Abstract

Triacetin offers a higher added value compared to glycerol and can be obtained during the interesterification reaction between methyl acetate and triglycerides. In the same reaction, diacetinmonoglyceride is produced as an intermediate compound. The objective of this study was to assess whether the biodiesel produced, with varying concentrations of these compounds, meets the requirements established by the EN 14214 and ASTM D6751 standards. To achieve this, several properties were measured, including density, kinematic viscosity, cloud point, pour point, cold filter plugging point, methyl ester content, mono-, di-, triglyceride and total glycerol content, as well as the vacuum distillation curve. These measurements were conducted on mixtures of triacetin, diacetinmonoglyceride, and biodiesel, using different types of biodiesel such as palm, soybean, sunflower and rapeseed. Additionally, the solubility of these ternary mixtures in conventional diesel was evaluated. The results indicated that the EN 14214 standard imposes limits on the density and viscosity of biodiesel, restricting the content of triacetin (up to 5–10% by weight) and diacetinmonoglyceride (up to 3–4% by weight). However, the content of monoglycerides presents the most restrictive condition, as the chromatographic technique used cannot differentiate between monoglycerides and diacetinmonoglycerides. Consequently, their content is limited to a range of 0.15% to 0.70% by weight, depending on the prevailing climate conditions. Similarly, the ASTM D6751 standard sets a limitation of 0.40% by weight for monoglycerides to three out of six grades of biodiesel. Based on the findings of this study, which demonstrate that diacetinmonoglycerides do not have adverse effects on the cold performance of biodiesel, the inclusion of diacetinmonoglycerides in biodiesel production would still necessitate the development of standard test methods capable of differentiating between monoglycerides and diacetinmonoglycerides.

1. Introduction

The interesterification of oils with methyl acetate offers an interesting alternative to transesterification, thanks to the higher added value of triacetin [1,2,3]. Triacetin, also known as glycerol triacetate, serves multiple functions. It is predominantly utilized to enhance the plasticity and consistency within polymers and explosives. Moreover, it is employed as an additive in the tobacco industry and finds various applications in the pharmaceutical and cosmetic sectors [4,5]. In the interesterification reaction, diacetinmonoglyceride is also obtained as an intermediate compound. Diacetinmonoglycerides can be seen as monoglycerides in which the alcohol groups are connected to acetate groups via an ester linkage. While the removal of this compound has been examined in previous works [2,6], considering it is not typically part of biodiesel, we propose to explore the possibility of retaining it in the biodiesel formulation to understand its effects.

The International Standard ASTM D6751-23a [7] covers six grades of biodiesel (B 100) for use as a blend component with middle distillate fuels. The European Standard EN 14214:2013 V2+A2:2019 [8] specifies requirements and test methods for marketed and delivered fatty acid methyl esters (FAME) to be used as fuel for diesel engines [9,10] and for heating applications at 100 % concentration, or as an extender for automotive diesel fuel and for heating fuel. These standards have been established within the context of the prevalent method of biodiesel production, which is via transesterification. Therefore, it becomes imperative to first examine the effects of triacetin and diacetinmonoglyceride in accordance with these existing regulations.

To undertake this, parameters expected to be most significantly impacted were selected. These include density at 15 °C, kinematic viscosity at 40 °C, cloud point (CP), cold filter plugging point (CFPP), content of methyl esters, mono-, di-, triglycerides and glycerol, and the distillation temperature for 90% of the distilled volume. Additionally, other parameters not listed in these standards but offering valuable insights into the effects of these compounds were also considered, such as pour point (PP) and solubility in diesel.

There is research in the literature on the effect of the addition of triacetin on some biodiesel quality parameters. Some authors found that the addition of glycerin triacetate (triacetin), in amounts greater than 10% by weight, slightly increased the density and lowered the freezing point of biodiesel [11]. Later, Garcia et al., studied the effect of triacetin on oxidation stability, density, kinematic viscosity, flash point, cold filter plugging point (CFPP) and acid number of biodiesel [12]. On the other hand, Saka and Isayama confirmed how incorporating triacetin led to a reduction in the cetane number and an elevation in both density and viscosity. Concurrently, it marginally enhanced the cold properties and augmented the stability against oxidation [3]. Finally, Melero et al., also studied density, viscosity, PP, CFPP, oxidation stability and flash point, obtaining similar results [13]. Recent studies indicate that triacetin enhances both CP and PP, without any adverse effects on the CFPP [9,14,15]. Regarding diacetinmonoglyceride, there are no previous studies in the literature related to its properties.

Therefore, the objective of this work has been the study of the effect of diacetinmonoglyceride and its mixtures with triacetin on the quality of biodiesel. For this, the fuel quality specifications set by the ASTM D6751 and EN 14214 standards [7,8] have been used as a reference framework. This work has been carried out with the intention of determining the maximum content of triacetin and diacetinmonoglyceride in biodiesel. The influence of the origin of the biodiesel (rapeseed, sunflower, soybean and palm) on this maximum content has also been studied.

2. Methods

2.1. Materials

Henry Lamotte, GmbH supplied the refined oils of rapeseed, soybean, and palm. The sunflower oil came from Sovena España, while a local service station furnished the diesel sample. PANREAC was the source for methanol (99.8%), acetic acid (99.5%), ortho-phosphoric acid (85%), and desiccant (3 Å). Sigma-Aldrich and BASF were the suppliers of methyl acetate (99%) and potassium methoxide (97%), respectively. Triacetin (99%) was obtained from ALFA CAESAR.

The biodiesel and diacetinmonoglycerides used in this work were synthesized following the experimental procedures described in Section 2.3. All biodiesel used in this study adhered to the EN14214 standard for B100 [8], which specifies a minimum methyl ester content of 96.5%. Our measurements routinely fell within the range of 98.5% to 99.5%.

Heptane (puriss. p.a. ≥99.5% GC, FLUKA) and methyl heptadecanoate (puriss. p.a., standard for GC, ≥99.7%, FLUKA) were employed to measure the concentrations of methyl esters and fatty acids in compliance with EN 14103 [16], as well as the concentrations of triglycerides, diglycerides, monoglycerides and glycerol, in accordance with EN 14105 [17] and ASTM D6584 [18]. Additionally, tricaprin, butanetriol and N-Methyl-N-(trimethylsilyl) trifluoroacetamide were provided by Sigma-Aldrich (St. Louis, MI, USA).

2.2. Equipment

The transesterification reactions were performed in a batch reactor with a 200 mL capacity, which was outfitted with a reflux condenser, a thermocouple linked to a heating plate to regulate temperature, and a magnetic stirrer. Interesterification reactions were performed using Buchi Rotavapor R-210 machinery. A Sulzer DX Structured Packing Vacuum Distillation Column was utilized for the purification of diacetinmonoglyceride.

Blends comprising triacetin and biodiesel were precisely formulated with a Sartorius, TE 214S balance that provided an accuracy of ±7 × 10−5 g.

2.3. Experimental Procedure

The biodiesel used in this work has been synthesized from refined vegetable oils through transesterification reactions. Utilizing a methanol/oil molar ratio of 6:1 and a catalyst/oil molar ratio of 0.1:1, transesterification reactions were conducted. The reactor was initially loaded with the refined oil and pre-warmed to the targeted temperature of 60 °C. Methanol was used to dissolve the catalyst (potassium methoxide), and the mixture was introduced into the stirred reactor. This commenced the reaction, and the temperature of the reactor was sustained at roughly 60 °C for a duration of 60 min. Acetic acid was then used to halt the reaction and neutralize the catalyst. The mixture underwent three water washes and centrifugation (Orto Alresa, Madrid, Spain, Digitor-C) to segregate the water, glycerol, catalyst and methanol. Rotary evaporation (R-210; Büchi, Flawil, Switzerland) was employed to remove the methanol from the biodiesel fraction (80 °C, 1 h under vacuum). To conclude the process, desiccant (3 Å) were incorporated to adsorb residual water.

The diacetinmonoglycerides used in this work were prepared through interesterification reaction between biodiesel and triacetin using a molar ratio of 3 to 1, respectively, and a catalyst/triacetin molar ratio of 0.1:1. Biodiesel, triacetin and potassium methoxide (catalyst) were added to the distillation flask. The distillation flask was connected to the rotary evaporator and the bath temperature was set at 60 °C. Following this, the vacuum and flask rotation were turned on. The reaction time was 2 h, after which the stoichiometric amount of phosphoric acid was added to neutralize the catalyst. The liquid obtained was centrifuged to remove the salts formed after neutralization. The purified reaction mixture was distilled in the vacuum rectification column to separate the diacetinmonoglyceride from the rest of the compounds. To avoid the degradation of the unsaturated compounds, an operating pressure of 4 mmHg was used.

Subsequently, the impacts of triacetin and diacetinmonoglycerides were investigated by blending them with the biodiesel at set concentrations, reaching up to 20 and 10 wt.%, respectively. It is important to emphasize that biodiesel, diacetinmonoglycerides and triacetin were fully miscible in all quantities.

Finally, pure biodiesel samples (B100) along with all the formulated blends were subjected to analysis, following the specific methods described in the next section.

2.4. Analytical Methods

In Table 1, the limits of the parameters related to biodiesel quality chosen for this study, in accordance with the ASTM D6751 and EN 14214 standards [7,8] for biodiesel, are shown.

Table 1.

Limits of the biodiesel quality parameters chosen according to the ASTM D6751 and EN 14214 standards [7,8].

The analyses were carried out following the methodologies outlined in the ASTM D6751 and EN 14214 standards [7,8]. Every experiment was conducted in threefold, and the various measurements yielded no statistically notable disparities. The final result was determined by taking the arithmetic mean of the three assessments. Moreover, to ensure that each instrument conformed to the precision demands stipulated by the method standard specifications, the uncertainties were computed and evaluated.

The total uncertainty associated with the different properties was evaluated, and the details are depicted in the figures. This total uncertainty was ascertained by performing reproducibility and repeatability tests and verifying the accuracy of the instruments within the working range using the appropriate certified reference materials.

The chromatographic analyses were conducted following EN14103 standard [16] for methyl ester contents and fatty acid profiles; and EN14105 [17] and ASTM D6584 [18] standards for glycerol, monoglyceride, diglyceride, triglyceride and triacetin contents, respectively.

The density was ascertained at 15 °C, in compliance with EN ISO 3675 [19] while the kinematic viscosity was evaluated in accordance with EN ISO 3104 [20].

The cold characteristics of the samples were assessed using a device (ISL, FPP 5GS) designed to measure the cloud point (CP), pour point (PP) and cold filter plugging point (CFPP). PP and CP analyses were executed in line with the ASTM D97 [21] and EN 3015 [22] standards, respectively, while CFPP evaluations were performed following the EN 116 [23] standard.

Distillation Curves were derived in conformity with the methodology outlined in the ASTM D1160 [24] regulations. For this purpose, a D1160 instrument, procured from Normalab Analis, S.A., was utilized.

3. Results and Discussion

Among all the biodiesel parameters listed in the ASTM D6751 and EN 14214 [7,8] guidelines, focus was placed on density at 15 °C, kinematic viscosity at 40 °C, low temperature parameters (i.e., CFPP and CP), methyl ester content, monoglycerides content, total glycerol content, and distillation temperature. The assumption was that these parameters would be most significantly impacted by the presence of triacetin and diacetinmonoglycerides. Although not explicitly mentioned in the ASTM D6751 and EN 14214 [7,8], other parameters such as PP, and the solubility of the mixtures with diesel fuel, were also examined to provide an understanding of the effects of triacetin and diacetinmonoglycerides.

All the parameters mentioned are also affected by the profile of fatty acids groups in the methyl esters and diacetinmonoglycerides. This profile comes from the vegetable oils from which they have been synthesized and is shown in Table 2. As a starting point for this work, the vegetable oils with the largest volumes of global production have been used [2,25,26]. By selecting these oils, a wide range of compositions is also obtained, ranging from a high content of saturated compounds (such as palm), to a high content of polyunsaturated compounds (with two and three double bonds in the molecule, such as those contained in soybeans and sunflower), going through mainly monounsaturated oils (rapeseed).

Table 2.

Profile of fatty acids for the different biodiesel types used in this work.

3.1. Density at 15 °C and Kinematic Viscosity at 40 °C

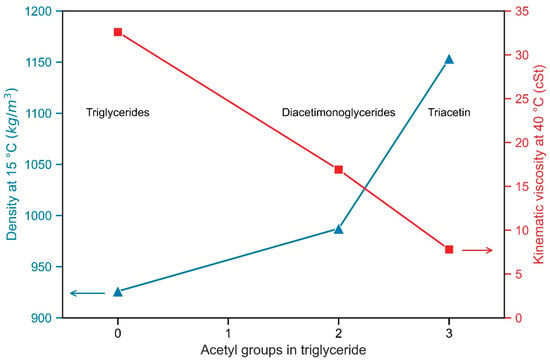

In Figure 1, properties such as the density and viscosity of acetylacylglycerides are correlated with the number of acetate groups present in the molecule.

Figure 1.

Evolution of density and kinematic viscosity at different numbers of acetate groups in acetylacylglycerides (soybean oil).

As can be seen, an increase in the number of acetyl groups implies a decrease in viscosity. This is due to the substitution of fatty acids (with chains of 14 to 24 carbons) in the triglyceride molecule for acetate groups (with two carbons). Therefore, owing to this interchange, the molecule size diminishes, subsequently heightening its packing degree and density. This leads triacetin to achieve a density value that approaches that of glycerol (1261 kg/m3 at 20 °C).

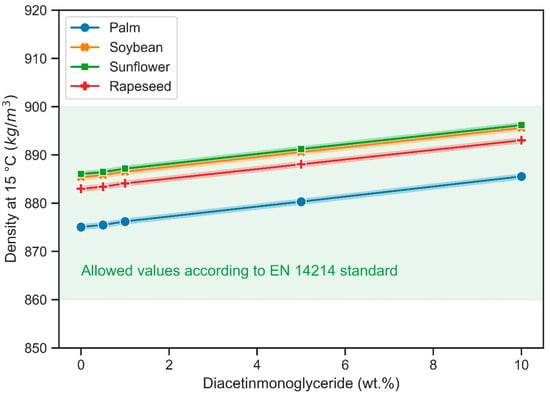

Figure 2 shows the density measured in the biodiesel–diacetinmonoglycerides mixtures.

Figure 2.

Density for different blends of diacetinmonoglyceride and biodiesel. Shadowed values show uncertainty interval.

It can be seen, as with triacetin [14,15,27], how the addition of this compound to biodiesel implies a linear increase in density. However, thanks to the lower density of diacetinmonoglyceride with respect to triacetin, it is possible to add quantities of diacetinmonoglyceride of 10% by weight without exceeding the limitation of 900 kg/m3 set by standard EN 14214 [8].

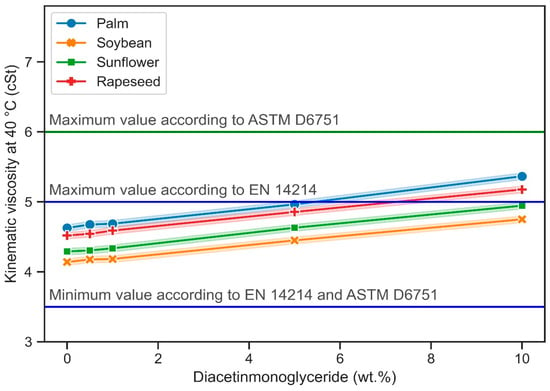

In Figure 3, the kinematic viscosity measurements are shown for the diacetinmonoglyceride–biodiesel blends.

Figure 3.

Kinematic viscosity at 40 °C for different diacetinmonoglyceride and biodiesel blends. Shadowed values show uncertainty interval.

The kinematic viscosity of diacetinmonoglyceride is significantly higher than that of triacetin. Its addition to biodiesel compromises compliance with the maximum limit set by EN 14214 standard [8] of 5 cSt. The more unsaturated types of biodiesel (soybean and sunflower) are less affected thanks to their lower starting viscosity. Concentrations of up to 10% by weight of diacetinmonoglyceride can be maintained in them without compromising the quality of the final biodiesel. It should be noted that the approximate content of diacetinmonoglyceride is 5% by weight when the optimum molar ratio of methyl acetate/oil of 48:1 is used in the interesterification reaction [1,2,28]. Therefore, although larger amounts are studied in this work, they will never be found in practice.

Once measurements were completed on binary mixtures, the study progressed to measurements on ternary mixtures. The objective was to investigate the combined influence of triacetin and diacetinmonoglyceride on the density and viscosity of various types of biodiesel. The results obtained from these evaluations can be found in Table 3.

Table 3.

Experimental values of density and kinematic viscosity of ternary blends of biodiesel–triacetin–diacetinmonoglyceride for different types of biodiesel.

Upon evaluating the results showcased in Table 3, it can be concluded that the triacetin content may be primarily limited by the maximum density threshold as per EN 14214 standard [8].

It is noteworthy to mention that some biodiesel types will face more constraints than others. For example, biodiesels with higher densities, such as those derived from soybean and sunflower, may experience increased limitations in the incorporation of triacetin. Conversely, saturated biodiesel types like palm oil, which exhibit higher viscosity, will likely limit the inclusion of diacetinmonoglyceride owing to their intrinsic viscous nature.

As previously mentioned, European regulations are more restrictive than American ones, limiting the maximum density value to 900 kg/m3 and the kinematic viscosity to 5 cSt.

3.2. Content of Methyl Esters, Mono-, di-, Triglycerides, and Total Glycerol

The content of methyl esters (considering those whose fatty acids range from C14:0 to C24:1) is set in the EN 14214 standard [8] with a minimum value of 96.5% by weight. This avoids the presence of unreacted substances, non-saponifiable compounds, polymers, etc. This lower limit of 96.5% by weight poses a problem for the use of triacetin or diacetinmonoglyceride since no more than 3.5% by weight of these compounds can be added to biodiesel.

Although the use of this parameter is not accepted in the ASTM standard, it poses a problem for a potential raw materials such as lauric oils (C12:0), which include coconut oil and palm kernel oil, that cannot be used for biodiesel production. This is because methyl laurate (C12:0) is not considered in the calculation of the methyl ester content [29,30] in the European regulations. The ASTM D6751 standard [7] does not consider the measurement of ester content due to a lack of precision and instead relies on other tests (such as the distillation curve and total glycerol content) to control biodiesel purity [31].

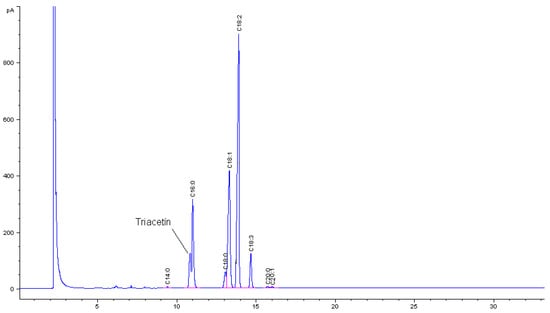

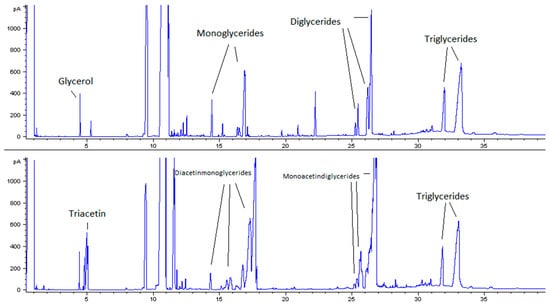

To study the interferences of triacetin and diacetinmonoglyceride in the measurement of this parameter, Figure 4 shows the chromatogram of a ternary mixture of triacetin–biodiesel–diacetinmonoglyceride. Additionally, the chromatograms corresponding to incomplete transesterification and interesterification reactions, obtained using EN 14105 [17] and ASTM D6584 [18] (analogous to the European standard), are shown in Figure 5.

Figure 4.

Chromatogram obtained according to EN 14103 [16] standard. Diacetinmonoglyceride was not detected with this test.

Figure 5.

Chromatograms from incomplete transesterification (top) and interesterification (bottom) reactions obtained following the EN 14105 [17] and ASTM D6584 [18] standards.

As shown in Figure 4, the peak of triacetin has a retention time close to that of the methyl ester of palmitic acid (C16:0). Therefore, the use of triacetin requires a modification of the test method for determining the content of methyl esters. If not, the triacetin content will be reflected within the methyl ester content.

In Figure 5, it can be seen that diacetinmonoglycerides have the same retention times as monoglycerides. According to EN 14214 [8] and ASTM D6751 [7], the content of diacetinmonoglycerides should not exceed 0.15–0.7% by weight (depending on the climatic region) and 0.4% by weight (in three of six biodiesel grades), respectively. This limitation aligns with the upper limit set for monoglycerides.

Due to the differences between diacetinmonoglyceride and monoglyceride specially in cold temperature behavior, it would be necessary to review the chromatographic method used and establish independent limits for diacetinmonoglyceride [32].

3.3. Behavior of Biodiesel-Diacetinmonoglyceride Blends at Low Temperatures

Before starting this section, it is important to note that the results observed at low concentrations with mixtures of soybean biodiesel and diacetinmonoglycerides seemed very unusual. This could be attributed to a potential experimental error. Therefore, the results of soybean biodiesel data will be omitted from this section.

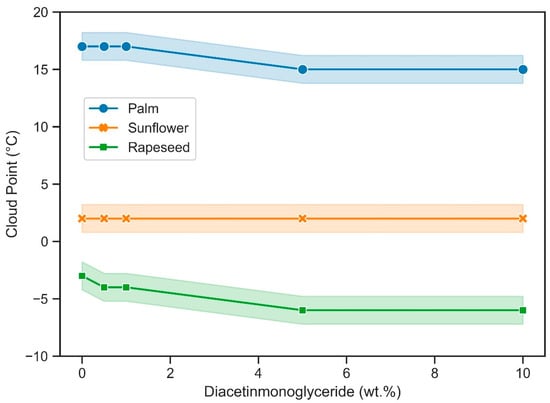

In Figure 6, the cloud point for biodiesel–diacetinmonoglyceride blends for rapeseed, sunflower and palm oil is shown. It can be observed that the addition of diacetinmonoglyceride causes a decrease in the temperature at which freezing begins. This reduction in CP is greater for rapeseed (from −3 °C to −6 °C) than for palm oil (from 17 °C to 15 °C), at diacetinmonoglyceride concentrations greater than 5% by weight. For sunflower biodiesel, the diacetinmonoglycerides do not affect its cold behavior.

Figure 6.

Cloud point (CP) of biodiesel–diacetinmonoglyceride blends. Shadowed values show uncertainty intervals.

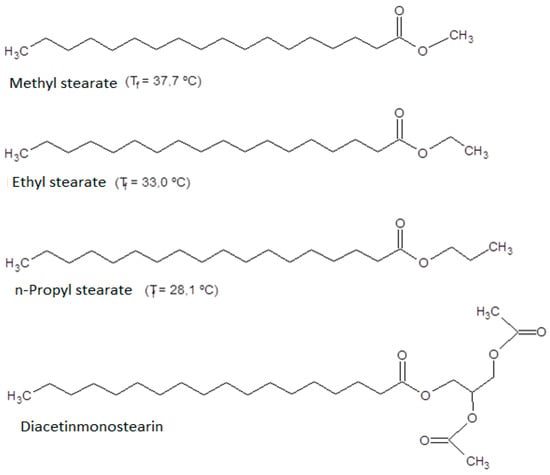

In Figure 7, the structures corresponding to methyl, ethyl and n-propyl stearate are shown, along with their melting points [33]. Alongside them, the diacetinmonoestearin (the diacetinmonoglyceride of stearic acid) is also shown.

Figure 7.

Molecular structure and melting points of methyl, ethyl, and n-propyl stearate. Comparison with diacetinmonostearin.

The solidification of biodiesel occurs primarily due to the stacking of chains of fatty acids, a process that can be negatively influenced by the size of the alkyl group within the ester. It is believed that the structure of diacetinmonoglycerides could interrupt this stacking process, enhancing the cold properties of biodiesel in the process. Such enhancement contrasts with the behavior observed in their transesterification counterparts—the monoglycerides [34].

According to some authors [33,35,36], the crystallization process of biodiesel, comprising fatty acid methyl esters, is similar to that of long-chain paraffins. Throughout this crystallization process, molecules line up along the direction of the hydrocarbon chain, leading to the formation of large planar layers, otherwise known as the XY plane. However, growth along the Z-axis could be disrupted by the alkyl group present in the ester bond. This disruption is minimal when the alkyl group is a methyl group, but with higher molecular weight branching, the space between the layers could alter, leading to rotational disorder in the hydrocarbon chains. This is observable in the case of diacetinmonoglycerides. Further experimentation will be needed to understand the behavior of sunflower biodiesel.

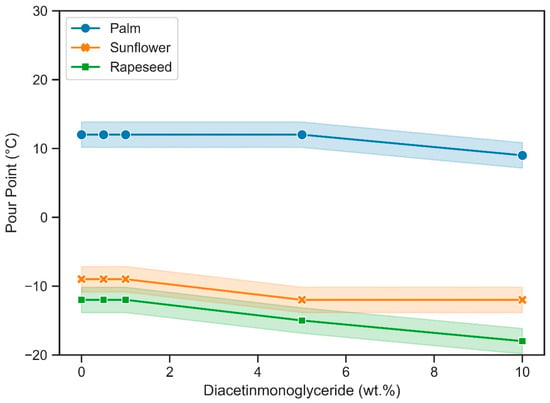

Figure 8 shows the pour point (PP) of biodiesel–diacetinmonoglyceride blends for rapeseed, sunflower, and palm. It can be observed how diacetinmonoglyceride reduces the value of the PP for all biodiesels, even reducing the PP of rapeseed biodiesel by 6 °C with a 10% weight concentration of diacetinmonoglyceride.

Figure 8.

Pour point (PP) of biodiesel–diacetinmonoglyceride blends. Shadowed values show uncertainty interval.

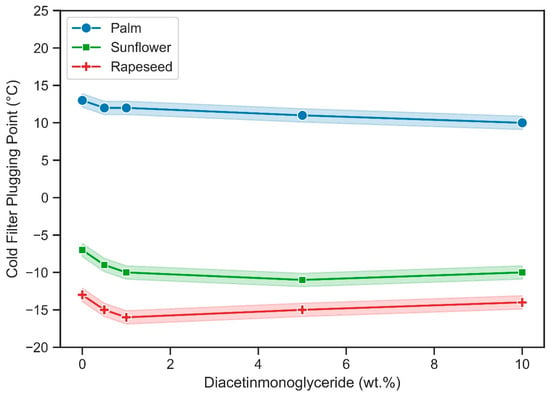

In Figure 9, the cold filter plugging point (CFPP) of biodiesel–diacetinmonoglyceride blends for rapeseed, sunflower, and palm are shown. As seen in the figure, when the concentration of diacetinmonoglyceride is small, there is a decrease in the value of CFPP. This trend is reversed for higher concentrations in sunflower and rapeseed biodiesel. This situation is due to two different causes with opposite effects. On the one hand, as already mentioned, the addition of diacetinmonoglyceride reduces the freezing point. On the other hand, the high viscosity of diacetinmonoglyceride hinders a filtration-based test such as CFPP. Therefore, negative effects on CFPP are only observed at low temperatures (rapeseed and sunflower biodiesel) and not when CFPP is high (palm), in this case, the inhibition of the crystallization phenomenon prevails over the increase in the viscosity of the mixture [15,37].

Figure 9.

Cold filter plugging point (CFPP) of biodiesel–diacetinmonoglyceride blends. Shadowed values show uncertainty interval.

Regarding cold properties, it can be concluded that the presence of low concentrations of diacetinmonoglyceride (up to 2% by weight) does not adversely affect the cold behavior of the starting biodiesel.

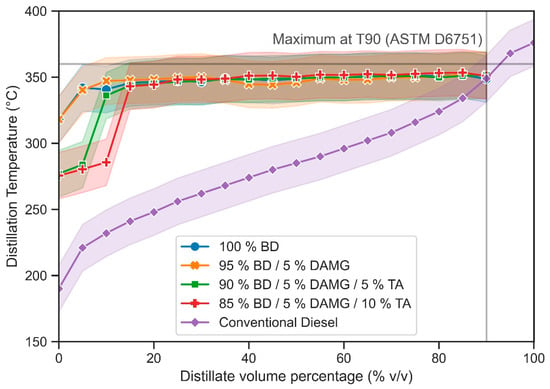

3.4. Distillation Curve

The distillation curve of the biodiesel (95% by weight)-diacetinmonoglyceride (5% by weight) mixture, along with the ternary mixture curves of biodiesel–triacetin–diacetin monoglyceride and conventional diesel, are shown in Figure 10.

Figure 10.

Distillation curve of biodiesel (BD), conventional diesel and biodiesel (BD)–diacetinmonoglyceride (DAMG)–triacetin (TA) blends (expressed as weight percentage). BD and DAMG were obtained from rapeseed oil. Shadowed values show uncertainty interval.

The distillation curve of biodiesel-diacetinmonoglyceride is hardly modified compared to that of the original biodiesel. The addition of only 5% by weight of diacetinmonoglyceride barely increases the distillation temperature for 90% of the collected volume, which is the parameter limited by the ASTM D6751 [7] standard [9,10,38]. Furthermore, as previously mentioned, the presence of triacetin results in a decrease in temperature values for the first collected fractions of distillate, bringing the distillation curve closer to that of conventional diesel. Based on the results obtained, diacetinmonoglyceride does not affect compliance with ASTM D6751 [7] standards for concentrations below 5% by weight.

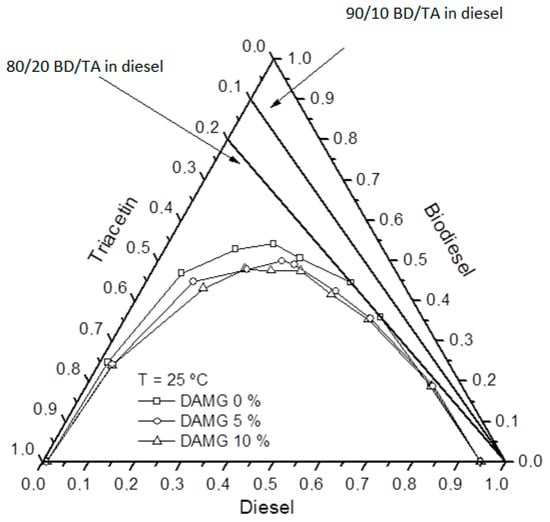

3.5. Solubility in Conventional Diesel

The solubility in conventional diesel is shown in Figure 11. The ternary mixture of triacetin–biodiesel–diesel solubility curve at 25 °C is presented, along with two lines corresponding to biodiesel–triacetin mixtures of 80–20 and 90–10, both expressed in weight percentage, to which diesel is added. These two lines represent all possible mixtures of diesel with the two biodiesel–triacetin mixtures. The results in Figure 11 correspond to rapeseed biodiesel, with no significant differences observed between different types of biodiesel.

Figure 11.

Curves of L-L equilibrium of the ternary system triacetin–biodiesel–diesel (in mass fractions) with different proportions of diacetinmonoglyceride in biodiesel.

Figure 11 shows the low solubility of triacetin in diesel, which is due to the absence of aliphatic chains in the triacetin molecule (unlike biodiesel). The experimental solubility value of pure triacetin in diesel is 2% by weight at 25 °C. This result is critical since currently almost all produced biodiesel is used mixed with diesel.

It can be seen that the 80–20 line crosses the two-phase zone in the range of 45–55% by weight of diesel. That is, biodiesel with a 20% weight of triacetin in its formulation will have solubility problems when present in diesel in quantities of 45–55% by weight. This situation does not occur with the 90–10 mixture at 25 °C, although solubility problems may arise at lower temperatures.

Currently, this situation is not a problem since the European Standard EN 590 consider the use of 7% by volume of biodiesel in diesel (B7), while the ASTM D7467 standard sets the use of B6-B20 blends. If future objectives involve augmenting biodiesel concentration, the limited solubility of triacetin in diesel could emerge as a substantial issue.

Regarding diacetinmonoglyceride, it has been experimentally proven to be completely soluble in diesel (regardless of its fatty acid profile), as is the case with biodiesel and triglycerides. This is an important advantage of interesterification compared to transesterification, since its analogous compounds in transesterification (monoglycerides) present filter clogging problems due to their reduced solubility in diesel (100–1000 mg/kg for saturated monoglycerides) [34,37,39].

Furthermore, by observing Figure 11, it is confirmed that the presence of diacetinmonoglyceride in biodiesel improves the solubility of triacetin in diesel thanks to its intermediate nature between fatty acid esters and triacetin. Therefore, it also provides a solution to the low solubility that triacetin presents in diesel.

It is noteworthy to mention that although our study has been focused on the compatibility of diacetinmonoglyceride and triacetin with biodiesel standards, further research is necessary to evaluate the impact of these blends on combustion and emission properties. Compounds with structural similarity to glycerol, present in these blends, may potentially form harmful by-products during combustion such as various types of aldehydes, particularly acrolein [40,41]. These by-products not only affect engine performance but also have implications for environmental health. Therefore, it is crucial that future work includes a thorough examination of the combustion characteristics of these biodiesel blends.

4. Conclusions

The main conclusions obtained from the results presented in this work are the following:

- −

- The density and viscosity limits of the European standard EN 14214 [8] allow a maximum content of triacetin and diacetinmonoglyceride in biodiesel of 5 to 10% by weight, and 3 to 4% by weight, respectively. The density is not limited by the ASTM D6751 [7] standard, and the kinematic viscosity has a less restrictive limit (6 cSt).

- −

- According to chromatographic tests, if triacetin is considered a methyl ester there would be no limitation for its use in EN 14214 [8] or ASTM D6751 [7]. On the other hand, if the diacetinmonoglyceride is assimilated to a monoglyceride, the value of 0.15–0.7% by weight (EN 14214 [8]) or 0.4% by weight (ASTM D6751 [7]) could not be exceeded.

- −

- The presence of low concentrations of diacetinmonoglyceride (up to 2% by weight) does not adversely affect the cold behavior of the starting biodiesel.

- −

- The distillation temperature (for 90% volume of distillate collected) is not affected by the addition of triacetin or amounts less than 5% by weight of diacetinmonoglyceride.

- −

- Although the solubility of triacetin in diesel is very low (2% by weight), once mixed with biodiesel in quantities that do not exceed 20% by weight, it would not have this problem.

- −

- The solubility of triacetin in diesel is slightly favored by the presence of diacetinmonoglyceride.

Author Contributions

Conceptualization, Á.P.; Methodology, A.C., Á.P. and M.J.R.; Formal analysis, A.C.; Investigation, A.C.; Writing—original draft, A.C.; Writing—review & editing, Á.P. and M.J.R.; Visualization, A.C.; Funding acquisition, Á.P. and M.J.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by ECOPRIBER, S.A.

Data Availability Statement

Due to privacy restrictions, the data supporting the reported results are not available for public access.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Casas, A.; Ramos, M.J.; Pérez, Á. New Trends in Biodiesel Production: Chemical Interesterification of Sunflower Oil with Methyl Acetate. Biomass Bioenergy 2011, 35, 1702–1709. [Google Scholar] [CrossRef]

- Dougher, M.; Soh, L.; Bala, A.M. Techno-Economic Analysis of Interesterification for Biodiesel Production. Energy Fuels 2023, 37, 2912–2925. [Google Scholar] [CrossRef]

- Saka, S.; Isayama, Y. A New Process for Catalyst-Free Production of Biodiesel Using Supercritical Methyl Acetate. Fuel 2009, 88, 1307–1313. [Google Scholar] [CrossRef]

- Bonet, J.; Costa, J.; Sire, R.; Reneaume, J.-M.; Pleşu, A.E.; Pleşu, V.; Bozga, G. Revalorization of Glycerol: Comestible Oil from Biodiesel Synthesis. Food Bioprod. Process. 2009, 87, 171–178. [Google Scholar] [CrossRef]

- Cornejo, A.; Barrio, I.; Campoy, M.; Lázaro, J.; Navarrete, B. Oxygenated Fuel Additives from Glycerol Valorization. Main Production Pathways and Effects on Fuel Properties and Engine Performance: A Critical Review. Renew. Sustain. Energy Rev. 2017, 79, 1400–1413. [Google Scholar] [CrossRef]

- Casas, A.; Ramos, M.J.; Pérez, Á. Product Separation after Chemical Interesterification of Vegetable Oils with Methyl Acetate. Part I: Vapor–Liquid Equilibrium. Ind. Eng. Chem. Res. 2012, 51, 8087–8094. [Google Scholar] [CrossRef]

- ASTM D6751-23a; Standard Specification for Biodiesel Fuel Blendstock (B100) for Middle Distillate Fuels. ASTM: West Conshohocken, PA, USA, 2023.

- EN 14214:2013 V2+A2:2019; Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2019.

- Zare, A.; Nabi, M.N.; Bodisco, T.A.; Hossain, F.M.; Rahman, M.M.; Chu Van, T.; Ristovski, Z.D.; Brown, R.J. Diesel Engine Emissions with Oxygenated Fuels: A Comparative Study into Cold-Start and Hot-Start Operation. J. Clean. Prod. 2017, 162, 997–1008. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Aghbashlo, M.; Najafi, B.; Hosseinzadeh-Bandbafha, H.; Faizollahzadeh Ardabili, S.; Akbarian, E.; Khalife, E.; Mohammadi, P.; Rastegari, H.; Ghaziaskar, H.S. Environmental Impact Assessment of the Mechanical Shaft Work Produced in a Diesel Engine Running on Diesel/Biodiesel Blends Containing Glycerol-Derived Triacetin. J. Clean. Prod. 2019, 223, 466–486. [Google Scholar] [CrossRef]

- Puche, J.D. Procedure to Obtain Biodiesel Fuel with Improved Properties at Low Temperature. U.S. Patent 7,637,969, 29 December 2009. [Google Scholar]

- García, E.; Laca, M.; Pérez, E.; Garrido, A.; Peinado, J. New Class of Acetal Derived from Glycerin as a Biodiesel Fuel Component. Energy Fuels 2008, 22, 4274–4280. [Google Scholar] [CrossRef]

- Melero, J.A.; Vicente, G.; Morales, G.; Paniagua, M.; Bustamante, J. Oxygenated Compounds Derived from Glycerol for Biodiesel Formulation: Influence on EN 14214 Quality Parameters. Fuel 2010, 89, 2011–2018. [Google Scholar] [CrossRef]

- Casas, A.; Ruiz, J.R.; Ramos, M.J.; Pérez, A. Effects of Triacetin on Biodiesel Quality. Energy Fuels 2010, 24, 4481–4489. [Google Scholar] [CrossRef]

- Elias, R.C.; Senra, M.; Soh, L. Cold Flow Properties of Fatty Acid Methyl Ester Blends with and without Triacetin. Energy Fuels 2016, 30, 7400–7409. [Google Scholar] [CrossRef]

- EN 14103:2020; Fat and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Ester and Linolenic Acid Methyl Ester Contents. European Committee for Standardization: Brussels, Belgium, 2020.

- EN 14105:2021; Fat and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Free and Total Glycerol and Mono-, Di-, Triglyceride Contents. European Committee for Standardization: Brussels, Belgium, 2021.

- ASTM D6584-21; Standard Test Method for Determination of Total Monoglycerides, Total Diglycerides, Total Triglycerides, and Free and Total Glycerin in B-100 Biodiesel Methyl Esters by Gas Chromatography. ASTM: West Conshohocken, PA, USA, 2021.

- EN ISO 3675:1999; Crude Petroleum and Liquid Petroleum Products. Laboratory Determination of Density. Hydrometer Method. European Committee for Standardization: Brussels, Belgium, 1999.

- EN ISO 3104:2021; Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. European Committee for Standardization: Brussels, Belgium, 2021.

- ASTM D97-17b; Standard Test Method for Pour Point of Petroleum Products. ASTM: West Conshohocken, PA, USA, 2022.

- EN 3015:2019; Petroleum and Related Products from Natural or Synthetic Sources—Determination of Cloud Point. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 116: 2015; Diesel and Domestic Heating Fuels—Determination of Cold Filter Plugging Point—Stepwise Cooling Bath Method. European Committee for Standardization: Brussels, Belgium, 2015.

- ASTM D1160-18; Standard Test Method for Distillation of Petroleum Products at Reduced Pressure. ASTM: West Conshohocken, PA, USA, 2018.

- Ansori, A.; Mahfud, M. Ultrasound Assisted Interesterification for Biodiesel Production from Palm Oil and Methyl Acetate: Optimization Using RSM. J. Phys. Conf. Ser. 2021, 1747, 012044. [Google Scholar] [CrossRef]

- Sendzikiene, E.; Makareviciene, V. Biodiesel Fuel Synthesis by Interesterification of Triglycerides with Carboxylate Esters of Low Molecular Weight. Rev. Chem. Eng. 2021, 37, 259–276. [Google Scholar] [CrossRef]

- Zare, A.; Nabi, M.N.; Bodisco, T.A.; Hossain, F.M.; Rahman, M.M.; Ristovski, Z.D.; Brown, R.J. The Effect of Triacetin as a Fuel Additive to Waste Cooking Biodiesel on Engine Performance and Exhaust Emissions. Fuel 2016, 182, 640–649. [Google Scholar] [CrossRef]

- Casas, A.; Ramos, M.J.; Pérez, Á. Kinetics of Chemical Interesterification of Sunflower Oil with Methyl Acetate for Biodiesel and Triacetin Production. Chem. Eng. J. 2011, 171, 1324–1332. [Google Scholar] [CrossRef]

- Schober, S.; Seidl, I.; Mittelbach, M. Ester Content Evaluation in Biodiesel from Animal Fats and Lauric Oils. Eur. J. Lipid Sci. Technol. 2006, 108, 309–314. [Google Scholar] [CrossRef]

- Bachler, C.; Schober, S.; Mittelbach, M. Simulated Distillation for Biofuel Analysis. Energy Fuels 2010, 24, 2086–2090. [Google Scholar] [CrossRef]

- Tripartite Task Force—Brazil, European Union & United States of America. In White Paper on Internationally Compatible Biofuel Standards; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007.

- Ribeiro, J.S.; Celante, D.; Brondani, L.N.; Trojahn, D.O.; da Silva, C.; de Castilhos, F. Synthesis of Methyl Esters and Triacetin from Macaw Oil (Acrocomia Aculeata) and Methyl Acetate over γ-Alumina. Ind. Crops Prod. 2018, 124, 84–90. [Google Scholar] [CrossRef]

- Knothe, G.; Dunn, R.O. A Comprehensive Evaluation of the Melting Points of Fatty Acids and Esters Determined by Differential Scanning Calorimetry. J. Am. Oil Chem. Soc. 2009, 86, 843–856. [Google Scholar] [CrossRef]

- Sugami, Y.; Yoshidomi, S.; Minami, E.; Shisa, N.; Hayashi, H.; Saka, S. The Effect of Monoglyceride Polymorphism on Cold-Flow Properties of Biodiesel Model Fuel. J. Am. Oil Chem. Soc. 2017, 94, 1095–1100. [Google Scholar] [CrossRef]

- Lee, I.; Johnson, L.A.; Hammond, E.G. Use of Branched-Chain Esters to Reduce the Crystallization Temperature of Biodiesel. J. Am. Oil Chem. Soc. 1995, 72, 1155–1160. [Google Scholar] [CrossRef]

- Foglia, T.A.; Nelson, L.A.; Dunn, R.O.; Marmer, W.N. Low-Temperature Properties of Alkyl Esters of Tallow and Grease. J. Am. Oil Chem. Soc. 1997, 74, 951–955. [Google Scholar] [CrossRef]

- Dunn, R.O. Cold-Flow Properties of Soybean Oil Fatty Acid Monoalkyl Ester Admixtures. Energy Fuels 2009, 23, 4082–4091. [Google Scholar] [CrossRef]

- Calero, J.; Luna, D.; Sancho, E.D.; Luna, C.; Bautista, F.M.; Romero, A.A.; Posadillo, A.; Berbel, J.; Verdugo-Escamilla, C. An Overview on Glycerol-Free Processes for the Production of Renewable Liquid Biofuels, Applicable in Diesel Engines. Renew. Sustain. Energy Rev. 2015, 42, 1437–1452. [Google Scholar] [CrossRef]

- Dunn, R.O. Effects of Minor Constituents on Cold Flow Properties and Performance of Biodiesel. Prog. Energy Combust. Sci. 2009, 35, 481–489. [Google Scholar] [CrossRef]

- Olson, A.L.; Tunér, M.; Verhelst, S. A Concise Review of Glycerol Derivatives for Use as Fuel Additives. Heliyon 2023, 9, e13041. [Google Scholar] [CrossRef]

- Steinmetz, S.A.; Herrington, J.S.; Winterrowd, C.K.; Roberts, W.L.; Wendt, J.O.L.; Linak, W.P. Crude Glycerol Combustion: Particulate, Acrolein, and Other Volatile Organic Emissions. Proc. Combust. Inst. 2013, 34, 2749–2757. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).