Crystalline Silicon (c-Si)-Based Tunnel Oxide Passivated Contact (TOPCon) Solar Cells: A Review

Abstract

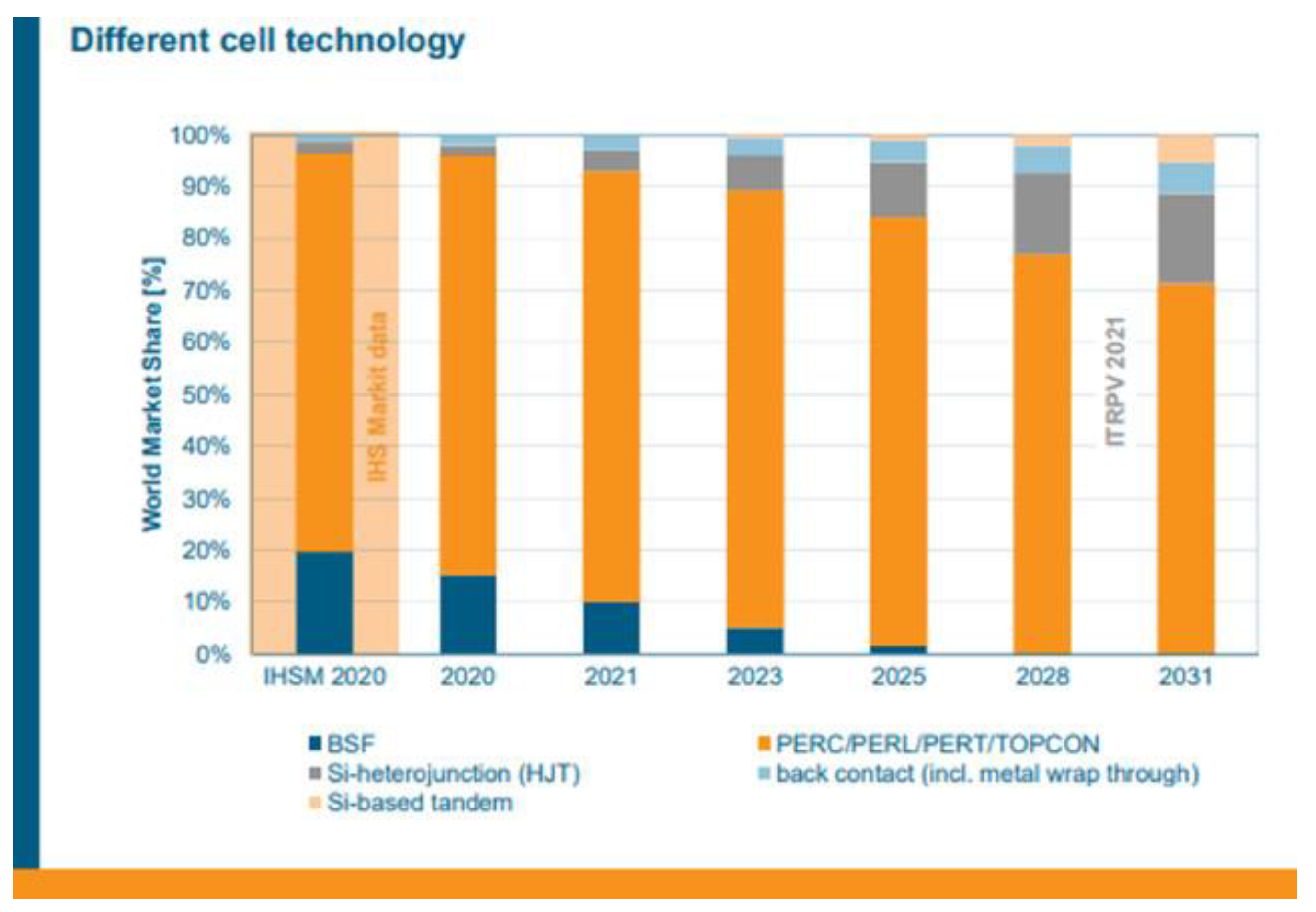

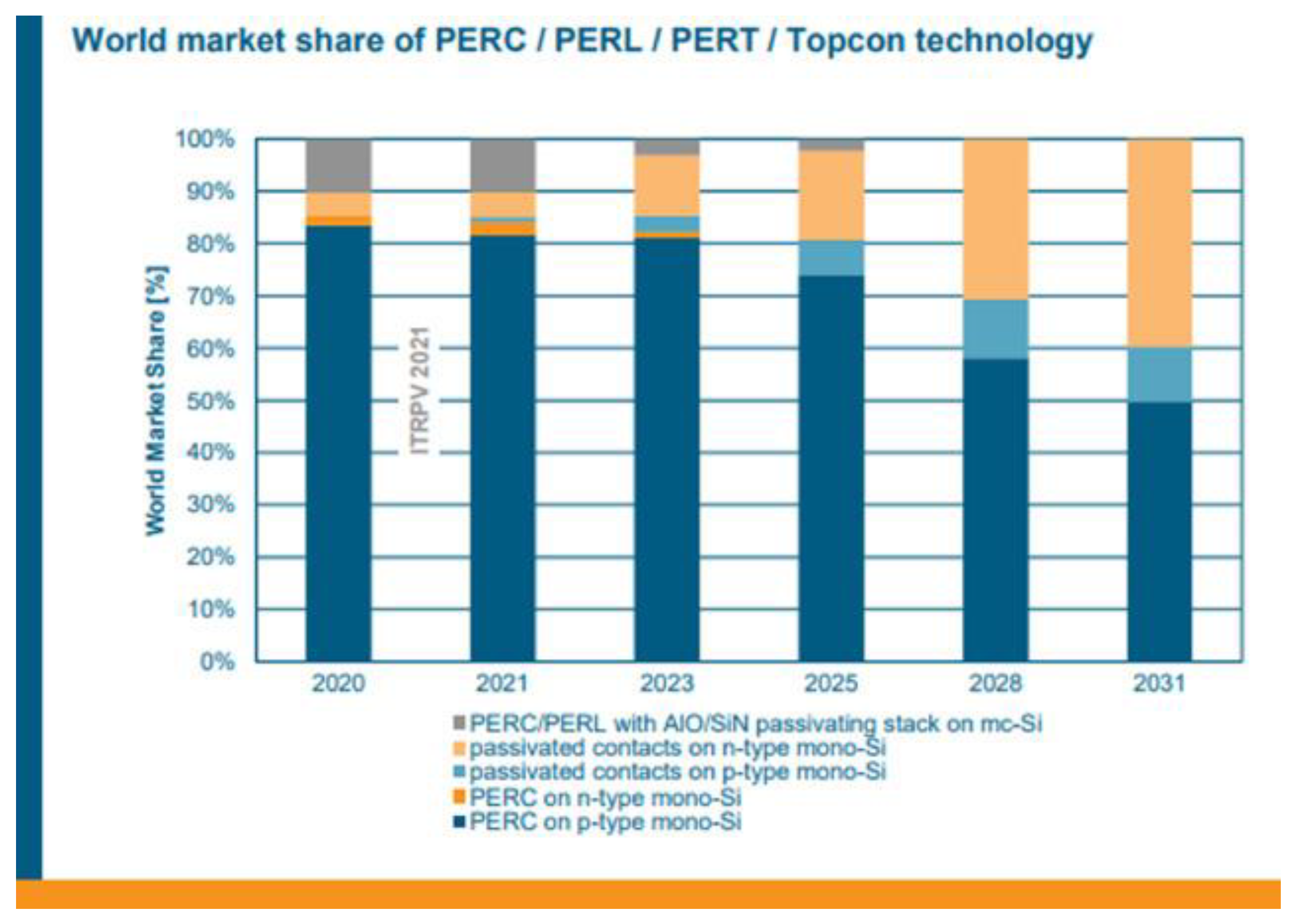

1. Introduction

2. Structure and Electrostatics of TOPCon Solar Cell

3. Configurations of the TOPCon in c-Si-Based Solar Cells

- n-TOPCon rear contact for n-type c-Si solar cell

- p-TOPCon rear contact for p-type c-Si solar cell.

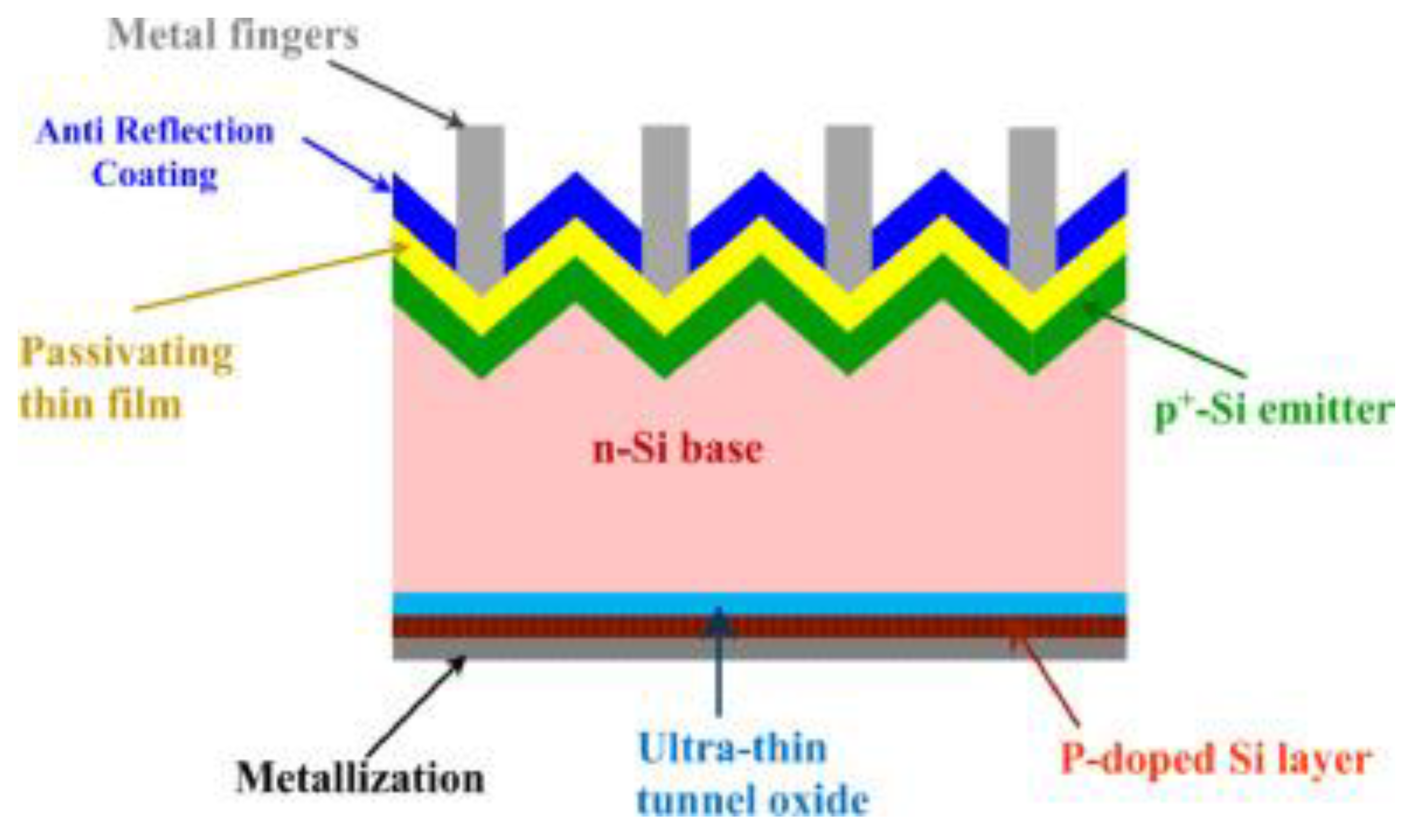

3.1. n-TOPCon Rear Contact for n-Type c-Si Solar Cell

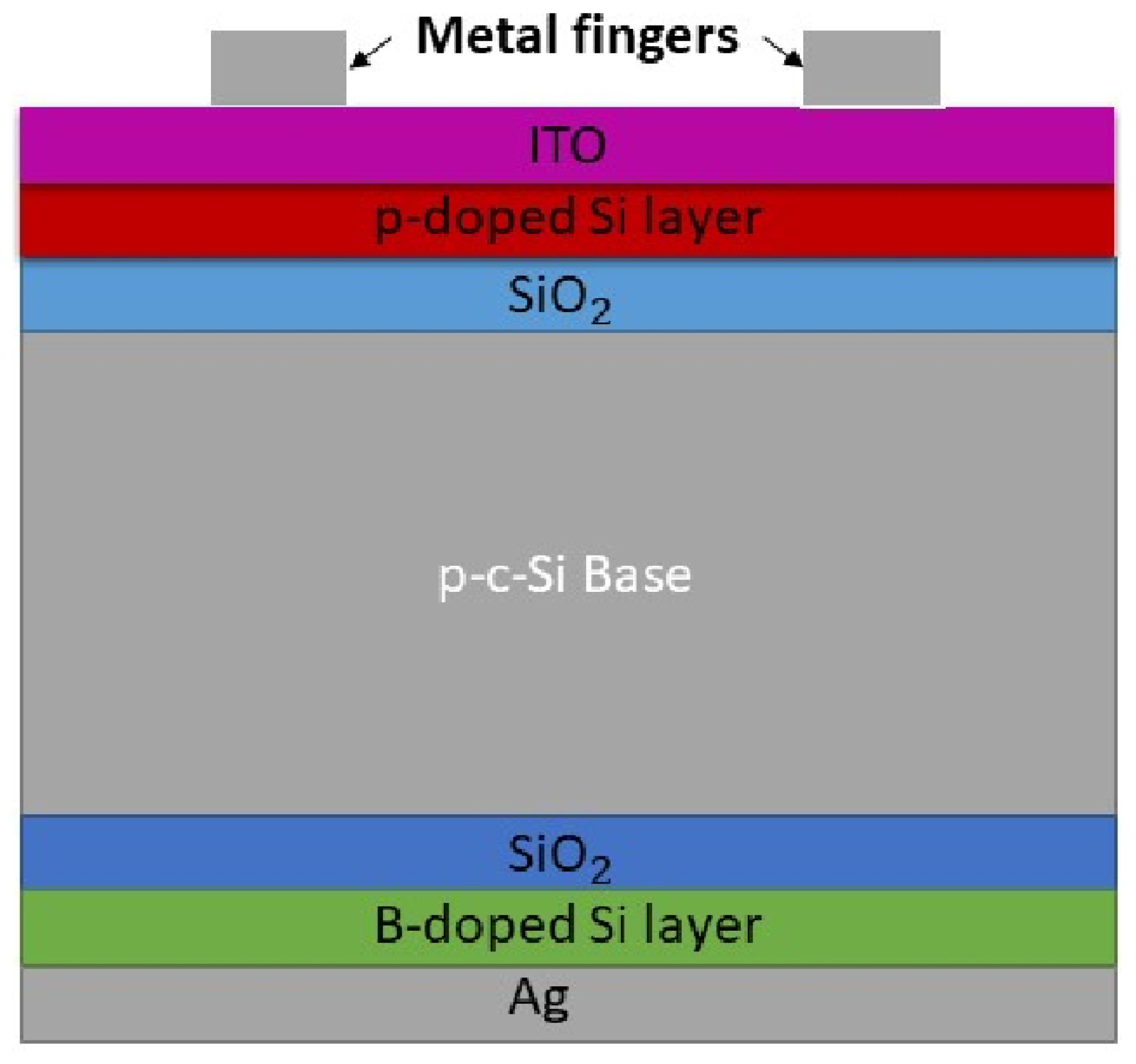

3.2. p-TOPCon Rear Contact for p-Type c-Si Solar Cell

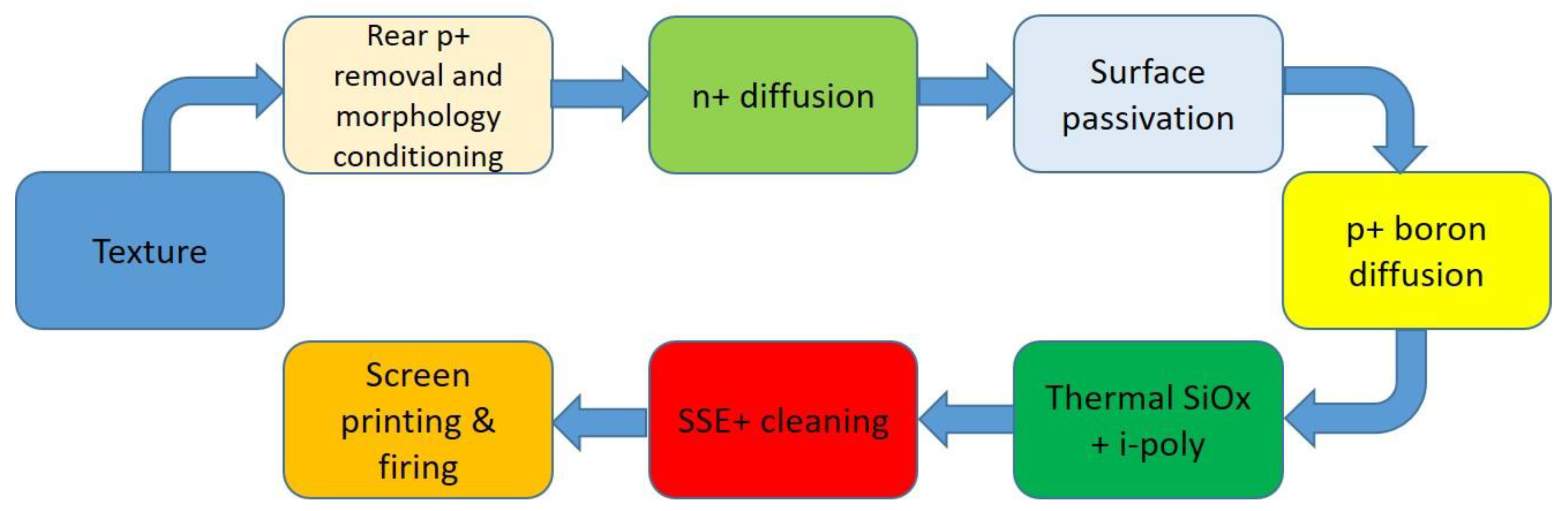

4. Fabrication of TOPCon Solar Cell

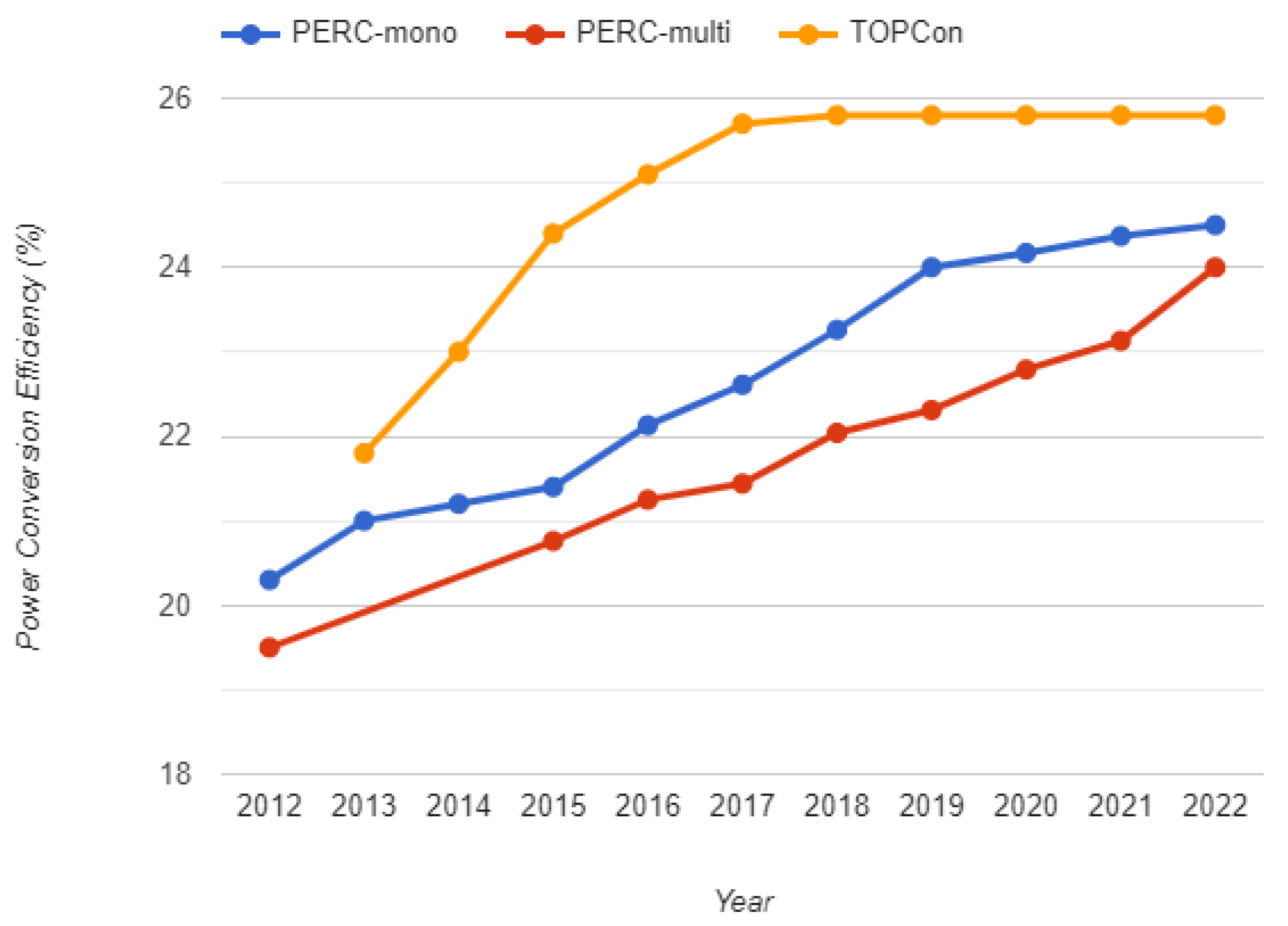

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA) Home Page. Available online: https://iea.blob.core.windows.net/assets/1a24f1fe-c971-4c25-964a-57d0f31eb97b/Renewables_2020-PDF.pdf (accessed on 26 November 2022).

- The International Renewable Energy Agency (IRENA) Home Page. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2021/Apr/IRENA_-RE_Capacity_Highlights_2021.pdf?la=en&hash=1E133689564BC40C2392E85026F71A0D7A9C0B91 (accessed on 23 November 2022).

- Fraunhofer Institute for Solar Energy Systems (ISE) Home Page. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 23 November 2022).

- Blakers, A. Development of the PERC solar cell. IEEE J. Photovolt. 2019, 9, 629–635. [Google Scholar] [CrossRef]

- Richter, A.; Hermle, M.; Glunz, S.W. Reassessment of the limiting efficiency for crystalline silicon solar cells. IEEE J. Photovolt. 2013, 3, 1184–1191. [Google Scholar] [CrossRef]

- Cuevas, A.; Macdonald, D.H. Measuring and interpreting the lifetime of silicon wafers. Sol. Energy 2004, 76, 255–262. [Google Scholar] [CrossRef]

- Green, M.A. The Passivated Emitter and Rear Cell (PERC): From conception to mass production. Sol. Energy Mater Sol. Cells. 2015, 143, 190–197. [Google Scholar] [CrossRef]

- Kumar, A.; Bieri, M.; Reindl, T.; Aberle, A.G. Economic viability analysis of silicon solar cell manufacturing: Al-BSF versus PERC. Energy Procedia 2017, 130, 43–49. [Google Scholar] [CrossRef]

- Taguchi, M.; Terakawa, A.; Maruyama, E.; Tanaka, M. Obtaining a higher Voc in HIT cells. Prog. Photovolt. Res. Appl. 2005, 13, 481–488. [Google Scholar] [CrossRef]

- Taguchi, M.; Yano, A.; Tohoda, S.; Matsuyama, K.; Nakamura, Y.; Nishiwaki, T.; Fujita, K.; Maruyama, E. 24.7% record efficiency HIT solar cell on thin silicon wafer. IEEE J. Photovolt. 2013, 4, 96–99. [Google Scholar] [CrossRef]

- Masuko, K.; Shigematsu, M.; Hashiguchi, T.; Fujishima, D.; Kai, M.; Yoshimura, N.; Yamaguchi, T.; Ichihashi, Y.; Mishima, T.; Matsubara, N.; et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 2014, 4, 1433–1435. [Google Scholar] [CrossRef]

- Baert, K.A.; Roggen, J.; Nijs, J.F.; Mertens, R.P. Amorphous-silicon solar cells with screen-printed metallization. IEEE Trans. Electron. Devices 1990, 37, 702–707. [Google Scholar] [CrossRef]

- Melskens, J.; Smets, A.H.M.; Schouten, M.; Eijt, S.W.H.; Schut, H.; Zeman, M. New insights in the nanostructure and defect states of hydrogenated amorphous silicon obtained by annealing. IEEE J. Photovolt. 2013, 3, 65–71. [Google Scholar] [CrossRef]

- Holman, Z.C.; Descoeudres, A.; Barraud, L.; Fernandez, F.Z.; Seif, J.P.; De Wolf, S.; Ballif, C. Current losses at the front of silicon heterojunction solar cells. IEEE J. Photovolt. 2012, 2, 7–15. [Google Scholar] [CrossRef]

- Imran, H.; Abdolkader, T.M.; Butt, N.Z. Carrier-selective NiO/Si and TiO2/Si contacts for silicon heterojunction solar cells. IEEE Trans. Electron. Devices 2016, 63, 3584–3590. [Google Scholar] [CrossRef]

- Ullah, H.; Imran, H.; Butt, N.Z. Modeling of TiO2-Based Electron-Selective Contacts for Crystalline Silicon Solar Cells. IEEE Trans. Electron. Devices 2018, 65, 4421–4428. [Google Scholar] [CrossRef]

- Nagamatsu, K.A.; Avasthi, S.; Sahasrabudhe, G.; Man, G.; Jhaveri, J.; Berg, A.H.; Schwartz, J.; Kahn, A.; Wagner, S.; Sturm, J.C. Titanium dioxide/silicon hole-blocking selective contact to enable double-heterojunction crystalline silicon-based solar cell. Appl. Phys. Lett. 2015, 106, 123906. [Google Scholar] [CrossRef]

- Stodolny, M.K.; Lenes, M.; Wu, Y.; Janssen, G.; Romijn, I.G.; Luchies, J.; Geerligs, L.J. n-Type polysilicon passivating contact for industrial bifacial n-type solar cells. Sol. Energy Mater. Sol. Cells 2016, 158, 24–28. [Google Scholar] [CrossRef]

- Tao, Y.; Upadhyaya, V.; Chen, C.W.; Payne, A.; Chang, E.L.; Upadhyaya, A.; Rohatgi, A. Large area tunnel oxide passivated rear contact n-type Si solar cells with 21.2% efficiency. Prog. Photovolt. Res. Appl. 2016, 24, 830–835. [Google Scholar] [CrossRef]

- Swanson, R.M. A proposed thermophotovoltaic solar energy conversion system. Proc. IEEE 1979, 67, 446–447. [Google Scholar] [CrossRef]

- Green, M.A.; Blakers, A.W. Advantages of metal-insulator-semiconductor structures for silicon solar cells. Sol. Cells 1983, 8, 3–16. [Google Scholar] [CrossRef]

- Inoue, N.; Miyakawa, T.; Wilmsen, C.W. An analysis of EBIC Response of ITO/poly-Si Solar cells. JJAP 1981, 20, 11–15. [Google Scholar] [CrossRef]

- Yablonovitch, E.; Gmitter, T.; Swanson, R.M.; Kwark, Y.H. A 720 mV open circuit voltage SiO x: C-Si: SiO x double heterostructure solar cell. Appl. Phys. Lett. 1985, 47, 1211–1213. [Google Scholar] [CrossRef]

- Tarr, N.G. A polysilicon emitter solar cell. IEEE Electron. Device Lett. 1985, 6, 655–658. [Google Scholar] [CrossRef]

- Lindholm, F.A.; Neugroschel, A.; Arienzo, M.; Iles, P.A. Heavily doped polysilicon-contact solar cells. IEEE Electron. Device Lett. 1985, 6, 363–365. [Google Scholar] [CrossRef]

- Kwark, Y.H.; Swanson, R.M. N-type SIPOS and poly-silicon emitters. Solid-State Electron. 1987, 30, 1121–1125. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. Passivated rear contacts for high-efficiency n-type Si solar cells providing high interface passivation quality and excellent transport characteristics. Sol. Energy Mater. Sol. Cells 2014, 120, 270–274. [Google Scholar] [CrossRef]

- Robertson, J. Band offsets of wide-band-gap oxides and implications for future electronic devices. J. Vac. Sci. Technol. B 2000, 18, 1785–1791. [Google Scholar] [CrossRef]

- Younas, R.; Imran, H.; Shah, S.I.; Abdolkader, T.M.; Butt, N.Z. Computational modeling of polycrystalline silicon on oxide passivating contact for silicon solar cells. IEEE Trans. Electron. Devices 2019, 66, 1819–1826. [Google Scholar] [CrossRef]

- Hollemann, C.; Haase, F.; Schafer, S.; Krügener, J.; Brendel, R.; Peibst, R. 26.1%- efficient POLO-IBC cells: Quantification of electrical and optical loss mechanisms. Prog. Photovolt. Res. Appl. 2019, 27, 950–958. [Google Scholar] [CrossRef]

- Rohatgi, A.; Rounsaville, B.; Ok, Y.W.; Tam, A.M.; Zimbardi, F.; Upadhyaya, A.D.; Tao, Y.; Madani, K.; Richter, A.; Benick, J.; et al. Fabrication and modeling of high-efficiency front junction n-type silicon solar cells with tunnel oxide passivating back contact. IEEE J. Photovolt. 2017, 7, 1236–1243. [Google Scholar] [CrossRef]

- Peibst, R.; Römer, U.; Larionova, Y.; Rienäcker, M.; Merkle, A.; Folchert, N.; Reiter, S.; Turcu, M.; Min, B.; Krügener, J.; et al. Working principle of carrier selective poly-Si/c-Si junctions: Is tunnelling the whole story? Sol. Energy Mater. Sol. Cells 2016, 158, 60–67. [Google Scholar] [CrossRef]

- Römer, U. Polycrystalline Silicon/Monocrystalline Silicon Junctions and Their Application as Passivated Contacts for Si Solar Cells. Doctoral Thesis, Gottfried Wilhelm Leibniz Universität Hannover, Hannover, Germany, 2016. Available online: https://www.repo.uni-hannover.de/handle/123456789/8614?locale-attribute=en (accessed on 22 November 2022).

- Römer, U.; Peibst, R.; Ohrdes, T.; Lim, B.; Krügener, J.; Wietler, T.; Brendel, R. Ion implantation for poly-Si passivated back-junction back-contacted solar cells. IEEE J. Photovolt. 2015, 5, 507–514. [Google Scholar] [CrossRef]

- Rienäcker, M.; Bossmeyer, M.; Merkle, A.; Römer, U.; Haase, F.; Krügener, J.; Brendel, R.; Peibst, R. Junction resistivity of carrier-selective polysilicon on oxide junctions and its impact on solar cell performance. IEEE J. Photovolt. 2017, 7, 11–18. [Google Scholar] [CrossRef]

- Richter, A.; Benick, J.; Feldmann, F.; Fell, A.; Hermle, M.; Glunz, S.W. n-Type Si solar cells with passivating electron contact: Identifying sources for efficiency limitations by wafer thickness and resistivity variation. Sol. Energy Mater. Sol. Cells 2017, 173, 96–105. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (Version 58). Prog. Photovolt. Res. Appl. 2021, 29, 657–667. [Google Scholar] [CrossRef]

- Shaw, V. Pv Magazine Home Page. Available online: https://www.pv-magazine.com/2021/05/03/longi-sets-topcon-cell-record-of-25-09/ (accessed on 23 November 2022).

- International Technology Roadmap for Photovoltaic (ITRPV) Home Page. Available online: https://itrpv.vdma.org/documents/27094228/67038244/2021-04-29%20PR%20VDMA%20PV%20ITRPV%202021%20EN_1619690887765.pdf/644380bd-85a3-99d9-e25f-c4ccc6556e64 (accessed on 23 November 2022).

- Ghosh, D.K.; Bose, S.; Das, G.; Acharyya, S.; Nandi, A.; Mukhopadhyay, S.; Sengupta, A. Fundamentals, present status and future perspective of TOPCon solar cells: A comprehensive review. Surf. Interfaces 2022, 30, 101917. [Google Scholar] [CrossRef]

- Wilson, G.M.; Al-Jassim, M.; Metzger, W.K.; Glunz, S.W.; Verlinden, P.; Xiong, G.; Mansfield, L.M.; Stanbery, B.J.; Zhu, K.; Yanfa, Y.; et al. The 2020 photovoltaic technologies roadmap. J. Phys. D. 2020, 53. [Google Scholar] [CrossRef]

- Kafle, B.; Goraya, B.S.; Mack, S.; Feldmann, F.; Nold, S.; Rentsch, J. TOPCon–Technology options for cost efficient industrial manufacturing. Sol. Energy Mater. Sol. Cells 2021, 227, 111100. [Google Scholar] [CrossRef]

- Yang, X.; Weber, K. N-type silicon solar cells featuring an electron-selective TiO2 contact. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC 2015), New Orleans, LA, USA, 14–19 June 2015; pp. 1–4. [Google Scholar]

- Yang, X.; Bi, Q.; Ali, H.; Davis, K.; Schoenfeld, W.V.; Weber, K. High-performance TiO2-based electron-selective contacts for crystalline silicon solar cells. Adv. Mater. 2016, 28, 5891–5897. [Google Scholar] [CrossRef]

- Macco, B.; Vos, M.F.; Thissen, N.F.; Bol, A.A.; Kessels, W.M. Low-temperature atomic layer deposition of MoOx for silicon heterojunction solar cells. Phys. Status Solidi RRL Rapid Res. Lett. 2015, 9, 393–396. [Google Scholar] [CrossRef]

- Bivour, M.; Temmler, J.; Steinkemper, H.; Hermle, M. Molybdenum and tungsten oxide: High work function wide band gap contact materials for hole selective contacts of silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 34–41. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. A passivated rear contact for high-efficiency n-type silicon solar cells enabling high Vocs and FF > 82%. In Proceedings of the 28th European PV Solar Energy Conference and Exhibition, Villepinte, France, 30 September–4 October 2013; pp. 988–992. [Google Scholar] [CrossRef]

- Battaglia, C.; De Nicolas, S.M.; De Wolf, S.; Yin, X.; Zheng, M.; Ballif, C.; Javey, A. Silicon heterojunction solar cell with passivated hole selective MoOx contact. Appl. Phys. Lett. 2014, 104, 113902. [Google Scholar] [CrossRef]

- Kiaee, Z.; Fellmeth, T.; Steinhauser, B.; Reichel, C.; Nazarzadeh, M.; Nölken, A.C.; Keding, R. TOPCon Silicon Solar Cells with Selectively Doped PECVD Layers Realized by Inkjet-Printing of Phosphorus Dopant Sources. IEEE J. Photovolt. 2021, 13, 31–37. [Google Scholar] [CrossRef]

- Feldmann, F.; Simon, M.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. Efficient carrier-selective p-and n-contacts for Si solar cells. Sol. Energy Mater. Sol. Cells 2014, 131, 100–104. [Google Scholar] [CrossRef]

- Chen, D.; Chen, Y.; Wang, Z.; Gong, J.; Liu, C.; Zou, Y.; He, Y.; Wang, Y.; Yuan, L.; Lin, W.; et al. 24.58% total area efficiency of screen-printed, large area industrial silicon solar cells with the tunnel oxide passivated contacts (i-TOPCon) design. Sol. Energy Mater. Sol. Cells 2020, 206, 110258. [Google Scholar] [CrossRef]

- Bullock, J.; Cuevas, A.; Allen, T.; Battaglia, C. Molybdenum oxide MoOx: A versatile hole contact for silicon solar cells. Appl. Phys. Lett. 2014, 105, 232109. [Google Scholar] [CrossRef]

| Single Junction Structure | Cell Efficiency (%) | Cell Area (cm2) | Year | Group/Institute |

|---|---|---|---|---|

| p-type PERC | 25.0 | 4 | 1998 | UNSW |

| IBC | 25.2 | 153.5 | 2012 | SunPower |

| HIT Rear Junction | 25.6 | 143.7 | 2014 | Panasonic |

| TOPCon | 25.7 | 4 | 2017 | Fraunhofer |

| HBC | 26.7 | 79 | 2017 | Kaneka |

| p-type POLO-IBC | 26.1 | 3.98 | 2018 | ISFH |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, H.; Czapp, S.; Szultka, S.; Tariq, H.; Qasim, U.B.; Imran, H. Crystalline Silicon (c-Si)-Based Tunnel Oxide Passivated Contact (TOPCon) Solar Cells: A Review. Energies 2023, 16, 715. https://doi.org/10.3390/en16020715

Ullah H, Czapp S, Szultka S, Tariq H, Qasim UB, Imran H. Crystalline Silicon (c-Si)-Based Tunnel Oxide Passivated Contact (TOPCon) Solar Cells: A Review. Energies. 2023; 16(2):715. https://doi.org/10.3390/en16020715

Chicago/Turabian StyleUllah, Hayat, Stanislaw Czapp, Seweryn Szultka, Hanan Tariq, Usama Bin Qasim, and Hassan Imran. 2023. "Crystalline Silicon (c-Si)-Based Tunnel Oxide Passivated Contact (TOPCon) Solar Cells: A Review" Energies 16, no. 2: 715. https://doi.org/10.3390/en16020715

APA StyleUllah, H., Czapp, S., Szultka, S., Tariq, H., Qasim, U. B., & Imran, H. (2023). Crystalline Silicon (c-Si)-Based Tunnel Oxide Passivated Contact (TOPCon) Solar Cells: A Review. Energies, 16(2), 715. https://doi.org/10.3390/en16020715