Experimental Tests of Conduction/Convection Heat Transfer in Very High Porosity Foams with Lattice Structures, Immersed in Different Fluids

Abstract

:1. Introduction

- -

- Assessing the possibility of measuring the thermal conductivity with the probe method [3] of the above-described structures;

- -

- Identifying which heat transfer mechanism was present in the structures during the tests, if pure conduction, pure convection or mixed conduction and convection, and also identifying the difference in steady and transient state (for thermal conductivity);

- -

- Finding empirical relations to interpolate the experimental results to foresee the thermophysical properties in the examined temperature ranges and for the tested structures.

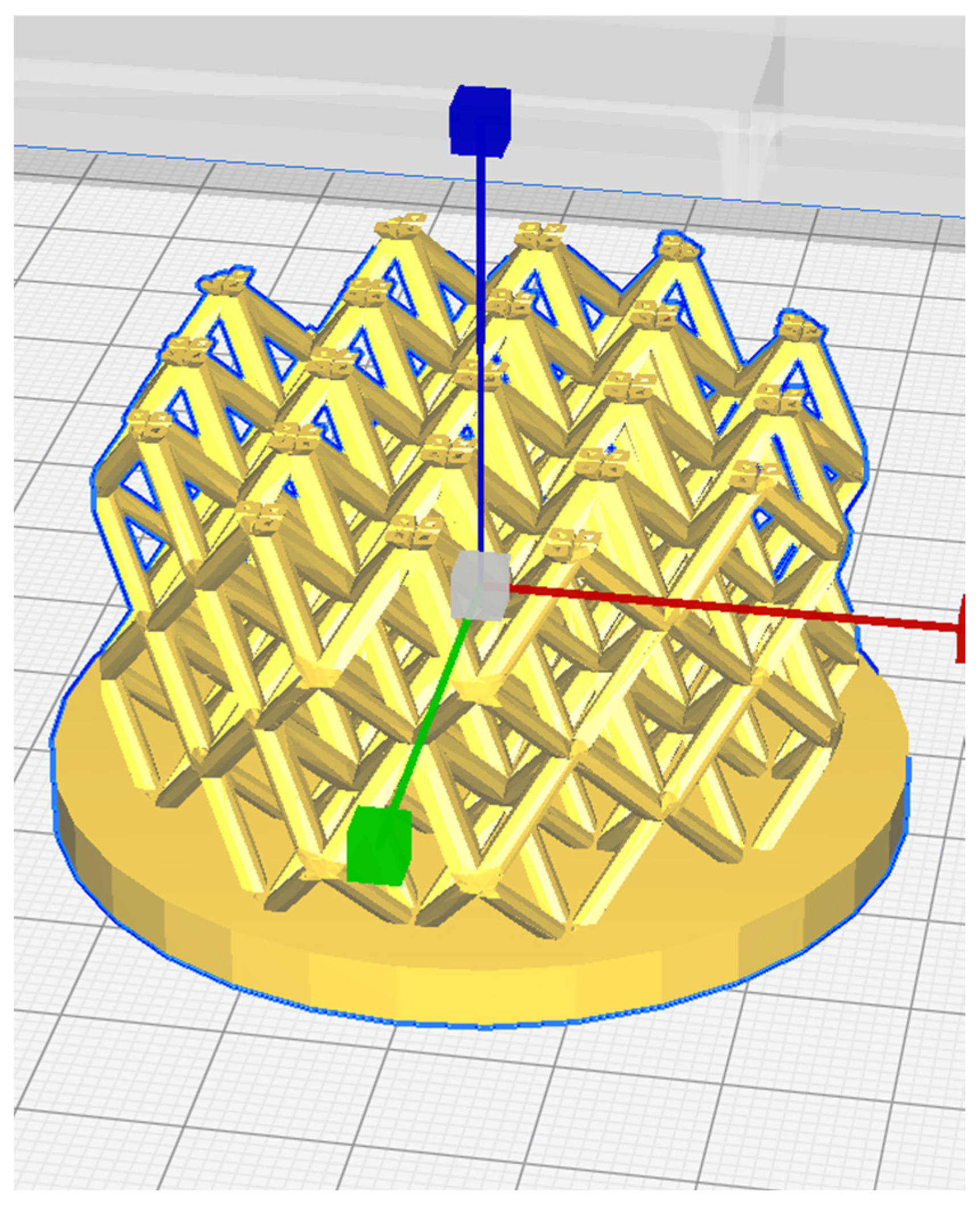

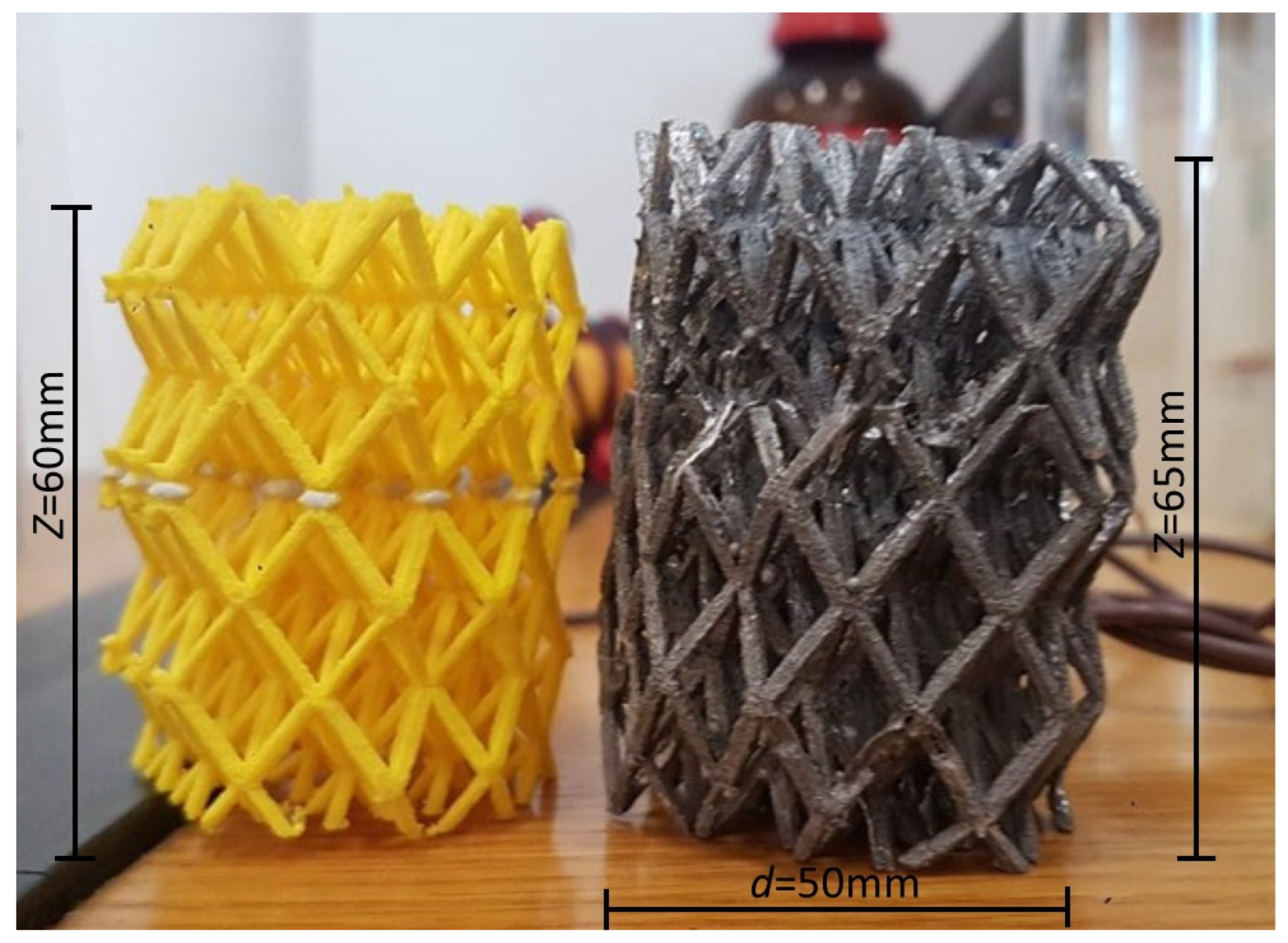

2. Materials and Sample Preparations

3. Experimental Section

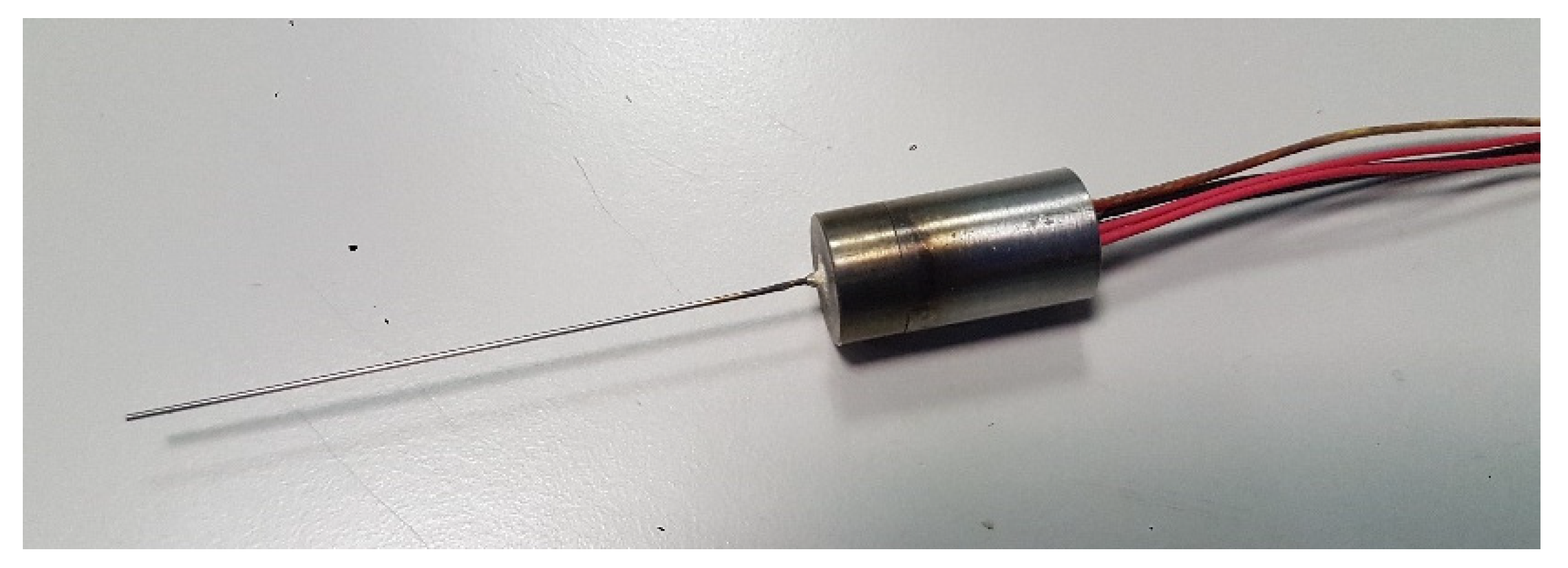

3.1. Thermal Conductivity Probe (TCP)

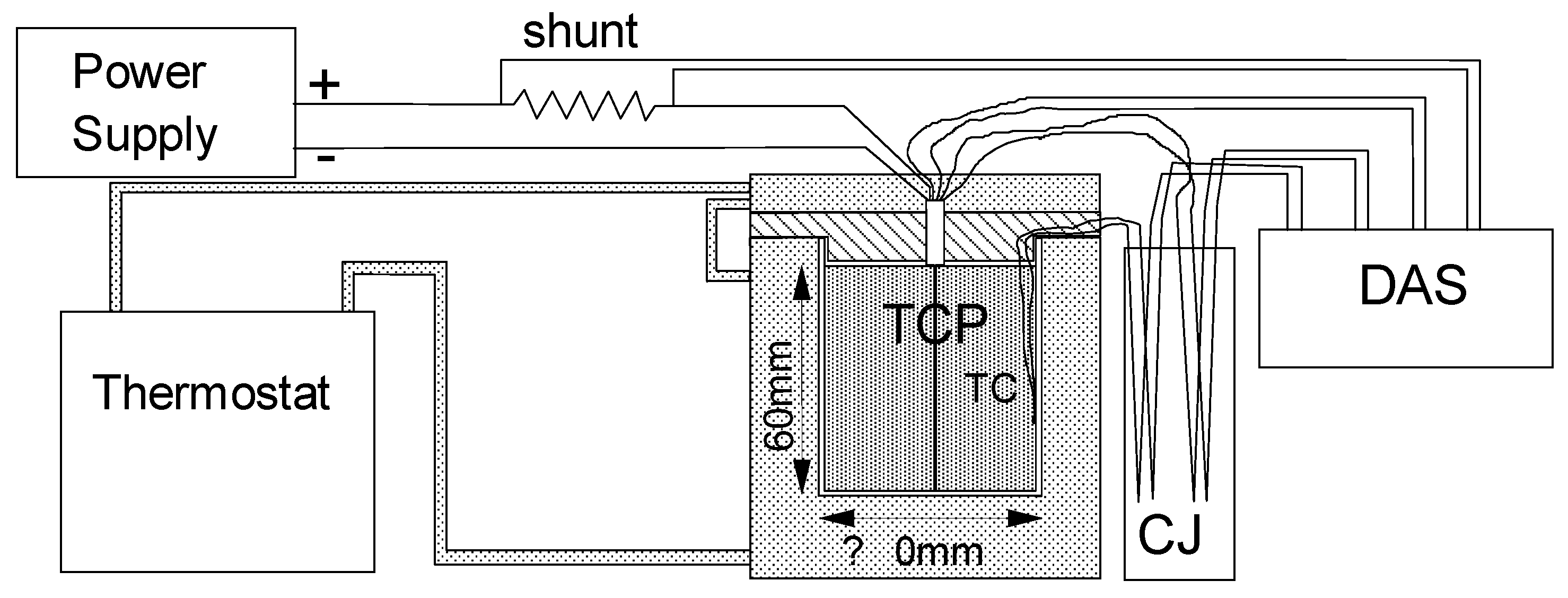

3.2. Experimental Apparatus

3.3. Test Procedure

3.4. Tests

- -

- Pure air tests;

- -

- Pure water tests;

- -

- Tests on pure water mixed with agar agar;

- -

- Tests on Al structures with water and agar agar;

- -

- PLA test in water;

- -

- PLA test in water +agar agar;

- -

- Al tests in air;

- -

- PLA tests in air.

4. Results

5. Discussion of Results

5.1. Thermal Conductivity

- (1)

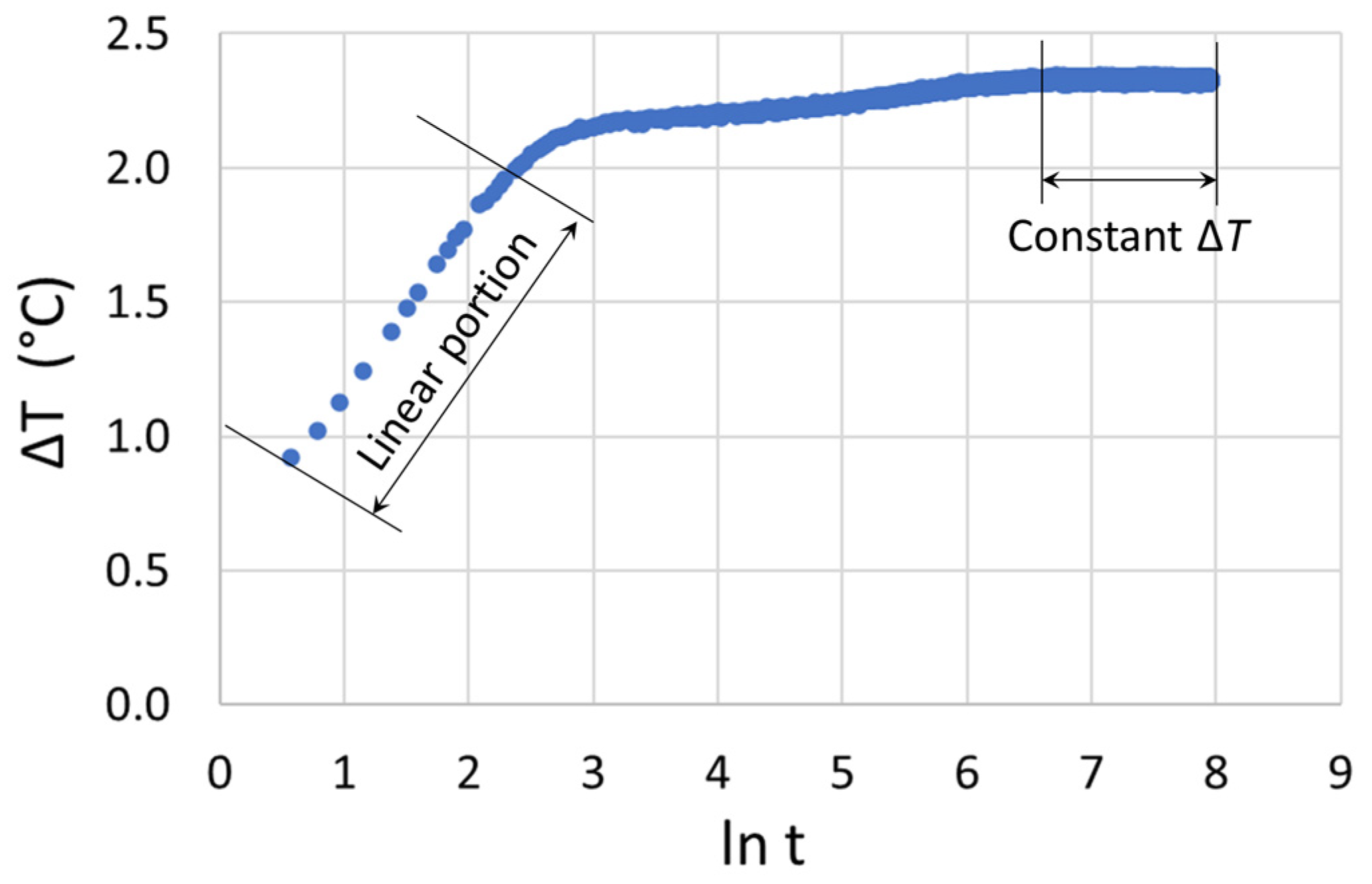

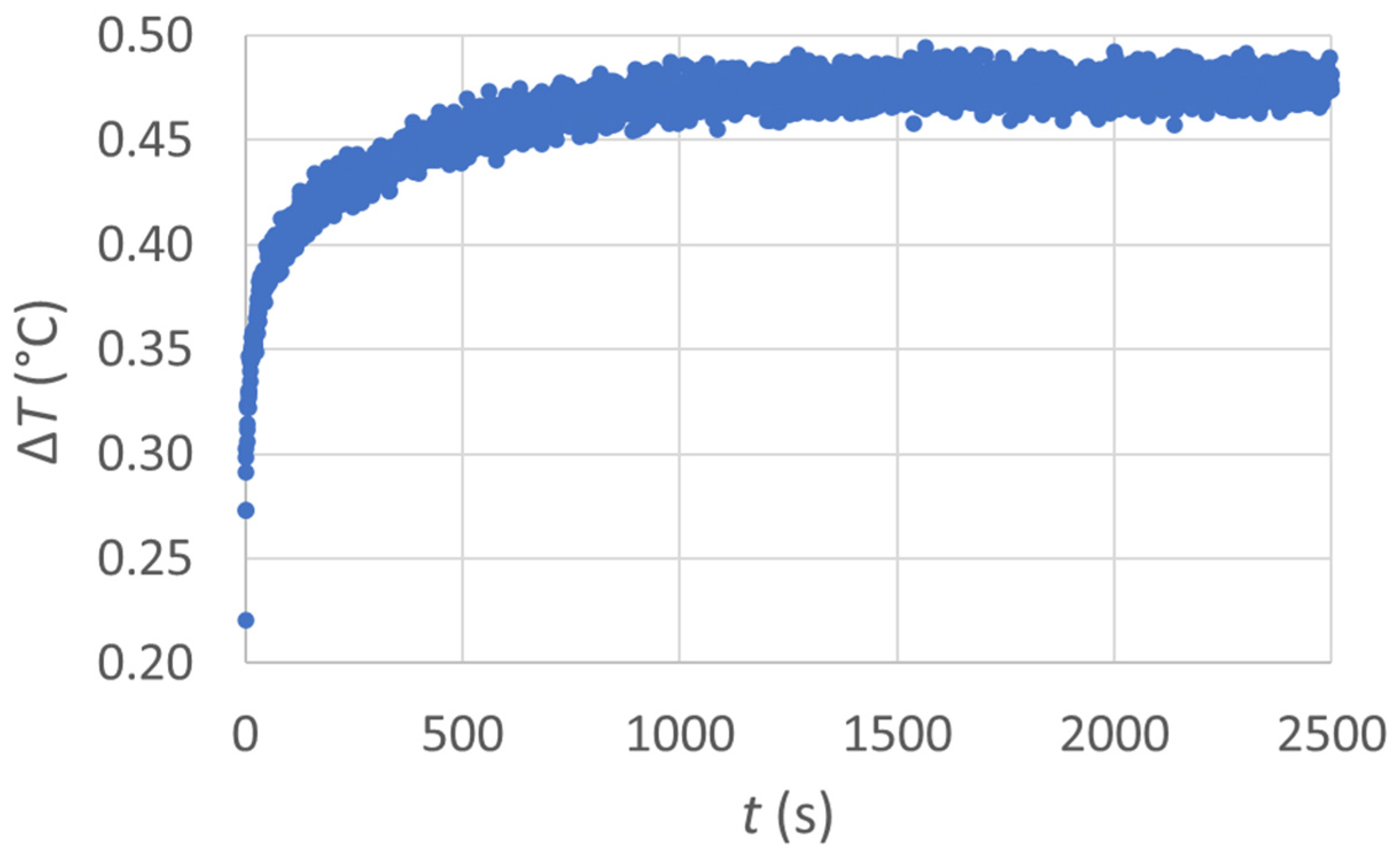

- ΔT vs. ln t trends (see, for instance, Figure 6) often present different slopes: only the first is generally connected to the true λ value, and the others are due to mixed convection/conduction, or steady-state convection when this trend is horizontal.

- (2)

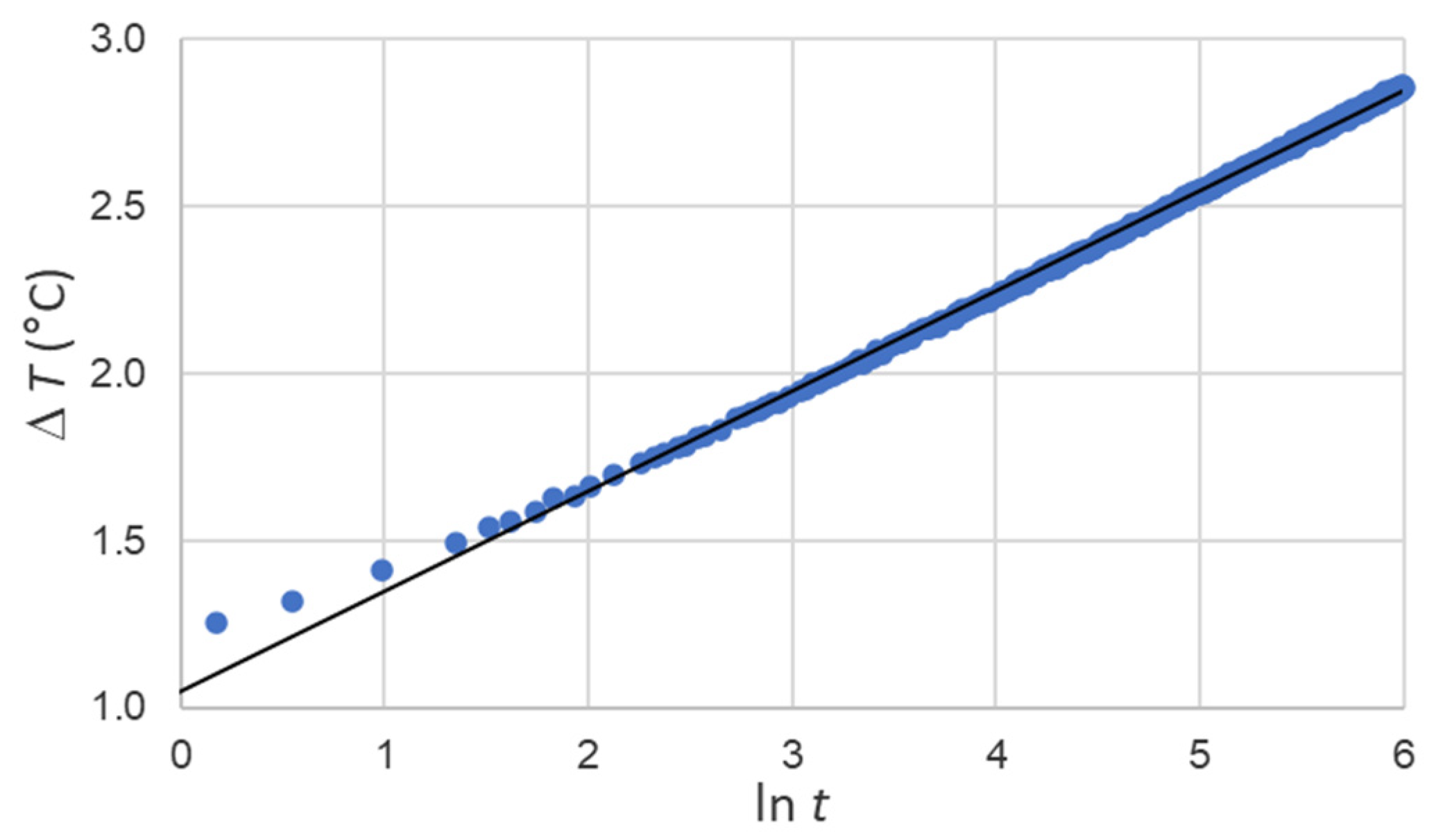

- Only water and only air (above all, this latter) tests give values affected by high uncertainties, due to the difficulty in identifying the linear zone in the ΔT vs. ln t trends: see, for instance, Figure 8a–c and Figure 9a,b, which show a relevant data spread (till 30%) and difference with respect to references. This is the reason why, at least for water, adding agar agar highly reduces the uncertainty (see in Figure 9a this reduction for water, from 9% to 2.3‰). Moreover, the obtained values of water fall within 1.7% from tables of ref. [33].

- (3)

- Comparing λ values of the PLA foam in water + agar agar, obtained from the TCP theory (from the slope of the ΔT vs. ln t) and in steady state (GHP), different trends appear, as seen in Figure 9c. This is likely due to the different volume interested by the two procedures: the whole composite volume for the GHP, and only a layer around the probe in the TCP, which increases during the measurement. Furthermore, the presence of a pure liquid layer around the probe needle results in an effect similar to the so-called wall effect. Water + agar agar viscosity lowers with temperature, producing an apparent thermal conductivity which increases with temperature. When the same comparison is made on the Al foam in water, this shift appears also at lower temperatures (Figure 9d), probably due to the high conductivity of aluminium, which produces this effect (apparent thermal conductivity) at lower temperatures as well.

- (4)

- (5)

- In Figure 9d, while the aluminium foam in water+agar agar presents the same λ steady-state value of pure water, in the TCP tests, λ results in being increased about 3.6 times, from 0.6 to 2 ÷ 2.25 W/m K: this demonstrates the effect of the solid material λ, at least in the neighbourhood of the heat source.

- (6)

- In Figure 9d, Al foam samples in water, measured with TCP and with a temperature increase during the test of about 2.5 °C, show λ values of about 2 W/m K, while in Figure 9b with only ΔT = 0.3 °C, λ assumes 1.25 ± 0.13 W/m K. This indicates the importance of high-enough values of the temperature increase during the TCP test in order to avoid uncertainties and biases during the measurements that are too high.

- (7)

5.2. Convection Heat Transfer Coefficient

- (1)

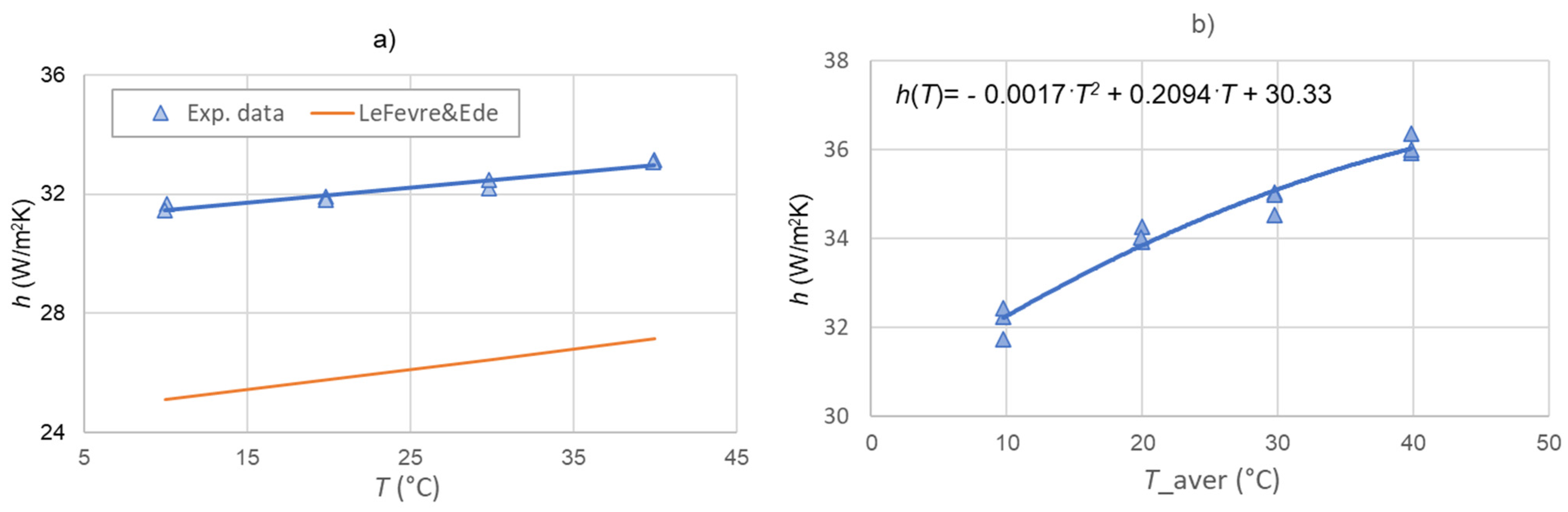

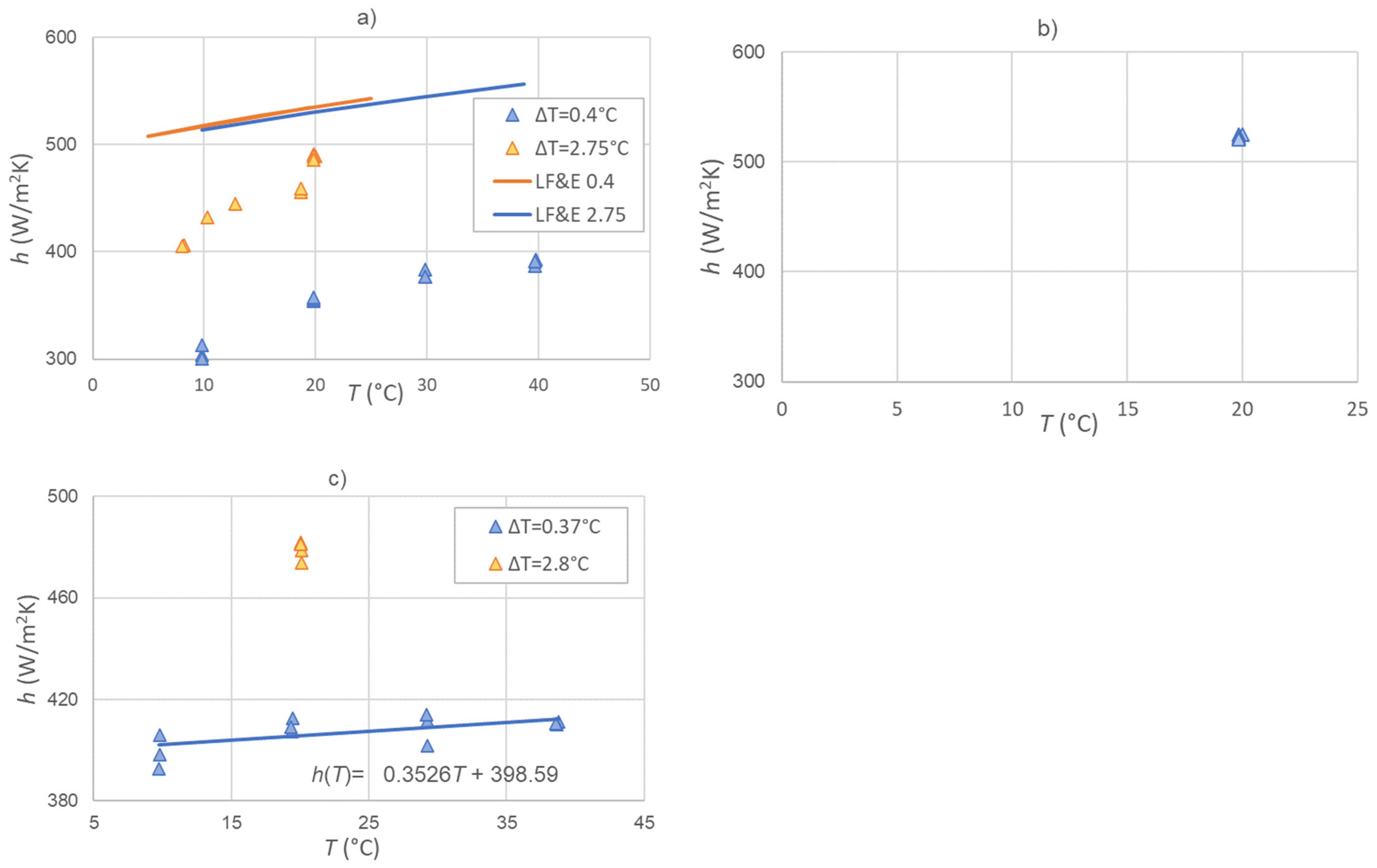

- Figure 10a shows the comparison of h values measured with the TCP immersed in air and computed with the empirical correlation of LeFevre & Ede [32]: both trends present the same slope but different absolute values. However, the difference lay within 20%, as usually occurs when dealing with a comparison between empirical correlations and experimental data.

- (2)

- The same comparison for pure water (Figure 11a) shows an analogue agreement, again within 20%, but only if enough high ΔT (~3 °C) is supplied.

- (3)

- (4)

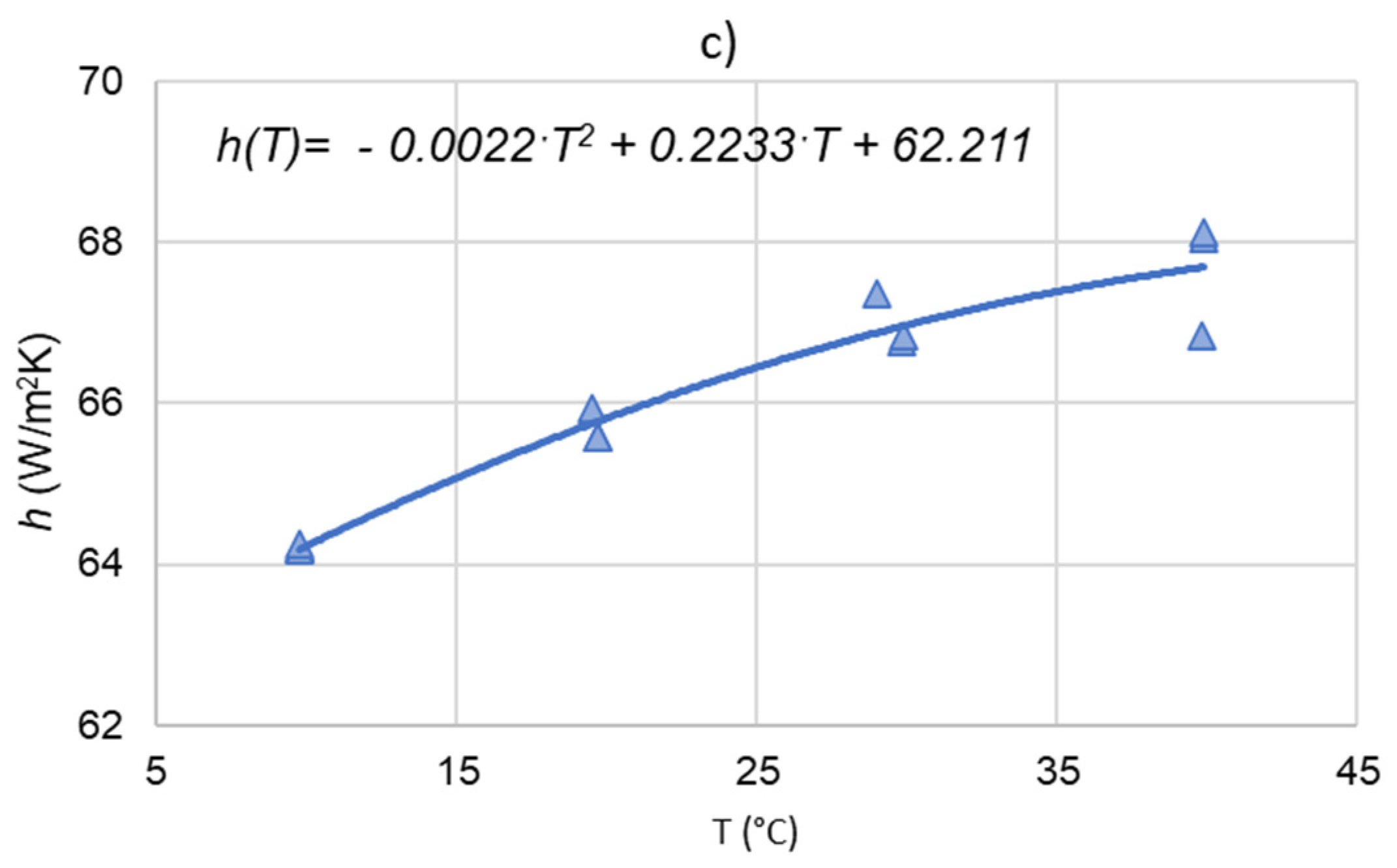

- Figure 10c and Figure 11c show a meaningful increase of h vs. average test temperature T for the Al foam both in air and water: from 10 to 40 °C, h increases by 5.5% in air and by 2.5% in water. On the contrary, with pure fluids, h increases by 4.5% in air (from 31.5 to 33 W/m K, Figure 10a) and 25% in water (from 300 to 400 W/m K, Figure 11a).

- (5)

- At low ΔT (0.4 °C), h of Al foam in water (Figure 11d) increases with respect to pure water (Figure 11a), from 300 ÷ 400 W/m2K to 400 ÷ 410 W/m2K. At higher ΔT (3 °C), the two h remain about the same (480 and 490 W/m2K). This can indicate a higher effect of the heat conduction in aluminium for low ΔT. The PLA foam shows an even higher h: this could be possibly due to the higher temperature of the probe when inserted into the PLA lattice, which presents a much lower λ with respect to Al. Thus, the higher temperature difference produces a higher h.

- (6)

6. Uncertainty Analysis

6.1. Thermal Conductivity

6.1.1. Type A Uncertainty

6.1.2. Type B Uncertainty

- -

- Calibration uncertainty of thermocouple and TCP: when comparing the results obtained on a reference material (glycerol), an uncertainty of 4% was obtained [3];

- -

- Uncertainty due to uncalibrated thermocouples: generally, a 0.3 °C is attributed to this source, but considering the high number of TC measurements carried out during each test, this cause is negligible, and furthermore, calibration uncertainty already takes it into account; the same can be said about the uncertainty available in manuals and books, and the one due to the experience of the experimenter and previous tests.

6.2. Convection Heat Transfer Coefficient

- -

- The convective cell generation, and the secondary and third order cells;

- -

- The influence of the ambient conditions: temperature, humidity, pressure, etc.;

- -

- The statistical nature of the phenomenon: even in the same experimental conditions, the exact repetition of the results is very difficult to obtain;

- -

- The presence of obstacles in the fluid movement, as the foam can be considered, which leads to the declared uncertainty (20%).

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms | |

| TCP | Thermal Conductivity Probe |

| PS | Power Supply |

| TC | Thermocouple |

| DAS | Data Acquisition System |

| GHR | Guarded Hot Ring |

| PLA | Poly Lactic Acid |

| Latin | |

| A | Area (m2) |

| Thermal power (W) | |

| d | diameter (m) |

| Z | height (m) |

| h | convection heat transfer coefficient (W/m2K) |

| T | Temperature |

| I | Electric current (A) |

| R | Electric resistance (Ω) |

| L | length (m) |

| t | time (s) |

| Greek | |

| λ | thermal conductivity (W/m K) |

| Δ | difference |

References

- Abdul-Sahib, A.A.; Muneer, A. Experimental Steam Condensation Enhancement on Metal Foam Filled Heat Exchanger. J. Mech. Eng. Res. Dev. 2021, 44, 145–167. [Google Scholar]

- Pulvirenti, B.; Celli, M.; Barletta, A. Flow and Convection in Metal Foams: A Survey and New CFD Results. Fluids 2020, 5, 155. [Google Scholar] [CrossRef]

- Bovesecchi, G.; Coppa, P.; Pistacchio, S. A new thermal conductivity probe for high temperature tests for the characterization of molten salts. Rev. Sci. Instrum. 2018, 89, 055107. [Google Scholar] [CrossRef]

- Potenza, M.; Coppa, P.; Corasaniti, S.; Bovesecchi, G. Numerical Simulation of Thermal Diffusivity Measurements with the Laser-Flash Method to Evaluate the Effective Property of Composite Materials. J. Heat Transf. 2021, 143, 072102. [Google Scholar] [CrossRef]

- Hong, J.T.; Tien, C.L.; Kaviany, M. Non-Darcian effects on vertical-plate natural convection in porous media with high porosities. Int. J. Heat Mass Transf. 1985, 28, 2149–2157. [Google Scholar] [CrossRef]

- Andreozzi, A.; Buonomo, B.; Jaluria, Y.; Manca, O. Numerical Investigation on Natural Convection in Inclined Channels Partially Filled with Asymmetrically Heated Metal Foam. J. Heat Mass Transf. 2022, 145, 042602. [Google Scholar] [CrossRef]

- Ranut, P.; Nobile, E.; Mancini, L. High resolution microtomography-based CFD simulation of flow and heat transfer in aluminum metal foams. Appl. Therm. Eng. 2014, 69, 230–240. [Google Scholar] [CrossRef]

- Piller, M.; Stalio, E. Numerical Investigation of Natural Convection in Inclined Parallel-Plate Channels Partly Filled with Metal Foams. Int. J. Heat Mass Transf. 2012, 55, 6506–6513. [Google Scholar] [CrossRef]

- Corasaniti, S.; De Luca, E.; Gori, F. Effect of structure, porosity, saturating fluid and solid material on the effective thermal conductivity of open-cells foams. Int. J. Heat Mass Transf. 2019, 138, 41–48. [Google Scholar] [CrossRef]

- Calmidi, V.V.; Mahajan, R.L. The Effective Conductivity of High Porosity Fibrous Metal Foams. ASME J. Heat Transf. 1999, 121, 466–471. [Google Scholar] [CrossRef]

- Calmidi, V.V.; Mahajan, R.L. Forced Convection in High Porosity Metal Foams. J. Heat Transf. 2000, 122, 557–565. [Google Scholar] [CrossRef]

- Shih, W.H.; Chou, F.C.; Hsieh, W.H. Experimental Investigation of the Heat Transfer Characteristics of Aluminum-Foam Heat Sinks with Restricted Flow Outlet. J. Heat Transf. 2007, 129, 1554–1563. [Google Scholar] [CrossRef]

- Kuang, J.J.; Wang, X.L.; Lu, T.J.; Kim, T. Role of Laminar Length of Round Jet Impinging on Metal Foams. J. Thermophys. Heat Transf. 2015, 30, 103–110. [Google Scholar] [CrossRef]

- Dukhan, N.; Chen, K.C. Heat transfer measurements in metal foam subjected to constant heat flux. Exp. Therm. Fluid Sci. 2007, 32, 624–631. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Lu, T.J.; Hodson, H.P. Natural convection in metal foams with open cells. Int. J. Heat Mass Transf. 2005, 48, 2452–2463. [Google Scholar] [CrossRef]

- Singh, P.; Nithyanandam, K.; Zhang, M.; Mahajan, R.L. The Effect of Metal Foam Thickness on Jet Array Impingement Heat Transfer in High-Porosity Aluminum Foams. J. Heat Transf. 2020, 142, 052301. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Hwang, J.J.; Hwang, G.J.; Yeh, R.H.; Chao, C.H. Measurement of Interstitial Convective Heat Transfer and Frictional Drag for Flow Across Metal Foams. ASME J. Heat Transf. 2002, 124, 120–129. [Google Scholar] [CrossRef]

- Buonomo, B.; Manca, O.; Nardini, S.; Diana, A. Experimental and Numerical Investigation on Natural Convection in Horizontal Channels Partially Filled with Aluminium Foam and Heated from Below. In Proceedings of the ASME 2016 Heat Transfer Summer Conference collocated with the ASME 2016 Fluids Engineering Division Summer Meeting and the ASME 2016 14th International Conference on Nanochannels, Microchannels, and Minichannels, Washington, DC, USA, 10–14 July 2016. ASME Paper No: HT2016-7257. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Diani, A.; Rossetto, L. Air forced convection through metal foams: Experimental results and modeling. Int. J. Heat Mass Transf. 2013, 62, 112–123. [Google Scholar] [CrossRef]

- Duarte, A.P.C.; Mazzuca, P.; de Carvalho, J.L.; Tiago, C.; Firmo, J.P.; Correia, J.R. Determination of the temperature-dependent thermophysical properties of polymeric foams using numerical inverse analysis. Constr. Build. Mater. 2023, 394, 131980. [Google Scholar] [CrossRef]

- Boomsma, K.; Poulikakos, D.; Zwick, F. Metal foams as compact high performance heat exchangers. Mech. Mater. 2003, 35, 1161–1176. [Google Scholar] [CrossRef]

- Krishnan, S.; Murthy, J.Y.; Garimella, S.V. Metal foams as passive thermal control systems. In Emerging Topics in Heat and Mass Transfer in Porous Media; Vadász, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 261–282. [Google Scholar]

- Mahjoob, S.; Vafai, K. A synthesis of fluid and thermal transport models for metal foam heat exchangers. Int. J. Heat Mass Transf. 2008, 51, 3701–3711. [Google Scholar] [CrossRef]

- Zhao, C.Y. Review on thermal transport in high porosity cellular metal foams with open cells. Int. J. Heat Mass Transf. 2012, 55, 3618–3632. [Google Scholar] [CrossRef]

- Ranut, P. On the effective thermal conductivity of aluminum metal foams: Review and improvement of the available empirical and analytical models. Appl. Therm. Eng. 2016, 101, 496–524. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E.; Trillicoso, G. Al foams manufactured by PLA replication and sacrifice. Int. J. Lightweight Mater. Manuf. 2021, 4, 62–66. [Google Scholar] [CrossRef]

- Costanza, G.; Del Ferraro, A.; Tata, M.E. Experimental set-up of the production process and mechanical characterization of metal foams manufactured by lost-PLA technique with different cell morphology. Metals 2022, 12, 1385. [Google Scholar] [CrossRef]

- Wechsler, A.E. The Probe Method for Measuring Thermal Conductivity. In Compendium of Thermophysical Property Measurement Methods; Recommended Measuring Techniques and Practices; Maglić, K.D., Cezairliyan, A., Peletsky, V.E., Eds.; Plenum Press: London, UK, 1992; Volume 2. [Google Scholar]

- D’Alessandro, G.; Potenza, M.; Corasaniti, S.; Sfarra, S.; Coppa, P.; Bovesecchi, G.; de Monte, F. Modeling and Measuring Thermodynamic and Transport Thermophysical Properties: A Review. Energies 2022, 15, 8807. [Google Scholar] [CrossRef]

- ASTM D5334-14; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. ASTM International: West Conshohocken, PA, USA, 2014.

- Le Fevre, E.J.; Ede, A.J. Laminar free convection from the outer surface of a vertical circular cylinder. In Proceedings of the 9th International Congress on Applied Mechanics, Brussels, Belgium, 5–13 September 1956; Volume 4, pp. 175–183. [Google Scholar]

- Haar, L.; Gallagher, J.S.; Kell, G.S. Thermodynamic and Transport Properties and Computer Programs for Vapor and Liquid State of Water; NBS/NRC; Hemisphere: Washington, DC, USA, 1984. [Google Scholar]

- Incropera, F.P.; Dewitt, D.P. Fundamental of Heat Transfer; John Wiley &Sons: Hoboken, NJ, USA, 1981. [Google Scholar]

- Blanco, I.; Cicala, G.; Recca, G.; Tosto, C. Specific Heat Capacity and Thermal Conductivity Measurements of PLA-Based 3D-Printed Parts with Milled Carbon Fiber Reinforcement. Entropy 2022, 24, 654. [Google Scholar] [CrossRef]

- ISO-IEC 98-3:2008; Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement (GUM:1995). ISO: Geneva, Switzerland, 2008.

- Brandt, S. Data Analysis: Statistical and Computational Methods for Scientists and Engineers; Springer: Cham, Switzerland, 2014. [Google Scholar]

| 1 | build-up of the model with 3D CAD |

| 2 | export to CAM software for 3D printing |

| 3 | 3D printing of the model using PLA |

| 4 | plaster casting on the PLA model |

| 5 | mould drying |

| 6 | PLA removing from the plaster |

| 7 | metal casting into the plaster mould |

| 8 | plaster removal to obtain a foam |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bovesecchi, G.; Coppa, P.; Corasaniti, S.; Costanza, G.; Potenza, M.; Tata, M.E. Experimental Tests of Conduction/Convection Heat Transfer in Very High Porosity Foams with Lattice Structures, Immersed in Different Fluids. Energies 2023, 16, 5959. https://doi.org/10.3390/en16165959

Bovesecchi G, Coppa P, Corasaniti S, Costanza G, Potenza M, Tata ME. Experimental Tests of Conduction/Convection Heat Transfer in Very High Porosity Foams with Lattice Structures, Immersed in Different Fluids. Energies. 2023; 16(16):5959. https://doi.org/10.3390/en16165959

Chicago/Turabian StyleBovesecchi, Gianluigi, Paolo Coppa, Sandra Corasaniti, Girolamo Costanza, Michele Potenza, and Maria Elisa Tata. 2023. "Experimental Tests of Conduction/Convection Heat Transfer in Very High Porosity Foams with Lattice Structures, Immersed in Different Fluids" Energies 16, no. 16: 5959. https://doi.org/10.3390/en16165959

APA StyleBovesecchi, G., Coppa, P., Corasaniti, S., Costanza, G., Potenza, M., & Tata, M. E. (2023). Experimental Tests of Conduction/Convection Heat Transfer in Very High Porosity Foams with Lattice Structures, Immersed in Different Fluids. Energies, 16(16), 5959. https://doi.org/10.3390/en16165959