Optimization of Brake Feedback Efficiency for Small Pure Electric Vehicles Based on Multiple Constraints

Abstract

:1. Introduction

2. Numerical Approaches

2.1. Vehicle Braking System and Dynamometer Bench Test

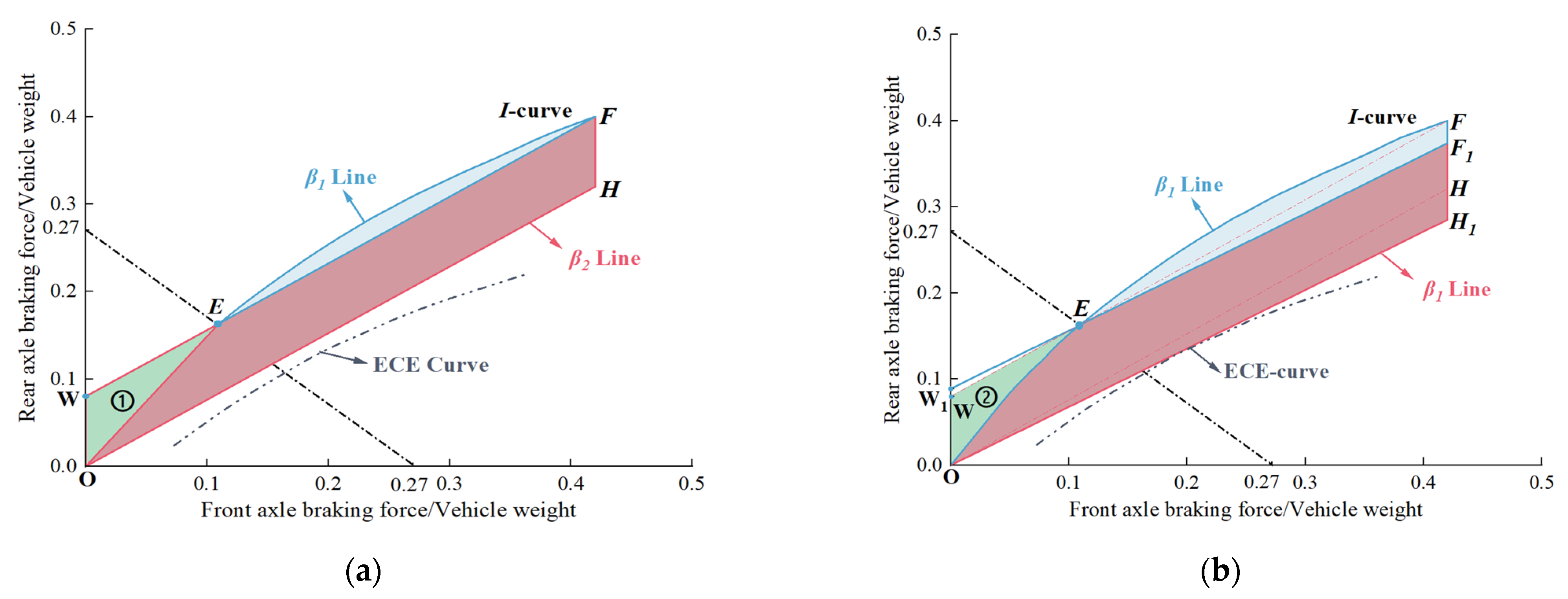

2.2. Definition of Constraints

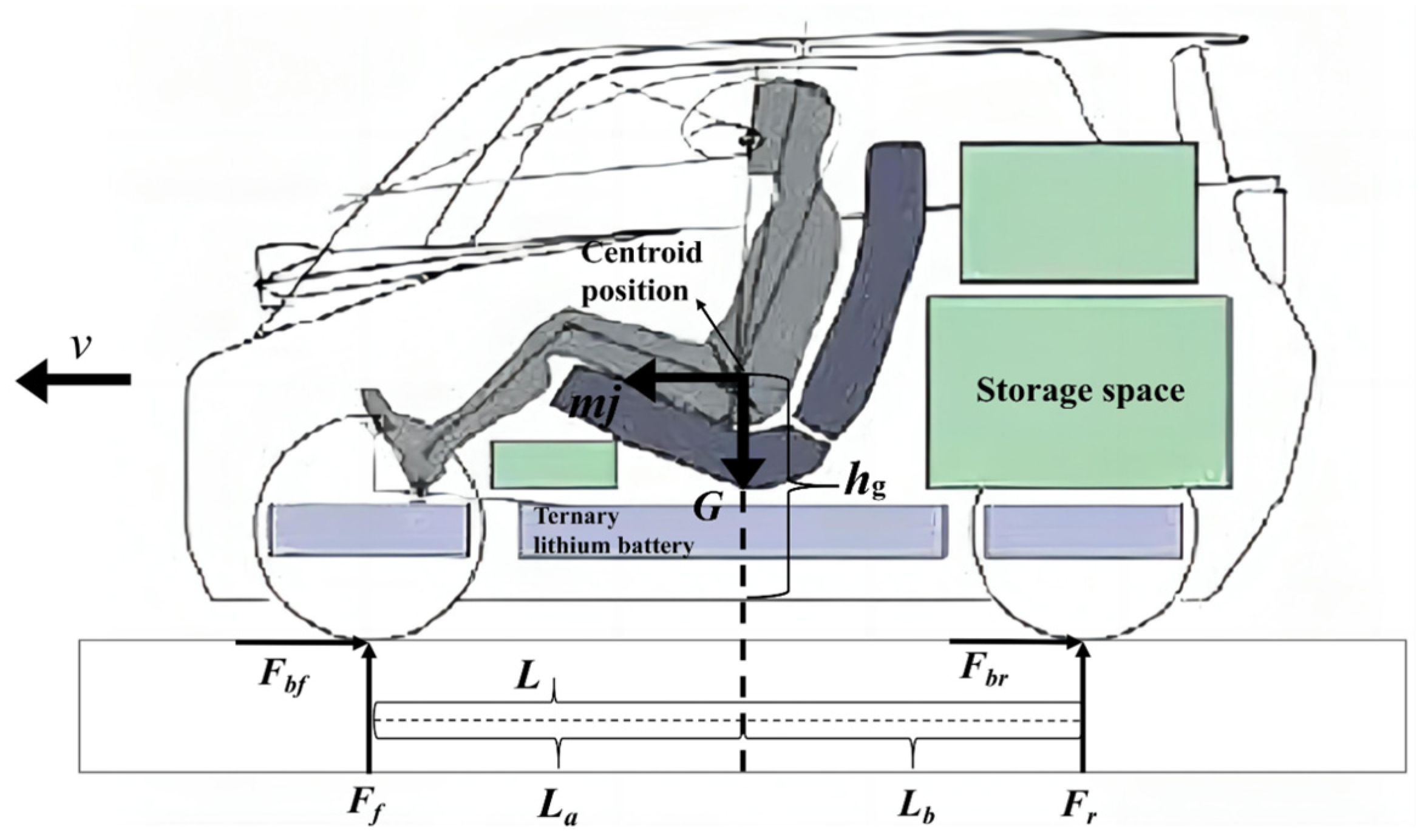

2.2.1. Vehicle Braking Mechanics Analysis

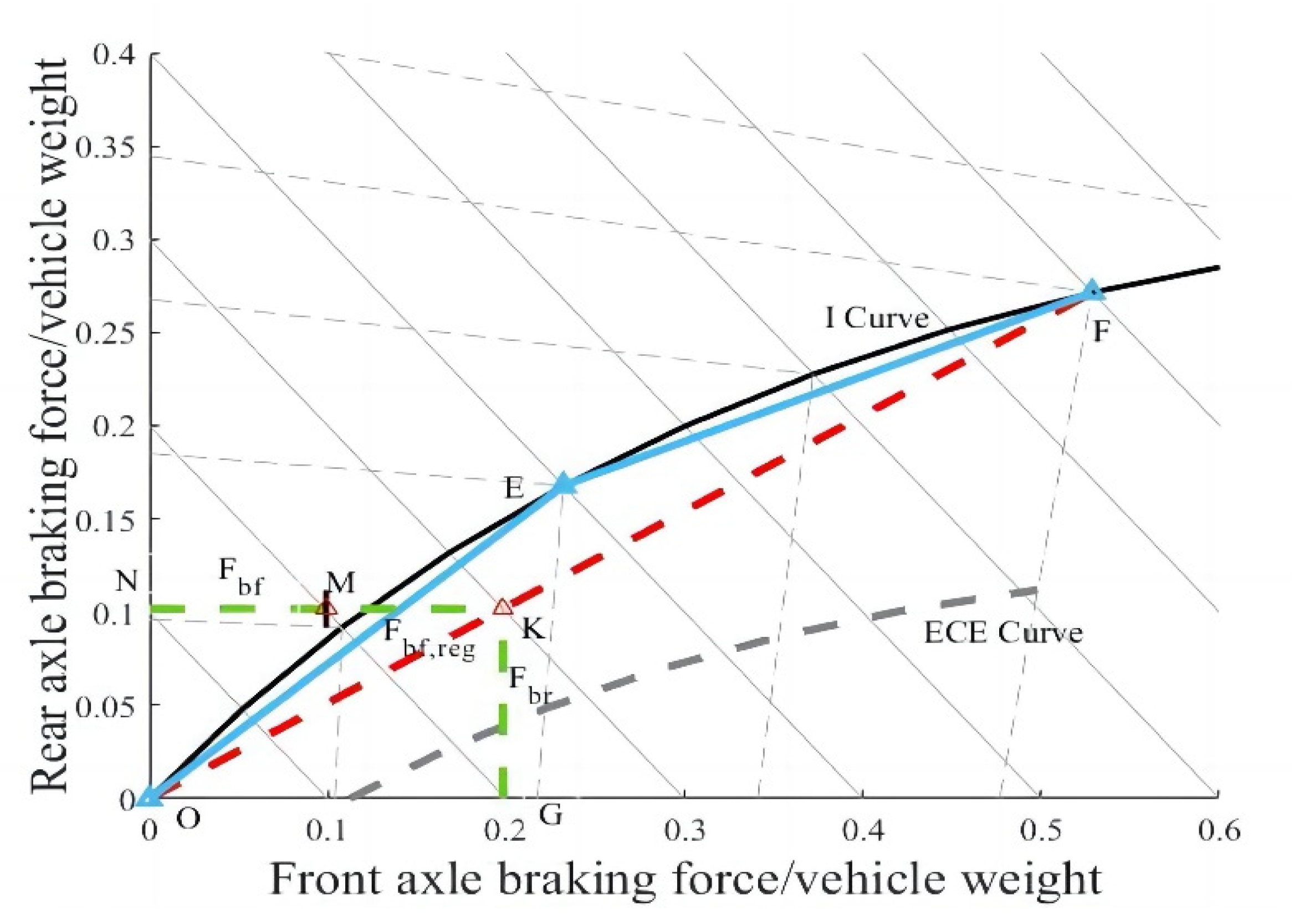

2.2.2. Regulatory Constraints

2.2.3. Decoupling Control Constraints

2.2.4. Redundancy Constraints

2.2.5. Optional Vehicle Configuration Constraints

2.3. Feedback Efficiency and Braking Efficiency

2.4. Application Algorithms and Flow Charts

3. Results and Discussion

3.1. Brake Feedback Scheme for Rear Drive

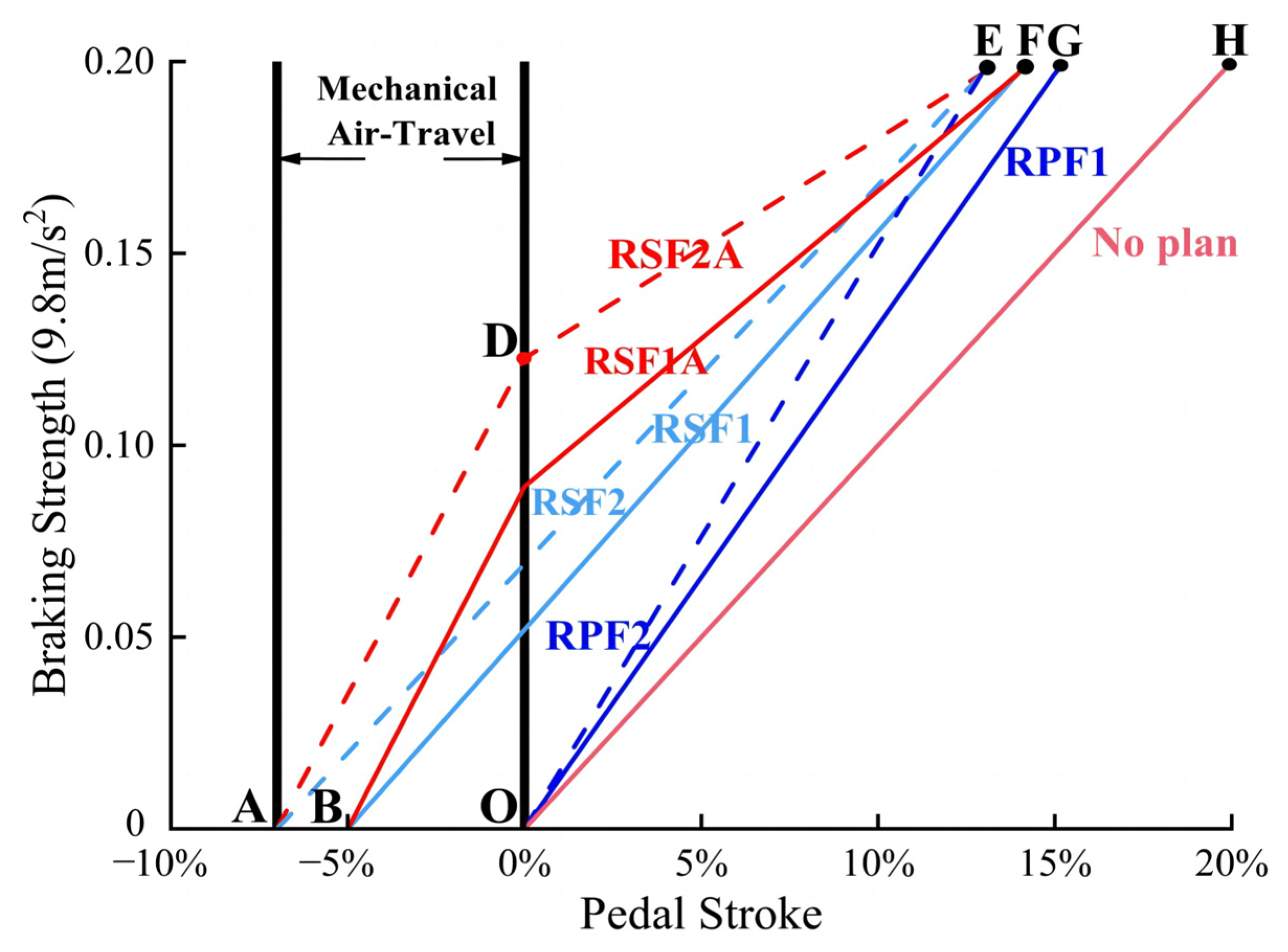

3.1.1. Parallel Braking Feedback Scheme RPF1/RPF2

3.1.2. Series Brake Feedback Scheme RSF1/RSF2

3.1.3. Series Brake Feedback Scheme RSF1A/RSF2A

3.2. Brake Feedback Scheme for Front-Wheel Drive

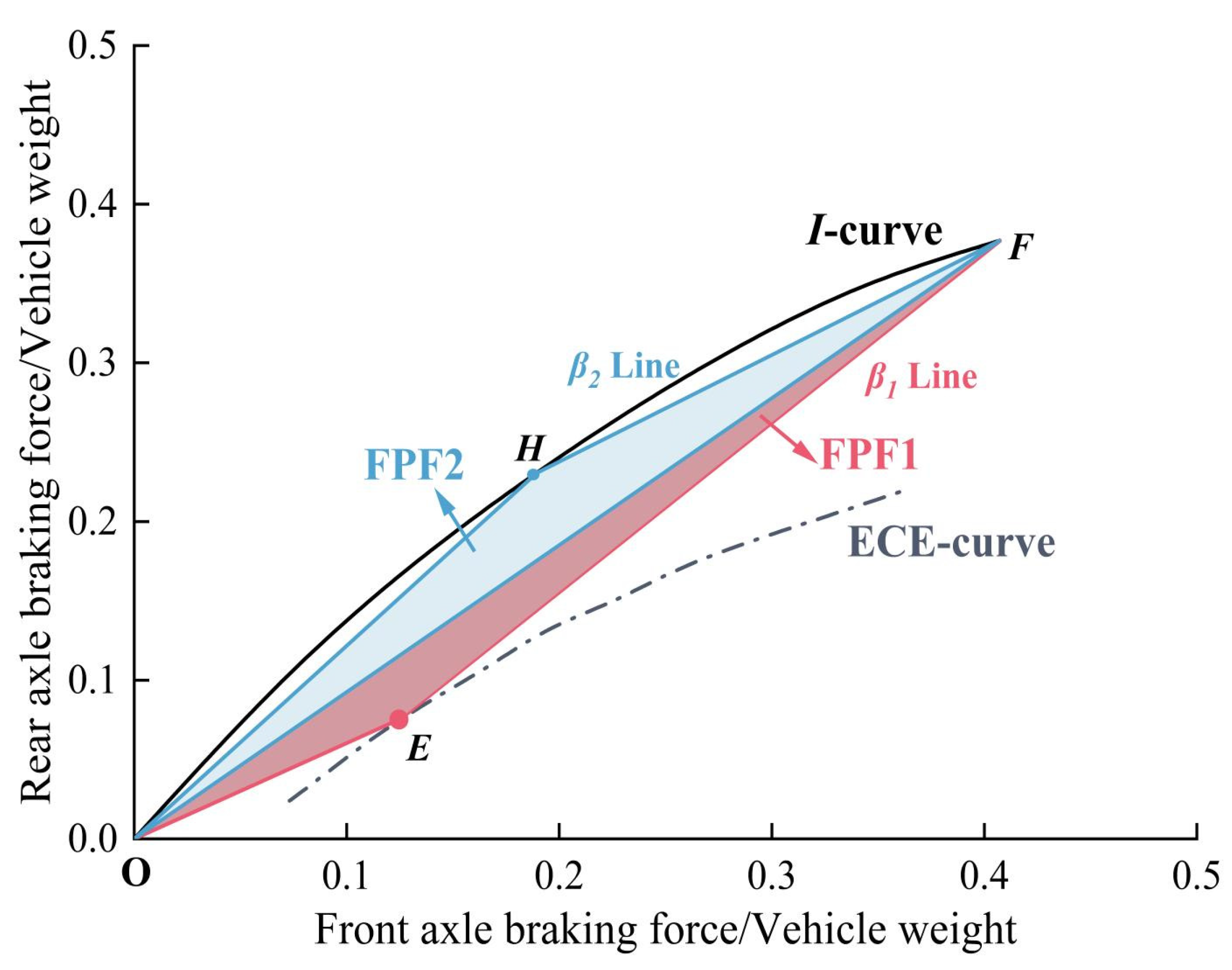

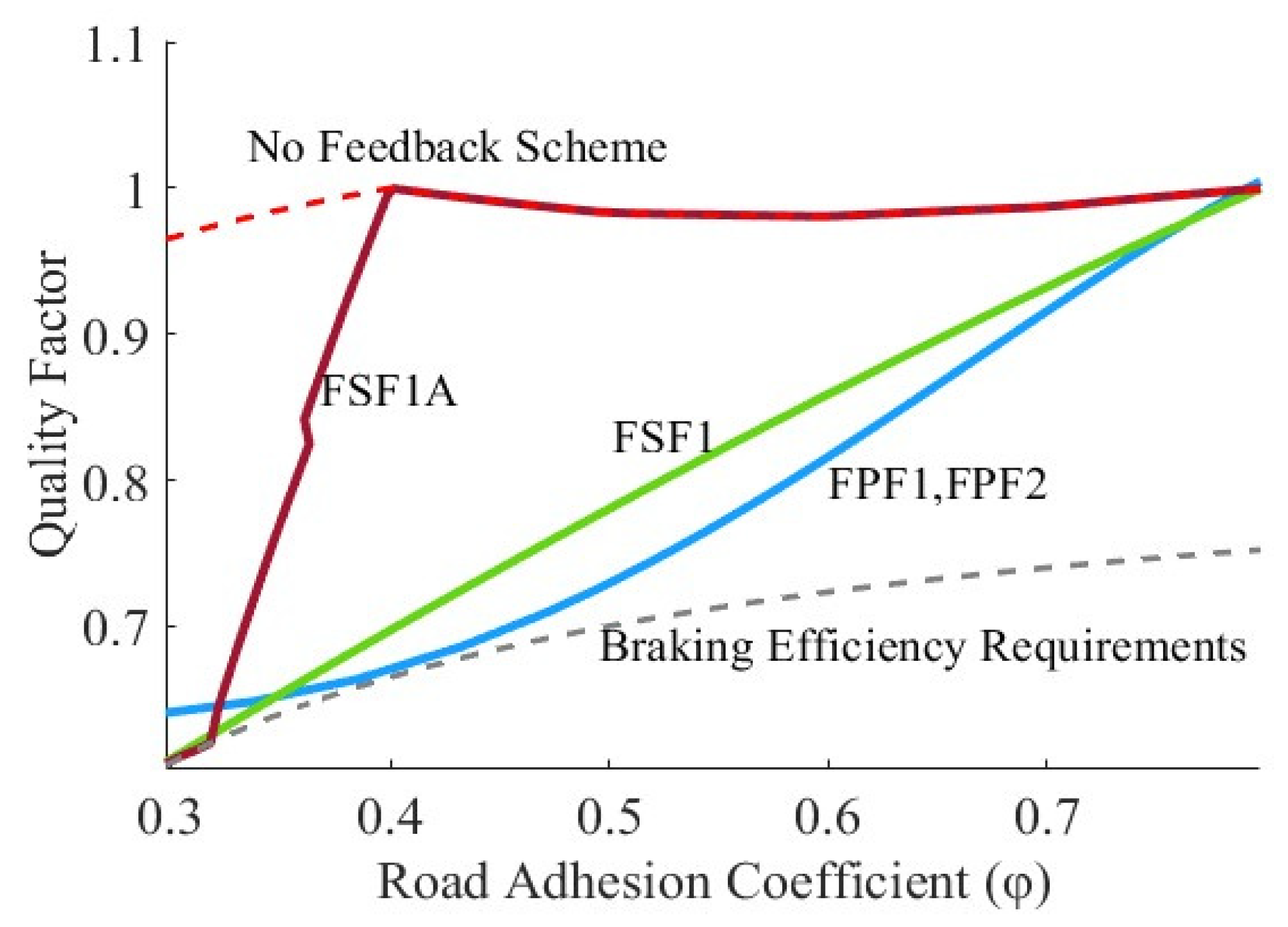

3.2.1. Parallel Braking Scheme FPF1/FPF2

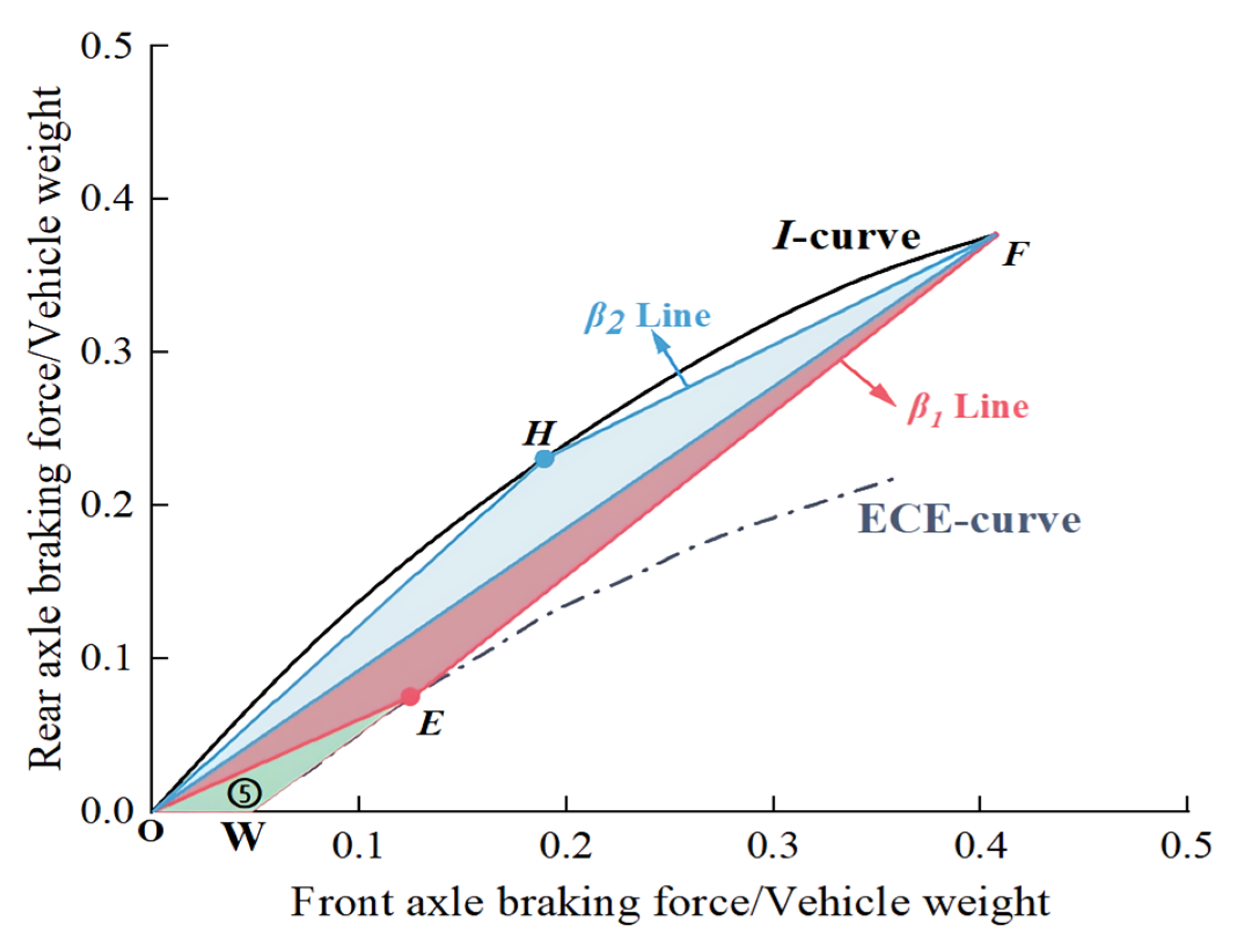

3.2.2. Series Braking Scheme FSF1

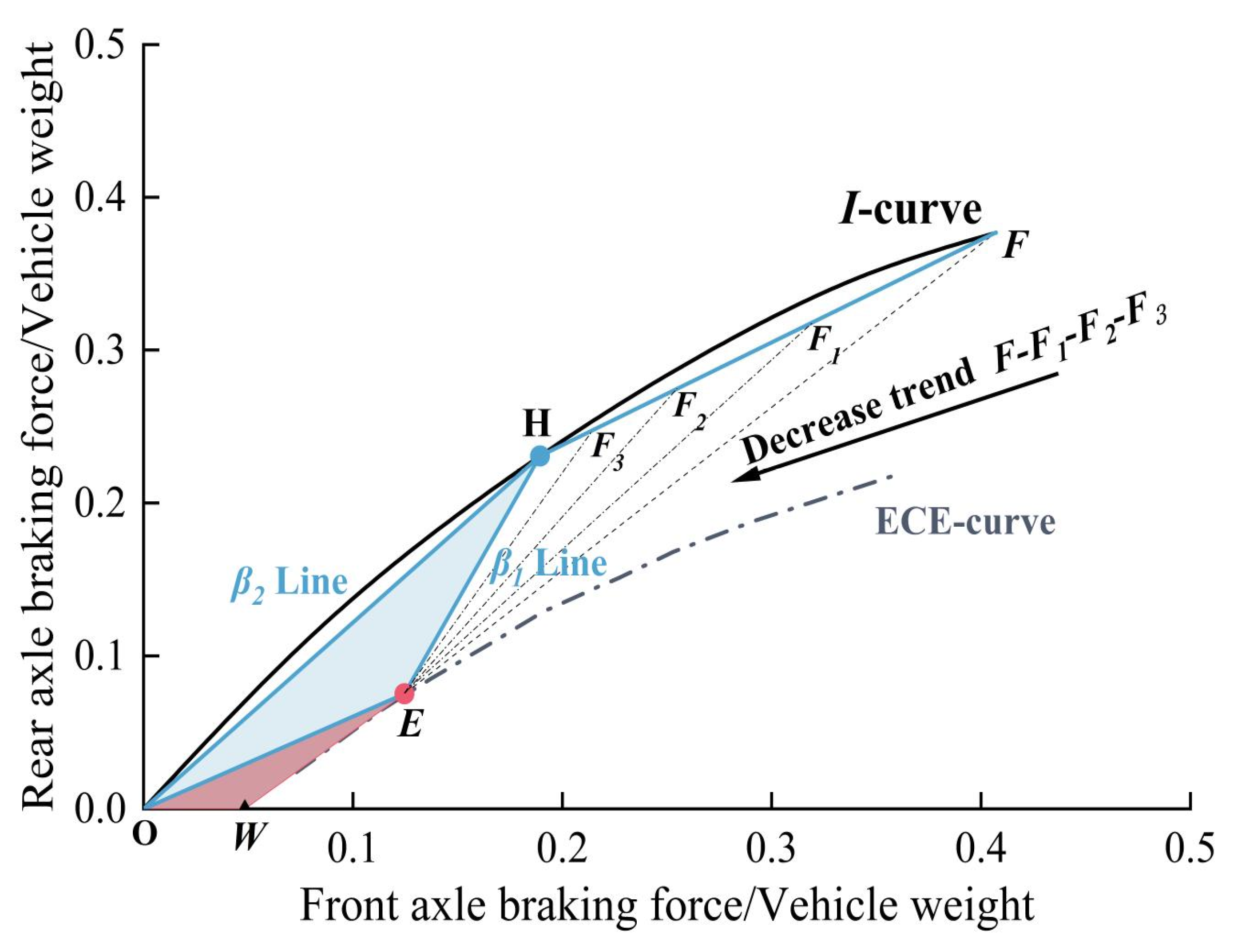

3.2.3. Series Braking Scheme FSF1A

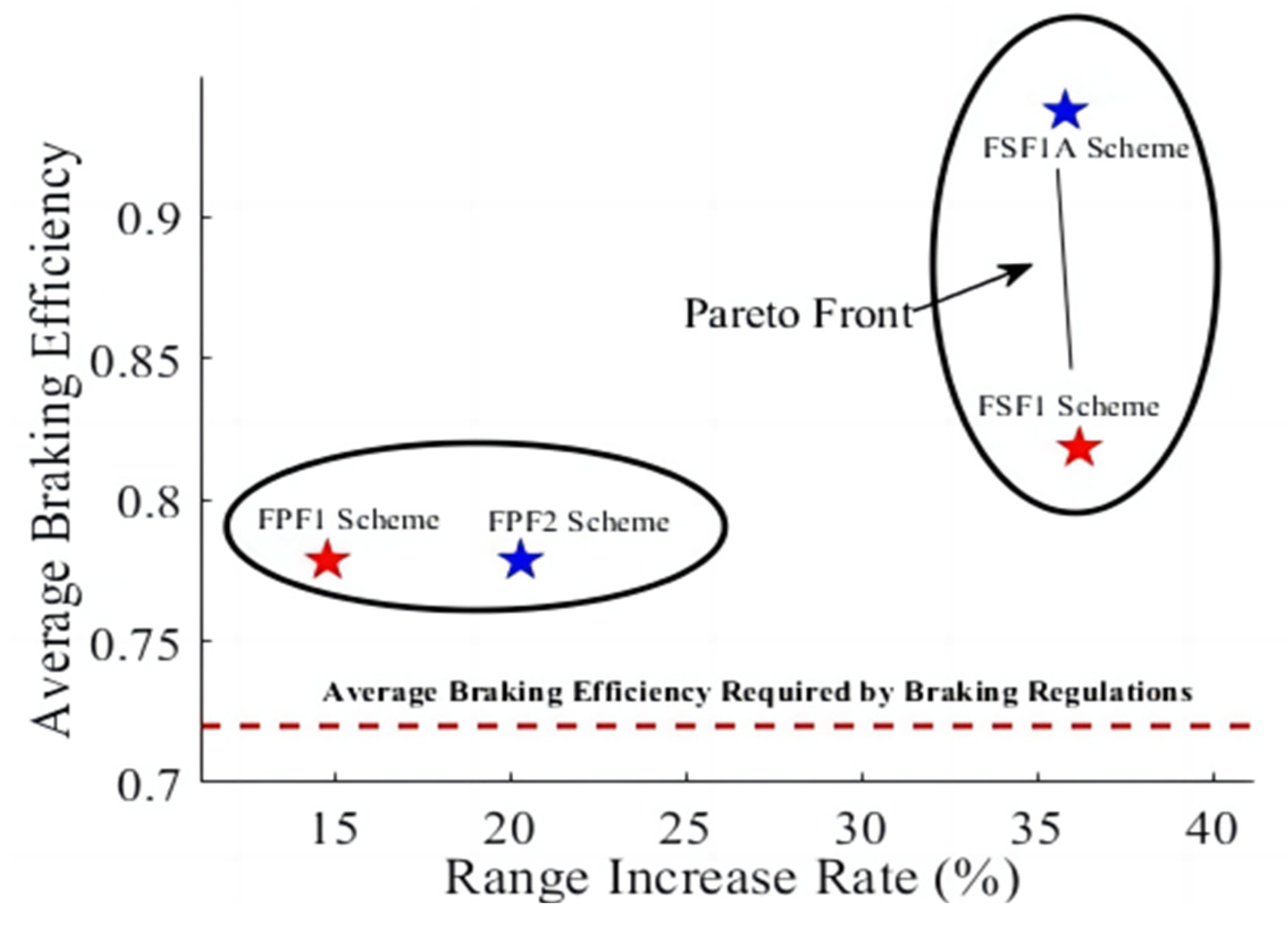

3.3. Comparison and Optimization Analysis of Braking Feedback Schemes

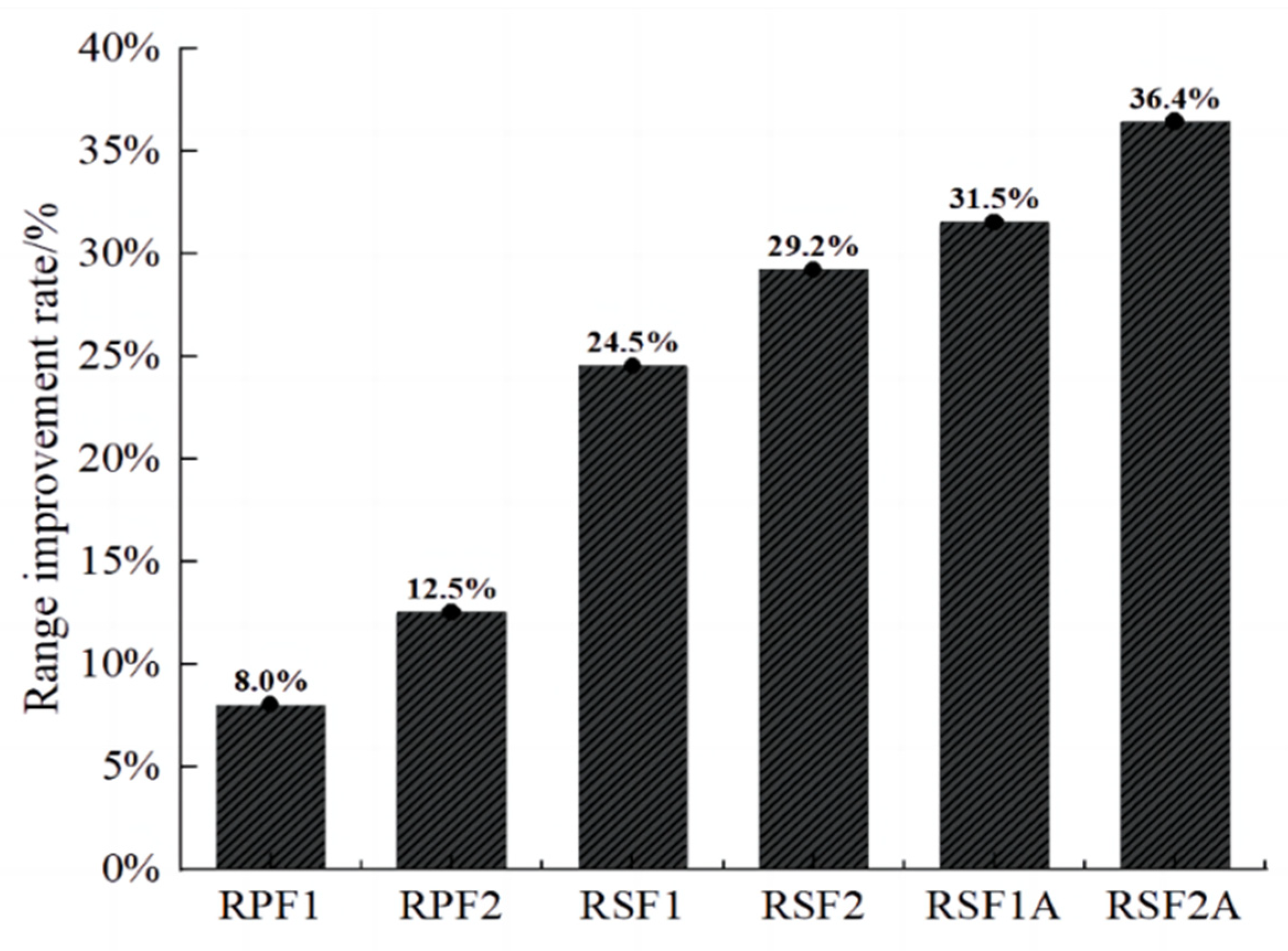

3.3.1. Rear-Drive Scheme

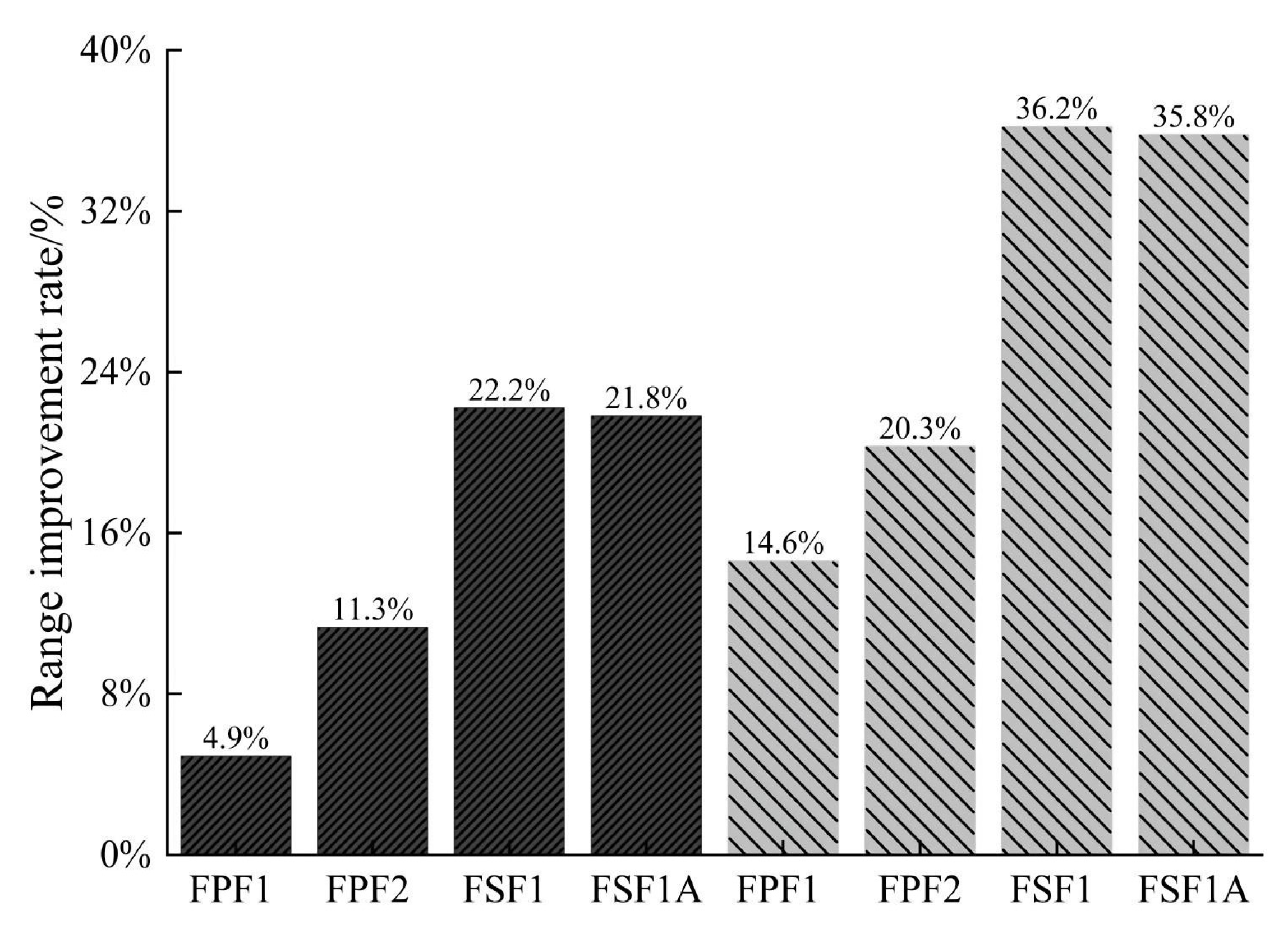

3.3.2. Front-Wheel Drive Scheme

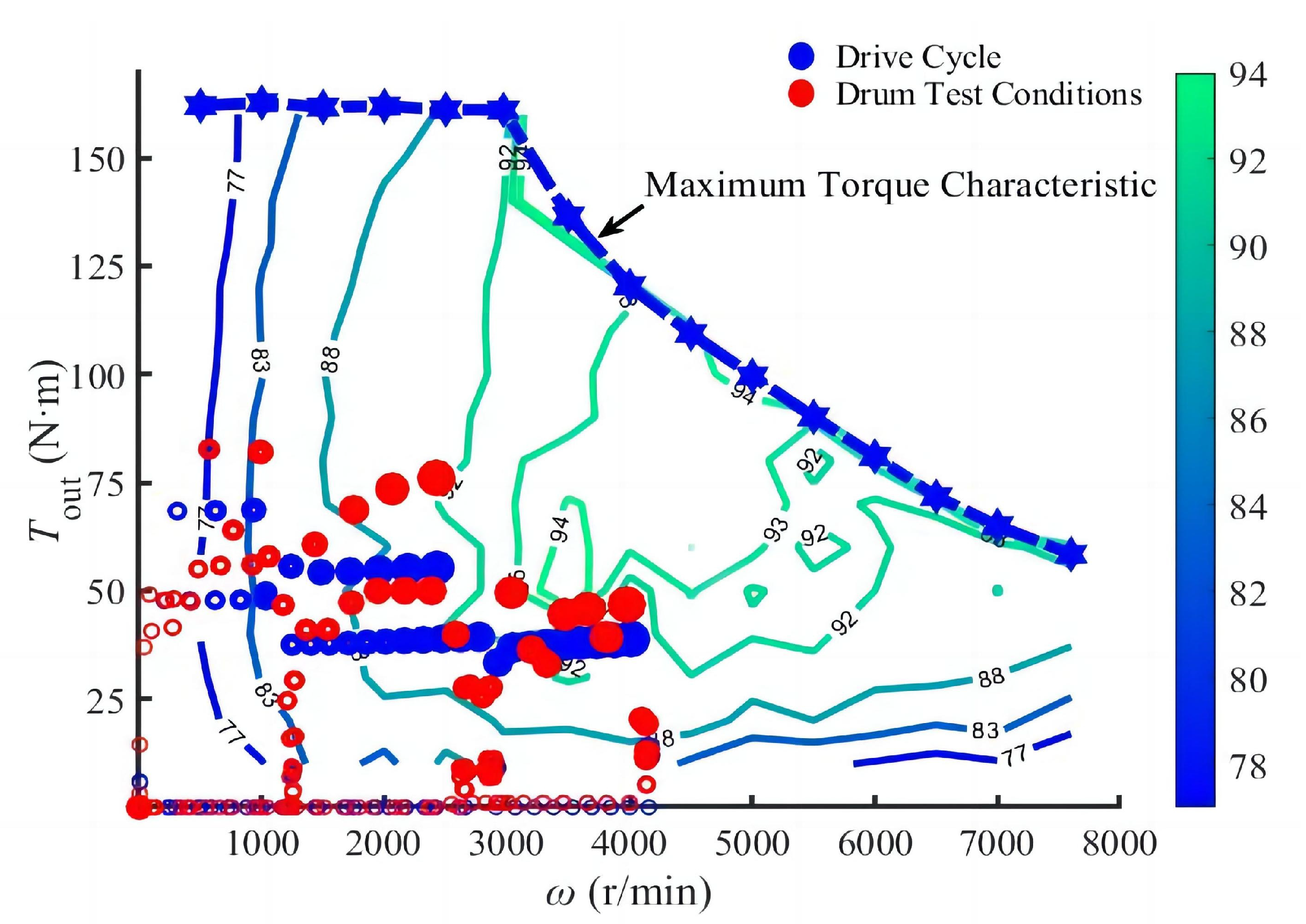

3.4. The Feasibility Verification of the Braking Feedback Scheme

4. Conclusions

- (1)

- For the rear-driving type, the braking feedback efficiency is gradually improved from the PRF1 scheme with higher constraints on vehicle configuration to the RSF2A scheme with lower constraints on vehicle configuration. Therefore, with the increase in vehicle configuration constraints, the lower the optional vehicle configuration constraints, the higher the mileage improvement rate.

- (2)

- For rear-drive models, RSF2A schemes that over-rely on vehicle configuration condition 3, pedal characteristics, have poor overall performance. On the contrary, the RSF2 scheme which is not highly dependent on “pedal characteristics” under decoupling control constraints obtains a mileage improvement rate of 29.2%, and the comprehensive performance is the best. Therefore, RSF2 is the best brake feedback scheme for rear-drive vehicles.

- (3)

- For front-drive models, a competitive perspective is based on brake feedback efficiency and brake efficiency constraints. Considering that the RSF2 scheme not only has high braking feedback efficiency but also a high braking efficiency, as well as achieving a significant improvement in driving range by 35.8%, the RSF1A is the best braking feedback scheme for the overall performance of front-wheel drive vehicles.

- (4)

- For the brake feedback scheme proposed for the two models, the feasibility of the proposed brake feedback scheme is verified by comparing the drum test data with the simulated city cycle condition data, which lays a theoretical foundation for optimizing the brake feedback energy efficiency of pure electric vehicles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ABS | Antilock braking system |

| BERS | Braking energy recovery system |

| BTE | Brake thermal efficiency |

| CLTC | China Light-Duty Vehicle Test Cycle |

| EBA | Electronic brake assist |

| EBD | Electric brakeforce distribution |

| ECE | Economic Commission of Europe |

| FPF1 | Front-drive parallel braking feedback scheme 1 |

| FPF2 | Front-drive parallel braking feedback scheme 2 |

| FSF1 | Front-drive parallel braking feedback scheme 1 |

| FSF1A | Front-drive parallel braking feedback scheme 1 with Assist |

| FTP75 | Federal Test Procedure 75 |

| RC circuit | Resistor–capacitor circuit |

| RPF1 | Rear-drive parallel braking feedback scheme 1 |

| RPF2 | Rear-drive parallel braking feedback scheme 2 |

| RSF1 | Rear-drive series brake feedback scheme 1 |

| RSF1A | Rear-drive series brake feedback scheme 1 with pedal assist |

| RSF2 | Rear-drive series brake feedback scheme 2 |

| RSF2A | Rear-drive series brake feedback scheme 2 with pedal assist |

| SoC | State of charge |

References

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Jiang, F.; Zhou, J.; Hu, J.; Tan, X.; Mo, Q.; Cao, W. Performance Comparison and Optimization of 16V265H Diesel Engine Fueled with Biodiesel Based on Miller Cycle. Process 2022, 10, 1412. [Google Scholar] [CrossRef]

- Tan, Q.; Wang, Z.; Fan, W.; Li, X.; Li, X.; Li, F.; Zhao, Z. Development Path and Model Design of a New Energy Vehicle in China. Energies 2023, 16, 220. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Van, M.; Berecibar, M. Experimental and numerical analysis of holistic active and passive thermal management systems for electric vehicles: Fast charge and discharge applications. Results Eng. 2022, 15, 100486. [Google Scholar] [CrossRef]

- Hosseini Salari, A.; Mirzaeinejad, H.; Fooladi Mahani, M. A new control algorithm of regenerative braking management for energy efficiency and safety enhancement of electric vehicles. Energy Convers. Manag. 2023, 276, 116564. [Google Scholar] [CrossRef]

- Wu, Y.; Shu, M.; Ge, H. Research on Brake Force Distribution Control Strategy of Electric Vehicle Subtitle as needed. IOP Conf. Ser. Mater. Sci. Eng. 2018, 452, 032054. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Youssef, R.; Suresh Patil, M.; Van Mierlo, J.; Berecibar, M. Comprehensive Passive Thermal Management Systems for Electric Vehicles. Energies 2021, 14, 3881. [Google Scholar] [CrossRef]

- Geng, C.; Ning, D.; Guo, L.; Xue, Q.; Mei, S. Simulation Research on Regenerative Braking Control Strategy of Hybrid Electric Vehicle. Energies 2021, 14, 2202. [Google Scholar] [CrossRef]

- Broatch, A.; Olmeda, P.; Plá, B.; Dreif, A. Novel Energy Management Control Strategy for Improving Efficiency in Hybrid Powertrains. Energies 2023, 16, 107. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Shen, S.; Liu, Y.; Guo, F.; Zhang, Y. Co-optimization of velocity planning and energy management for autonomous plug-in hybrid electric vehicles in urban driving scenarios. Energy 2023, 263, 126060. [Google Scholar] [CrossRef]

- Hu, J.; Cao, W.; Jiang, F.; Hu, L.; Chen, Q.; Zheng, W.; Zhou, J. Study on Multi-Objective Optimization of Power System Parameters of Battery Electric Vehicles. Sustainability 2023, 15, 8219. [Google Scholar] [CrossRef]

- Juliette, T.; Mats, J.; Yang, D.; Bengt, J. Energy reduction by power loss minimization through wheel torque allocation in electric vehicles: A simulation-based approach. Veh. Syst. Dyn. 2022, 60, 1488–1511. [Google Scholar]

- Yang, Y.; He, Q.; Chen, Y.; Fu, C. Efficiency Optimization and Control Strategy of Regenerative Braking System with Dual Motor. Energies 2020, 13, 711. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Hu, M.; Yang, Z.; Fu, C. Longitudinal–vertical comprehensive control for four-wheel drive pure electric vehicle considering energy recovery and ride comfort. Energy 2021, 236, 121417. [Google Scholar] [CrossRef]

- Wang, D.; Guan, C.; Wang, J.; Wang, H.; Zhang, Z.; Guo, D.; Yang, F. Review of Energy-Saving Technologies for Electric Vehicles, from the Perspective of Driving Energy Management. Sustainability 2023, 15, 7617. [Google Scholar] [CrossRef]

- Yi, F.; Lu, D.; Wang, X.; Pan, C.; Tao, Y.; Zhou, J.; Zhao, C. Energy Management Strategy for Hybrid Energy Storage Electric Vehicles Based on Pontryagin’s Minimum Principle Considering Battery Degradation. Sustainability 2022, 14, 1214. [Google Scholar] [CrossRef]

- Lv, C.; Zhang, J.; Li, Y.; Yuan, Y. Novel control algorithm of braking energy regeneration system for an electric vehicle during safety–critical driving maneuvers. Energy Convers. Manag. 2015, 106, 520–529. [Google Scholar] [CrossRef]

- Vignesh, R.; Bragadeshwaran, A. Intelligent energy management through neuro-fuzzy based adaptive ECMS approach for an optimal battery utilization in plugin parallel hybrid electric vehicle. Energy Convers. Manag. 2023, 280, 116792. [Google Scholar] [CrossRef]

- Liu, H.; Lei, Y.; Fu, Y.; Li, X. An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle. Energies 2020, 13, 1526. [Google Scholar] [CrossRef]

- Henao-Muñoz, A.; Pereirinha, P.; Bouscayrol, A. Regenerative Braking Strategy of a Formula SAE Electric Race Car Using Energetic Macroscopic Representation. World Electr. Veh. J. 2020, 11, 45. [Google Scholar] [CrossRef]

- Liu, H.; Lei, Y.; Fu, Y.; Li, X. Multi-Objective Optimization Study of Regenerative Braking Control Strategy for Range-Extended Electric Vehicle. Appl. Sci. 2020, 10, 1789. [Google Scholar] [CrossRef]

- Rezaei, A.; Burl, J.; Zhou, B.; Rezaei, M. A New Real-Time Optimal Energy Management Strategy for Parallel Hybrid Electric Vehicles. IEEE Trans. Control Syst. Technol. 2019, 27, 830–837. [Google Scholar] [CrossRef]

- Passalacqua, M.; Carpita, M.; Gavin, S.; Marchesoni, M.; Repetto, M.; Vaccaro, L.; Wasterlain, S. Supercapacitor Storage Sizing Analysis for a Series Hybrid Vehicle. Energies 2019, 12, 1759. [Google Scholar] [CrossRef]

- Guo, H.; He, H.; Sun, F. A Combined Cooperative Braking Model with a Predictive Control Strategy in an Electric Vehicle. Energies 2013, 6, 6455–6475. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, G.; Meng, M.; Shen, Y. A novel control strategy of regenerative braking system for electric vehicles under safety critical driving situations. Energy 2018, 149, 329–340. [Google Scholar] [CrossRef]

- Sun, B.; Gu, T.; Xie, M.; Wang, P.; Gao, S.; Zhang, X. Strategy Design and Performance Analysis of an Electromechanical Flywheel Hybrid Scheme for Electric Vehicles. Sustainability 2022, 14, 11017. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, H.; Zhang, J. Regenerative Braking Control Strategy for Electric Vehicles Based on Optimization of Switched Reluctance Generator Drive System. IEEE Access 2020, 8, 76671–76682. [Google Scholar] [CrossRef]

- Zhai, Y.; Feng, H.; Meng, Y.; Xu, E.; Wu, Y. Braking energy management strategy for electric vehicles based on working condition prediction. AIP Adv. 2022, 12, 015220. [Google Scholar]

- Zhang, H.; Chen, D.; Zhang, H.; Liu, Y. Research on the influence factors of brake regenerative energy of pure electric vehicles based on the CLTC. Energy Rep. 2022, 8, 85–93. [Google Scholar] [CrossRef]

- He, Q.; Yang, Y.; Luo, C.; Zhai, J.; Luo, R.; Fu, C. Energy recovery strategy optimization of dual-motor drive electric vehicle based on braking safety and efficient recovery. Energy 2022, 248, 123543. [Google Scholar] [CrossRef]

- Qi, L.; Wu, X.; Zeng, X.; Feng, Y.; Pan, H.; Zhang, Z.; Yuan, Y. An electro-mechanical braking energy recovery system based on coil springs for energy saving applications in electric vehicles. Energy 2020, 200, 117472. [Google Scholar] [CrossRef]

- Ji, F.; Pan, Y.; Zhou, Y.; Du, F.; Zhang, Q.; Li, G. Energy recovery based on pedal situation for regenerative braking system of electric vehicle. Veh. Syst. Dyn. 2020, 58, 144–173. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, H.; Xin, Y. Research on Control Strategy of Hydraulic Regenerative Braking of Electrohydraulic Hybrid Electric Vehicles. Math. Probl. Eng. 2021, 6, 5391351. [Google Scholar] [CrossRef]

- Zhou, J.; Feng, C.; Su, Q.; Jiang, S.; Fan, Z.; Ruan, J.; Sun, S.; Hu, L. The Multi-Objective Optimization of Powertrain Design and Energy Management Strategy for Fuel Cell–Battery Electric Vehicle. Sustainability 2022, 14, 6320. [Google Scholar] [CrossRef]

- Xu, L.; He, X.; Shen, X. Improving Energy Recovery Rate of the Regenerative Braking System by Optimization of Influencing Factors. Appl. Sci. 2019, 9, 3807. [Google Scholar] [CrossRef]

- Pugi, L.; Alfatti, F.; Berzi, L.; Favilli, T.; Pierini, M.; Forrier, B.; D’hondt, T.; Sarrazin, M. Fast Modelling and Identification of Hydraulic Brake Plants for Automotive Applications. Int. J. Fluid Power 2020, 21, 169–210. [Google Scholar] [CrossRef]

- Min, C.; Pan, Y.; Dai, W.; Ibna, K.; Li, Z.; Wang, G. Trajectory optimization of an electric vehicle with minimum energy consumption using inverse dynamics model and servo constraints. Mech. Mach. Theory 2023, 181, 105185. [Google Scholar] [CrossRef]

- Zuska, A.; Kurczyński, D.; Jackowski, J.T. Study of Loads Acting on the Load during the Sudden Braking of a Vehicle. Appl. Sci. 2023, 13, 1559. [Google Scholar] [CrossRef]

- Koylu, H.; Tural, E. Experimental study on braking and stability performance during low speed braking with ABS under critical road conditions. Eng. Sci. Technol. Int. J. 2021, 24, 1224–1238. [Google Scholar] [CrossRef]

- Li, S.; Yu, B.; Feng, X. Research on braking energy recovery strategy of electric vehicle based on ECE regulation and I curve. Sci. Prog. 2020, 103, 0036850419877762. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Zhao, Z.; Dong, H.; Wang, S.; Liu, J.; Guan, J.; Duan, X. Microsimulation of electric vehicle energy consumption and driving range. Appl. Energy 2020, 267, 115081. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, H.; Zhen, C. Regenerative braking control under sliding braking condition of electric vehicles with switched reluctance motor drive system. Energy 2021, 230, 120901. [Google Scholar] [CrossRef]

| Model Name | Baojun E300 | Baojun E100 |

|---|---|---|

| Dimensions/mm | 2625 × 1647 × 1588 | 2488 × 1506 × 1670 |

| Wheelbase/mm | 1750 | 1600 |

| Distance between front and rear centroids/mm | 800, 950 | 720, 880 |

| Front and rear axle loads/kg | 416, 624 | 509, 340 |

| Curb weight/kg | 1040 | 849 |

| Rolling radius/mm | 253.9 | 253.9 |

| Centroid distance/mm | 500 | 500 |

| Front-rear axis charge ratio/% | 40/60 | 60/40 |

| Driving mode | Rear-wheel drive | Front-wheel drive |

| Braking Feedback Scheme | RPF1 | RPF2 | RSF1/RSF2 | RSF1A/RSF2A |

|---|---|---|---|---|

| Vehicle configuration condition 1 “EBD” | × | √ | √ | √ |

| Vehicle configuration condition 2 “ABS” | × | × | √ | √ |

| Vehicle configuration condition 3 “Pedal Characteristics” | × | × | × | √ |

| Feedback Scheme | No Plan | RPF1 | RPF2 | RSF1 | RSF2 | RSF1A | RSF2A |

|---|---|---|---|---|---|---|---|

| Least Square Error | 1.0000 | 0.9990 | 0.9989 | 0.9991 | 0.9980 | 0.9550 | 0.9540 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhou, J.; Guan, W.; Jiang, F.; Xie, G.; Wang, C.; Zheng, W.; Fang, Z. Optimization of Brake Feedback Efficiency for Small Pure Electric Vehicles Based on Multiple Constraints. Energies 2023, 16, 6531. https://doi.org/10.3390/en16186531

Li X, Zhou J, Guan W, Jiang F, Xie G, Wang C, Zheng W, Fang Z. Optimization of Brake Feedback Efficiency for Small Pure Electric Vehicles Based on Multiple Constraints. Energies. 2023; 16(18):6531. https://doi.org/10.3390/en16186531

Chicago/Turabian StyleLi, Xiaoping, Junming Zhou, Wei Guan, Feng Jiang, Guangming Xie, Chunfeng Wang, Weiguang Zheng, and Zhijie Fang. 2023. "Optimization of Brake Feedback Efficiency for Small Pure Electric Vehicles Based on Multiple Constraints" Energies 16, no. 18: 6531. https://doi.org/10.3390/en16186531

APA StyleLi, X., Zhou, J., Guan, W., Jiang, F., Xie, G., Wang, C., Zheng, W., & Fang, Z. (2023). Optimization of Brake Feedback Efficiency for Small Pure Electric Vehicles Based on Multiple Constraints. Energies, 16(18), 6531. https://doi.org/10.3390/en16186531