1. Introduction

Pure air is important for the well-being of life on this planet. However, the incessant use of fossil fuels, particularly by the road transport sector, has degraded the air quality over the years. Although enormous improvements in the engine and exhaust after-treatment systems have been made, they are still contributing to the emission of harmful gases. The main toxic components of the engine exhaust gas are unburned hydrocarbons (HCs), carbon monoxide (CO), nitrogen oxides (NOxs), sulphur oxide and particulate matter. Prolonged exposure to toxic fumes can have an ill effect on human health, such as cardiovascular and respiratory ailments, cancer or nervous system breakdown [

1]. It is therefore imperative to look for alternatives, not only from a human health point of view but also from the fact that fossil resources are depleting and the costs incurred are rapidly increasing. One such alternative is biofuel, whose share in the global energy consumption by the transport sector is a mere 4%. Fatty acid methyl ester (FAME), also known as biodiesel, which is produced by the transesterification of vegetable oil using methanol as a catalyst, has a 32% share in the world biofuel market [

2]. Another technology known as hydroprocessing can also be utilized in producing diesel-like fuel from vegetable oil [

3,

4]. Similar to FAME, this technology produces fuel using a variety of feedstocks without competing with food production. Hence, the fuel can be classified as a second-generation fuel [

5]. Both fuels require natural gas to obtain the chemicals necessary for their processes, i.e., methanol is required by FAME and hydrogen is required for hydroprocessing [

6]. Moreover, well-to-wheel analysis of carbon footprints shows that hydrotreated vegetable oil (HVO) is more sustainable than diesel [

7].

In the presence of a catalyst, the raw feedstock is hydrotreated, and to further improve the quality, isomerization of the intermediates, carboxylic acid, monoglyceride and diglyceride treatment is also carried out [

8,

9,

10]. The individual stage processes define the resulting products formed, which can be either normal paraffins or a mixture of iso- and n-paraffinic hydrocarbons, which are free from sulphur and aromatics and have a low level of toxicity [

11]. The chemical structure of HVO provides good auto-ignition properties and enables cleaner combustion [

8]. Due to the higher cetane number of HVO, the start of combustion is faster, especially at low and medium loads [

12]. Other advantages of HVO are better cold-start properties, shorter primary combustion, less white smoke and low noise [

13]. Due to low lubricity, it is suggested that the content of HVO while blending with diesel should be limited to 50% [

14]. Also, it was found that 30% blending of HVO in diesel can meet the EN590 norms [

15]. Studies showed significant reductions in particulate, NOx, CO and HC emissions with the use of HVO in heavy-duty engines [

3,

16] or in tractors [

17]. Similar results were also reported in non-mobile applications, such as underground mining operations [

18] and gensets [

19].

When comparing diesel with HVO, it was found that HVO fuel droplets penetrate more than diesel, resulting in the formation of a more combustible homogeneous mixture. Furthermore, lower physical ignition delay and improved mixture dispersion result in lower local temperatures [

15,

20]. Vo et al. [

14] found no difference in the cone angle with an up to 30% blend of HVO with diesel and mineral diesel. Moreover, the spray cone angle was significantly wider with neat HVO compared with diesel. Cheng et al. [

20] and Bohl et al. [

15] also made similar observations. Moreover, modelling showed no difference in fuel penetration and distribution. The results were confirmed experimentally in an optical engine. In contrast, Preuss et al. [

21] used a high-pressure injection chamber to investigate spray characteristics and found a longer liquid penetration length but smaller vapor phase penetration for HVO compared with diesel. Engine testing on a large scale was conducted by Neste Oil, Helsinki Region Transport, VTT Technical Research Centre and Proventia Emission Control [

22]. The tests conducted on nearly 300 EURO IV buses showed a reduction in emissions with a 30% blend of HVO in diesel fuel. Moreover, the studies did not find any reliability issues [

23,

24]. When using HVO in heavy-duty engines, the unburned hydrocarbon emissions were reduced by 48%, carbon monoxide emissions were reduced by 28%, NOx emissions were reduced by 10% and particulate matter emissions were reduced by 28% [

16]. Also, aromatics were not produced by HVO combustion. In light-duty engines, however, the emissions were reduced with HVO but the results were engine dependent [

12]. Some studies found a reduction in NOx emissions with unchanged particulate levels, whereas some studies suggest a trade-off. Sugiyama et al. [

25] explained that this trade-off was dependent upon the use of either single injection or split injection of the fuel. The HVO ignited earlier with a single fuel injection with a lower heat release rate, resulting in lower NOx emissions but higher particulate emissions. With the split-injection strategy, the main combustion remained the same and HVO was ignited earlier. The lower chemical propensity of HVO was the governing mechanism for lower particulate creation during split injection. Wu et al. [

26] also found that the smoke emission was halved with HVO compared with diesel for the entire engine operating map. However, Bortel et al. [

13] found that the particulate number was unaffected by the HVO, but still, an 80% reduction in HVO was found.

The literature shows that there is scope for realizing the full potential of HVO properties by recalibrating the engine. In this context, Ezzitouni et al. [

27] tuned the pilot fuel injection and found improvement in thermal efficiency by delaying the pilot fuel injection, especially under cold-start conditions. Mikulski et al. [

28] also found an improvement in combustion efficiency with the same strategy. However, the particulate emissions were found to increase due to less premixed combustion caused by advancing the injection. The HVO recalibration potential was investigated by Aatola et al. by varying the main injection timing and fixed pilot injection [

3]. The NOx–PM trade-off was found to be variable at different speeds and loads. Moreover, the particulate emissions were 30–40% lower with HVO than diesel for a given NOx level, thereby providing additional control flexibility. Double pilot injection was used by Liu et al. [

29] for a 60% HVO blend. The authors found that only the combustion of the first pilot was advanced, whereas other injected fuel burnt with similar rates and timings as diesel, HVO and FAME. The timings of the pilot and major injections were changed by Dimitriadis et al. [

30], who discovered complex trends in efficiency and emissions as a result of the superposition of the aforementioned effects. Since HVO’s high cetane number and chemical structure make it less likely to produce particle emissions, exhaust gas recirculation is another method that researchers have studied and offers better trade-offs than HVO [

31]. Lehto et al. [

32] and Liu et al. [

29] confirmed this in their studies. Liu et al. [

29], by applying a Miller cycle and an advanced start of ignition, showed a reduction in PM and NOx simultaneously.

The literature shows that there are inherent advantages to using HVO in a diesel engine, mainly due to its properties, such as low viscosity shortening the evaporation time and improving the homogenization process. However, a high cetane number, along with its paraffinic structure, shortens the ignition delay but lengthens the soot oxidation time [

33]. Hence, additives can also be potentially explored for improving the combustion process. Dobrzynska et al. [

34] doped cerium dioxide and ferrocene nanoparticles into a blend of diesel (B7: blends of diesel and 7% FAME) and HVO. An 11-year-old passenger vehicle was tested on an NEDC cycle. The authors found a reduction in particulate emissions and a slight increase in NOx emission with cerium dioxide doping. In contrast, ferrocene doping resulted in a reduction in NOx emissions, along with a particulate matter reduction. Apart from the abovementioned study, no other work (as per the authors’ knowledge) is available in the literature that explored the potential of additives/blends of biofuel in the blends of diesel and HVO. The authors noted in their earlier work [

19,

35] that using 30% hydrotreated oil produced lower emissions, although the thermal efficiency was poor. Moreover, although the emissions were greater with the 20% blend of hydrotreated oil than with the 30% blend, the efficiency with the 20% blend was higher. In the current work, the addition of biodiesel was investigated as a potential remedy for the deficiencies of the two samples. The novelty of this study lies in the fact that experimental work was carried out by mixing waste cooking oil biodiesel in a blend of diesel and hydrotreated oil. The aim of this study was to determine a relationship between the addition of biofuels to diesel and a change in engine exhaust emission levels from an agricultural diesel engine. Such low-cost diesel engines are abundantly available on farms and they have fixed injection timing and pressure with no after-treatment system in place. To optimize the engine performance in a full-load condition, a fuzzy-logic-based Taguchi method was also used to find the best blend of HVO and biodiesel.

4. Performance Optimization

To improve the performance of a process, it is necessary to optimize the factors that affect the process. However, to optimize each parameter, several experiments need to be carried out. The Taguchi method is one such technique wherein by using fewer experiments, a process can be optimized, thus saving time and experimentation costs. Genichi Taguchi was a Japanese engineer who devised this technique. The thinking behind the technique’s development was to improve product quality, as poor quality leads to societal loss. Many experimental studies have been carried out using this technique. To improve the engine torque and power and reduce fuel consumption, Ozel and coworkers used the Taguchi method to find the best engine speed and type of coating [

58]. For the optimization, an L16 orthogonal array was used. The signal-to-noise (S/N) ratio was the highest with an AL

2O

3 + 15%TiO

2 coating and a 2600 rpm engine speed for torque and fuel consumption. Moreover, for engine power, the highest S/N ratio was found with an AL

2O

3 + 15%TiO

2 coating and a 3200 rpm engine speed. It was seen that both the engine speed and coating material significantly affected the engine performance. Using the Taguchi method, the hydrogen energy share, biodiesel blend and exhaust gas recirculation rate were optimized to improve the performance of a dual-fuel diesel engine [

59]. The output parameters considered for optimization were fuel consumption, thermal efficiency, and smoke and NOx emissions. All the parameters in that study were optimized one at a time, making this process tedious and time consuming. Orthogonal arrays are used in this method and a generic signal-to-noise ratio was utilized to represent the factor variations. The parametric S/N ratio can be characterized as the nominal-the-better (NTB), the smaller-the-better (STB) and the larger-the-better (LTB) [

60]. The S/N ratio for LTB and STB was calculated using Equations (1) and (2), respectively. The factors or process parameters used in this study were the percentage of HVO in the blend and the percentage of biodiesel in the blend. The HVO ratio had two levels and the biodiesel blend had four levels.

Table 3 tabulates their values. An L8 algorithm was selected for the Taguchi optimization process, as shown in

Table 4. The brake thermal efficiency and smoke and NO emissions were the output parameters.

where

yi is the value of the performance characteristic measured during the trial,

n is the number of tests in a trial and the S/N ratio has a unit of decibels (dB).

The engine optimization was carried out only for the full load conditions. The S/N ratios for the output parameters were calculated. For the thermal efficiency, the larger-the-better S/N ratio characteristic was selected since a higher thermal efficiency will lead to engine performance improvement and simultaneously reduce fuel consumption. However, the lower-the-better S/N ratio characteristic was selected for both smoke and NO emissions since emission reduction is necessary for engine performance improvement. The S/N ratio for the eight experiments is shown in

Table 5. The highest S/N ratio for thermal efficiency was observed in experiment seven and the lowest S/N ratio for NO emission was also observed in experiment seven. Meanwhile, the lowest S/N ratio for smoke emission was observed in experiment one.

There are several processes in engineering that require the optimization of multiple performance characteristics. The optimization of the input parameters was carried out based on an engineering judgment, which was later verified using experiments. For example, each performance characteristic has a different category, engineering unit and importance [

61]. Hence, optimizing the process parameters may not be straightforward. The previous study showed that multi-objective optimization using the Taguchi method alone is not possible; hence, researchers have combined other theories with the Taguchi method. Grey’s relational analysis was combined with the Taguchi method by Roy et al. to optimize the load, injection pressure and compressed natural gas energy share [

62]. The output parameters considered for optimization were the energy consumption and the particulate and HC emissions. The air–fuel ratio, compression ratio, load, spark advance and knocking tendency were optimized using Taguchi and Grey relational analyses [

63]. The output parameters considered were the HC and CO emissions and fuel consumption. For Grey’s relational analysis, a weight is allocated for each response. These weights are assigned using assumptions, which may lead to uncertainty in the solution. Fuzzy logic overcomes this problem and has been used in studies for the multi-objective optimization of parameters. Bose et al. [

64] used a fuzzy-logic-based Taguchi method to optimize the injection duration of hydrogen in the intake manifold and load for a dual-fuel engine. They used the volumetric efficiency, energy consumption and thermal efficiency as the response variables. They found that optimizing the parameters using the combined method was efficient, along with the desired improvement in parameters. Similarly, Kumar et al. [

65] optimized the injection timing and compression ratio for a diesel- and DEE-fueled compression ignition engine using the Taguchi method combined with fuzzy logic. The optimized parameters were found to be 19:1 compression ratio and 21°bTDC injection timing.

In a fuzzy control system, human logic is used in controlling a process, which is represented in the form of fuzzy rules or relations. The control system comprises a fuzzifier, a function of inputs, a rule base, an engine that infers the output using the rule base and a defuzzifier. The inputs are first normalized using Equation (3) and sent to the fuzzifier.

where i takes values 1, 2, 3, …, etc. X

i denotes the value at the ith position, X

min is the minimum value and X

max is the maximum value of the input.

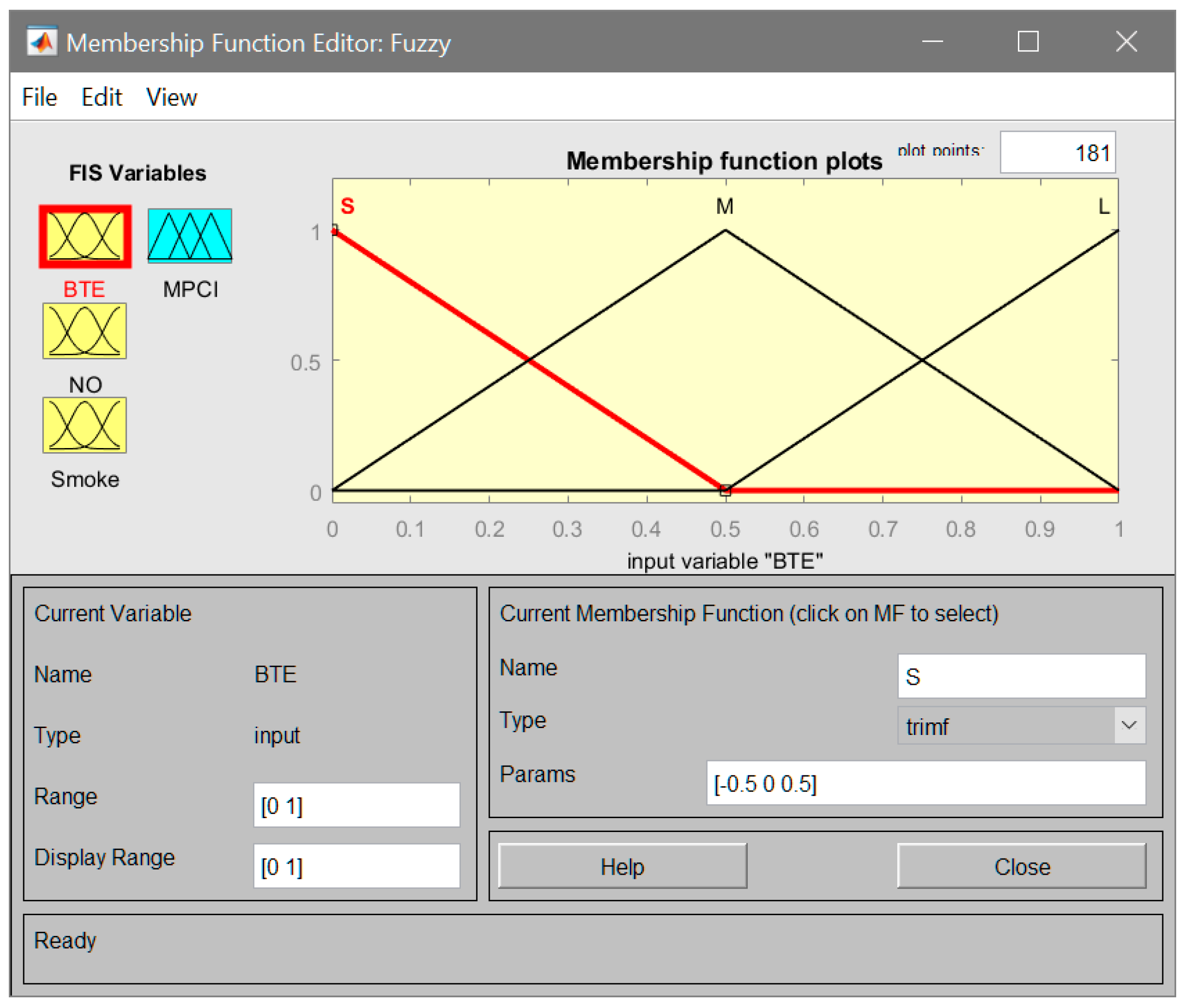

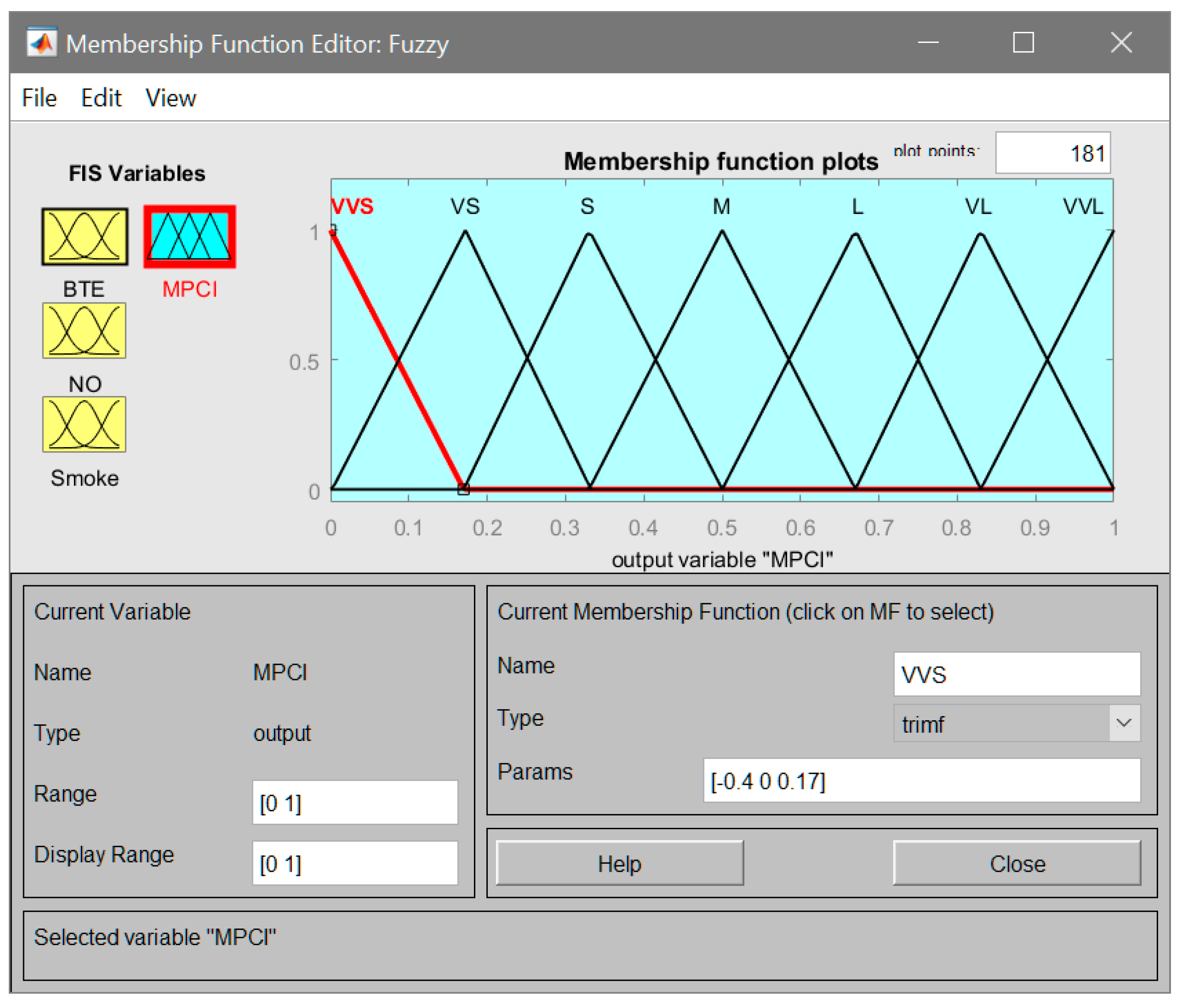

The fuzzifier fuzzifies each input using its member function, which is triangular in this study. The output member function is also triangular, which is named the multi-performance characteristics index (MPCI) in this study. The membership functions contain three levels, namely, large, medium and small, for fuzzifying the normalized S/N ratios.

Figure 15 displays the membership functions for the two performance characteristics. Using fuzzy rules that are based on human reasoning, such as big, medium and tiny, the relationships between the input and output variables were constructed. The links between the input and output variables using fuzzy rules are shown in

Table 6, where ‘VVS’ stands for ‘very very small’, ‘VS’ stands for ‘very small’, ‘S’ stands for ‘small’, ‘M’ stands for ‘medium’, ‘L’ stands for ‘large’, ‘VL’ stands for ‘very large’ and ‘VVL’ stands for ‘very very large’. These guidelines are used by the inference engine to produce a fuzzy value via fuzzy reasoning. The MPCI membership function, shown in

Figure 16, defuzzifies this value and gives a single-value output. The output value was defuzzified using the centre of gravity method.

Table 5 shows the MPCI value for each experiment. The fuzzy control system used in this study was developed using MATLAB.

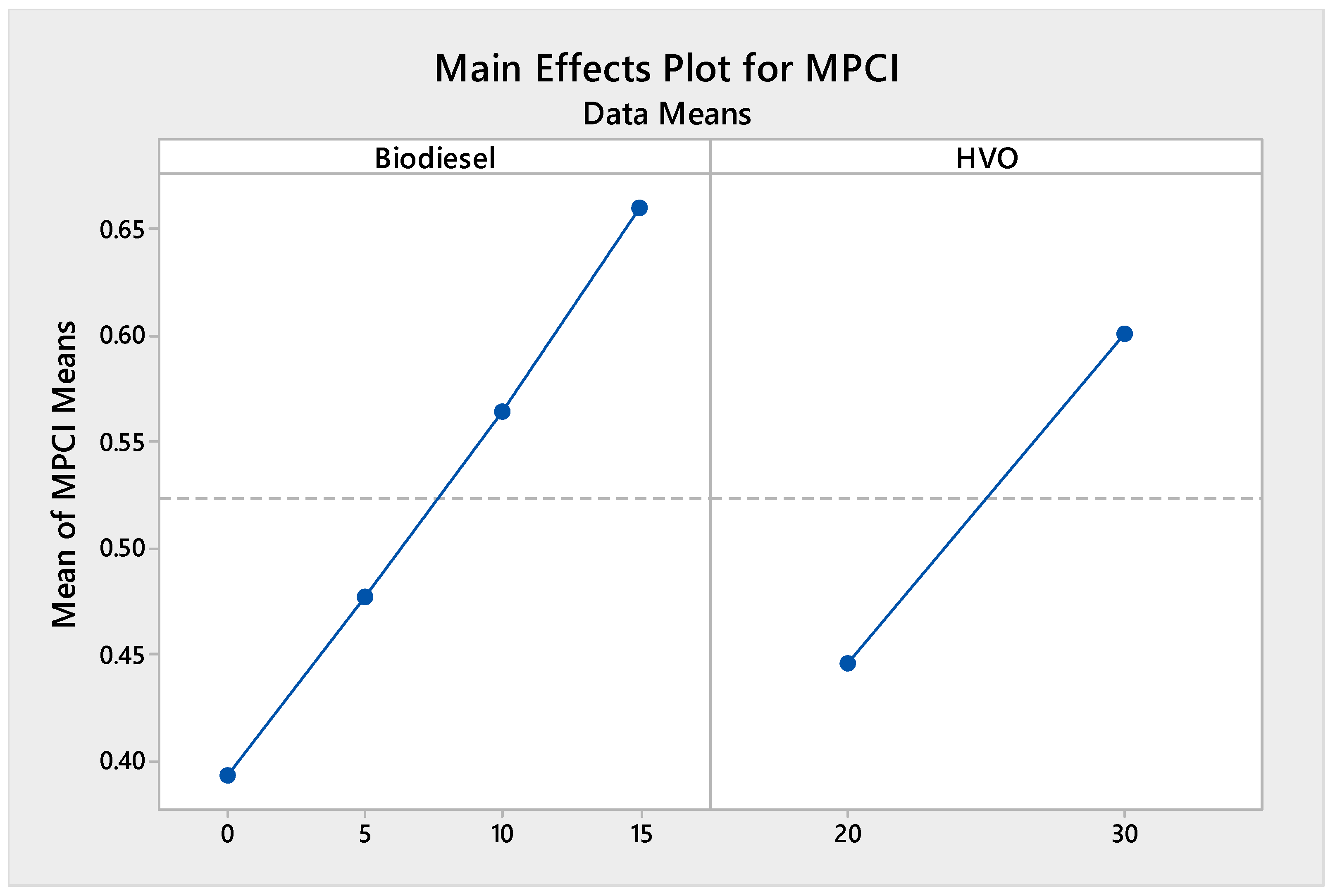

Using the MPCI values for each experiment, the input parameters were optimized using the Taguchi method. For each level of biodiesel and HVO percentage, the mean of the MPCI was calculated and is shown in

Table 7. The mean MPCI for a variable and its level was calculated by averaging the MPCI values of that level. For example, the mean MPCI of level 1 for HVO percentage was calculated by averaging the MPCI values of experiments 1, 3, 5 and 7. The effects of both parameters on the mean MPCI are plotted in

Figure 17. The total mean MPCI was found to be 0.5238, which is plotted as a dashed line in

Figure 17. The mean MPCI value with the greatest value was considered to be the best for each performance attribute. It was found that there was little variance in performance around the desired value. The optimal HVO percentage was therefore determined to be 30%, and the optimal biodiesel percentage was found to be 15%. The performance attributes enhancement was then confirmed using a confirmation experiment. The MPCI and S/N ratio for the ideal values were also predicted using Equation (4).

Table 8 displays the mean MPCI and S/N ratio values for the experiment, as well as the forecast made using Equation (4). It is seen that the experimental values were slightly higher than the predicted values and were within appropriate limits. This confirms the reliability of the prediction carried out using the Taguchi method combined with the fuzzy-based method.

where η is the estimated MPCI, η

m is the total mean of S/N ratio, ηi is the mean of the S/N ratio at the optimal level and q is the number of parameters that affect the output.

5. Conclusions

In this investigation, engine tests were conducted utilizing ternary mixes of biodiesel made from spent cooking oil, hydrotreated vegetable oil and diesel. Comparisons were made between the combustion, performance and emission characteristics of basic diesel and HVO-and-diesel mixes. Studying the effects of adding biodiesel to diesel blends with 20% and 30% HVO was the primary goal of the experiment. The findings led to the following deductions:

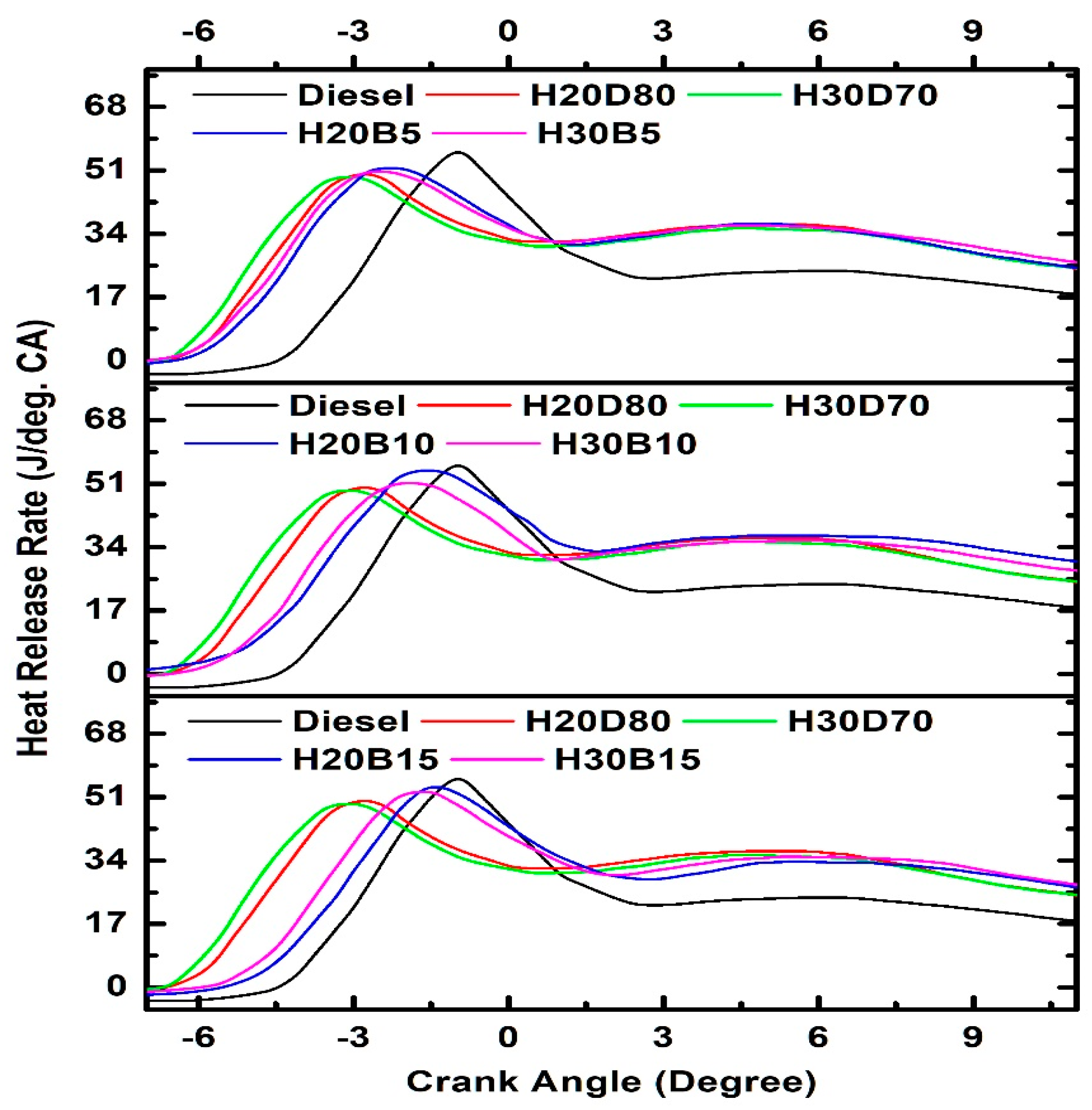

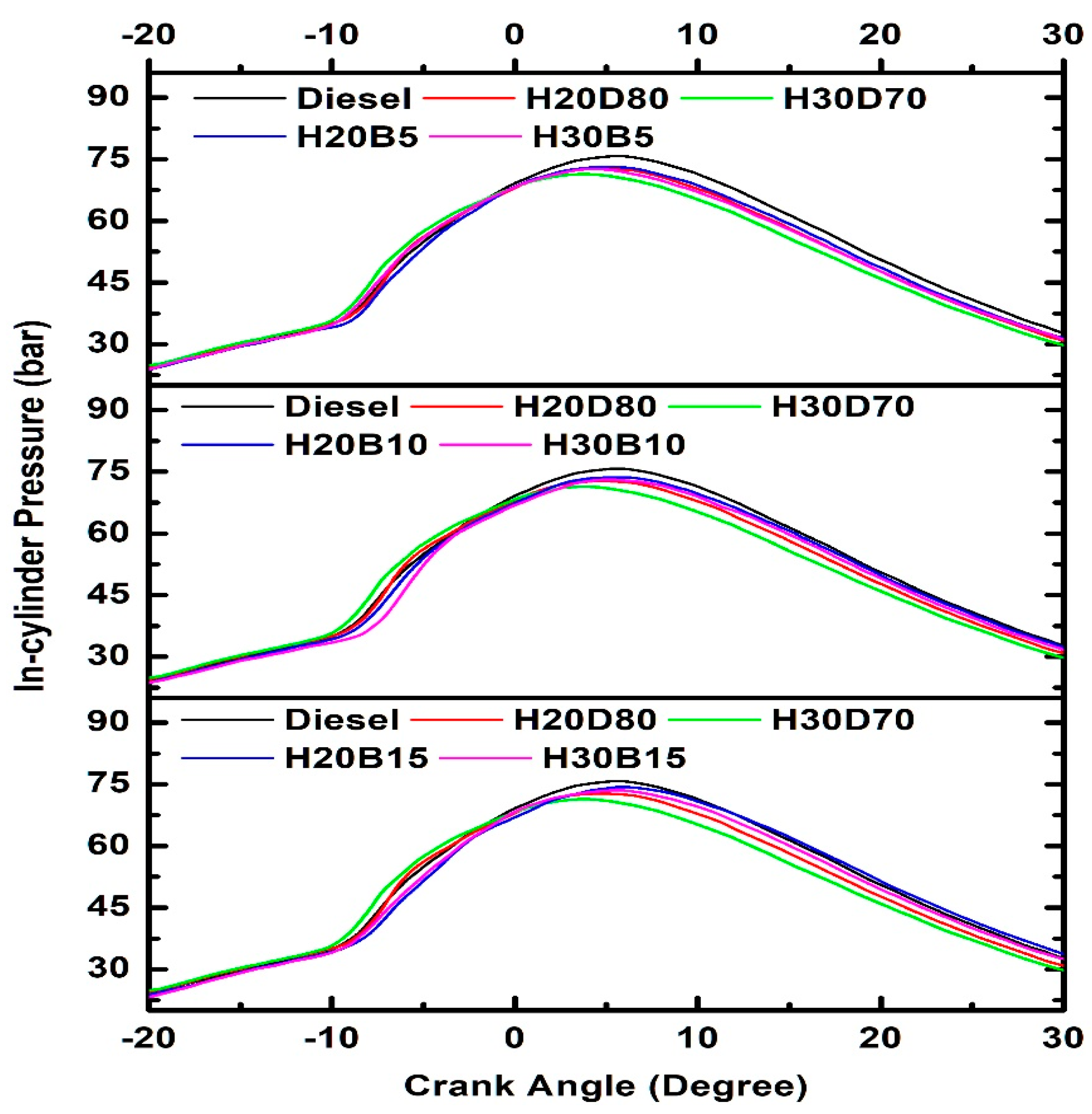

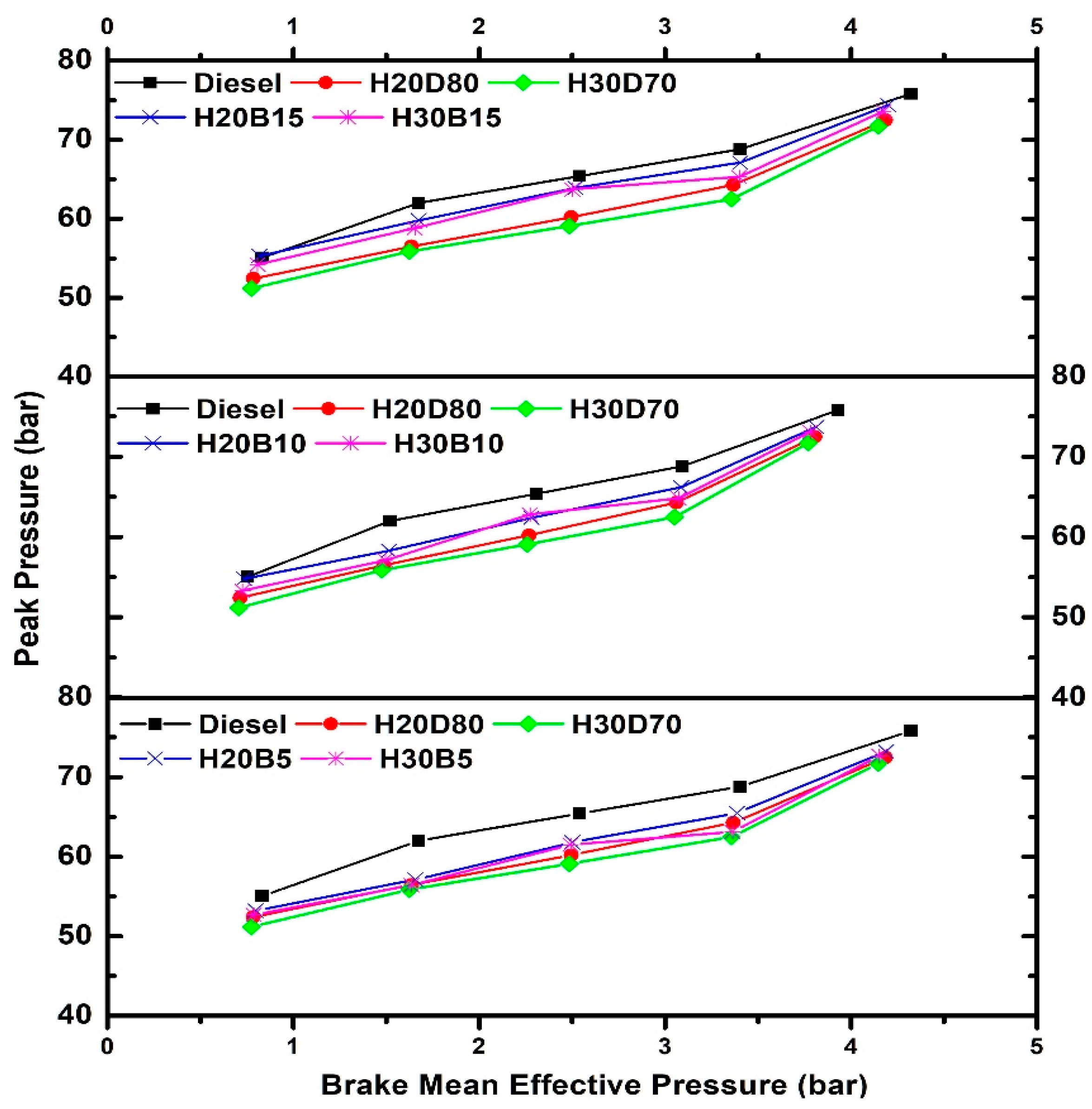

With the addition of biodiesel, the engine’s heat release rate increased, and this trend was continued as the proportion of biodiesel rose. Additionally, a rise in the peak in-cylinder pressure was observed.

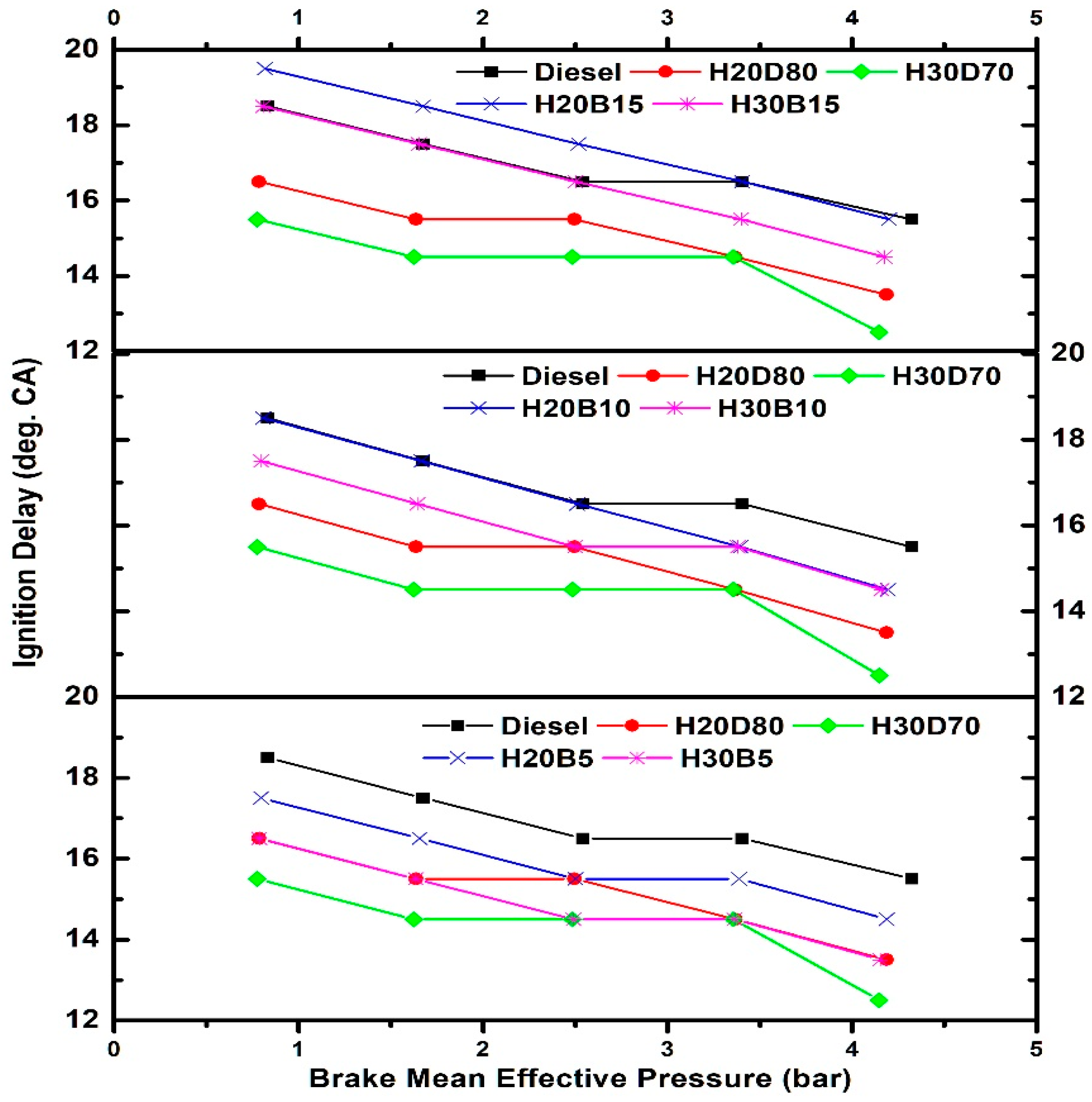

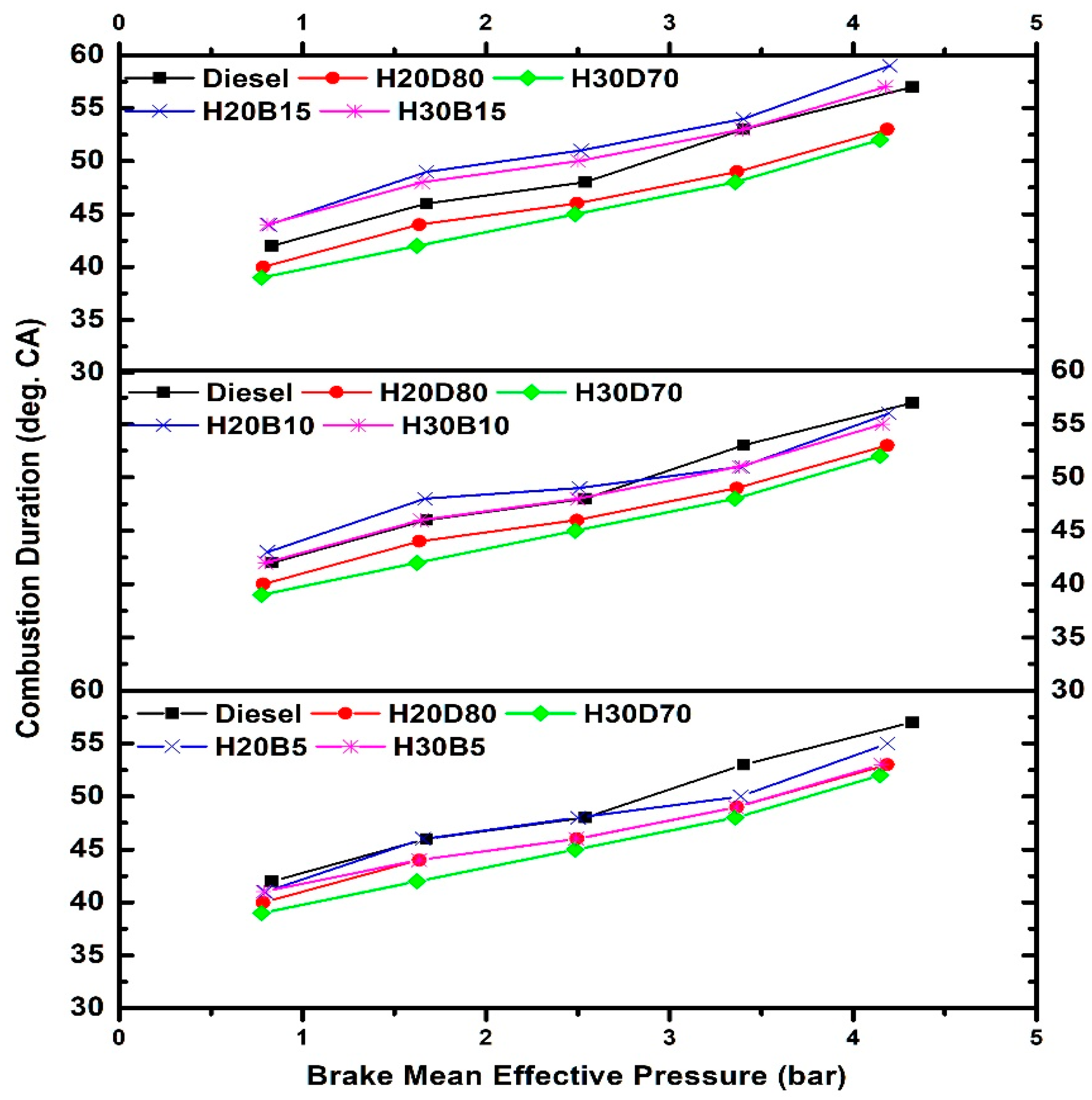

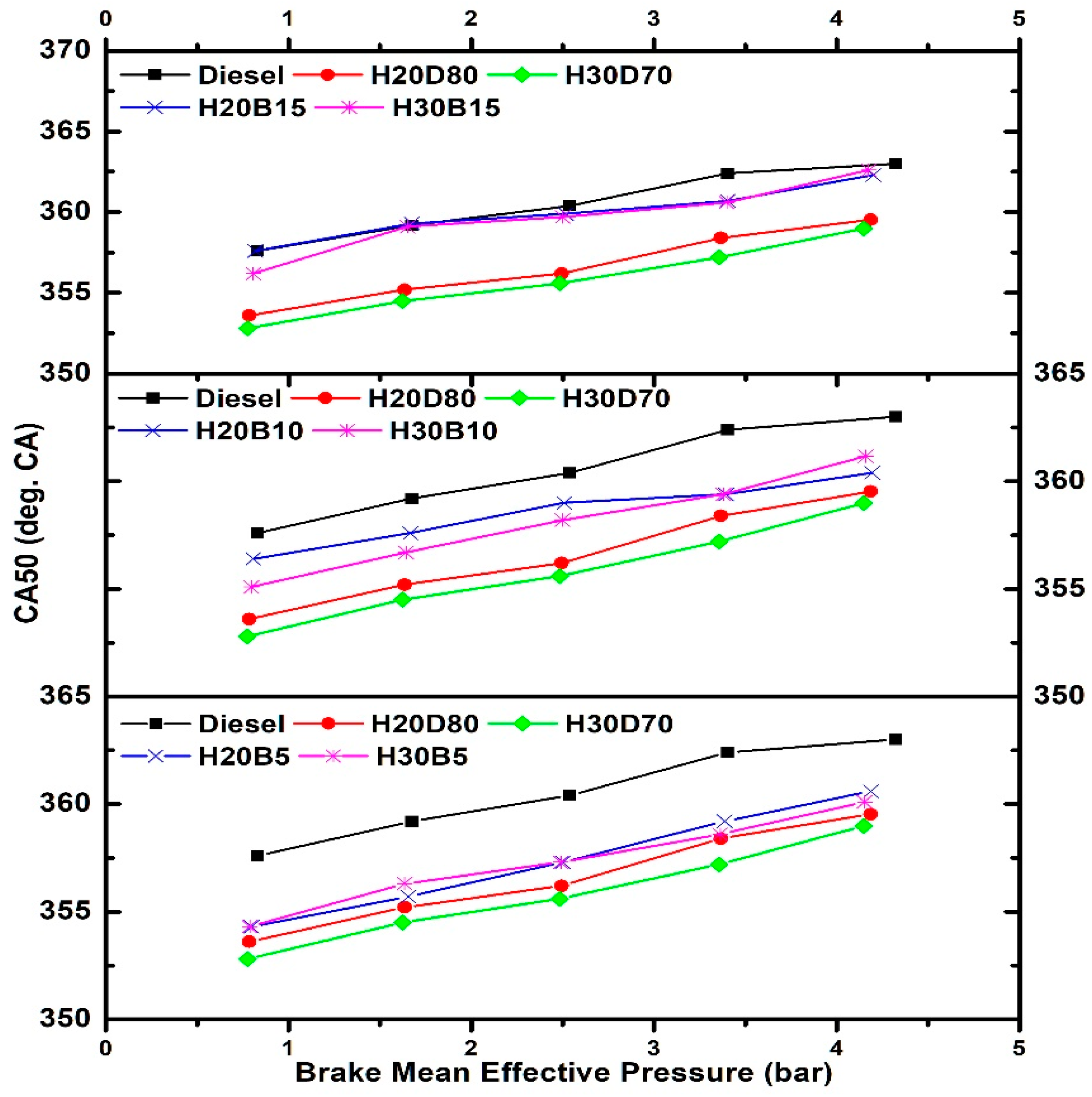

In comparison with blends without biodiesel, the ignition delay and combustion duration were longer with the biodiesel mixes.

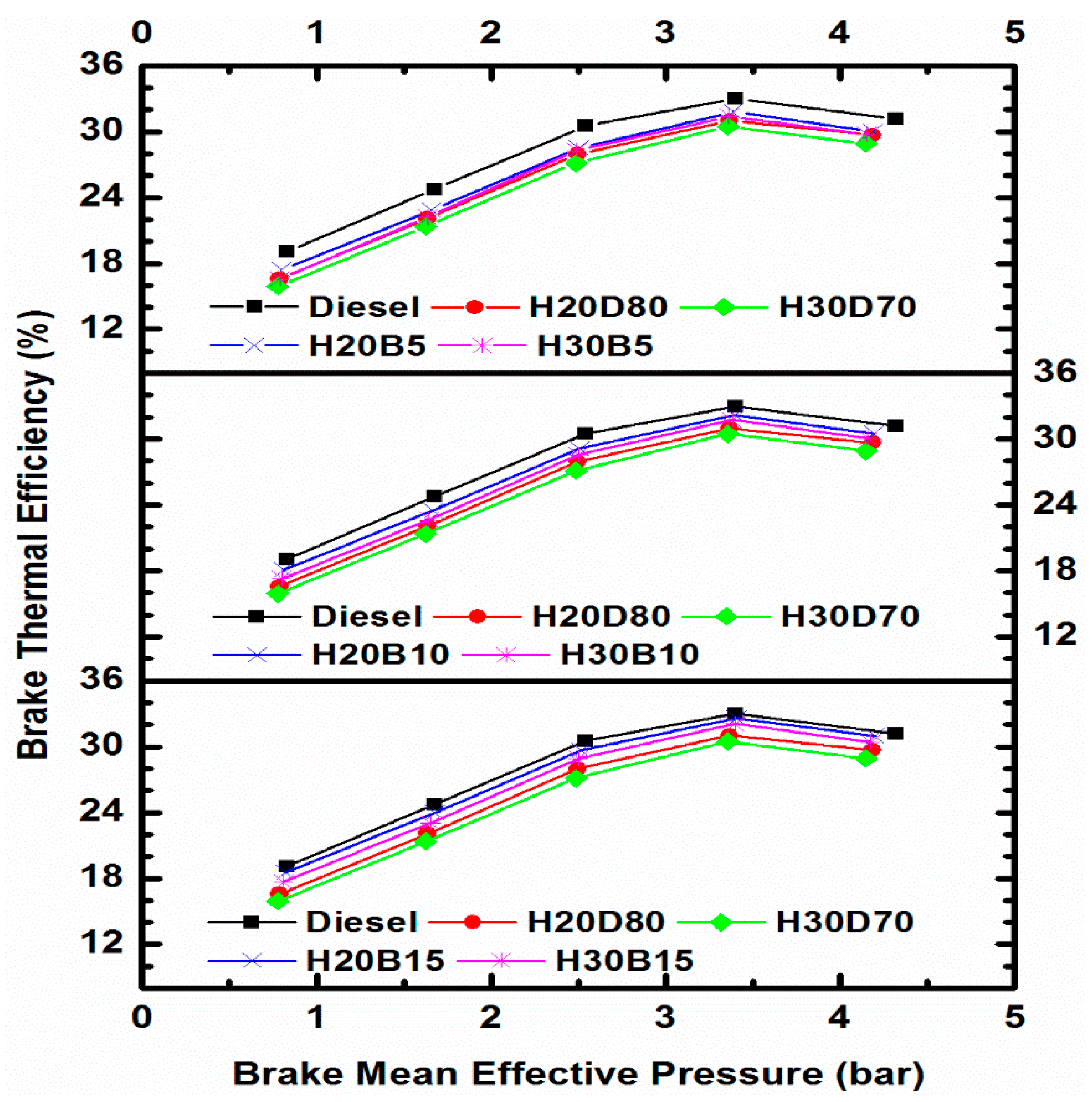

It was discovered that the biodiesel blends had a greater thermal efficiency than H20D80 and H30D70. The thermal efficiency increased with the amount of biodiesel in the blend, although it was still less efficient than diesel. The thermal efficiency was greatest with H20B15.

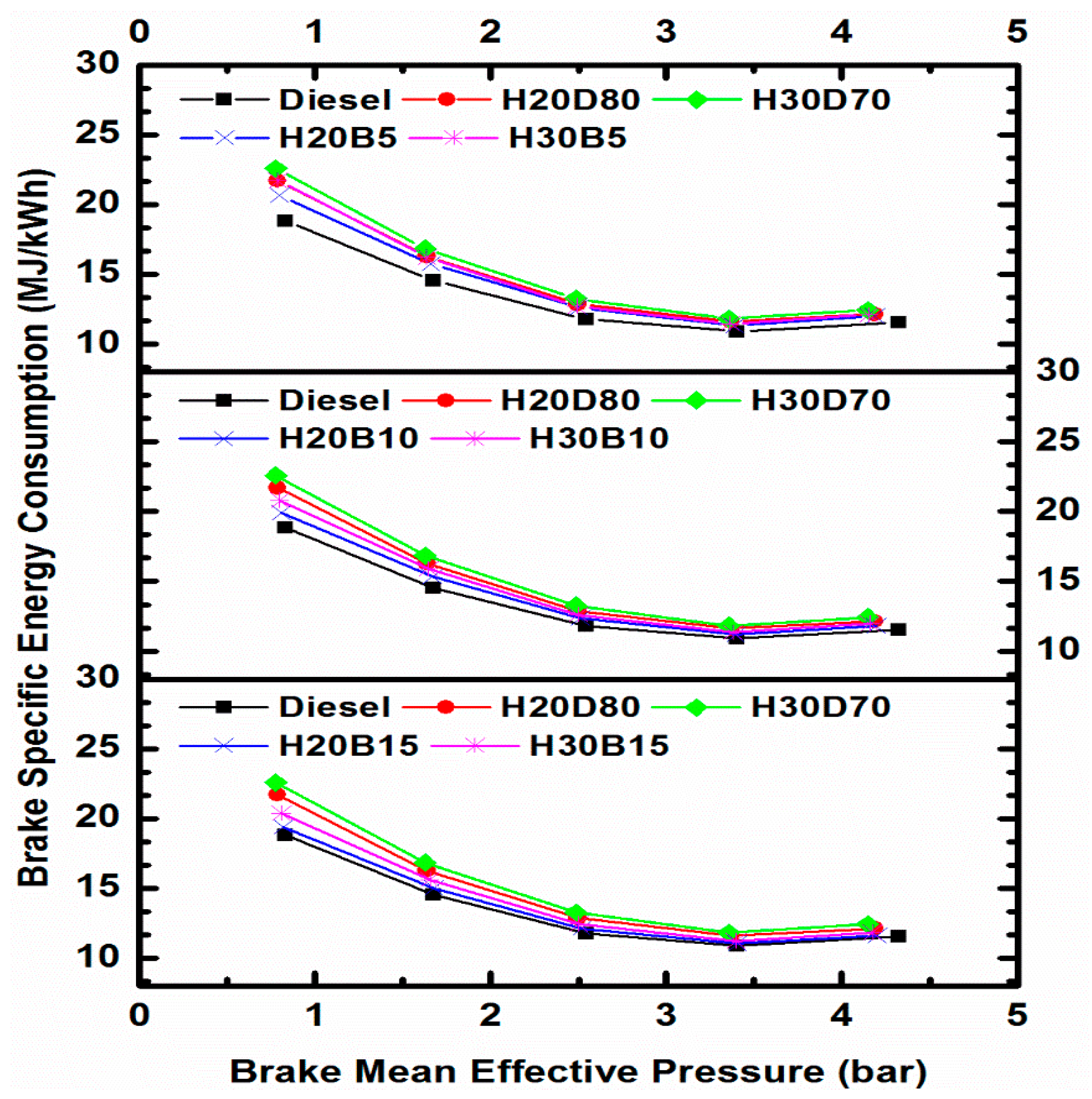

Compared with hydrotreated oil blends without biodiesel, the energy consumption was decreased with biodiesel, but it was still greater than diesel. H20B15 had the lowest energy use when running at full capacity.

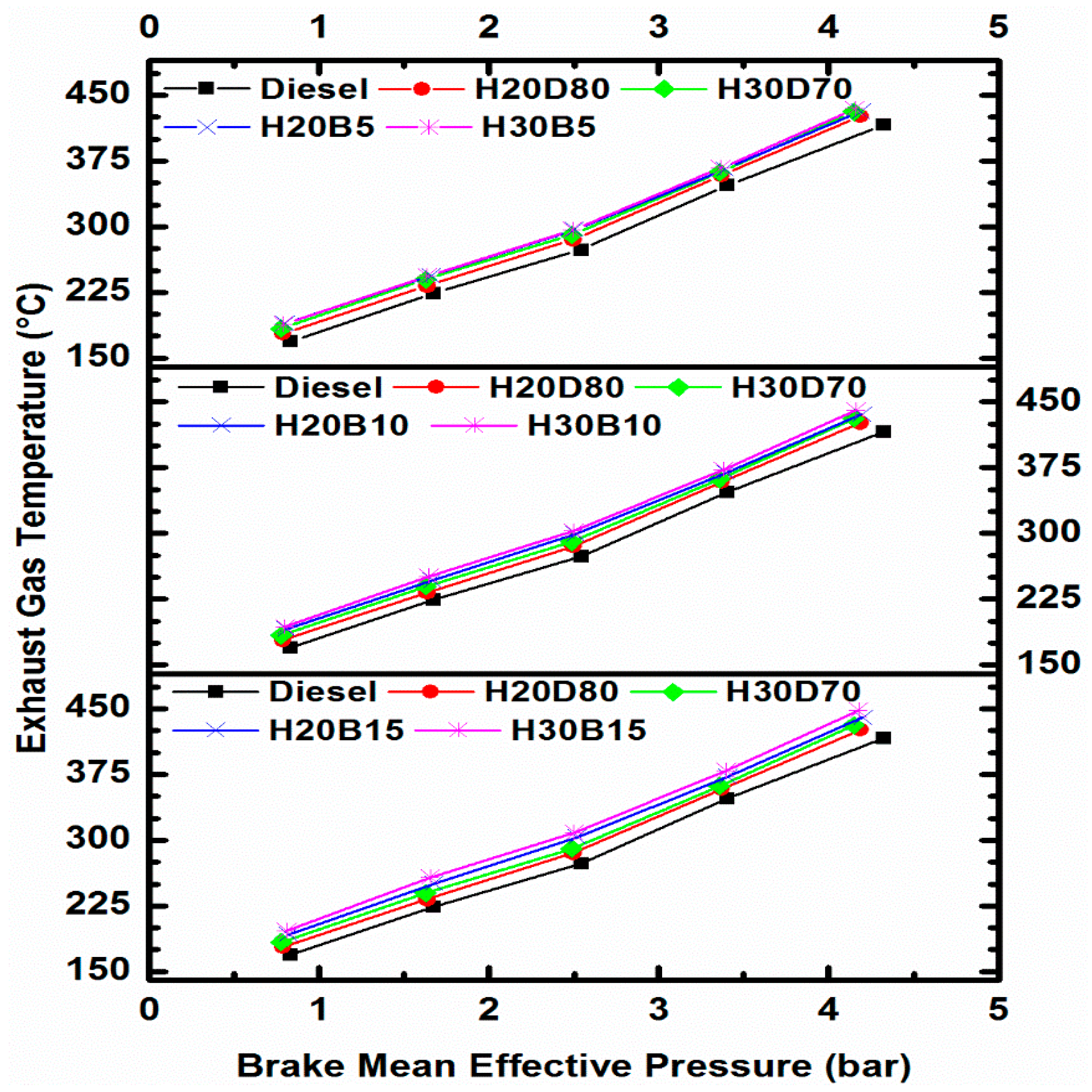

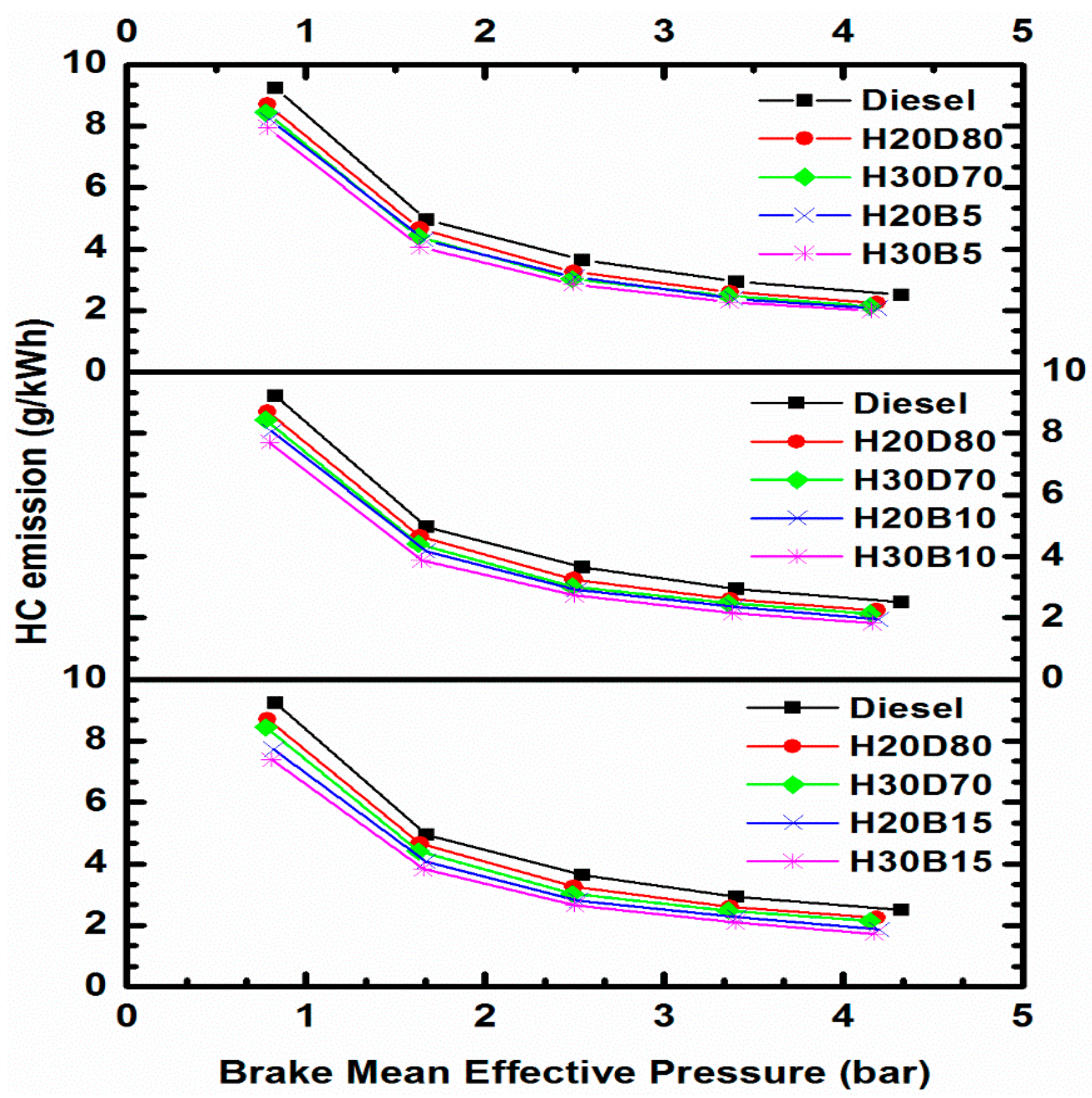

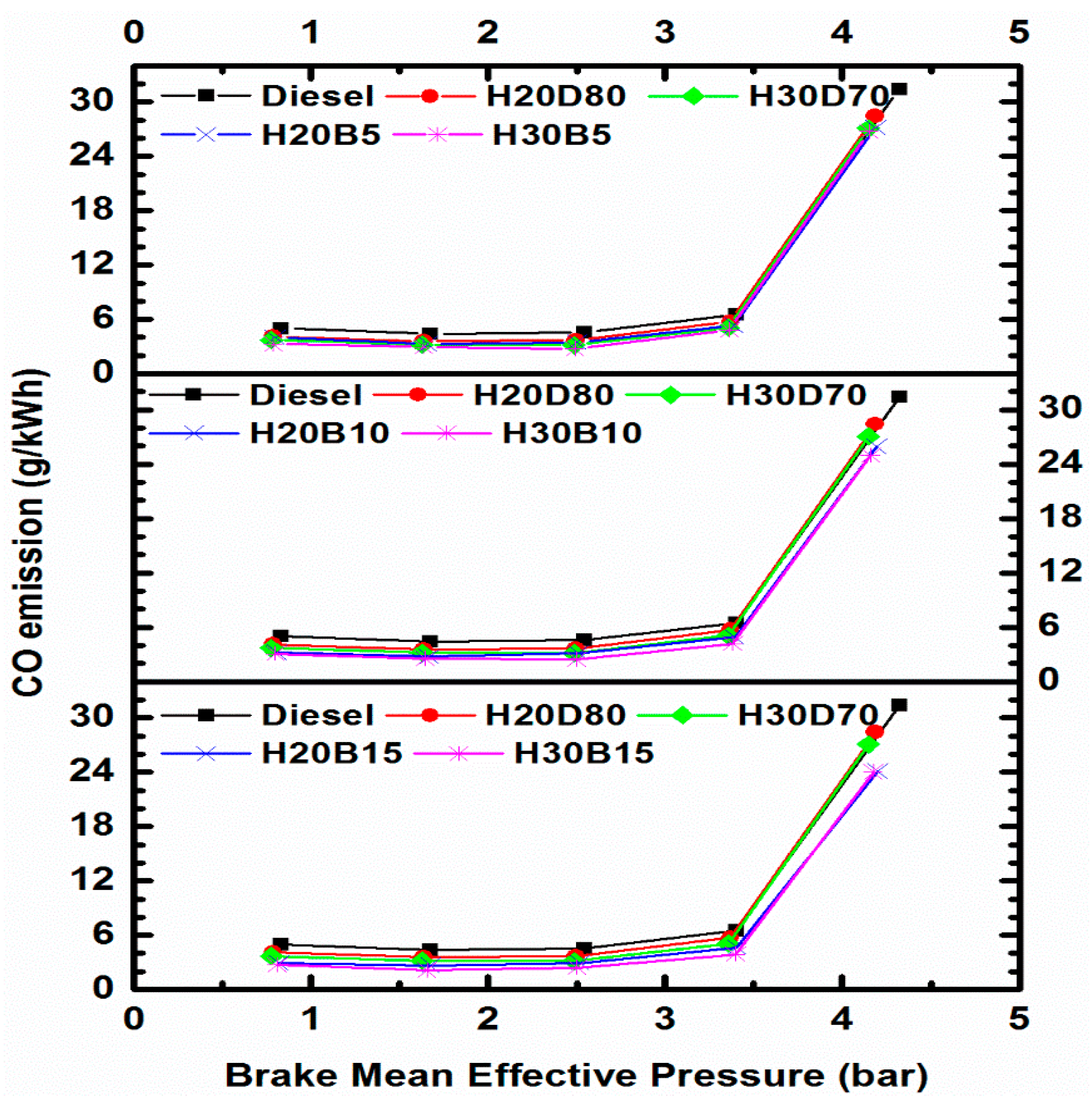

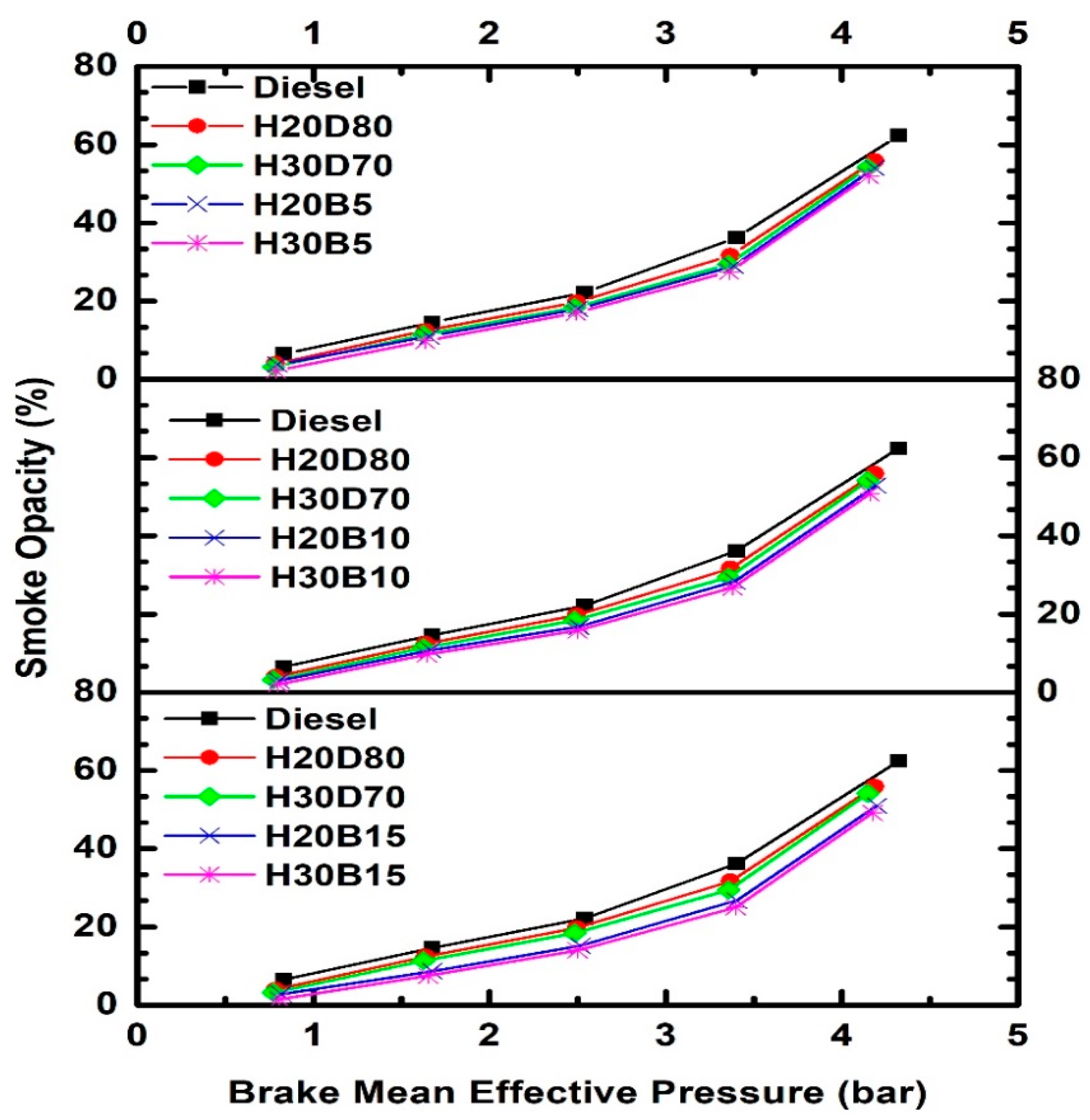

With the blend’s biodiesel percentage rising, a drop in HC, CO and smoke emissions was seen. With H30B15, the lowest emissions were noted. H30B15 reduced the HC, CO and smoke emissions at full load by 30%, 23.5% and 21.1%, respectively.

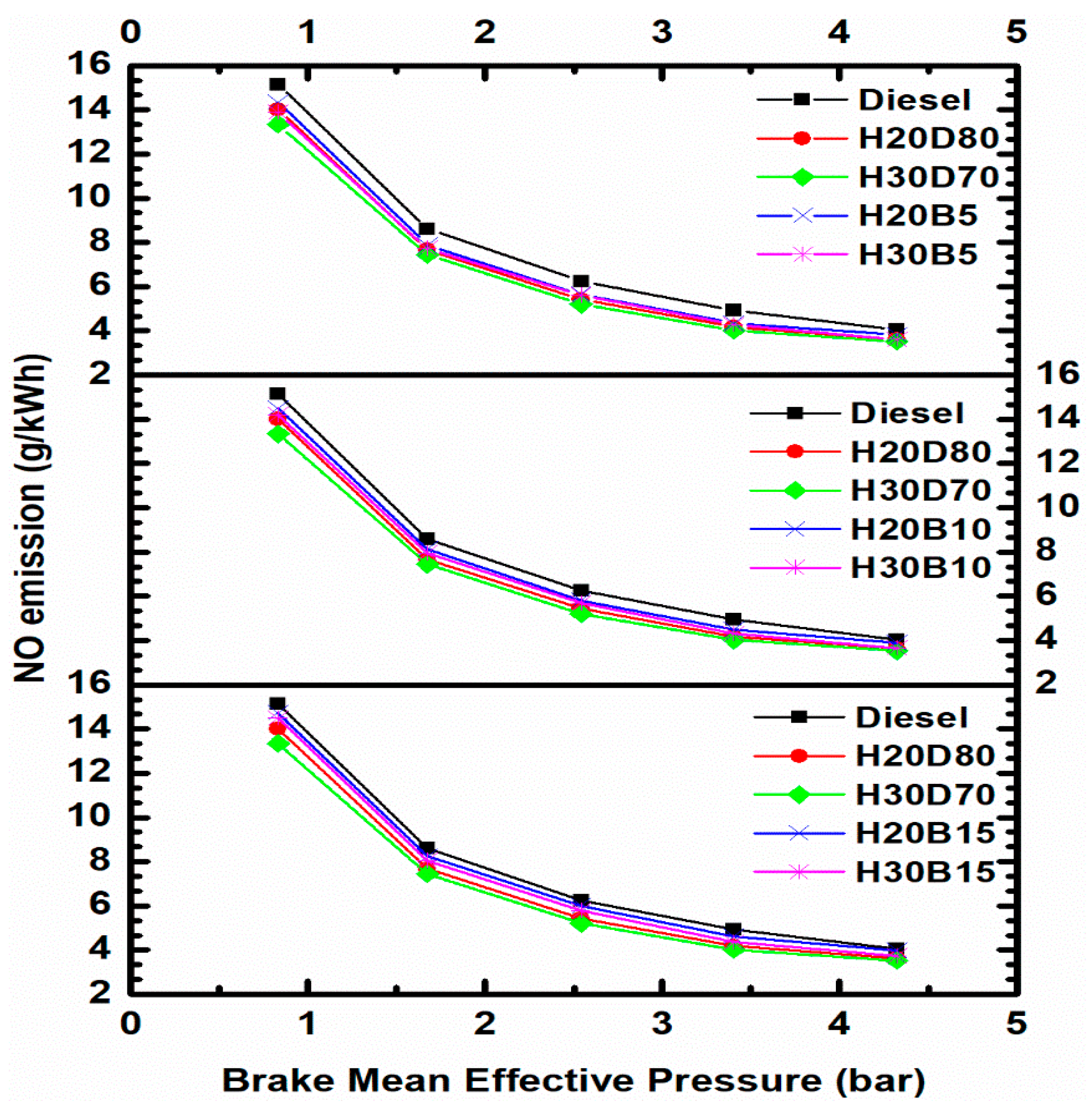

The amount of biodiesel in the mix was found to increase the NO emissions, although they were still less than for diesel.

From the results, there is no clarity as to which blend can be considered the best. Hence, fuzzy-logic-based Taguchi optimization was carried out using HVO and biodiesel percentage as the input parameters and BTE, NO and smoke as the output parameters. The best blend from the optimization was found to be H30B15. The confirmation experiment showed that the regulated emission reduction was highest with the blend. However, there was a slight compromise in the thermal efficiency of the engine.

The optimized fuel blend fulfiled the objective of the study, which was to prepare a fuel blend that can be easily used in diesel engines. The use of the proposed blend resulted in lower emissions without modifying the engine. It is difficult to modify those engines that are already in use. Such engines also have no exhaust aftertreatment system; hence, lower emissions due to the fuel itself are cost effective and environmentally friendly. As a future study, modifications in the engine can be explored so that the fuel economy of the engine can be improved, along with even further lowering of the emissions. The shelf-life of the fuel is one aspect that can be studied. Another study can be carried out by doping the blend with different nanoparticles and their effect on engine performance and emission can be analyzed. Lastly, the long-term impact of the fuel blend on the engine parts, especially the injection system and filtration system, can be explored.