Preparation and Characterization of Shell-Based CaO Catalysts for Ultrasonication-Assisted Production of Biodiesel to Reduce Toxicants in Diesel Generator Emissions

Abstract

1. Introduction

Transesterification

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preliminary Preparation of Shells

2.2.1. Preparation of CaO Catalyst via Calcination

2.2.2. Preparation of CaO-ZnO Mixed Catalyst

2.3. Catalyst Characterization

2.4. Ultrasonication-Assisted Biodiesel Synthesis and Yield Measurement

2.5. GC-MS Analysis of Diesel Generator Emissions

3. Results

3.1. Catalyst Characterization

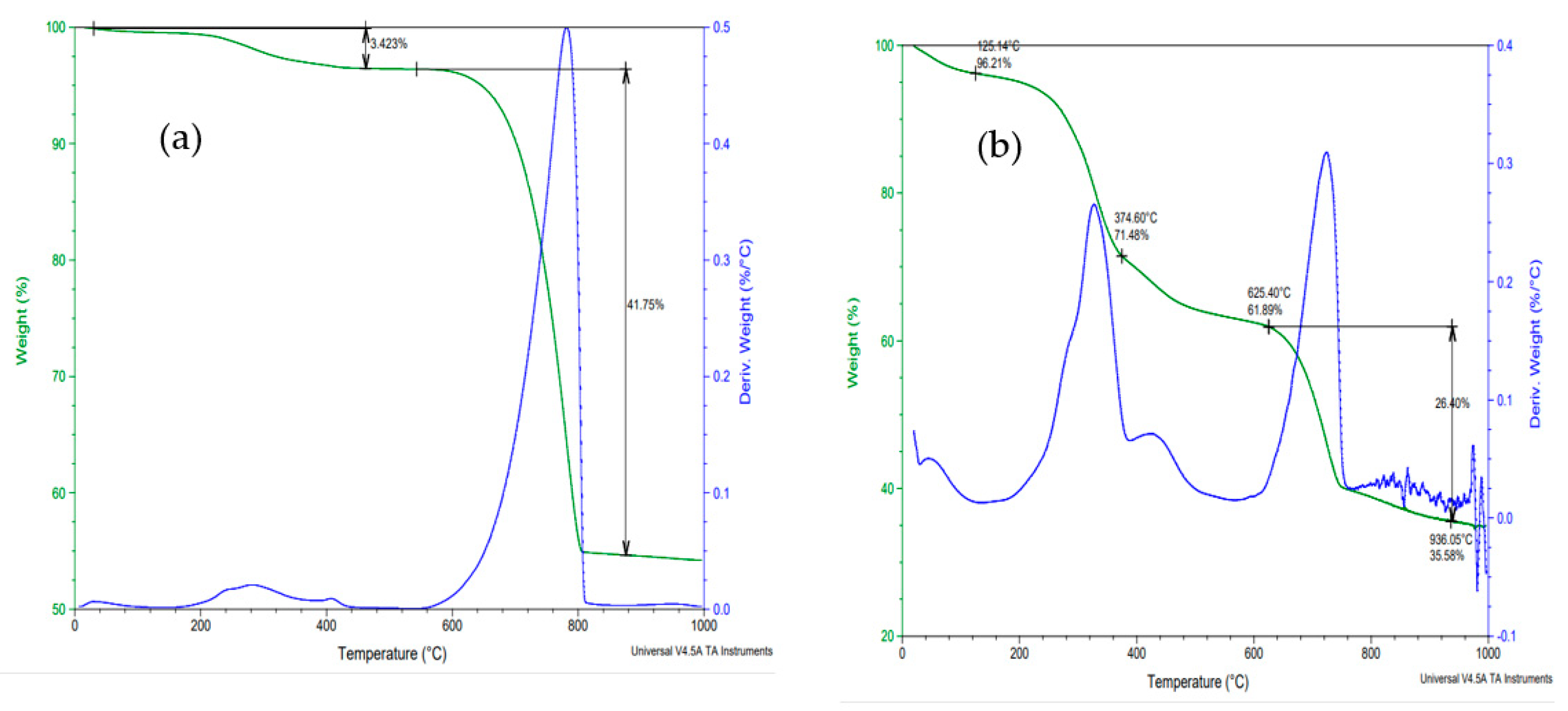

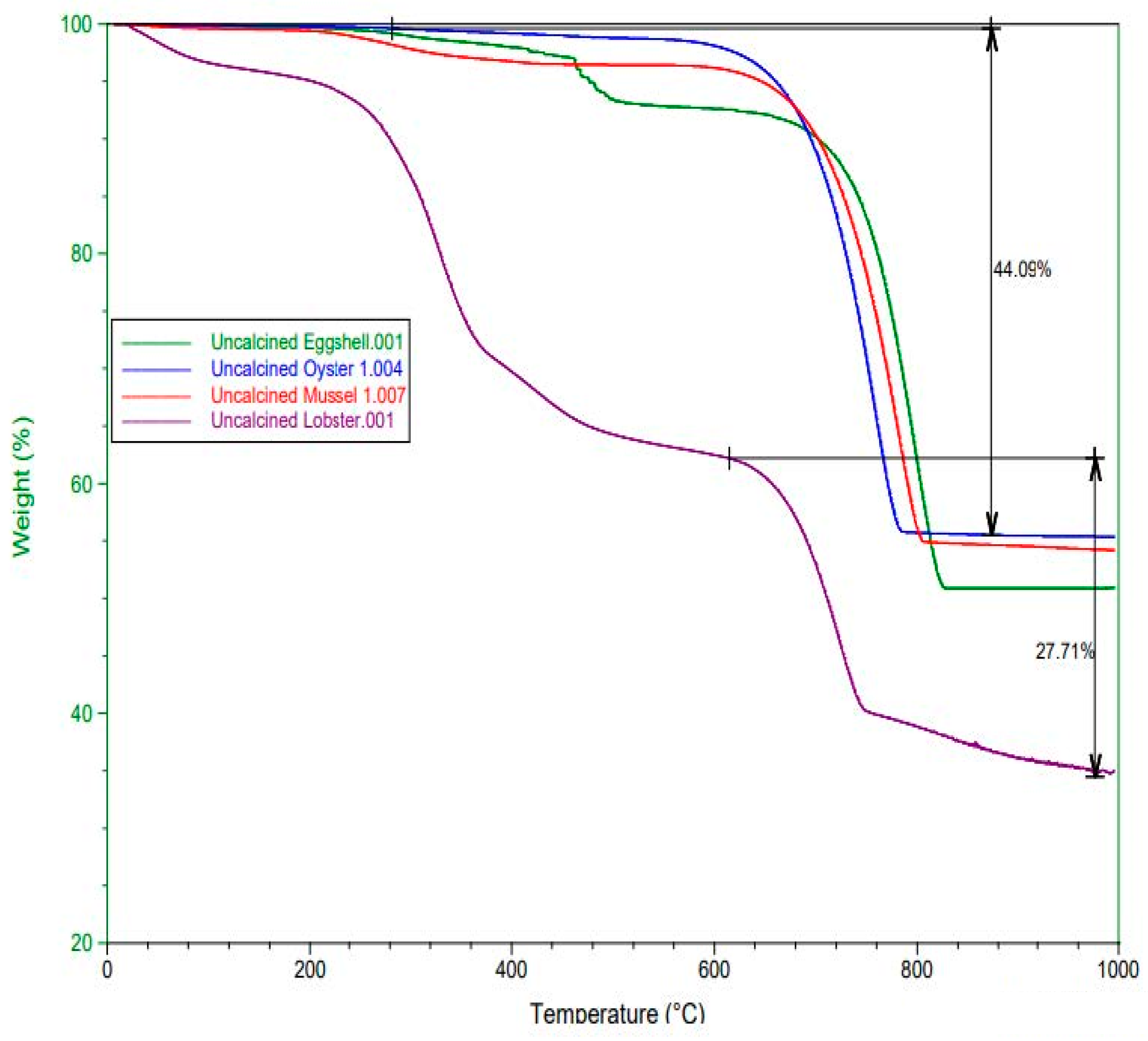

3.1.1. Thermogravimetric Analysis (TGA)

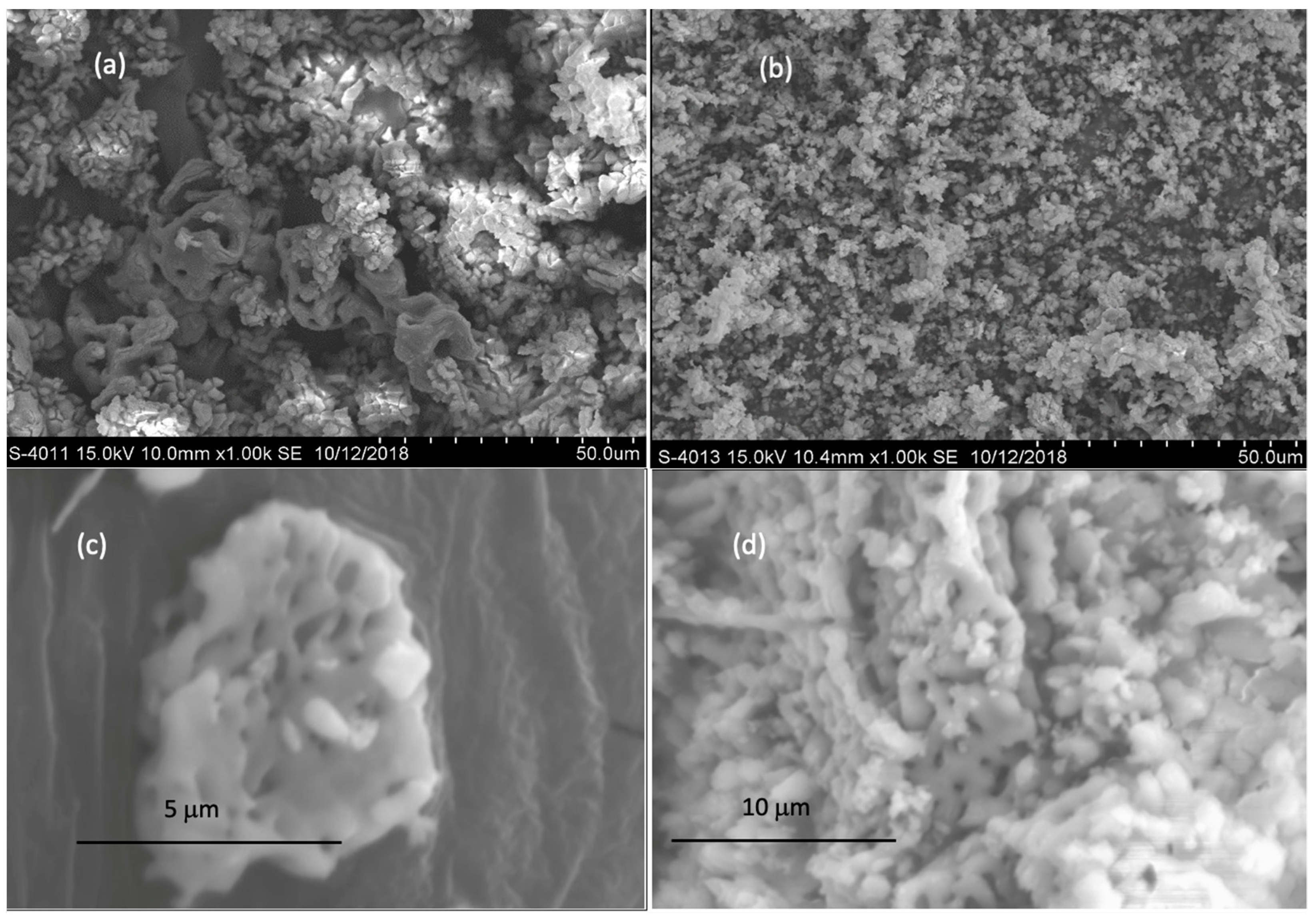

3.1.2. Characterization of Catalysts by SEM/EDX and XRF Methods

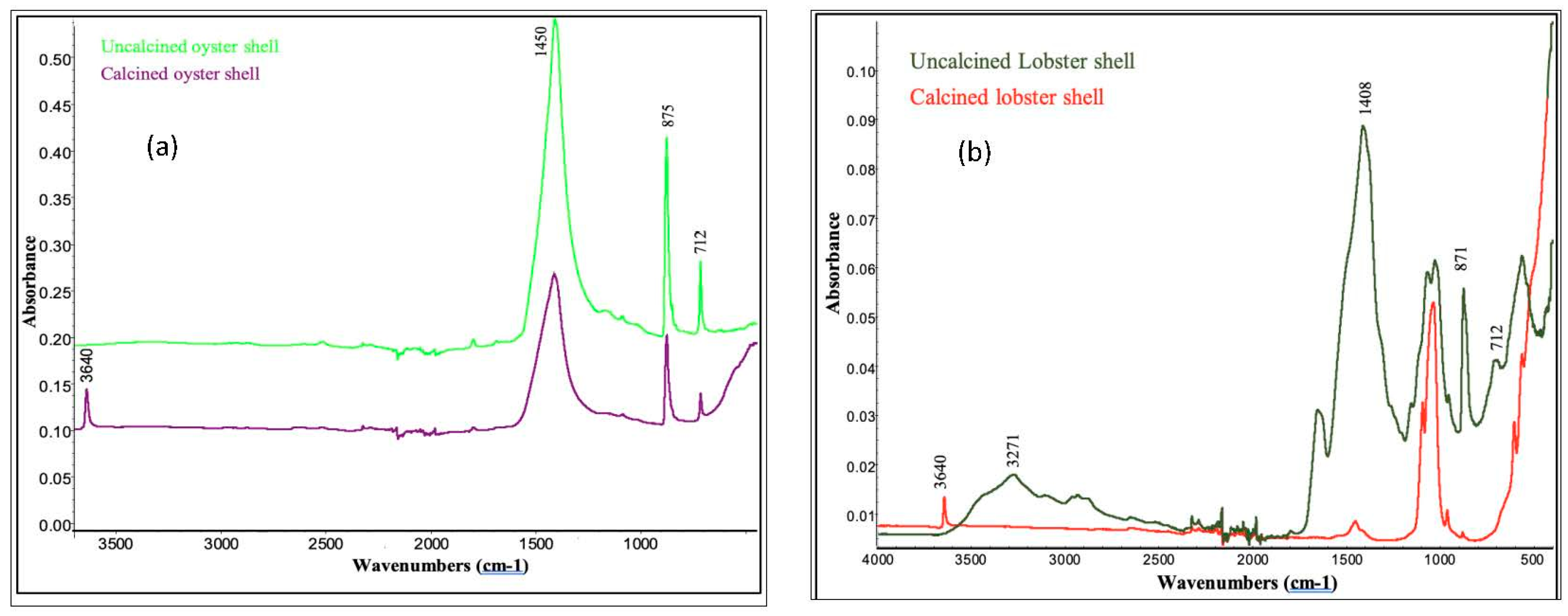

3.1.3. FTIR Analysis of CaO and CaO-ZnO Mixed Catalysts Derived from Shell Samples

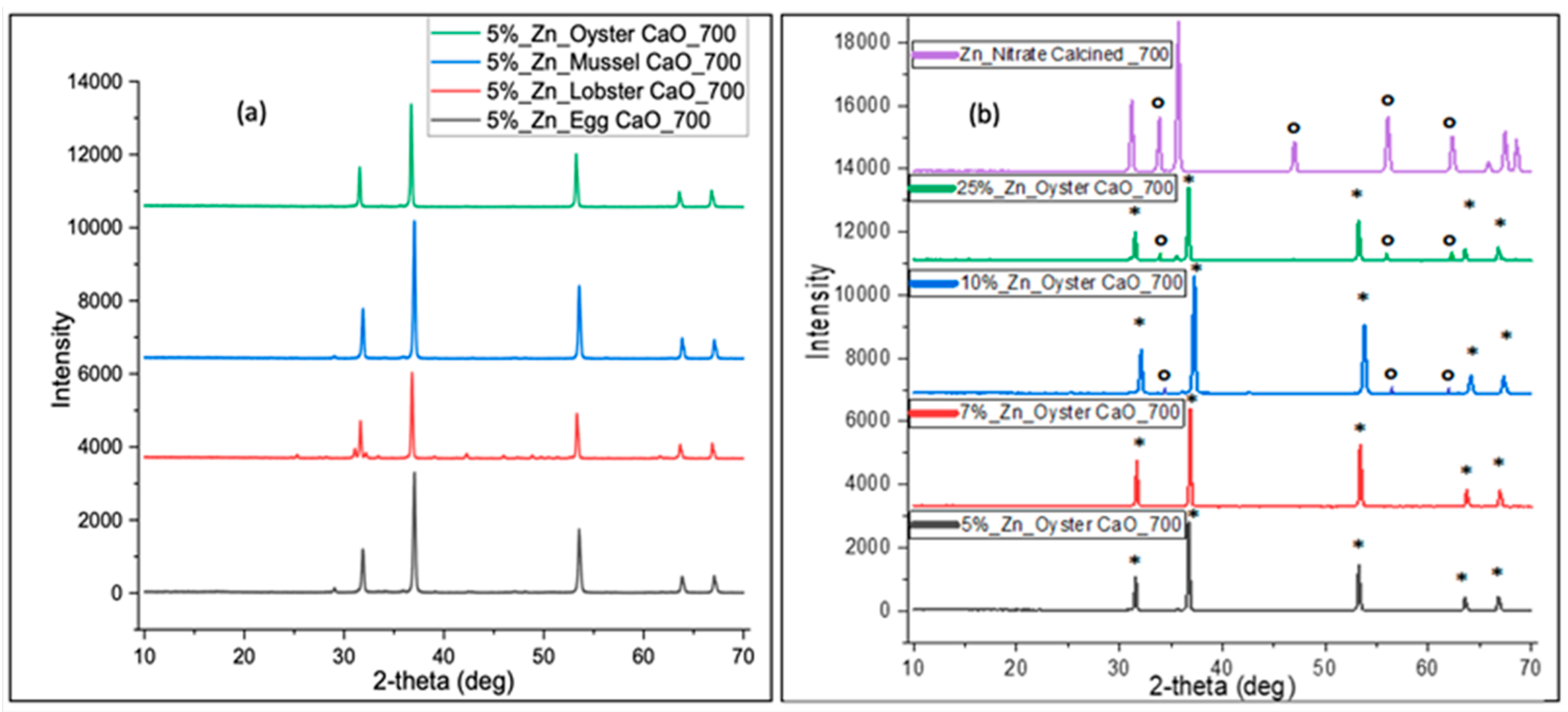

3.1.4. X-ray Diffraction Patterns of the Shell-Derived CaO and CaO-ZnO Mixed Catalysts

- Lobster CaO: → 32.1°, 37.0°, 53.5°, 63.8° and 67.0°

- Eggshell CaO: → 32.3°, 37.5°, 54.0°, 64.5° and 67.5°

- Mussel CaO: → 32.8°, 38.0°, 54.5°, 64.8° and 68.1°

- Oyster CaO: → 32.8°, 38.0°, 54.5°, 64.8° and 68.1°

3.2. Comparison of Biodiesel Yields Using Different Calcined Catalysts

| Catalyst (Weight %) | Method | Time (min) | Yield (%) |

|---|---|---|---|

| Oyster CaO (1%) | Present ultrasonication study | 10 | 92.9 |

| Mussel CaO (1%) | Present ultrasonication study | 10 | 89.0 |

| Eggshell CaO (1%) | Present ultrasonication study | 10 | 90.3 |

| Lobster CaO (1%) | Present ultrasonication study | 10 | 50.6 |

| 5%Zn-Mussel-CaO (1%) | Present ultrasonication study | 10 | 92.8 |

| 5%Zn-Eggshell-CaO (1%) | Present ultrasonication study | 10 | 92.5 |

| 5%Zn-Lobster-CaO (1%) | Present ultrasonication study | 10 | 59.5 |

| 5%Zn-Oyster-CaO (1%) | Present ultrasonication study | 10 | 93.9 |

| 7%Zn-Oyster-CaO (1%) | Present ultrasonication study | 10 | 67.2 |

| 10%Zn-Oyster-CaO (1%) | Present ultrasonication study | 10 | 62.3 |

| CaO (3%) | Hotplate with stirring, 25:1 CH3OH-jatropha oil, [44] | 180 | 91 |

| CaO-ZnO (3%) | Hotplate with stirring, 25:1 CH3OH-jatropha oil, [44] | 180 | 94 |

| CaZn2(OH)6.2H2O (2%) | Hotplate with stirring, 10:1 CH3OH-sunflower oil, [45] | 120 | 92 |

| 1.5-Zn/CaO-550 (5%) | Hotplate with stirring, 9:1 CH3OH-cottonseed oil, 1.5 wt.% Zn-CaO calcined at 550 °C [27] | 45 | >99 |

| CaO-ZnO (10%) | Hotplate with stirring, 40:1 CH3OH-soybean oil, [46] | 360 | 73 |

| Eggshell CaO (6.04%) | Ultrasonication 299.7 W; 8.3:1 CH3OH-waste cooking oil, 55 °C [12] | 39.8 | 98.6 |

| Crab shell CaO (3%) | 250 rpm stirring rate; 9:1 CH3OH-fishmeal plant oil, 60 °C [21] | 60 | 88.2 |

| Snail shell CaO (3%) | Heating mantle, 65 °C; 6:1 CH3OH-waste palm cooking oil [20] | 180 | 80 |

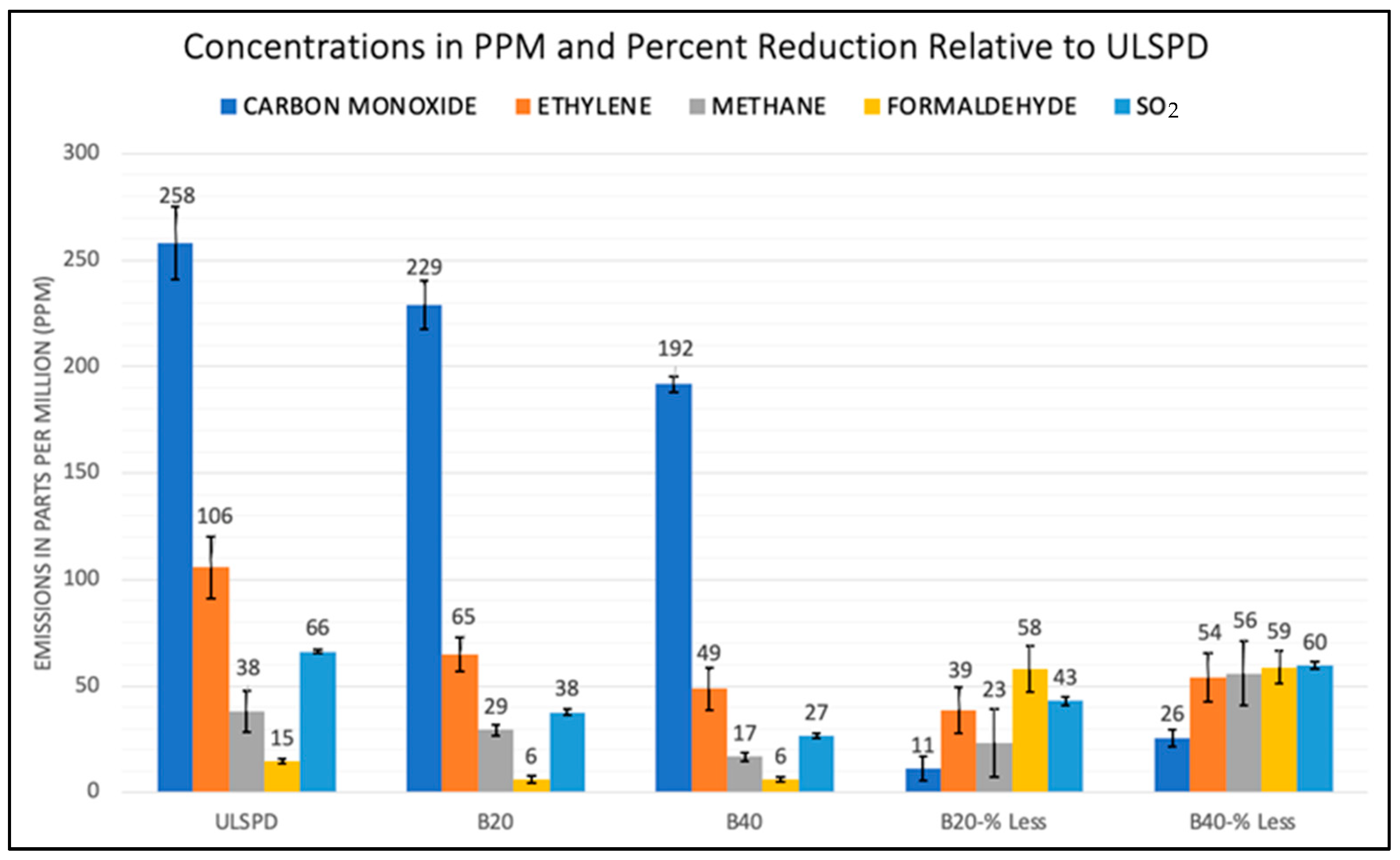

3.3. Emissions of Biodiesel Fuel Blends in Diesel Generators

3.3.1. FTIR Analysis of Emissions from Diesel Power Generators

3.3.2. GC-MS Analysis of VOCs

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wong, K.Y.; Ng, J.-H.; Chong, C.T.; Lam, S.S.; Chong, W.T. Biodiesel Process Intensification through Catalytic Enhancement and Emerging Reactor Designs: A Critical Review. Renew. Sustain. Energy Rev. 2019, 116, 109399. [Google Scholar] [CrossRef]

- Efavi, J.K.; Kanbogtah, D.; Apalangya, V.; Nyankson, E.; Tiburu, E.K.; Dodoo-Arhin, D.; Onwona-Agyeman, B.; Yaya, A. The Effect of NaOH Catalyst Concentration and Extraction Time on the Yield and Properties of Citrullus Vulgaris Seed Oil as a Potential Biodiesel Feed Stock. S. Afr. J. Chem. Eng. 2018, 25, 98–102. [Google Scholar] [CrossRef]

- Ling, J.; Tan, Y.; Mujawar, M.; Kansedo, J.; Saptoro, A.; Nolasco-Hipolito, C. A Review of Heterogeneous Calcium Oxide Based Catalyst from Waste for Biodiesel Synthesis. SN Appl. Sci. 2019, 1, 810. [Google Scholar] [CrossRef]

- Banerjee, N.; Barman, S.; Saha, G.; Jash, T. Optimization of Process Parameters of Biodiesel Production from Different Kinds of Feedstock. Mater. Today: Proc. 2018, 5, 23043–23050. [Google Scholar] [CrossRef]

- Yang, C.; He, K.; Xue, Y.; Li, Y.; Lin, H.; Han, S. Factors Affecting the Cold Flow Properties of Biodiesel: Fatty Acid Esters. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 516–522. [Google Scholar] [CrossRef]

- Etim, A.O.; Musonge, P.; Eloka-Eboka, A.C. Effectiveness of Biogenic Waste-derived Heterogeneous Catalysts and Feedstock Hybridization Techniques in Biodiesel Production. Biofuels Bioprod. Bioref. 2020, 14, 620–649. [Google Scholar] [CrossRef]

- Nayak, S.N.; Bhasin, C.P.; Nayak, M.G. A Review on Microwave-Assisted Transesterification Processes Using Various Catalytic and Non-Catalytic Systems. Renew. Energy 2019, 143, 1366–1387. [Google Scholar] [CrossRef]

- Arumugam, A.; Ponnusami, V. Production of Biodiesel by Enzymatic Transesterification of Waste Sardine Oil and Evaluation of Its Engine Performance. Heliyon 2017, 3, e00486. [Google Scholar] [CrossRef] [PubMed]

- Van Gerpen, J.; Shanks, B.; Pruszko, R.; Clements, D.; Knothe, G. Biodiesel Analytical Methods: August 2002–January 2004; NREL/SR-510-36240; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2004; p. 15008800. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A Review on Biodiesel Production Using Catalyzed Transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- Ashine, F.; Kiflie, Z.; Prabhu, S.V.; Tizazu, B.Z.; Varadharajan, V.; Rajasimman, M.; Joo, S.-W.; Vasseghian, Y.; Jayakumar, M. Biodiesel Production from Argemone Mexicana Oil Using Chicken Eggshell Derived CaO Catalyst. Fuel 2023, 332, 126166. [Google Scholar] [CrossRef]

- Attari, A.; Abbaszadeh-Mayvan, A.; Taghizadeh-Alisaraei, A. Process Optimization of Ultrasonic-Assisted Biodiesel Production from Waste Cooking Oil Using Waste Chicken Eggshell-Derived CaO as a Green Heterogeneous Catalyst. Biomass Bioenergy 2022, 158, 106357. [Google Scholar] [CrossRef]

- Mekonnen, K.D.; Sendekie, Z.B. NaOH-Catalyzed Methanolysis Optimization of Biodiesel Synthesis from Desert Date Seed Kernel Oil. ACS Omega 2021, 6, 24082–24091. [Google Scholar] [CrossRef]

- Sharma, A.; Kodgire, P.; Kachhwaha, S.S. Investigation of Ultrasound-Assisted KOH and CaO Catalyzed Transesterification for Biodiesel Production from Waste Cotton-Seed Cooking Oil: Process Optimization and Conversion Rate Evaluation. J. Clean. Prod. 2020, 259, 120982. [Google Scholar] [CrossRef]

- Mishra, V.; Goswami, R. A Review of Production, Properties and Advantages of Biodiesel. Biofuels 2017, 9, 273–289. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumar Sharma, P.; Jhalani, A. A Review on Feedstocks, Production Processes, and Yield for Different Generations of Biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- El-sherif, A.A.; Hamad, A.M.; Shams-Eldin, E.; Mohamed, H.A.A.E.; Ahmed, A.M.; Mohamed, M.A.; Abdelaziz, Y.S.; Sayed, F.A.-Z.; El Qassem Mahmoud, E.A.A.; Abd El-Daim, T.M.; et al. Power of Recycling Waste Cooking Oil into Biodiesel via Green CaO-Based Eggshells/Ag Heterogeneous Nanocatalyst. Renew. Energy 2023, 202, 1412–1423. [Google Scholar] [CrossRef]

- Chen, G.-Y.; Shan, R.; Yan, B.-B.; Shi, J.-F.; Li, S.-Y.; Liu, C.-Y. Remarkably Enhancing the Biodiesel Yield from Palm Oil upon Abalone Shell-Derived CaO Catalysts Treated by Ethanol. Fuel Process. Technol. 2016, 143, 110–117. [Google Scholar] [CrossRef]

- Gaide, I.; Makareviciene, V.; Sendzikiene, E.; Kazancev, K. Snail Shells as a Heterogeneous Catalyst for Biodiesel Fuel Production. Processes 2023, 11, 260. [Google Scholar] [CrossRef]

- Kedir, W.M.; Wondimu, K.T.; Weldegrum, G.S. Optimization and Characterization of Biodiesel from Waste Cooking Oil Using Modified CaO Catalyst Derived from Snail Shell. Heliyon 2023, 9, e16475. [Google Scholar] [CrossRef] [PubMed]

- Karkal, S.S.; Rathod, D.R.; Jamadar, A.S.; Mamatha, S.S.; Kudre, T.G. Production Optimization, Scale-up, and Characterization of Biodiesel from Marine Fishmeal Plant Oil Using Portunus Sanguinolentus Crab Shell Derived Heterogeneous Catalyst. Biocatal. Agric. Biotechnol. 2023, 47, 102571. [Google Scholar] [CrossRef]

- Nahas, L.; Dahdah, E.; Aouad, S.; El Khoury, B.; Gennequin, C.; Abi Aad, E.; Estephane, J. Highly Efficient Scallop Seashell-Derived Catalyst for Biodiesel Production from Sunflower and Waste Cooking Oils: Reaction Kinetics and Effect of Calcination Temperature Studies. Renew. Energy 2023, 202, 1086–1095. [Google Scholar] [CrossRef]

- Hangun-Balkir, Y. Green Biodiesel Synthesis Using Waste Shells as Sustainable Catalysts with Camelina Sativa Oil. J. Chem. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Nakatani, N.; Takamori, H.; Takeda, K.; Sakugawa, H. Transesterification of Soybean Oil Using Combusted Oyster Shell Waste as a Catalyst. Bioresour. Technol. 2009, 100, 1510–1513. [Google Scholar] [CrossRef] [PubMed]

- Aigbodion, V.S. Modified of CaO-Nanoparticle Synthesized from Waste Oyster Shells with Tin Tailings as a Renewable Catalyst for Biodiesel Production from Waste Cooking Oil as a Feedstock. Chem. Afr. 2023, 6, 1025–1035. [Google Scholar] [CrossRef]

- Hu, S.; Wang, Y.; Han, H. Utilization of Waste Freshwater Mussel Shell as an Economic Catalyst for Biodiesel Production. Biomass Bioenergy 2011, 35, 3627–3635. [Google Scholar] [CrossRef]

- Kumar, D.; Ali, A. Transesterification of Low-Quality Triglycerides over a Zn/CaO Heterogeneous Catalyst: Kinetics and Reusability Studies. Energy Fuels 2013, 27, 3758–3768. [Google Scholar] [CrossRef]

- Chong, N.S.; Okejiri, F.U.; Abdulramoni, S.; Perna, S.; Ooi, B.G. Evaluation of Shell-Derived Calcium Oxide Catalysts for the Production of Biodiesel Esters from Cooking Oils. AJC 2021, 6, 20–27. [Google Scholar] [CrossRef]

- Chong, N.S.; Abdulramoni, S.; Patterson, D.; Brown, H. Releases of Fire-Derived Contaminants from Polymer Pipes Made of Polyvinyl Chloride. Toxics 2019, 7, 57. [Google Scholar] [CrossRef]

- Romano, P.; Fabritius, H.; Raabe, D. The Exoskeleton of the Lobster Homarus Americanus as an Example of a Smart Anisotropic Biological Material. Acta Biomater. 2007, 3, 301–309. [Google Scholar] [CrossRef]

- Mergelsberg, S.T.; Ulrich, R.N.; Xiao, S.; Dove, P.M. Composition Systematics in the Exoskeleton of the American Lobster, Homarus Americanus and Implications for Malacostraca. Front. Earth Sci. 2019, 7, 69. [Google Scholar] [CrossRef]

- Rodriguez-Navarro, C.; Ruiz-Agudo, E.; Luque, A.; Rodriguez-Navarro, A.B.; Ortega-Huertas, M. Thermal Decomposition of Calcite: Mechanisms of Formation and Textural Evolution of CaO Nanocrystals. Am. Miner. 2009, 94, 578–593. [Google Scholar] [CrossRef]

- Boßelmann, F.; Romano, P.; Fabritius, H.; Raabe, D.; Epple, M. The Composition of the Exoskeleton of Two Crustacea: The American Lobster Homarus Americanus and the Edible Crab Cancer Pagurus. Thermochim. Acta 2007, 463, 65–68. [Google Scholar] [CrossRef]

- Jacobsson, T.J.; Pazoki, M.; Hagfeldt, A.; Edvinsson, T. Goldschmidt’s Rules and Strontium Replacement in Lead Halogen Perovskite Solar Cells: Theory and Preliminary Experiments on CH3NH3SrI3. J. Phys. Chem. C 2015, 119, 25673–25683. [Google Scholar] [CrossRef]

- Kesić, Ž.; Lukić, I.; Brkić, D.; Rogan, J.; Zdujić, M.; Liu, H.; Skala, D. Mechanochemical Preparation and Characterization of CaO·ZnO Used as Catalyst for Biodiesel Synthesis. Appl. Catal. A Gen. 2012, 427–428, 58–65. [Google Scholar] [CrossRef]

- Gheisari, H.; Karamian, E.; Abdellahi, M. A Novel Hydroxyapatite –Hardystonite Nanocomposite Ceramic. Ceram. Int. 2015, 41, 5967–5975. [Google Scholar] [CrossRef]

- Mohan, K.; Muralisankar, T.; Jayakumar, R.; Rajeevgandhi, C. A Study on Structural Comparisons of α-Chitin Extracted from Marine Crustacean Shell Waste. Carbohydr. Polym. Technol. Appl. 2021, 2, 100037. [Google Scholar] [CrossRef]

- Samantaray, S.; Pradhan, D.K.; Hota, G.; Mishra, B.G. Catalytic Application of CeO2–CaO Nanocomposite Oxide Synthesized Using Amorphous Citrate Process toward the Aqueous Phase One Pot Synthesis of 2-Amino-2-Chromenes. Chem. Eng. J. 2012, 193–194, 1–9. [Google Scholar] [CrossRef]

- Laskar, I.B.; Rajkumari, K.; Gupta, R.; Chatterjee, S.; Paul, B.; Rokhum, S.L. Waste Snail Shell Derived Heterogeneous Catalyst for Biodiesel Production by the Transesterification of Soybean Oil. RSC Adv. 2018, 8, 20131–20142. [Google Scholar] [CrossRef] [PubMed]

- Dinatha, I.K.H.; Jamilludin, M.A.; Supii, A.I.; Wihadmadyatami, H.; Partini, J.; Yusuf, Y. Characteristics of Bioceramic Hydroxyapatite Based on Sand Lobster Shells (Panulirus Homarus) as Sources of Calcium with Optimal Calcination Temperature. Mater. Sci. Forum 2023, 1090, 39–44. [Google Scholar] [CrossRef]

- Widiarti, N.; Lailun Ni’mah, Y.; Bahruji, H.; Prasetyoko, D. Development of CaO From Natural Calcite as a Heterogeneous Base Catalyst in the Formation of Biodiesel: Review. J. Renew. Mater. 2019, 7, 915–939. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the Art of Catalysts for Biodiesel Production. Front. Energy Res. 2020, 8, 101. [Google Scholar] [CrossRef]

- Castro, L.D.S.; Barañano, A.G.; Pinheiro, C.J.G.; Menini, L.; Pinheiro, P.F. Biodiesel Production from Cotton Oil Using Heterogeneous CaO Catalysts from Eggshells Prepared at Different Calcination Temperatures. Green Process. Synth. 2019, 8, 235–244. [Google Scholar] [CrossRef]

- Lee, H.; Juan, J.; Yun Hin, T.-Y.; Ong, H. Environment-Friendly Heterogeneous Alkaline-Based Mixed Metal Oxide Catalysts for Biodiesel Production. Energies 2016, 9, 611. [Google Scholar] [CrossRef]

- Kaewdaeng, S.; Sintuya, P.; Nirunsin, R. Biodiesel Production Using Calcium Oxide from River Snail Shell Ash as Catalyst. Energy Procedia 2017, 138, 937–942. [Google Scholar] [CrossRef]

- Toledo Arana, J.; Torres, J.J.; Acevedo, D.F.; Illanes, C.O.; Ochoa, N.A.; Pagliero, C.L. One-Step Synthesis of CaO-ZnO Efficient Catalyst for Biodiesel Production. Int. J. Chem. Eng. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Awofeso, N. Generator Diesel Exhaust: A Major Hazard to Health and the Environment in Nigeria. Am. J. Respir. Crit. Care Med. 2011, 183, 1437. [Google Scholar] [CrossRef] [PubMed]

- “Hot Spots” Stationary Diesel Engine Screening Risk Assessment Tables|California Air Resources Board. Available online: https://ww2.arb.ca.gov/hot-spots-stationary-diesel-engine-screening-risk-assessment-tables (accessed on 28 May 2023).

- Pereira, R.G.; Oliveira, C.D.; Oliveira, J.L.; Oliveira, P.C.P.; Fellows, C.E.; Piamba, O.E. Exhaust Emissions and Electric Energy Generation in a Stationary Engine Using Blends of Diesel and Soybean Biodiesel. Renew. Energy 2007, 32, 2453–2460. [Google Scholar] [CrossRef]

- IRIS Advanced Search. United States Environmental Protection Agency. Available online: https://iris.epa.gov/AdvancedSearch/ (accessed on 4 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chong, N.S.; Nwobodo, I.; Strait, M.; Cook, D.; Abdulramoni, S.; Ooi, B.G. Preparation and Characterization of Shell-Based CaO Catalysts for Ultrasonication-Assisted Production of Biodiesel to Reduce Toxicants in Diesel Generator Emissions. Energies 2023, 16, 5408. https://doi.org/10.3390/en16145408

Chong NS, Nwobodo I, Strait M, Cook D, Abdulramoni S, Ooi BG. Preparation and Characterization of Shell-Based CaO Catalysts for Ultrasonication-Assisted Production of Biodiesel to Reduce Toxicants in Diesel Generator Emissions. Energies. 2023; 16(14):5408. https://doi.org/10.3390/en16145408

Chicago/Turabian StyleChong, Ngee S., Ifeanyi Nwobodo, Madison Strait, Dakota Cook, Saidi Abdulramoni, and Beng G. Ooi. 2023. "Preparation and Characterization of Shell-Based CaO Catalysts for Ultrasonication-Assisted Production of Biodiesel to Reduce Toxicants in Diesel Generator Emissions" Energies 16, no. 14: 5408. https://doi.org/10.3390/en16145408

APA StyleChong, N. S., Nwobodo, I., Strait, M., Cook, D., Abdulramoni, S., & Ooi, B. G. (2023). Preparation and Characterization of Shell-Based CaO Catalysts for Ultrasonication-Assisted Production of Biodiesel to Reduce Toxicants in Diesel Generator Emissions. Energies, 16(14), 5408. https://doi.org/10.3390/en16145408