Hybrid Source Multi-Port Quasi-Z-Source Converter with Fuzzy-Logic-Based Energy Management

Abstract

1. Introduction

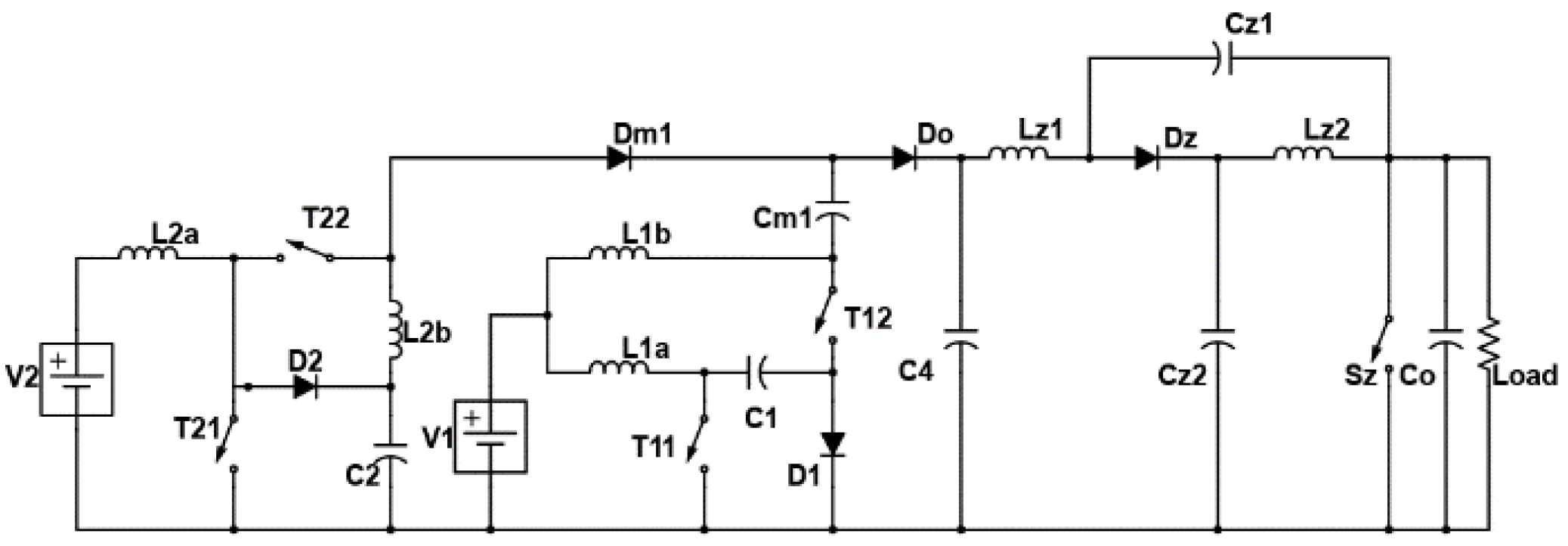

2. Proposed Multi-Port Converter with Quasi-Z-Source Network

Working Modes and Mathematical Expressions

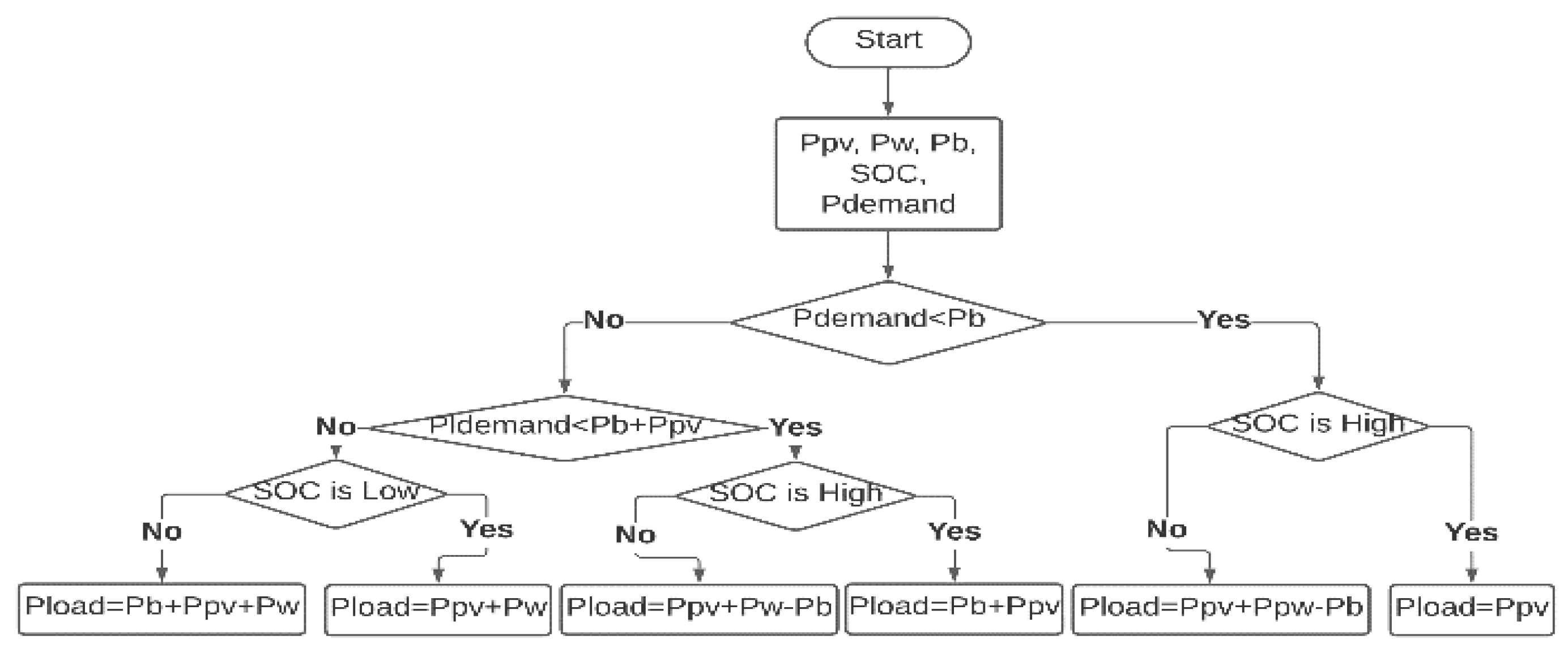

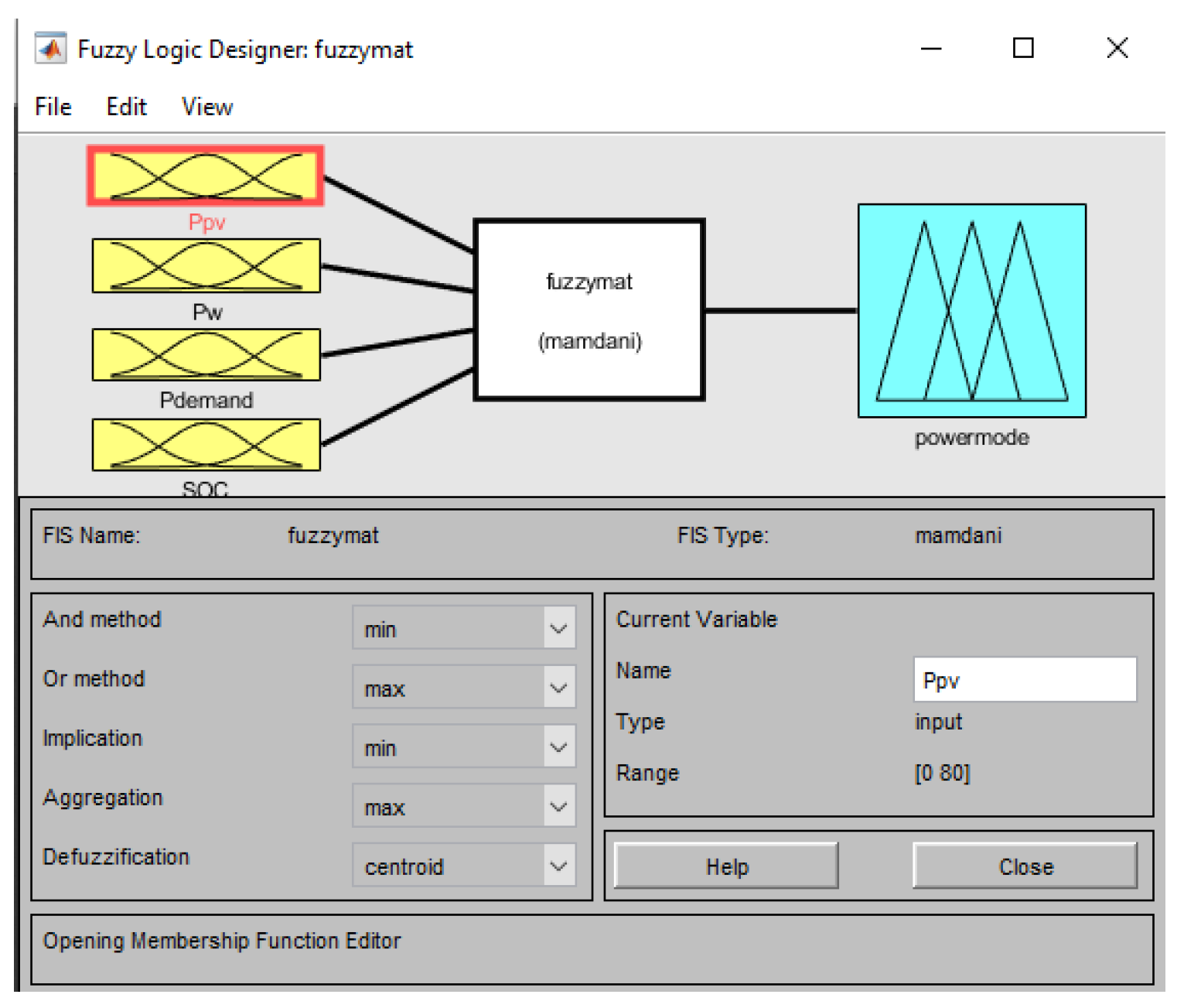

3. Proposed Energy Management Strategy

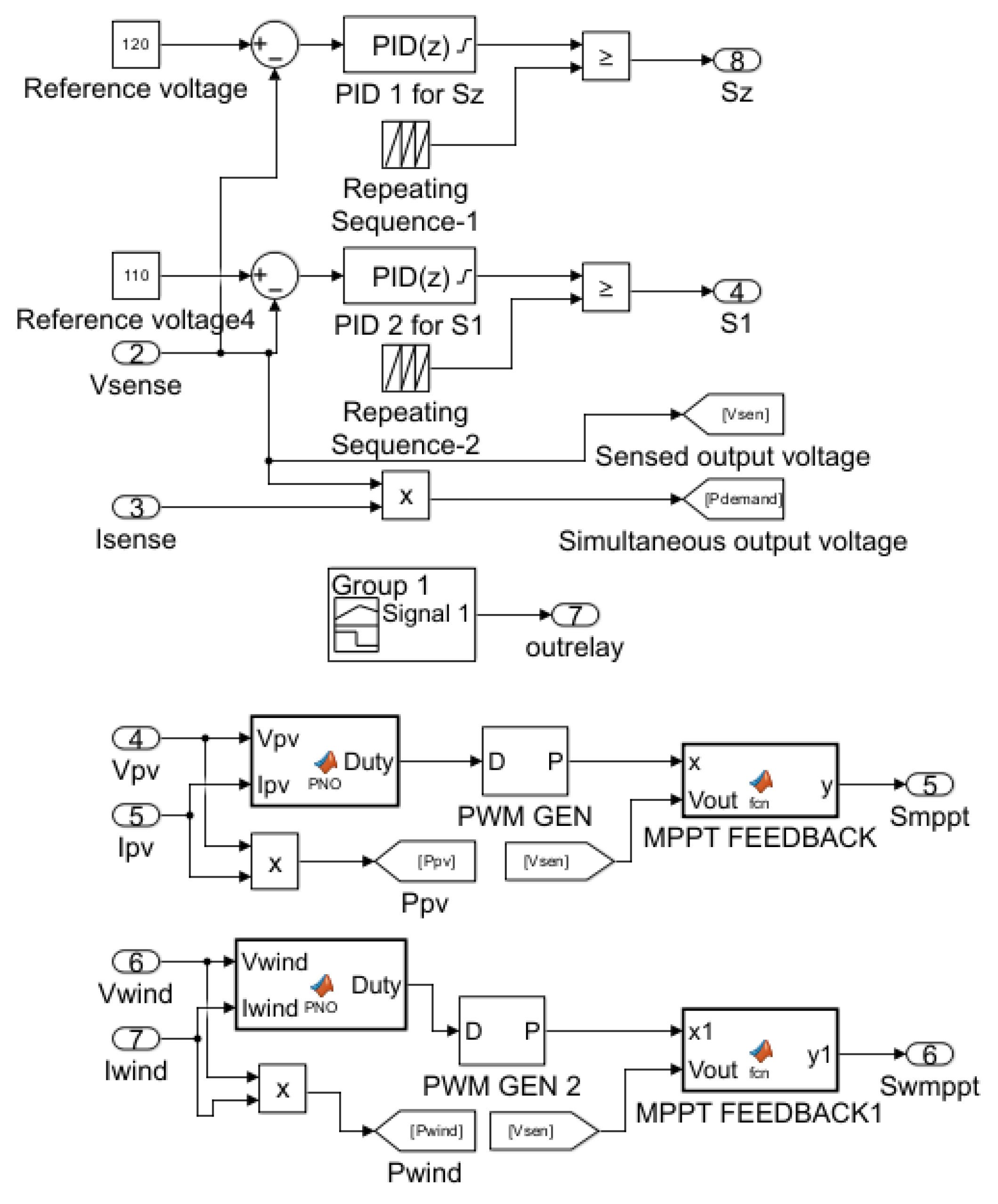

4. Simulation of the Proposed Control System

4.1. Simulink Model

4.2. Other Control Parameters

4.3. Simulation Results

5. Experimental Test

Experimental Results

6. Discussion and Comparison

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- If SOC is low and Ppv is low and Pwind is low and Pout is low, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is low and Pout is low, the power mode is P2.

- If SOC is high and Ppv is low and Pwind is low and Pout is low, then the power mode is P1.

- If SOC is low and Ppv is low and Pwind is low and Pout is medium, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is low and Pout is medium, then power mode is P3.

- If SOC is high and Ppv is low and Pwind is low and Pout is medium, then power mode is P3.

- If SOC is low and Ppv is low and Pwind is low and Pout is high, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is low and Pout is high, then power mode is P3.

- If SOC is high and Ppv is low and Pwind is low and Pout is high, then power mode is P3.

- If SOC is low and Ppv is low and Pwind is medium and Pout is low, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is medium and Pout is low, then power mode is P2.

- If SOC is high and Ppv is low and Pwind is medium and Pout is low, then power mode is P1.

- If SOC is low and Ppv is low and Pwind is medium and Pout is medium, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is medium and Pout is medium, then power mode is P3.

- If SOC is high and Ppv is low and Pwind is medium and Pout is medium, then power mode is P3.

- If SOC is low and Ppv is low and Pwind is medium and Pout is high, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is medium and Pout is high, then power mode is P3.

- If SOC is high and Ppv is low and Pwind is medium and Pout is high, then power mode is P3.

- If SOC is low and Ppv is low and Pwind is high and Pout is low, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is high and Pout is low, then power mode is P2.

- If SOC is high and Ppv is low and Pwind is high and Pout is low, then power mode is P1.

- If SOC is low and Ppv is low and Pwind is high and Pout is medium, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is high and Pout is medium, then power mode is P3.

- If SOC is high and Ppv is low and Pwind is high and Pout is medium, then power mode is P3.

- If SOC is low and Ppv is low and Pwind is high and Pout is high, then power mode is P3.

- If SOC is medium and Ppv is low and Pwind is high and Pout is high, then power mode is P3.

- If SOC is high and Ppv is low and Pwind is high and Pout is high, then power mode is P3.

- If SOC is low and Ppv is medium and Pwind is low and Pout is low, then power mode is P3.

- If SOC is medium and Ppv is medium and Pwind is low and Pout is low, then power mode is P2.

- If SOC is high and Ppv is medium and Pwind is low and Pout is low, then power mode is P1.

- If SOC is low and Ppv is medium and Pwind is low and Pout is medium, then power mode is P3.

- If SOC is medium and Ppv is medium and Pwind is low and Pout is medium, then power mode is P3.

- If SOC is high and Ppv is medium and Pwind is low and Pout is medium, then power mode is P3.

- If SOC is low and Ppv is medium and Pwind is low and Pout is high, then power mode is P3.

- If SOC is medium and Ppv is medium and Pwind is low and Pout is high, then power mode is P3.

- If SOC is high and Ppv is medium and Pwind is low and Pout is high, then power mode is P3.

- If SOC is low and Ppv is medium and Pwind is medium and Pout is low, then power mode is P3.

- If SOC is medium and Ppv is medium and Pwind is medium and Pout is low, then power mode is P2.

- If SOC is high and Ppv is medium and Pwind is medium and Pout is low, then power mode is P1.

- If SOC is low and Ppv is medium and Pwind is medium and Pout is medium, then power mode is P3.

References

- Li, Y.; Yang, D.; Ruan, X. A Systematic Method for Generating Multiple-Input DC/DC Converters. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Milan, Italy, 23–27 October 2023; IEEE: New York, NY, USA, 2008; pp. 1–6. [Google Scholar]

- Nejabatkhah, F.; Danyali, S.; Hosseini, S.H.; Sabahi, M.; Niapour, S.M. Modeling and Control of a New Three-Input Dc-Dc Boost Converter for Hybrid PV/FC/Battery Power System. IEEE Trans. Power Electron. 2012, 27, 2309–2324. [Google Scholar] [CrossRef]

- Argentini, S.; Pietroni, I.; Mastrantonio, G.; Viola, A.; Zilitinchevich, S. Characteristics of The Multiple-Input DC-DC Converter. In Proceedings of the IEEE Power Electronics Specialist Conference PESC ’93, Seattle, WA, USA, 20–24 June 1993; pp. 115–120. [Google Scholar]

- Dobbs, B.G.; Chapman, P.L. A Multiple-Input DC-DC Converter Topology. IEEE Power Electron. Lett. 2003, 1, 6–9. [Google Scholar] [CrossRef]

- Karthikeyan, V.; Gupta, R. Multiple-Input Configuration of Isolated Bidirectional DC–DC Converter for Power Flow Control in Combinational Battery Storage. IEEE Trans. Ind. Inform. 2018, 14, 2–11. [Google Scholar] [CrossRef]

- Ahrabi, R.R.; Ardi, H.; Elmi, M.; Ajami, A. A Novel Step-Up Multiinput DC–DC Converter for Hybrid Electric Vehicles Application. IEEE Trans. Power Electron. 2017, 32, 3549–3561. [Google Scholar] [CrossRef]

- Dezhbord, M.; Mohseni, P.; Hosseini, S.H.; Mirabbasi, D.; Islam, M.d.R. A High Step-Up Three-Port DC–DC Converter with Reduced Voltage Stress for Hybrid Energy Systems. IEEE J. Emerg. Sel. Top. Ind. Electron. 2022, 3, 998–1009. [Google Scholar] [CrossRef]

- Nazih, Y.; Abdel-Moneim, M.G.; Aboushady, A.A.; Abdel-Khalik, A.S.; Hamad, M.S. A Ring-Connected Dual Active Bridge Based DC-DC Multiport Converter for EV Fast-Charging Stations. IEEE Access 2022, 10, 52052–52066. [Google Scholar] [CrossRef]

- Jalilzadeh, T.; Rostami, N.; Babaei, E.; Hosseini, S.H. Bidirectional Multi-port Dc–Dc Converter with Low Voltage Stress on Switches and Diodes. IET Power Electron. 2020, 13, 1593–1604. [Google Scholar] [CrossRef]

- Ninma Jiya, I.; Van Khang, H.; Kishor, N.; Ciric, R.M. Novel Family of High-Gain Nonisolated Multiport Converters with Bipolar Symmetric Outputs for DC Microgrids. IEEE Trans. Power Electron. 2022, 37, 12151–12166. [Google Scholar] [CrossRef]

- Varesi, K.; Hosseini, S.H.; Sabahi, M.; Babaei, E. Modular Non-Isolated Multi-Input High Step-up Dc-Dc Converter with Reduced Normalised Voltage Stress and Component Count. IET Power Electron. 2018, 11, 1092–1100. [Google Scholar] [CrossRef]

- Varesi, K.; Hosseini, S.H.; Sabahi, M.; Babaei, E. A Multi-Port High Step-Up DC-DC Converter with Reduced Normalized Voltage Stress on Switches/Diodes. In Proceedings of the 9th Annual International Power Electronics, Drive Systems, and Technologies Conference, PEDSTC 2018, Tehran, Iran, 14–15 February 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Peng, F.Z. Z-Source Inverter. IEEE Trans. Ind. Appl. 2003, 39, 504–510. [Google Scholar] [CrossRef]

- Tang, Y.; Xie, S.; Zhang, C. An Improved Z-Source Inverter. IEEE Trans. Power Electron. 2011, 26, 3865–3868. [Google Scholar] [CrossRef]

- Shen, H.; Zhang, B.; Qiu, D.; Zhou, L. A Common Grounded Z-Source DC–DC Converter with High Voltage Gain. IEEE Trans. Ind. Electron. 2016, 63, 2925–2935. [Google Scholar] [CrossRef]

- Anderson, J.; Peng, F.Z. Four Quasi-Z-Source Inverters. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; IEEE: New York, NY, USA, 2008; pp. 2743–2749. [Google Scholar]

- Hosseini, S.M.; Ghazi, R.; Nikbahar, A.; Eydi, M. A New Enhanced-boost Switched-capacitor Quasi Z-source Network. IET Power Electron. 2021, 14, 412–421. [Google Scholar] [CrossRef]

- Torki Harchegani, A.; Asghari, A.; Jazaeri, M. A New Soft-switching Multi-input Quasi-Z-source Converter for Hybrid Sources Systems. IET Renew. Power Gener. 2021, 15, 1451–1468. [Google Scholar] [CrossRef]

- Biasini, R.; Onori, S.; Rizzoni, G. A Near-Optimal Rule-Based Energy Management Strategy for Medium Duty Hybrid Truck. Int. J. Powertrains 2013, 2, 232. [Google Scholar] [CrossRef]

- Petrović, D.J.; Lazić, M.M.; Lazić, B.V.J.; Blanuša, B.D.; Aleksić, S.O. Hybrid Power Supply System with Fuzzy Logic Controller: Power Control Algorithm, Main Properties, and Applications. J. Mod. Power Syst. Clean Energy 2021, 10, 923–931. [Google Scholar] [CrossRef]

- Ganguly, P.; Kalam, A.; Zayegh, A. Fuzzy Logic-Based Energy Management System of Stand-Alone Renewable Energy System for a Remote Area Power System. Aust. J. Electr. Electron. Eng. 2019, 16, 21–32. [Google Scholar] [CrossRef]

- Koulali, M.; Mankour, M.; Negadi, K.; Mezouar, A. Energy Management of Hybrid Power System PV Wind and Battery Based Three Level Converter. TECNICA ITALIANA-Ital. J. Eng. Sci. 2019, 63, 297–304. [Google Scholar] [CrossRef]

- Baset, D.A.-E.; Rezk, H.; Hamada, M. Fuzzy Logic Control Based Energy Management Strategy for Renewable Energy System. In Proceedings of the 2020 International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), Moscow, Russia, 12–14 March 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar]

- Teo, T.T.; Logenthiran, T.; Woo, W.L.; Abidi, K.; John, T.; Wade, N.S.; Greenwood, D.M.; Patsios, C.; Taylor, P.C. Optimization of Fuzzy Energy-Management System for Grid-Connected Microgrid Using NSGA-II. IEEE Trans. Cybern. 2021, 51, 5375–5386. [Google Scholar] [CrossRef]

- Zhang, Z.; Guan, C.; Liu, Z. Real-Time Optimization Energy Management Strategy for Fuel Cell Hybrid Ships Considering Power Sources Degradation. IEEE Access 2020, 8, 87046–87059. [Google Scholar] [CrossRef]

- Wang, T.; Li, Q.; Wang, X.; Qiu, Y.; Liu, M.; Meng, X.; Li, J.; Chen, W. An Optimized Energy Management Strategy for Fuel Cell Hybrid Power System Based on Maximum Efficiency Range Identification. J. Power Sources 2020, 445, 227333. [Google Scholar] [CrossRef]

- Kim, N.; Cha, S.; Peng, H. Optimal Control of Hybrid Electric Vehicles Based on Pontryagin’s Minimum Principle. IEEE Trans. Control Syst. Technol. 2011, 19, 1279–1287. [Google Scholar] [CrossRef]

- Yu, J.; Dou, C.; Li, X. MAS-Based Energy Management Strategies for a Hybrid Energy Generation System. IEEE Trans. Ind. Electron. 2016, 63, 3756–3764. [Google Scholar] [CrossRef]

- Garcia, P.; Garcia, C.A.; Fernandez, L.M.; Llorens, F.; Jurado, F. ANFIS-Based Control of a Grid-Connected Hybrid System Integrating Renewable Energies, Hydrogen and Batteries. IEEE Trans. Ind. Inform. 2014, 10, 1107–1117. [Google Scholar] [CrossRef]

- Li, Q.; Wang, T.; Dai, C.; Chen, W.; Ma, L. Power Management Strategy Based on Adaptive Droop Control for a Fuel Cell-Battery-Supercapacitor Hybrid Tramway. IEEE Trans. Veh. Technol. 2018, 67, 5658–5670. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Sun, F. Model Predictive Control for Power Management in a Plug-in Hybrid Electric Vehicle with a Hybrid Energy Storage System. Appl. Energy 2017, 185, 1654–1662. [Google Scholar] [CrossRef]

- Suthar, S.; Pindoriya, N.M. Energy Management Platform for Integrated Battery-Based Energy Storage—Solar PV System: A Case Study. IET Energy Syst. Integr. 2020, 2, 373–381. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Roy, T.K.; Pramanik, M.A.H.; Mahmud, M.A. A Nonlinear Double-integral Sliding Mode Controller Design for Hybrid Energy Storage Systems and Solar Photovoltaic Units to Enhance the Power Management in DC Microgrids. IET Gener. Transm. Distrib. 2022, 16, 2228–2241. [Google Scholar] [CrossRef]

- Liu, K.; Wang, R.; Wang, X.; Wang, X. Anti-saturation adaptive finite-time neural network based fault-tolerant tracking control for a quadrotor UAV with external disturbances. Aerosp. Sci. Technol. 2021, 115, 106790. [Google Scholar] [CrossRef]

| Open-circuit voltage VOC (V) | 22.77 V |

| Short-circuit current ISC (A) | 5.86 A |

| Voltage at maximum power point Vmp (V) | 18.3 V |

| Current at maximum power point Imp (A) | 5.5 A |

| Components | Values |

|---|---|

| L1a, L2a, L1b, L2b, L3a, L3b | 100 µH |

| C1, C3 | 47 µF |

| C2 | 470 µF |

| Cm1, Cm2 | 470 µF |

| Co | 680 µF |

| CPV, CWind | 470 µF |

| CZ1, CZ2 | 33 µF |

| LZ1, LZ2 | 100 µH |

| Load 1 | 440 ohm, 33 µH |

| Load 2 | 680 ohm |

| Reference | Adv./Disadv. | Response Time | Complexity | No. of Inputs |

|---|---|---|---|---|

| [25] | Fuel economy is good; system durability is high; complex system, limited application area. | − | High | Three inputs (fuel cell, battery, and super capacitor), |

| [27] | Reasonable assumptions; complex system. | + | High | |

| [28] | Long decision-making time; complex system. | − | High | Three inputs (PV, wind turbine, and battery). |

| [29] | Hybrid sources; needs datasets. | + | Medium | Five inputs (grid, PV, wind turbine, fuel cell, and battery). |

| [31] | Can predict the future; large-scale operations are difficult; needs datasets. | + | Medium | Two inputs (LTO, Li-Ti-O battery; NCM, Ni-Co-Mn battery). |

| Proposed System | No mathematical algorithm; fuzzy rules; can adapt high number of sources. | + | Low | N numbered (any type of source, including renewable sources). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Say, G.; Hosseini, S.H.; Esmaili, P. Hybrid Source Multi-Port Quasi-Z-Source Converter with Fuzzy-Logic-Based Energy Management. Energies 2023, 16, 4801. https://doi.org/10.3390/en16124801

Say G, Hosseini SH, Esmaili P. Hybrid Source Multi-Port Quasi-Z-Source Converter with Fuzzy-Logic-Based Energy Management. Energies. 2023; 16(12):4801. https://doi.org/10.3390/en16124801

Chicago/Turabian StyleSay, Gorkem, Seyed Hossein Hosseini, and Parvaneh Esmaili. 2023. "Hybrid Source Multi-Port Quasi-Z-Source Converter with Fuzzy-Logic-Based Energy Management" Energies 16, no. 12: 4801. https://doi.org/10.3390/en16124801

APA StyleSay, G., Hosseini, S. H., & Esmaili, P. (2023). Hybrid Source Multi-Port Quasi-Z-Source Converter with Fuzzy-Logic-Based Energy Management. Energies, 16(12), 4801. https://doi.org/10.3390/en16124801