1. Introduction

In today’s environment, where renewable energy and electric mobility are continuously expanding, rotating machines endorse a role of great importance. This situation boosts the need for the next generation of electrical machines to design and develop more high-performance rotating machines [

1,

2,

3,

4]. In this way, multiphase machines provide various benefits over conventional three-phase arrangements, including enhanced fault tolerance (e.g., loss of phases or converter legs) [

5,

6], less power per phase [

7], and a substantial number of degrees of freedom [

8,

9].

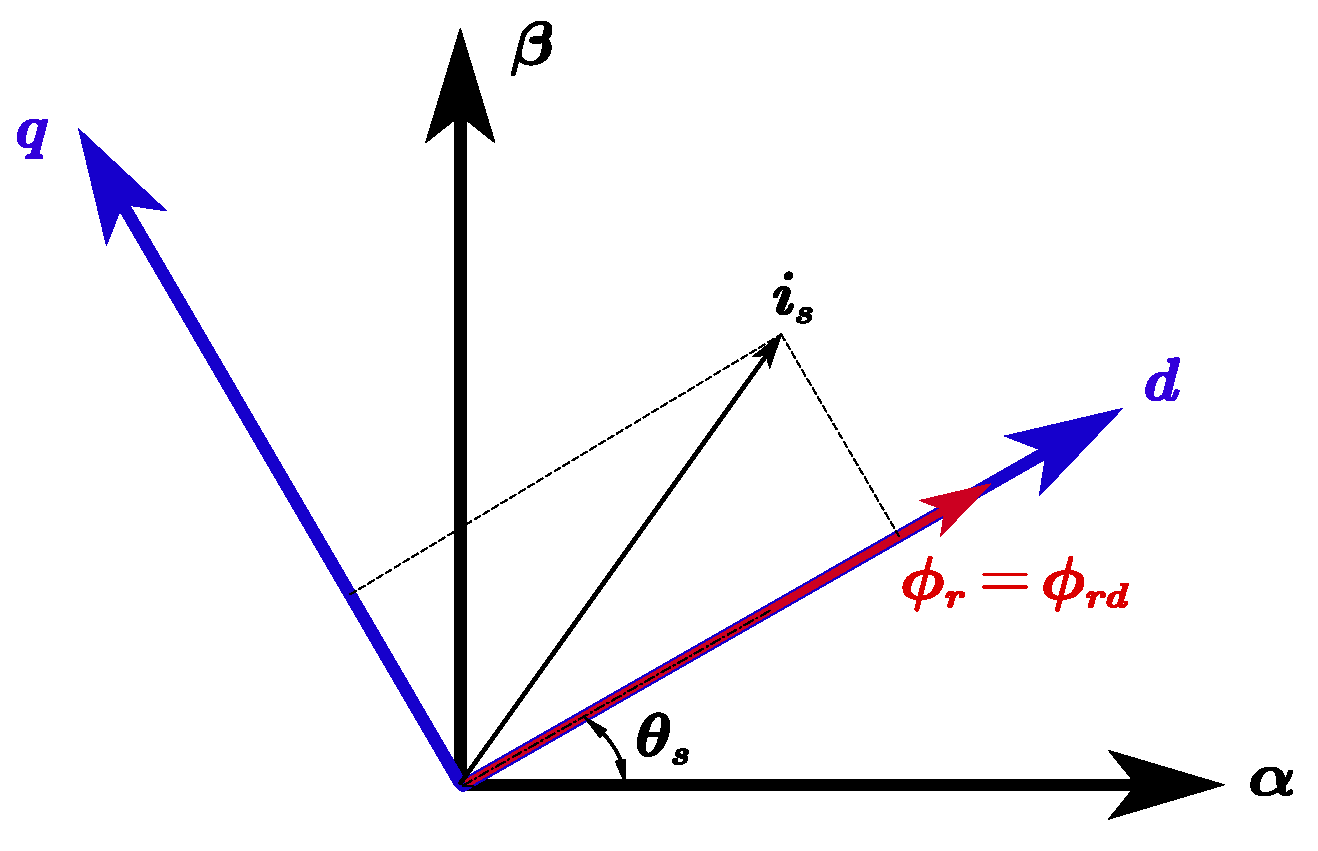

Unlike classical three-phase machines, multiphase ones offer an interesting alternative due to their enhanced fault tolerance during the open phase circuit (

OPC) without any control reconfiguration. However, some additional ripples appear in the delivered torque and power under this degraded condition compared to the healthy mode operation (

HMO). Therefore, the use of suitable controllers is required to increase the robustness and reject the disturbances in faulty mode operation (

FMO). For this purpose, an adapted proportional integral controller was firstly proposed using indirect rotor field-oriented control (

IRFOC) [

10], where the controller gains were tuned in the

dq reference frame for each

OPC occurrence by using a phase fault detection algorithm. Moreover, the vector space decomposition matrix must also be reconfigured each time with the number of remaining phases to keep a better decoupling between the different subspaces. This technique demonstrates a good reduction of the torque ripples on

OPC occurrence, but a lower torque value is to be expected in the machine. Furthermore, switching between different controllers requires a fault detection algorithm that can be critical.

In the literature on nonlinear controllers, model predictive control (

MPC) has recently been widely used for multiphase machines [

11,

12,

13]. This control technique uses a dynamic model of the system to predict its future behavior and then optimizes the control inputs to achieve a certain desired performance.

MPC presents the advantage of considering the constraints and disturbances that we desire to integrate into the control, such as those found in multiphase machines, by trying not only to control the torque and the flux but also to improve the efficiency of the machine [

14]. Nevertheless, the success of

MPC depends on the quality of the model used; therefore, an accurate representation of the dynamics of the machine is required. In addition, the implementation of

MPC requires powerful computing resources because it involves solving real-time optimization problems.

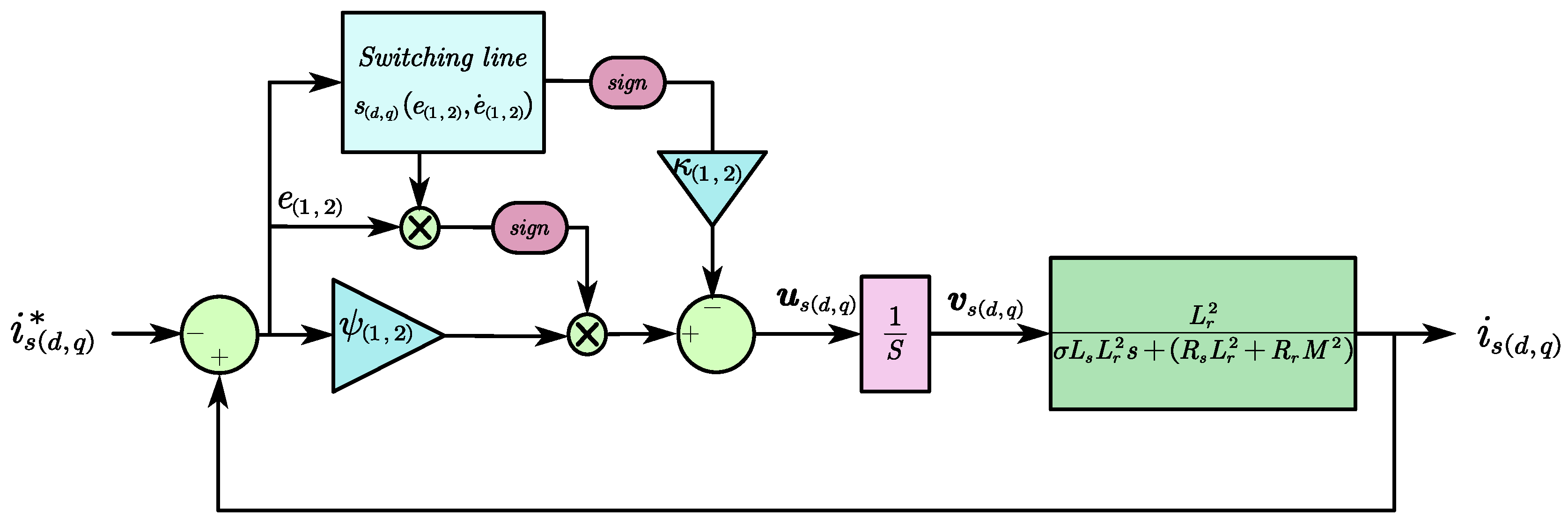

However, sliding mode control (

SMC) is among the most robust control techniques [

15,

16]. Indeed, despite its intrinsic issue, the chattering phenomenon, it has attracted particular interest from scientific researchers over the last two decades due to its low sensitivity to the parameter variations, disturbances, and uncertainties of the realistic model. In this way, a high-order sliding mode, based on a super-twisting algorithm to control the inner current loops in

HMO, has been tested and compared to the

MPC control. However, it turns out that the choice of gain for the discontinuous

SMC function can make the control signals more aggressive. In our laboratory, the sliding mode control with linear feedback and switched gains (

SMC–LFSG) has been experimentally tested and compared with a classical proportional integral controller under one

OPC [

17]. In comparison, by using the

SMC–

LFSG, the system robustness is guaranteed under

HMO and

FMO. Furthermore, using the

SMC–

LFSG, the chattering effect in the control signals is much less than when using the classical

SMC, which retains practically the same performance in

HMO and

FMO [

18]. Otherwise, the combination of

SMC with neural networks [

19], fuzzy logic systems [

20], and backstepping control [

21] has been also proposed in the literature to avoid the intrinsic problem of the

SMC.

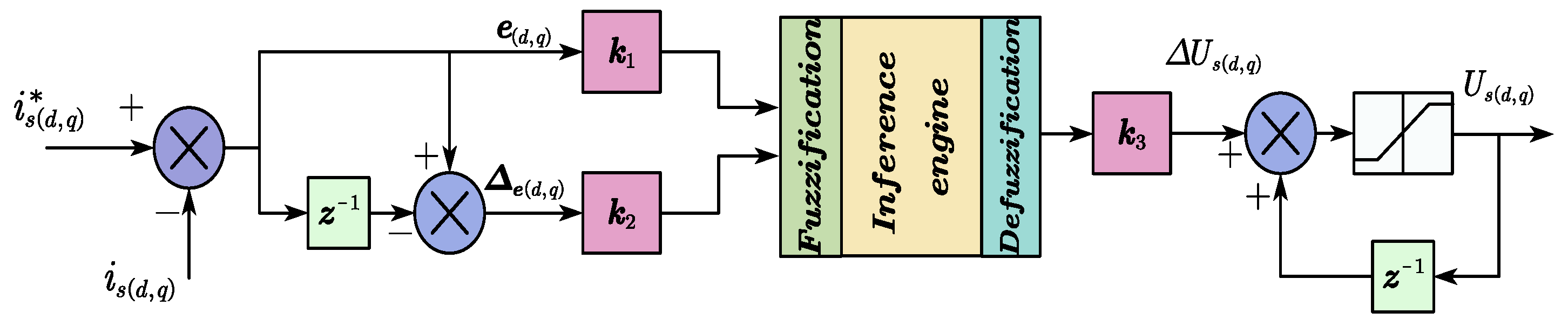

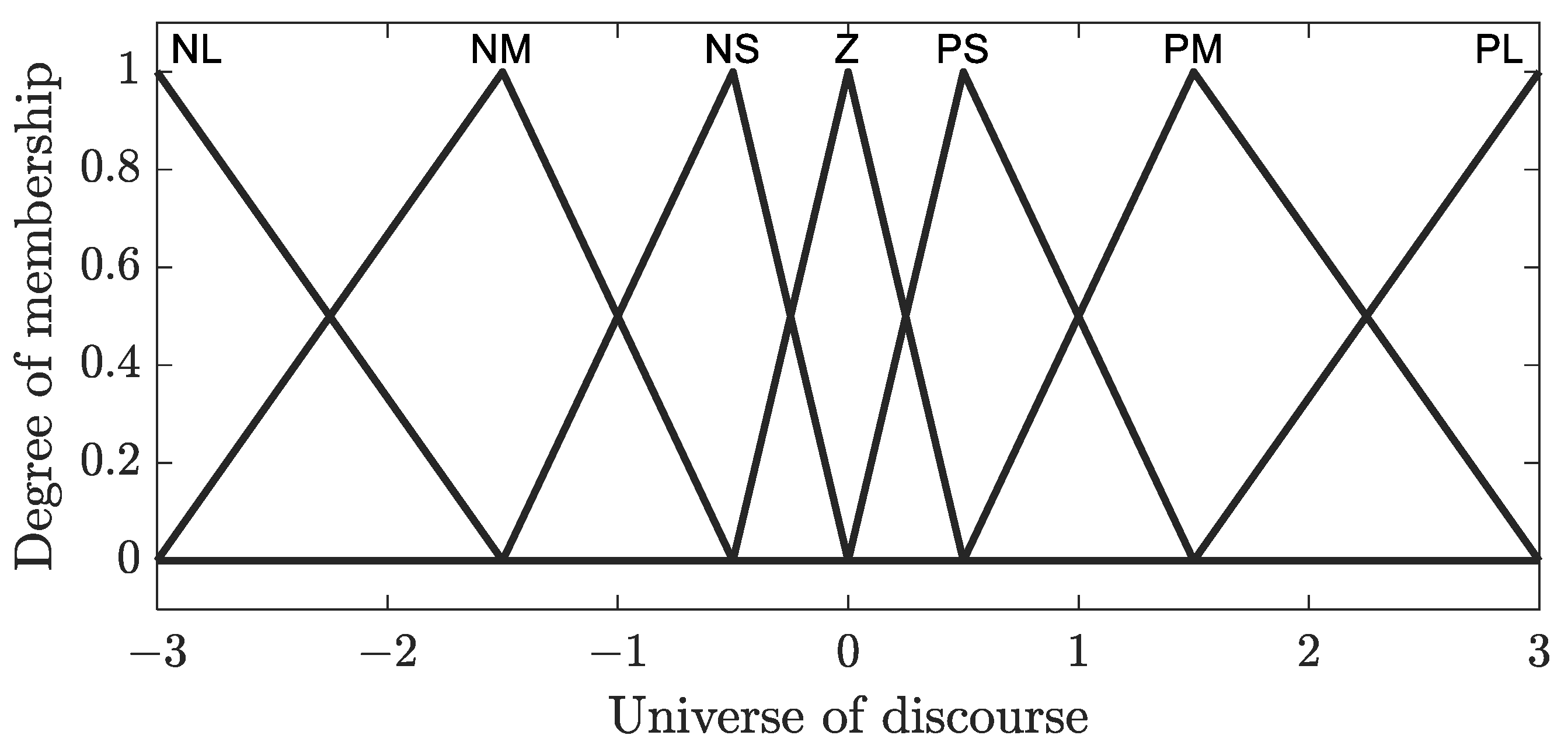

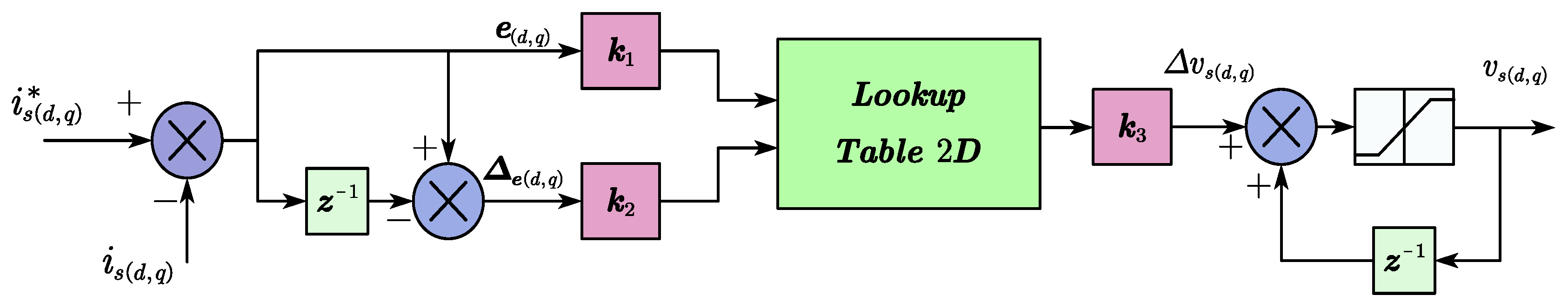

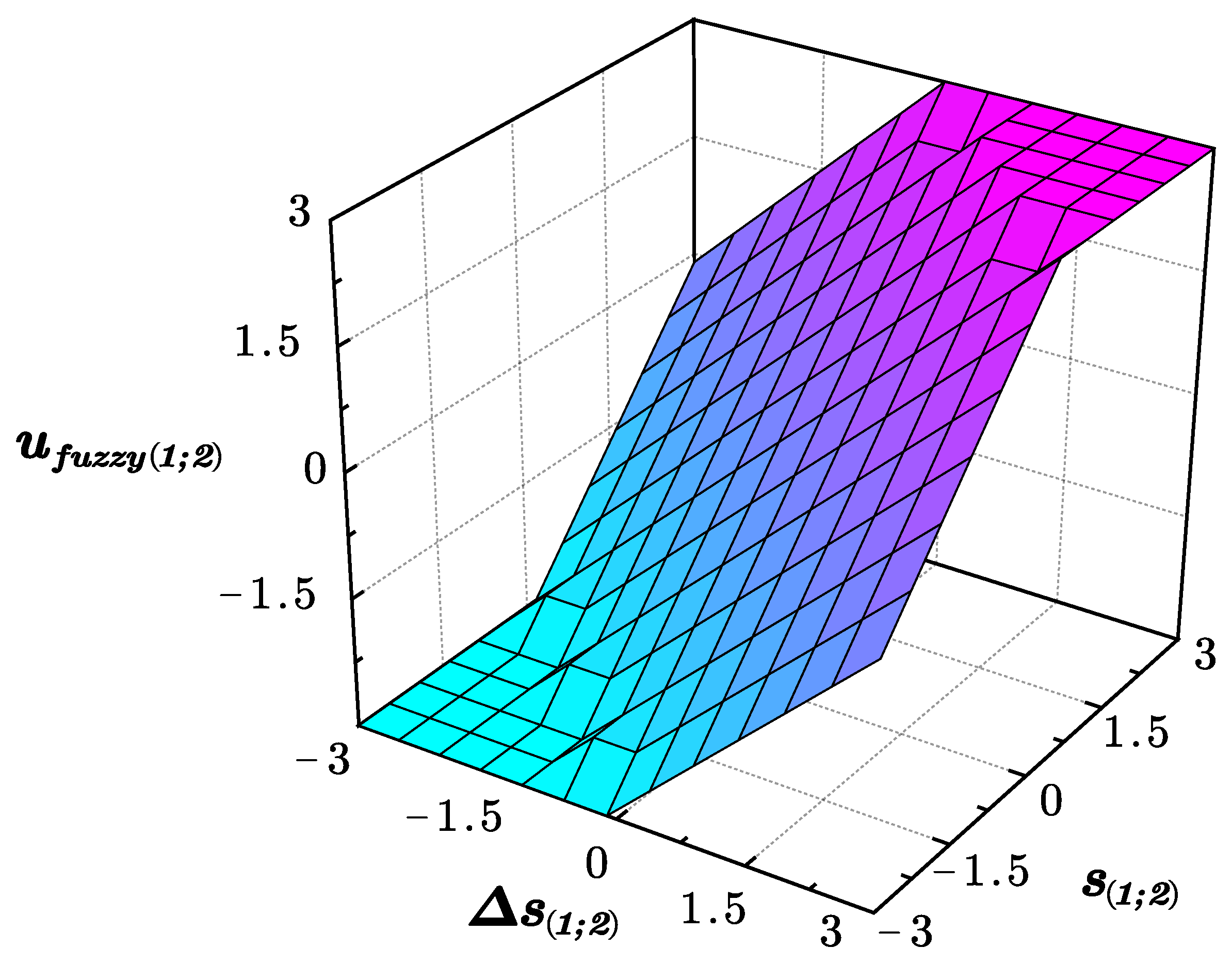

An additional nonlinear strategy is the fuzzy logic control (

FLC), often known as “intelligent control.” It is one of the most recently used controllers to regulate or model systems that have non-linear and complex behaviors. Indeed, many processes, notably electrical machines including the induction machine [

22,

23,

24], the stepping motor [

25], and the synchronous machine [

26], have been controlled using a fuzzy proportional integral controller (FPIC), which is widely employed and especially appreciated by many scientific researchers for its robustness against parameter variations and disturbances.

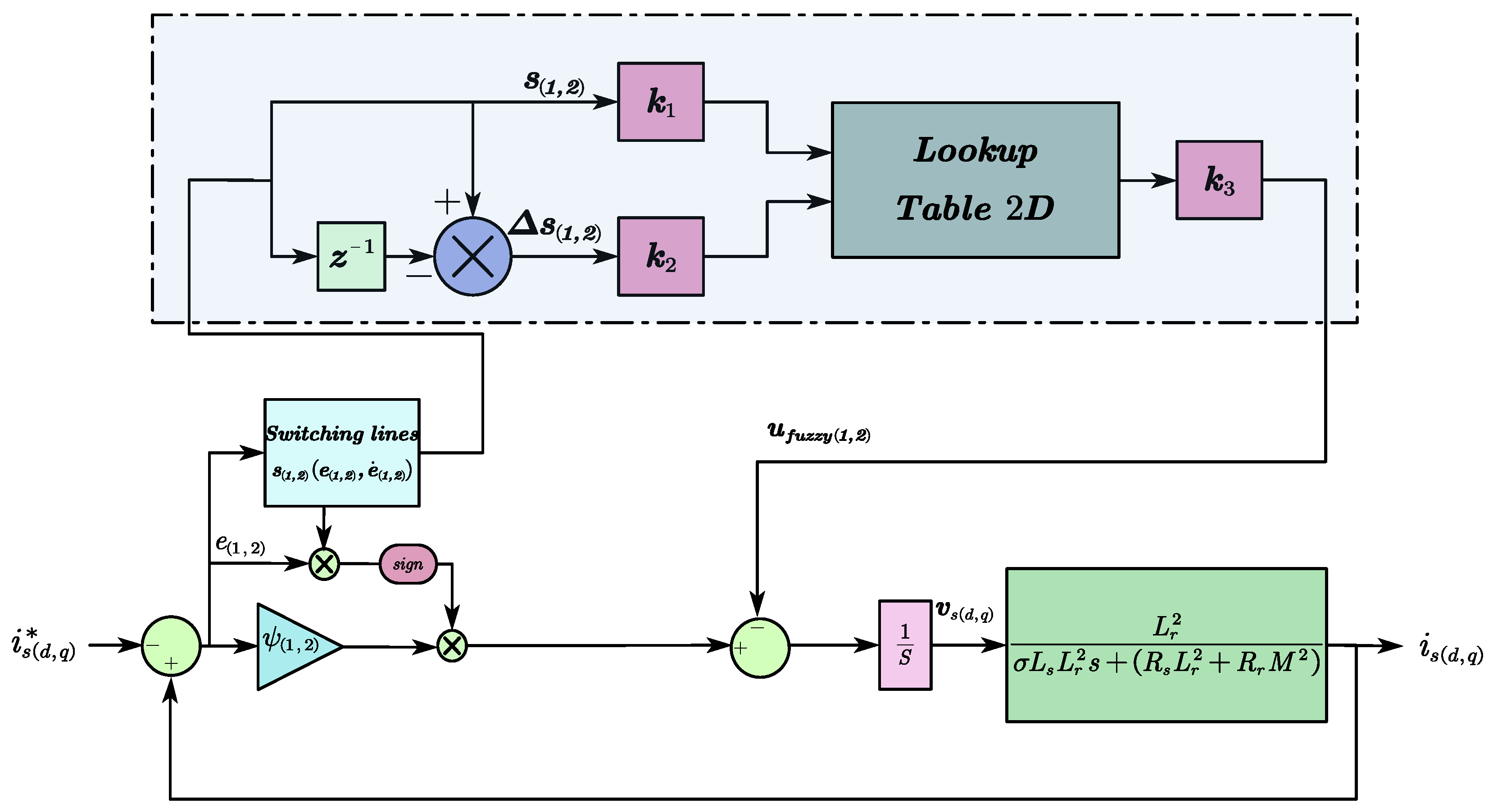

In this way, the combination of

SMC and

FLC, known as fuzzy sliding mode control (

FSMC), can provide several advantages over using either technique alone. Indeed, by using the classical SMC, discontinuous gain, which stays fixed for the entire control time and has to be large enough to cope with the parametric and external disturbances, can lead to the chattering effect. In this way, the

FLC can help to further reduce this problem [

27], which is a common issue in sliding mode control, by adjusting the control behavior smoothly [

28]. Additionally, this combination can improve the controller’s performance in the presence of uncertainties and disturbances. This strategy will also be presented and then evaluated in this paper to improve the performance of the

SMC–LFSG.

In this paper, these three nonlinear controllers (

FPIC,

SMC–LFSG, and

FSMC) are tested under different disturbances caused by the loss of one or two stator phases and compared with a classical proportional integral controller (

PIC), for the purpose of evaluating their capabilities in

HMO and

FMO. The second section will be dedicated to the prototype presentation, its mathematical model, and the

IRFOC approach. The third section is dedicated to the

SMC–LFSG algorithm based on the

Lyapunov stability theory, to the basic

FPIC structure with its real time implementation using a lookup table, and then to the

FSMC structure applied to the symmetrical six-phase induction machine (S6IM) in generation mode. Experimental results in healthy and faulty conditions are presented in

Section 4 and numerical comparisons in

Section 5. The last section of this article provides an overview of this article and some future works.

4. Experimental Results in Healthy and Faulty Conditions

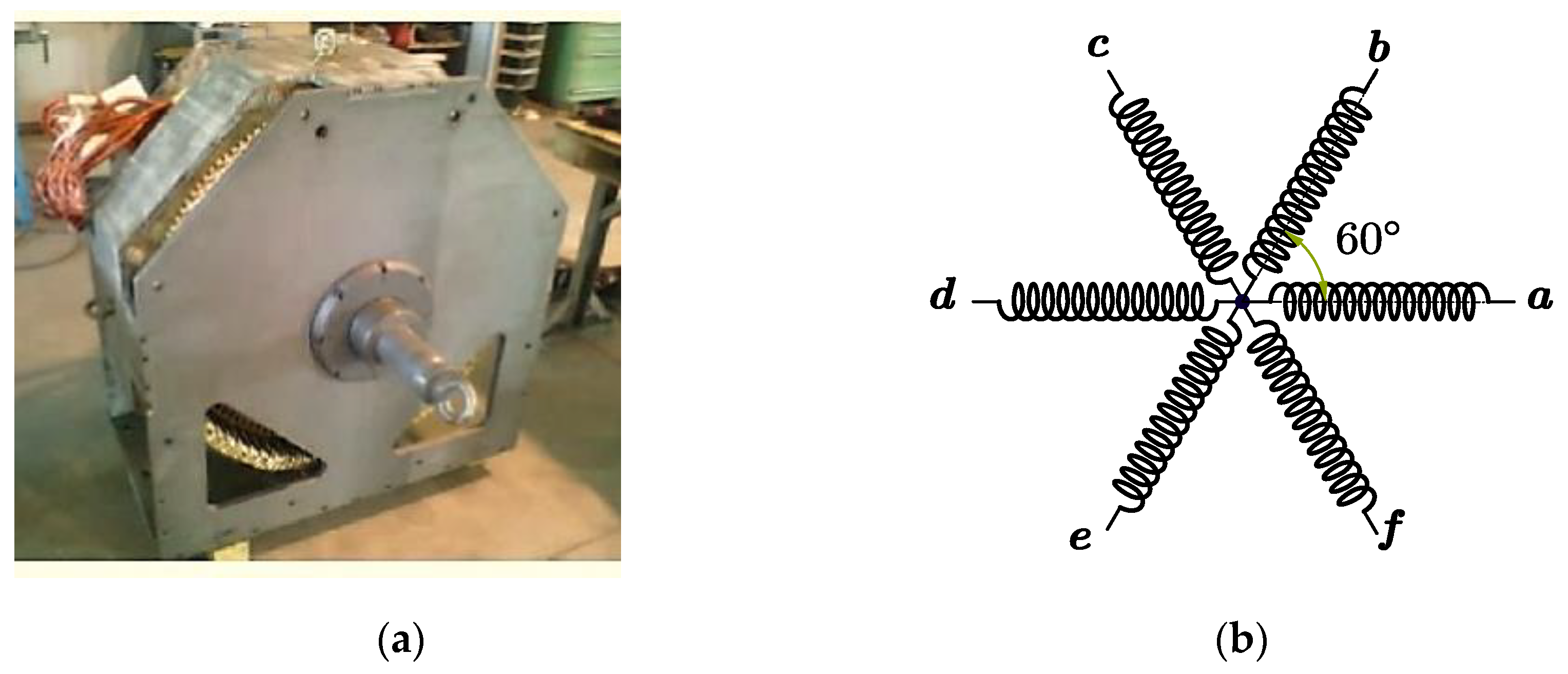

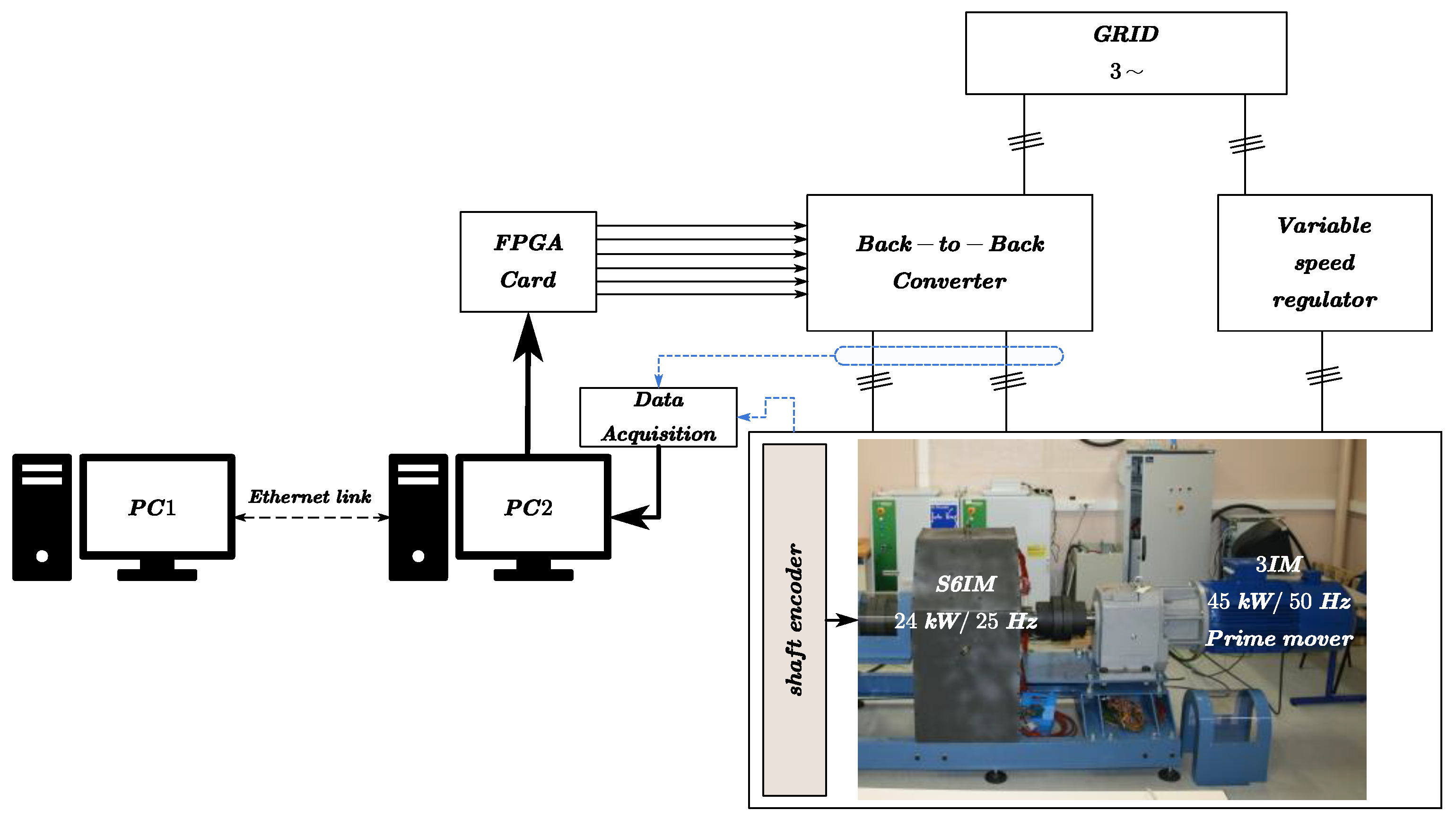

As shown in

Figure 9, a geared triphase induction motor (45 kW/1474 rpm) with an output ratio of 1/11 is used to drive the 24 kW

S6IM with an industrial variable-speed regulator. In our study, we are interested in the torque control in generator mode. Therefore, the desired electromagnetic torque of the

S6IM can be imposed by choosing a negative

q-axis stator current reference and the shaft speed is kept constant at 125 rpm.

The generated active power of the S6IM is injected into the grid using back-to-back converters.

The control algorithms are developed using MATLAB/Simulink R2012b software, which are first compiled on the first computer (PC1) and then transferred to the second computer (PC2). The two computers are linked to an ordinary Ethernet network via an IP address. To establish real-time communication between PC1 and PC2, the Secure Shell (SSH) protocol is used, which operates through port TCP/22.

The switching frequency is set to 10 kHz by using the classical Pulse Width Modulation (PWM) generated by a field programmable gate array (FPGA) card. The speed of the shaft is measured by an inductive angle encoder with a resolution of 4096 pulses per revolution.

The parameters of the various controllers (

PIC,

SMC–LFSG,

FSMC–LFSG, and

FPIC) are given in

Appendix B.

In this section, the capabilities of

PIC,

SMC-LFSG,

FSMC-LFSG, and

FPIC applied to the

S6IM will be tested experimentally in healthy and faulty conditions.

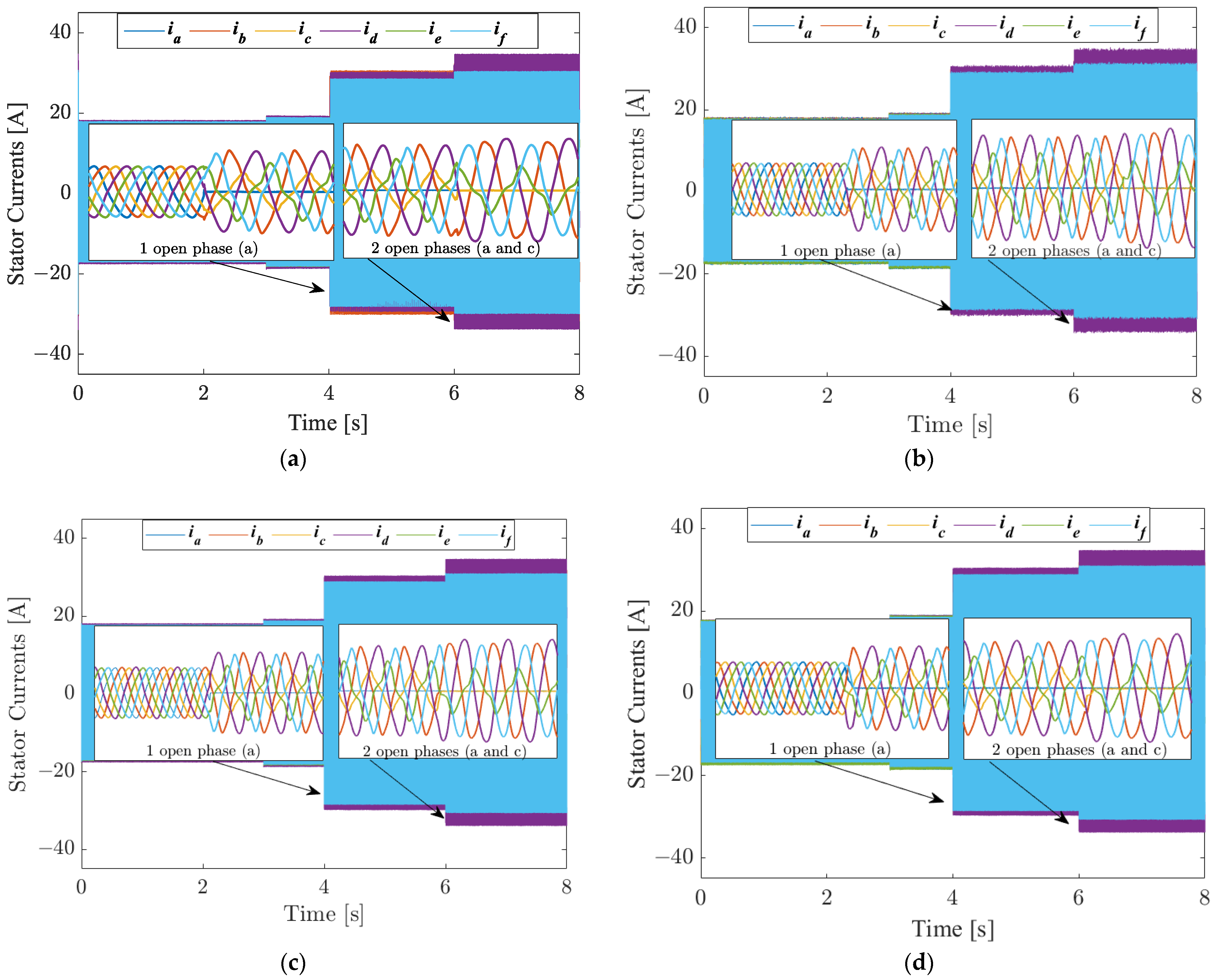

Figure 10 depicts the stator currents of the S6IM controlled by these four different control algorithms.

To ensure that the currents provided by the converters on the machine side do not exceed their maximum values after the loss of one or two phases, the isq current reference has been limited to −10 A at time t = 3 s. As can be seen, the loss of phase “a” has been introduced at time t = 4 s and then phases “a” and “c” at time t = 6 s. We can observe the stator currents’ behaviors on the zooms with each controller under HMO and FMO.

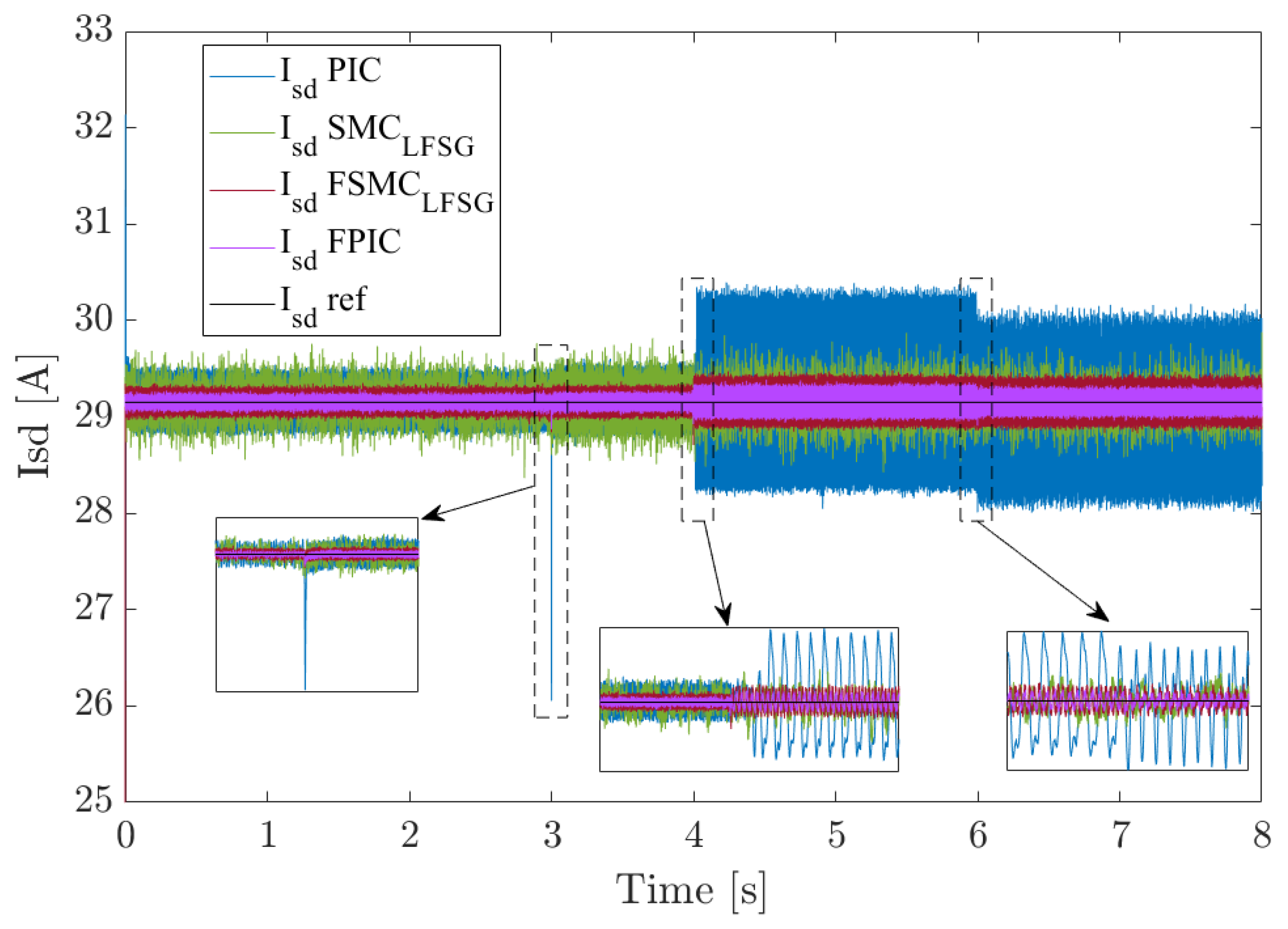

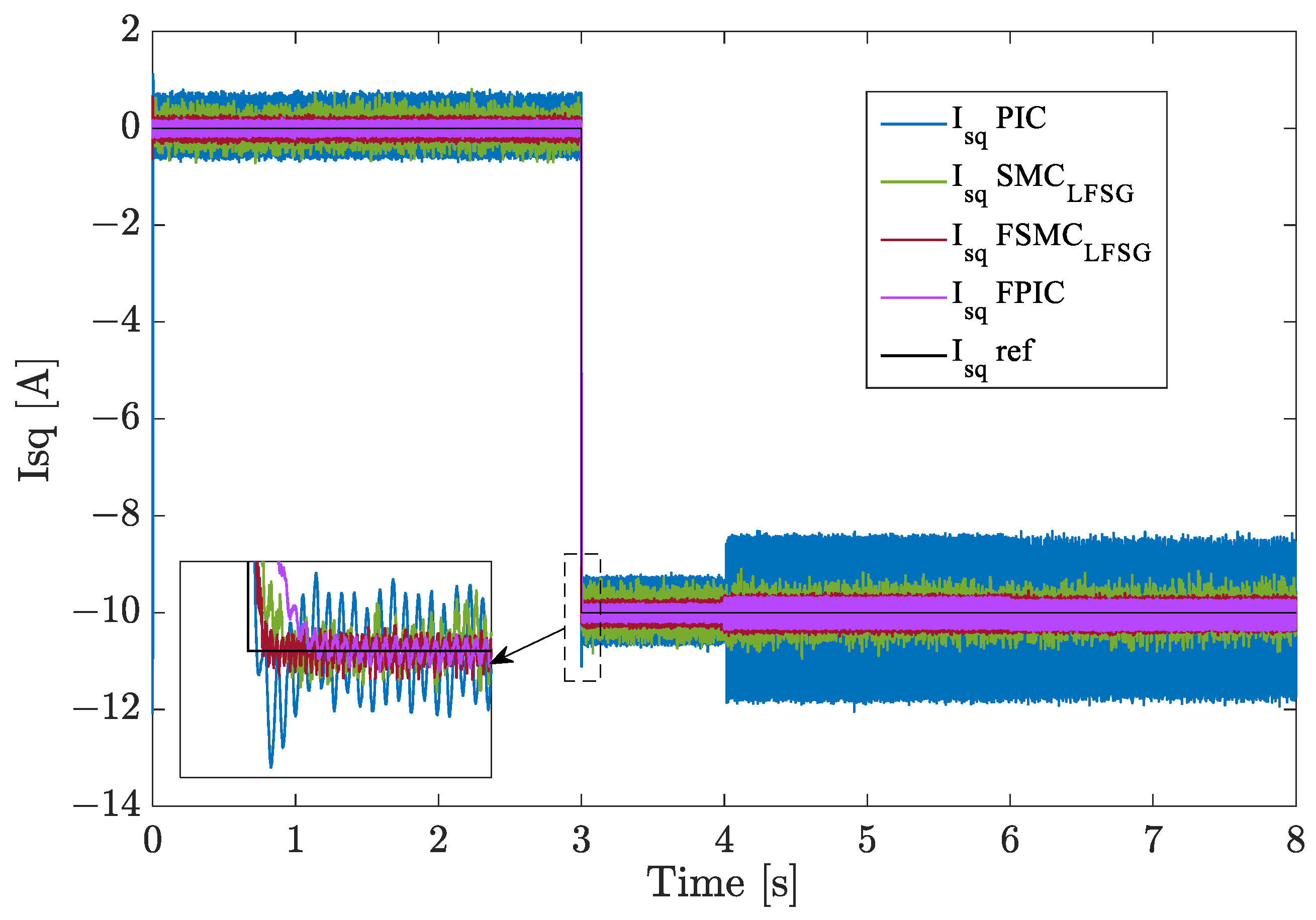

Figure 11 and

Figure 12 depict the experimental evolution of the stator currents along the

d and

q axes, respectively, with the same four controllers (

PIC,

SMC-LFSG,

FPIC, and

FSMC–LFSG) tested under the same test conditions. At time 3 s, we can see that the classical controller (

PIC) is very sensitive to reference variation, as can be clearly seen during the reference for both

dq currents. Moreover, it exhibits significant ripples following the loss of one phase at time 4 s. Otherwise, the use of

SMC–

LFSG results in fewer oscillations compared to the

PIC in both

d and

q stator currents. In the same way, the

FPIC and the

FSMC–

LFSG demonstrate consistent performance in both conditions (

HMO and

FMO). Nevertheless, by comparing all controller results,

FPIC presents the best adaptability, with reduced ripples in the

dq stator currents and improved accuracy.

5. Comparison of the Controllers under Healthy and Faulty Modes

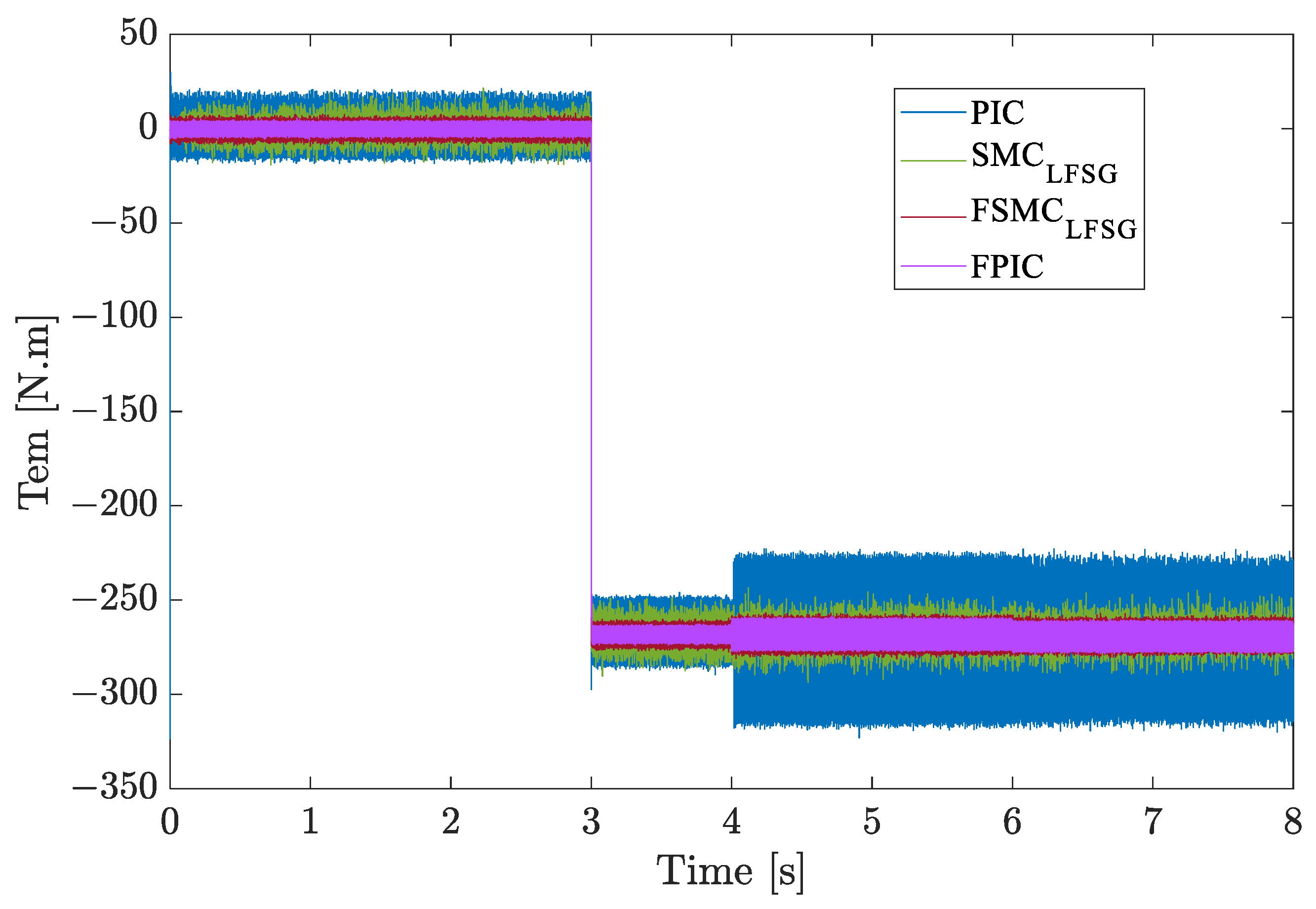

In this section, the estimated electromagnetic torque (see

Figure 13) of the

S6IM using the four controllers (

PIC,

SMC–

LFSG,

FSMC–

LFSG, and

FPIC) is depicted in the same conditions as those in

Section 4. When the phases (“a” and “c”) are lost (after t = 4 s), it is obvious that the

PIC is no longer at all suitable. Additionally, the

SMC–LFSG proves to be robust by allowing the compensation of parameter variations and uncertainties related to this type of electrical fault. We also notice that this technique of

SMC based on

LFSG presents less overshoot compared to the other sliding mode algorithms implemented in [

16,

35]. With

FSMC–LFSG, the torque ripples minimization is improved compared to the

SMC–LFSG by integrating the fuzzy logic component, providing better performances in terms of rising time and overshoot (see

Table 3). The electromagnetic torque ripples are also reduced compared to the

SMC–LFSG, with better tracking of desired trajectories. However, despite the long rise time of the

FPIC, it generates the least amount of electromagnetic torque ripples and exhibits improved tolerance after

OPCs (“a” and “c”), which justifies its high robustness compared to the other controllers.

Table 4 introduces a synthesis of the mean squared error (MSE) for the

dq stator currents in

HMO and

FMO. We can clearly deduce that the

FPIC allows a better reduction of the MSE compared to other controllers (

PIC, SMC–LFSG, and

FSMC–LFSG) in both operational conditions

HMO and

FMO.

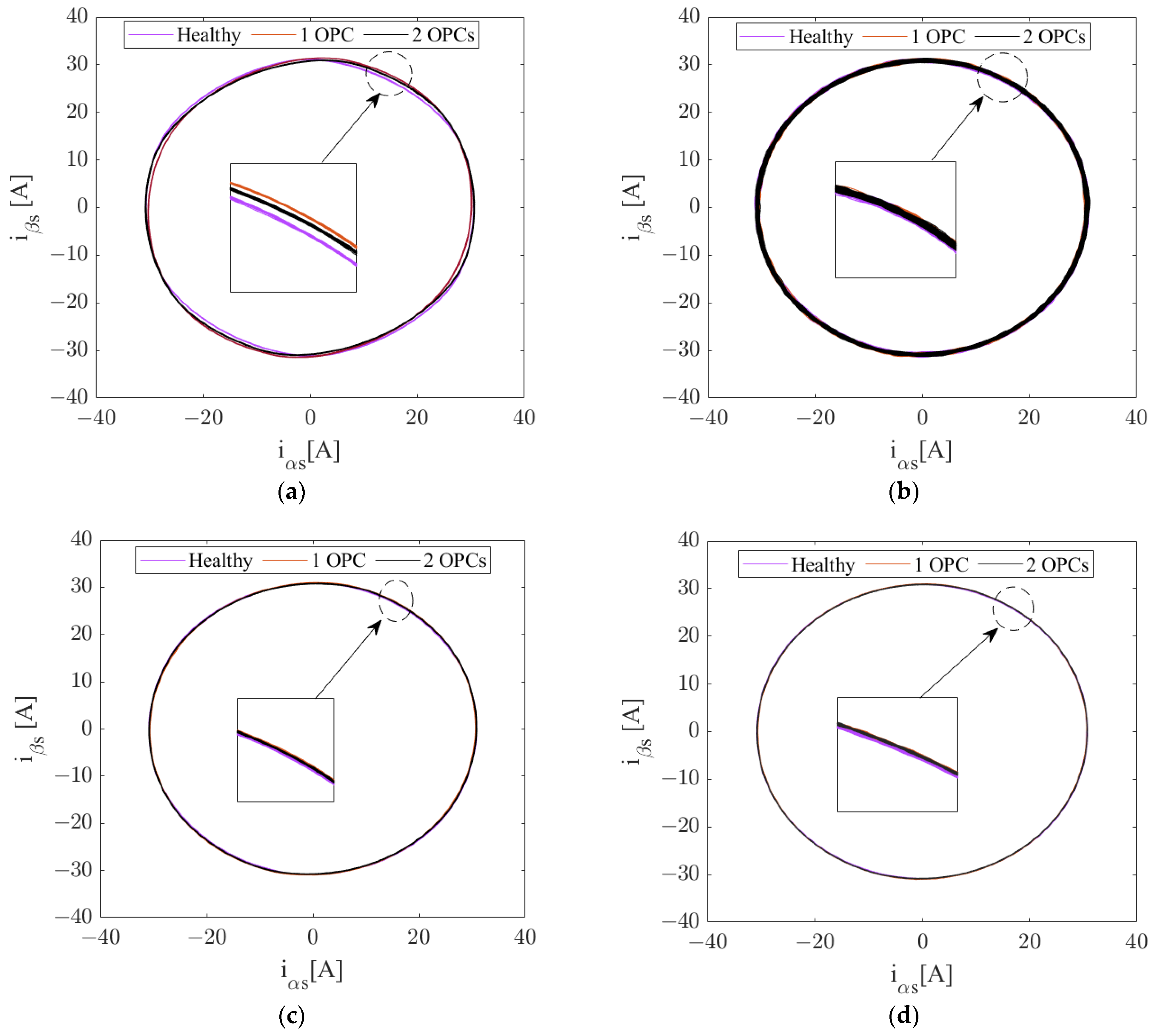

Always in the same conditions,

Figure 14 depicts the

αβ stator currents with the four proposed controllers in

HMO and

FMO. For the

PIC (see

Figure 14a), we can see in the zoom that the trajectories of the

αβ stator currents are disturbed after the opening of the phases, which explains the large oscillations in the extracted electromagnetic torque of the

S6IM. On the other hand, the other algorithms,

SMC–

LFSG,

FPIC and

FSMC–

LSFG, maintain the same circular pattern in

HMO and

FMO.

6. Conclusions

In this paper, the proposed robust algorithms (SMC–LFSG, FPIC, and FSMC–LFSG) for the inner current loops of the S6IM have been experimentally tested and compared under HMO and FMO of the S6IM in our laboratory.

The stability of the SMC–LFSG has been proved for the S6IM to ensure convergence of the control law. The experimental results with SMC–LFSG show good performance in terms of robustness and accuracy in HMO and FMO for the regulation of inner currents and electromagnetic torque. The only drawback of this control strategy is that the gain of the discontinuous part has to be chosen so that it is large enough to eliminate the upper limit of the model’s uncertainties and parameter variations, which can lead to the undesirable phenomenon of chattering.

This effect can be reduced by introducing fuzzy logic in the determination of the discontinuous part. Indeed, with this association, called FSMC–LFSG, the control signal can be smoothed, alleviating the chattering effect in HMO and FMO.

Finally, with FPIC, the extracted electromagnetic torque presents a higher quality since the ripples are advantageously minimized. Indeed, this control strategy demonstrates a very efficient robustness in comparison with the other controllers. Combining this algorithm with S6IM makes the energy conversion process even more robust to the disturbances and parameter variations.

The next challenge of this study is to increase the machine’s efficiency by minimizing losses and finding the optimum point of operation in faulty mode operation for different possible open-phase scenarios.