Investigation of the Impact of Natural Fracture Geomechanics on the Efficiency of Oil Production and CO2 Injection from/to a Petroleum Structure: A Case Study

Abstract

1. Introduction

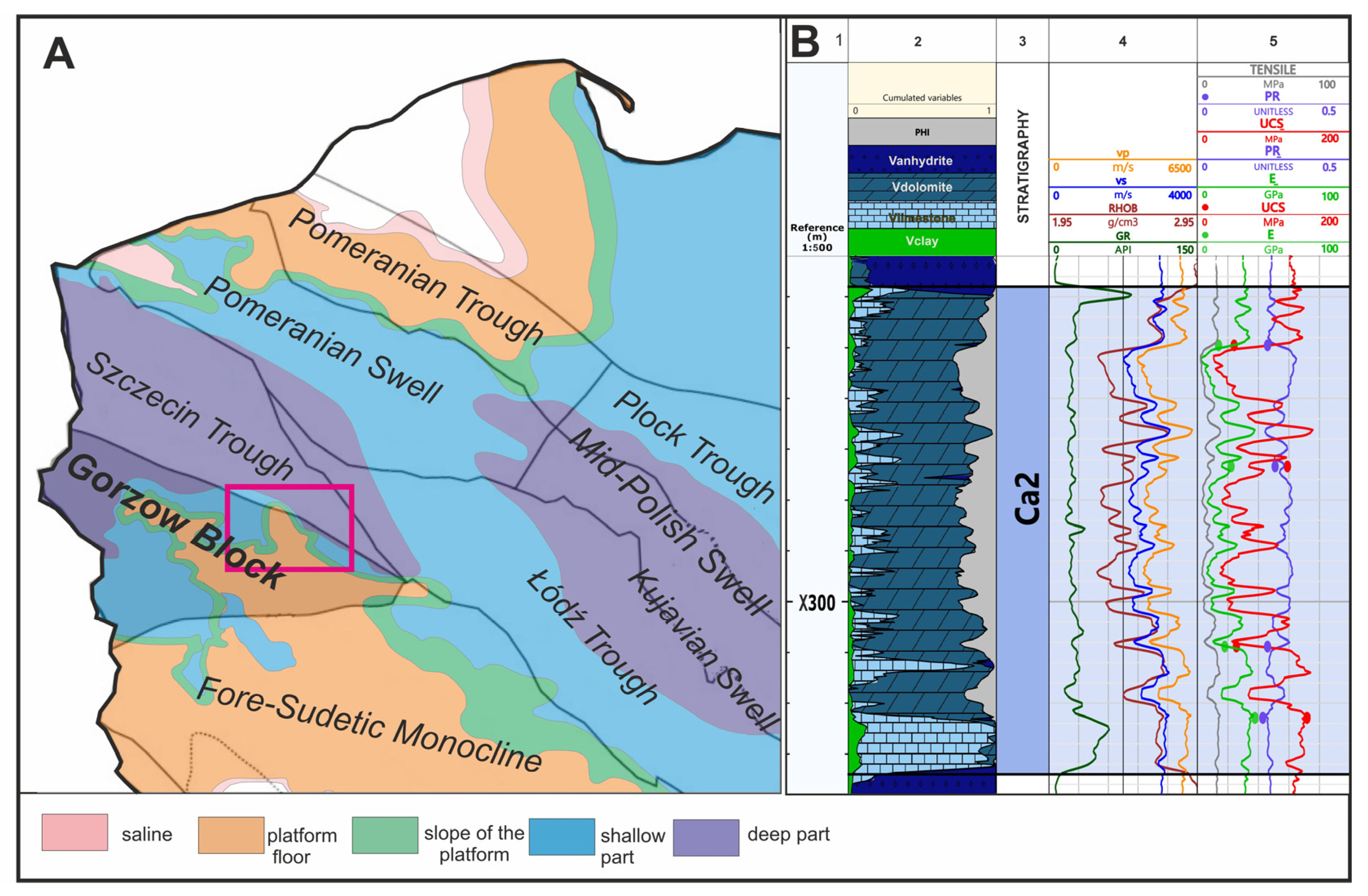

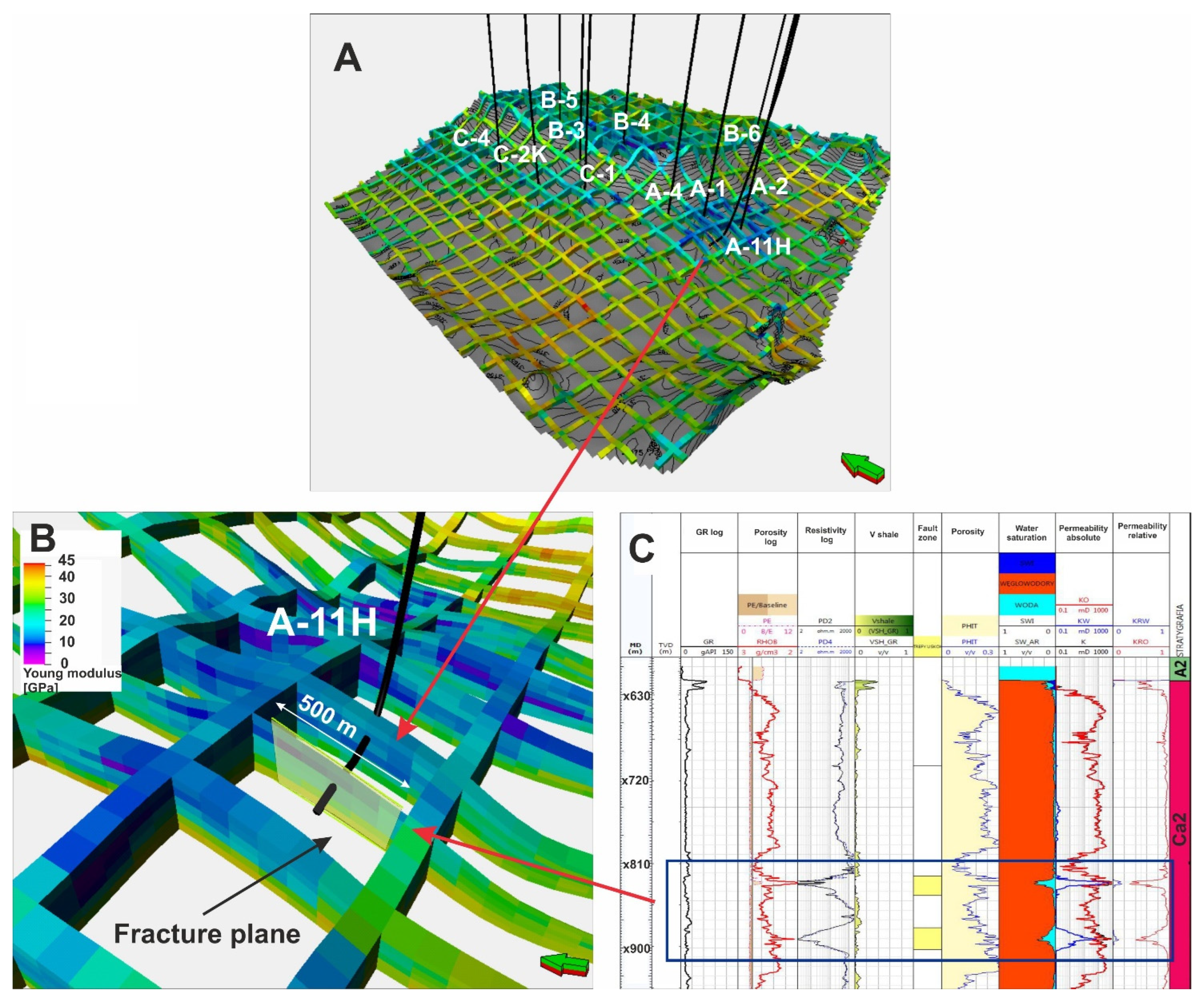

Geological Setting

2. Geomechanical Effects on EOR Performance

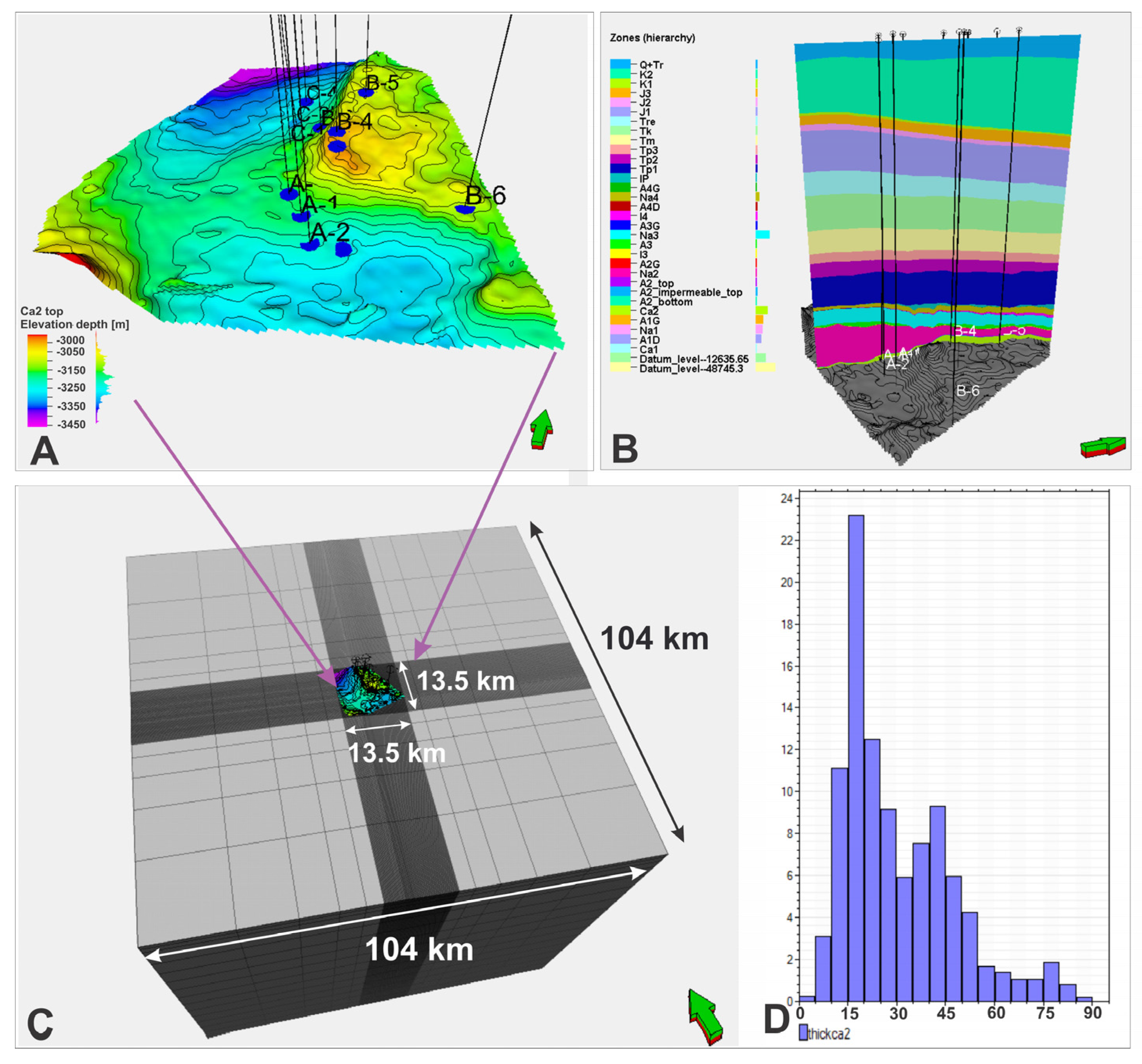

3. Geological Modeling

3.1. Structural Modeling

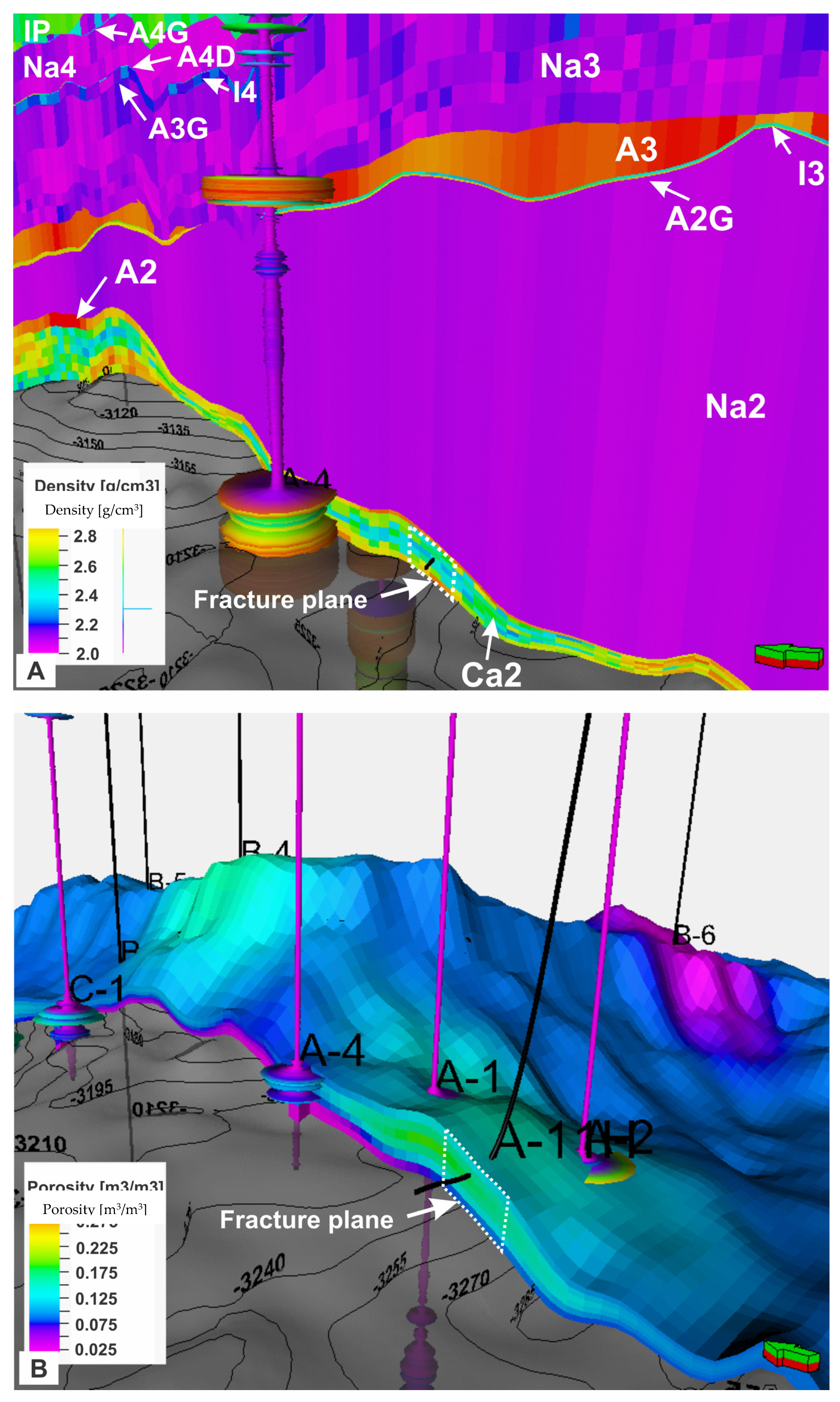

3.2. Petrophysical Properties

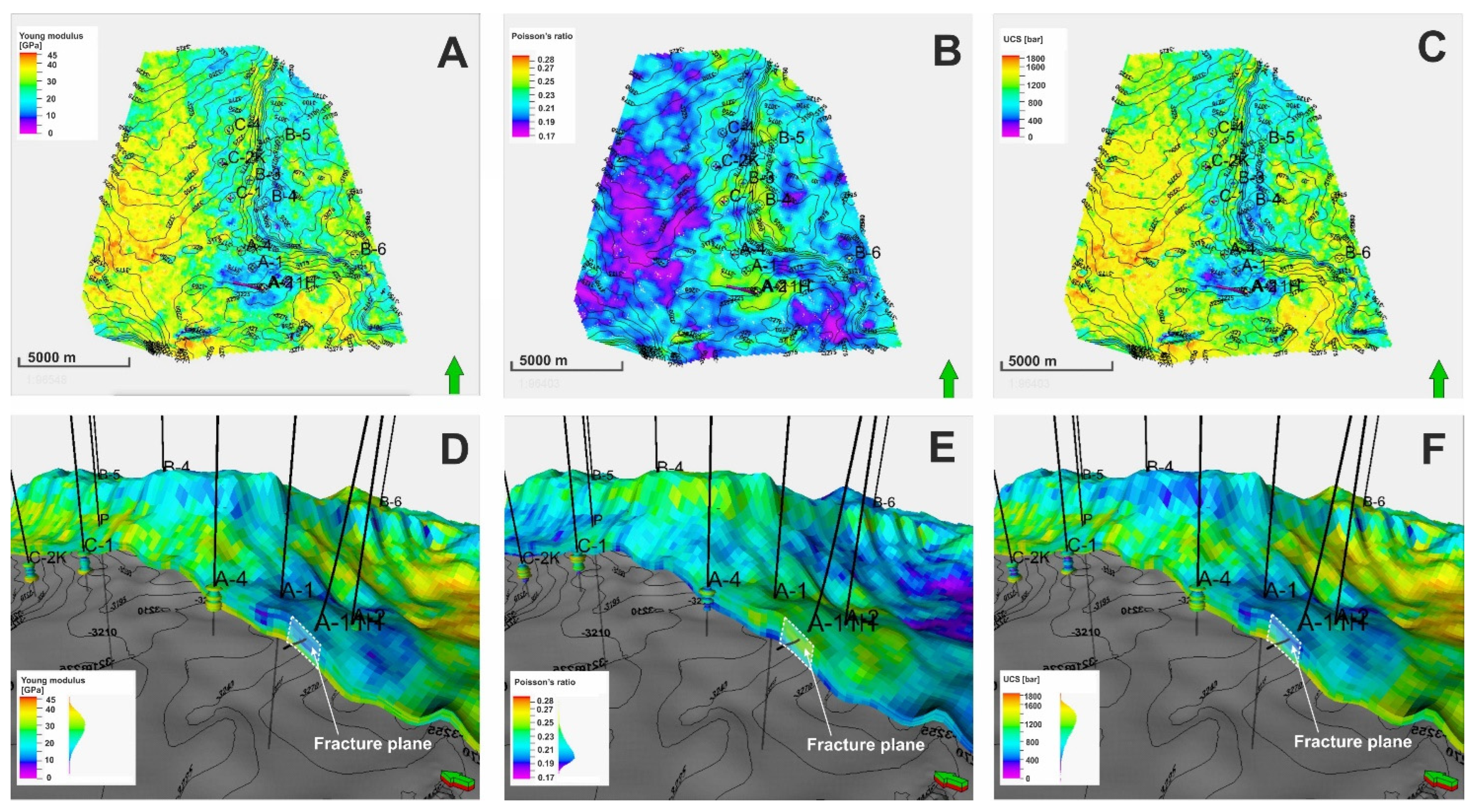

4. Geomechanical Modeling

4.1. Modeling of Geomechanical Properties

4.2. Fracture Properties

4.3. Boundary Conditions

5. Dynamical Modeling

- -

- Initial distributions of reservoir fluids (oil, gas, and water) under the hydrostatically balanced conditions were generated with the J-Leverett function [85] approach so that the fluid saturation depth profiles, as determined from geophysical measurements in all the wells, were reproduced;

- -

- Reservoir fluid transport properties (relative permeabilities)—a standard power-like Brooks–Corey model [86], krx = krx,max (x = w,o,g), was adopted for the relative permeability, krx, and dependence upon the reduced fluid saturation, Srx, where . The exponent nx and endpoint parameters krx,max, Sx,min, and Sx,max were determined in the model calibration procedure, and their values are given in Table 4. Detailed information on the calibration procedure is given in Section 7.

- -

- A reservoir, hydrocarbon fluid thermodynamical model—a compositional, thermodynamical model of the reservoir hydrocarbon fluid (oil and gas) was constructed and calibrated independently of the reservoir model the history matching procedure, and using the measurement data obtained from the laboratory PVT studies [87], including the pressure of the saturation point, flash tests, differential liberation tests, and separator tests. The model employed the Soave–Redlich–Kwong equation of state and Lorenz–Bray–Clark viscosity model and was characterized by a complete set of EOS parameters for the effective eight-component fluid including both hydrocarbon and non-hydrocarbon ones (Table 5).

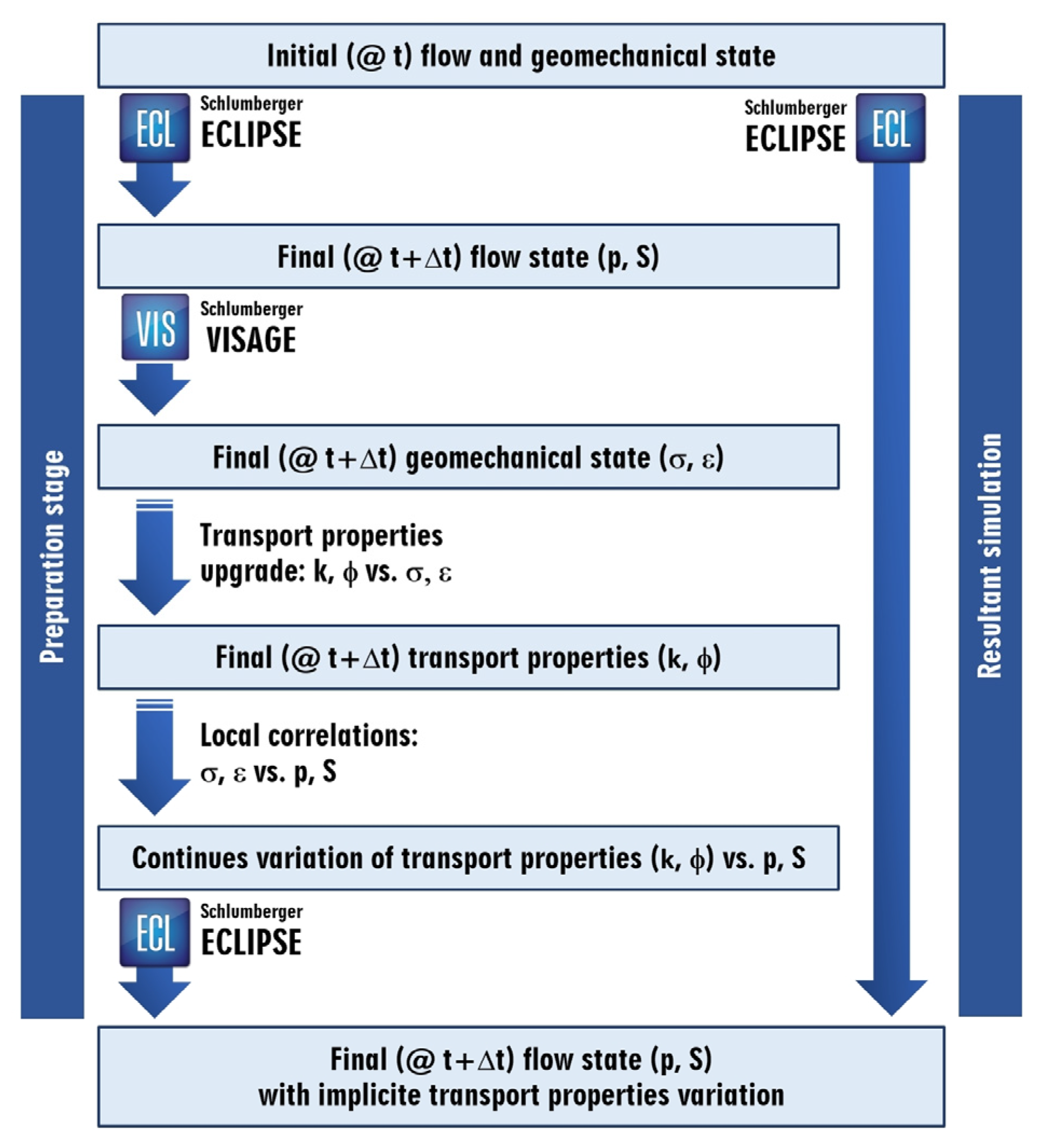

6. Two-Way Simulation Coupling

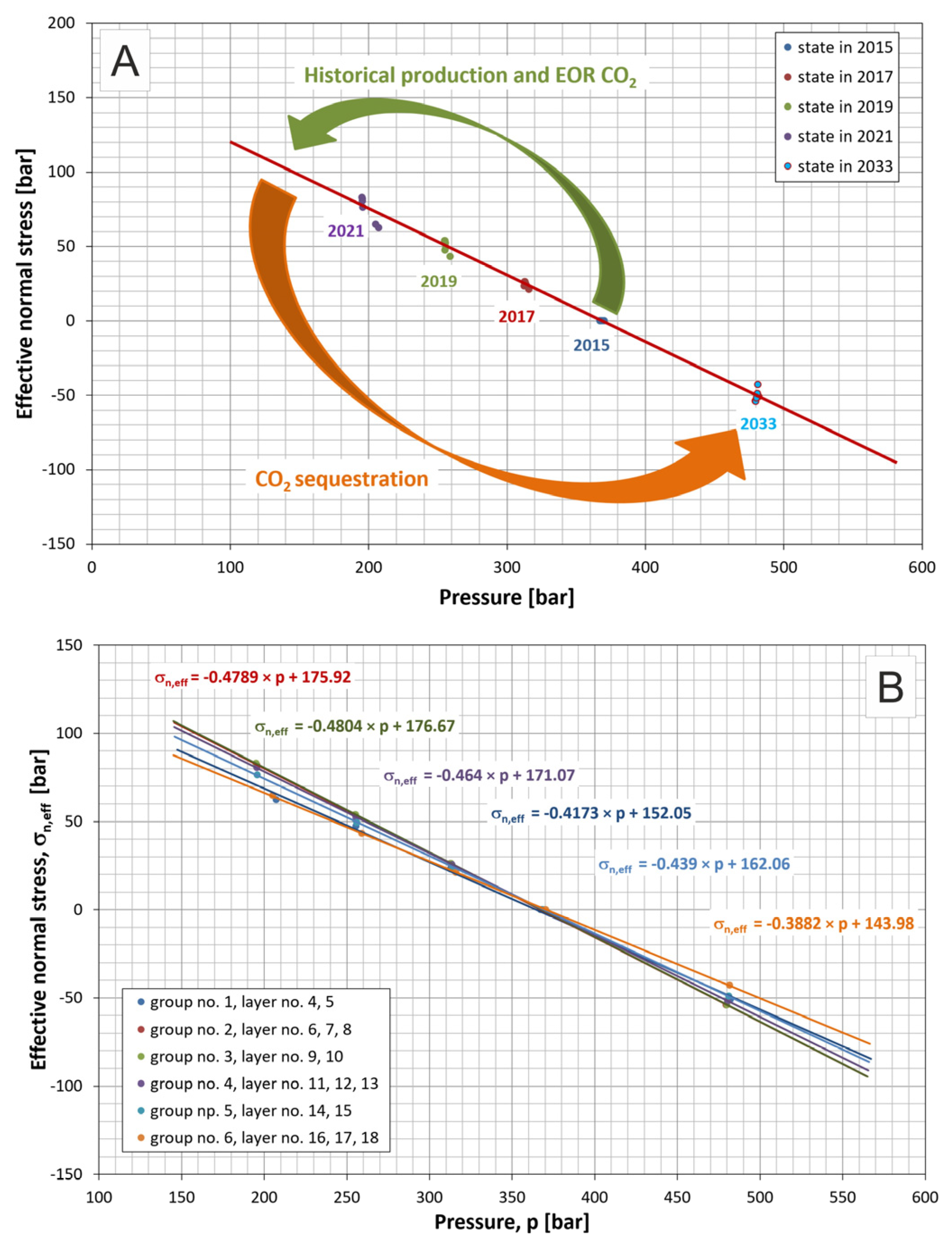

6.1. Correlation of Geomechanical State and Transport Parameters

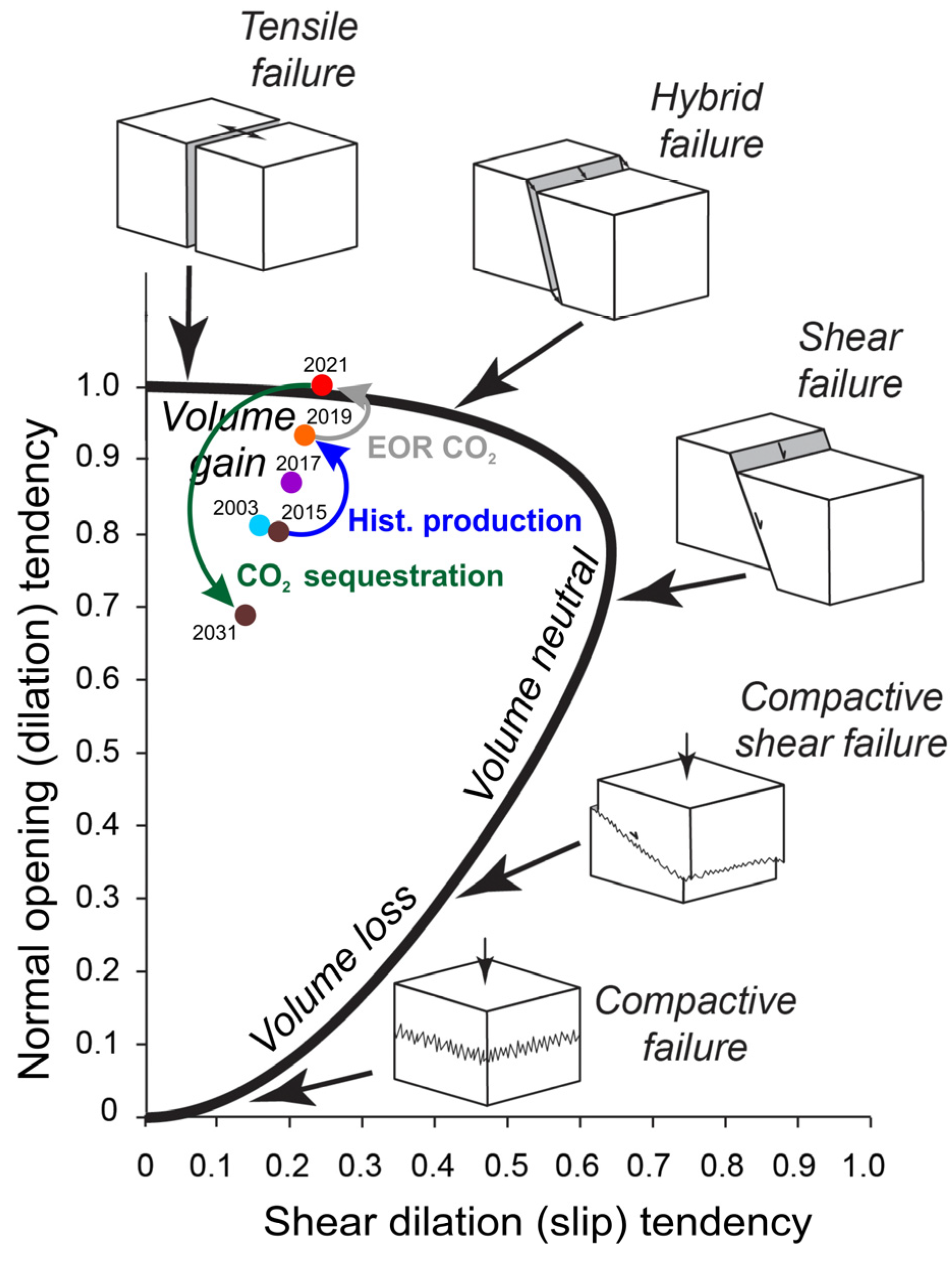

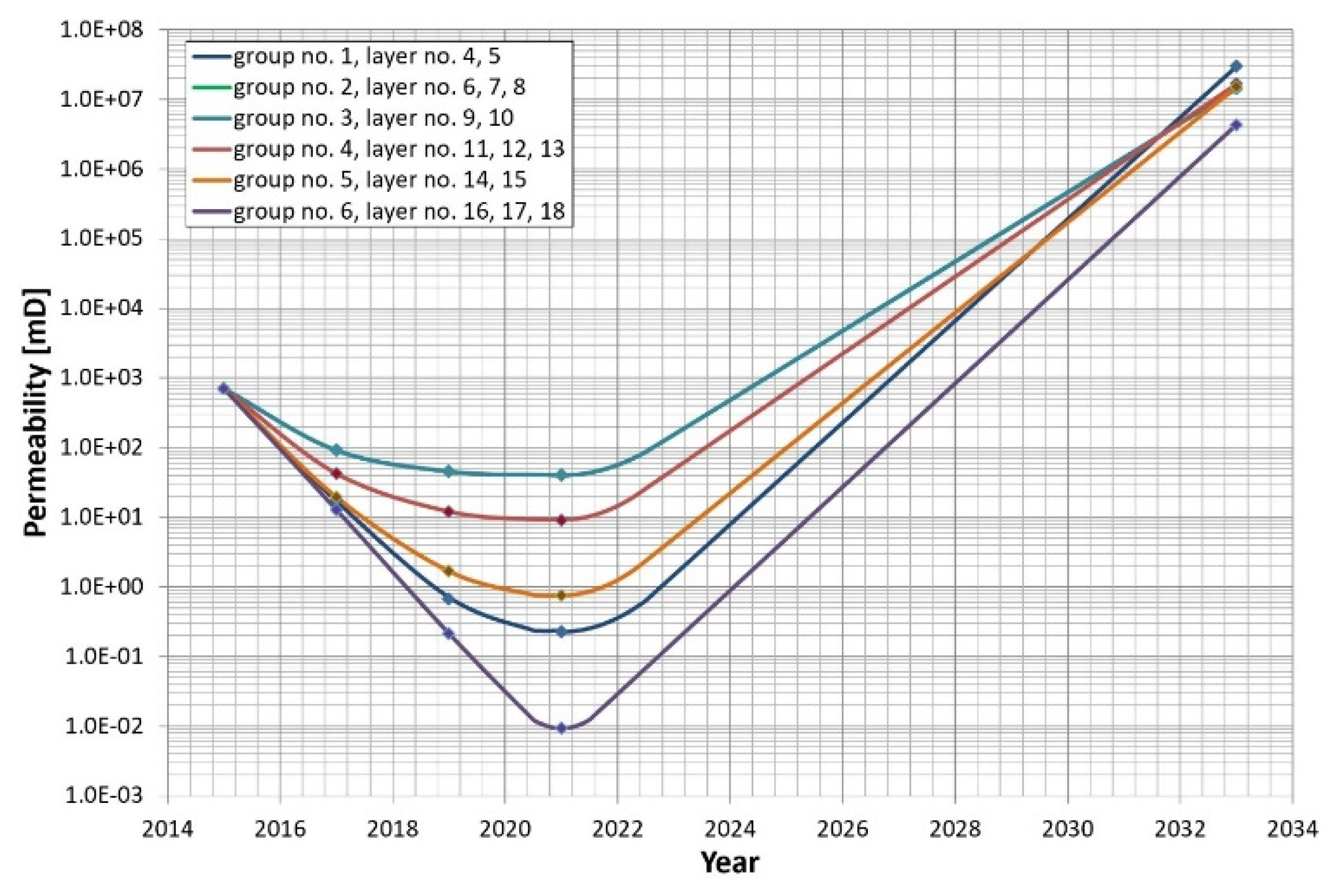

6.2. Fracture Response to Changes in Geomechanical State

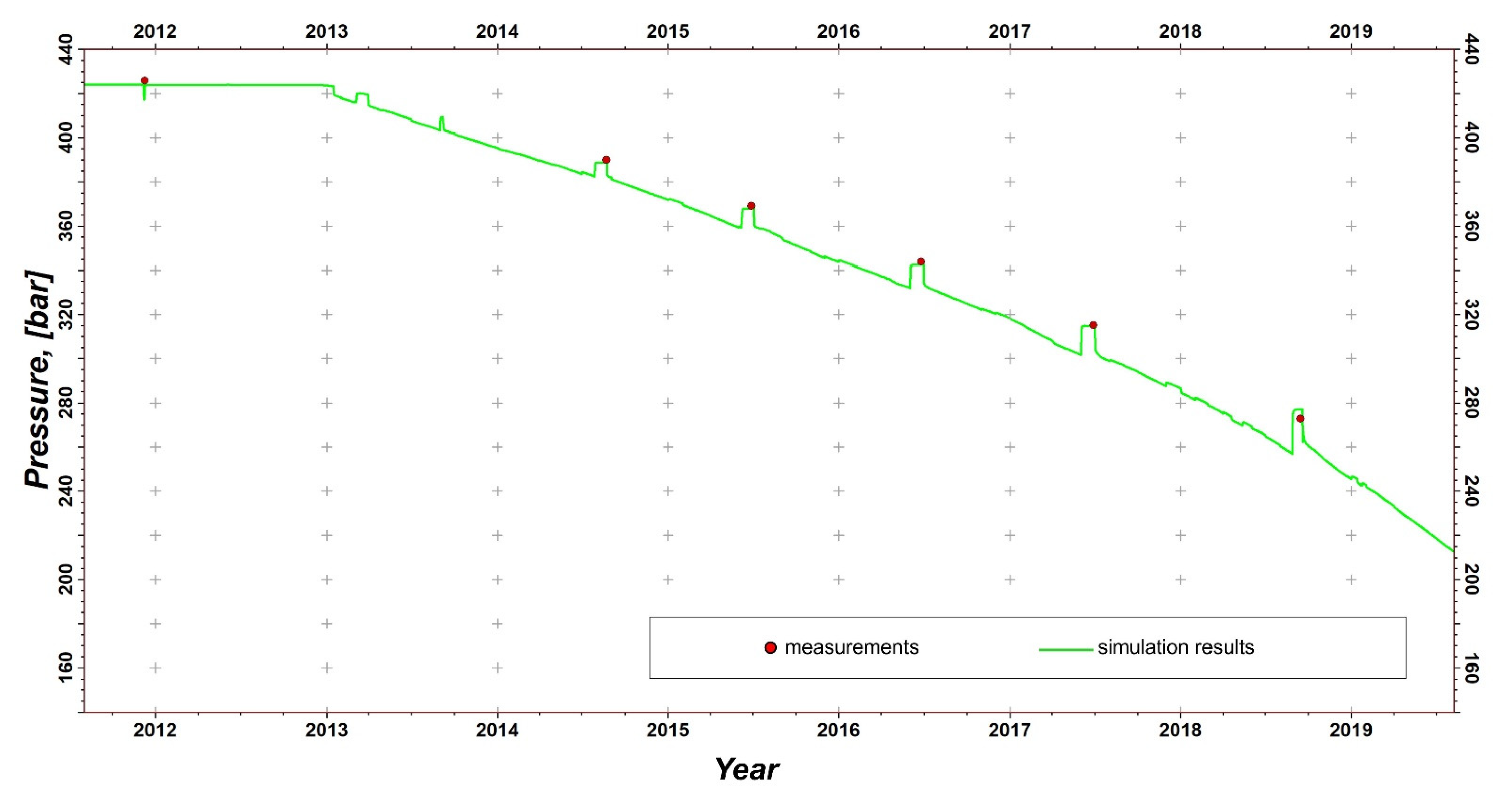

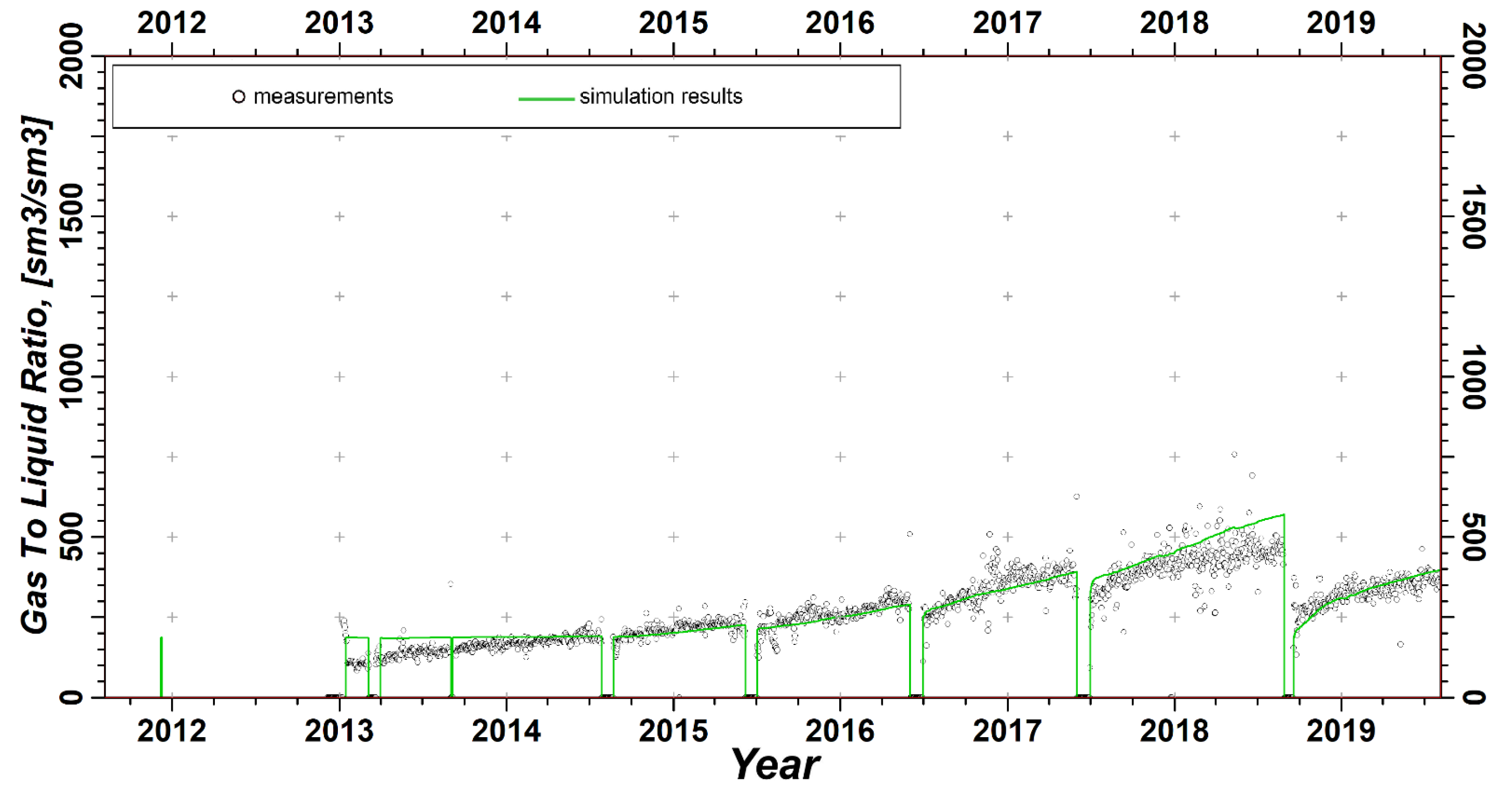

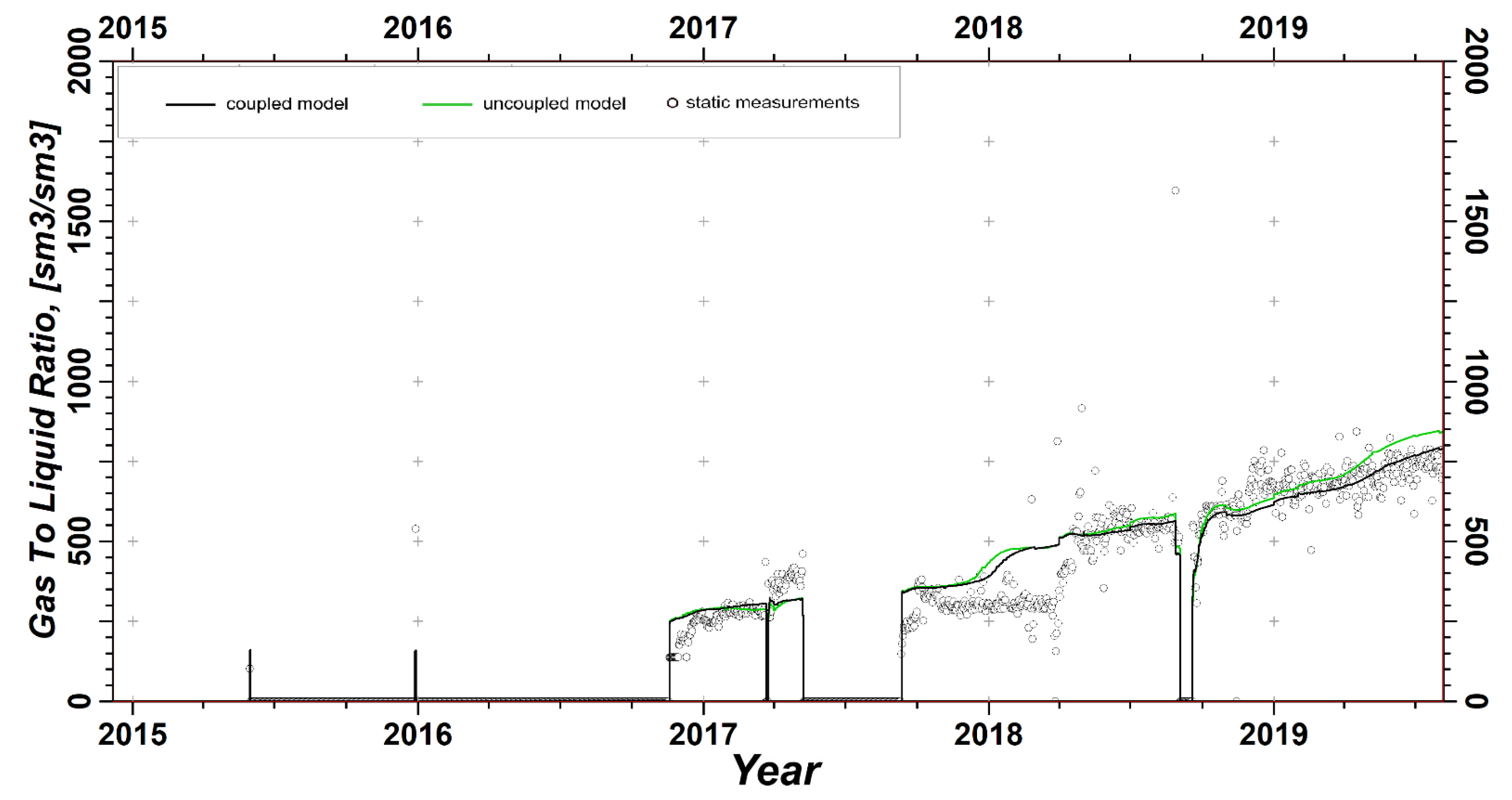

7. Model Calibration

7.1. Calibration Results

7.2. Model Characterization after Calibration

- -

- Total area of the model: 234.0 km2 = 15.2 × 15.3 km;

- -

- Model type: single porosity and permeability;

- -

- Lateral dimensions of the model grid: 160 × 152 blocks;

- -

- Lateral sizes of model blocks: 100 × 100 m;

- -

- Lateral dimensions of the refined model zone: 5–25 × 100 m;

- -

- Layered structure: 15 layers;

- -

- Number of active blocks: 29,464;

- -

- Initial contact depth:

- ▪

- Oil–water contact: 3282 m b.s.l.;

- ▪

- Gas–oil contact: 3178 m b.s.l.;

- -

- Initial pressure: 430.2 bar (@ 3282 m b.s.l.);

- -

- Reservoir temperature (constant): 126.8 °C;

- -

- Total model pore volume: 50.84 million m3;

- -

- Average values of parameters:

- ▪

- Porosity: 9.6%;

- ▪

- Horizontal permeability: 52.52 mD;

- ▪

- Vertical permeability: 6.37 mD;

- ▪

- Average thickness of a single simulation layer: 2.46 m.

8. Simulation Results of Production/Injection Forecasts

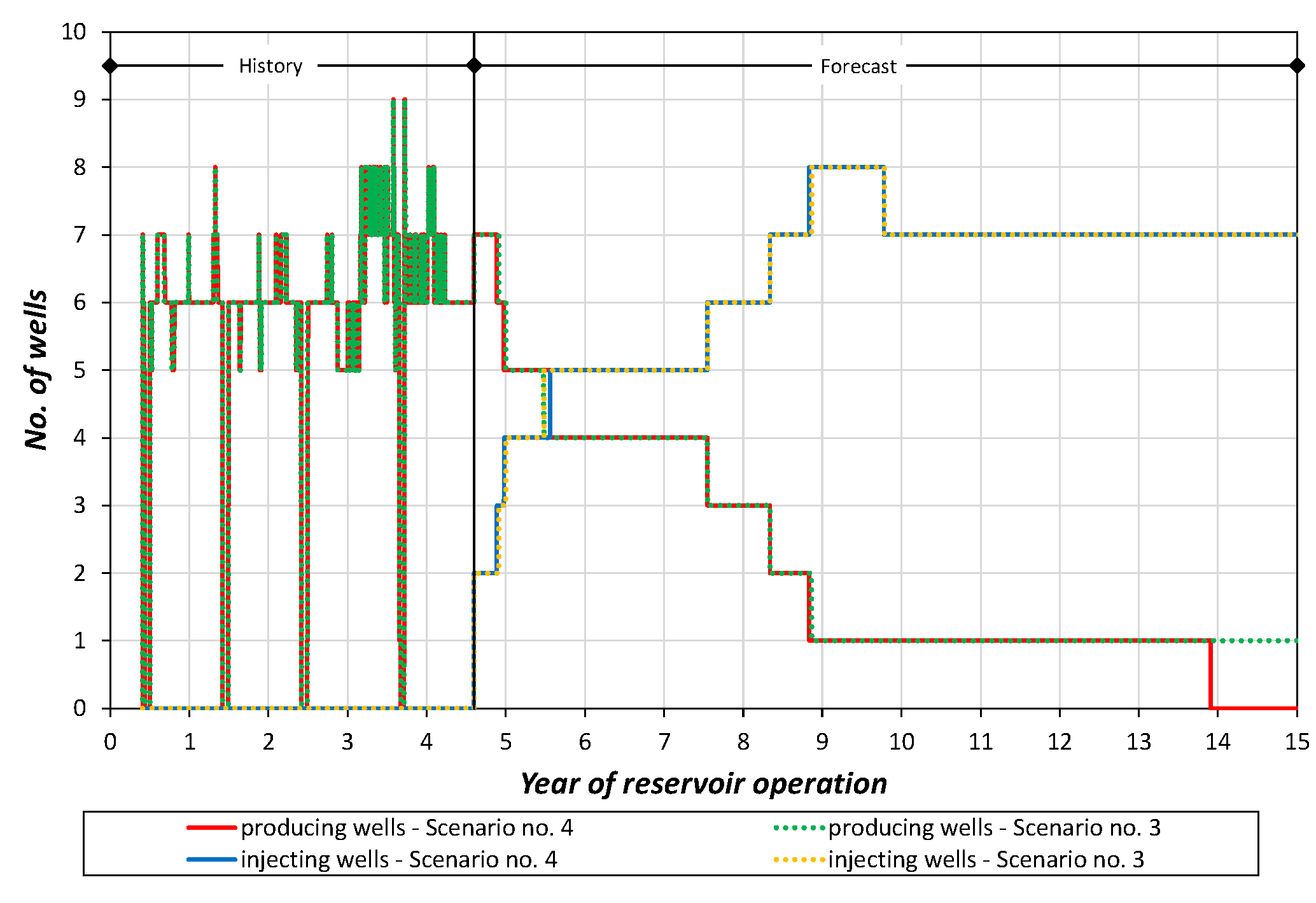

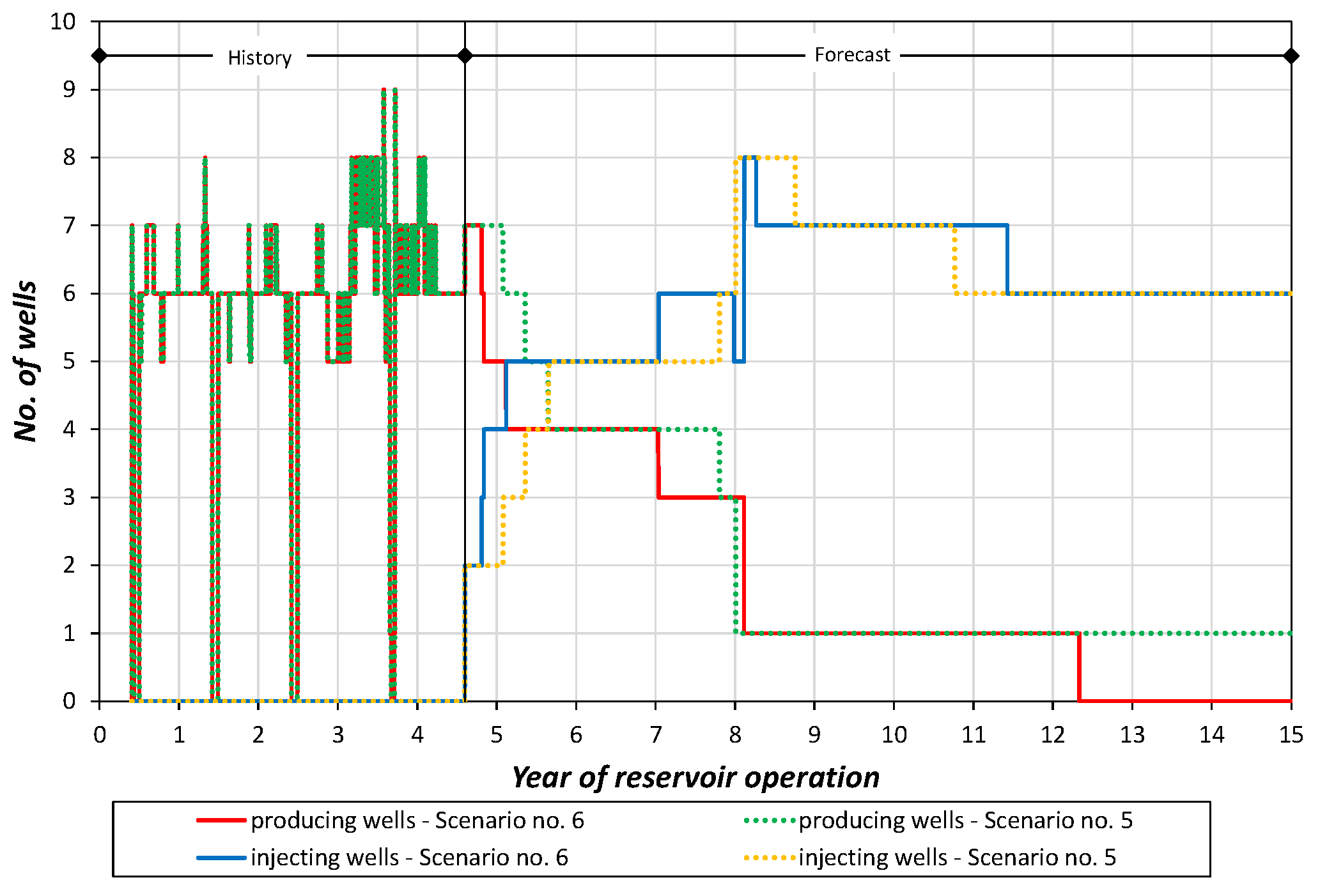

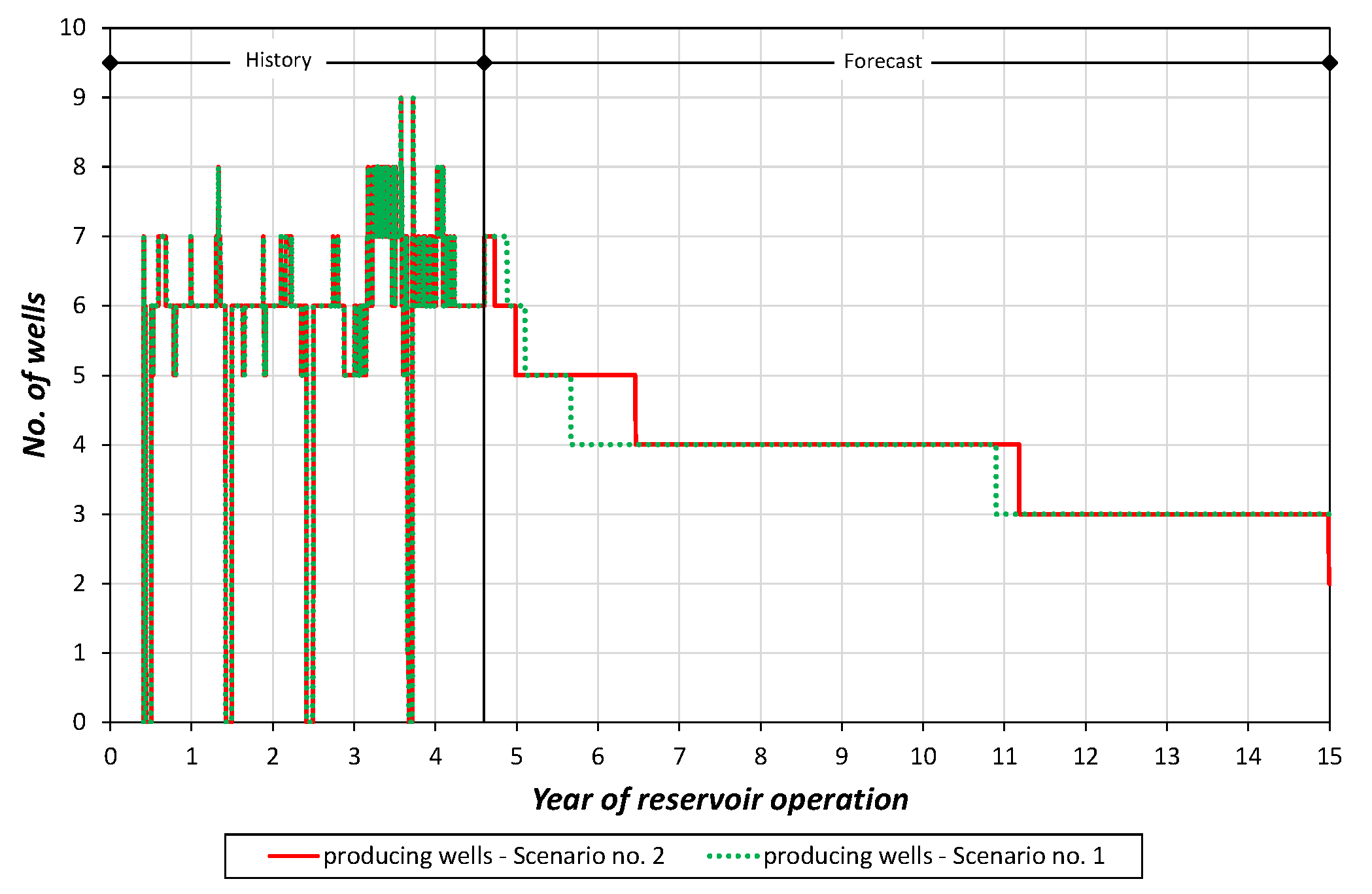

8.1. Technical and Operational Conditions of Production/Injection Forecasts

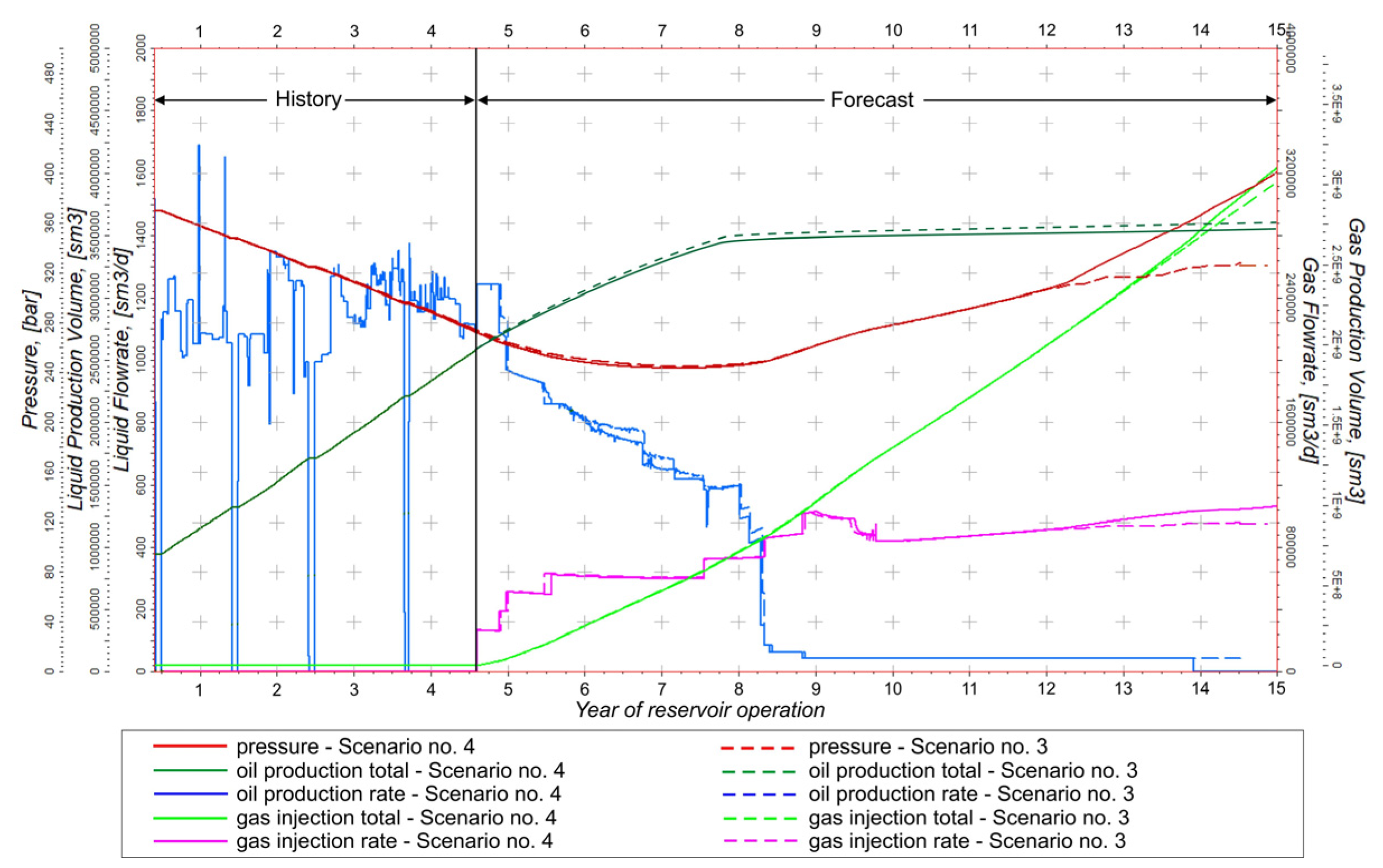

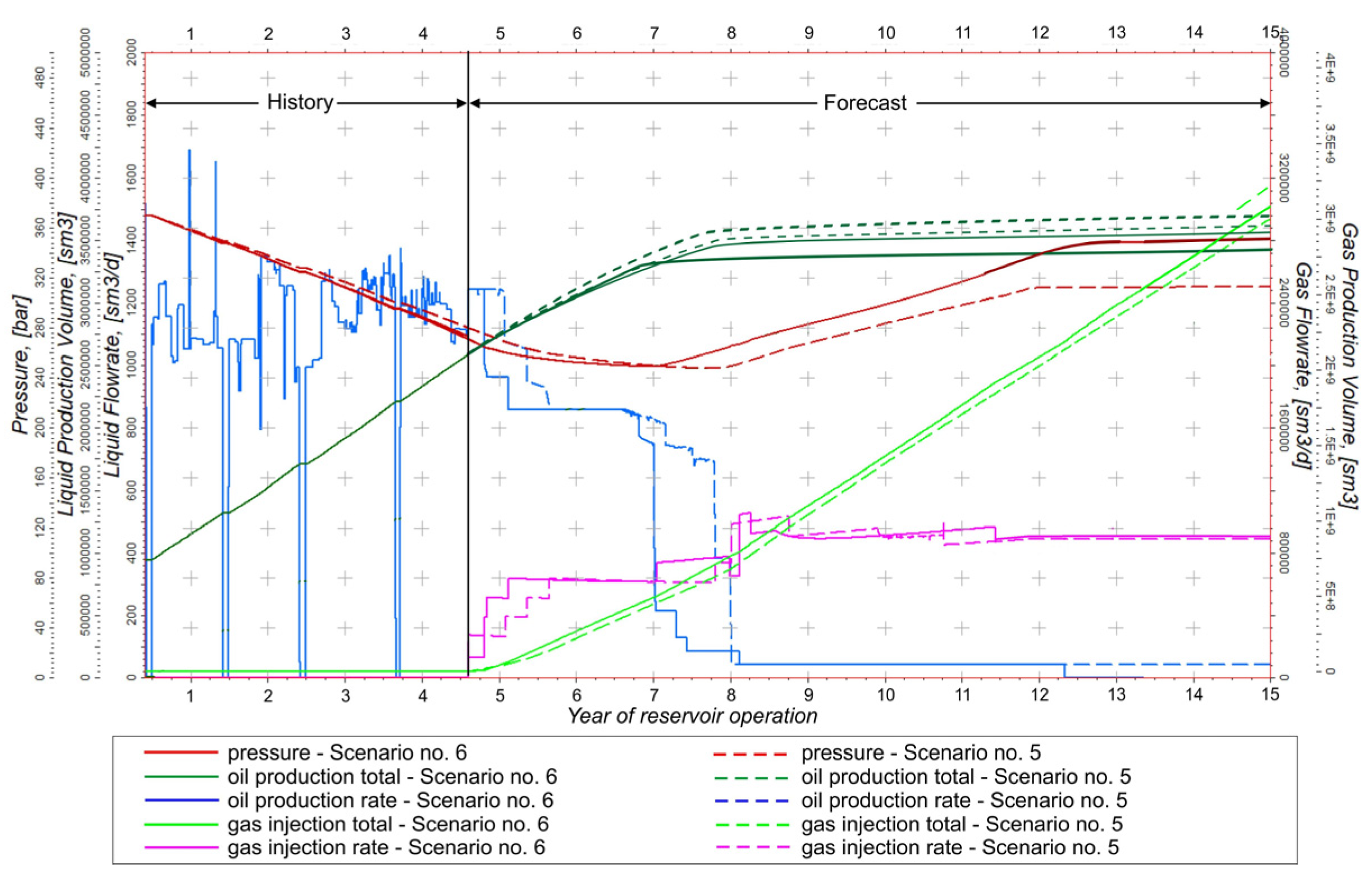

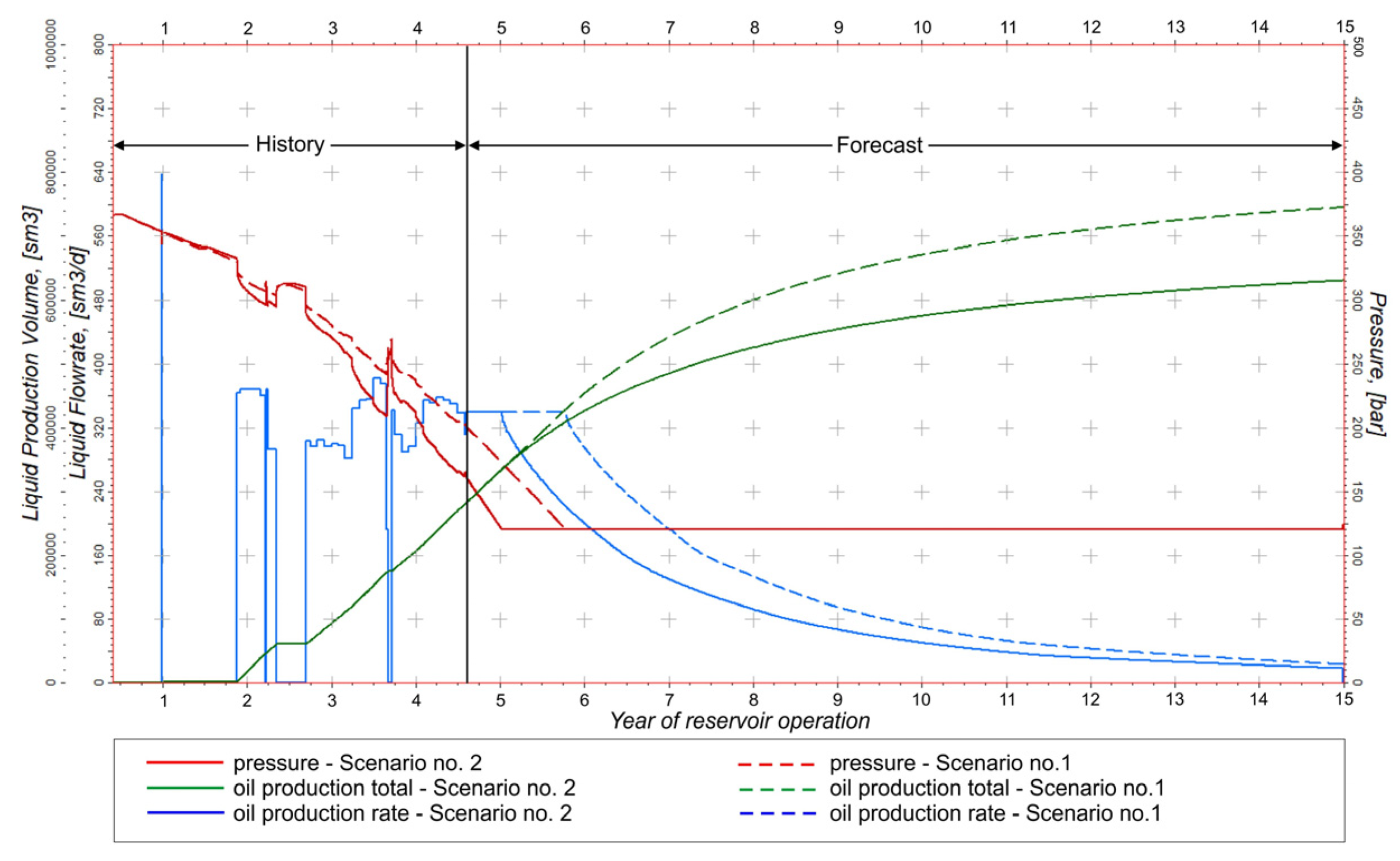

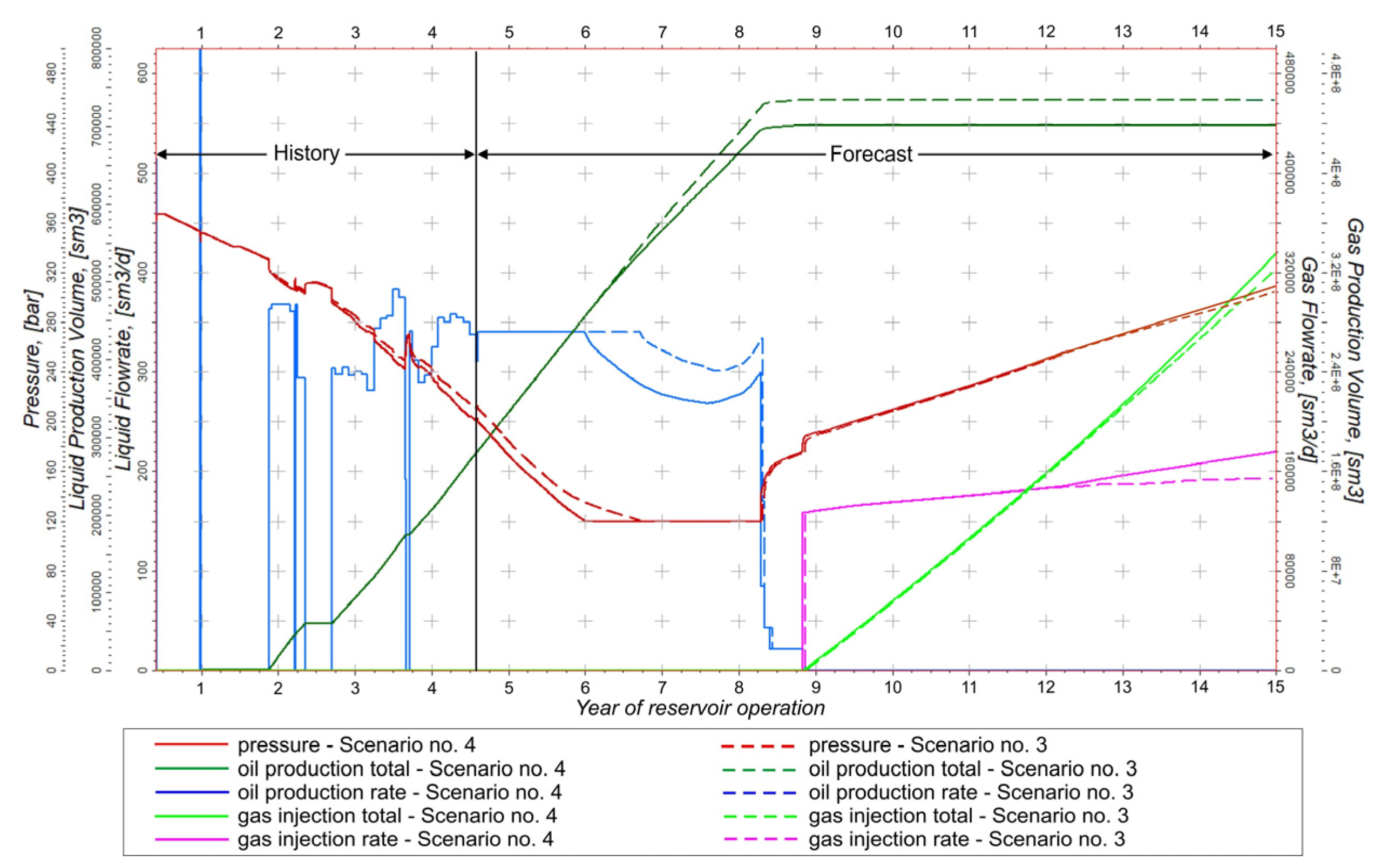

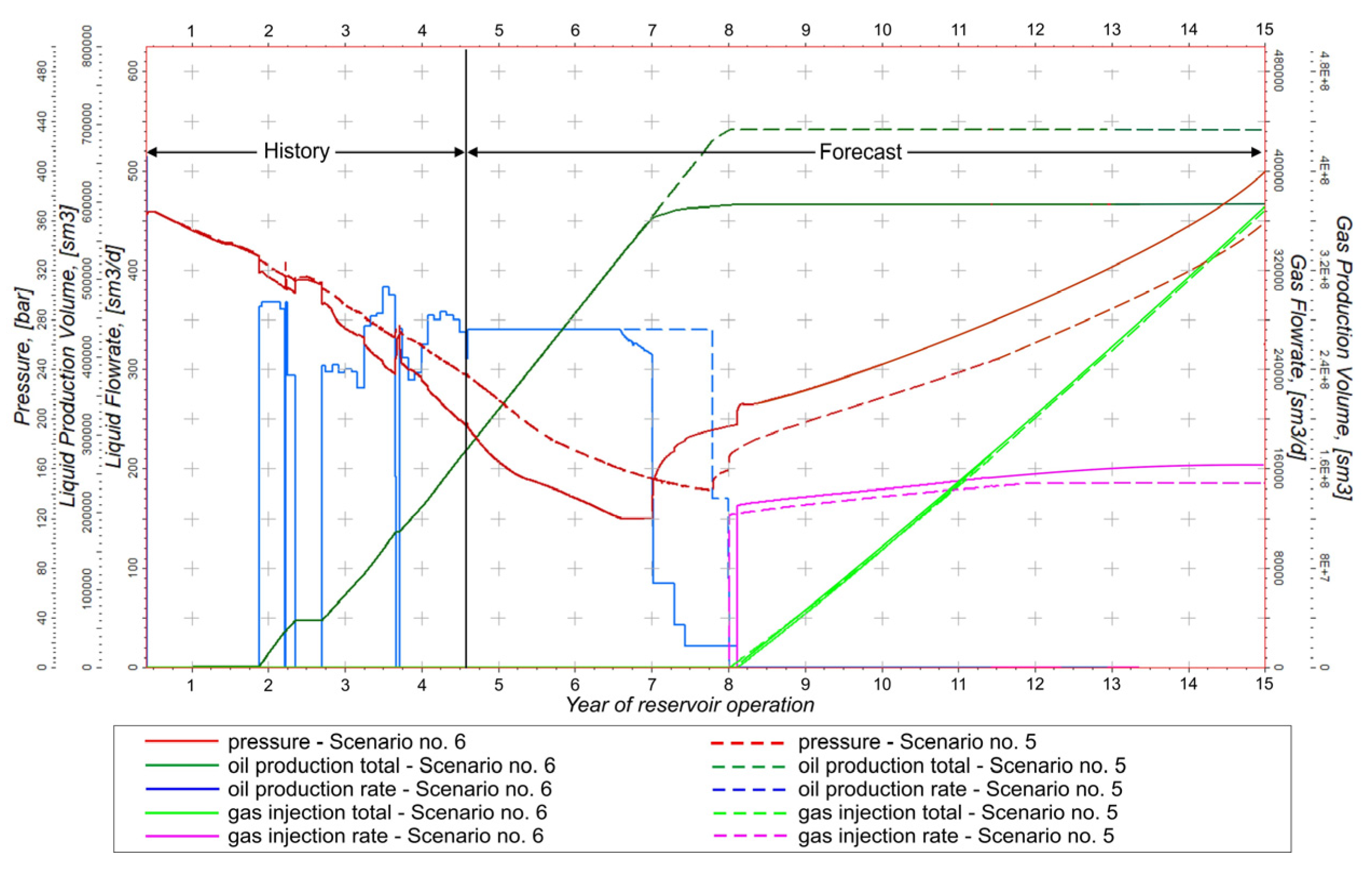

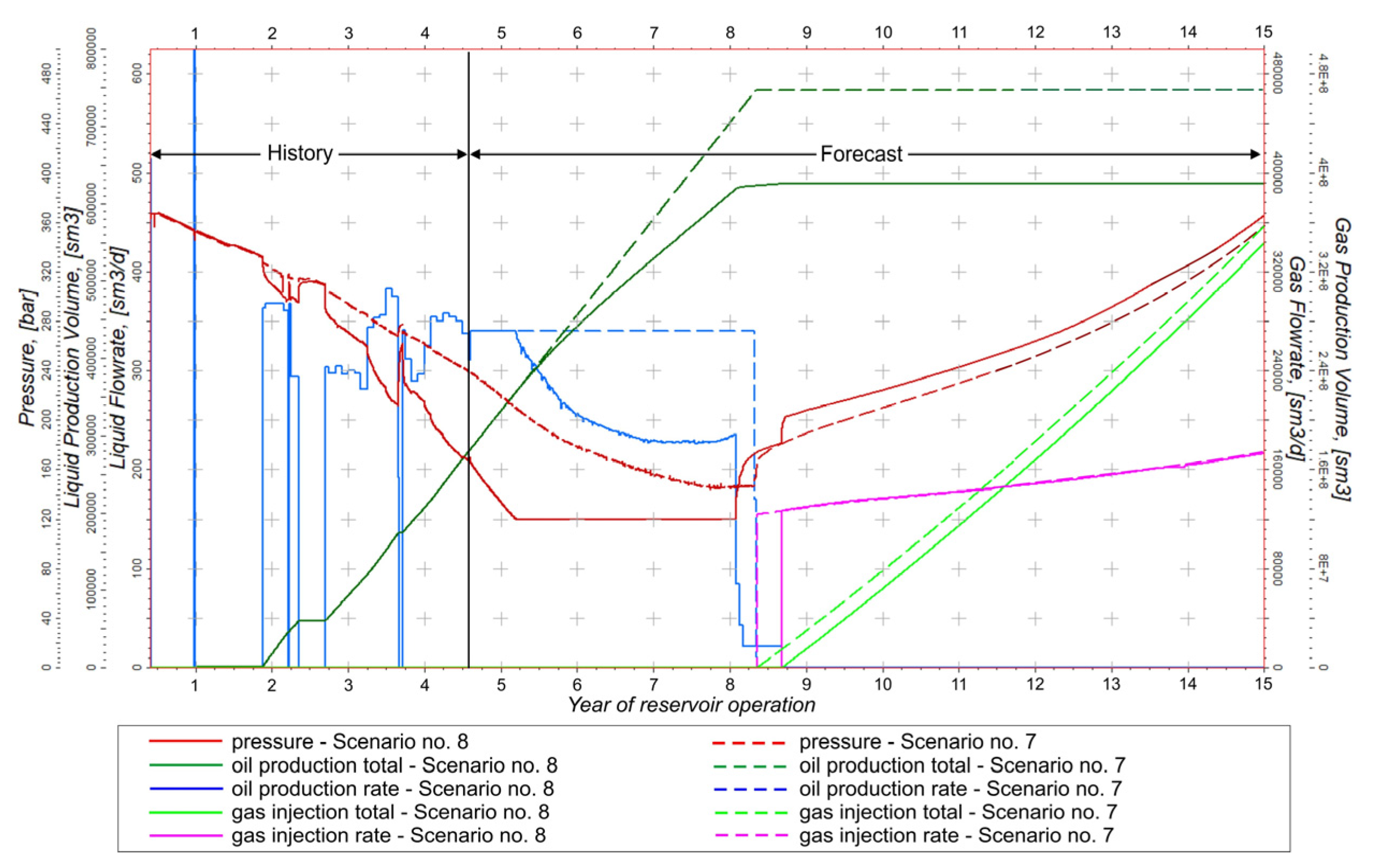

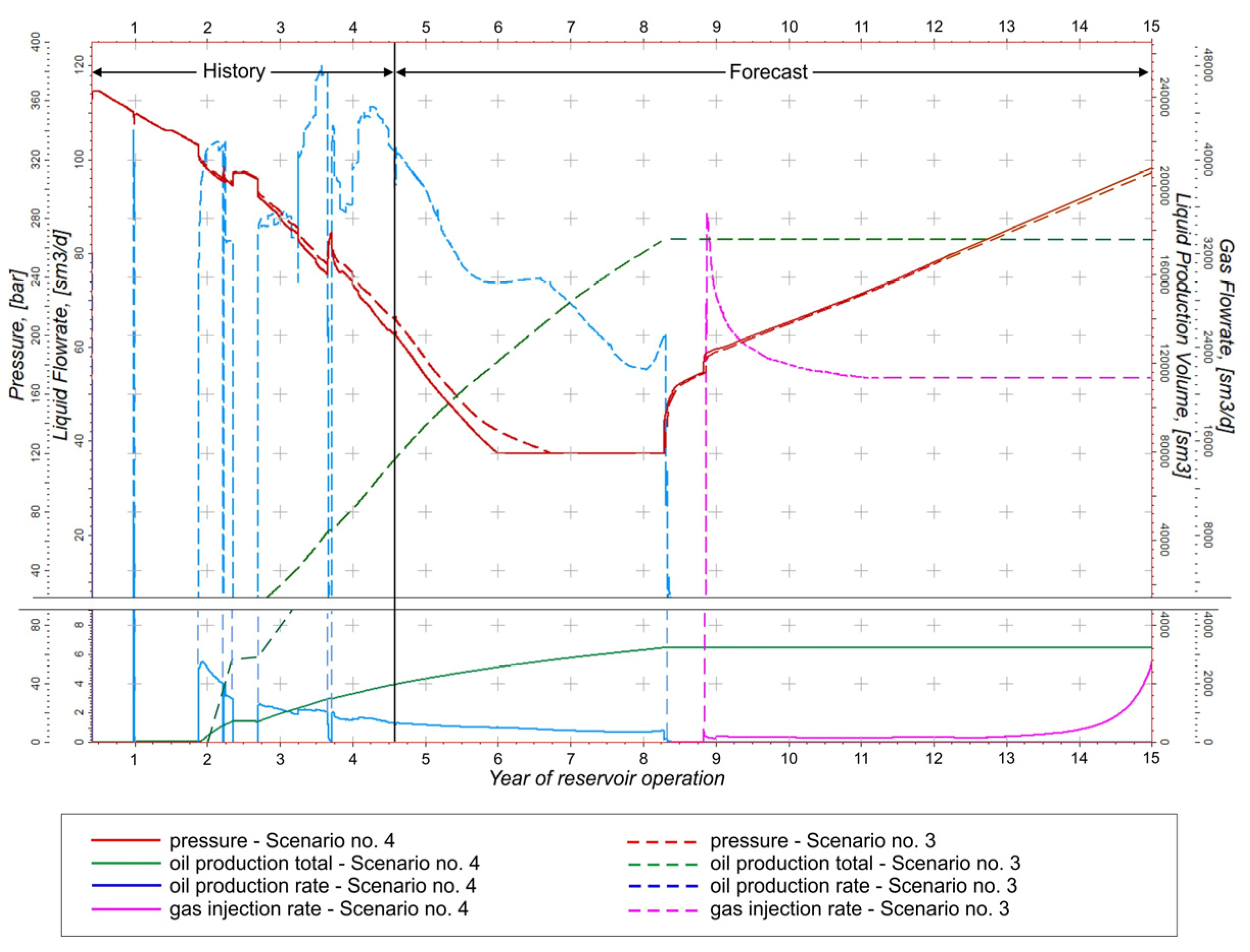

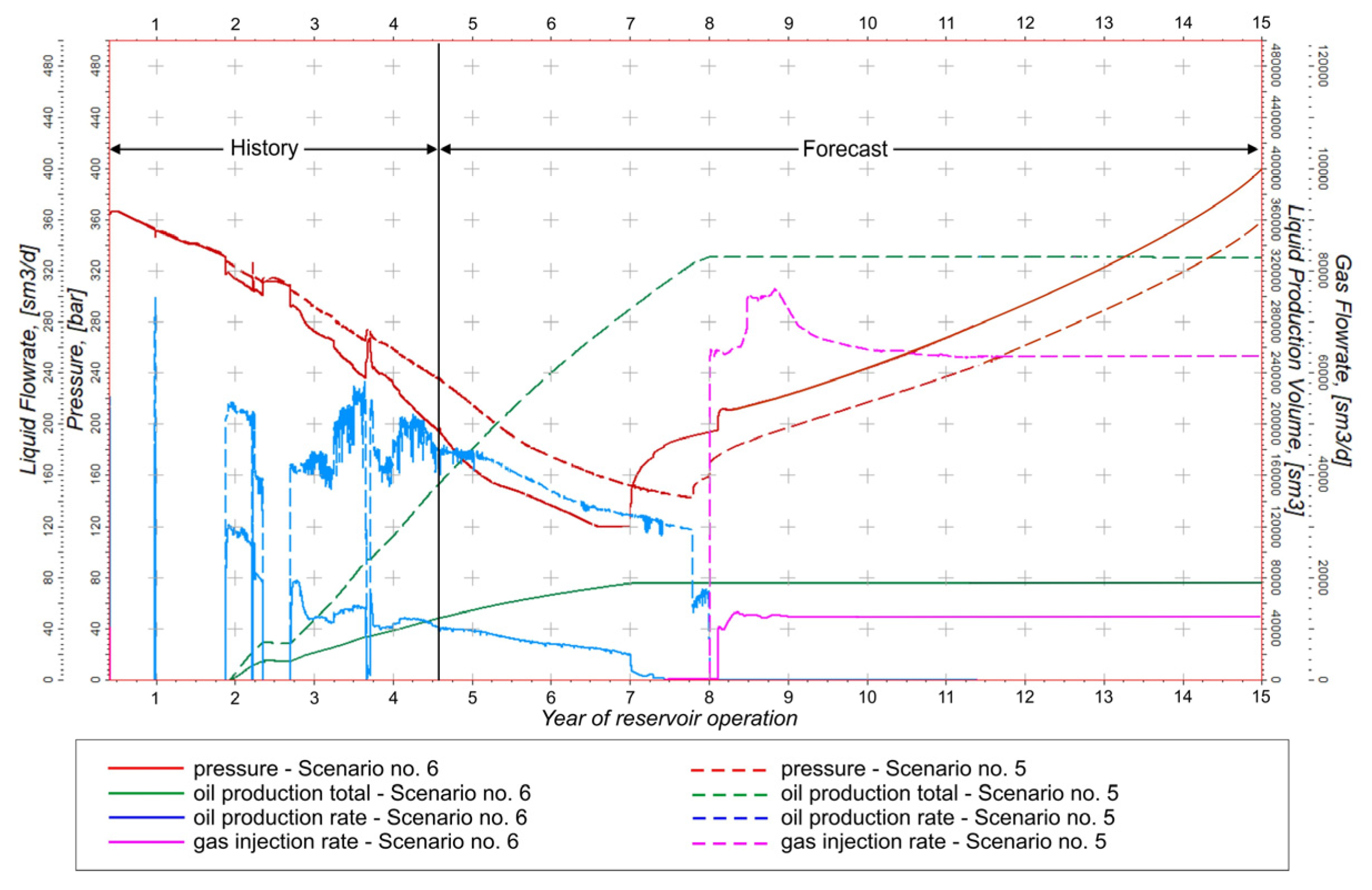

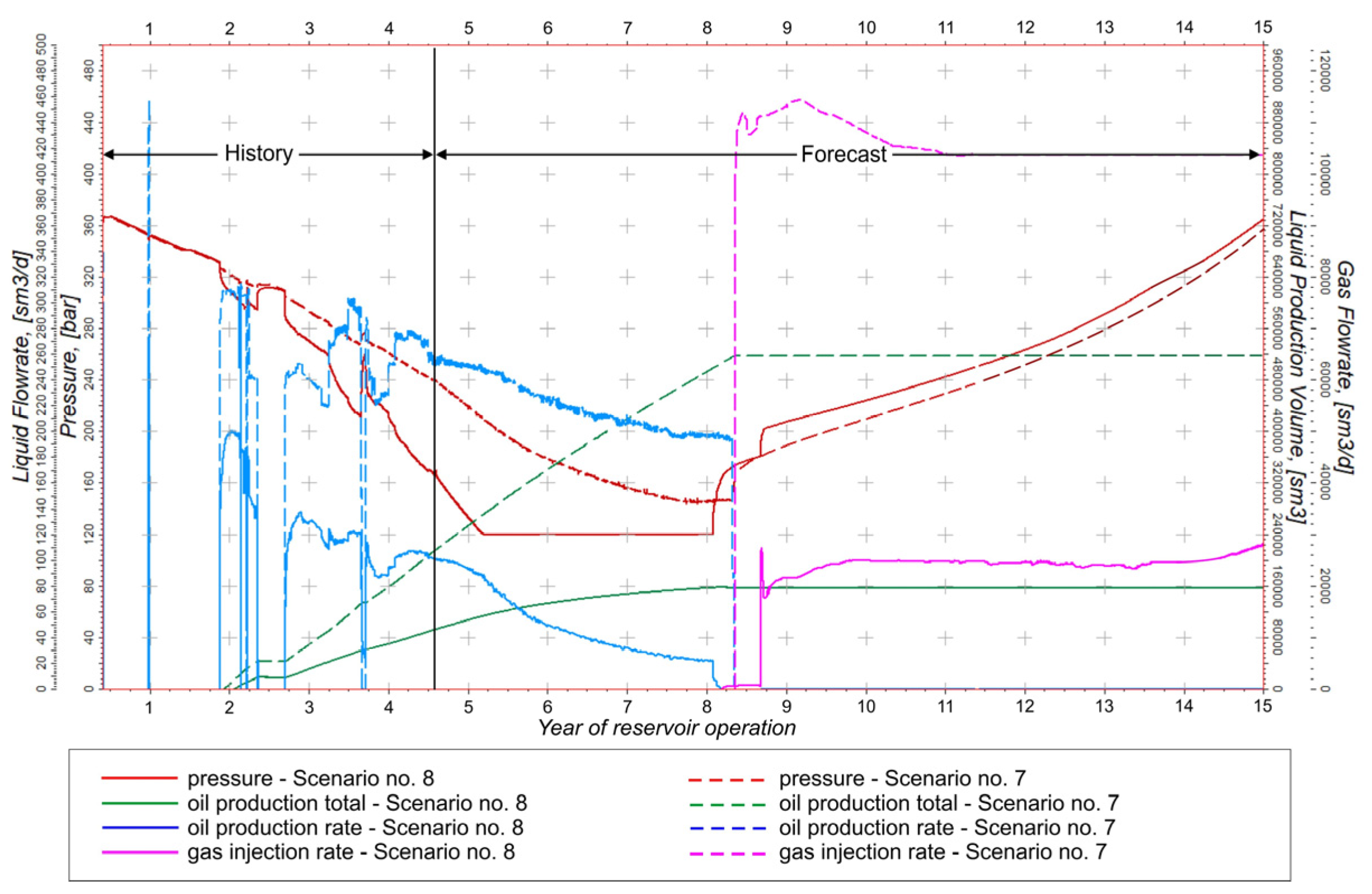

8.2. Results at Reservoir Level

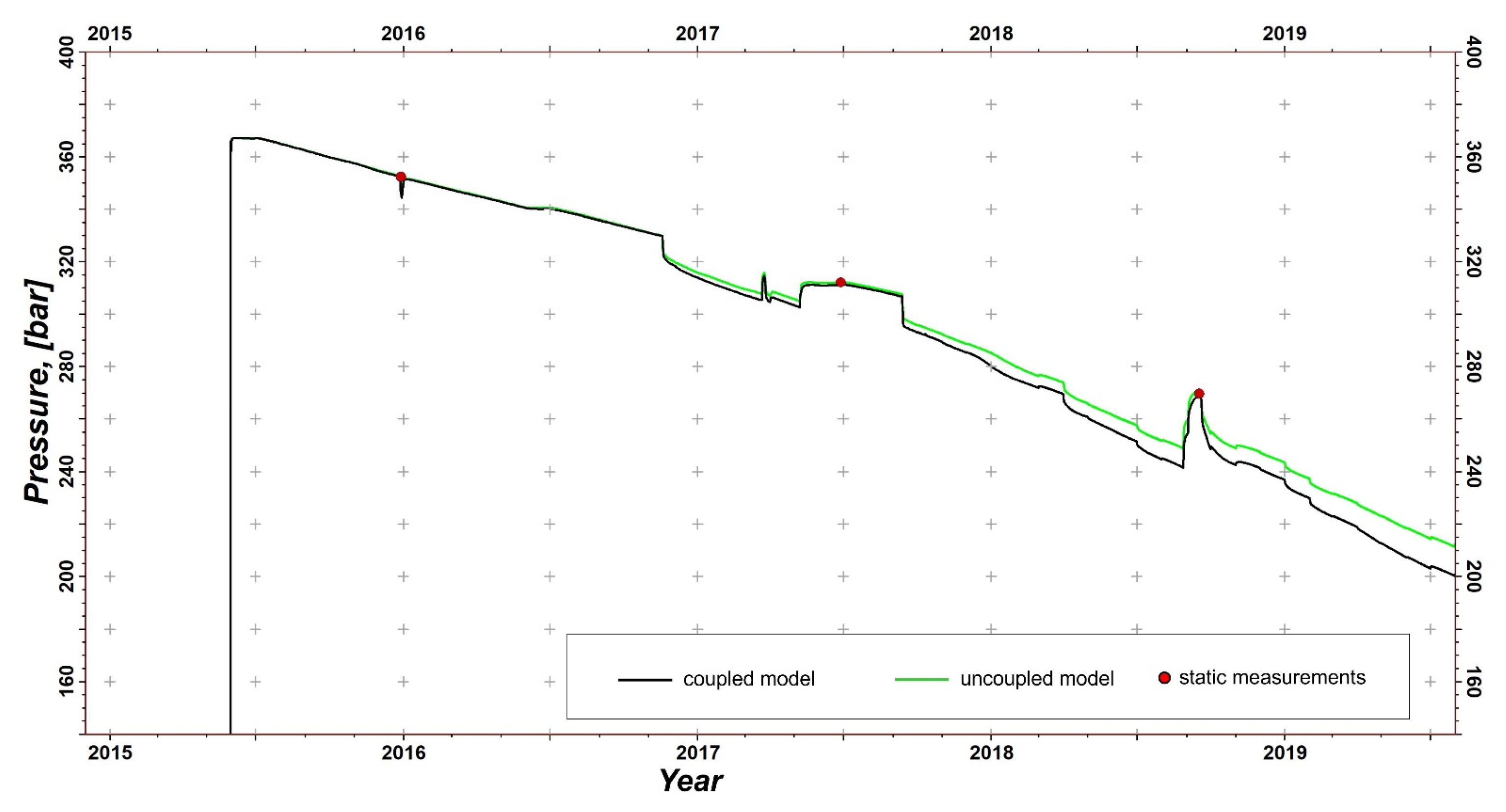

8.3. Results at A-11H Well Level

- -

- The direct factor determining the geomechanical effects, as well as the oil production, is the reservoir pressure evolution;

- -

- In particular, the injection of the CO2 makes the reservoir pressure decrease slower and, consequently, maintains the total oil production at a much higher level as can be seen by comparing basic scenarios (Scenario 1 and Scenario 2 of the total oil production after 81/3 years of operation equal to 0.53 and 0.62 × 106 Sm3, respectively) with enhanced oil recovery scenarios (Scenario 3 and Scenario 4 of the total oil production after 81/3 years of operation equal to 0.71 and 0.77 × 106 Sm3, respectively)—the solid and dashed curves in Figure 22 vs. the ones in Figure 23;

- -

- The decrease in the oil production in all the scenarios with the geomechanical effects included due to the fracture closure with pressure decline as can be seen by comparing scenarios with geomechanical effects taken into account (Scenario 1 and Scenario 3 of the total oil production after 81/3 years of operation equal to 0.53 and 0.71 × 106 Sm3, respectively) with the scenarios with the geomechanical effects neglected (Scenario 2 and Scenario 4 of the total oil production after 81/3 years of operation equal to 0.62 and 0.77 × 106 Sm3, respectively)—the solid curve vs. the dashed one in Figure 22 for the basic scenarios and the solid curve vs. the dashed one in Figure 23 for the enhanced recovery scenarios.

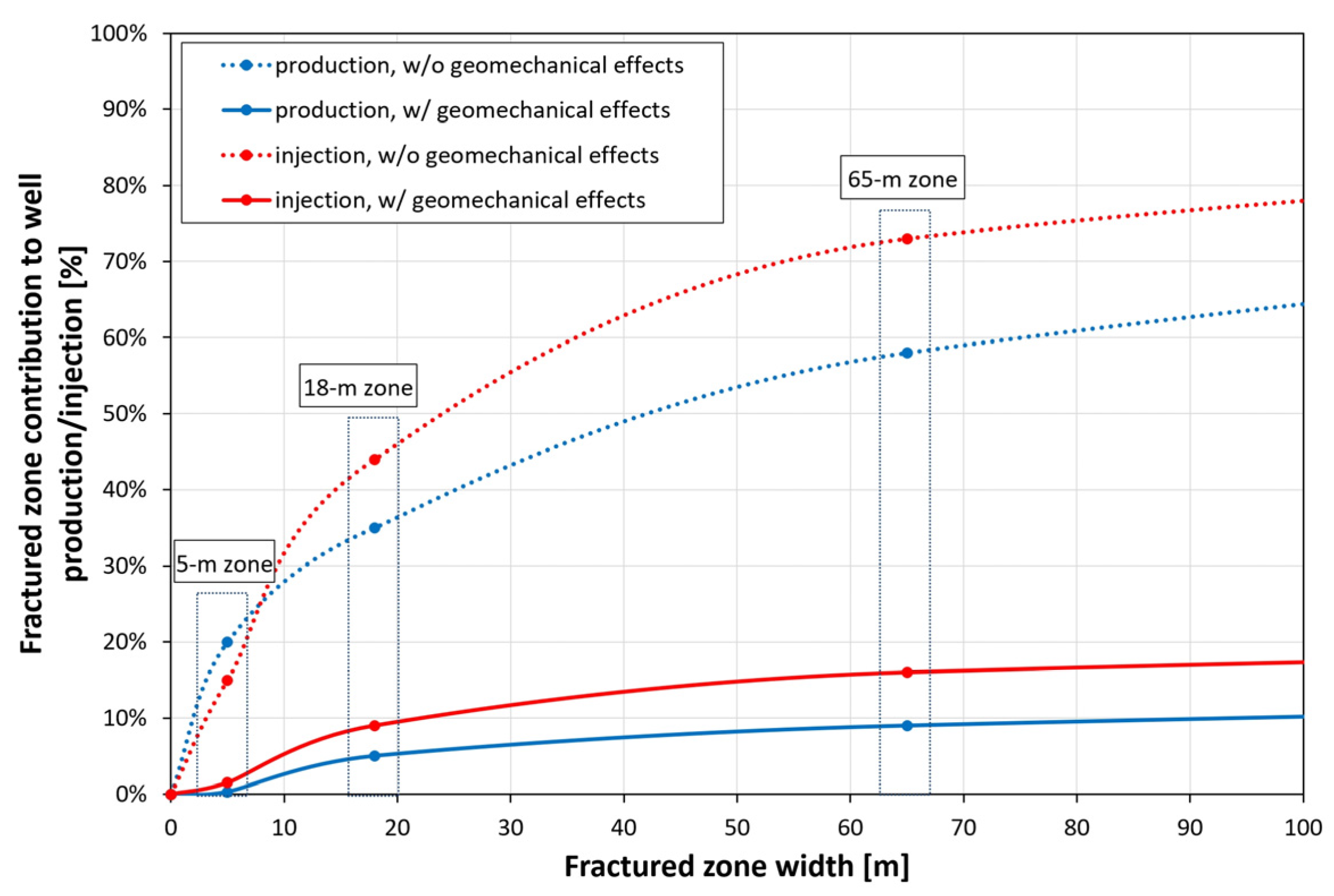

8.4. Results at the Fracture Zone Level

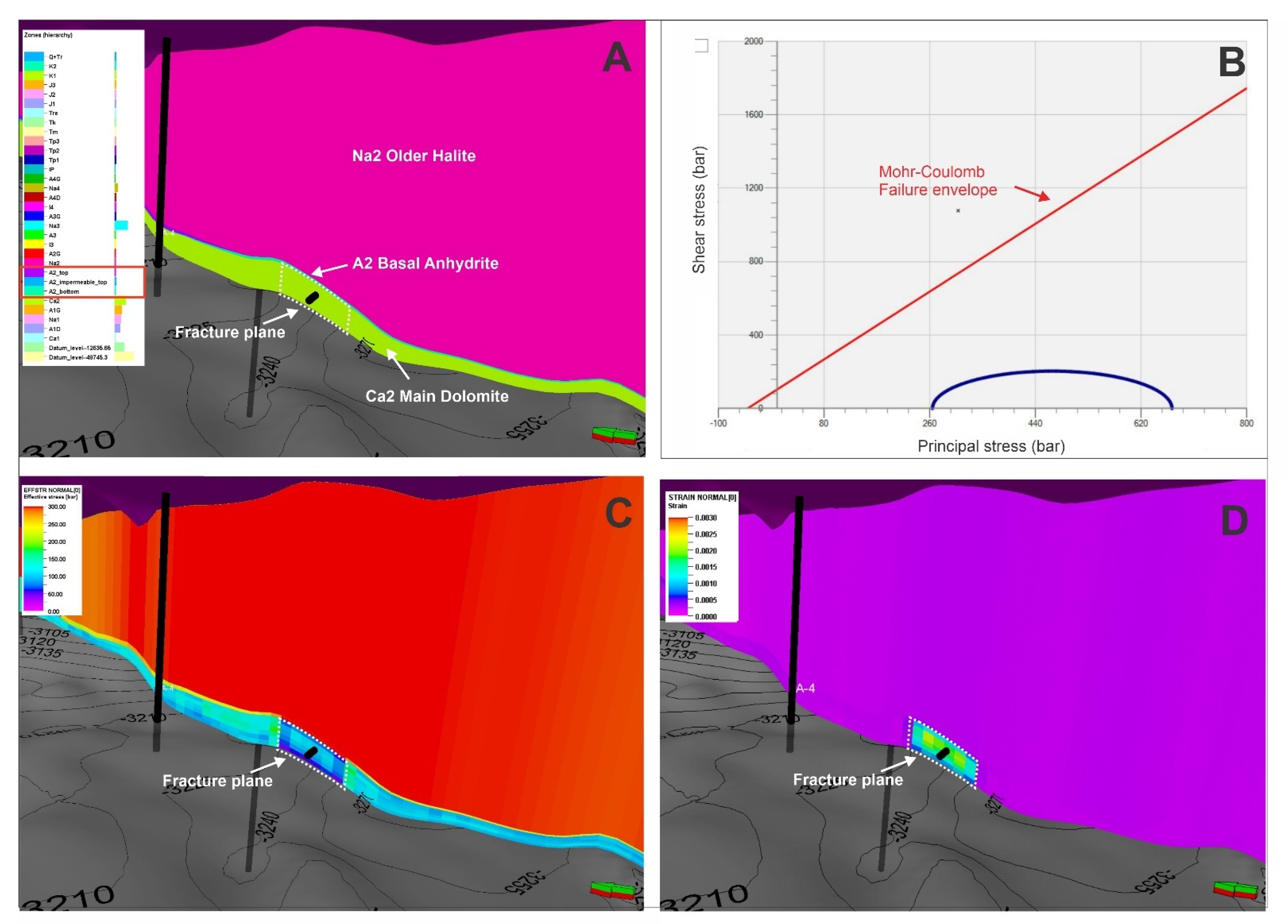

9. Fracture Propagation Analysis

10. Summary and Conclusions

- 1.

- The method proposed in the studies and comprising effectively coupled geomechanical and dynamical simulations of reservoir region and its extension allows us to take into account the influence of geomechanical effects upon transport properties of reservoir rock and, consequently, upon the operation of the reservoir in various stages including primary production, enhanced oil production by CO2 injection, and CO2 sequestration;

- 2.

- The geomechanical effects induced primarily by the redistribution of reservoir pressure may drastically modify transport properties of fracture zones contributing to well performance and thus determining the operational results of the involved reservoir;

- 3.

- The quantitative results of those geomechanical effects depend upon detailed properties of both geomechanical state evolution and geological characteristics of the reservoir;

- 4.

- The following two correlations are key factors when the effective transport properties of the reservoir rock are a concern:

- -

- The correlation between the geomechanical state (stress and strain field) and the rock pore matrix and fracture characteristics;

- -

- The correlation between pore matrix/fracture characteristics and their effective transport properties.

- Assumed geometries of discontinuities and the reservoir stress field indicate that fractures are reactivated in tensile/hybrid failure mode caused by pressure build-up during CO2 injection; induced aperture changes result from the normal stress while the shear stress can be neglected;

- Under the geomechanical stress state resulting from the simulations of both production and injection stages of the reservoir operation, the fracture zone will not propagate within the underlying main dolomite formation or the anhydrite caprock; hence, no CO2 leakage upward into the anhydrite formation via induced fractures is observed;

- The geomechanical effects significantly determine simulation forecasts of oil production by an oil-producing well with completion including a fracture zone, and the pressure reduction results in fracture closure and a reduction in the fracture contribution to the well productivity depending on the size of the fractured zone;

- Similar results for geomechanical effects are found in well injectivity due to fracture apertures not regaining their primary size despite the increasing reservoir pressure during the injection phase of the CO2-EOR and CO2 sequestration;

- In the cases of carbonate reservoir rocks with more frequent fracture occurrences, the evaluated geomechanical effects in the field performance are expected to be enhanced at the reservoir scale.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| equivalent normal closure aperture; | |

| maximum aperture; | |

| residual aperture; | |

| equivalent shear dilation aperture; | |

| maximum shear dilation; | |

| E | Young modulus; |

| Edyn | dynamic Young modulus; |

| equivalent shear dilation frequency; | |

| equivalent fracture frequency; | |

| pore pressure; | |

| equivalent frictional coefficient; | |

| tensile strength; | |

| ν | Poisson’s ratio; |

| νdyn | dynamic Poisson’s ratio; |

| vp | compressional wave velocity; |

| vs | shear wave velocity; |

| Biot’s coefficient; | |

| stress coefficient for the normal closure aperture; | |

| minimum horizontal stress; | |

| maximum horizontal stress; | |

| maximum principal stress in the plane perpendicular to the fracture surface; | |

| minimum principal stress in the plane perpendicular to the fracture surface; | |

| ratio of maximum principal stress; | |

| σv | vertical stress; |

| stress coefficient for shear dilation; | |

| ɛH | tectonic strains parallel to the maximum horizontal stress direction; |

| ɛh | tectonic strains parallel to the minimum horizontal stress direction; |

| ρ | rock density. |

References

- Azzolina, N.; Gorecki, C.; Pu, H.; Peck, W.; Ayash, S.; Melzer, S.; Nakles, D.; Chatterjee, S. Statistical analysis of CO2 EOR production and injection data to examine ongoing and ultimate CO2 EOR incidental storage. In Proceedings of the Thirteenth Annual Conference on Carbon Capture, Utilization & Storage Conference, Pittsburgh, PA, USA, 28 April–1 May 2014; David L. Lawrence Convention Center: Pittsburgh, PA, USA, 2014. 20p. [Google Scholar]

- Ghedan, S. Global Laboratory Experience of CO2-EOR Flooding. In Proceedings of the 2009 SPE/EAGE Reservoir Characterization and Simulation Conference, Abu Dhabi, United Arab Emirates, 19–21 October 2009; Society of Petroleum Engineers: Richardson, TX, USA, 2009. 15p. [Google Scholar] [CrossRef]

- Holm, L. Carbon Dioxide Solvent Flooding for Increased Oil Recovery. Trans. AIME 1959, 216, 225–231. [Google Scholar] [CrossRef]

- Jarrell, P.M.; Fox, C.E.; Stein, M.H.; Webb, S.L. Practical Aspects of CO2 Flooding; Society of Petroleum Engineers Monograph Series, v. 22; Society of Petroleum Engineers: Richardson, TX, USA, 2002; 220p, ISBN 978-1-55563-096-6. [Google Scholar] [CrossRef]

- Martin, D.F.; Taber, J.J. Carbon Dioxide Flooding. J. Pet. Technol. 1992, 44, 396–400. [Google Scholar] [CrossRef]

- Mungan, N. Carbon Dioxide Flooding—Fundamentals. In Heavy Crude Oil Recovery; Springer: Dordrecht, The Netherlands, 1981; pp. 87–92. ISBN 978-94-009-6140-1. [Google Scholar] [CrossRef]

- Peng, B. CO2 Storage in the Oil Reservoir and Enhanced Oil Recovery; University of Petroleum, Enhanced Oil Recovery Research Center: Beijing, China, 11–15 July 2011; 39p. [Google Scholar]

- Remson, D. Storing CO2 and Producing Domestic Crude Oil with Next-Generation CO2-EOR Technology; DOE/NETL–2010/1417; National Energy Technology Laboratory: Albany, OR, USA, April 2010; 59p.

- Tzimas, E.; Georgakaki, A.; Cortes, C.G.; Peteves, S.D. Enhanced Oil Recovery Using Carbon Dioxide in the European Energy System; Report EUR 21895 EN, European Commission, Directorate General Joint Research Centre (DG JRC); Institute of Energy: Petten, The Netherlands, December 2005; 118p, ISBN 92-79-01044-1. EUR 21895 EN, JRC32102. [Google Scholar]

- Bradshaw, J.; Rigg, A. The GEODISC Program: Research into Geological Sequestration of CO2 in Australia. Environ. Geosci. 2001, 8, 166–176. [Google Scholar] [CrossRef]

- Streit, J.E.; Siggins, A.F. Predicting, monitoring and controlling geomechanical effects of CO2 injection. In Greenhouse Gas Control Technologies, Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies, Vancouver, BC, Canada, 5–9 September 2004; Rubin, E.S., Keith, D.W., Gilboy, C.F., Eds.; Elsevier: Oxford, UK, 2005; pp. 643–651. ISBN 0-08-044881-X. TRN: 000600155. [Google Scholar]

- Islam, M.; Chakma, A. Storage and utilization of CO2 in petroleum reservoirs—A simulation study. Energy Convers. Manag. 1993, 34, 1205–1212. [Google Scholar] [CrossRef]

- Bachu, S. Sequestration of CO2 in geological media: Criteria and approach for site selection in response to climate change. Energy Convers. Manag. 2000, 41, 953–970. [Google Scholar] [CrossRef]

- Koide, H.; Tazaki, Y.; Noguchi, Y.; Nakayama, S.; Iijima, M.; Ito, K.; Shindo, Y. Subterranean containment and long-term storage of carbon dioxide in unused aquifers and in depleted natural gas reservoirs. Energy Convers. Manag. 1992, 33, 619–626. [Google Scholar] [CrossRef]

- Ennis-King, J.; Paterson, L. Reservoir engineering issues in the geological disposal of carbon dioxide. In Greenhouse Gas Control Technologies: Proceedings of the 5th International Conference on Greenhouse Gas Control Technologies; Williams, D.J., Durie, R.A., McMullan, P., Paulson, C.A.J., Smith, A.Y., Eds.; CSIRO Publishing: Cairns, Australia, 2001; pp. 290–295. ISBN 0-643-06672-1. TRN: 000900074. [Google Scholar]

- Al-Masri, W.; Papaspyrou, C.; Shapiro, A.; Suicmez, V. Study of the Feasibility of the Carbon Dioxide Injection in a North Sea Petroleum Reservoir. In Proceedings of the SPE Europec Featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar] [CrossRef]

- Ettehadtavakkol, A.; Lake, L.W.; Bryant, S.L. CO2-EOR and storage design optimization. Int. J. Greenh. Gas Control 2014, 25, 79–92. [Google Scholar] [CrossRef]

- Ghomian, Y.; Sepehrnoori, K.; Pope, G.A. Efficient Investigation of Uncertainties in Flood Design Parameters for Coupled CO2 Sequestration and Enhanced Oil Recovery. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, New Orleans, LA, USA, 10–12 November 2010. [Google Scholar] [CrossRef]

- Safi, R.; Agarwal, R.K.; Banerjee, S. Numerical simulation and optimization of CO2 utilization for enhanced oil recovery from depleted reservoirs. Chem. Eng. Sci. 2016, 144, 30–38. [Google Scholar] [CrossRef]

- Arnaut, M.; Vulin, D.; Lamberg, G.J.G.; Jukić, L. Simulation Analysis of CO2-EOR Process and Feasibility of CO2 Storage during EOR. Energies 2021, 14, 1154. [Google Scholar] [CrossRef]

- Karimaie, H.; Nazarian, B.; Aurdal, T.; Nøkleby, P.H.; Hansen, O. Simulation Study of CO2 EOR and Storage Potential in a North Sea Reservoir. Energy Procedia 2017, 114, 7018–7032. [Google Scholar] [CrossRef]

- Liu, Y.; Rui, Z. A Storage-Driven CO2 EOR for a Net-Zero Emission Target. Engineering 2022, 18, 79–87. [Google Scholar] [CrossRef]

- Liu, Y.; Rui, Z.; Yang, T.; Dindoruk, B. Using propanol as an additive to CO2 for improving CO2 utilization and storage in oil reservoirs. Appl. Energy 2022, 311, 118640. [Google Scholar] [CrossRef]

- Zhao, X.; Rui, Z.; Liao, X. Case studies on the CO2 storage and EOR in heterogeneous, highly water-saturated, and extra-low permeability Chinese reservoirs. J. Nat. Gas Sci. Eng. 2016, 29, 275–283. [Google Scholar] [CrossRef]

- Teklu, T.W.; Alameri, W.; Graves, R.M.; Tutuncu, A.N.; Kazemi, H.; Alsumaiti, A.M. Geomechanics Considerations in Enhanced Oil Recovery. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar] [CrossRef]

- Correa, A.C.F.; Newman, R.B.; Naveira, V.P.; de Souza, A.L.S.; Araujo, T.; da Silva, A.A.C.; Soares, A.C.; Herwanger, J.V.; Meurer, G.B. Integrated Modeling for 3D Geomechanics and Coupled Simulation of Fractured Carbonate Reservoir. In Proceedings of the OTC Brasil, Rio de Janeiro, Brazil, 29–31 October 2013. [Google Scholar] [CrossRef]

- Jabbari, H.; Ostadhassan, M.; Salehi, S. Geomechanical Modeling in CO2 Enhanced Oil Recovery. In Proceedings of the 49th U. S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 28 June–1 July 2015. ARMA-2015-262. [Google Scholar]

- Elyasi, A.; Goshtasbi, K.; Hashemolhosseini, H.; Barati, S. Coupled solid and fluid mechanics simulation for estimating optimum injection pressure during reservoir CO2-EOR. Struct. Eng. Mech. 2016, 59, 37–57. [Google Scholar] [CrossRef]

- Rahman, J.; Fawad, M.; Mondol, N.H. 3D Field-Scale Geomechanical Modeling of Potential CO2 Storage Site Smeaheia, Offshore Norway. Energies 2022, 15, 1407. [Google Scholar] [CrossRef]

- Chiaramonte, L.; Zoback, M.D.; Friedmann, J.; Stamp, V. Seal integrity and feasibility of CO2 sequestration in the Teapot Dome EOR pilot: Geomechanical site characterization. Environ. Geol. 2007, 54, 1667–1675. [Google Scholar] [CrossRef]

- White, J.A.; Chiaramonte, L.; Ezzedine, S.; Foxall, W.; Hao, Y.; Ramirez, A.; McNab, W. Geomechanical behavior of the reservoir and caprock system at the In Salah CO2 storage project. Proc. Natl. Acad. Sci. USA 2014, 111, 8747–8752. [Google Scholar] [CrossRef]

- Sharma, P.; Ghosh, S.; Tandon, A. Study of CO2 injection in a depleted oil reservoir using geomechanically coupled and non-coupled simulation models. Mater. Today Proc. 2022, 57, 1805–1812. [Google Scholar] [CrossRef]

- Chadwick, A.; Arts, R.; Bernstone, C.; May, F.; Thibeau, S.; Zweigel, P. Best Practice for the Storage of CO2 in Saline Aquifers, Observations and Guidelines from the SACS and CO2 STORE Projects; British Geological Survey Halstan & Co. Ltd.: Amersham, UK, 2008; ISBN 978-0-85272-610-5. [Google Scholar]

- Jia, C.-J.; Xu, W.-Y.; Wang, H.-L.; Wang, R.-B.; Yu, J.; Yan, L. Stress dependent permeability and porosity of low-permeability rock. J. Cent. South Univ. 2017, 24, 2396–2405. [Google Scholar] [CrossRef]

- Wójcicki, A. Realization Status and Prospects for the National Program. Assessment of Geological Formations and Structures for Safe Geological Storage of CO2, with the Monitoring Program; Prace Naukowe Instytutu Nafty i Gazu Państwowego Instytutu Badawczego: Kraków, Poland, 2013; Volume 170, pp. 361–365. [Google Scholar]

- Davies, P.B. Evaluation of the Role of Threshold Pressure in Controlling Flow of Waste-Generated Gas into Bedded Salt at the Waste Isolation Pilot Plant; Sandia Report prepared for the United States Department of Energy under Contract DE-AC04-76DP00789; Sandia National Laboratories: Albuquerque, NM, USA, 1991; Volume 23, pp. 17–19, RN: 23009058.

- Ibrahim, M.A.; Tek, M.R.; Katz, D.L. Threshold Pressure in Gas Storage; American Gas Association, Inc.: Arlington, VA, USA, 1970; ISBN 9780318127248. [Google Scholar]

- Tarkowski, R.; Stopa, J. Tightness of geological structure destined for underground carbon dioxide storage. Gospod. Surowcami Miner. 2007, 23, 129–137. [Google Scholar]

- Settari, A.; Mounts, F.M. A Coupled Reservoir and Geomechanical Simulation System. SPE J. 1998, 3, 219–226. [Google Scholar] [CrossRef]

- Settari, A.; Price, T.R.; Yee, C.T. Coupling of Fluid Flow and Soil Behavior to Model Injection into Unconsolidated Oil Sands. In Proceedings of the 1988 Petroleum Society of CIM Annual Technical Meeting, Calgary, AB, Canada, 12–16 June 1988. CIM 88-39-72. [Google Scholar]

- Minkoff, S.E.; Stone, C.M.; Arguello, J.G.; Bryant, S.; Eaton, J.; Peszynska, M.; Wheeler, M. Staggered in Time Coupling of Reservoir Flow Simulation and Geomechanical Deformation: Step 1—One-Way Coupling. In Proceedings of the SPE Reservoir Simulation Symposium, Houston, TX, USA, 14–17 February 1999. [Google Scholar] [CrossRef]

- Ito, Y.; Settari, A.; Kry, P.; Jha, K. Development and Application of Pseudo-Functions for Reservoir Simulation to Represent Shear Failure During the Cyclic Steam Process. In Proceedings of the SPE International Thermal Operations Symposium, Bakersfield, CA, USA, 8–10 February 1993. [Google Scholar] [CrossRef]

- Gutierrez, M. Fully Coupled Analysis of Reservoir Compaction and Subsidence. In Proceedings of the European Petroleum Conference, London, UK, 25–27 October 1994. [Google Scholar] [CrossRef]

- Du, J.; Wong, R. Development of a Coupled Geomechanics-Thermal Reservoir Simulator Using Finite Element Method. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 7–9 June 2005. [Google Scholar] [CrossRef]

- Morkos, P.; Gildin, E. Development of Agile Framework for Model-Order Reduction of Large-Scale Geomechanical Models: A Novel Workflow for Coupled Simulations. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Virtual, 20–22 July 2020. [Google Scholar] [CrossRef]

- An, C.; Fang, Y.; Liu, S.; Alfi, M.; Yan, B.; Wang, Y.; Killough, J. Impacts of Matrix Shrinkage and Stress Changes on Permeability and Gas Production of Organic-Rich Shale Reservoirs. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 8–10 May 2017. [Google Scholar] [CrossRef]

- Amirlatifi, A.; Eckert, A.; Nygaard, R.; Bai, B. Estimation of Reservoir Uplift, Seismicity and Failure Likelihood during CO2 Injection through Coupled Reservoir Simulation. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 15–17 November 2011. [Google Scholar] [CrossRef]

- Xu, T.; Lindsay, G. Unique Multidisciplinary Approach to Model and Optimize Pad Refracturing in the Haynesville Shale. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017. [Google Scholar] [CrossRef]

- Han, H.; Higgins-Borchardt, S.M.; Mata, D.; Gonzales, V.M. In-Situ and Induced Stresses in the Development of Unconventional Resources. In Proceedings of the SPE/CSUR Unconventional Resources Conference–Canada, Calgary, AB, Canada, 30 September–2 October 2014. [Google Scholar] [CrossRef]

- Pei, Y.; Yu, W.; Sepehrnoori, K. Investigation of Vertical Fracture Complexity Induced Stress Interference in Multilayer Shale Gas Reservoirs with Complex Natural Fractures. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Lei, Z.; Yang, X.; Li, X.; Hu, D.; Wu, Y.; Peng, Y. Advanced Modeling of Horizontal Well Performance Under Different Re-fracturing Designs in Tight Oil Reservoir. In Proceedings of the SPE Europec Featured at 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019. [Google Scholar] [CrossRef]

- French, S.; Puspitasari, R.; Isherwood, A.; Cox, P.; Marsden, R.; Mbang, M.N.E.; Tan, C.P.; John, Z. 4-D Geomechanics to Predict Compaction and Subsidence for Development of Unconsolidated Sandstone Reservoirs: Fortuna Project Case Study, Offshore Equatorial Guinea. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, The Hague, The Netherlands, 14–16 March 2017. [Google Scholar] [CrossRef]

- Shokri, A.R.; Chalaturnyk, R.J.; Nickel, E. Non-Isothermal Injectivity Considerations for Effective Geological Storage of CO2 at the Aquistore Site, Saskatchewan, Canada. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar] [CrossRef]

- Kim, G.W.; Kim, T.H.; Lee, K.S. Impact of Heterogeneous Hydro-Geomechanical Properties of Caprock on CO2 Leakage by Tensile Fracture Reactivation During CCS. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016. [Google Scholar] [CrossRef]

- Restrepo, A.; Rendón, N.; Marin, R.; Lara, V.; Osorio, G.; Velásquez, J.; Lopez, C.; Ocampo, A. Geomechanics Coupled Simulation of Different Completion Schemes in a Stress Sensitive Reservoir. In Proceedings of the EAGE Annual Conference & Exhibition incorporating SPE Europe, London, UK, 10–13 June 2013. [Google Scholar] [CrossRef]

- Onaisi, A.; Samier, P.; Koutsabeloulis, N.; Longuemare, P. Management of Stress Sensitive Reservoirs Using Two Coupled Stress-Reservoir Simulation Tools: ECL2VIS and ATH2VIS. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 October 2002. [Google Scholar] [CrossRef]

- Bourgeois, F.; Koutsabeloulis, N. Geomechanical Modeling of a Full Reservoir of the North Sea. In Proceedings of the SPE/EAGE Reservoir Characterization and Simulation Conference, Abu Dhabi, United Arab Emirates, 28–31 October 2007. [Google Scholar] [CrossRef]

- Wagner, R. Stratygrafia Osadów i Rozwój Basenu Cechsztyńskiego na Niżu Polskim. Prace Państwowego Instytutu Geologicznego, 146; Państwowy Inst. Geologiczny: Warszawa, Poland, 1994; OL924861M, LCCN: 95223745. [Google Scholar]

- Kotarba, M.; Wagner, R. Generation potential of the Zechstein Main Dolomite (Ca2) carbonates in the Gorzów Wielkopolski-Miedzychód-Lubiatów area: A geological and geochemical approach to microbial-algal source rock. Przegląd Geol. 2007, 55, 1025–1036. [Google Scholar]

- Czekański, E.; Kwolek, K.; Mikołajewski, Z. Hydrocarbon fields in the Zechstein Main Dolomite (Ca2) on the Gorzów Block (NW Poland). Przegląd Geol. 2010, 58, 695–703. [Google Scholar]

- Protas, A.; Wojtkowiak, Z. The Gorzów Block. Geology of the Lower Zechstein. In Guide to 71st Congress of the Polish Geological Society; Państwowy Inst. Geologiczny: Warszawa, Poland, 2000; pp. 163–171. [Google Scholar]

- Dadlez, R. Budowa Geologiczna Niecki Szczecińskiej i Bloku Gorzowa; Prace PIG, 96; Państwowy Inst. Geologiczny: Warszawa, Poland, 1979; ISBN 108322000200. LCCN: 81118351. [Google Scholar]

- Peryt, T.; Dyjaczyński, K. An isolated carbonate bank in the Zechstein Main Dolomite basin, western Poland. J. Pet. Geol. 1991, 14, 445–458. [Google Scholar] [CrossRef]

- Jaworowski, K.; Mikołajewski, Z. Oil- and gas-bearing sediments of the Main Dolomite (Ca2) in the Międzychód region: A depositional model and the problem of the boundary between the second and third depositional sequences in the Polish Zechstein Basin. Przegląd Geol. 2007, 55, 1017–1024. [Google Scholar]

- Slowakiewicz, M.; Mikolajewski, Z. Sequence stratigraphy of the Upper Permian Zechstein Main Dolomite carbonates in Western Poland: A new approach. J. Pet. Geol. 2009, 32, 215–233. [Google Scholar] [CrossRef]

- Słowakiewicz, M.; Mikołajewski, Z. Upper Permian Main Dolomite microbial carbonates as potential source rocks for hydrocarbons (W Poland). Mar. Pet. Geol. 2011, 28, 1572–1591. [Google Scholar] [CrossRef]

- Wagner, R.; Dyjaczyński, K.; Papiernik, B.; Peryt, T.M.; Protas, A. Palaeogeographic map of the Main Dolomite (Ca2) in Poland. In Balance and Hydrocarbon Potential of the Dolomite in the Main Perm Basin of Poland; Kotarba, M.J., Ed.; Archiwum WGGiOOE AGH: Kraków, Poland, 2000. [Google Scholar]

- Terzaghi, K. Stress Conditions for the Failure of Saturated Concrete and Rock. Reproduced in From Theory to Practice in Soil Mechanics. Proc. Am. Soc. Test. Mater. 1945, 45, 181–197. [Google Scholar]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2010; ISBN -978-0-521-77069-9. [Google Scholar]

- Belyadi, H.; Fathi, E.; Belyadi, F. (Eds.) Chapter Thirteen: Rock Mechanical Properties and In Situ Stresses. In Hydraulic Fracturing in Unconventional Reservoirs; Gulf Professional Publishing: Oxford, UK, 2017; pp. 207–224. ISBN 9780128498712. [Google Scholar] [CrossRef]

- Guo, B.; Liu, X.; Tan, X. (Eds.) Petroleum Production Engineering, 2nd ed.; Gulf Professional Publishing: Oxford, UK, 2017; pp. i–iii. ISBN 9780128093740. [Google Scholar] [CrossRef]

- Bratton, T.; Cooper, I. Wellbore Measurements: Tools, Techniques, and Interpretation. In Advanced Drilling and Well Technology; Aadnoy, B., Cooper, I., Miska, S., Mitchell, R., Payne, M., Eds.; Society of Petroleum Engineers: Richardson, TX, USA, 2009; pp. 443–457. ISBN 978-1-55563-145-1. [Google Scholar]

- Herwanger, J.; Koutsabeloulis, N. Seismic Geomechanics: How to Build and Calibrate Geomechanical Models Using 3D and 4D Seismic Data; EAGE Publications, 181; EAGE: Bunnik, The Netherlands, 2011; ISBN 9781680156973. [Google Scholar]

- Słota-Valim, M.; Gołąbek, A.; Szott, W.; Sowiżdżał, K. Analysis of Caprock Tightness for CO2 Enhanced Oil Recovery and Sequestration: Case Study of a Depleted Oil and Gas Reservoir in Dolomite, Poland. Energies 2021, 14, 3065. [Google Scholar] [CrossRef]

- Kahraman, S.; Fener, M.; Kozman, E. Predicting the compressive and tensile strength of rocks from indentation hardness index. J. South. Afr. Inst. Min. Metall. 2012, 112, 331–339. [Google Scholar]

- Sheorey, P.R. Empirical Rock Failure Criteria; A.A. Balkema: Rotterdam Brookfield, VT, USA, 1997; ISBN 9054106700. [Google Scholar]

- Hoek, E. Rock Mechanics–An Introduction for the Practical Engineer Parts I, II, and III. Min. Mag. 1966, 144, 236–243. [Google Scholar]

- Karaman, K.; Cihangir, F.; Ercikdi, B.; Kesimal, A.; Demirel, S. Utilization of the Brazilian test for estimating the uniaxial compressive strength and shear strength parameters. J. South. Afr. Inst. Min. Met. 2015, 115, 185–192. [Google Scholar] [CrossRef]

- Yetkin, M.E.; Simsir, F.; Ozfirat, M.K.; Ozfirat, P.M.; Yenice, H. A Fuzzy Approach to selecting roof support in longwall mining. S. Afr. J. Ind. Eng. 2016, 27, 162–177. [Google Scholar] [CrossRef]

- Tajduś, A.; Cała, M. Regarding the possibility of vertical delamination of the rocks overlying the mining excavations in LGOM. In Proceedings of the XXV Winter School of Rock Mechanics and Geoengineering, Zakopane, Poland, 18–20 March 2022; KGBiG AGH: Kraków, Poland, 2002; pp. 701–712. [Google Scholar]

- Adach-Pawelus, K.; Butra, J.; Pawelus, D. Assessment of the mining excavations stability using numerical methods. In Aktualia i Perspektywy Górnictwa; Wydział Geoinżynierii, Górnictwa i Geologii Politechniki Wrocławskiej: Wrocław, Poland, 2018; ISBN 978-83-946706-8-9. [Google Scholar]

- Kolano, M.; Flisiak, D. Comparison of geomechanical properties of white rock salt and pink rock salt in Kłodawa salt diapir. Stud. Geotech. Et Mech. 2013, 35, 119–127. [Google Scholar] [CrossRef]

- Jiang, D.; Lin, S.; Williams, P. Deformation path in high-strain zones, with reference to slip partitioning in transpressional plate-boundary regions. J. Struct. Geol. 2001, 23, 991–1005. [Google Scholar] [CrossRef]

- Jarosiński, M. Recent tectonic stress regime in Poland based on analyses of hydraulic fracturing of borehole walls. Przegląd Geol. 2005, 53, 863–872. [Google Scholar]

- Leverett, M. Capillary Behavior in Porous Solids. Trans. AIME 1941, 142, 152–169. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Hydraulic Properties of Porous Media and Their Relation to Drainage Design. Trans. ASAE 1964, 7, 0026–0028. [Google Scholar] [CrossRef]

- Szott, W.; Pańko, A.; Łętkowski, P.; Malaga, M. Wykonanie Modeli Symulacyjnych dla złóż Ropy Naftowej Grotów–Międzychód–Lubiaków–Sowia Góra (Simulation Models of Grotów–Międzychód–Lubiaków–Sowia Góra Oil Field); INiG, Krosno; Dokumentacja wykonana dla PGNiG S.A.: Warszawa, Poland, 2007. [Google Scholar]

- Rutqvist, J.; Wu, Y.-S.; Tsang, C.-F.; Bodvarsson, G. A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 429–442. [Google Scholar] [CrossRef]

- Settari, A.; Walters, D.A. Advances in Coupled Geomechanical and Reservoir Modeling with Applications to Reservoir Compaction. In Proceedings of the SPE Reservoir Simulation Symposium, Houston, TX, USA, 14–17 February 1999. [Google Scholar] [CrossRef]

- Thomas, L.K.; Katz, D.L.; Tek, M.R. Threshold Pressure Phenomena in Porous Media. Soc. Pet. Eng. J. 1968, 8, 174–184. [Google Scholar] [CrossRef]

- Vidal-Gilbert, S.; Nauroy, J.-F.; Brosse, E. 3D geomechanical modelling for CO2 geologic storage in the Dogger carbonates of the Paris Basin. Int. J. Greenh. Gas Control. 2009, 3, 288–299. [Google Scholar] [CrossRef]

- Lewis, R.W.; Sukirman, Y. Finite element modelling of three-phase flow in deforming saturated oil reservoirs. Int. J. Numer. Anal. Methods Géoméch. 1993, 17, 577–598. [Google Scholar] [CrossRef]

- Tortike, W.; Ali, S.F. Reservoir Simulation Integrated with Geomechanics. J. Can. Pet. Technol. 1993, 32. [Google Scholar] [CrossRef]

- Xikui, L.; Zienkiewicz, O. Multiphase flow in deforming porous media and finite element solutions. Comput. Struct. 1992, 45, 211–227. [Google Scholar] [CrossRef]

- Inoue, N.; Fontoura, S.A.B. Explicit coupling between flow and geomechanical simulators. In Proceedings of the International Con-ference on Computational Methods for Coupled Problems in Science and Engineering, Ischia Island, Italy, 8–10 June 2009. [Google Scholar]

- Tsang, C.-F. Linking thermal, hydrological, and mechanical processes in fractured rocks. Annu. Rev. Earth Planet. Sci. 1999, 27, 359–384. [Google Scholar] [CrossRef]

- Słota-Valim, K.; Szott, W.; Łetkowski, P.; Rucinski, P.; Milek, K. A coupled flow—Geomechanics study on the effectiveness of methane drainage in multi-seam coal mine with the use of long-reach directional drilling. In Proceedings of the 2022 International Pittsburgh Coal Conference, Virtual, 19–22 September 2022. [Google Scholar]

- Bear, J. Dynamics of Fluids in Porous Media; American Elsevier Publishing Company: New York, NY, USA, 1972; 764p, ISBN 9780444001146. [Google Scholar]

- Min, K.-B.; Rutqvist, J.; Tsang, C.-F.; Jing, L. Stress-dependent permeability of fractured rock masses: A numerical study. Int. J. Rock Mech. Min. Sci. 2004, 41, 1191–1210. [Google Scholar] [CrossRef]

- Min, K.-B.; Jing, L. Numerical determination of the equivalent elastic compliance tensor for fractured rock masses using the distinct element method. Int. J. Rock Mech. Min. Sci. 2003, 40, 795–816. [Google Scholar] [CrossRef]

- Min, K.-B.; Rutqvist, J.; Tsang, C.-F.; Jing, L. Thermally induced mechanical and permeability changes around a nuclear waste repository—A far-field study based on equivalent properties determined by a discrete approach. Int. J. Rock Mech. Min. Sci. 2005, 42, 765–780. [Google Scholar] [CrossRef]

- Ferrill, D.A.; Winterle, J.; Wittmeyer, G.; Sims, D.; Colton, S.; Armstrong, A.; Morris, A.P. Stressed Rock Strains Groundwater at Yucca Mountain, Nevada. GSA Today–A Publ. Geol. Soc. Am. 1999, 5, 1–8. [Google Scholar]

- Byerlee, J. Friction of rocks. Pure Appl. Geophys. 1978, 116, 615–626. [Google Scholar] [CrossRef]

- Ferrill, D.A.; Smart, K.J.; Morris, A.P. Resolved stress analysis, failure mode, and fault-controlled fluid conduits. Solid Earth 2020, 11, 899–908. [Google Scholar] [CrossRef]

- Hangx, S.; Spiers, C.; Peach, C. The mechanical behavior of anhydrite and the effect of deformation on permeability development–Implications for caprock integrity during geological storage of CO2. Energy Procedia 2011, 4, 5358–5363. [Google Scholar] [CrossRef]

- Labuz, J.F.; Zang, A. Mohr–Coulomb Failure Criterion. Rock Mech. Rock Eng. 2012, 45, 975–979. [Google Scholar] [CrossRef]

- Zhang, Y.; Langhi, L.; Schaubs, P.; Piane, C.D.; Dewhurst, D.; Stalker, L.; Michael, K. Geomechanical stability of CO2 containment at the South West Hub Western Australia: A coupled geomechanical–fluid flow modelling approach. Int. J. Greenh. Gas Control. 2015, 37, 12–23. [Google Scholar] [CrossRef]

- Pan, P.; Wu, Z.; Feng, X.; Yan, F. Geomechanical modeling of CO2 geological storage: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 936–947. [Google Scholar] [CrossRef]

- Hoek, E.; Bieniawski, Z.T. Brittle fracture propagation in rock under compression. Int. J. Fract. 1965, 1, 137–155. [Google Scholar] [CrossRef]

| Parameter (Unit) | Cenozoic (Clay, Sand, Gravel) | Cretaceous (Clayey Shales) | Jurassic (Sandy Shales) | Triassic (Sandstones) | Zechstein | ||||

|---|---|---|---|---|---|---|---|---|---|

| Rock Salt | Anhydrite | Reservoir Main Dolomite Min–Max; Median | Limestone | Rotliegend (Underburden) | |||||

| Porosity (%) | 3D model | 3D model | 3D model | 3D model | 3D model | 3D model | 0–25.8; 0.6 3D model | 2.99 | 4 |

| Density (g/cm3) | 3D model | 3D model | 3D model | 3D model | 3D model | 3D model | 2.21–2.96; 2.65 3D model | 2.75 | 2.3 |

| Poisson ratio (-) | 0.3 | 0.32 | 0.19 | 0.17 | 0.3 | 0.25 | 0.12–0.4; 0.21 3D model | 0.18 | 0.3 |

| Young’s modulus (GPa) | 0.5 | 4 | 5.56 | 28.5 | 6.89 | 52.69 | 3.2–52.7; 29.1 3D model | 42.06 | 46.19 |

| Rock strength UCS (bar) | 28 | 480 | 569.8 | 507 | 273.3 | 903 | 181.4–1861.5; 1120.6 3D model | 149.3 | 500 |

| Friction angle (°) | 30 | 32 | 20 | 59 | 29.08 | 64 | 28.6 | 22.8 | 30 |

| Biot constant (-) | 1 | 1 | 1 | 1 | 0 | 0.10 | 0.7 | 0.8 | 1 |

| Dilatation angle (°) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Dimension x, dx (m) | 5 |

| Dimension y, dy (m) | 500 |

| Dimension z, dz (m) | 33–45 |

| Permeability x, kfx (mD) | 0.5–450 |

| Permeability y, kfy (mD) | 700 |

| Permeability z, kfz (mD) | 700 |

| Porosity, ϕf (%) | 0.1 |

| Fracture normal stiffness (bar/m) | 22,620 |

| Fracture shear stiffness (bar/m) | 9048 |

| Cohesion (bar) | 0.01 |

| Friction angle (°) | 20 |

| Dilation angle (°) | 10 |

| Tensile strength (bar) | 0.01 |

| Fracture spacing (m) | 0.5 |

| Initial opening (-) | 0 |

| Phase | Parameter | Initial Value | Value after Calibration |

|---|---|---|---|

| water | nw | 2 | 2 |

| water | Sw,min (=Srw) | 0.1 | 0.0528 |

| water | Sw,max | 1 | 1 |

| oil (oil–water system) | no | 2 | 2 |

| oil (oil–water system) | So,min | 0.4 | 0.4917 |

| oil (oil–water system) | So,max | 1.0 | 0.9964 |

| oil (oil–gas system) | no | 2 | 2 |

| oil (oil–gas system) | So,min | 1 − Sg,max | 1 − Sg,max |

| oil (oil–gas system) | So,max | 1 − Sg,min | 1 − Sg,min |

| gas | ng | 2 | 2 |

| gas | Sg,min (=Srg) | 0.1 | 0.1 |

| gas | Sg,max | 1 | 0.9964 |

| Component | % mol |

|---|---|

| N2 | 31.588 |

| CO2 | 0.612 |

| H2S | 5.085 |

| C1 | 19.353 |

| C2 | 3.567 |

| C3–C6 | 11.990 |

| C7–C11 | 12.270 |

| C12+ | 15.500 |

| Scenario No. | Scenario Name | Scenario Description | ||

|---|---|---|---|---|

| Production Method | Geomechanical Effects | Fracture Zone Width (m/Blocks) | ||

| 1 | Basic_w/o_geomechanics_5m_fracture_zone | Primary | Disabled | 5/1 |

| 2 | Basic_w/_geomechanics_5m_fracture_zone | Primary | Enabled | 5/1 |

| 3 | EOR_w/o_geomechanics_5m_fracture_zone | EOR with CO2 injection * | Disabled | 5/1 |

| 4 | EOR_w/_geomechanics_5m_fracture_zone | EOR with CO2 injection * | Enabled | 5/1 |

| 5 | EOR_w/o_geomechanics_18m_fracture_zone | EOR with CO2 injection * | Disabled | 18/3 |

| 6 | EOR_w/_geomechanics_18m_fracture_zone | EOR with CO2 injection * | Enabled | 18/3 |

| 7 | EOR_w/o_geomechanics_65m_fracture_zone | EOR with CO2 injection * | Disabled | 65/5 |

| 8 | EOR_w/_geomechanics_65m_fracture_zone | EOR with CO2 injection * | Enabled | 65/5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szott, W.; Ruciński, P.; Słota-Valim, M.; Sowiżdżał, K. Investigation of the Impact of Natural Fracture Geomechanics on the Efficiency of Oil Production and CO2 Injection from/to a Petroleum Structure: A Case Study. Energies 2023, 16, 4219. https://doi.org/10.3390/en16104219

Szott W, Ruciński P, Słota-Valim M, Sowiżdżał K. Investigation of the Impact of Natural Fracture Geomechanics on the Efficiency of Oil Production and CO2 Injection from/to a Petroleum Structure: A Case Study. Energies. 2023; 16(10):4219. https://doi.org/10.3390/en16104219

Chicago/Turabian StyleSzott, Wiesław, Piotr Ruciński, Małgorzata Słota-Valim, and Krzysztof Sowiżdżał. 2023. "Investigation of the Impact of Natural Fracture Geomechanics on the Efficiency of Oil Production and CO2 Injection from/to a Petroleum Structure: A Case Study" Energies 16, no. 10: 4219. https://doi.org/10.3390/en16104219

APA StyleSzott, W., Ruciński, P., Słota-Valim, M., & Sowiżdżał, K. (2023). Investigation of the Impact of Natural Fracture Geomechanics on the Efficiency of Oil Production and CO2 Injection from/to a Petroleum Structure: A Case Study. Energies, 16(10), 4219. https://doi.org/10.3390/en16104219