A Brief Review of the Latest Advancements of Massive Solar Thermal Collectors

Abstract

:1. Introduction

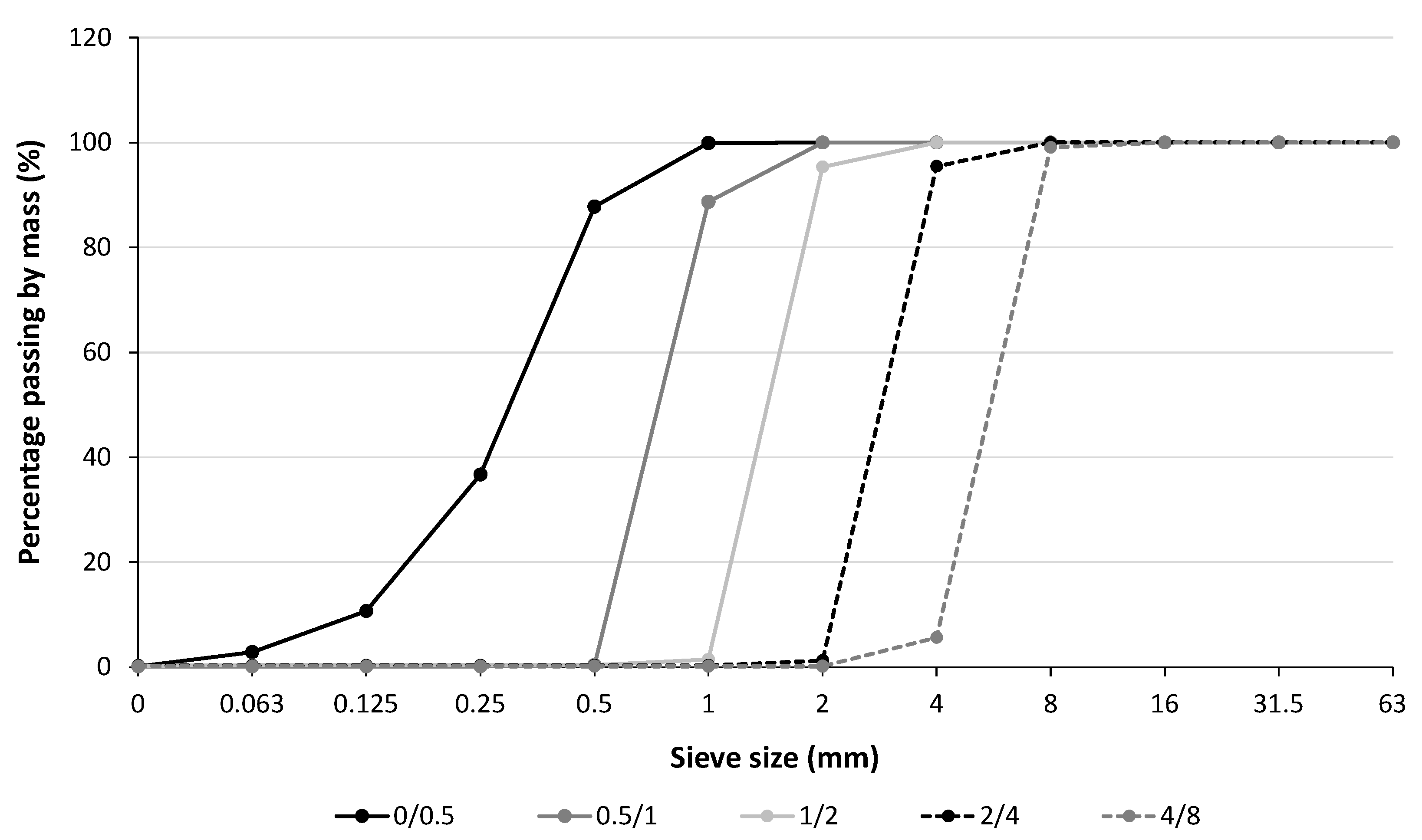

2. Experimental Methods

- Type of end application: heating, cooling, or production of domestic hot water (DHW).

- Use of collected heat: direct or indirect method. The first method occurs when solar energy covers partially or entirely the energy demand to produce domestic hot water and/or internal heating in buildings, or when the collected heat from the MSTC can reduce the internal temperature of the building, thus covering part of the demand for space cooling. The indirect method, on the other hand, occurs when the heat collected by the MSTC is used as a source for a heat generation system, such as a heat pump.

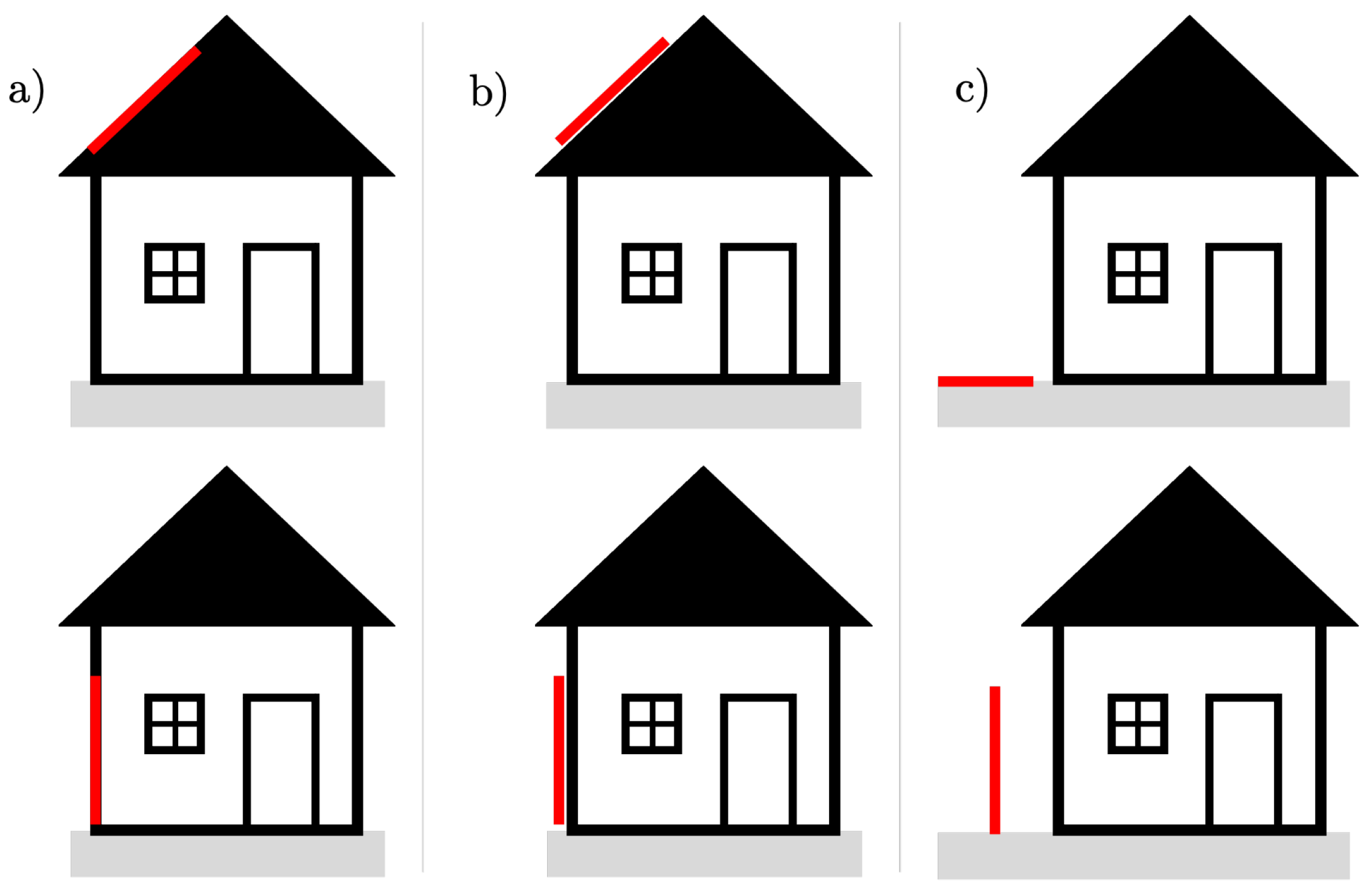

- Degree of integration into the building envelope: MSTCs can be fully integrated into the building (Figure 1a) or into the roof or façades; partially integrated (Figure 1b) and detached from the building (Figure 1c). The latter type includes systems that are completely detached from the building envelope such as, for example, horizontal pavements like road surfaces and driveways, or vertical external walls or prefabricated structures like garden perimeter walls and external garage structures. It is evident that in MSTCs completely detached from the building there is no optimization concerning orientation and inclination of the surfaces to better capture the solar radiation, because they are structures or parts of structures that already have a main function.

- The thickness of the plate affects the performance of the collector. In fact, as the thickness of the collector increases, the efficiency factor and heat removal rate increase, around 47% and 39%, respectively, and tend to become constant with 0.04 m plate thickness.

- As the space between the pipes increases, given constant pipe diameter, overall heat transfer coefficient and fluid flow rate, the heat removal values decrease around 30% and 55%, whatever the plate thickness.

- As the diameter of the tubes increases, the space between the tubes, the water flow rate and the heat transfer coefficient being constant, the fin effectiveness of the collector increases between 4% and 8.9% for all collector thicknesses analyzed. The effectiveness of the collector increases with increasing pipe diameter as the transfer by conduction decreases.

- Given constant pipe spacing and pipe diameter, as the water flow rate increases, the heat reduction factor of the collector increases regardless of the collector thickness.

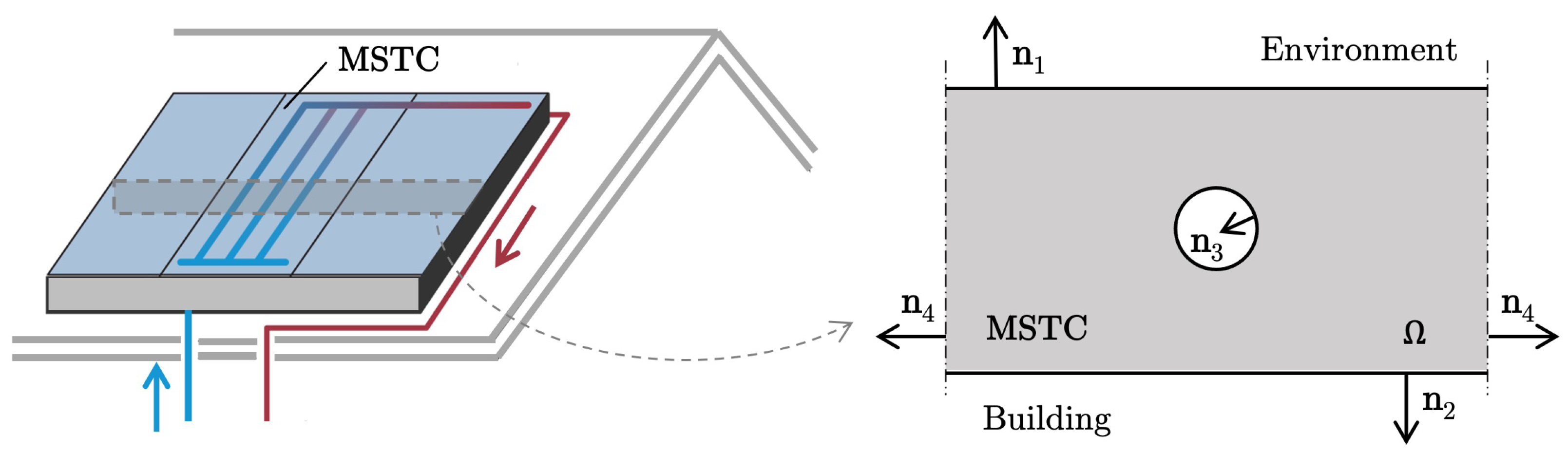

3. Numerical Modeling

4. Future Directions

5. Conclusions

- MSTCs are simple devices to build and are easy to operate. They can be implemented as modular systems with reduced construction costs compared to the costs required to construct traditional collectors and are also easy to maintain. For instance, these reduced costs make these devices suitable for rural or remote areas where there is not always a supply of electricity.

- The durability of metallic materials of traditional flat solar collectors is limited by the threat of corrosion. Concrete, instead, is inherently durable, maintenance-free, and has good thermal storage qualities, which make this material an excellent candidate for MSTCs.

- Attention should be paid to the main parameters of MSTCs. In this sense, the thickness of the plate affects the performance of the collector. As the thickness of the collector increases, the efficiency factor and heat removal rate increase around 47% and 39%, respectively. Also, as the diameter of the tubes increases the fin effectiveness of the collector increases between 4% and 8.9%. On the contrary, as the space between the pipes increases the heat removal values decrease around 30% and 55%, whatever the plate thickness.

- There is a linear correlation between the solar collector area and hot water consumption. The integration of massive collectors in façades could be a good solution when there is a high demand for hot water but a small roof area of the building.

- The modeling of an MSTC can be done in different ways, from simple 2D models up to complete, fully 3D simulations, which of course improves the accuracy at the expense of increasing the computational cost of solving these problems. Finite element and finite volume methods are generally used to solve the physical problem. Additionally, artificial neural network models were also implemented to reduce the computational cost of the simulations.

- Simulation analyses showed that attached collectors (integrated with the façade) can reduce the heat gains into the building while at the same time producing hot water. Another key point is that the payback period for these systems is only 2.54 years, an important characteristic for improving the market’s penetration of this technology.

- Sensitivity analysis by numerical modeling confirmed that the diameter of the tubes, the spacing between them, and the absorber thickness are the main design parameters that influence the collector’s energy output, as was also demonstrated by experimental studies.

- Other studies showed that concrete thermal conductivity and solar absorptance are also pointed out as two important parameters that influence the performance of the device. Modification of these properties can increase the efficiency by 10% and 33%, respectively. In this sense, thermal conductivity can be increased by adding highly conductive materials, like metallic scrap and wire mesh, which have been shown to improve the performance of the collector.

- Using asphalt as an alternative material to concrete showed that thermal conductivity and asphalt surface absorptivity are also important parameters for MSTCs. Changing these properties can lead to an increase in efficiency up to 6.4% and 12.2%, respectively.

- Regarding the integration with buildings, it was found that in the presence of a well-insulated back of the concrete absorber material, the collector has a negligible influence on the interior environment of a building. This is an important point that allows us to simplify the modeling of solar collectors in general by assuming detached configurations.

- Regarding the inclusion of TES systems in solar collectors it was found that the correct inclusion of latent-based TES materials can improve the energy performance of MSTCs. Improvements of 38.9% and 27.4% were possible in warm and cold climates, respectively.

- The use of recycled aggregates could be an interesting choice for the use in MSTCs. They can contribute positively in two ways, by increasing the TES capacity of the collector by using PCMs, and by reducing the negative environmental impact of construction wastes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CO | Carbon dioxide |

| MSTC | Massive solar thermal collector |

| TES | Thermal Energy Storage |

| PCM | Phase Change Material |

| DHW | Domestic hot water |

| PVC | Polyvinyl chloride |

| PSC | Pavement solar collector |

| MFRC | Metal-fiber-reinforced concrete |

| ASC | Asphalt solar collector |

| TMY | Typical meteorological year |

| CFD | Computational fluid dynamics |

| ANN | Artificial neural network |

| MIP | Mercury Intrusion Porosimetry |

| PB | Poroton® fired-clay block |

| HDPE | High density polyethylene |

| PE-X | Polyethylene |

| GRC | Glass-reinforced concrete |

| CCC | Cellular-clayey concrete |

Appendix A

| Year | Analysis (T/E) | Application | Massive Material | Main Characteristics A (m), t (m) | Pipe Material | Main Characteristics Ø (mm), (mm), (L/min) | Efficiency (Yes/No) Glazing, Back Insulation, Black Paint | References |

|---|---|---|---|---|---|---|---|---|

| 2023 | E | HR | Asphalt | A = 0.08, t = 0.05 | Copper | = 24.5, = only 1 pipe, = - | no, yes, no | [38] |

| 2022 | T | DHW | Concrete | A = -, t = 0.127 | - | = 25.4, = 165, = - | no, no, no | [8] |

| 2021 | E | DHW | Concrete | A = 2.24, t = 0.10 | Aluminum | = 12.5, = -, = 0.24, 0.38 and 0.50 | no, no, yes | [39] |

| 2020 | T and E | W | Asphalt mixture | A = 1.2, t = 0.2 | Stainless steel | = 15.8, = 110, = 0.4, 1.34, 0.98 and 1.07 | no, no, no | [17] |

| 2020 | T and E | W | Asphalt | A = 1.0, t = 0.062 | Galvanised steel | = 14.0, = 117, = 0.25–1.50 | no, yes, no | [18] |

| 2019 | E | W | Asphalt | A = 0.50, t = 0.05 | Copper | = 9.52, = 50, = 1.20 | yes, yes, no | [40] |

| 2019 | E | W | Reinforced Concrete | A = 2.0, t = 0.03 | - | = 12.7, = 150, = 1.0 | yes, yes, yes | [16] |

| 2018 | T | DHW | Concrete and refractory carborundum brick | A = 16.0, t = 0.23 | Copper | = 10.0–20.0, = -, = 0.12–0.22 | no, yes, no | [25] |

| 2018 | E | W | Concrete | A = 2.0, t = 0.03 | Copper | Ø = 8.0, = 80, = 0.33–0.75 | yes, yes, no | [15] |

| 2017 | T | DHW and H | Concrete | A = 1.0, t = 0.08 | Copper | = 15.0, = 50, = 0.30 | no, yes, yes | [22] |

| 2017 | T and E | DHW | Concrete | A = 1.0, t = 0.08 | Copper | = 15.0, = 50, = 1.20 | no, yes, yes | [11] |

| 2017 | E | DHW | Reinforced Concrete | A = 2.0, t = 0.035 | Copper | = 10.0, = 80, = 0.50 | yes, yes, yes | [14] |

| 2017 | E | W | Ceramic | A = 1.597, t = 0.027 | Ceramic | = 17.0, = 40, = 1.98, 2.34, 2.70 | yes, yes, yes | [29] |

| 2016 | T and E | W | Asphalt concrete | A = 1.67, t = 0.119 | Copper | = 15.0, = 457, = 1–4 | no, no, no | [13] |

| 2016 | T and E | H | Concrete | A = 2.20, t = 0.07 | - | = 12.0, = -, = 2.50 | no, yes, no | [24] |

| 2016 | E | SWH | Reinforced Concrete | A = 2.0, t = 0.10 | Copper | = 12.0, = 80, = 0.417 | yes, yes, yes | [12] |

| 2014 | E | W | Concrete with/without aluminum wire mesh and iron scraps | A = 2.24, t = 0.10 | Aluminum and | Ø = 12.5, = 1.20 PVC | no, no, yes | [9] |

| 2013 | T | W | Concrete | A = 3.50, t = 0.127 | PE-X | = 25.4, = 16.5, = 15–75 (kg/h m) | no, no, no | [5] |

| 2013 | T | H | Concrete | A = -, t = 0.07 | - | Ø = 16.0, = 200, = - | no, yes, no | [41] |

| 2013 | E | W | Asphalt concrete (upper and bottom layers) | A = 0.104, t = 0.09 | Porous asphalt layer instead | Ø = -, = -, = - of embedded pipe network | no, no, no | [42] |

| 2012 | E | W | Concrete | A = -, t = 0.25 | Acrylic plastic | Ø = -, = -, = - | no, no, yes | [43] |

| 2011 | T and E | H | Plaster | A = 2.5–5, t = - | PE | Ø = -, = -, = - | no, yes, yes | [44] |

| 2011 | T and E | W | Concrete | A = 5.75, t = 0.12 | PVC | = 25.4, = 100, = - | no, no, no | [23] |

| 2011 | T and E | IM | Asphalt concrete | A = 2.7, t = 0.1 | Copper | = 20, = 300, = 0–1 | no, yes, no | [45] |

| 2011 | E | HR | Asphalt | A = 0.09, t = 0.15 | Copper | = 20, = 100, = 0–2 | no, yes, no | [46] |

| 2010 | T and E | DHW | Concrete | A = 2.0, t = 0.04 | Copper | = 14, = 100, = 2.48 | yes, yes, yes | [47] |

| 2010 | T | IM | Asphalt | A = 0.72, t = 0.078 | - | = 20, = 90–150, = 1.17, 1.33 and 1.67 | no, no, no | [48] |

| 2009 | E | HEE | Asphalt concrete | A = 0.09, t = 0.15 | Copper | = 20, = 100, = 0–1 | no, yes, no | [49] |

| 2008 | E | IM | Concrete pavement | A = 1, t = 0.3 | HDPE | = 25, = 200, = <83 | no, yes, no | [50] |

| 2007 | T | DHW and H | Concrete | A = 5.25, t = 0.229 | Copper | Ø = 6.35, = -, = 11.4–0.00016 | yes, yes, yes | [51] |

| 2004 | T | W and H | Concrete | A = 1.16, t = 0.038 | PE | = 20, = 19, = - | yes, no, yes | [52] |

| 2002 | T and E | HT | Concrete | A = 0.312, t = 0.10 | Not present | Ø = -, = -, = - | no, yes, no | [53] |

| 2000 | E | DHW | Reinforced Concrete | A = 1.06, t = 0.055 | Aluminum | = 19.0, = 60, = 1.33–1.67 | no, no, yes | [7] |

| 2000 | T and E | H | CCC | A = 1.88, t = 0.20 | - | Ø = -, = -, = 5.6 and 9.0 | no, no, no | [21] |

| 1994 | E | W | Concrete | A = 0.90, t = 0.050 | Galvanised steel | = 16.4, = 100, = 0.011, 0.022 and 0.033 (kg/s m) | yes, yes, yes | [54] |

| Concrete | A = 0.90, t = 0.050 | Propyleneglycol | = 13.0, = 100, = 0.011, 0.022 and 0.033 (kg/s m) | yes, yes, yes | ||||

| Concrete | A = 0.93, t = 0.050 | PVC | = 13.5, = 100, = 0.011, 0.022 and 0.033 (kg/s m) | yes, yes, yes | ||||

| 1992 | T | W | GRC | A = -, t = 0.020 | - | Ø = 10.0, = 40–100, = - | no, no, no | [55] |

| 1992 | T | W | Cellular concrete | A = 0.90, t = 0.035 | PVC | = 20.0, = 60–150, = 0.60–1.20 | yes, yes, yes | [56] |

| 1989 | E | W | Cellular concrete | A = 0.90, t = 0.035 | PVC | = 20.0, = 60–150, = 0.60–1.20 | yes, yes, yes | [57] |

References

- European Union. Causes of Climate Change; European Union: Maastricht, The Netherlands, 2021.

- IEA. Key World Energy Statistics (KWES); IEA: Paris, France, 2021.

- D’Antoni, M.; Saro, O. Massive Solar-Thermal Collectors: A critical literature review. Renew. Sustain. Energy Rev. 2012, 16, 3666–3679. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- D’Antoni, M.; Saro, O. Energy potential of a Massive Solar-Thermal Collector design in European climates. Sol. Energy 2013, 93, 195–208. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Energy Conservation in Building & Communities Systems (ECBCS). Annex 44—Integrating Environmentally Responsive Elements in Buildings; Project Summary Report by Prof. Per Heiselberg (2012); IEA: Paris, France, 2012.

- Chaurasia, P. Solar water heaters based on concrete collectors. Energy 2000, 25, 703–716. [Google Scholar] [CrossRef]

- Peralta, I.; Fachinotti, V.D.; Koenders, E.A.; Caggiano, A. Computational design of a Massive Solar-Thermal Collector enhanced with Phase Change Materials. Energy Build. 2022, 274, 112437. [Google Scholar] [CrossRef]

- Krishnavel, V.; Karthick, A.; Murugavel, K.K. Experimental analysis of concrete absorber solar water heating systems. Energy Build. 2014, 84, 501–505. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O.; McCormack, S. A Case for façade located solar thermal collectors. Energy Procedia 2015, 70, 103–110. [Google Scholar] [CrossRef] [Green Version]

- O’Hegarty, R.; Kinnane, O.; McCormack, S.J. Concrete solar collectors for façade integration: An experimental and numerical investigation. Appl. Energy 2017, 206, 1040–1061. [Google Scholar] [CrossRef]

- Patil, S.R.; Keste, A.A.; Sable, A.B. Investigation and development of liquid flat plate solar collector using concrete as absorber plate and its performance testing. Int. J. Renew. Energy Res. (IJRER) 2016, 6, 1212–1220. [Google Scholar]

- Guldentops, G.; Nejad, A.M.; Vuye, C.; den bergh, W.V.; Rahbar, N. Performance of a pavement solar energy collector: Model development and validation. Appl. Energy 2016, 163, 180–189. [Google Scholar] [CrossRef]

- Sable, A. Experimental and economic analysis of concrete absorber collector solar water heater with use of dimpled tube. Resour.-Effic. Technol. 2017, 3, 483–490. [Google Scholar]

- Patil, S.R.; Lodha, R.; Keste, A. Concrete solar collector-an experimental investigation in solar passive energy. Mater. Today Proc. 2020, 23, 366–372. [Google Scholar] [CrossRef]

- Al Hoqani, T.M.; Bhambare, P.S.; Kaithari, D.K. Solar Thermal Energy Utilization using Metal Fiber Reinforced Concrete (MFRC) Collector for Producing Hot Water in Sultanate of Oman. Int. J. Innov. Technol. Explor. Eng. (IJITEE) 2019, 8, 1335–1340. [Google Scholar] [CrossRef]

- Zaim, E.H.; Farzan, H.; Ameri, M. Assessment of pipe configurations on heat dynamics and performance of pavement solar collectors: An experimental and numerical study. Sustain. Energy Technol. Assess. 2020, 37, 100635. [Google Scholar] [CrossRef]

- Masoumi, A.P.; Tajalli-Ardekani, E.; Golneshan, A.A. Investigation on performance of an asphalt solar collector: CFD analysis, experimental validation and neural network modeling. Sol. Energy 2020, 207, 703–719. [Google Scholar] [CrossRef]

- Lopez, J.P.A.; Kuznik, F.; Baillis, D.; Virgone, J. Numerical modeling and experimental validation of a PCM to air heat exchanger. Energy Build. 2013, 64, 415–422. [Google Scholar] [CrossRef]

- Morgan, K.; Lewis, R.W.; Zienkiewicz, O.C. An improved algrorithm for heat conduction problems with phase change. Int. J. Numer. Methods Eng. 1978, 12, 1191–1195. [Google Scholar] [CrossRef]

- Marmoret, L.; Glouannec, P.; Douzane, O.; t’Kint de Roodenbeke, A.; Queneudec, M. Use of a cellular clayey concrete for a wall specially fitted with water pipes. Energy Build. 2000, 31, 89–95. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O.; McCormack, S.J. Parametric investigation of concrete solar collectors for façade integration. Sol. Energy 2017, 153, 396–413. [Google Scholar] [CrossRef]

- Sarachitti, R.; Chotetanorm, C.; Lertsatitthanakorn, C.; Rungsiyopas, M. Thermal performance analysis and economic evaluation of roof-integrated solar concrete collector. Energy Build. 2011, 43, 1403–1408. [Google Scholar] [CrossRef]

- Tanzer, B.; Schweigler, C. Façade-integrated Massive Solar-thermal Collectors Combined with Long-term Underground Heat Storage for Space Heating. Energy Procedia 2016, 91, 505–516. [Google Scholar] [CrossRef] [Green Version]

- Prakash, D. Thermal analysis of building roof assisted with water heater and insulation material. Sādhanā 2018, 43, 30. [Google Scholar] [CrossRef] [Green Version]

- Benkaddour, A.; Faraji, M.; Faraji, H. Numerical study of the thermal energy storage behaviour of a novel composite PCM/Concrete wall integrated solar collector. Mater. Today Proc. 2020, 30, 905–908. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Q.; Xiu, D.; Zhao, Z.; Sun, Q. A building integrated solar collector: All-ceramic solar collector. Energy Build. 2013, 62, 15–17. [Google Scholar] [CrossRef]

- Xu, J.; Yang, Y.; Cai, B.; Wang, Q.; Xiu, D. All-ceramic solar collector and all-ceramic solar roof. J. Energy Inst. 2014, 87, 43–47. [Google Scholar] [CrossRef]

- Zukowski, M.; Woroniak, G. Experimental testing of ceramic solar collectors. Sol. Energy 2017, 146, 532–542. [Google Scholar] [CrossRef]

- Ramón-Álvarez, I.; Sánchez-Delgado, S.; Peralta, I.; Caggiano, A.; Torres-Carrasco, M. Experimental Characterization and Modelling of Geopolymers and Hybrid Materials for Solar Thermal Energy. In International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures; Springer Nature: Cham, Switzerland, 2023; pp. 1176–1188. [Google Scholar] [CrossRef]

- Ramón-Álvarez, I.; Sánchez-Delgado, S.; Peralta, I.; Caggiano, A.; Torres-Carrasco, M. Experimental and computational optimization of eco-friendly mortar blocks for high temperature thermal energy storage of concentrated solar power plants. J. Energy Storage 2023, 71, 108076. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Ibrahim, N.I.; Mahbubul, I.; Ali, H.M.; Saidur, R.; Al-Sulaiman, F.A. Evaluation of solar collector designs with integrated latent heat thermal energy storage: A review. Sol. Energy 2018, 166, 334–350. [Google Scholar] [CrossRef]

- Lee, T.; Hawes, D.; Banu, D.; Feldman, D. Control aspects of latent heat storage and recovery in concrete. Sol. Energy Mater. Sol. Cells 2000, 62, 217–237. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Sharma, R.K.; Sari, A. PCM integrated glass in glass tube solar collector for low and medium temperature applications: Thermodynamic & techno-economic approach. Energy 2020, 198, 117238. [Google Scholar] [CrossRef]

- Mankel, C.; Caggiano, A.; Koenders, E. Thermal energy storage characterization of cementitious composites made with recycled brick aggregates containing PCM. Energy Build. 2019, 202, 109395. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Berodier, E.; Bizzozero, J.; Muller, A.C. Mercury intrusion porosimetry. In A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; Volume 419. [Google Scholar]

- Abbas, F.A.; Alhamdo, M.H. Thermal performance of asphalt solar collector by improving tube and slab characteristics. Int. J. Thermofluids 2023, 17, 100293. [Google Scholar] [CrossRef]

- Chandrika, V.; Karthick, A.; Kumar, N.M.; Kumar, P.M.; Stalin, B.; Ravichandran, M. Experimental analysis of solar concrete collector for residential buildings. Int. J. Green Energy 2021, 18, 615–623. [Google Scholar] [CrossRef]

- Pukdum, J.; Phengpom, T.; Sudasna, K. Thermal performance of mixed asphalt solar water heater. Int. J. Renew. Energy Res. 2019, 9, 712–720. [Google Scholar]

- Karabay, H.; Arıcı, M.; Sandık, M. A numerical investigation of fluid flow and heat transfer inside a room for floor heating and wall heating systems. Energy Build. 2013, 67, 471–478. [Google Scholar] [CrossRef]

- Pascual-Muñoz, P.; Castro-Fresno, D.; Serrano-Bravo, P.; Alonso-Estébanez, A. Thermal and hydraulic analysis of multilayered asphalt pavements as active solar collectors. Appl. Energy 2013, 111, 324–332. [Google Scholar] [CrossRef] [Green Version]

- Bellamy, L.A. An experimental assessment of the energy performance of novel concrete walls embedded with mini solar collectors. Energy Procedia 2012, 30, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Ruschenburg, J.; Baisch, K.; Oltersdorf, T.; Courtot, F.; Herkel, S. Experimental and Simulation Results on a Solar-Assisted Heat Pump Prototype for Decentral Applications. In Proceedings of the IEA 10th Heat Pump Conference 2011, Tokyo, Japan, 27 June–31 August 2011; Volume 16. [Google Scholar]

- Chen, M.; Wu, S.; Wang, H.; Zhang, J. Study of ice and snow melting process on conductive asphalt solar collector. Sol. Energy Mater. Sol. Cells 2011, 95, 3241–3250. [Google Scholar] [CrossRef]

- Shaopeng, W.; Mingyu, C.; Jizhe, Z. Laboratory investigation into thermal response of asphalt pavements as solar collector by application of small-scale slabs. Appl. Therm. Eng. 2011, 31, 1582–1587. [Google Scholar] [CrossRef]

- Hazami, M.; Kooli, S.; Lazâar, M.; Farhat, A.; Belghith, A. Energetic and exergetic performances of an economical and available integrated solar storage collector based on concrete matrix. Energy Convers. Manag. 2010, 51, 1210–1218. [Google Scholar] [CrossRef]

- Gao, Q.; Huang, Y.; Li, M.; Liu, Y.; Yan, Y. Experimental study of slab solar collection on the hydronic system of road. Sol. Energy 2010, 84, 2096–2102. [Google Scholar] [CrossRef]

- Wu, S.; Chen, M.; Wang, H.; Zhang, Y. Laboratory study on solar collector of thermal conductive asphalt concrete. Int. J. Pavement Res. Technol. 2009, 2, 130–136. [Google Scholar]

- Wang, H.; Zhao, J.; Chen, Z. Experimental investigation of ice and snow melting process on pavement utilizing geothermal tail water. Energy Convers. Manag. 2008, 49, 1538–1546. [Google Scholar] [CrossRef]

- Hassan, M.M.; Beliveau, Y. Design, construction and performance prediction of integrated solar roof collectors using finite element analysis. Constr. Build. Mater. 2007, 21, 1069–1078. [Google Scholar] [CrossRef]

- Abbott, A. Analysis of Thermal Energy Collection form Precast Concrete Roof Assemblies. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2004. [Google Scholar]

- Bilgen, E.; Richard, M.A. Horizontal concrete slabs as passive solar collectors. Sol. Energy 2002, 72, 405–413. [Google Scholar] [CrossRef]

- Al-Saad, M.; Jubran, B.; Abu-Faris, N. Development and testing of concrete solar collectors. Int. J. Sol. Energy 1994, 16, 27–40. [Google Scholar] [CrossRef]

- Sokolov, M.; Reshef, M. Performance simulation of solar collectors made of concrete with embedded conduit lattice. Sol. Energy 1992, 48, 403–411. [Google Scholar] [CrossRef]

- Bopshetty, S.; Nayak, J.; Sukhatme, S. Performance analysis of a solar concrete collector. Energy Convers. Manag. 1992, 33, 1007–1016. [Google Scholar] [CrossRef]

- Nayak, J.; Sukhatme, S.; Limaye, R.; Bopshetty, S. Performance studies on solar concrete collectors. Sol. Energy 1989, 42, 45–56. [Google Scholar] [CrossRef]

| Properties | Sample Identification Number | |||||

|---|---|---|---|---|---|---|

| Sample 1 (2–4 mm) | Sample 2 (2–4 mm) | Sample 3 (2–4 mm) | Sample 1 (4–8 mm) | Sample 2 (4–8 mm) | Sample 3 (4–8 mm) | |

| Sample skeleton density () | 2.643 | 2.643 | 2.641 | 2.634 | 2.630 | 2.631 |

| Sample mass (g) | 0.839 | 0.637 | 1.247 | 1.008 | 1.128 | 1.101 |

| Properties | Sample Identification Number | |||||

|---|---|---|---|---|---|---|

| Sample 1 (2–4 mm) | Sample 2 (2–4 mm) | Sample 3 (2–4 mm) | Sample 1 (4–8 mm) | Sample 2 (4–8 mm) | Sample 3 (4–8 mm) | |

| Open porosity (Vol.-%) | 34.33 | 34.30 | 34.29 | 35.59 | 35.02 | - |

| Closed porosity (Vol.-%) | 2.95 | 1.64 | 1.78 | 0.45 | 0.79 | - |

| Total porosity (Vol.-%) | 37.28 | 35.94 | 36.07 | 36.04 | 35.81 | - |

| Properties | Value | |||

|---|---|---|---|---|

| Skeleton density () | 2.637 | |||

| Bulk density () | 1.682 | |||

| Open porosity (Vol.-%) | 34.706 | |||

| Closed porosity (Vol.-%) | 1.522 | |||

| Total porosity (Vol.-%) | 36.228 | |||

| Capillarity pores (Vol.-%) | 94.394 | |||

| RT 44 HC | RT 62 HC | |||

| Paraffin liquid density * () | 0.70 | 0.84 | ||

| Heat storage capacity * () | 250 | 230 | ||

| Filling degree (Vol.-%) | 65 | 80 | 65 | 80 |

| Amount of Paraffin (M.-%) | 8.86 | 10.91 | 10.64 | 13.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aquilanti, A.; Peralta, I.; Koenders, E.A.B.; Di Nicola, G. A Brief Review of the Latest Advancements of Massive Solar Thermal Collectors. Energies 2023, 16, 5953. https://doi.org/10.3390/en16165953

Aquilanti A, Peralta I, Koenders EAB, Di Nicola G. A Brief Review of the Latest Advancements of Massive Solar Thermal Collectors. Energies. 2023; 16(16):5953. https://doi.org/10.3390/en16165953

Chicago/Turabian StyleAquilanti, Alessia, Ignacio Peralta, Eduardus A. B. Koenders, and Giovanni Di Nicola. 2023. "A Brief Review of the Latest Advancements of Massive Solar Thermal Collectors" Energies 16, no. 16: 5953. https://doi.org/10.3390/en16165953

APA StyleAquilanti, A., Peralta, I., Koenders, E. A. B., & Di Nicola, G. (2023). A Brief Review of the Latest Advancements of Massive Solar Thermal Collectors. Energies, 16(16), 5953. https://doi.org/10.3390/en16165953