2.2.2. Influence of Different Light Conditions on the Production of Photovoltaic Modules

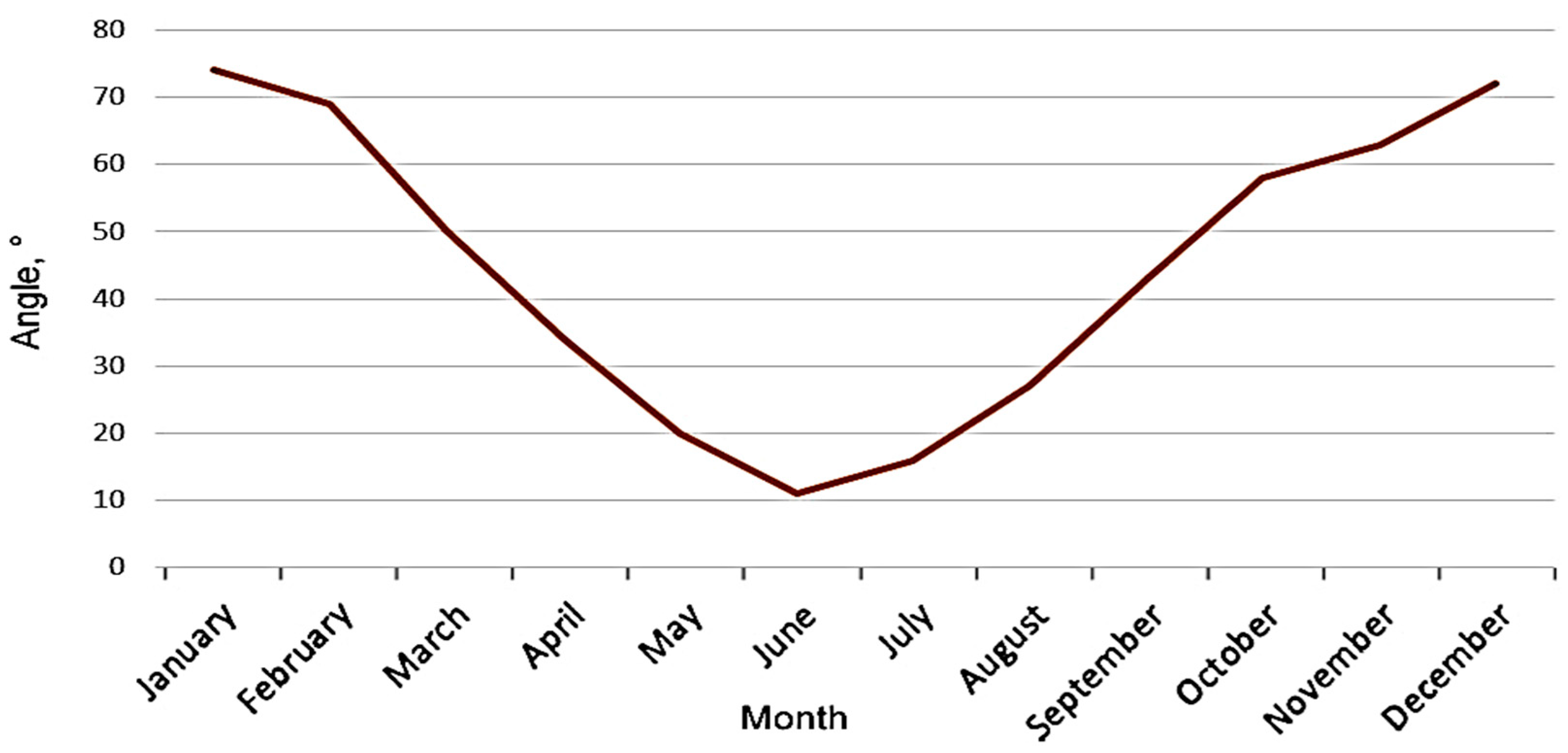

The Sun moves across the sky from east to west. The Sun’s position in the sky is determined by two coordinates, declination and azimuth. Declination is the angle between the line connecting the observer and the Sun and the horizontal surface. The azimuth is the angle between the direction to the Sun and the direction to the south.

It should also be taken into account that the direction to the magnetic south does not always coincide with the direction to the true south. There are true and magnetic poles that do not coincide with each other [

32]. Accordingly, there are true and magnetic meridians and, from both of them, it is possible to read off the direction to the desired object. In one case, we deal with the true azimuth; in the other, with a magnetic azimuth. The true azimuth is the angle between the true (geographical) meridian and the direction to the object. The magnetic azimuth is the angle between the magnetic meridian and the direction to a given object. It is clear that the true and magnetic azimuths differ by the same value by which the magnetic meridian differs from the true meridian [

33]. This value is called magnetic declination. If the compass needle deviates from the true meridian to the east, the magnetic declination is called east, and if the needle deviates to the west, the declination is called west. Eastern declination is often referred to as “+” (plus) and western declination as “−” (minus). Magnetic declination varies from place to place. Thus, for the Moscow region in Russia, for example, the declination is +6.5… +8.2° and, in general, in the territory of Russia, it varies within more significant limits [

34].

In practice, the solar panels must be oriented at a certain angle to the horizontal surface. Near the equator, the solar panels should be positioned at a very small angle (almost horizontal) in order for the rain to wash the dust and dirt off the PV modules.

Small deviations from this orientation do not play a significant role because, during the day, the Sun moves across the sky from east to west.

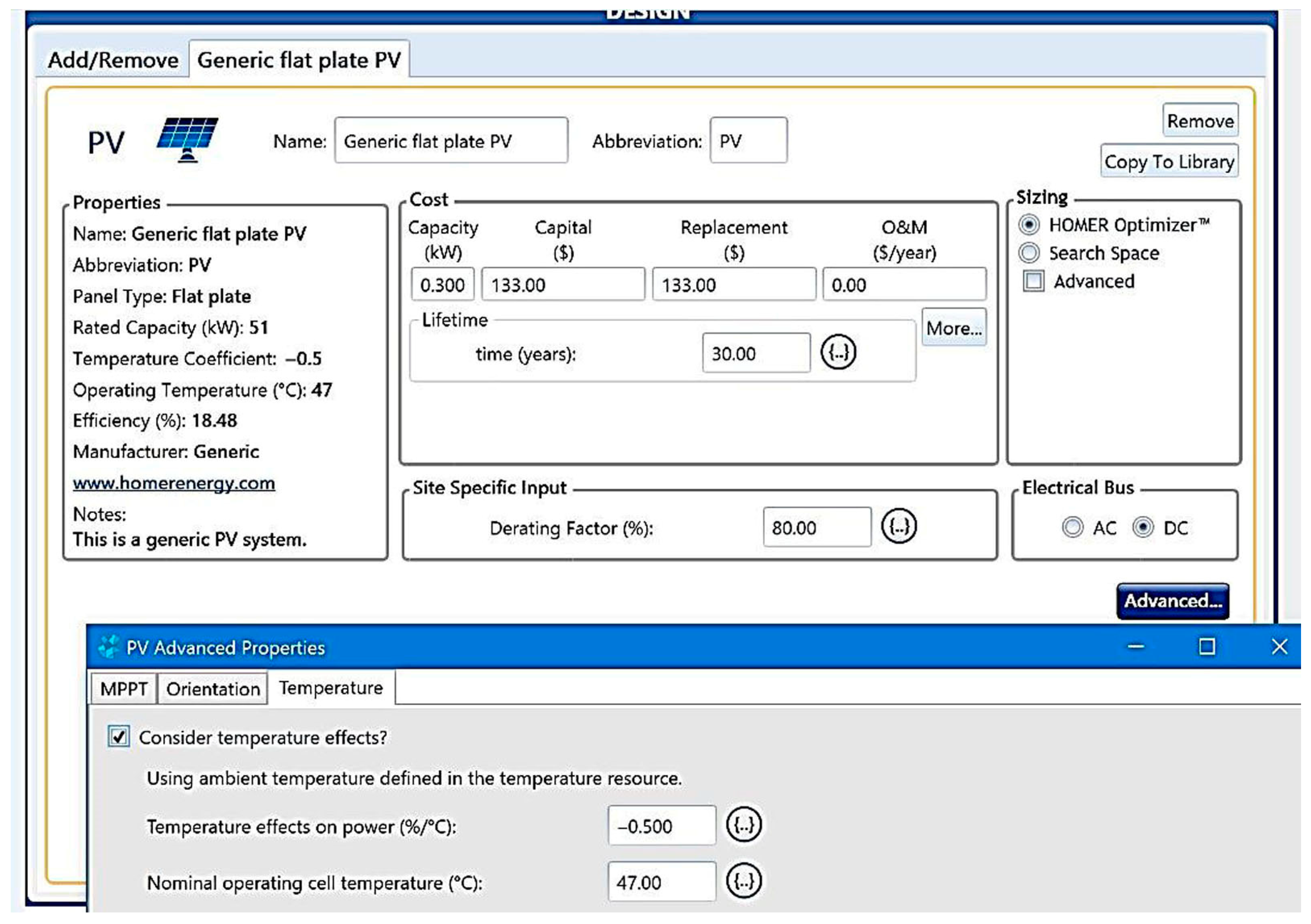

To maintain maximum power extraction from the solar panels, special algorithms called maximum power point tracking (MPPT) algorithms are used.

When reviewing the existing MPPT algorithms, it can be noted that there is a large variety of control algorithms. Among them, we can often distinguish:

Perturbation and observation algorithm (POA).

Adaptive perturbation and observation algorithm (APOA).

Algorithm of increasing conductivity (AIC).

Algorithm based on fuzzy control logic (ABFCL).

Algorithm based on neural networks (ABNN).

Fixed voltage algorithm (FVA).

In the perturbation and observation method, the device changes the input resistance of the inverter by some small amount while changing the voltage on the solar cell (SC). If the power increases, the device continues to change the set parameter until the power no longer increases. This method is widely used, although it has certain disadvantages. Its main advantage is simplicity. Among the disadvantages are: the inability to clearly define the maximum power point (MPP), fluctuations in the operating point around the MPP, a reduced efficiency at a low value of light, and erroneous results when there is a sudden change in the light level.

- 2.

Adaptive perturbation and observation algorithm (APOA).

The main difference in the adaptive perturbation and observation algorithm (APOA) is that, when the MPP is found, the step by which the given parameter is changed changes depending on the value by which the power has changed. If, at the previous step, the power increased by a larger value than at the current step, then the step of increment will decrease. This allows for a faster and more accurate determination of the MPP.

- 3.

Algorithm of increasing conductivity (AIC).

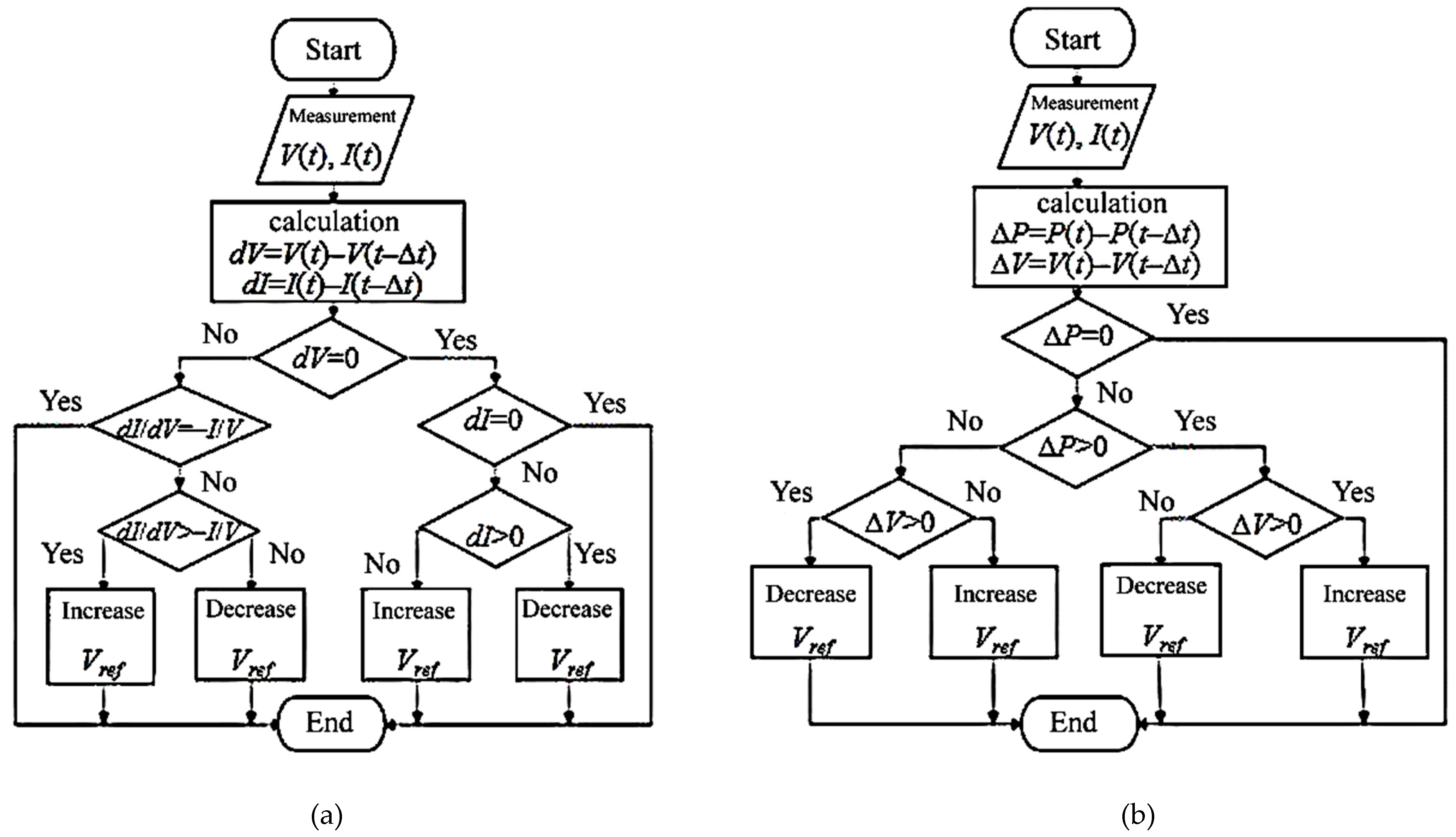

In the algorithm of increasing conductivity (AIC), the values of the incremental source voltage and current are measured with a transducer [

35]. Based on these data, the effect of changes in voltage is predicted. The computational complexity increases, but the speed of tracking changes in ambient conditions also increases. This method uses the increasing conductivity dI/dU to calculate the sign of the change in power with respect to the voltage dP/dU. This calculates the maximum power point and compares the increasing conductivity DI/DU with the solar panel conductivity (I/U). When the condition I/DU = I/U is fulfilled, the output voltage of the SC corresponds to the value of maximum power. The values are then maintained until the illuminance level changes.

As with the APOA method, the main drawback is that this method can easily make mistakes when the light level changes abruptly. Both of these methods are effective at finding the MPP at constant illuminance. However, when the illuminance changes on a slope, the tangent on which the algorithms are based continuously changes with the illuminance as a consequence of changes in the current and voltage not only being due to voltage perturbation. Therefore, the algorithms cannot determine what exactly the change in power is related to [

35].

Another disadvantage is that the power value oscillates around the MPP in steady-state mode. This is due to the fact that the control is discrete and that the current and voltage are not constantly at the point of maximum power but fluctuate around it. The main differences in the algorithms AIC and APOA are shown in

Figure 8.

Constant voltage algorithm. This method takes advantage of the fact that the ratio between the maximum power point voltage and the CB no-load voltage is approximately linear:

where

is a constant that depends on the characteristics of the photocells and must be determined initially;

is a voltage corresponding to the maximum power point;

is a no-load voltage of the battery circuit.

To achieve this, we need to compare the values of and at different levels of light and temperature. In general, the value of this constant ranges from 0.71 to 0.78.

When the value of the constant is determined, the MPP voltage values can be determined by measuring the no-load voltage of the battery. This requires the power converter to be switched off for a moment, which leads to a loss of power. The disadvantage is also the fact that this algorithm is not able to track a constant change in illumination since the voltage measurement process is not continuous. Another disadvantage is that the MPP selected by this method is not valid since the value of the constant is an approximation.

Depending on the application, this algorithm can be used. It is cheap and simple. It does not require a microcontroller (only one voltage sensor is used).

- 4.

Algorithm based on fuzzy control logic (ABFCL).

Another algorithm that has been gaining popularity lately is the algorithm based on fuzzy control logic (ABFCL), which has become popular in the last decade because it can handle imprecise input data, does not need an exact mathematical model and can handle nonlinearity [

36]. Microcontrollers have played no small role in the popularization of fuzzy logic control. Fuzzy logic consists of three stages: phasification, fuzzy inference and defuzzification [

4]. Phasification involves the process of converting numerical fuzzy input data into linguistic variables based on the degree of certain sets. Accessory functions are used to bind the score to each linguistic term. The number of affiliation functions used depends on the accuracy of the controller, but typically ranges from 5 to 7.

The input to a fuzzy controller is usually an error, E, and its increment Δ

E. The error value can be chosen by the designer, but most often it is chosen as ΔP/ΔV. Thus,

where

and

are the power of the photoelectric transducer on the current and previous cycle, respectively;

and are output voltages of the photoelectric transducer on the current and previous cycles, respectively;

and are the error on the current and previous measure, respectively;

is the incremental error between measures.

The output of a fuzzy converter logic is usually a change in the power converter fill factor, ΔD, or a change in the DC circuit reference voltage, ΔV. The rule base, also known as fuzzy algorithm rules, relates the fuzzy output to fuzzy inputs based on the power converter used [

5], which is shown in

Table 3.

The last stage of fuzzy logic control is defuzzification. In this step, the output is converted from a linguistic variable to a numeric crisp variable, again using the membership functions. There are various methods for converting linguistic variables into crisp values. The most popular among them is the “center of gravity” method. The advantages of these controllers, in addition to dealing with imprecise input data, a lack of an exact mathematical model and handling nonlinearity, are a fast convergence and minimal fluctuations around the MPP. In addition, they have been shown to work well for step changes in illumination. It is worth noting, however, that no evidence has been found to support the fact that they work well for abrupt changes in illuminance. Another drawback is that their effectiveness depends largely on the skills of the designer, not only in choosing the right error calculation but also in creating an appropriate rule base.

- 5.

Algorithm based on neural networks (ABNN).

Another method well adapted to microcontrollers is the one based on neural networks. The simplest neural network consists of three layers: input, hidden and output. More complex neural networks are created with hidden layers added. The number of layers and the number of nodes in each layer, as well as the functions used in each layer, vary and depend on user knowledge. Thus, the input variables can be the parameters of the solar panel, its voltage and current, illumination and temperature or a combination of these. The outputs are usually one or more reference signals, such as the duty cycle value or DC link voltage. The performance of the neural network depends on the functions used by the hidden layer and how well the network has been trained [

2]. To perform this learning process, pattern data between the inputs and outputs of the neural network are recorded over a long period of time so that the MPP can be accurately tracked [

6]. The main disadvantage of this method is the fact that the data required for the training process must be specifically obtained for each PV array and its location because the characteristics of the PV array vary from model to model and the atmospheric conditions vary from location to location. These characteristics also change over time, so the neural network needs to be trained periodically.

- 6.

Fixed voltage algorithm (FVA).

This algorithm is based on the laws of circuit power and is based on applying a bias voltage from the collector voltage source through a voltage divider with respect to the operating point. The main drawback is the instability of the operating point. The reason for the instability of the operating point is that transistor amplifier stages do not operate under ideal conditions. They are influenced by a variety of factors: ambient temperature, fluctuations in the supply voltage and the presence of electric or magnetic fields in the space (the creation of parasitic inductions). Therefore, it is necessary to stabilize the operating point of the amplifier.

Let us compare the described algorithms in

Table 4.

Thus, of the above algorithms, the fuzzy logic algorithm is optimal for the weather station. It has a high efficiency, while its operation is much easier than the algorithm based on neural networks, at a comparable cost. In addition, despite the fact that the implementation of this algorithm is a relatively complex task, it is assumed that, given the specifics of the structure, the implementation will be carried out by a qualified engineer, which, in general, eliminates problems during installation.

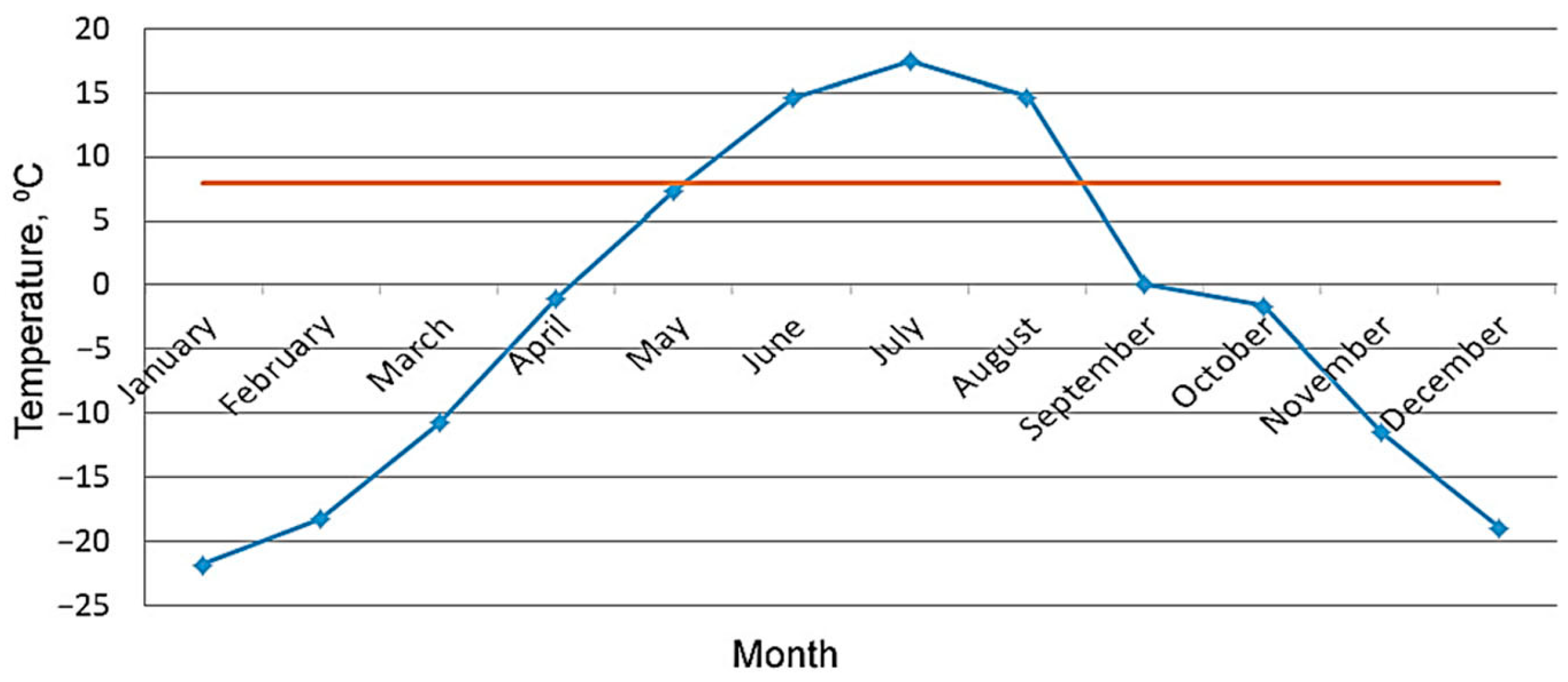

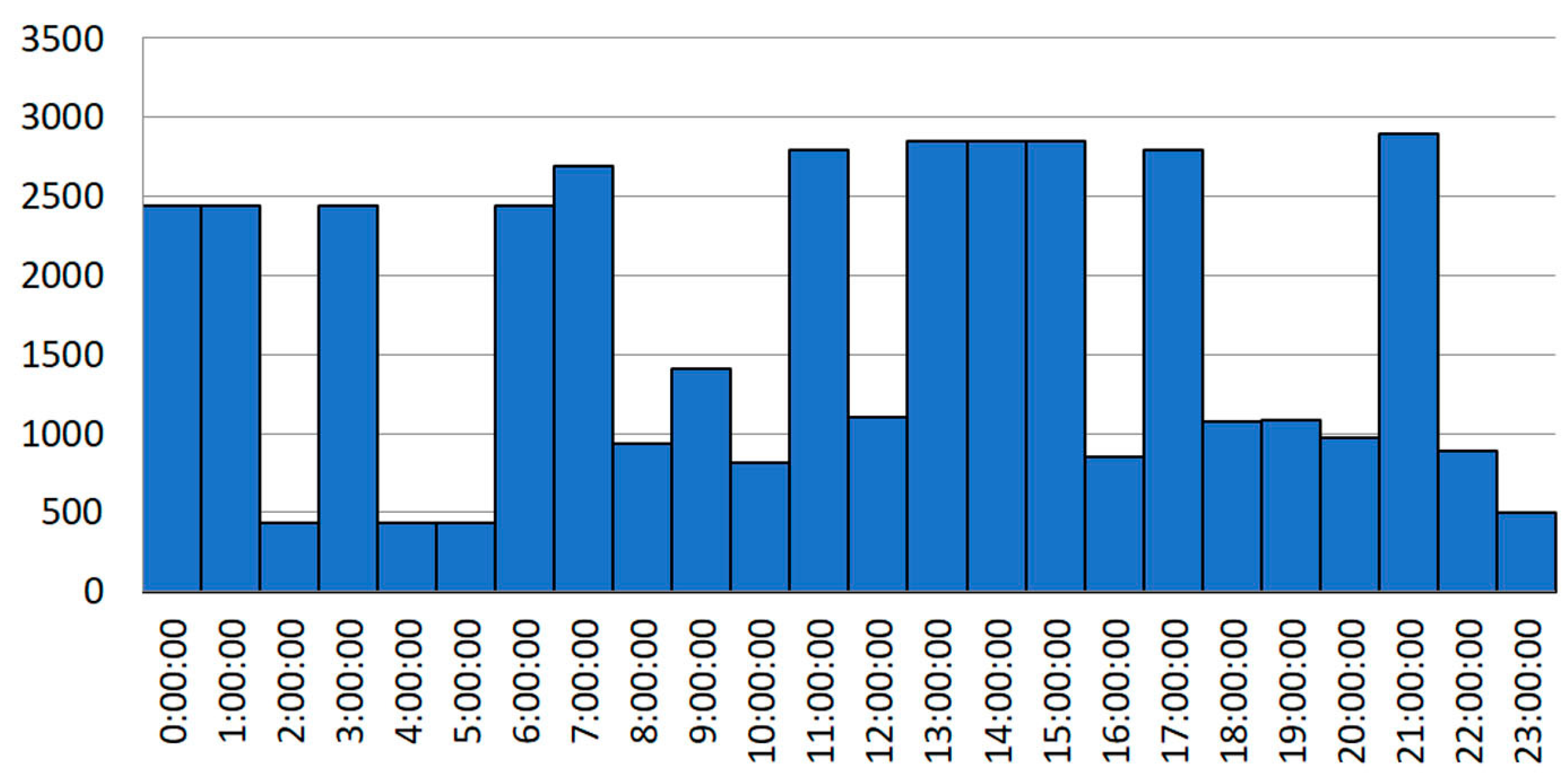

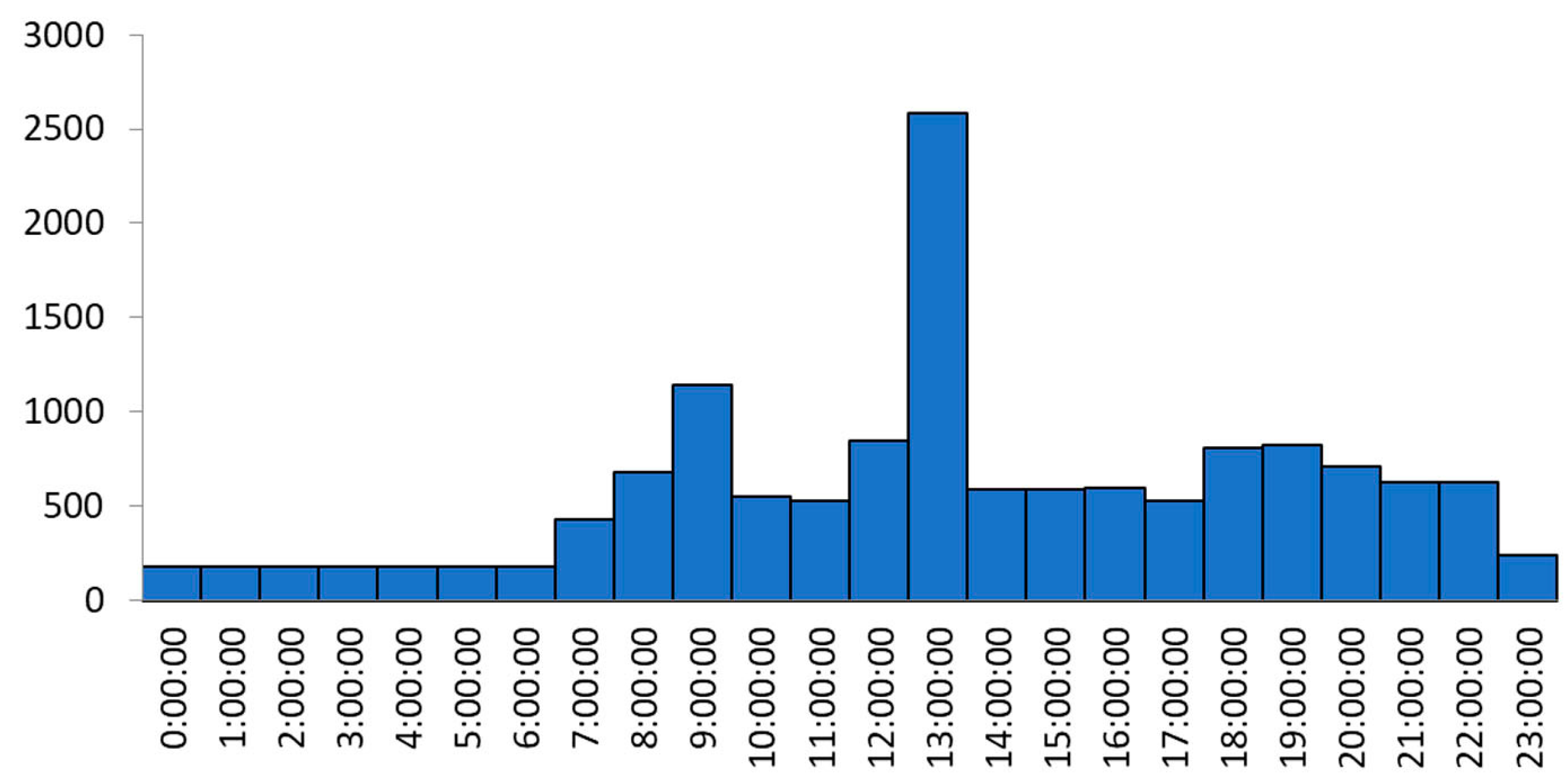

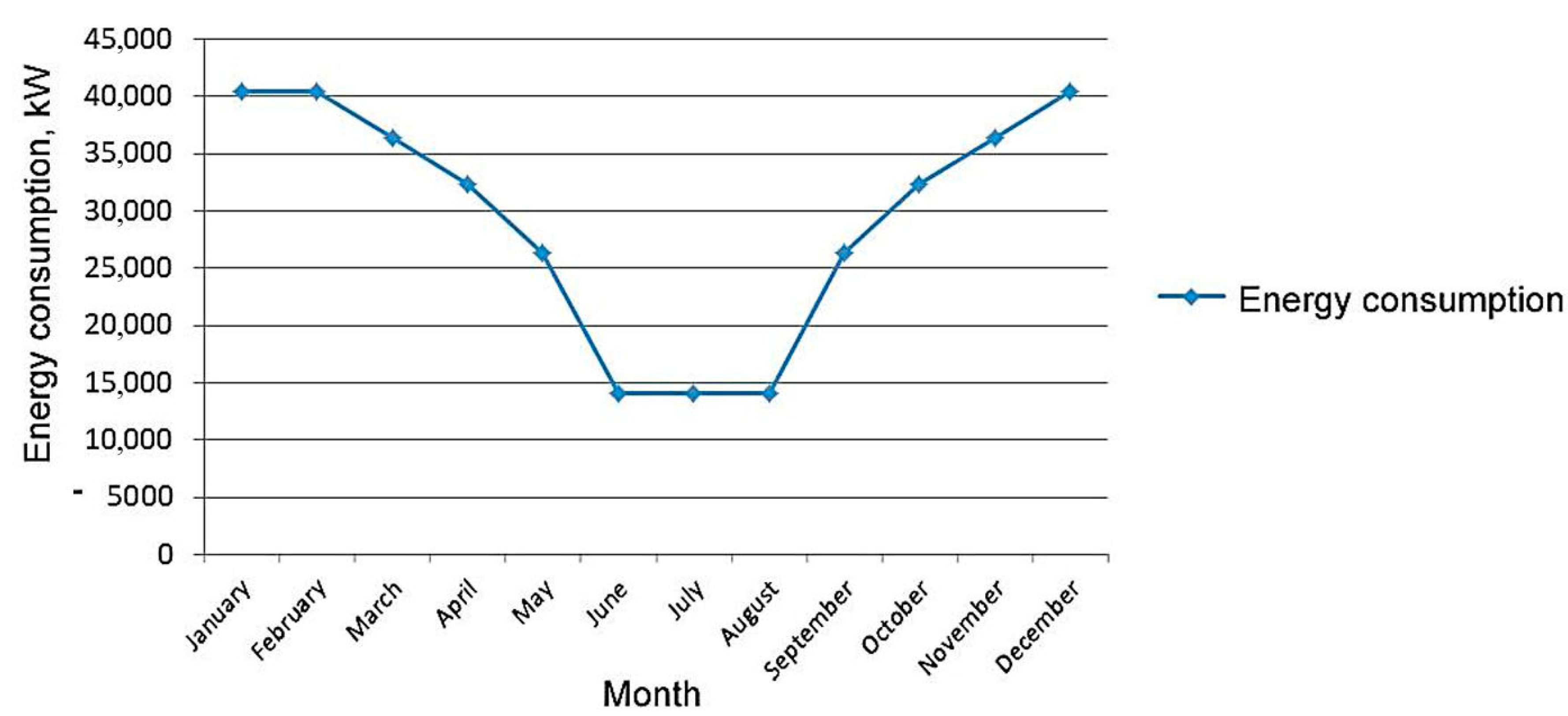

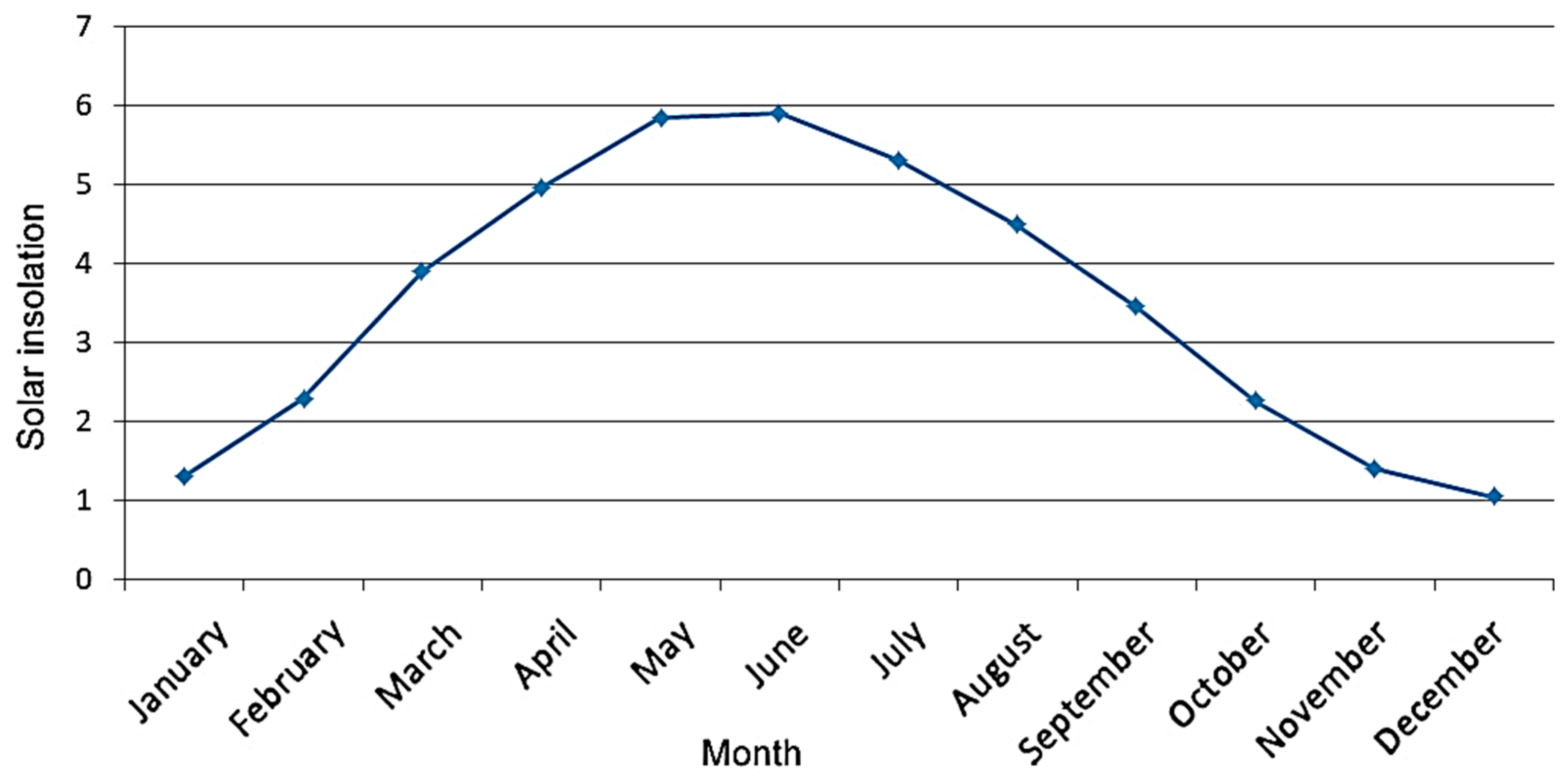

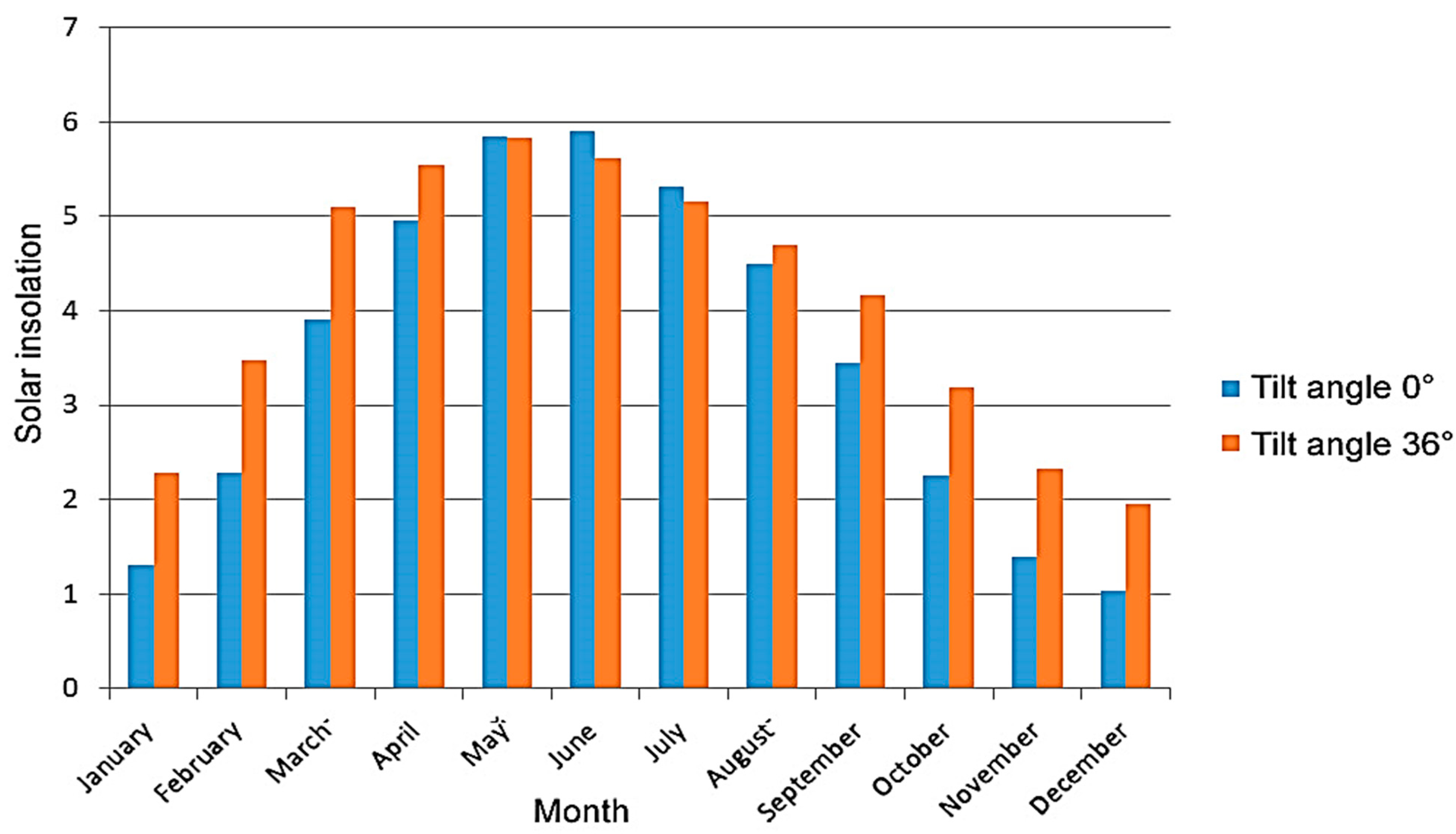

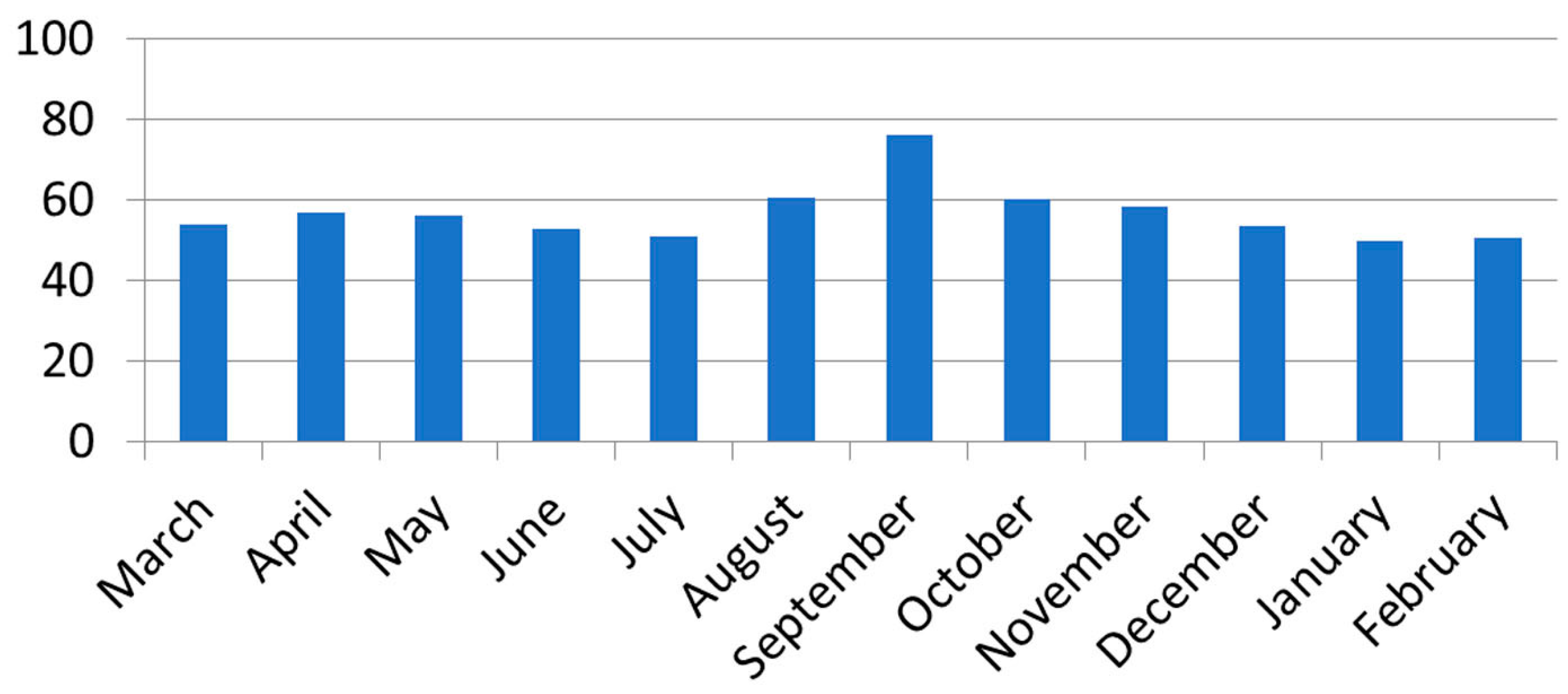

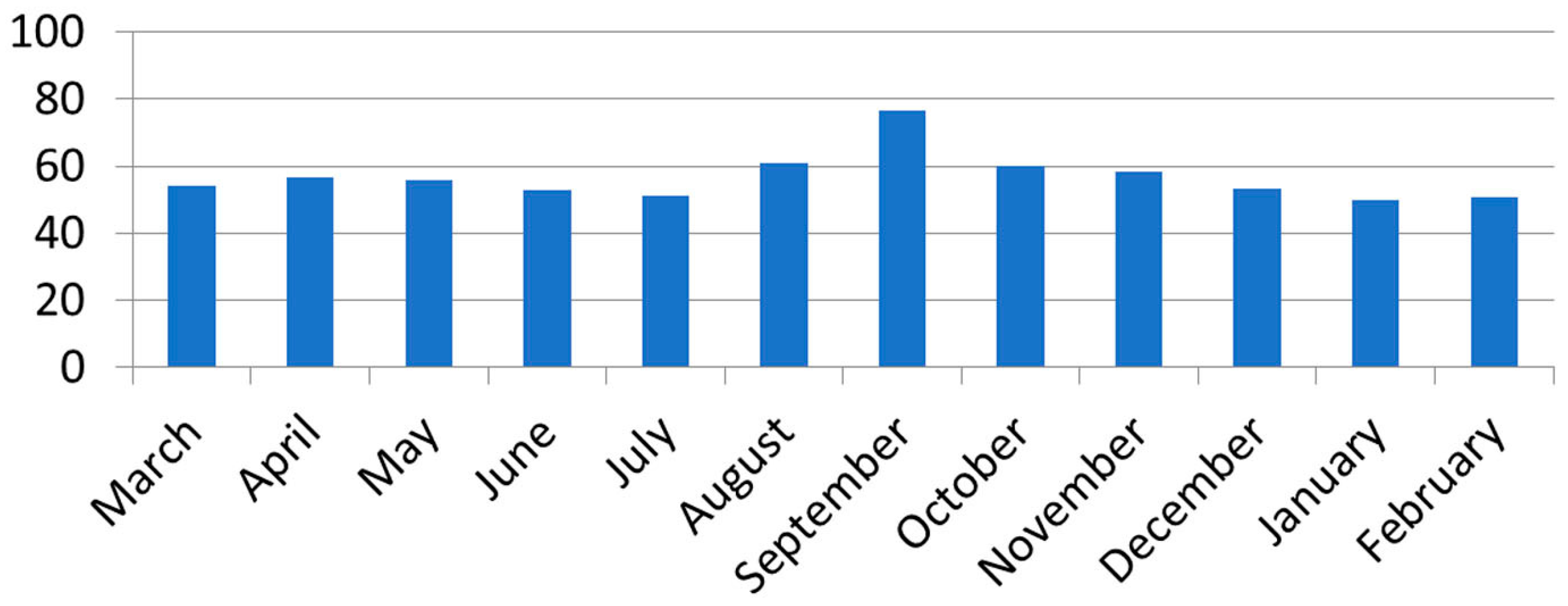

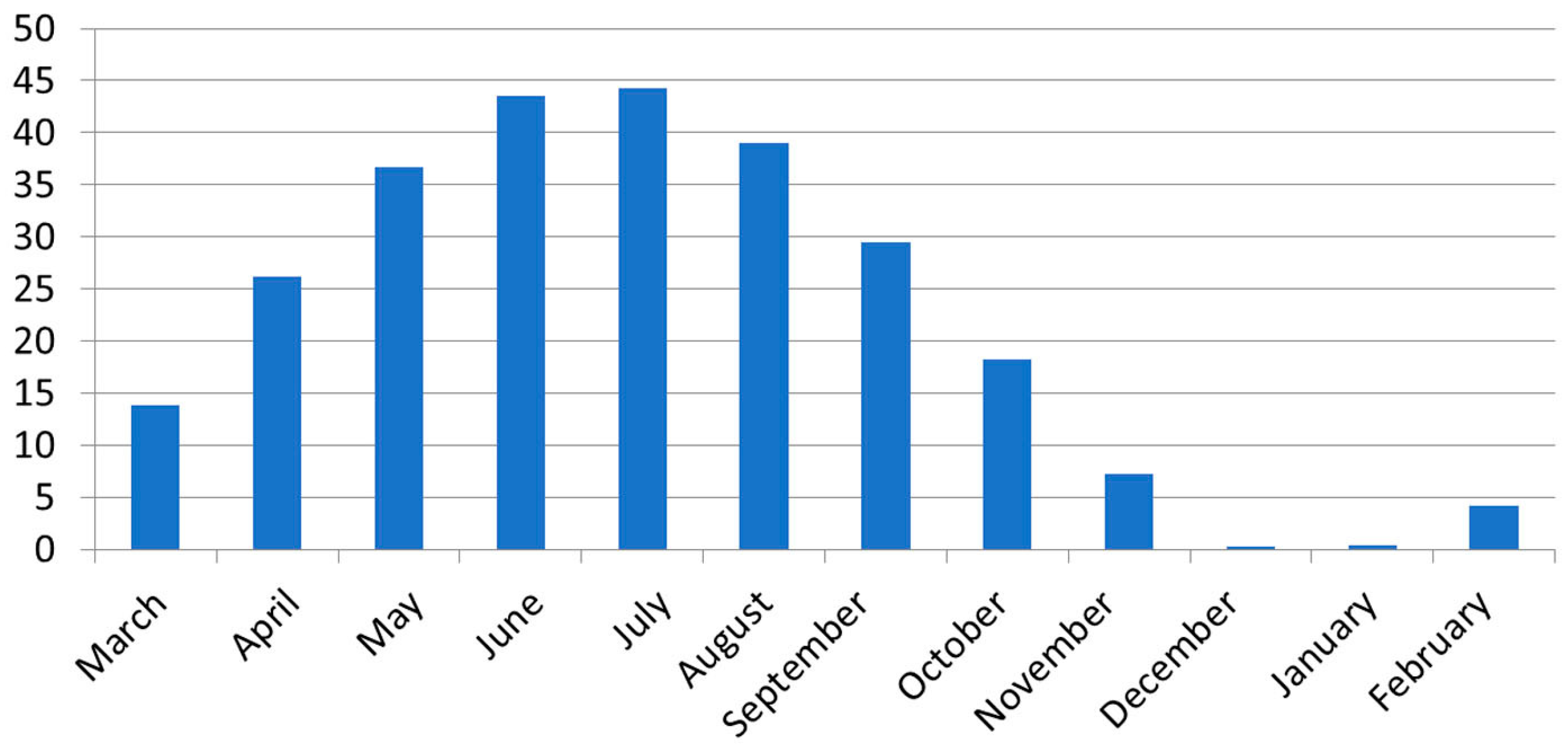

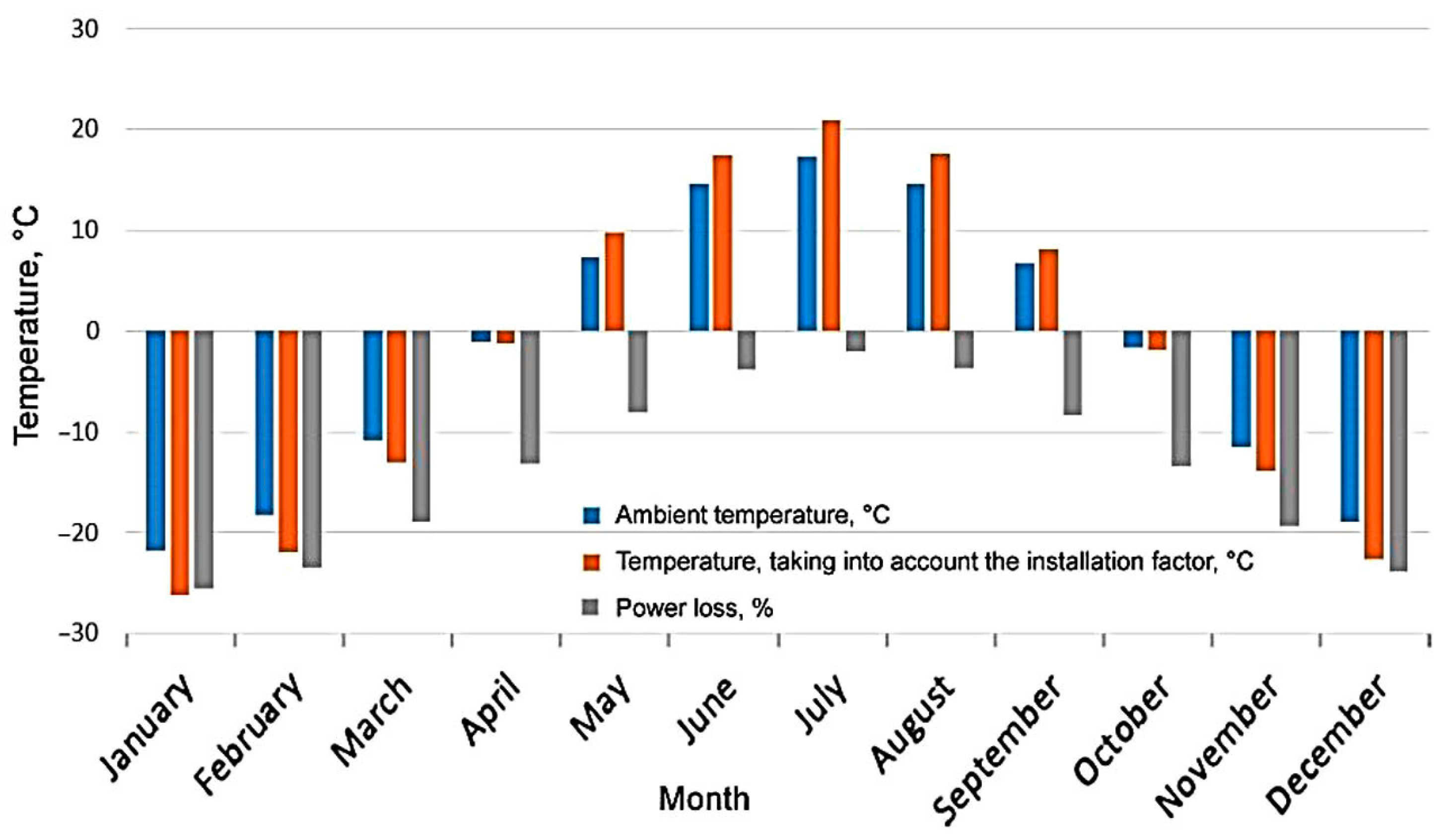

Depending on the spatial location and surrounding conditions, different positioning methods can be selected. In dense urban areas, the use of the static positioning method is more justified due to the lack of sufficient free space and the presence of shading from various objects, despite the fact that the efficiency of this method is significantly (18% or more) lower. When powering remote objects located in places with a low population density and large areas, such as small villages, weather stations and hotels, their use is more reasonable. In addition, when choosing a positioning method, it is important to consider the geographical location and it is desirable to perform calculations to identify the best one for the area (

Figure 1,

Figure 2 and

Figure 3). For example, a comparison of tracking methods relative to Bangladesh [

37] showed no significant difference in performance between single-axis and dual-axis positioning. The difference was 4.4%, which is disproportionate to the investment in the two-axis system.