Determination and Modeling of Proximate and Thermal Properties of De-Watered Cassava Mash (Manihot esculenta Crantz) and Gari (Gelatinized cassava mash) Traditionally Processed (In Situ) in Togo

Abstract

1. Introduction

2. Material and Methods

2.1. Description of the Study Area

- Coopérative des femmes NOVIVA de Tokpo, code-named as NOVIVA;

- Agro Pastoral (Ganave) code-named as AP;

- An individual processor in Ganave, code-named as AT;

- An individual processor in Wogba, Vagan) code-named as WB;

- Coopérative d’Action pour le Développement (CAD) de (Wogba, Vagan) code-named as CAD.

2.2. Sampling and Data Collection

2.3. Raw Materials

2.3.1. Cassava Samples

- (a)

- Coopérative des femmes NOVIVA, code-named NVC (used for processing gari using four cookstoves code-named NVCS1, NVCS2, NVCS3 and NVCS4);

- (b)

- Agro Pastoral code-named as APC. The de-watered cassava mash was used for gari processing at AP and AT with a cookstove code-named APCS and ATCS, respectively;

- (c)

- Coopérative d’Action pour le Développement (CAD) de in Wogba, Vagan code-named as CADC. Processed into gari at participant WB’s facility with cookstoves WBCS1 and WBCS2 and at CAD with a cookstove code-named CADCS.

2.3.2. Experimental Methodology

2.4. Proximate Composition Determination

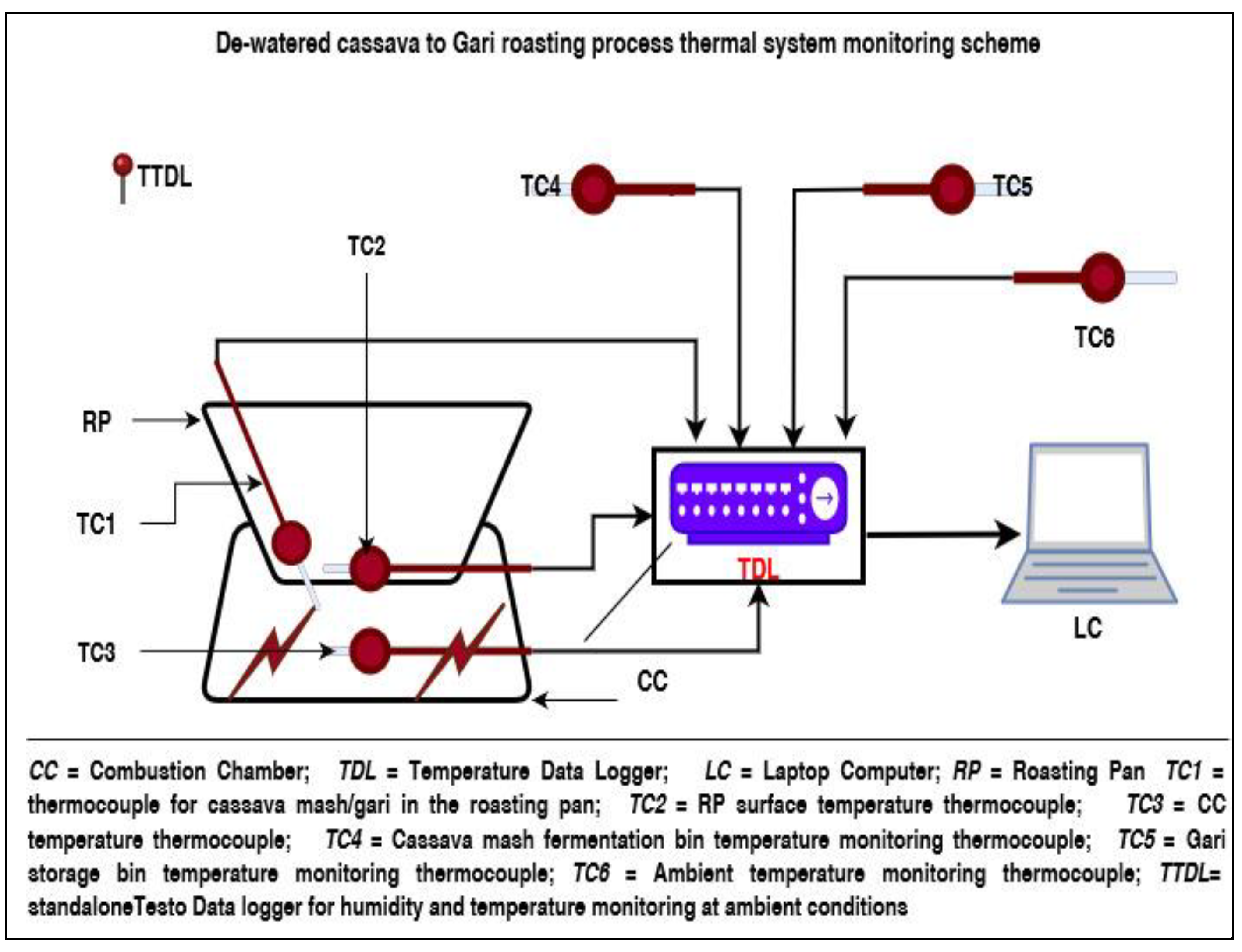

2.5. Determination of Temperatures

2.6. Determination of Density and Thermal Properties

| Thermal Property | Food Component | Thermal Property Model | |

|---|---|---|---|

| Thermal conductivity, W/(m·°C) | Water | (2) | |

| Protein | |||

| Fat | |||

| Carbohydrate | |||

| Fiber | |||

| Ash | |||

| Density (kg/m3) | Water | ||

| Protein | |||

| Fat | |||

| Carbohydrate | |||

| Fiber | |||

| Ash | |||

| Specific Heat J/(kg·°C) | Water | ||

| Protein | |||

| Fat | |||

| Carbohydrate | |||

| Fiber | |||

| Ash |

2.6.1. Thermal Conductivity

2.6.2. Determination of Specific Heat Capacities

2.6.3. True Density Determination

2.6.4. Thermal Diffusivity Determination

2.6.5. Prediction Models Validation (Average Percentage Errors Method)

- Specific heat capacities: Differential scanning calorimeter [28];

2.7. Statistical Analysis

3. Results and Discussion

3.1. Mean Operations Parameters Achieved

3.2. Proximate Analysis of Cassava and Gari

3.3. Thermal Properties and Density

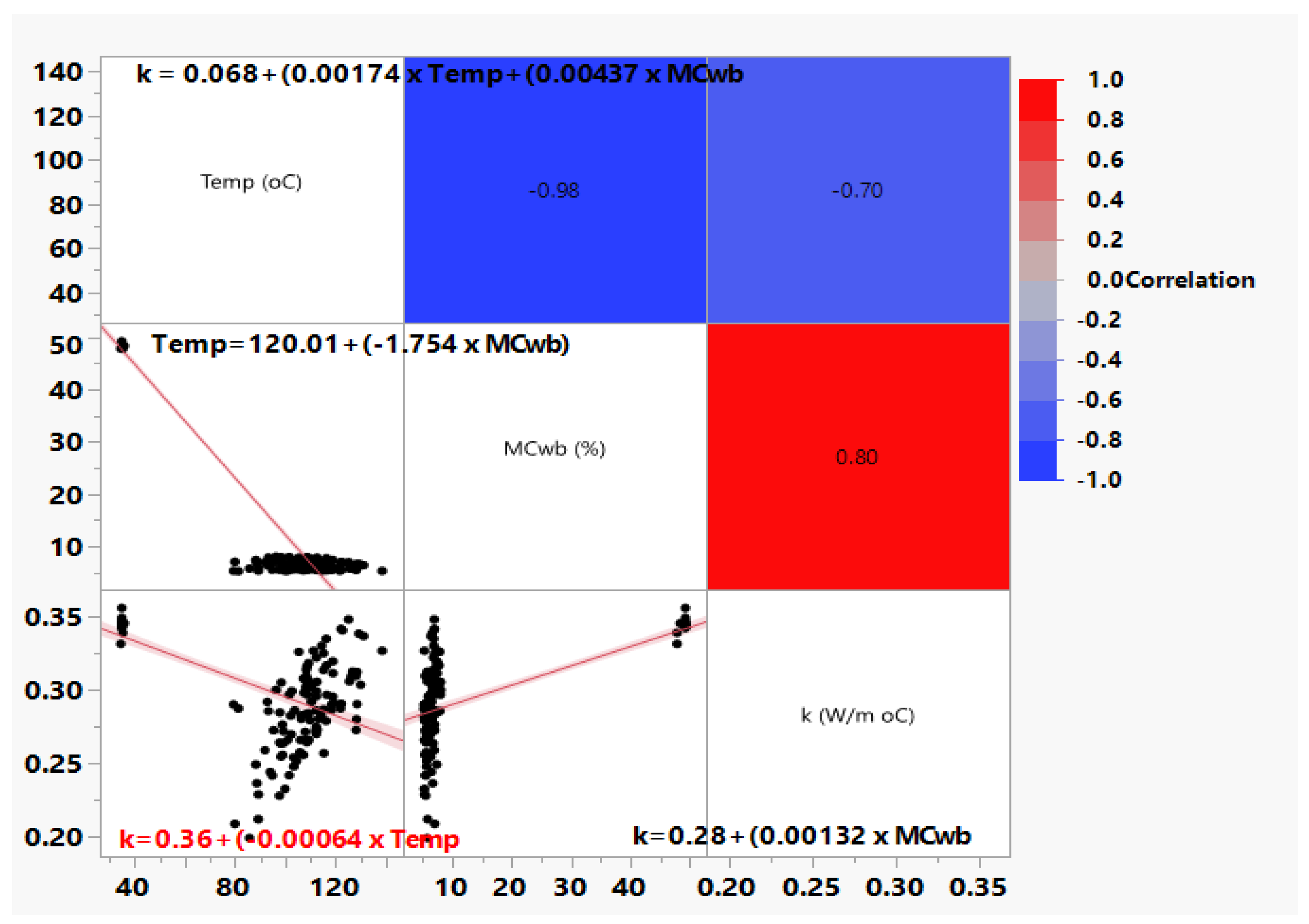

3.3.1. Thermal Conductivities

Correlation and Prediction Models of Thermal Conductivity, Temperature and Moisture

Validation of k Prediction Models

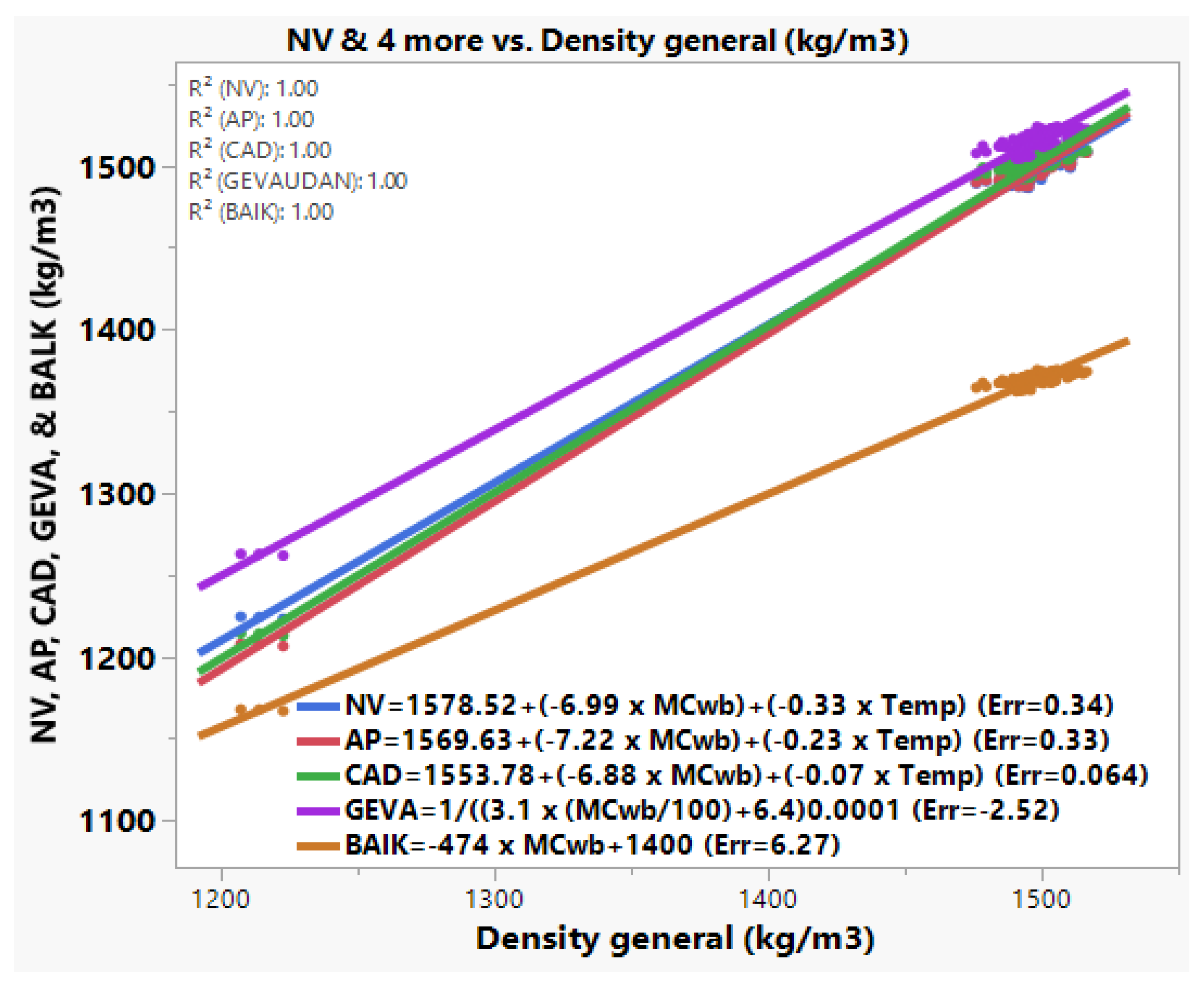

3.3.2. Density

Correlation and Prediction Models of Moisture, Temperature and Density

Validation of Density Prediction Models

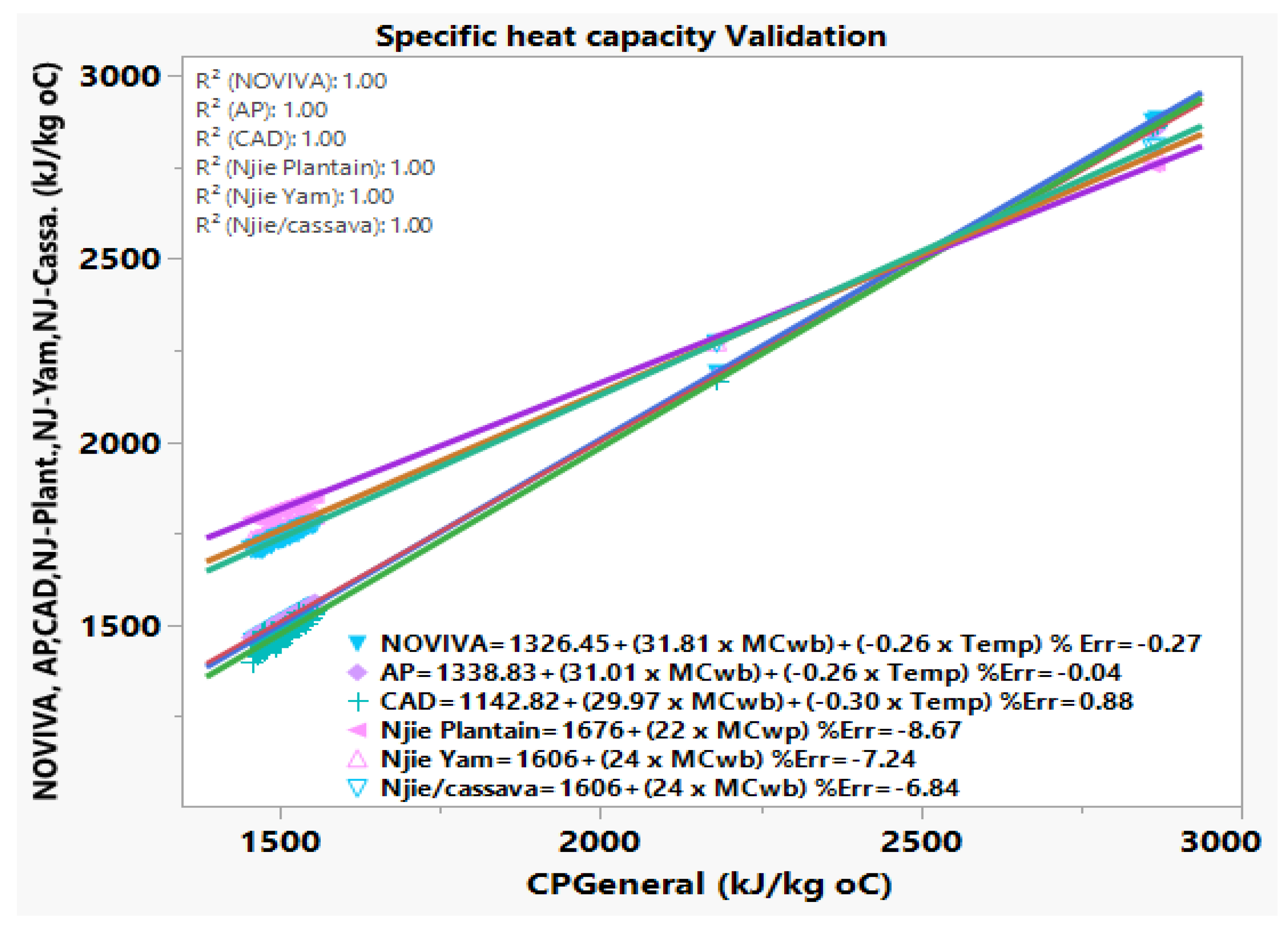

3.3.3. Specific Heat Capacities

Correlation and Prediction Models of Cp MCwb and Temperature

Validation of the Cp Models

3.3.4. Thermal Diffusivity

3.4. Multivariate Interaction Analysis of All Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carson, J.K.; Wang, J.; North, M.F.; Cleland, D.J. Effective thermal conductivity prediction of foods using composition and temperature data. J. Food Eng. 2016, 175, 65–73. [Google Scholar] [CrossRef]

- Choi, Y.-H. Effects of Temperature and Composition on the Thermal Conductivity and Thermal Diffusivity of Some Food Components. Korean J. Food Sci. Technol. 1986, 18, 357–363. [Google Scholar]

- Heldman, D.R. Food preservation process design. Procedia Food Sci. 2011, 1, 685–689. [Google Scholar] [CrossRef][Green Version]

- Tan, L.W.; Ibrahim, M.N.; Kamil, R.; Taip, F.S. Empirical modeling for spray drying process of sticky and non-sticky products. Procedia Food Sci. 2011, 1, 690–697. [Google Scholar] [CrossRef]

- Baik, O.; Mittal, G.S. Determination and Modeling of Thermal Properties of Tofu. Int. J. Food Prop. 2007, 6, 9–24. [Google Scholar] [CrossRef]

- Gevaudan, A.; Chuzel, G.; Didier, S.; Andrieu, J. Physical properties of cassava mash. Int. J. Food Sci. Technol. 1989, 24, 637–645. [Google Scholar] [CrossRef]

- Modi, S.K.; Prasad, B.D.; Basavaraj, M. Effect of moisture content and temperature on thermal conductivity of Psidium guajava L. by line heat source method (transient analysis). Int. J. Heat Mass Transf. 2014, 78, 354–359. [Google Scholar] [CrossRef]

- Ngoualem Kégah, F.; Ndjouenkeu, R. Gari, a Cassava (Manihot esculenta Crantz) Derived Product: Review on Its Quality and Their Determinants. J. Food Qual. 2023, 2023, 7238309. [Google Scholar] [CrossRef]

- Abass, A.B.; Dziedzoave, N.T.; Alenkhe, B.E.; James, B.D. Quality Management Manual for the Production of Gari. 2012. Available online: www.iita.org (accessed on 13 July 2023).

- Chuzel, G.; Gévaudan, A.; Griffon, D. Cassava processing for gari production. In Proceedings of the Agricultural Engineering International Conference, Paris, France, 2–5 March 1988. [Google Scholar]

- Laya, A.; Koubala, B.B.; Kouninki, H.; Nukenine, E.N. Effect of Harvest Period on the Proximate Composition and Functional and Sensory Properties of Gari Produced from Local and Improved Cassava (Manihot esculenta) Varieties. Int. J. Food Sci. 2018, 2018, 6241035. [Google Scholar] [CrossRef]

- Ajewole, P.O.; Adeosun, E.O. Design Analysis of a Cassava Mash Roaster. 2018. Available online: www.globalscientificjournal.comwww.globalscientificjournal.com (accessed on 13 July 2023).

- Ibrahim, J.S.; Gaji, M.M. Energy Use Patterns of Local Gari Production Industries in North Central Nigeria. 2016. Available online: www.ijrrset.com (accessed on 16 July 2023).

- SustainCERT. SustainCERT Home. Website. 2023. Available online: https://www.sustain-cert.com/ (accessed on 25 June 2023).

- Choi, Y.H.; Okos, M.R. Effect of Food Temperature and Composition on the Thermal Properties of Food. Food Eng. Process Appl. Transp. Phenom. Elsevier 1986, 1, 99–101. Available online: https://iifiir.org/en/fridoc/effect-of-food-temperature-and-composition-on-the-thermal-properties-of-82845 (accessed on 5 February 2023).

- Naderifar, M.; Goli, H.; Ghaljaie, F. Snowball Sampling: A Purposeful Method of Sampling in Qualitative Research. Strides Dev. Med. Educ. 2017, 14, 1–6. [Google Scholar] [CrossRef]

- Ajibola, O.O.; Ige, M.T.; Makanjuola, G.A. Preliminary studies of a new technique of cassava mash gelatinization. J. Agric. Eng. Res. 1987, 36, 97–100. [Google Scholar] [CrossRef]

- (Cereals & Grains Association) CGA. Approved Methods of Analysis. 2023. Available online: https://www.cerealsgrains.org/resources/methods/Pages/default.aspx (accessed on 7 February 2023).

- (FuehlerSysteme eNET International) FSI. DATA SHEET MT1/T Sheathed Thermocouple with TC-Mini-Connector. 2023. Available online: www.fuehlersysteme.de (accessed on 1 February 2023).

- (John Fluke Mfg. Co. Inc) JFM. Hydra Series II Data Acquisition Unit Hydra Series II Data Logger Users Manual. 1997. Available online: https://eu.flukecal.com/de/literature/product-manuals/2620a2625a-hydra-series-data-acquisition-unitdata-logger-users-manual (accessed on 23 October 2022).

- Sahin, S.; Sumnu, S.G. Thermal Properties of Foods. In Physical Properties of Foods; Springer: New York, NY, USA, 2007; pp. 107–155. [Google Scholar]

- Sanni, L.A.; Oke, O.O.; Oladimeji, F.M.; Ogbozomivaze, K.F. Thermal Properties and Energy Utilization of Cassava Meal in Conductive Rotary Drying. Am. J. Food Sci. Technol. 2016, 4, 160–167. [Google Scholar] [CrossRef]

- Dahdouh, L.; Escobar, A.; Rondet, E.; Ricci, J.; Fliedel, G.; Adinsi, L.; Dufour, D.; Cuq, B.; Delalonde, M. Role of dewatering and roasting parameters in the quality of handmade gari. Int. J. Food Sci. Technol. 2021, 56, 1298–1310. [Google Scholar] [CrossRef]

- Erdogdu, F.; Linke, M.; Praeger, U.; Geyer, M.; Schlüter, O. Experimental determination of thermal conductivity and thermal diffusivity of whole green (unripe) and yellow (ripe) Cavendish bananas under cooling conditions. J. Food Eng. 2013, 128, 46–52. [Google Scholar] [CrossRef]

- Kustermann, M.; Scherer, R.; Kutzbach, H.D. Thermal Conductivity and Diffusivity of Shelled Corn and Grain. J. Food Process Eng. 1981, 4, 137–153. [Google Scholar] [CrossRef]

- Sweat, V.E. Experimental Values of Thermal Conductivity of Selected Fruits and Vegetables. J. Food Sci. 1974, 39, 1080–1083. [Google Scholar] [CrossRef]

- Cansee, S.; Watyotha, C.; Thivavarnvongs, T.; Uriyapongson, J.; Varith, J. Effects of Temperature and Concentration on Thermal Properties of Cassava Starch Solutions. Thaiscience.info. 2008. Available online: https://www.thaiscience.info/journals/Article/SONG/10617681.pdf (accessed on 22 May 2023).

- Njie, D.N.; Rumsey, T.R.; Singh, R.P. Thermal Properties of Cassava, Yam and Plantain. J. Food Eng. 1998, 37, 63–76. [Google Scholar] [CrossRef]

- Ayetigbo, O.; Latif, S.; Idris, W.; Müller, J. Physical properties of white-fleshed and yellow-fleshed cassava (Manihot esculenta) foam powder. Powder Technol. 2023, 420, 118366. [Google Scholar] [CrossRef]

- Oriola, K.O. Effects of Ageing and Moisture Content on Thermal Properties of Cassava Roots Using Response Surface Methodology. Int. J. Appl. Agric. Apic. Res. 2016, 10, 54–63. Available online: https://www.ajol.info/index.php/ijaaar/article/view/141508 (accessed on 22 June 2023).

- Hassan, H.F.; Ramaswamy, H.S. Measurement and targeting of thermophysical properties of carrot and meat based alginate particles for thermal processing applications. J. Food Eng. 2011, 107, 117–126. [Google Scholar] [CrossRef]

- Daniel, W.W.; Chad, C.L. 5.3 Distribution of the Sample Mean. In Biostatistics: A Foundation for Analysis in the Health Sciences; Hoboken, N., Ed.; Wiley Publishing, Inc.: New York, NY, USA, 2018; p. 120. [Google Scholar]

- Sobowale, S.S.; Adebiyi, J.A.; Adebo, O.A. Design, construction, and performance evaluation of a gari roaster. J. Food Process Eng. 2017, 40, e12493. [Google Scholar] [CrossRef]

- Akinoso, R.; Kasali, W.O. Energy Expended in Processing Gari (Cassava Flakes) Manihot esculenta Crantz, Using Three Levels of Mechanization. Pakistan J. Sci. Ind. Res. Ser. B Biol. Sci. 2012, 55, 114–116. [Google Scholar] [CrossRef]

- Oke, O.L. Chemical Studies on Some Nigerian Foodstuffs—‘Gari’. Nature 1966, 212, 1055–1056. [Google Scholar] [CrossRef] [PubMed]

- Akely, P.M.T.; Gnagne, E.H.; Lou, G.M.L.T.T.; Amani, G.N.G. Varietal influence of cassava on chemical composition and consumer acceptability of gari. Int. J. Food Sci. Technol. 2021, 56, 1239–1246. [Google Scholar] [CrossRef]

- Rajapaksha, K.D.S.C.N.; Somendrika, M.A.D.; Wickramasinghe, I. Nutritional and toxicological composition analysis of selected cassava processed products. Potravin. Slovak J. Food Sci. 2017, 11, 35–42. Available online: https://www.potravinarstvo.com/journal1/index.php/potravinarstvo/article/view/689/pdf (accessed on 5 July 2020).

- Nwabanne, J.T. Drying characteristics and engineering properties of fermented ground cassava. Afr. J. Biotechnol. 2010, 8, 873–876. [Google Scholar] [CrossRef]

- Olapade, G.M.; Karim, O.R.; Olawuyi, I.F.; Karim, C.R.O. Physicochemical, thermal, and functional properties of gari (fermented-cassava product) enriched with cowpea hull at different stages of production. Food Bioeng. 2023, 2, 42–52. [Google Scholar] [CrossRef]

- Krishnakumar, T.; Sajeev, M.S.; Pradeepika, C.; Namrata, A.G.; Sanket, J.M.; Jeevarathinam, G.; Muthusamy, V. Physical and mechanical properties of cassava (Manihot esculenta Crantz) cultivars: Implications for the design of mechanical peeling machines. J. Food Process Eng. 2022, 45, e13923. [Google Scholar] [CrossRef]

- Ndam, Y.N.; Mounjouenpou, P.; Kansci, G.; Kenfack, M.J.; Meguia, M.P.F.; Eyenga, N.S.N.N.; Akhobakoh, M.M.; Nyegue, A. Influence of cultivars and processing methods on the cyanide contents of cassava (Manihot esculenta Crantz) and its traditional food products. Sci. Afr. 2019, 5, e00119. [Google Scholar] [CrossRef]

- Agbodan, K.; Akpavi, S.; Agbodan, K.; Kanda, M.; Amegnaglo, K.; Adrou-Aledji, A.; Batawila, K.; Akpagana, K. Agromorphological description and determination of the antioxidant potential of the underutilized and newly introduced varieties of maize cassava, cowpea and hot pepper in the Maritime-East region of Togo. Afr. J. Food Agric. Nutr. Dev. 2020, 20, 15936–15953. [Google Scholar] [CrossRef]

- Oboh, G.; Akindahunsi, A.A. Biochemical changes in cassava products (flour & gari) subjected to Saccharomyces cerevisae solid media fermentation. Food Chem. 2003, 82, 599–602. [Google Scholar] [CrossRef]

- Ibukun, E.O. Changes in Antinutrient and Nutritional Values of Fermented Eesame (Sesanum indicum), Musk Melon (Cucumis melo) And White Melon. Int. J. Adv. Biotechnol. Res. 2013, 4, 131–214. [Google Scholar]

- Boonnop, K.; Wanapat, M.; Nontaso, N.; Wanapat, S. Enriching nutritive value of cassava root by yeast fermentation. Sci. Agric. 2009, 66, 629–633. [Google Scholar] [CrossRef]

- Fagbemi, A.O.; Ijah, U.J.J. Microbial population and biochemical changes during production of protein-enriched fufu. World J. Microbiol. Biotechnol. 2006, 22, 635–640. [Google Scholar] [CrossRef]

- Padmaja, G.; George, M.; Moorthy, S.N. Detoxification of cassava during fermentation with a mixed culture inoculum. J. Sci. Food Agric. 1993, 63, 473–481. [Google Scholar] [CrossRef]

- Nilusha, R.A.T.; Jayasinghe, J.M.J.K.; Perera, O.D.A.N.; Perera, P.I.P.; Jayasinghe, C.V.L. Proximate Composition, Physicochemical, Functional, and Antioxidant Properties of Flours from Selected Cassava (Manihot esculenta Crantz) Varieties. Int. J. Food Sci. 2021, 2021, 6064545. [Google Scholar] [CrossRef] [PubMed]

- Nuwamanya, E.; Patrick, R.R.; Ssetumba, M.; Samuel, K.; Joseph, F.H.; Yona, B. Biochemical and secondary metabolites changes under moisture and temperature stress in cassava (Manihot esculenta Crantz). Afr. J. Biotechnol. 2014, 13, 3173–3186. [Google Scholar] [CrossRef]

- Rodrigues, B.M.; Souza, B.D.; Nogueira, R.M.; Santos, M.G. Tolerância ao déficit hídrico em plantas jovens de jaqueira e pinheira. Rev. Cienc. Agron. 2010, 41, 245–252. [Google Scholar] [CrossRef]

- Bradbury, J.H.; Bradbury, M.G.; Egan, S.V. Picrate paper kits for determination of total cyanogens in cassava roots and all forms of cyanogens in cassava products. J. Sci. Food Agric. 1999, 79, 593–601. [Google Scholar] [CrossRef]

- Kannangara, R.; Motawia, M.S.; Hansen, N.K.K.; Paquette, S.M.; Olsen, C.E.; Møller, B.L.; Jørgensen, K. Characterization and expression profile of two UDP-glucosyltransferases, UGT85K4 and UGT85K5, catalyzing the last step in cyanogenic glucoside biosynthesis in cassava. Plant J. 2011, 68, 287–301. [Google Scholar] [CrossRef]

- Bradbury, J.H.; Egan, S.V.; Lynch, M.J. Analysis of cyanide in cassava using acid hydrolysis of cyanogenic glucosides. J. Sci. Food Agric. 1991, 55, 277–290. [Google Scholar] [CrossRef]

- Oduro, I.; Ellis, W.O.; Dziedzoave, N.T.; Nimako-Yeboah, K. Quality of gari from selected processing zones in Ghana. Food Control 2000, 11, 297–303. [Google Scholar] [CrossRef]

- Felber, C.; Azouma, Y.O.; Reppich, M. Evaluation of analytical methods for the determination of the physicochemical properties of fermented, granulated, and roasted cassava pulp—Gari. Food Sci. Nutr. 2017, 5, 46–53. [Google Scholar] [CrossRef] [PubMed]

- Hobani, A.I.; Elansari, A.M. Effect of temperature and moisture content on thermal properties of four types of meat part two: Specific heat enthalpy. Int. J. Food Prop. 2008, 11, 571–584. [Google Scholar] [CrossRef]

- Diniz, R.S.; Coimbra, J.S.d.R.; Martins, M.A.; Santos, M.d.O.d.; Diniz, M.D.M.S.; Santos, E.d.S.; Santánna, D.D.; da Rocha, R.A.; de Oliveira, E.B. Physical properties of red guava (Psidium guajava L.) Pulp as affected by soluble solids content and temperature. Int. J. Food Eng. 2014, 10, 437–445. [Google Scholar] [CrossRef]

- Zainal, B.S.; Rahman, R.A.; Ariff, A.B.; Saari, B.N.; Asbi, B.A. Thermophysical Properties of Pink Guava Juice at 9 and 11 Brix. J. Food Process Eng. 2001, 24, 87–100. [Google Scholar] [CrossRef]

- Siddiq, M.; Ahmed, J.; Lobo, M.G.; Ozadali, F. Tropical and Subtropical Fruits: Postharvest Physiology, Processing and Packaging; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 1–631. [Google Scholar] [CrossRef]

- Gratzek, J.P.; Toledo, R.T. Solid Food Thermal Conductivity Determination at High Temperatures. J. Food Sci. 1993, 58, 908–913. [Google Scholar] [CrossRef]

- Zhang, J.; Farkas, B.E.; Hale, S.A. Thermal properties of skipjack tuna (katsuwonus pelamis). Int. J. Food Prop. 2001, 4, 81–90. [Google Scholar] [CrossRef]

- Kara, M.; Boydas, M.G.; Kara, Y.A.; Ozturk, I. The Effect of Moisture Content on the Thermal Properties of Red Lentil Seeds. Trans. ASABE 2012, 55, 2301–2306. [Google Scholar] [CrossRef]

- Xu, C.; Xu, S.; Zhang, Z.; Lin, H. Research on In Situ Thermophysical Properties Measurement during Heating Processes. Nanomaterials 2022, 13, 119. [Google Scholar] [CrossRef]

- Lancaster, P.A.; Ingram, J.S.; Lim, M.Y.; Coursey, D.G. Traditional cassava-based foods: Survey of processing techniques. Econ. Bot. 1982, 36, 12–45. [Google Scholar] [CrossRef]

- Aghogho, C.I.; Eleblu, S.J.Y.; Bakare, M.A.; Kayondo, I.S.; Asante, I.; Parkes, E.Y.; Kulakow, P.; Offei, S.K.; Rabbi, I. Genetic variability and genotype by environment interaction of two major cassava processed products in multi-environments. Front. Plant Sci. 2022, 13, 974795. [Google Scholar] [CrossRef] [PubMed]

- Mwape, M.C.; Muchilwa, I.E.; Siagi, Z.O.; Yamba, F.D. Waste to Energy: Heat Recovery from the Compost Reactor as a Source of Renewable Energy. Int. J. Energy Eng. 2020, 10, 10–15. [Google Scholar] [CrossRef]

- Mwape, M.C.; Muchilwa, I.E.; Siagi, Z.O.; Yamba, F.D. Design and Performance Evaluation of a Hydronic Type Compost Heat Exchanger. Cogent Eng. 2020, 7, 1846253. [Google Scholar] [CrossRef]

| Description | Dry Matter (%) | MCwb (%) | Total Ash (%) | Crude Fiber (%) | Crude Protein (%) | Crude Fat (%) | CHO (%) | pH | HCN (ppm) | Temp (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| NVC | 50.77 ± 0.72 a | 49.23 ± 0.72 f | 1.75 ± 0.02 | 1.31 ± 0.03 d | 2.44 ± 0.02 a | 0.64 ± 0.03 d | 44.64 ± 0.71 de | 6.54 ± 0.17 a | 17.84 ± 0.15 d | 34.82 ± 0.96 z |

| NVG1 | 94.24 ± 0.05 | 5.76 ± 0.05 a | 2.33 ± 0.05 a | 1.99 ± 0.05 a | 1.33 ± 0.06 d | 0.62 ± 0.09 d | 87.98 ± 0.10 a | 4.09 ± 0.29 | 3.17 ± 0.01 a | 111.44 ± 0.56 c |

| NVG2 | 92.63 ± 0.05 | 7.37 ± 0.05 b | 2.36 ± 0.05 a | 2.05 ± 0.06 a | 1.31 ± 0.03 d | 0.65 ± 0.04 d | 86.25 ± 0.19 b | 4.18 ± 0.05 e | 3.25 ± 0.03 b | 104.51 ± 1.15 a |

| NVG3 | 94.55 ± 0.07 | 5.45 ± 0.07 a | 2.33 ± 0.05 a | 2.00 ± 0.11 a | 1.37 ± 0.05 d | 0.62 ± 0.01 d | 88.24 ± 0.04 c | 4.13 ± 0.07 e | 3.09 ± 0.03 c | 112.83 ± 0.62 c |

| NVG4 | 93.16 ± 0.02 | 6.84 ± 0.02 c | 2.35 ± 0.09 a | 1.99 ± 0.04 a | 1.34 ± 0.05 d | 0.63 ± 0.01 d | 86.86 ± 0.11 b | 4.55 ± 0.06 fe | 3.24 ± 0.04 b | 107.71 ± 0.44 h |

| APC | 52.18 ± 1.47 a | 47.82 ± 1.47 f | 1.46 ± 0.07 | 1.96 ± 0.03 x | 2.16 ± 0.10 x | 0.73 ± 0.05 c | 45.87 ± 1.42 de | 6.55 ± 0.13 a | 24.65 ± 1.51 g | 35.22 ± 0.54 g |

| APG | 94.23 ± 0.06 | 5.77 ± 0.06 a | 3.14 ± 0.04 b | 2.37 ± 0.05 b | 1.87 ± 0.06 b | 0.56 ± 0.02 a | 86.30 ± 0.02 b | 3.72 ± 0.03 c | 4.55 ± 0.11 e | 109.44 ± 0.39 b |

| ATG | 93.59 ± 0.04 | 6.41 ± 0.04 c | 3.15 ± 0.06 b | 2.68 ± 0.62 b | 1.88 ± 0.07 b | 0.56 ± 0.03 a | 85.32 ± 0.64 d | 3.71 ± 0.04 c | 4.51 ± 0.06 e | 108.10 ± 0.11 a |

| CADC | 51.70 ± 0.99 a | 48.3 ± 0.99 f | 0.83 ± 0.04 | 1.35 ± 0.04 r | 1.21 ± 0.02 q | 0.52 ± 0.05 a | 47.80 ± 1.02 e | 7.82 ± 0.03 d | 45.69 ± 0.74 z | 35.89 ± 0.78 g |

| WBG1 | 93.12 ± 0.06 | 6.88 ± 0.06 c | 2.42 ± 0.03 a | 1.73 ± 0.02 c | 0.63 ± 0.02 c | 0.52 ± 0.05 b | 87.82 ± 0.10 a | 4.82 ± 0.03 f | 6.82 ± 0.03 | 106.28 ± 0.61 f |

| WBG2 | 94.78 ± 0.04 | 5.22 ± 0.04 a | 2.44 ± 0.04 a | 1.65 ± 0.03 c | 0.64 ± 0.03 c | 0.49 ± 0.02 b | 89.56 ± 0.08 e | 4.39 ± 0.06 b | 6.19 ± 0.06 a | 114.81 ± 0.27 k |

| CADG | 92.12 ± 0.05 | 7.88 ± 0.05 b | 2.35 ± 0.03 a | 1.73 ± 0.05 c | 0.64 ± 0.03 c | 0.49 ± 0.02 b | 86.91 ± 0.05 b | 4.39 ± 0.06 b | 6.19 ± 0.06 a | 94.5 ± 4.00 g |

| Parameter | Temp (°C) | MCwb (%) | k (W m−1 °C−1) | Density (kg m−3) | Cp (J kg−1 °C−1) | α (m2 s−1) |

|---|---|---|---|---|---|---|

| NVC | 34 82 ± 0.96 a | 49.23 ± 0.72 f | 0.34 ± 0.002 c | 1223.09 ± 0.35 x | 2883.17 ± 0.32 u | 9.74 × 10−8 ± 3.63 × 10−10 v |

| APC | 34.84 ± 0.83 a | 47.82 ± 1.47 f | 0.34 ± 0.004 c | 1207.72 ± 0.12 y | 2849.95 ± 0.15 t | 9.62 × 10−8 ± 1.003 × 10−10 h |

| CADC | 35.89 ± 0.78 b | 48.30 ± 0.99 f | 0.35 ± 0.00002 f | 1214.33 ± 0.52 z | 2859.87 ± 0.35 | 9.76 × 10−8 ± 2.89 × 10−11 v |

| Parameter | Temp (°C) | MCwb (%) | k (W m−1 °C−1) | Density (kg m−3) | Cp (J kg−1 °C−1) | α (m2 s−1) |

|---|---|---|---|---|---|---|

| NVG1 | 111.57 ± 2.64 a | 5.76 ± 0.05 a | 0.28 ± 0.01 a | 1502.01 ± 1.72 b | 1843.94 ± 2.89 a | 1.02 × 10−7 ± 2.64 10−9 a |

| NVG2 | 104.65 ± 4.43 b | 7.37 ± 0.05 b | 0.31 ± 0.01 b | 1490.07 ± 1.41 c | 1879.43 ± 2.67 b | 1.09 × 10−7 ± 4.55 10−9 b |

| NVG3 | 112.58 ± 10.34 a | 5.45 ± 0.07 a | 0.27 ± 0.03 c | 1505.37 ± 4.28 b | 1834.52 ± 7.11 c | 9.76 × 10−8 ± 9.10 × 10−9 c |

| NVG4 | 107.75 ± 9.95 c | 6.84 ± 0.02 c | 0.30 ± 0.03 d | 1492.25 ± 8.08 c | 1870.53 ± 14.55 d | 1.07 × 10−7 ± 1.07 × 10−8 d |

| APG | 109.31 ± 12.43 d | 5.77 ± 0.06 a | 0.27 ± 0.03 c | 1502.63 ± 9.02 d | 1844.85 ± 16.01 c | 9.64 × 10−8 ± 1.15 × 10−8 e |

| ATG | 108.78 ± 9.21 c | 6.41 ± 0.04 c | 0.29 ± 0.02 e | 1496.76 ± 6.88 d | 1860.61 ± 12.01 e | 1.02 × 10−7 ± 8.50 × 10−9 a |

| WBG1 | 106.77 ± 8.78 c | 6.88 ± 0.06 c | 0.31 ± 0.03 b | 1498.96 ± 2.71 b | 1862.97 ± 5.13 d | 1.09 × 10−7 ± 9.55 × 10−9 b |

| WBG2 | 114.29 ± 5.78 e | 5.22 ± 0.04 a | 0.28 ± 0.01 a | 1511.11 ± 1.30 e | 1827.71 ± 2.19 c | 1.01 × 10−7 ± 3.69 × 10−9 f |

| CADG | 98.90 ± 13.60 f | 7.88 ± 0.05 b | 0.30 ± 0.01 d | 1493.14 ± 1.82 f | 1882.61 ± 3.39 f | 1.09 × 10−7 ± 4.15 × 10−9 b |

| Authors | Model with Coefficients | Methods | Average (k) | R2 | Pr > F | E (%) |

|---|---|---|---|---|---|---|

| TP | kGeneral = 0.068 + (1.74 × 10−3 × Temp) + (4.37 × 10−3 × MCwb) | CHOI | 0.31 ± 0.03 | |||

| TP | kNV = 0.014 + (2.2 × 10−3 × Temp) + (5.1 × 10−3 × MCwb) | CHOI | 0.31 ± 0.03 | 0.98 | <0.0001 | −0.2 |

| TP | kAP = 0.024 + (2.0 × 10−3 × Temp) + (5.1 × 10−3 × MCwb) | CHOI | 0.32 ± 0.03 | 0.93 | <0.0001 | −3.0 |

| TP | kCAD = 0.16 + (1.12 × 10−3 × Temp) + (2.9 × 10−3 × MCwb) | CHOI | 0.32 ± 0.02 | 0.97 | <0.0001 | −3.3 |

| [25] | kKust = 0.008 + (4.43 × 10−4 × Temp) + (5.84 × 10−3 × MCwb) | TM-HWP | 0.27 ± 0.11 | 0.93 | <0.0001 | 13.1 |

| [26] | kSweat (meats and fish) = 0.08 + 0.52 × (MCwb/100) (cassava mash/all process) | TCP | 0.22 ± 0.10 | 0.92 | <0.0001 | 6.18/31.2 |

| [26] | kSweat (fruits and vegetables) = 0.148 + 0.493 × (MCwb/100) | TCP | 0.28 ± 0.10 | 0.92 | <0.0001 | 9.4 |

| [5] | kBalk = 0.2112 + (8.943 × 10−3 × (MCwb/100)Temp) + (0.3077) × (MCwb/100)2 | DPM | 0.26 ± 0.04 | 0.93 | <0.0001 | 17.3 |

| [27] | kCansee = 0.408 − (1.380 × 10−3 × Temp) − (5.865 × 10−4 × C) | TM-LHSM | 0.29 ± 0.04 | 0.8 | <0.0001 | 6.3 |

| [7] | kAnderson = (MCwb/100) × kwater + (1 − (MCwb/100)) × ksolids | TM-LHSM | 0.36 ± 0.08 | 0.92 | <0.0001 | −14.1 |

| CHO (%) | CP (%) | CF (%) | TA (%) | CFb (%) | HCN (ppm) | MCwb (%) | Temp (°C) | Dnsit (kg/m3) | TC (W/m °C) | Cp (J/kg °C) | Diff (m2/s) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CHO (%) | 1.00 | −0.64 | −0.54 | 0.84 | 0.66 | −0.82 | −0.99 | 0.98 | 0.99 | −0.80 | −0.99 | 0.36 |

| CP (%) | −0.64 | 1.00 | 0.65 | −0.17 | −0.11 | 0.19 | 0.61 | −0.59 | −0.59 | 0.36 | 0.60 | −0.41 |

| CF (%) | −0.54 | 0.65 | 1.00 | −0.39 | −0.05 | 0.18 | 0.52 | −0.51 | −0.52 | 0.36 | 0.52 | −0.26 |

| TA (%) | 0.84 | −0.17 | −0.39 | 1.00 | 0.75 | −0.89 | −0.86 | 0.85 | 0.87 | −0.75 | −0.86 | 0.21 |

| CFb (%) | 0.66 | −0.11 | −0.05 | 0.75 | 1.00 | −0.57 | −0.68 | 0.66 | 0.69 | −0.65 | −0.69 | 0.09 |

| HCN (ppm) | −0.82 | 0.19 | 0.18 | −0.89 | −0.57 | 1.00 | 0.83 | −0.82 | −0.83 | 0.68 | 0.83 | −0.28 |

| MCwb (%) | −0.99 | 0.61 | 0.52 | −0.86 | −0.68 | 0.83 | 1.00 | −0.98 | −0.99 | 0.80 | 0.99 | −0.35 |

| Temp (°C) | 0.98 | −0.59 | −0.51 | 0.85 | 0.66 | −0.82 | −0.98 | 1.00 | 0.98 | −0.71 | −0.98 | 0.48 |

| Density (kg/m3) | 0.99 | −0.59 | −0.52 | 0.87 | 0.70 | −0.83 | −0.99 | 0.98 | 1.00 | −0.82 | −0.99 | 0.33 |

| TC (W/m °C) | −0.80 | 0.36 | 0.36 | −0.75 | −0.65 | 0.68 | 0.80 | −0.71 | −0.82 | 1.00 | 0.81 | 0.28 |

| Cp (J/kg °C) | −0.99 | 0.60 | 0.52 | −0.86 | −0.69 | 0.83 | 0.99 | −0.98 | −0.99 | 0.81 | 1.00 | −0.34 |

| Diff (m2/s) | 0.36 | −0.41 | −0.26 | 0.21 | 0.09 | −0.28 | −0.35 | 0.48 | 0.33 | 0.28 | −0.34 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mwape, M.C.; Parmar, A.; Roman, F.; Azouma, Y.O.; Emmambux, N.M.; Hensel, O. Determination and Modeling of Proximate and Thermal Properties of De-Watered Cassava Mash (Manihot esculenta Crantz) and Gari (Gelatinized cassava mash) Traditionally Processed (In Situ) in Togo. Energies 2023, 16, 6836. https://doi.org/10.3390/en16196836

Mwape MC, Parmar A, Roman F, Azouma YO, Emmambux NM, Hensel O. Determination and Modeling of Proximate and Thermal Properties of De-Watered Cassava Mash (Manihot esculenta Crantz) and Gari (Gelatinized cassava mash) Traditionally Processed (In Situ) in Togo. Energies. 2023; 16(19):6836. https://doi.org/10.3390/en16196836

Chicago/Turabian StyleMwape, Mwewa Chikonkolo, Aditya Parmar, Franz Roman, Yaovi Ouézou Azouma, Naushad M. Emmambux, and Oliver Hensel. 2023. "Determination and Modeling of Proximate and Thermal Properties of De-Watered Cassava Mash (Manihot esculenta Crantz) and Gari (Gelatinized cassava mash) Traditionally Processed (In Situ) in Togo" Energies 16, no. 19: 6836. https://doi.org/10.3390/en16196836

APA StyleMwape, M. C., Parmar, A., Roman, F., Azouma, Y. O., Emmambux, N. M., & Hensel, O. (2023). Determination and Modeling of Proximate and Thermal Properties of De-Watered Cassava Mash (Manihot esculenta Crantz) and Gari (Gelatinized cassava mash) Traditionally Processed (In Situ) in Togo. Energies, 16(19), 6836. https://doi.org/10.3390/en16196836