization heat supplied from electricity, H2 for upgrading from SOEC electrolysis | X | X | ||||||||

| ATJ_3 | EtOH_3, Dehydration and Oligomerization heat supplied from electricity, H2 for upgrading from PEM electrolysis | X | X | ||||||||

| HTL | HTL_ref | HTL at 300 °C and 200 bar converts feedstock to bio-oil, char, aqueous and non-condensable gas (NCG) phases, bio-oil upgrades to biofuel using H2 sourced from external biogas (through SMR), char exported as solid fuel, NCG phase utilized for H2 production | X | ||||||||

| HTL_1 | H2 for upgrading sourced from SOEC electrolysis | X | |||||||||

| HTL_2 | H2 for upgrading sourced from PEM electrolysis | X | |||||||||

| HTL_3 | H2 for upgrading sourced from SOEC electrolysis, HTL heat delivered from electricity | X | X | ||||||||

| HTL_4 | H2 for upgrading sourced from PEM electrolysis, HTL heat delivered from electricity | X | X | ||||||||

| FP | FP_ref | FP at 520 °C and 1 bar converts feedstock to pyrolysis oil, char and NCG phases, pyrolysis oil upgrades to biofuel using H2 sourced from imported biogas reforming, char combusted to preheat sand for pyrolysis reaction and generate HP steam for electricity production, NCG phase utilized for H2 production | X | X | |||||||

| FP_1 | H2 for upgrading sourced from SOEC electrolysis | X | X | ||||||||

| FP_2 | H2 for upgrading sourced from PEM electrolysis | X | X | ||||||||

| BLG-MeOH | BLG-MeOH_ref | BLG, WGS, AGR, MYS, methanol upgrading | X | ||||||||

| BLG-MeOH_1 | BLG, H2 addition from SOEC electrolysis, AGR, MYS, methanol upgrading | X | |||||||||

| BLG-MeOH_2 | BLG, H2 addition from PEM electrolysis, AGR, MYS, methanol upgrading | X | |||||||||

| BLG-MeOH_3 | BLG, H2 addition from SOEC electrolysis, rWGS, MYS, methanol upgrading | X | X | ||||||||

| BLG-MeOH_4 | BLG, H2 addition from PEM electrolysis, rWGS, MYS, methanol upgrading | X | X | ||||||||

| BLG-FT | BLG-FT_ref | BLG, WGS, AGR, FTS, FT upgrading, SMR, IP steam self sufficient | X | X | |||||||

| BLG-FT_1 | BLG, WGS, AGR, FTS, FT upgrading, SMR | X | X | ||||||||

| BLG-FT_2 | BLG, H2 addition from SOEC, AGR, FTS, FT upgrading, SMR | X | X | ||||||||

| BLG-FT_3 | BLG, H2 addition from PEM, AGR, FTS, FT upgrading, SMR | X | X | ||||||||

| BLG-FT_4 | BLG, H2 addition from SOEC, rWGS, FTS, FT upgrading, SMR | X | X | X | |||||||

| BLG-FT_5 | BLG, H2 addition from PEM, rWGS, FTS, FT upgrading, SMR | X | X | X | |||||||

| BLG-FT_6 | BLG, WGS, AGR, FTS, FT upgrading, eSMR, IP steam self sufficient | X | X | ||||||||

| BLG-FT_7 | BLG, WGS, AGR, FTS, FT upgrading, eSMR | X | X | ||||||||

| BLG-FT_8 | BLG, H2 addition from SOEC, AGR, FTS, FT upgrading, eSMR | X | X | ||||||||

| BLG-FT_9 | BLG, H2 addition from PEM, AGR, FTS, FT upgrading, eSMR | X | X | ||||||||

| BLG-FT_10 | BLG, H2 addition from SOEC, AGR, FTS, FT upgrading, eSMR/rWGS | X | X | X | |||||||

| BLG-FT_11 | BLG, H2 addition from PEM, AGR, FTS, FT upgrading, eSMR/rWGS | X | X | X | |||||||

| DFB-SNG | DFB-SNG_ref | DFBG, WGS, Premethanation, AGR, SNGSYN, SNG upgrading | X | X | |||||||

| DFB-SNG_1 | DFBG assisted with electric preheating of gasification media, WGS, Premethanation, AGR, SNGSYN, SNG upgrading | X | X | X | |||||||

| DFB-SNG_2 | DFBG, Premethanation, H2 addition from SOEC after premethanation, AGR, SNGSYN, SNG upgrading | X | X | ||||||||

| DFB-SNG_3 | DFBG, Premethanation, H2 addition from PEM after premethanation, AGR, SNGSYN, SNG upgrading | X | X | ||||||||

| DFB-SNG_4 | DFBG, H2 addition from SOEC before premethanation, Premethanation, AGR, SNGSYN, SNG upgrading | X | X | ||||||||

| DFB-SNG_5 | DFBG, H2 addition from PEM before premethanation, Premethanation, AGR, SNGSYN, SNG upgrading | X | X | ||||||||

| DFB-SNG_6 | DFBG, Premethanation, H2 addition from SOEC after premethanation, rWGS, AGR, SNGSYN, SNG upgrading | X | X | X | |||||||

| DFB-SNG_7 | DFBG, Premethanation, H2 addition from PEM after premethanation, rWGS, AGR, SNGSYN, SNG upgrading | X | X | X | |||||||

| DFB-FT | DFB-FT_ref | DFBG, WGS, SMR, AGR, FTS, FT upgrading | X | X | X | ||||||

| DFB-FT_1 | DFBG, WGS, eSMR, AGR, FTS, FT upgrading | X | X | X | |||||||

| DFB-FT_2 | DFBG, H2 addition from SOEC, eSMR, AGR, FTS, FT upgrading | X | X | X | |||||||

| DFB-FT_3 | DFBG, H2 addition from PEM, eSMR, AGR, FTS, FT upgrading | X | X | X | |||||||

| DFB-FT_4 | DFBG, H2 addition from SOEC, eSMR/rWGS, AGR, FTS, FT upgrading | X | X | X | X | ||||||

| DFB-FT_5 | DFBG, H2 addition from PEM, eSMR/rWGS, AGR, FTS, FT upgrading | X | X | X | X | ||||||

| O2FB-SNG | O2FB-SNG_ref | O2FBG, WGS, Premethanation, AGR, SNGSYN, SNG upgrading | X | ||||||||

| O2FB-SNG_1 | O2FBG, Premethanation, H2 addition from SOEC after premethanation, AGR, SNGSYN, SNG upgrading | X | |||||||||

| O2FB-SNG_2 | O2FBG, Premethanation, H2 addition from PEM after premethanation, AGR, SNGSYN, SNG upgrading | X | |||||||||

| O2FB-SNG_3 | O2FBG, H2 addition from SOEC before premethanation, Premethanation, AGR, SNGSYN, SNG upgrading | X | |||||||||

| O2FB-SNG_4 | O2FBG, H2 addition from PEM before premethanation, Premethanation, AGR, SNGSYN, SNG upgrading | X | |||||||||

| O2FB-SNG_5 | O2FBG, H2 addition from SOEC before premethanation, Premethanation, rWGS, AGR, SNGSYN, SNG upgrading | X | X | ||||||||

| O2FB-SNG_6 | O2FBG, H2 addition from PEM before premethanation, Premethanation, rWGS, AGR, SNGSYN, SNG upgrading | X | X | ||||||||

| O2FB-FT | O2FB-FT_ref | O2FBG, WGS, SMR, AGR, FTS, FT upgrading | X | X | |||||||

| O2FB-FT_1 | O2FBG, WGS, eSMR, AGR, FTS, FT upgrading | X | X | ||||||||

| O2FB-FT_2 | O2FBG, H2 addition from SOEC, eSMR/rWGS, AGR, FTS, FT upgrading | X | X | X | |||||||

| O2FB-FT_3 | O2FBG, H2 addition from PEM, eSMR/rWGS, AGR, FTS, FT upgrading | X | X | X | |||||||

| Parameter | Unit | Value | Remarks | Ref. |

|---|---|---|---|---|

| Feedstock | EUR/MWh | 17.25 | Average market price for woodchips, sawdust and forest residue | [36] |

| Electricity | EUR/MWh | 30/40 | Based on electricity system scenarios from Svenska Kraftnät (Swedish grid operator) | [37] |

| Oxygen | EUR/ton | 60 | Same value used for purchase of oxygen and sales of excess oxygen from electrolysis | |

| Scrubbing oil | EUR/MWh | 106 | For tar scrubbing in DFB configurations, Rapeseed oil methyl ester (RME) | |

| Biogas | EUR/MWh | 90 | HTL, FP tracks | |

| Lignin pellets | EUR/MWh | 20 | Lignocellulosic ethanol, pellet 12% moisture. Recalculated from, i.e., 25 EUR/MWh for 10% moisture. | [38] |

| Char by-product | EUR/MWh | 20 | HTL byproduct, price assumed same as for lignin pellets. |

| Parameter | Emissions Factors | Unit | Technology Track | Ref. |

|---|---|---|---|---|

| Feedstock | 45 | kg CO2-eq/ODt | [39] | |

| Electricity | 7–13 | kg CO2-eq/GJ | [40] | |

| Natural gas | 67.0 | kg CO2-eq/GJ LHV | SNG | [40] |

| 60.9 | kg CO2-eq/GJ HHV | |||

| Diesel | 95.5 | kg CO2-eq/GJ LHV | HTL, FP, FT, ATJ | [40] |

| 89.4 | kg CO2-eq/GJ HHV | |||

| Gasoline | 93.5 | kg CO2-eq/GJ LHV | EtOH, MeOH | [40] |

| 87.4 | kg CO2-eq/GJ HHV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesfun, S.; Gustafsson, G.; Larsson, A.; Samavati, M.; Furusjö, E. Electrification of Biorefinery Concepts for Improved Productivity—Yield, Economic and GHG Performances. Energies 2023, 16, 7436. https://doi.org/10.3390/en16217436

Mesfun S, Gustafsson G, Larsson A, Samavati M, Furusjö E. Electrification of Biorefinery Concepts for Improved Productivity—Yield, Economic and GHG Performances. Energies. 2023; 16(21):7436. https://doi.org/10.3390/en16217436

Chicago/Turabian StyleMesfun, Sennai, Gabriel Gustafsson, Anton Larsson, Mahrokh Samavati, and Erik Furusjö. 2023. "Electrification of Biorefinery Concepts for Improved Productivity—Yield, Economic and GHG Performances" Energies 16, no. 21: 7436. https://doi.org/10.3390/en16217436

APA StyleMesfun, S., Gustafsson, G., Larsson, A., Samavati, M., & Furusjö, E. (2023). Electrification of Biorefinery Concepts for Improved Productivity—Yield, Economic and GHG Performances. Energies, 16(21), 7436. https://doi.org/10.3390/en16217436