Energizing Emergency Exit Signs with Wireless Energy Transfer

Abstract

1. Introduction

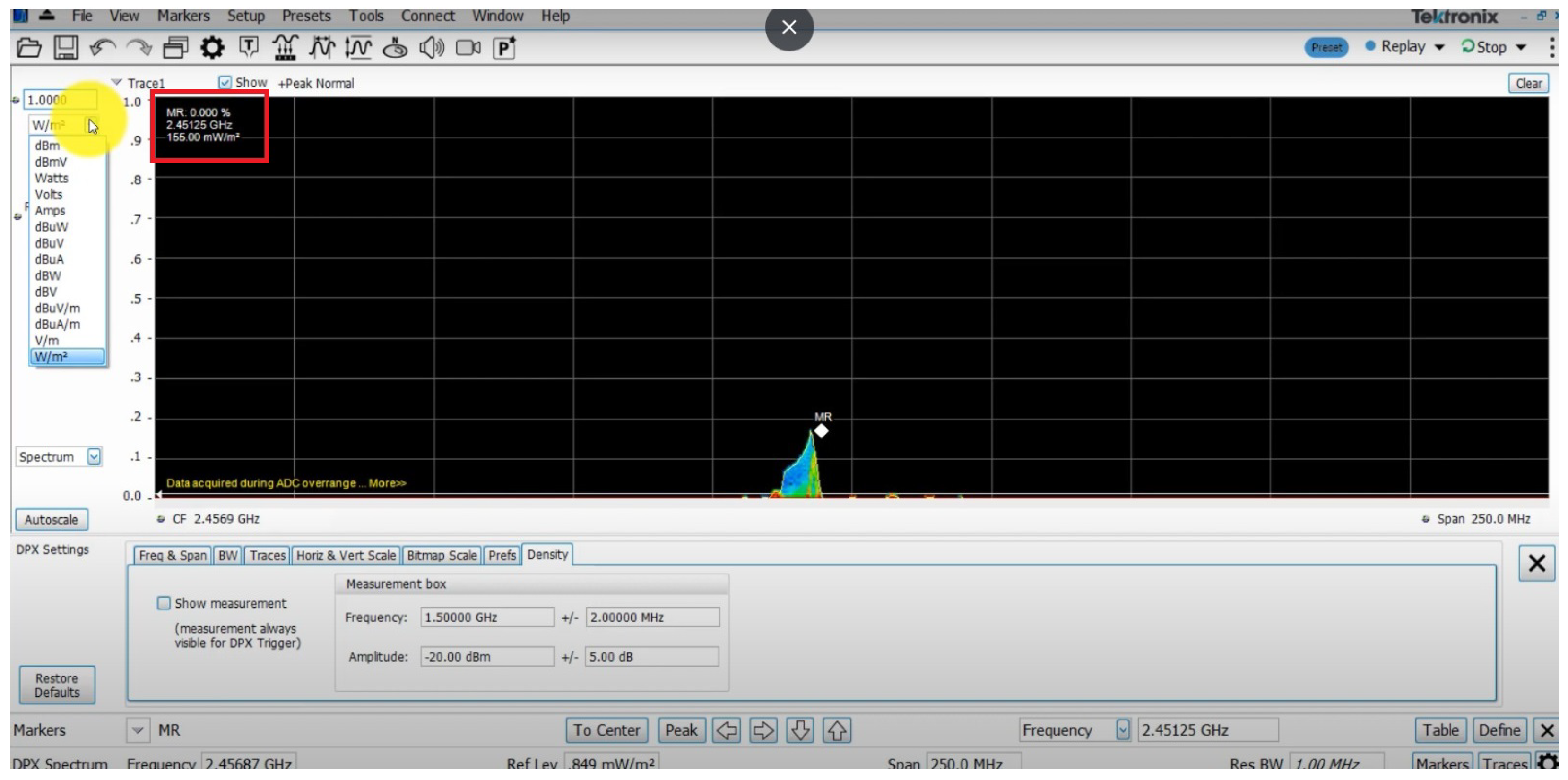

2. RF Microwave Transmitter and Power Budget

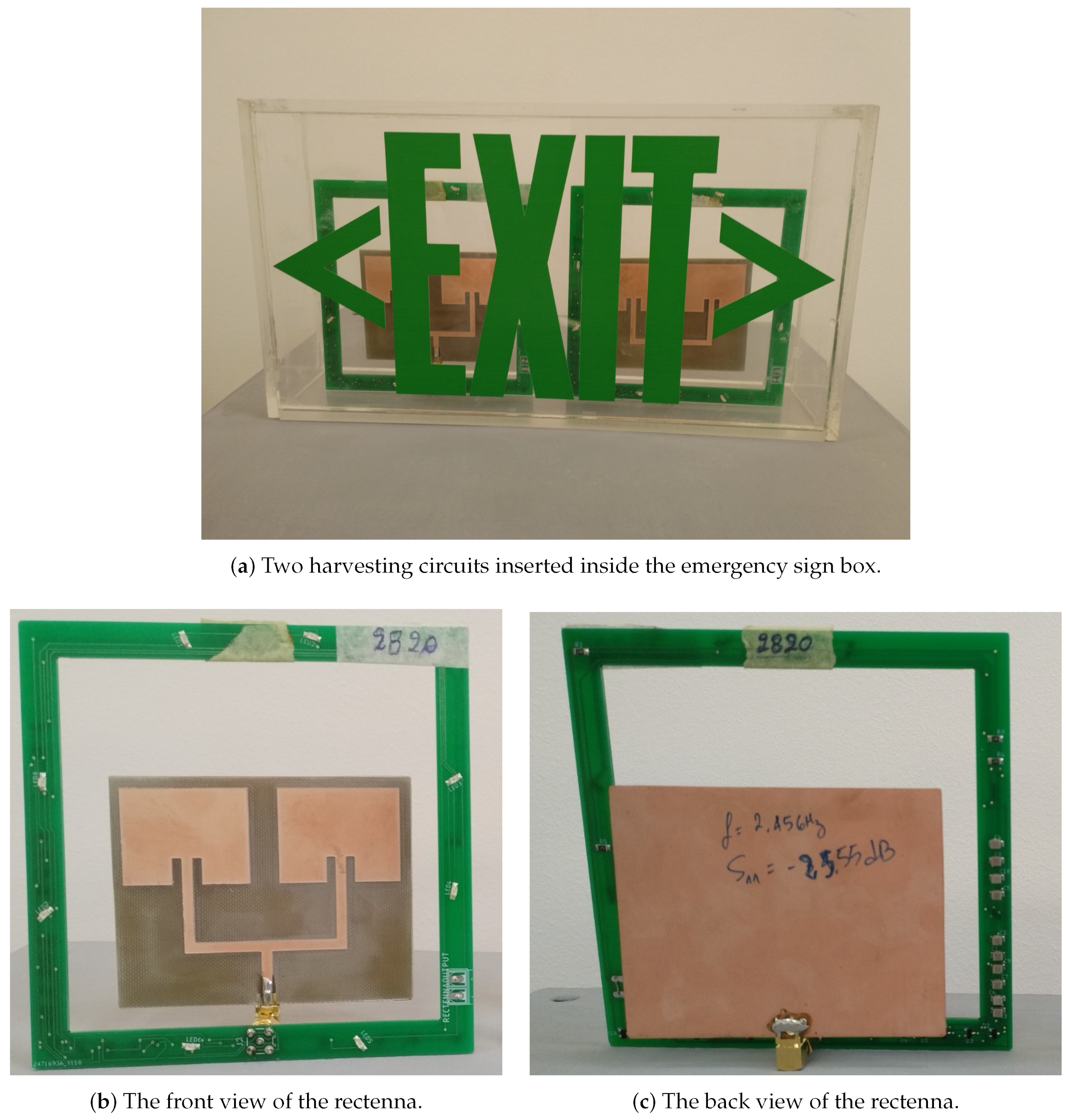

2.1. RF Microwave Transmitter Station Design

| = 253.64 mm (Aperture width) |

| = 183.18 mm (Aperture height) |

| = 76.78 mm |

- Back short length = 26 mm;

- Probe length = 16.36 mm.

2.2. RF Power Budget

- D = distance between emitter and receiver;

- = transmitter power;

- FSPL = free space path loss;

- = gain of the transmitting horn antenna;

- = gain of the receiving horn antenna.

- represents the transmission power;

- represents the effective area of the pyramidal transmitting horn antenna;

- D is the distance between transmitters and receivers.

A = 0.0314 m (Horn Antenna) |

A = 0.0026 m (Patch Antenna) |

3. Power Harvester Device

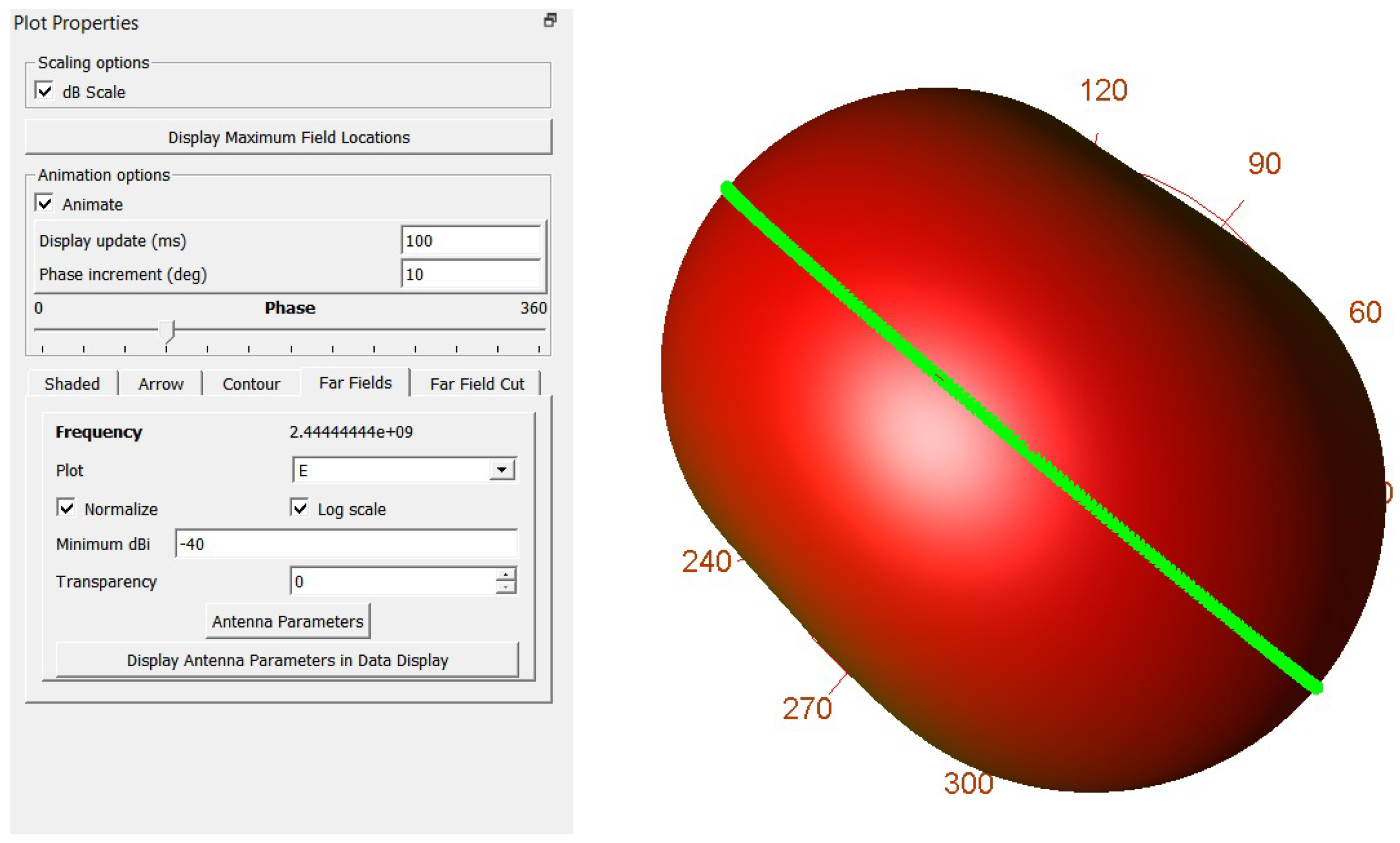

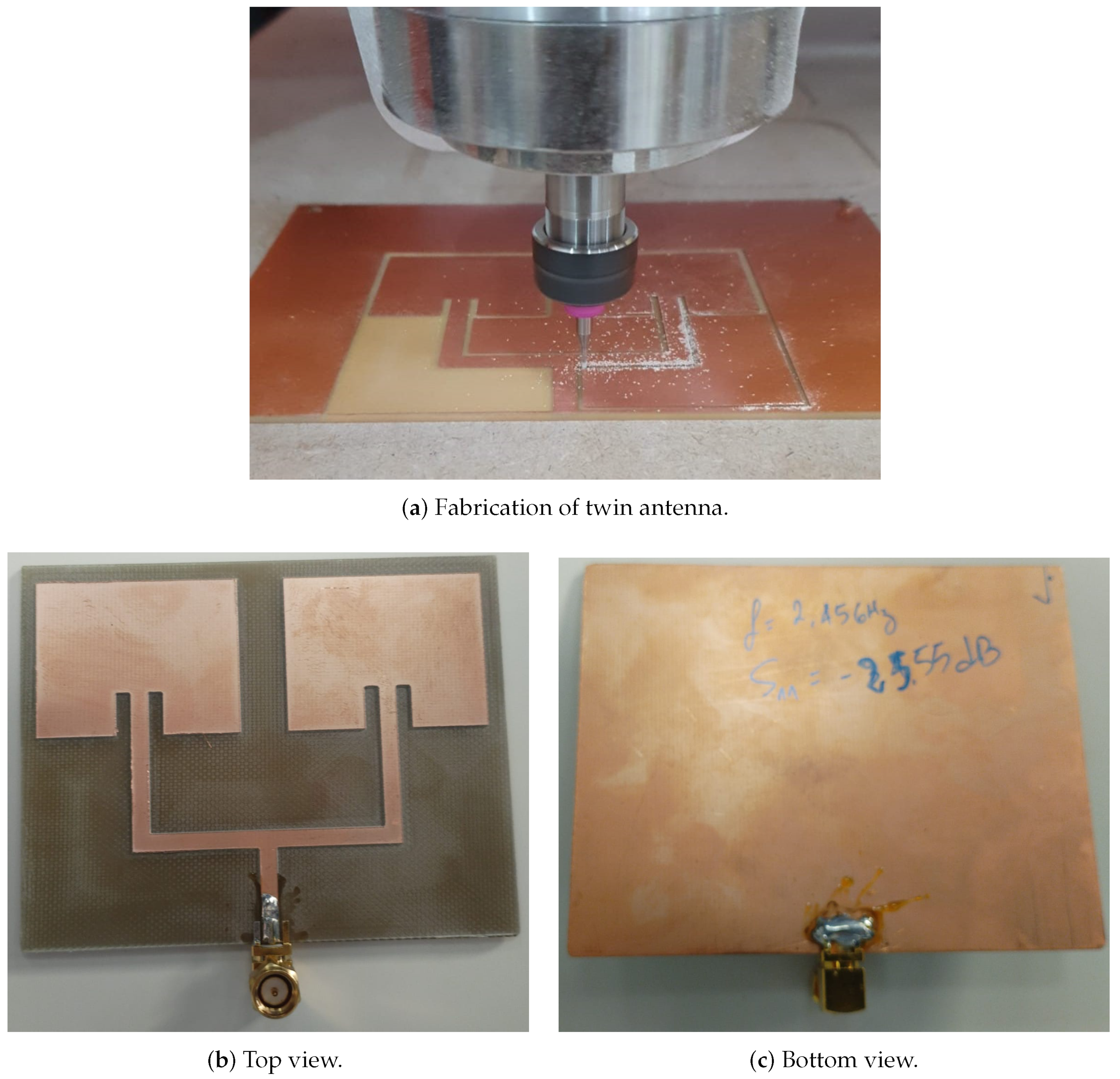

3.1. Twin-Patch Antenna

| in dB | VSWR | Gain in dB | ||||

|---|---|---|---|---|---|---|

| Simulated | Measured | Simulated | Measured | Simulated | Measured | |

| Patch antenna | −19.65 | −21.66 | 1.21 | 1.17 | 3.437 | 3.55 |

3.2. Rectifier Investigation

4. Prototype Results and Discussion

5. Conclusions and Perspectives

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| WPT | Wireless power transfer |

| RF | Radio frequency |

| LED | Light-emitting diode |

| DC | Direct current |

| VSWR | Voltage standing wave ratio |

| CNC | Computer numerical control |

| Tx | Transmitter |

| Rx | Receiver |

| VNA | Vector network analyzer |

References

- NCC. Part E4 Visibility in an Emergency, Exit Signs and Warning Systems (DtS). Available online: https://ncc.abcb.gov.au/editions/2019-a1/ncc-2019-volume-one-amendment-1/section-e-services-and-equipment/part-e4-dts (accessed on 14 June 2023).

- When Are Emergency & Exit Lights Required? Available online: https://resources.impactfireservices.com/when-are-emergency-exit-lights-required (accessed on 14 June 2023).

- Firesafe. Emergency Lighting. Available online: https://www.firesafe.org.uk/emergency-lighting/ (accessed on 14 June 2023).

- U.S. Energy Information Administration—EIA. Independent Statistics and Analysis. Available online: https://www.eia.gov/todayinenergy/detail.php?id=54639 (accessed on 5 June 2023).

- TEPCO. Top International Level of Quality. Available online: https://www.tepco.co.jp/en/pg/supply/quality/index-e.html (accessed on 5 June 2023).

- EverGlow NA, Inc. Replace Electrical Exit Signs. Available online: https://www.everglow.us/why-everglow/replace-electrical-exit-signs (accessed on 14 June 2023).

- What Is the Purpose of Emergency Lighting? Available online: https://www.enlighten.com.au/knowledge-centre/what-is-the-purpose-of-emergency-lighting (accessed on 5 June 2023).

- Importance of Emergency Lighting Highlighted after Death of Aberdeen Man. Available online: https://electricalreview.co.uk/2020/08/04/importance-of-emergency-lighting-highlighted-after-death-of-80-year-old-man/ (accessed on 12 December 2022).

- Emergency Lighting for Schools and Universities. Available online: https://www.emergencylighting.com/pages/106/ (accessed on 7 June 2023).

- Institute of Healthcare Engineering and Estate Management. BS 5266-1 Pocket Guide to Emergency Lighting. Available online: https://www.iheem.org.uk/wp-content/uploads/2021/04/Emergency_Lighting_Pocket_Guide_June_2021.pdf (accessed on 5 June 2023).

- Eaton. How to Meet Regulations for Emergency Lighting. Available online: https://www.eaton.com/ae/en-gb/markets/buildings/how-we-drive-building-efficiency-and-safety/safe-evacuation/evacuate/basics-emergency-lighting-systems/regulations-for-emergency-lighting.html (accessed on 5 June 2023).

- Mohsan, S.A.H.; Islam, A.; Khan, M.A.; Mahmood, A.; Rokia, L.S.; Mazinani, A.; Amjad, H. A Review on Research Challenges, Limitations and Practical Solutions for Underwater Wireless Power Transfer. Int. J. Adv. Comput. Sci. Appl. 2018, 11, 554–562. [Google Scholar] [CrossRef]

- Patil, P.S.; Padaganur, S. Challenging issues in wire less power transmission methods a survey. Int. J. Sci. Technol. Res. 2018, 7, 136–139. [Google Scholar]

- Ullah, M.A.; Keshavarz, R.; Abolhasan, M.; Lipman, J.; Esselle, K.P.; Shariati, N. A Review on Antenna Technologies for Ambient RF Energy Harvesting and Wireless Power Transfer: Designs, Challenges and Applications. IEEE Access 2022, 10, 17231–17267. [Google Scholar] [CrossRef]

- Pahlavan, S.; Shooshtari, M.; Jafarabadi Ashtiani, S. Star-Shaped Coils in the Transmitter Array for Receiver Rotation Tolerance in Free-Moving Wireless Power Transfer Applications. Energies 2022, 15, 8643. [Google Scholar] [CrossRef]

- Beckhusen, R. Army Plan: Wirelessly Recharge Gadgets… From 50 Feet Away. WIRED. Available online: https://www.wired.com/2012/06/wireless-power/ (accessed on 24 March 2022).

- Chaari, M.Z.; Al-Rahimi, R. The impact of Wireless Power Charging on the Future of the Battlefield. In Proceedings of the 2021 International Wireless Communications and Mobile Computing (IWCMC), Harbin, China, 28 June–2 July 2021; pp. 1563–1568. [Google Scholar] [CrossRef]

- Akter, N.; Hossain, B.; Kabir, H.; Bhuiyan, A.H.; Yeasmin, M.; Sultana, S. Design and Performance Analysis of 10-Stage Voltage Doublers RF Energy Harvesting Circuit for Wireless Sensor Network. J. Commn. Eng. Net. 2014, 2, 84–91. [Google Scholar] [CrossRef]

- Chaari, M.Z.; Al-maadeed, S. Wireless Power Transmission for the Internet of Things (IoT). In Proceedings of the 2020 IEEE International Conference on Informatics, IoT and Enabling Technologies (ICIoT), Doha, Qatar, 2–5 February 2020; pp. 549–554. [Google Scholar] [CrossRef]

- Chaari, M.Z.; Rahimi, R. Light LED directly lit up by the wireless power transfer technology. In Proceedings of the 2017 International Conference on Radar, Antenna, Microwave, Electronics, and Telecommunications (ICRAMET), Jakarta, Indonesia, 23–26 October 2017; pp. 137–141. [Google Scholar] [CrossRef]

- Park, Y.; Youii, D. kW-class Wireless Power Transmission Based on Microwave Beam. In Proceedings of the 2020 IEEE Wireless Power Transfer Conference (WPTC), Seoul, Republic of Korea, 15–19 November 2020; pp. 5–8. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Ji, J.; Hu, M. Research and application of wireless sensor network technology in power transmission and distribution system. Intell. Converg. Net. 2020, 1, 199–220. [Google Scholar] [CrossRef]

- Pinto, D.; Arun, A.; Lenka, S.; Colaco, L.; Khanolkar, S.; Betgeri, S.; Naik, A. Design and Performance Evaluation of a Wi-Fi Energy Harvester for Energizing Low Power Devices. In Proceedings of the 2021 IEEE Region 10 Symposium (TENSYMP), Jeju, Republic of Korea, 23–25 August 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Tran, L.G.; Cha, H.K.; Park, W.T. RF power harvesting: A review on designing methodologies and applications. Micro Nano Syst. Lett. 2017, 5, 14. [Google Scholar] [CrossRef]

- Sidhu, R.K.; Singh Ubhi, J.; Aggarwal, A. A Survey Study of Different RF Energy Sources for RF Energy Harvesting. In Proceedings of the 2019 International Conference on Automation, Computational and Technology Management (ICACTM), London, UK, 24–26 April 2019; pp. 530–533. [Google Scholar] [CrossRef]

- Kuhn, V.; Lahuec, C.; Seguin, F.; Person, C. A Multi-Band Stacked RF Energy Harvester With RF-to-DC Efficiency Up to 84%. IEEE Trans. Microw. Theory Tech. 2015, 63, 1768–1778. [Google Scholar] [CrossRef]

- Muncuk, U.; Alemdar, K.; Sarode, J.D.; Chowdury, K.R. Multiband Ambient RF Energy Harvesting Circuit Design for Enabling Batteryless Sensors and IoT. IEEE Internet Things J. 2018, 5, 2700–2714. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, L.; Zhang, Y.; Liu, R. Design of WPT RF Power Supply Based on Dual Directional Coupler and Capacitor Array Impedance Matching Network. IEEE Access. 2020, 8, 68209–68218. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Chiu, C.-W. Insertion Loss Characterization of Impedance Matching Networks for Low-Power Rectennas. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1632–1641. [Google Scholar] [CrossRef]

- Silva, E.F.D.; Gomes Neto, A.; Peixeiro, C. Fast and Accurate Rectenna Design Method. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 886–890. [Google Scholar] [CrossRef]

- Jang, S.-R.; Ryoo, H.-J.; Ahn, S.-H.; Kim, J.; Rim, G.H. Development and Optimization of High-Voltage Power Supply System for Industrial Magnetron. IEEE Trans. Ind. Electron. 2012, 59(3), 1453–1461. [Google Scholar] [CrossRef]

- He, Y.; Zhao, X.; Zhao, L.; Fan, Z.; Wang, J.K.; Zhang, L.; Ni, C.; Wu, W.J. Design of Broadband Double-Ridge Horn Antenna for Millimeter-Wave Applications. IEEE Access 2021, 9, 118919–118926. [Google Scholar] [CrossRef]

- Meena, M.S.; Prakash, V. Simulation Results of Rectangular Horn Antenna. Int. J. Adv. Trends Eng. Technol. 2018, 3, 171–179. [Google Scholar]

- Polat, B.; Daşbaşı, R. Analysis of Conical Horn Antenna Radiation over Ground by Directional Currents Method. In Proceedings of the 2021 20th International Conference on Microwave Techniques (COMITE), Brno, Czech Republic, 19–21 April 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Fat, J.; Alam, S.; Surjati, I. Performance analysis at the off body environment in terms of impedance matching, return loss and VSWR for wearable antenna system on different materials. IOP Conf. Ser. Mater. Sci. 2019, 508, 012075. [Google Scholar] [CrossRef]

- Sharma, R.; Suthar, A.C. Design and Analysis of Pyramidal Horn Antenna as Plane Wave Source for Anechoic Chamber. J. Adv. Sch. Res. Allied Educ. 2019, 16, 288–295. [Google Scholar] [CrossRef]

- Park, B.; Ryu, H.-G. Link Budget Investigation of Ambient Backscatter Communication. In Proceedings of the 2021 IEEE International Conference on Consumer Electronics-Asia (ICCE-Asia), Gangwon, Republic of Korea, 1–3 November 2021; pp. 1–3. [Google Scholar] [CrossRef]

- Gustafsson, M.; Capek, M. Maximum Gain, Effective Area, and Directivity. IEEE Trans. Antennas Propag. 2019, 67, 5282–5293. [Google Scholar] [CrossRef]

- Jackson, D.R.; Oliner, A.A. Leaky-Wave Antennas. In Modern Antenna Handbook; Balanis, C.A., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; pp. 325–367. [Google Scholar] [CrossRef]

- Chaari, M.Z. Wirelessly Powered an Alarm Clock ANENG HTC-1. In Proceedings of the 2022 IEEE International Conference on Consumer Electronics-Asia (ICCE-Asia), Yeosu, Republic of Korea, 26–28 October 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Chaari, M.Z.; Al-Rahimi, R. Energized IoT devices through RF Wireless Power Transfer. In Proceedings of the 2021 International Symposium on Electrical and Electronics Engineering (ISEE), Ho Chi Minh, Vietnam, 15–16 April 2021; pp. 199–203. [Google Scholar] [CrossRef]

- Li, Y.; Hao, Z.-C. A wideband switched beam antenna for full 360 coverage. In Proceedings of the 2017 Sixth Asia-Pacific Conference on Antennas and Propagation (APCAP), Xi’an, China, 16–19 October 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Matsunaga, T.; Nishiyama, E.; Toyoda, I. 5.8-GHz Stacked Differential Rectenna Suitable for Large-Scale Rectenna Arrays With DC Connection. IEEE Trans. Antennas Propag. 2015, 63, 5944–5949. [Google Scholar] [CrossRef]

- Da Silva, E.F.; Neto, A.G.; Peixeiro, C. Inset Feed Impedance Matching Technique for Rectennas. In Proceedings of the 2022 16th European Conference on Antennas and Propagation (EuCAP), Madrid, Spain, 27 March–1 April 2022; pp. 1–3. [Google Scholar] [CrossRef]

- Ishibashi, K.; Ida, J.; Nguyen, L.-T.; Ishikawa, R.; Satoh, Y.; Luong, D.-M. RF Characteristics of Rectifier Devices for Ambient RF Energy Harvesting. In Proceedings of the 2019 International Symposium on Electronics and Smart Devices (ISESD), Badung, Indonesia, 8–9 October 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Trikolikar, A.; Lahudkar, S. Investigation of Different Optimization Techniques for Rectenna. Int. J. Recent Innov. Trends Comput. Commun. 2023, 11, 6373. [Google Scholar] [CrossRef]

- Ali, E.M.; Yahaya, N.Z.; Perumal, N.; Zakariya, M.A. Development of Cockcroft Walton Voltage Multiplier for RF Energy Harvesting Applications. J. Sci. Res. Dev. 2016, 47–51. [Google Scholar]

- US EPA. Non-Ionizing Radiation from Wireless Technology. Available online: https://www.epa.gov/radtown/non-ionizing-radiation-wireless-technology (accessed on 21 June 2023).

- FDA. Microwave Ovens. Available online: https://www.fda.gov/radiation-emitting-products/resources-you-radiation-emitting-products/microwave-ovens (accessed on 21 June 2023).

| Name | Value | Description |

|---|---|---|

| wavelength_centre | 122.364 mm | |

| waveguide_width | 96.055 mm | Waveguide width |

| waveguide_length | 122.364 mm | Waveguide length |

| waveguide_height | 48.027 mm | Waveguide height |

| pin_inset | 22.989 mm | Feed pin inset (distance from the back wall) |

| pin_height | 27.661 mm | Feed pin height |

| pin_diameter | 1.223 mm | |

| metal_thickness | 0.124 mm | Antenna metal thickness |

| frequency_centre | 2.45 GHz | Centre frequency |

| flare_length | 76.78 mm | Flare length |

| S | 299.792458 m/s | Speed of light (corrected for the model units) |

| aperture_width | 253.645 mm | Aperture width |

| aperture_height | 183.183 mm | Aperture height |

| Name | Value | Description |

|---|---|---|

| wavelength_centre | 122.364 mm | |

| waveguide_width | 96.055 mm | Waveguide width |

| waveguide_length | 122.364 mm | Waveguide length |

| waveguide_height | 48.027 mm | Waveguide height |

| pin_inset | 22.989 mm | Feed pin inset (distance from the back wall) |

| pin_height | 26 | Feed pin height |

| pin_diameter | 16.36 | Feed pin diameter |

| metal_thickness | 2 | Antenna metal thickness |

| frequency_centre | 2.45 GHz | Centre frequency |

| flare_length | 76.78 mm | Flare length |

| S | 299.792458 m/s | Speed of light (corrected for the model units) |

| aperture_width | 253.645 mm | Aperture width |

| aperture_height | 183.183 mm | Aperture height |

| in dB | VSWR | Gain in dB | ||||

|---|---|---|---|---|---|---|

| Simulated | Measured | Simulated | Measured | Simulated | Measured | |

| Horn antenna | −23.28 | −14.82 | 1.10 | 1.41 | 14.5 | 12.33 |

| Diode | Minimum Breakdown Voltage (V) | Maximum Forward Voltage (mV) | Maximum Reverse Leakage Current (nA) | Maximum Capacitance (pF) |

|---|---|---|---|---|

| HSMS2820 | 15 @ = 100 A | 340 @ = 1 mA | 100 @ = 1 V | 1.0 @ = 0 V, f = 1.0 MHz |

| HSMS2810 | 20 @ = 10 mA | 410 @ = 1 mA | 200 @ = 15 V | 1.2 @ = 0 V, f = 1.0 MHz |

| HSMS2804 | 70 @ = 10 mA | 410 @ = 1 mA | 200 @ = 50 V | 2.0 @ = 0 V, f = 1.0 MHz |

| BAS40-04 | 40 @ = 10 A | 380 @ = 1 mA | 200 @ = 30 V | 5.0 @ = 0 V, f = 1.0 MHz |

| RF/DC Rectifier Diode Types | S Return Loss (dB) at 2.45 GHz |

|---|---|

| HSMS2820 | −9.03 |

| HSMS2810 | −7.43 |

| HSMS2804 | −3.41 |

| BAS40-04 | −5.45 |

| Diode | (dBm) | Load Resistance | (V) | (mA) | (W) | Efficiency |

|---|---|---|---|---|---|---|

| HSMS2804 | 33 | 50 | 9.75 | 20 | 0.19 | 5.91 |

| BAS40-04 | 33 | 50 | 2.00 | 4.12 | 0.0081 | 0.25 |

| HSMS2820 | 33 | 50 | 3.86 | 8 | 0.03 | 0.93 |

| HSMS2810 | 33 | 50 | 11.60 | 23 | 0.27 | 8.09 |

| Parameter | Receiving Patch Antenna (Rx) Value | Horn Antenna (Tx) Value |

|---|---|---|

| Return loss | −21.66 dB | −14.82 dB |

| BW (GHz) | 2.43 GHz to 2.58 GHz | 2.33 GHz to 2.62 GHz |

| Gain (dB) | 3.55 | 12.33 |

| Directivity (dB) | 7.9 | 11.03 |

| VSWR | 1.17 | 1.41 |

| RF Transmitter Power () | Distance between RF Transmitter and Observation Point (m) | Harvested Energy (W) |

|---|---|---|

| 500 W | 5 | 4.19 |

| 500 W | 15 | 2.79 |

| 500 W | 25 | 2.3 |

| 500 W | 45 | 1.2 |

| 500 W | 60 | 0.483 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaari, M.Z.; Pereira, G.P.; Abdelfatah, M.; Al-Rahimi, R.; Aghzout, O. Energizing Emergency Exit Signs with Wireless Energy Transfer. Energies 2023, 16, 5080. https://doi.org/10.3390/en16135080

Chaari MZ, Pereira GP, Abdelfatah M, Al-Rahimi R, Aghzout O. Energizing Emergency Exit Signs with Wireless Energy Transfer. Energies. 2023; 16(13):5080. https://doi.org/10.3390/en16135080

Chicago/Turabian StyleChaari, Mohamed Z., Gilroy P. Pereira, Mohamed Abdelfatah, Rashid Al-Rahimi, and Otman Aghzout. 2023. "Energizing Emergency Exit Signs with Wireless Energy Transfer" Energies 16, no. 13: 5080. https://doi.org/10.3390/en16135080

APA StyleChaari, M. Z., Pereira, G. P., Abdelfatah, M., Al-Rahimi, R., & Aghzout, O. (2023). Energizing Emergency Exit Signs with Wireless Energy Transfer. Energies, 16(13), 5080. https://doi.org/10.3390/en16135080