Fault Diagnosis and Condition Monitoring in Wave Energy Converters: A Review

Abstract

1. Introduction

Methodology and Structure of the Review

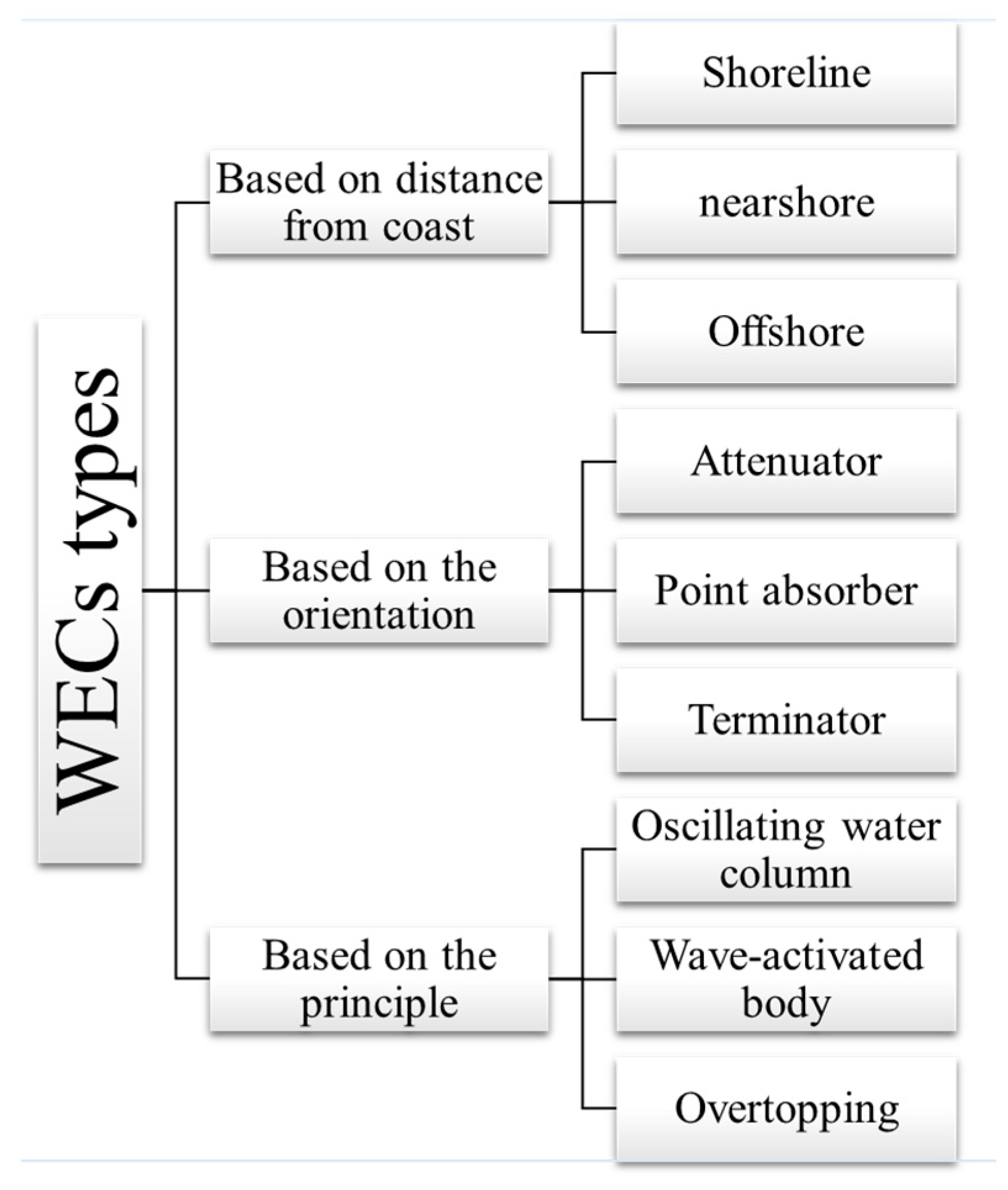

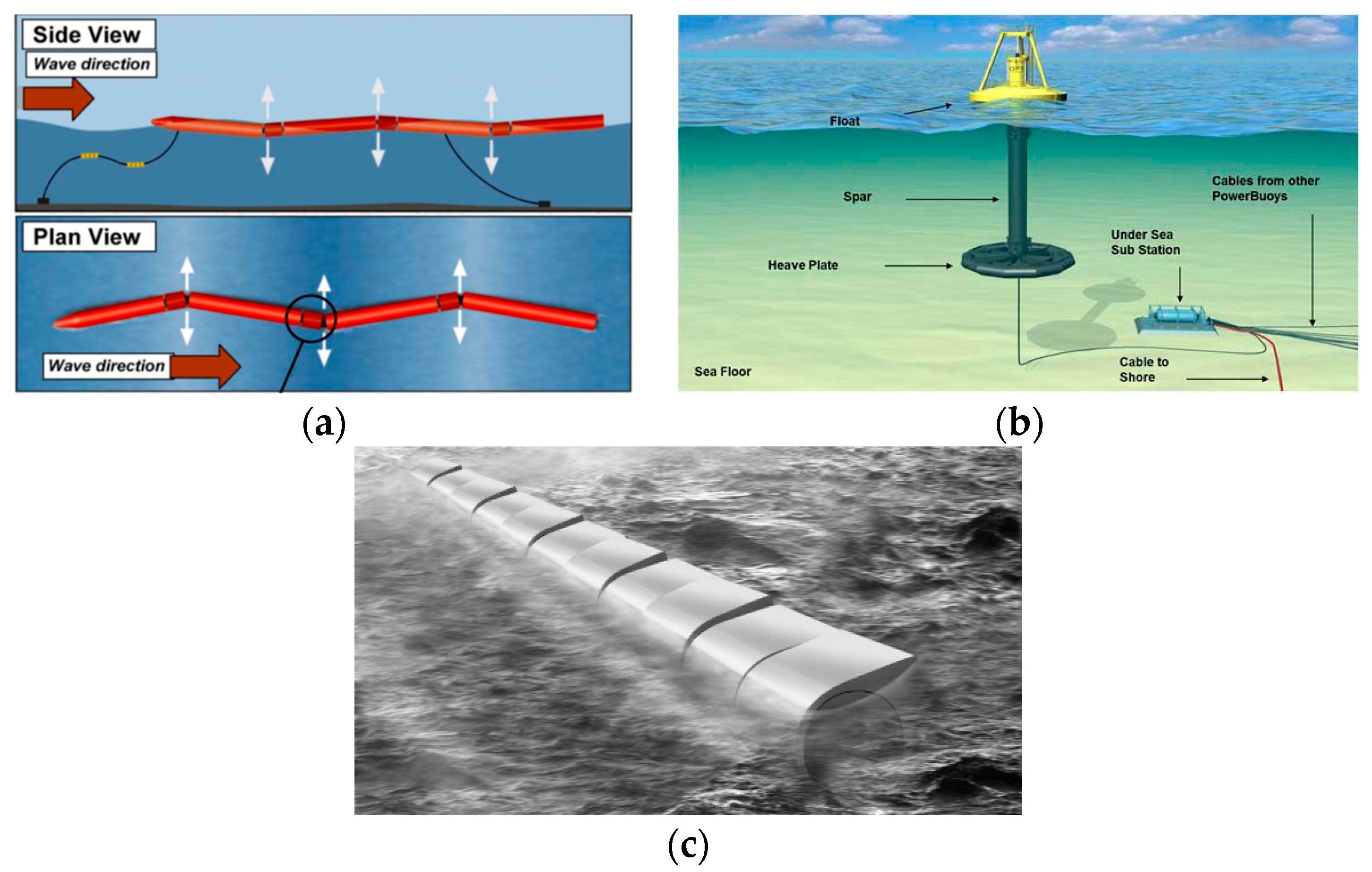

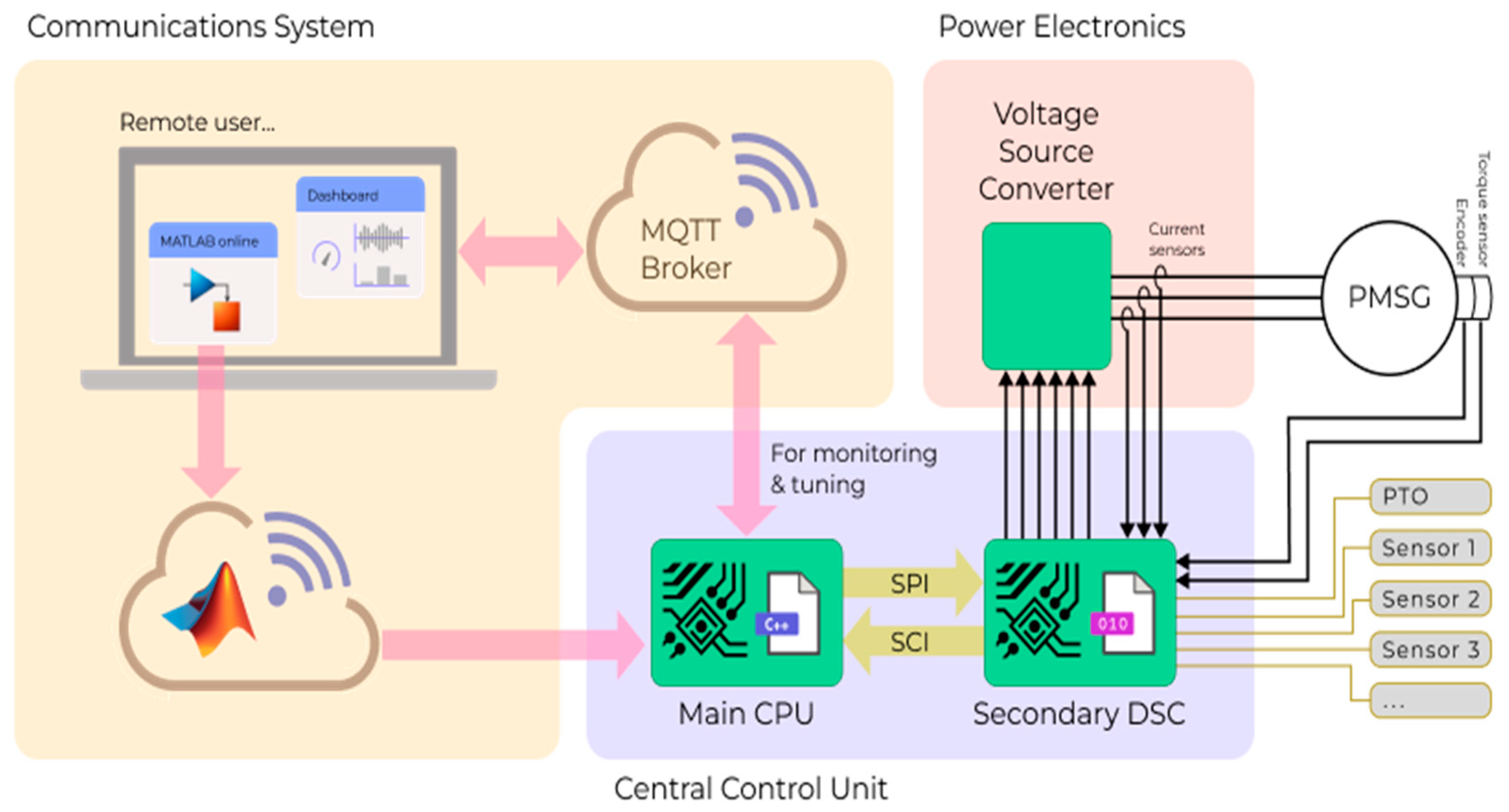

2. WECs Operation and Technology

3. Fault Diagnosis Methods for WECs

4. FDIR Units for WECs

5. Condition Monitoring for WECs

6. Fault-Tolerant Control for WECs

7. Future Research Direction

8. Conclusions

Funding

Conflicts of Interest

Abbreviations

| AWS | Archimedes wave swing |

| COE | Cost of energy |

| CPU | Central processing unit |

| DFIG | Doubly-fed induction generator |

| DSC | Digital signal controller |

| EPSRC | Engineering and Physical Sciences Research Council |

| ETA | Event tree analysis |

| FDIR | Fault detection, isolation and reconstruction |

| FFDM | Function failure design method |

| FFIP | Function failure identification and propagation |

| FFT | Fast Fourier transform |

| FMEA | Failure modes and effects analysis |

| FTA | Fault tree analysis |

| FTC | Fault-tolerant control |

| HAPIWEC | Holistic advanced prototyping and interfacing for wave energy control |

| HT | Hilbert transform |

| ICA | Independent component analysis |

| KF | Kalman filter |

| LCOE | Levelized cost of energy |

| MCSA | Machine current signature analysis |

| NREL | National renewable energy laboratory |

| O&M | Operation and maintenance |

| OPEX | Operational expenses |

| PCA | Principal component analysis |

| PMSG | Permanent magnet synchronous generator |

| PTO | Power take-off |

| SCADA | Supervisory control and data acquisition |

| SK | Spectral kurtosis |

| SVM | Support vector machine |

| TRL | Technology readiness level |

| WEC | Wave energy converter |

| WVD | Wigner–Ville distribution |

References

- Poguluri, S.; Bae, Y. A Study on Performance Assessment of WEC Rotor in the Jeju Western Waters. Ocean Syst. Eng. 2018, 8, 361–380. [Google Scholar]

- Fan, Y.; Mu, A.; Ma, T. Design and control of a point absorber wave energy converter with an open loop hydraulic transmission. Energy Convers. Manag. 2016, 121, 13–21. [Google Scholar] [CrossRef]

- Patil, V.C.; Ro, P.I. Modeling of liquid-piston based design for isothermal ocean compressed air energy storage system. J. Energy Storage 2020, 31, 101449. [Google Scholar] [CrossRef]

- Tokat, P. Performance Evaluation and Life Cycle Cost Analysis of the Electrical Generation Unit of a Wave Energy Converter; Chalmers Tekniska Hogskola: Gothenburg, Sweden, 2018. [Google Scholar]

- Magagna, D.; Uihlein, A. Ocean energy development in Europe: Current status and future perspectives. Int. J. Mar. Energy 2015, 11, 84–104. [Google Scholar] [CrossRef]

- Spotlight on Ocean Energy. 2018. Available online: https://tethys.pnnl.gov/sites/default/files/publications/OES-2018.pdf (accessed on 12 September 2023).

- Têtu, A. Power Take-Off Systems for WECs. In Handbook of Ocean Wave Energy; Springer Nature: Berlin/Heidelberg, Germany, 2016; pp. 203–220. [Google Scholar] [CrossRef]

- Wave and Tidal Energy: Part of the UK’s Energy Mix. Available online: https://www.gov.uk/guidance/wave-and-tidal-energy-part-of-the-uks-energy-mix (accessed on 12 September 2023).

- Babarit, A. Ocean Wave Energy Conversion: Resource, Technologies and Performance; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Ringwood, J.V. Wave energy control: Status and perspectives 2020. IFAC Pap. 2020, 53, 12271–12282. [Google Scholar] [CrossRef]

- Handoko, C.R. The development of power take-off technology in wave energy converter systems: A Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 739, 012081. [Google Scholar] [CrossRef]

- Gaebele, D.T.; Magana, M.E.; Brekken, T.K.A.; Henriques, J.C.C.; Carrelhas, A.A.D.; Gato, L.M.C. Second Order Sliding Mode Control of Oscillating Water Column Wave Energy Converters for Power Improvement. IEEE Trans. Sustain. Energy 2020, 12, 1151–1160. [Google Scholar] [CrossRef]

- Cradden, L.; Syrda, P.; Riordan, C.; Ingram, D. Accessibility risk for offshore platforms during maintenance. In Proceedings of the European Wave and Tidal Energy Conference, Aalborg, Denmark, 2–5 September 2013. [Google Scholar]

- O’Connor, M.; Lewis, T.; Dalton, G. Weather Window Analysis of Irish and Portuguese Wave Data with Relevance to Operations and Maintenance of Marine Renewables. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Nantes, France, 9–14 June 2013. [Google Scholar] [CrossRef]

- Ambühl, S.; Kramer, M.; Kofoed, J.P.; Sørensen, J.D. Reliability assessment of wave energy devices. In Proceedings of the 4th International Conference on Ocean Energy, Southampton, UK, 17–19 October 2012. [Google Scholar]

- Torre-Enciso, Y.; Ortubia, I.; De Aguileta, L.L.; Marqués, J. Mutriku wave power plant: From the thinking out to the reality. In Proceedings of the 8th European Wave and Tidal Energy Conference, Uppsala, Sweden, 7–10 September 2009; Volume 710, pp. 319–329. [Google Scholar]

- Ambühl, S.; Marquis, L.; Kofoed, J.P.; Sørensen, J.D. Operation and maintenance strategies for wave energy converters. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2015, 229, 417–441. [Google Scholar] [CrossRef]

- Entec, U. Cost Estimation Methodology: The Marine Energy Challenge Approach of Energy Produced by Marine Energy Systems; Commissioned by The Carbon Trust, Ed.; 2006. Available online: https://www.carbontrust.com/our-work-and-impact/guides-reports-and-tools/marine-cost-of-energy-methodology (accessed on 12 September 2023).

- Gray, A.; Findlay, D.; Johanning, L. Operations and Maintenance Planning for Community-Scale, Off-Grid Wave Energy Devices; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Abdulla, K.; Skelton, J.; Doherty, K.; O’Kane, P.; Doherty, R.; Bryans, G. Statistical availability analysis of wave energy converters. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Maui, HI, USA, 19–24 June 2011; p. ISOPE-I-11–553. [Google Scholar]

- Gray, A.; Johanning, L.; Dickens, B. The Modelling of Pelamis Wave Power’s Operations & Maintenance Strategy. In Proceedings of the ASRANet International Conference on Offshore Renewable Energy, Glasgow, UK, 15–17 September 2014; pp. 15–17. [Google Scholar]

- Johanson, M.; von Hacht, A.; Strang-Moran, C.; Hüffmeier, J.; Johannesson, P. Condition monitoring for wave energy converters. In Proceedings of the 12th European Wave and Tidal Energy Conference (EWTEC 2019), Naples, Italy, 1–6 September 2019; Volume 2019. [Google Scholar]

- Aderinto, T.; Li, H. Review on Power Performance and Efficiency of Wave Energy Converters. Energies 2019, 12, 4329. [Google Scholar] [CrossRef]

- de Andres, A.; Medina-Lopez, E.; Crooks, D.; Roberts, O.; Jeffrey, H. On the reversed LCOE calculation: Design constraints for wave energy commercialization. Int. J. Mar. Energy 2017, 18, 88–108. [Google Scholar] [CrossRef]

- Ringwood, J.; Simani, S. Overview of modelling and control strategies for wind turbines and wave energy devices: Comparisons and contrasts. Annu. Rev. Control 2015, 40, 27–49. [Google Scholar] [CrossRef]

- Charlier, R.H.; Justus, J.R. Ocean Energies: Environmental, Economic and Technological Aspects of Alternative Power Sources; Elsevier: Amsterdam, The Netherlands, 1993. [Google Scholar]

- Chowdhury, M.S.; Rahman, K.S.; Selvanathan, V.; Nuthammachot, N.; Suklueng, M.; Mostafaeipour, A.; Habib, A.; Akhtaruzzaman, M.; Amin, N.; Techato, K. Current trends and prospects of tidal energy technology. Environ. Dev. Sustain. 2020, 23, 8179–8194. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Yang, Y.; Wang, S. Ocean thermal energy application technologies for unmanned underwater vehicles: A comprehensive review. Appl. Energy 2020, 278, 115752. [Google Scholar] [CrossRef]

- Herrera, J.; Sierra, S.; Ibeas, A. Ocean Thermal Energy Conversion and Other Uses of Deep Sea Water: A Review. J. Mar. Sci. Eng. 2021, 9, 356. [Google Scholar] [CrossRef]

- Han, X.-W.; Zhang, W.-B.; Ma, X.-J.; Zhou, X.; Zhang, Q.; Bao, X.; Guo, Y.-W.; Zhang, L.; Long, J. Review—Technologies and Materials for Water Salinity Gradient Energy Harvesting. J. Electrochem. Soc. 2021, 168, 090505. [Google Scholar] [CrossRef]

- Khan, M.Z.A.; Khan, H.A.; Aziz, M. Harvesting Energy from Ocean: Technologies and Perspectives. Energies 2022, 15, 3456. [Google Scholar] [CrossRef]

- Curto, D.; Franzitta, V.; Guercio, A. Sea Wave Energy. A Review of the Current Technologies and Perspectives. Energies 2021, 14, 6604. [Google Scholar] [CrossRef]

- Xu, N.; Chen, L.; Yang, R.; Zhu, Y. Multi-controller-based fault tolerant control for systems with actuator and sensor failures: Application to 2-body point absorber wave energy converter. J. Frankl. Inst. 2022, 359, 5919–5934. [Google Scholar] [CrossRef]

- Clément, A.; McCullen, P.; Falcão, A.; Fiorentino, A.; Gardner, F.; Hammarlund, K.; Lemonis, G.; Lewis, T.; Nielsen, K.; Petroncini, S.; et al. Wave energy in Europe: Current status and perspectives. Renew. Sustain. Energy Rev. 2002, 6, 405–431. [Google Scholar] [CrossRef]

- Pelc, R.; Fujita, R.M. Renewable energy from the ocean. Mar. Policy 2002, 26, 471–479. [Google Scholar] [CrossRef]

- Drew, B.; Plummer, A.R.; Sahinkaya, M.N. A review of wave energy converter technology. Proc. Inst. Mech. Eng. Part A J. Power Energy 2009, 223, 887–902. [Google Scholar] [CrossRef]

- Veigas, M.; López, M.; Iglesias, G. Assessing the optimal location for a shoreline wave energy converter. Appl. Energy 2014, 132, 404–411. [Google Scholar] [CrossRef]

- Abu Hasim, A.S.; Ishak, A.M.; Burhanudin, J.; Dardin, S.M.F.B.S.M. A Review of Power Electronics for Nearshore Wave Energy Converter Applications. IEEE Access 2022, 10, 16670–16680. [Google Scholar] [CrossRef]

- Ruol, P.; Zanuttigh, B.; Martinelli, L.; Kofoed, P.; Frigaard, P. Near-shore floating wave energy converters: Applications for coastal protection. Coast. Eng. Proc. 2011, 1, 61. [Google Scholar] [CrossRef]

- Igic, P.; Zhou, Z.; Knapp, W.; MacEnri, J.; Sørensen, H.; Friis-Madsen, E. Multi-megawatt offshore wave energy converters—Electrical system configuration and generator control strategy. IET Renew. Power Gener. 2011, 5, 10–17. [Google Scholar] [CrossRef]

- Liao, Z.; Sun, T.; Al-Ani, M.; Jordan, L.-B.; Li, G.; Wang, Z.; Belmont, M.; Edwards, C. Modelling and Control Tank Testing Validation for Attenuator Type Wave Energy Converter—Part I: Experiment Setup and Control-Oriented Modelling. IEEE Trans. Sustain. Energy 2023, 14, 1747–1757. [Google Scholar] [CrossRef]

- Guo, B.; Wang, T.; Jin, S.; Duan, S.; Yang, K.; Zhao, Y. A Review of Point Absorber Wave Energy Converters. J. Mar. Sci. Eng. 2022, 10, 1534. [Google Scholar] [CrossRef]

- Suzuki, M.; Arakawa, C. Numerical methods to predict characteristics of oscillating water column for terminator type of wave energy converter. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 25–30 May 2003; p. ISOPE-I-03–050. [Google Scholar]

- Zhao, X.L.; Ning, D.Z.; Zou, Q.P.; Qiao, D.S.; Cai, S.Q. Hybrid floating breakwater-WEC system: A review. Ocean Eng. 2019, 186, 106126. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. Oscillating-water-column wave energy converters and air turbines: A review. Renew. Energy 2016, 85, 1391–1424. [Google Scholar] [CrossRef]

- Zanuttigh, B.; Angelelli, E.; Kofoed, J.P. Effects of mooring systems on the performance of a wave activated body energy converter. Renew. Energy 2013, 57, 422–431. [Google Scholar] [CrossRef]

- Liu, Z.; Han, Z.; Shi, H.; Yang, W. Experimental study on multi-level overtopping wave energy convertor under regular wave conditions. Int. J. Nav. Arch. Ocean Eng. 2018, 10, 651–659. [Google Scholar] [CrossRef]

- IEC TS 62600–2:2019; Marine Energy—Wave, Tidal and Other Water Current Converters. IEC: Geneva, Switzerland, 2019. Available online: https://webstore.iec.ch/publication/62399 (accessed on 12 September 2023).

- Val, D.V. Reliability of Marine Energy Converters. Energies 2023, 16, 3387. [Google Scholar] [CrossRef]

- Ahamed, R.; McKee, K.; Howard, I. Advancements of wave energy converters based on power take off (PTO) systems: A review. Ocean Eng. 2020, 204, 107248. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, R.; Xiao, H.; Wang, X. Survey of the mechanisms of power take-off (PTO) devices of wave energy converters. Acta Mech. Sin. 2020, 36, 644–658. [Google Scholar] [CrossRef]

- González-Esculpi, A.; Verde, C.; Maya-Ortiz, P. Nonlinear servocompensator for fault-tolerant control of a wave energy converter. J. Frankl. Inst. 2023, 360, 8339–8362. [Google Scholar] [CrossRef]

- Zadeh, L.G.; Brekken, T.K.; Fern, A.; Shahbaz, A.H. Hardware in the Loop Wave Energy Converter Control under Control Faults and Model Mismatch. IEEE Trans. Sustain. Energy 2023, 1–10. [Google Scholar] [CrossRef]

- Fusco, F.; Ringwood, J.V. Hierarchical Robust Control of Oscillating Wave Energy Converters with Uncertain Dynamics. IEEE Trans. Sustain. Energy 2014, 5, 958–966. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, X.P.; Ju, P.; Sterling, M.J.H. Optimal Control for AWS-Based Wave Energy Conversion System. IEEE Trans. Power Syst. 2009, 24, 1747–1755. [Google Scholar] [CrossRef]

- Xu, N.; Zhu, Y.; Yang, R.; Chen, X.; Su, C.-Y. Adaptive Fault-Tolerant Control for a 2-Body Point Absorber Wave Energy Converter Against Actuator Faults: An Iterative Learning Control Approach. IEEE Trans. Sustain. Energy 2023, 14, 1664–1675. [Google Scholar] [CrossRef]

- Thies, P.R. Advancing Reliability Information for Wave Energy Converters; University of Exeter: Exeter, UK, 2012. [Google Scholar]

- Yu, Z.; Zhang, Y.; Liu, Z.; Qu, Y.; Su, C.-Y.; Jiang, B. Decentralized finite-time adaptive fault-tolerant synchronization tracking control for multiple UAVs with prescribed performance. J. Frankl. Inst. 2019, 357, 11830–11862. [Google Scholar] [CrossRef]

- Tang, Y.; Huang, Y.; Lindbeck, E.; Lizza, S.; VanZwieten, J.; Tom, N.; Yao, W. WEC fault modelling and condition monitoring: A graph-theoretic approach. IET Electr. Power Appl. 2020, 14, 781–788. [Google Scholar] [CrossRef]

- Ramirez, D.; Blanco, M.; Zarei, M.E.; Gupta, M. Robust control of a floating OWC WEC under open-switch fault condition in one or in both VSCs. IET Renew. Power Gener. 2020, 14, 2538–2549. [Google Scholar] [CrossRef]

- Henderson, R. Design, simulation, and testing of a novel hydraulic power take-off system for the Pelamis wave energy converter. Renew. Energy 2006, 31, 271–283. [Google Scholar] [CrossRef]

- Edwards, K.; Mekhiche, M. Ocean Power Technologies Powerbuoy®: System-Level Design, Development and Validation Methodology. In Proceedings of the 2nd Marine Energy Technology Symposium METS2014, Seattle, WA, USA, 15–18 April 2014; Available online: https://vtechworks.lib.vt.edu/handle/10919/49232 (accessed on 12 September 2023).

- Renewable Energy, Salter’s Nodding Duck. Available online: https://baonguyen1994.wordpress.com/introduction-to-wave-energy/ocean-wave-technologies/terminators/salters-nodding-duck/ (accessed on 6 September 2023).

- Mortazavizadeh, S.A.; Mousavi, S.M.G. A Review on Condition Monitoring and Diagnostic Techniques of Rotating Electrical Machines. Phys. Sci. Int. J. 2014, 4, 310–338. [Google Scholar] [CrossRef]

- Mérigaud, A.; Ringwood, J.V. Condition-based maintenance methods for marine renewable energy. Renew. Sustain. Energy Rev. 2016, 66, 53–78. [Google Scholar] [CrossRef]

- Weber, J. WEC Technology Readiness and Performance Matrix–finding the best research technology development trajectory. In Proceedings of the 4th International Conference on Ocean Energy, Dublin, Ireland, 17–19 October 2012; Volume 17. [Google Scholar]

- Price, A.; Campos-Gaona, D.; McCallum, P.; Yazdanpanah, R.; Mortazavizadeh, S.A. HAPiWEC: Towards a Rapid Prototyping Rig for Wave Energy Control Co-Design and Testing. In Proceedings of the OCEANS 2023-Limerick, Limerick, Ireland, 5–8 June 2023; pp. 1–9. [Google Scholar] [CrossRef]

- Stock, A. Holistic Advanced Prototyping and Interfacing for Wave Energy Control. In Supergen ORE Hub Annual Assembly; Supergen ORE Hub Annual Assembly—University of Oxford: Oxford, UK, 29 September 2022. [Google Scholar]

- Price, A.; Campos-Gaona, D.; Davey, T.; Forehand, D.; Giles, T.; McCallum, P.; McDonald, A.; Onslow, M.; Sellar, B.; Stock, A.; et al. HAPiGYM: Two Rapid Prototyping Environments for Wave Energy Control. In Proceedings of the 15th European Wave and Tidal Energy Conference EWTEC, Bilbao, Spain, 3–7 September 2023. [Google Scholar]

- Walsh, J.; Bashir, I.; Thies, P.R.; Johanning, L.; Blondel, P. Acoustic emission health monitoring of marine renewables: Illustration with a wave energy converter in Falmouth Bay (UK). In Proceedings of the OCEANS 2015, Genova, Italy, 18–21 May 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Tran, T.T.; Krueger, A.M.; Gunawan, B.; Alam, M.-R. Predicting the Dynamic Characteristics of a Fully Submerged Wave Energy Converter Subjected to a Power Take-Off Failure Using a High-Fidelity Computational Fluid Dynamics Model; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2019. [Google Scholar]

- Zhang, Y.; Zeng, T.; Gao, Z. Fault Diagnosis and Fault-Tolerant Control of Energy Maximization for Wave Energy Converters. IEEE Trans. Sustain. Energy 2022, 13, 1771–1778. [Google Scholar] [CrossRef]

- González-Esculpi, A.; Verde, C.; Maya-Ortiz, P. Comparison of Estimates of the Excitation Force for Fault Diagnosis in a Wave Energy Converter. IFAC Pap. 2022, 55, 396–401. [Google Scholar] [CrossRef]

- Hodgins, N.; Mueller, M.; Tease, W.; Staton, D. Measurement and modelling of induction generator performance in an oscillating water column wave energy converter. In Proceedings of the 2008 4th IET Conference on Power Electronics, Machines and Drives, York, UK, 2–4 April 2008. [Google Scholar] [CrossRef]

- Strömstedt, E.; Savin, A.; Svensson, O.; Leijon, M. Time Series-, Time-Frequency- and Spectral Analyses of Sensor Measurements in an Offshore Wave Energy Converter Based on Linear Generator Technology. Energy Power Eng. 2013, 05, 70–91. [Google Scholar] [CrossRef]

- Garrido, I.; Garrido, A.J.; Lekube, J.; Otaola, E.; Carrascal, E. Oscillating water column control and monitoring. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Verde, C.; Maya-Ortiz, P. FDI Study for a Wave Energy Converter by Structural Analysis. IFAC Pap. 2020, 53, 13721–13726. [Google Scholar] [CrossRef]

- Brown, A.; Tumer, I.Y.; Paasch, R. Early Stage Failure Modeling and Analysis Applied to a Wave Energy Converter. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, New York, NY, USA, 3–6 August 2008; Volume 43284, pp. 469–479. [Google Scholar]

- Hillis, A.; Yardley, J.; Plummer, A.; Chapman, J. The impact of modelling and prediction errors on the performance of optimally controlled multi-DOF wave energy converters. IFAC Pap. 2020, 53, 12265–12270. [Google Scholar] [CrossRef]

- Elasha, D.M.F.; Teixeira, J.A. Condition monitoring philosophy for tidal turbines. Int. J. Perform. Eng. 2014, 10, 521. [Google Scholar]

- Hess, A.; Stecki, J.S.; Rudov-Clark, S.D. The maintenance aware design environment: Development of an aerospace phm software tool. Proc. PHM08 2008, 16, 17. [Google Scholar]

- Rudov-Clark, S.; Stecki, J. The language of FMEA: On the effective use and reuse of FMEA data. In Proceedings of the Sixth DSTO International Conference on Health & Usage Monitoring, Melbourne, Australia, 6–9 March 2009; pp. 9–12. [Google Scholar]

- Kenny, C.; Findlay, D.; Lazakis, I.; Shek, J.; Thies, P. Development of a Condition Monitoring System for an Articulated Wave Energy Converter; University of Exeter: Exeter, UK, 2016. [Google Scholar]

- Garcia Márquez, F.P.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Kusiak, A.; Zhang, Z.; Verma, A. Prediction, operations, and condition monitoring in wind energy. Energy 2013, 60, 1–12. [Google Scholar] [CrossRef]

- Tautz-Weinert, J.; Watson, S.J. Using SCADA data for wind turbine condition monitoring–A review. IET Renew. Power Gener. 2016, 11, 382–394. [Google Scholar] [CrossRef]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2013, 53, 365–376. [Google Scholar] [CrossRef]

- Kim, K.; Parthasarathy, G.; Uluyol, O.; Foslien, W.; Sheng, S.; Fleming, P. Use of SCADA Data for Failure Detection in Wind Turbines. In Proceedings of the on Energy Sustainability Conference and Fuel Cell Conference, Washington, DC, USA, 7–10 August 2011; pp. 2071–2079. [Google Scholar]

- Zaher, A.; McArthur, S.; Infield, D.; Patel, Y. Online wind turbine fault detection through automated SCADA data analysis. Wind Energy Int. J. Prog. Appl. Wind Power Convers. Technol. 2009, 12, 574–593. [Google Scholar] [CrossRef]

- Chen, B.; Zappalá, D.; Crabtree, C.J.; Tavner, P.J. Survey of Commercially Available SCADA Data Analysis Tools for Wind Turbine Health Monitoring; Durham University: Durham, UK, 2014. Available online: https://research.tudelft.nl/en/publications/survey-of-commercially-available-scada-data-analysis-tools-for-wi (accessed on 12 September 2023).

- Zappalá, D.; Tavner, P.J. Reliability and Condition Monitoring, in UK Wind Energy Technologies; Routledge: London, UK, 2016; pp. 100–160. [Google Scholar]

- Wang, L.; Jia, S.; Yan, X.; Ma, L.; Fang, J. A SCADA-Data-Driven Condition Monitoring Method of Wind Turbine Generators. IEEE Access 2022, 10, 67532–67540. [Google Scholar] [CrossRef]

- Marnoch, J. What should a condition monitoring system look like for a tidal turbine. In Proceedings of the International Conference on Ocean Energy, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar]

- Mba, D.; Rao, R.B. Development of acoustic emission technology for condition monitoring and diagnosis of rotating machines: Bearings, pumps, gearboxes, engines, and rotating structures. Shock Vib. Dig. 2006, 38, 3–16. [Google Scholar] [CrossRef]

- Jaros, R.; Byrtus, R.; Dohnal, J.; Danys, L.; Baros, J.; Koziorek, J.; Zmij, P.; Martinek, R. Advanced Signal Processing Methods for Condition Monitoring. Arch. Comput. Methods Eng. 2022, 30, 1553–1577. [Google Scholar] [CrossRef]

- Schulte, H.; Gauterin, E. Input-to-State Stability Condition for Passive Fault-Tolerant Control of Wave and Wind Energy Converters. IFAC Pap. 2015, 48, 257–262. [Google Scholar] [CrossRef]

- Lawson, M.; Yu, Y.-H.; Ruehl, K.; Michelen, C. Development and Demonstration of the WEC-Sim Wave Energy Converter Simulation Tool. In Proceedings of the 2nd Marine Energy Technology Symposium METS2014, Seattle, WA, USA, 15–18 April 2014; Available online: https://vtechworks.lib.vt.edu/handle/10919/49236 (accessed on 12 September 2023).

- Ogden, D.; Ruehl, K.; Yu, Y.-H.; Keester, A.; Forbush, D.; Leon, J.; Tom, N. Review of WEC-Sim development and applications. Int. Mar. Energy J. 2022, 5, 293–303. [Google Scholar] [CrossRef]

- Anderlini, E.; Husain, S.; Parker, G.G.; Abusara, M.; Thomas, G. Towards Real-Time Reinforcement Learning Control of a Wave Energy Converter. J. Mar. Sci. Eng. 2020, 8, 845. [Google Scholar] [CrossRef]

- Zadeh, L.G.; Brekken, T.K.; Fern, A. Resilient Control of a Wave Energy Converter under PTO Fault Conditions. IFAC Pap. 2022, 55, 144–149. [Google Scholar] [CrossRef]

- Adaryani, M.R.; Taher, S.A.; Guerrero, J.M. Improved direct model predictive control for variable magnitude variable frequency wave energy converter connected to constant power load. J. Energy Storage 2021, 43, 103175. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Liu, H.; Loh, P.C. Marine energy generation systems and related monitoring and control. IEEE Instrum. Meas. Mag. 2014, 17, 27–32. [Google Scholar] [CrossRef]

- Signorelli, C.D.; Basu, B. Optimal Real-Time Predictive Control for Maximising the Power-Take-Off Efficiency of the WaveRAM Wave Energy Converter; Trinity College Dublin: Dublin, Ireland, 2018. [Google Scholar]

- Abdelrahman, M.; Patton, R.; Guo, B.; Lan, J. Estimation of wave excitation force for wave energy converters. In Proceedings of the 2016 3rd Conference on Control and Fault-Tolerant Systems (SysTol), Barcelona, Spain, 7–9 September 2016; pp. 654–659. [Google Scholar] [CrossRef]

- Patton, R.J. Fault Tolerant Control in Marine Energy Systems: A Wave Energy Perspective. In Proceedings of the Maynooth Wave Energy Workshop, Maynooth, Ireland, 20 January 2017; Available online: https://coer.maynoothuniversity.ie/wp-content/uploads/2017/08/Patton_Presentation.pdf (accessed on 12 September 2023).

- Baker, N.J.; Chambers, L.; Asker, F.; Retzler, C.; Galbraith, M.; Spooner, E.; Moore, D. Development of a direct drive power take off system for a hinged wave energy converter. In Proceedings of the 11th International Conference on Renewable Power Generation-Meeting Net Zero Carbon (RPG 2022), Online, 22–23 September 2022; Volume 2022, pp. 28–32. [Google Scholar]

- Gonzalez-Esculpi, A.; Verde, C.; Maya-Ortiz, P. Fault-Tolerant Control for a Wave Energy Converter by Damping Injection. In Proceedings of the 2021 IEEE Conference on Control Technology and Applications (CCTA), San Diego, CA, USA, 9–11 August 2021; pp. 673–678. [Google Scholar] [CrossRef]

- Johannesson, P.; Svensson, T.; Santandrea, F.; Ng, C.; Jia, C.; Buck, E.; Shanks, A. Reliability Guidance for Marine Energy Converters; Report RiaSoR (Reliability in a Sea of Risk); RiaSoR: Coruña, Spain, 2016; Available online: http://riasor.com/wp-content/uploads/2016/12/ReliabilityGuidanceMECs_v1.0_20161216.pdf (accessed on 12 September 2023).

- Freire, N.M.A.; Cardoso, A.J.M. A Fault-Tolerant Direct Controlled PMSG Drive for Wind Energy Conversion Systems. IEEE Trans. Ind. Electron. 2013, 61, 821–834. [Google Scholar] [CrossRef]

- Zarei, M.E.; Ramirez, D.; Nicolas, C.V.; Arribas, J.R. Three-Phase Four-Switch Converter for SPMS Generators Based on Model Predictive Current Control for Wave Energy Applications. IEEE Trans. Power Electron. 2019, 35, 289–302. [Google Scholar] [CrossRef]

- Qiu, Y.; Feng, Y.; Tavner, P.; Richardson, P.; Erdős, F.G.; Chen, B. Wind turbine SCADA alarm analysis for improving reliability. Wind Energy 2012, 15, 951–966. [Google Scholar] [CrossRef]

| Method | References | Pros or Cons | Comments |

|---|---|---|---|

| Acoustic emission monitoring | [67] | Early detection | Extensively used in similar systems like offshore wind turbines |

| Observer-based methods | [69] | Offline parameter determination, economic solution | Fault detection for both actuators and sensors |

| Excitation force estimation | [70] | Time delay | Model-based technique |

| Temperature sensor | [71] | Used for PTO load monitoring as well | |

| MCSA | [73] | Generator different faults detection | No more sensors would be added to system |

| Vibration monitoring | [72] | Various faults detections | Used for wear detection |

| Structural analysis | [74] | Mechanical faults detection | Lots of faults can be detected |

| Reactive power monitoring | [73] | Electrical component faults detection | |

| System functionality method | [75] | Simple and early fault detection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mortazavizadeh, S.A.; Yazdanpanah, R.; Gaona, D.C.; Anaya-Lara, O. Fault Diagnosis and Condition Monitoring in Wave Energy Converters: A Review. Energies 2023, 16, 6777. https://doi.org/10.3390/en16196777

Mortazavizadeh SA, Yazdanpanah R, Gaona DC, Anaya-Lara O. Fault Diagnosis and Condition Monitoring in Wave Energy Converters: A Review. Energies. 2023; 16(19):6777. https://doi.org/10.3390/en16196777

Chicago/Turabian StyleMortazavizadeh, Seyed Abolfazl, Reza Yazdanpanah, David Campos Gaona, and Olimpo Anaya-Lara. 2023. "Fault Diagnosis and Condition Monitoring in Wave Energy Converters: A Review" Energies 16, no. 19: 6777. https://doi.org/10.3390/en16196777

APA StyleMortazavizadeh, S. A., Yazdanpanah, R., Gaona, D. C., & Anaya-Lara, O. (2023). Fault Diagnosis and Condition Monitoring in Wave Energy Converters: A Review. Energies, 16(19), 6777. https://doi.org/10.3390/en16196777