The Influence of a Photometric Distance on Luminance Measurements

Abstract

1. Introduction

1.1. Photometric Measurements

1.2. A Photometric Distance in Luminance Measurements

- Indirect methods of the luminance measurement:

- −

- a photometric method using illuminance measurement,

- −

- a photometric method using measurement of the luminous flux of a light source,

- −

- a spectrometric method (colorimetric method) using measurements of the spectral distribution of the light source;

- Direct methods for measuring luminance:

- −

- using a conventional luminance meter,

- −

- using a matrix (digital) luminance meter—ILMD (Image Luminance Measuring Device).

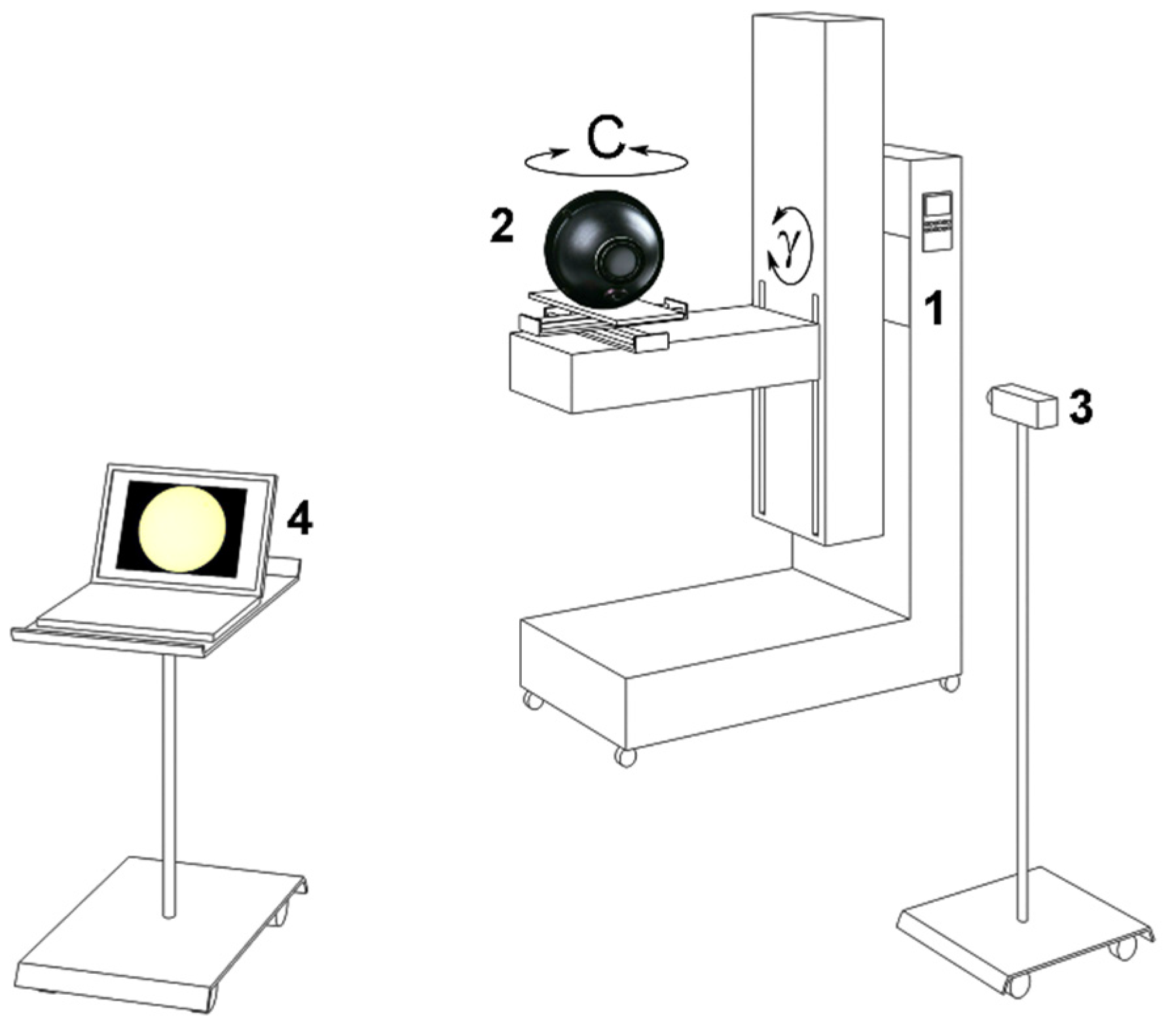

2. Materials and Methods

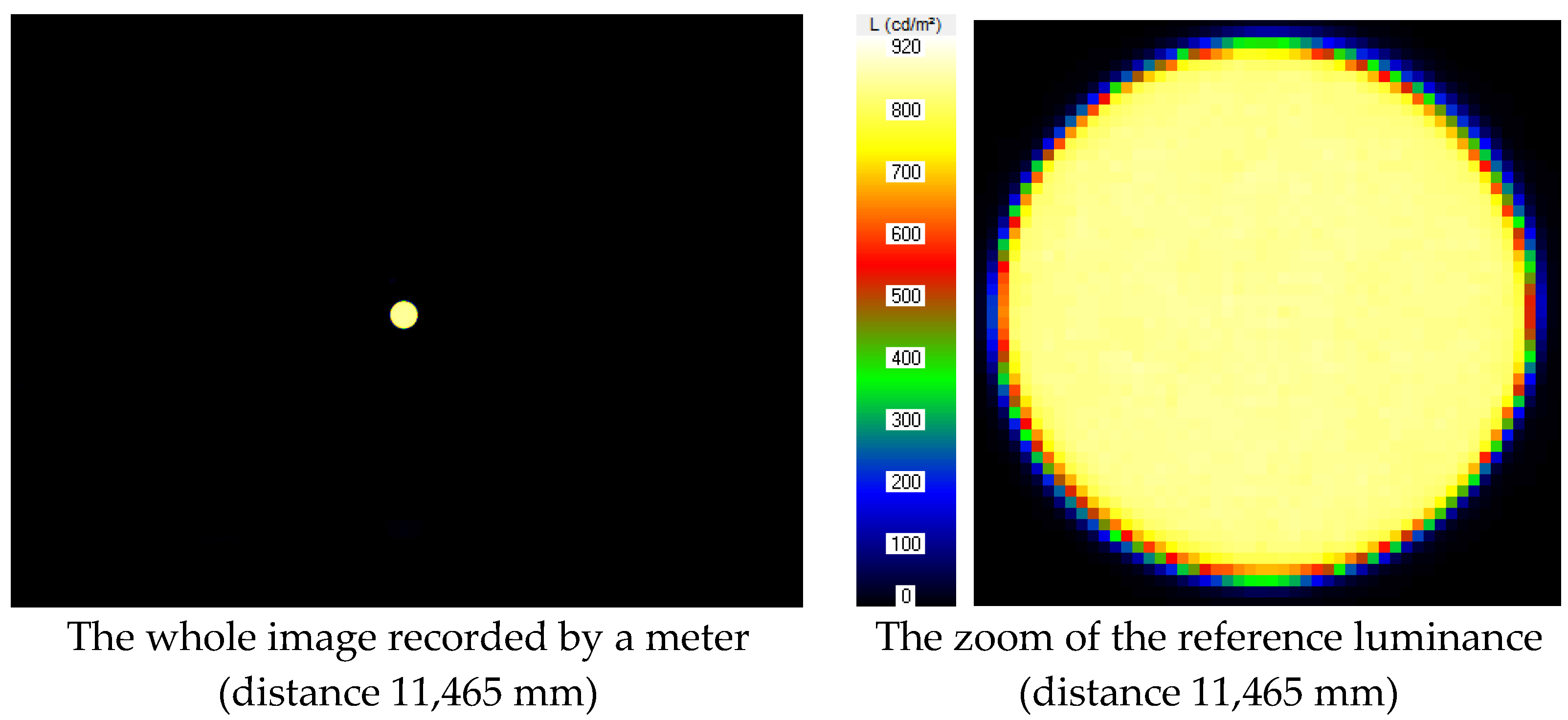

3. Results

4. Discussion

4.1. The Analysis Photometric Measurements

- the average luminance can be measured with 99% accuracy if the measured image covers at least 140,000 pixels,

- the average luminance can be measured with 95% accuracy if the measured image covers at least 14,000 pixels,

- the average luminance can be measured with 90% accuracy if the measured image covers at least 3200 pixels.

- the maximum luminance can be measured with 99% accuracy if the measured image covers at least 98,000 pixels,

- the maximum luminance can be measured with 95% accuracy if the measured image covers at least 3100 pixels,

- the measurement from the longest distance, where the measured image covered only about 2000 pixels, ensures a maximum luminance measurement accuracy of more than 94%.

- the average luminance can be measured with 99% accuracy if the measured image covers at least 660,000 pixels,

- the average luminance can be measured with 95% accuracy if the measured image covers at least 144,000 pixels,

- the average luminance can be measured with 90% accuracy if the measured image covers at least 8900 pixels.

- the maximum luminance can be measured with 99% accuracy if the measured image covers at least 91,000 pixels,

- the maximum luminance can be measured with 95% accuracy if the measured image covers at least 1800 pixels,

- measurement from the greatest distance, where the measured image covered only about 400 pixels, ensures a maximum luminance measurement accuracy of more than 94%.

4.2. The Impact of Luminaire Photometric Measurements on Indoor Electricity Consumption

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, T.; Lin, F.; Huang, B.; Ji, M.; Shi, L.; Xia, M.; Lai, L. The total luminous flux measurement of high-power LEDs. Proc. SPIE 2019, 11334, 151–156. [Google Scholar]

- Markovič, M.; Orgulan, A.; Sukič, P. Measuring System for Determining the Quality of LED Light Sources and an Overview of LED Light Bulbs for Household Use. Sensors 2022, 22, 8351. [Google Scholar] [CrossRef] [PubMed]

- Romero, R.J.A.; Caro-Ruiz, C. Uncertainty estimation in luminous flux measured with goniophotometers using monte carlo method. In Proceedings of the 2020 IEEE PES Transmission and Distribution Conference and Exhibition—Latin America, T and D LA, Montevideo, Uruguay, 28 September–2 October 2020. [Google Scholar]

- Lin, F.; Li, T.; Yin, D.; Lai, L.; Xia, M. Research on effects of baffle position in an integrating sphere on the luminous flux measurement. In Proceedings of the 8th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Optical Test, Measurement Technology, and Equipment, Suzhou, China, 26–29 April 2016; pp. 347–352. [Google Scholar]

- Zalesińska, M.; Zabłocka, J.; Wandachowicz, K. Measurement and evaluation of selected parameters for non-directional household lamps. Prz. Elektrotech. 2018, 1, 190–194. [Google Scholar] [CrossRef]

- CIE. International Commission on Illumination CIE S 025/E:2015 Test Method for Led Lamps, Led Luminaires and Led Modules; CIE: Vienna, Austria, 2015. [Google Scholar]

- Xu, Y.; Hu, H.; Chen, L.; Song, G.; Zhuang, W. Analysis on the high luminous flux white light from GaN-based laser diode. Appl. Phys. B Lasers Opt. 2010, 98, 83–86. [Google Scholar] [CrossRef]

- Narukawa, Y.; Ichikawa, M.; Sanga, D.; Sano, M.; Mukai, T. White light emitting diodes with super-high luminous efficacy. J. Phys. D Appl. Phys. 2010, 43, 354002. [Google Scholar] [CrossRef]

- Gasparovsky, D.; Raditschova, J. Lighting properties and efficiency of luminaires exceeding their lifetime. In Proceedings of the CIE Centenary Conference “Towards a New Century of Light”, Paris, France, 15–16 April 2013; pp. 15–16. [Google Scholar]

- Pan, J.; Qian, F.; Min, F.; Li, Y.; CIE. Total luminous flux and chromacity measurement for led luminaires using absolute interating sphere method. In Proceedings of the 27th Session of the CIE, Sun City, South Africa, 10–15 July 2011; Volume 1, pp. 478–481. [Google Scholar]

- Alawadhi, E.M. Effect of an incompletely closed window shutter on indoor illuminance level and heat gain. Energy Build. 2016, 110, 112–119. [Google Scholar] [CrossRef]

- Oshio, K.; Tsujimoto, M.; Taniguchi, K.; Obo, T.; Kubota, N. 2D-SLAM of Illuminance Measurement Robot using 3D-LiDAR and IMU on Slopes. In Proceedings of the 2022 Joint 12th International Conference on Soft Computing and Intelligent Systems and 23rd International Symposium on Advanced Intelligent Systems (SCIS&ISIS), Ise, Japan, 29 November–2 December 2022; pp. 1–6. [Google Scholar]

- Li, D.H.W.; Cheung, G.H.W.; Cheung, K.L. Evaluation of simplified procedure for indoor daylight illuminance determination against data in scale model measurements. Indoor Built Environ. 2006, 15, 213–223. [Google Scholar] [CrossRef]

- Jaskowski, P.; Tomczuk, P.; Chrzanowicz, M. Construction of a Measurement System with GPS RTK for Operational Control of Street Lighting. Energies 2022, 15, 9106. [Google Scholar] [CrossRef]

- Bhandary, S.K.; Dhakal, R.; Sanghavi, V.; Verkicharlai, P.K. Ambient light level varies with different locations and environmental conditions: Potential to impact myopia. PLoS ONE 2021, 16, e0254027. [Google Scholar] [CrossRef]

- Nabavi Niaki, M.S.; Saunier, N.; Miranda-Moreno, L.F.; Amador, L.; Bruneau, J.F. Method for road lighting audit and safety screening at urban intersections. Transp. Res. Rec. 2014, 2458, 27–36. [Google Scholar] [CrossRef]

- Fiorentin, P.; Scroccaro, A. The importance of testing road lighting plants: A simple system for their assessment. In Proceedings of the 2009 IEEE Intrumentation and Measurement Technology Conference, I2MTC 2009, Singapore, 5–7 May 2009. [Google Scholar]

- EN 12464-1:2021; Light and Lighting—Lighting of Work Places—Part 1: Indoor Work Places. CEN: Brussels Belgium, 2021.

- EN 12464-1: 2014; Light and Lighting—Lighting of Work Places—Part 2: Outdoor Work Places. CEN: Brussels Belgium, 2014.

- EN 13201-2:2015; Road Lighting—Part 2: Performance Requirements. CEN: Brussels Belgium, 2015; p. 23.

- Samedov, F.; Bazkir, Ö. Realization of photometric base unit of candela traceable to cryogenic radiometer at UME. EPJ Appl. Phys. 2005, 30, 205–213. [Google Scholar] [CrossRef]

- Mũoz-Martínez, V.F.; Serón-Barba, J.; Molina-Mesa, R.; Gómez-De-Gabriel, J.M.; Fernández-Lozano, J.; García-Cerezo, A. Double reflection goniophotometer. Metrologia 2006, 43, 185–194. [Google Scholar] [CrossRef]

- Legierski, M.; Michałek, P. Concept and implementation of H-V goniophotometer for fast measurement of luminous intensity distribution in C-γ system. Prz. Elektrotech. 2020, 1, 77–80. [Google Scholar] [CrossRef]

- Sauter, G. Goniophotometry: New calibration method and instrument design. In Metrologia; IOP Publishing: Bristol, UK, 1995. [Google Scholar]

- Oleszyński, T. Miernictwo Techniki Świetlnej (Eng. Metrology of Lighting Technology); PWN: Warsaw, Poland, 1957. [Google Scholar]

- CIE. International Commission on Illumination Technical Report No. 121: The Photometry and Goniophotometry of Luminaires; CIE: Vienna, Austria, 1996. [Google Scholar]

- CIE. International Commission on Illumination Technical Report No. 70: The Measurement of Absolute Luminous Intensity Distribution; CIE: Vienna, Austria, 1987. [Google Scholar]

- United Nations. United Nations Regulations 112—Uniform Provisions Concerning the Approval of Motor Vehicle Headlamps Emitting an Asymmetrical Passing-Beam or a Driving-Beam or Both and Equipped with Filament Lamps and/or Light-Emitting Diode (LED) Modules; United Nations: Geneva, Switzerland, 2014. [Google Scholar]

- Skarżyński, K.; Żagan, W.; Krajewski, K. Led luminaires: Many chips—Many photometric and lighting simulation issues to solve. Energies 2021, 14, 4646. [Google Scholar] [CrossRef]

- Czyzewski, D. Monitoring of the lighting conditions of a street illuminated with road lights equipped with LEDs. Prz. Elektrotech. 2010, 86, 170–172. [Google Scholar]

- Buyukkınacı, B.; Onaygil, S.; Guler, O.; Yurtseven, M.B. Comparison of road lighting calculations with measurements using conventional and camera luminance meters. Light Eng. 2016, 24, 56–63. [Google Scholar]

- Krupiński, R. Luminance distribution projection method in dynamic floodlight design for architectural features. Autom. Constr. 2020, 119, 103360. [Google Scholar] [CrossRef]

- Skarzynski, K. Field measurement of Floodlighting Utilisation Factor. In Proceedings of the 2016 IEEE Lighting Conference of the Visegrad Countries, Lumen V4 2016, Karpacz, Poland, 13–16 September 2016. [Google Scholar]

- Krupinski, R. Virtual reality system and scientific visualisation for smart designing and evaluating of lighting. Energies 2020, 13, 5518. [Google Scholar] [CrossRef]

- Sielachowska, M.; Tyniecki, D.; Zajkowski, M. Luminance distribution measurements in a classroom using the Skywatcher system. Prz. Elektrotech. 2019, 1, 267–270. [Google Scholar] [CrossRef]

- Piccoli, B.; Soci, G.; Zambelli, P.L.; Pisaniello, D. Photometry in the workplace: The rationale for a new method. Ann. Occup. Hyg. 2004, 48, 29–38. [Google Scholar]

- Hirning, M.B.; Isoardi, G.L.; Cowling, I. Discomfort glare in open plan green buildings. Energy Build. 2014, 70, 427–440. [Google Scholar] [CrossRef]

- Geerdinck, L.M.; Van Gheluwe, J.R.; Vissenberg, M.C.J.M. Discomfort glare perception of non-uniform light sources in an office setting. J. Environ. Psychol. 2014, 39, 5–13. [Google Scholar] [CrossRef]

- Wolska, A.; Sawicki, D. Practical application of HDRI for discomfort glare assessment at indoor workplaces. Meas. J. Int. Meas. Confed. 2019, 151, 107179. [Google Scholar] [CrossRef]

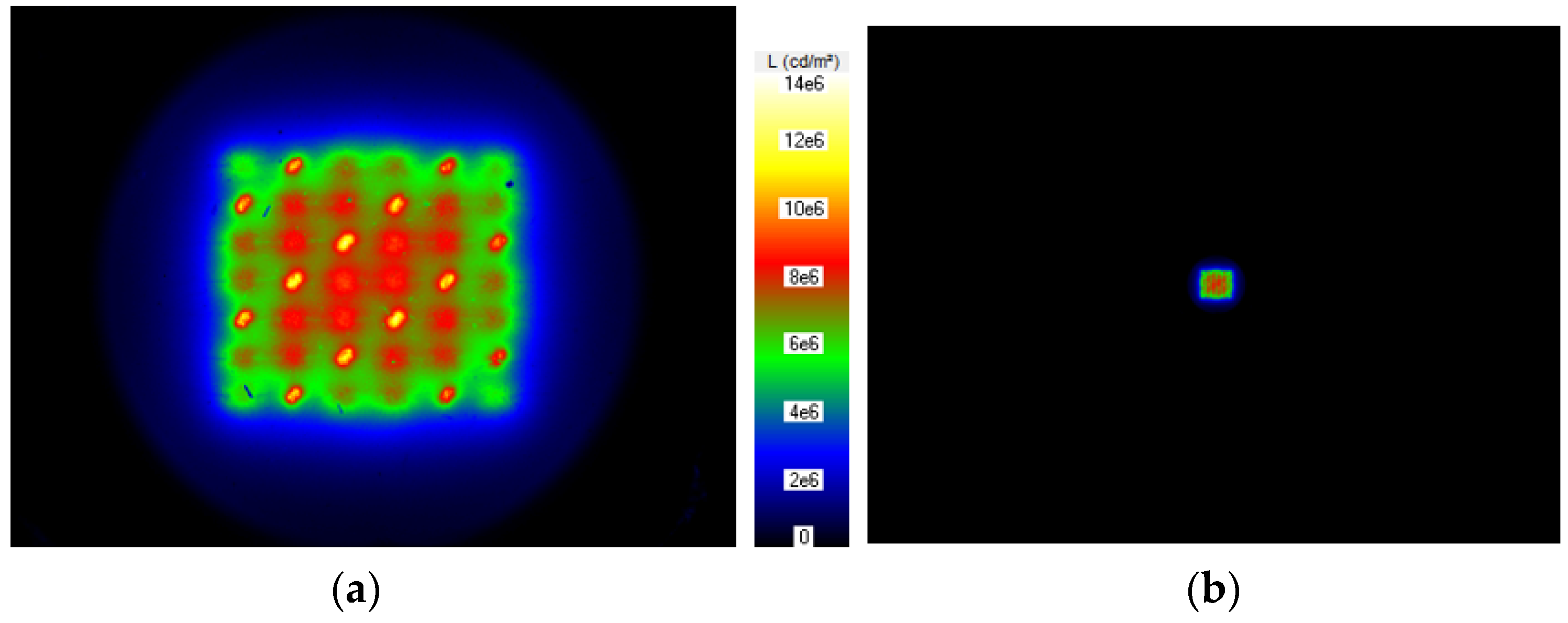

- Czyżewski, D. Research on luminance distributions of chip-on-board light-emitting diodes. Crystals 2019, 9, 645. [Google Scholar] [CrossRef]

- Zheng, L.; Guo, Z.; Yan, W.; Lin, Y.; Lu, Y.; Kuo, H.C.; Chen, Z.; Zhu, L.; Wu, T.; Gao, Y. Research on a Camera-Based Microscopic Imaging System to Inspect the Surface Luminance of the Micro-LED Array. IEEE Access 2018, 6, 51329–51336. [Google Scholar] [CrossRef]

- Czyzewski, D. Selected problems of defining the luminous area of electroluminescent diodes. Prz. Elektrotech. 2008, 84, 129–131. [Google Scholar]

- Chaves, J.; Falicoff, W.; Benitez, P.; Miñano, J.C.; Parkyn, W.A.; Dross, O. Luminance enhancement of LED light sources for etendue-limited applications. In Proceedings of the Nonimaging Optics and Efficient Illumination Systems III, San Diego, CA, USA, 13–15 August 2006. [Google Scholar]

- Czyzewski, D. Luminance distribution of LED luminous surface. Prz. Elektrotech. 2010, 86, 166–169. [Google Scholar]

- Cai, H. Camera aided luminance measurement of the luminous surfaces of different light sources. In Proceedings of the AEI 2011: Building Integrated Solutions—Proceedings of the AEI 2011 Conference, Oakland, CA, USA, 30 March–2 April 2011. [Google Scholar]

- Graef, K.; Schaeffel, F. Control of accommodation by longitudinal chromatic aberration and blue cones. J. Vis. 2012, 12, 14. [Google Scholar] [CrossRef]

- Czyżewski, D. The leds luminance distribution measurement quality dependency on image focusing. Photonics Lett. Pol. 2020, 12, 121–123. [Google Scholar] [CrossRef]

- Website of Lichtmesstechnik Gmbh Berlin. LUMINANCE METERS LMT L 1009. Available online: https://lmt.de/index.html@p=401.html (accessed on 5 May 2023).

- Website of Konica Minolta Chroma Meter CS-200. Available online: https://www.konicaminolta.com/instruments/download/catalog/light/pdf/cs200_catalog_eng.pdf (accessed on 13 May 2023).

- CEN/TC EN 13201-4:2015; Road lighting—Part 4: Methods of Measuring Lighting Performance. CEN: Brussels, Belgium, 2015.

- Website of GL OPTIC. GL OPTICAM. Available online: https://gloptic.com/products/luminance-cameras/#products (accessed on 15 May 2023).

- Website of TechnoTeam Vision USA Inc. LMK 6 Color. Available online: https://www.technoteamvision.com/product_overview/photometer_colorimeter/products/lmk_6_color/index_eng.html (accessed on 15 May 2023).

- Website of KONICA MINOLTA CA-2500. Available online: https://www.konicaminolta.eu/eu-en/hardware/measuring-instruments/light-and-display-measurement/luminance-meters/ca-2500 (accessed on 15 May 2023).

- Website of Hangzhou Hoptek Technology Co. CX-1000 Imaging Luminance Meter. Available online: https://hoptek.net/en/products/detail/CX1000.html (accessed on 15 May 2023).

- Salamone, F.; Sibilio, S.; Masullo, M. Assessment of the Performance of a Portable, Low-Cost and Open-Source Device for Luminance Mapping through a DIY Approach for Massive Application from a Human-Centred Perspective. Sensors 2022, 22, 7706. [Google Scholar] [CrossRef]

- Brebenariu, D.; Galatanu, C.D. Measuring Luminance with Digital Photometric Camera in Short Tunnels. In Proceedings of the EPE 2020—Proceedings of the 2020 11th International Conference and Exposition on Electrical and Power Engineering, Iasi, Romania, 22–23 October 2020. [Google Scholar]

- Hain, R.; Kähler, C.J.; Tropea, C. Comparison of CCD, CMOS and intensified cameras. Exp. Fluids 2007, 42, 403–411. [Google Scholar] [CrossRef]

- Xiong, P. Comparison of CCD and CMOS image sensors. Bandaoti Guangdian/Semicond. Optoelectron. 2004, 25, 1–4. [Google Scholar] [CrossRef]

- Website ManualZZ Luminance and Color Measuring Camera LMK 98. Available online: https://manualzz.com/doc/31466295/luminance-and-color-measuring-camera-lmk-98 (accessed on 5 May 2023).

- Rusu, A.V.; Galatanu, C.D.; Livint, G.; Lucache, D.D. Measuring average luminance for road lighting from outside the carriageway with imaging sensor. Sustainability 2021, 13, 9029. [Google Scholar] [CrossRef]

- Tyukhova, Y.; Waters, C. An assessment of high dynamic range luminance measurements with LED lighting. LEUKOS—J. Illum. Eng. Soc. N. Am. 2014, 10, 87–99. [Google Scholar] [CrossRef]

- Zalesinska, M.; Wandachowicz, K. On the quality of street lighting in pedestrian crossings. Energies 2021, 14, 7349. [Google Scholar] [CrossRef]

- Czyżewski, D. The Photometric Test Distance in Luminance Measurement of Light-Emitting Diodes in Road Lighting. Energies 2023, 16, 1199. [Google Scholar] [CrossRef]

- Beltrán, L.O.; Mogo, B.M. Assessment of luminance distribution using HDR photography. In Proceedings of the Solar World Congress 2005: Bringing Water to the World, Including Proceedings of 34th ASES Annual Conference and Proceedings of 30th National Passive Solar Conference, Orlando, FL, USA, 6–12 August 2005. [Google Scholar]

- Hiscocks, P.D. Measuring Luminance with a Digital Camera; Syscomp Electronic Design Limited: Richmond Hill, ON, Canada, 2014. [Google Scholar]

- Hoang, N.D.; Cao, X.Q.; Nguyen, H.L. Research and development of a luminance responsivity standard system at the Vietnam Metrology Institute. Vietnam J. Sci. Technol. Eng. 2020, 62, 3–6. [Google Scholar] [CrossRef]

- Słomiński, S. Mapowanie Rozkładu Luminacji Źródła Światła w Obliczeniach Fotometrycznych Odbłyśników Zwierciadlanych (eng. Mapping the Luminance Distribution of a Light Source in Photometric Calculations of Specular Reflectors). Doctoral Dissertation, OWPW, Warsaw, Poland, 2010. [Google Scholar]

- Żagan, W.; Zalewski, S.; Słomiński, S.; Kubiak, K. Methods for designing and simulating optical systems for luminaires. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 739–750. [Google Scholar] [CrossRef]

- Słomiński, S. Luminance mapping to the light source model—Possibilities to use a MML in the lighting technology field. Prz. Elektrotech. 2011, 201, 87. [Google Scholar]

- Słomiński, S. Advanced modelling and luminance analysis of LED optical systems. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 1107–1116. [Google Scholar] [CrossRef]

| Parameter | LMK98-3 Color | LMK Mobile Air |

|---|---|---|

| sensor | CCD Sony ICX 285 AL | CMOS Canon APS-C |

| resolution (luminance image resolution) | 1380 (H) × 1030 (V) | 5566 (H) × 3706 (V) (2748(H) × 1834(V)) |

| pixel ratio | 6.45 μm × 6.45 μm | 4.1 μm × 41.1 μm |

| sensor area | 8.9 (H) × 6.64 (V) mm | 22.5 (H) × 15.0 (V) mm |

| video signal | 12 bit digital | 14 bit digital |

| uniformity ∆L in % | ∆L ± 2% (f22 ≤ 4%) |

| Parameter | LMK98-3 Color | LMK Mobile Air |

|---|---|---|

| The measured average luminance of the reference plate [cd/m2] | 890 | 911.7 |

| The reference luminance [cd/m2] | 889 | 889 |

| Luminance measurement deviation [%] | 0.11 | 2.54 |

| Photometric Distance [mm] | Summary of Reference Luminance Research Results (LMK 98-3 Color) | Summary of Reference Luminance Calculation Results | ||||

|---|---|---|---|---|---|---|

| Lavr | Lmax | Number of Pixels (Px) | Lavr(x)/Lavr(655) · 100 | Lmax(x)/Lmax(655) · 100 | Px/Px(all pixels) · 100 | |

| [cd/m2] | [cd/m2] | [-] | [%] | [%] | [%] | |

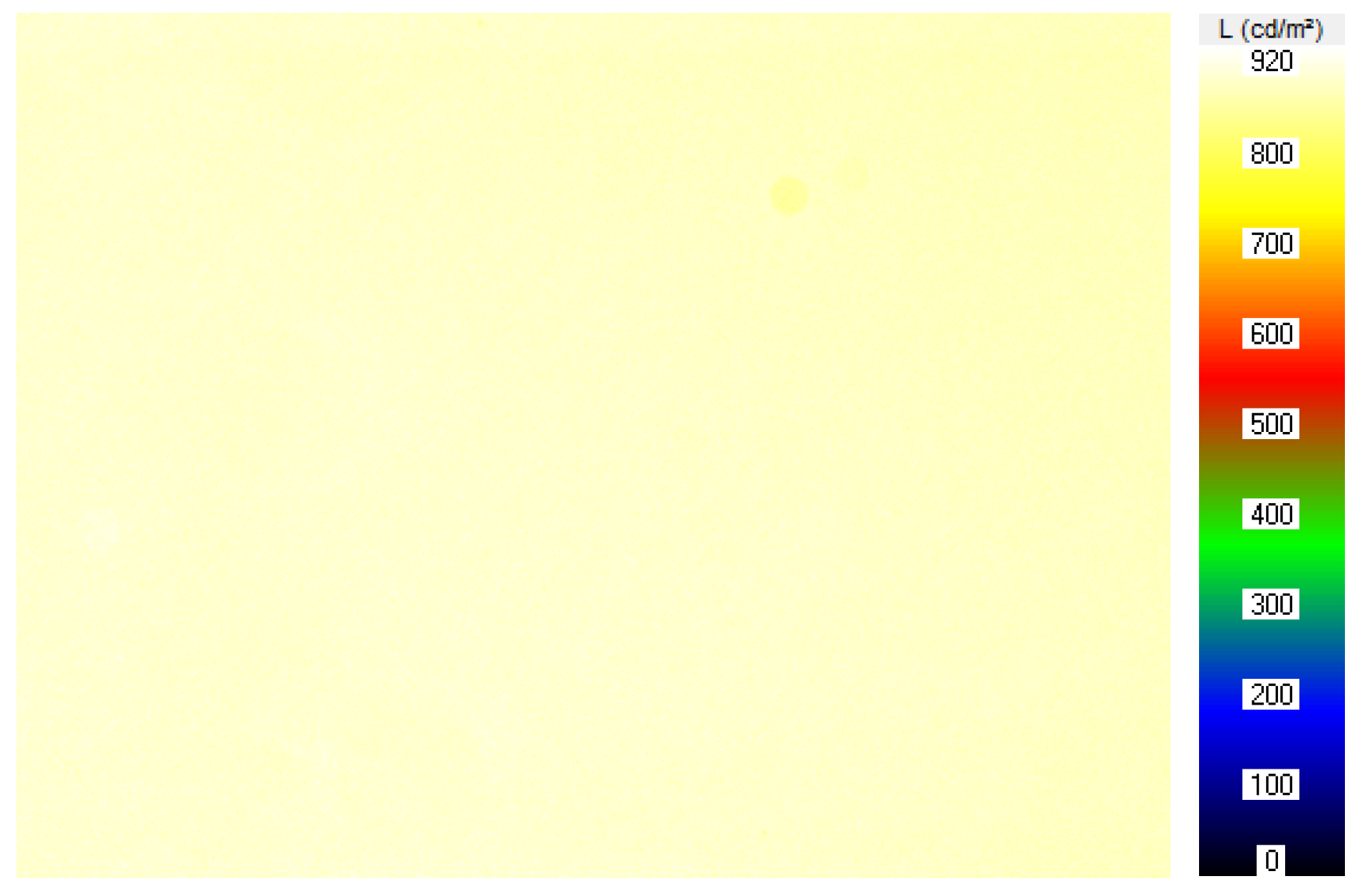

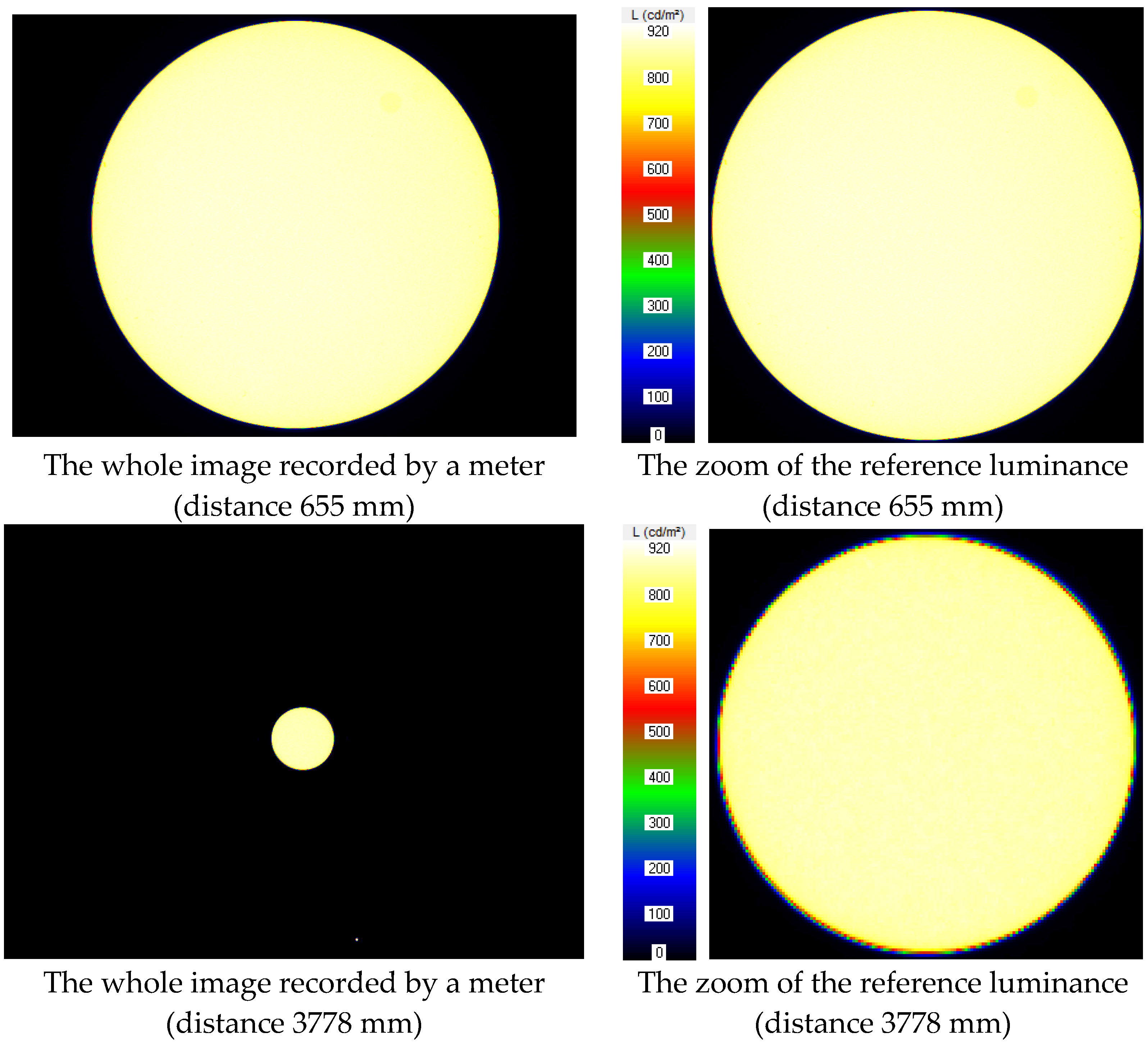

| 655 | 871.1 | 911.4 | 777,000 | 100 | 100 | 54.9 |

| 818 | 871.0 | 908.6 | 463,900 | 99.99 | 99.7 | 32.8 |

| 940 | 870.5 | 906.9 | 334,500 | 99.9 | 99.5 | 23.6 |

| 1354 | 862.7 | 904.6 | 151,100 | 99.25 | 99.0 | 10.7 |

| 1737 | 860.8 | 901.9 | 88,980 | 98.96 | 98.8 | 6.3 |

| 2401 | 849.3 | 896.6 | 45,460 | 97.5 | 98.4 | 3.2 |

| 3778 | 836.9 | 888.2 | 17,810 | 96.1 | 97.5 | 1.3 |

| 8049 | 805.2 | 869.8 | 3905 | 92.4 | 95.4 | 0.3 |

| 11,465 | 753.9 | 861.3 | 2005 | 86.5 | 94.5 | 0.1 |

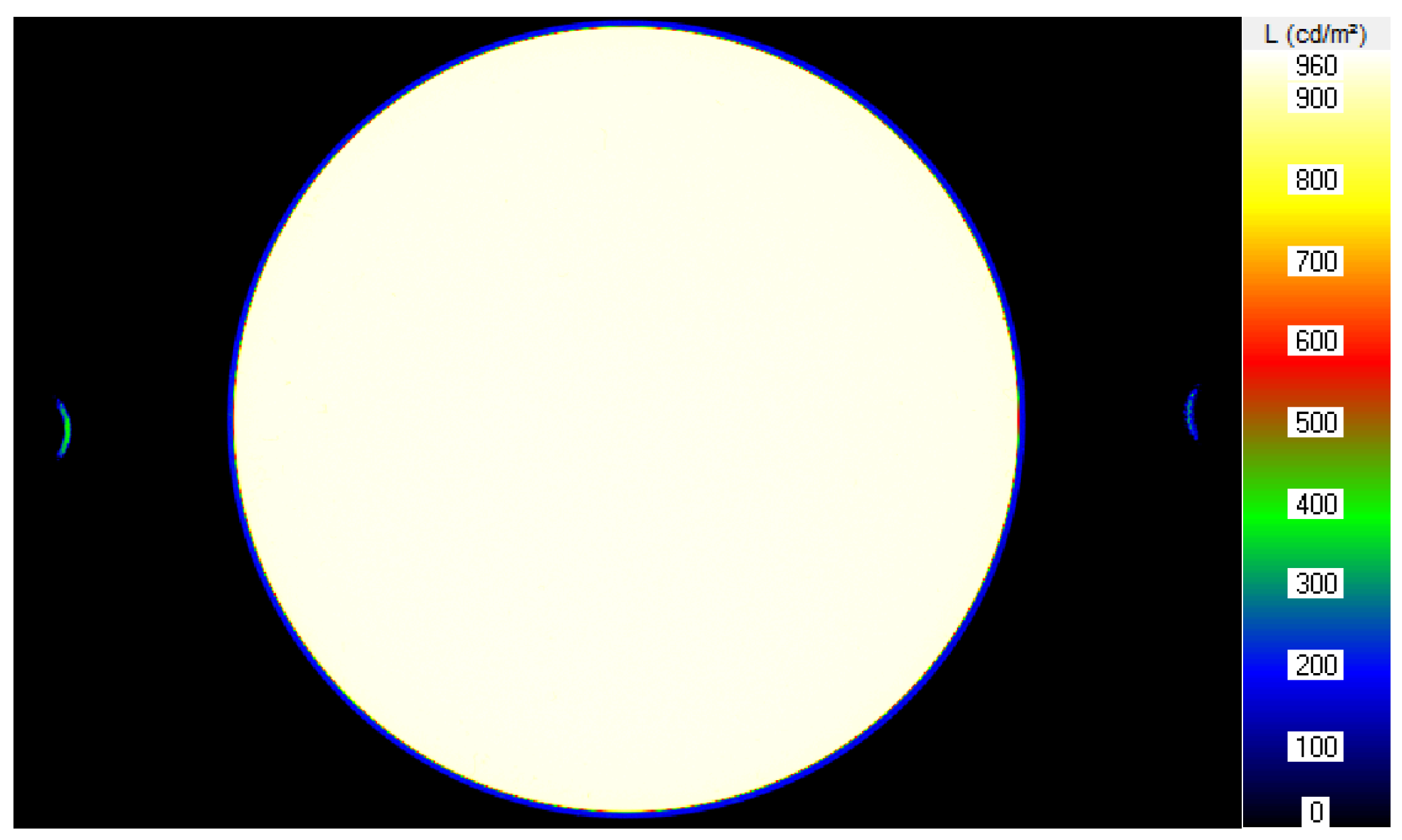

| Photometric Distance [mm] | Summary of Reference Luminance Research Results (LMK Air Mobile) for the Focal Length of 50 mm | Summary of Reference Luminance Calculation Results | ||||

|---|---|---|---|---|---|---|

| Lavr | Lmax | Number of pixels (Px) | Lavr(x)/Lavr(180) · 100 | Lmax(x)/Lmax(180) · 100 | Px/Px(all pixels) · 100 | |

| [cd/m2] | [cd/m2] | [-] | [%] | [%] | [%] | |

| 280 | 911.7 | 956.3 | 2,635,000 | 100.0 | 100.0 | 51.1 |

| 500 | 906.6 | 951.5 | 724,700 | 99.4 | 99.5 | 14.0 |

| 700 | 881.6 | 921.2 | 314,300 | 96.7 | 96.3 | 6.09 |

| 1000 | 868.1 | 918.1 | 155,200 | 95.2 | 96.0 | 3.01 |

| 2000 | 846.9 | 915.3 | 34,820 | 92.9 | 95.7 | 0.67 |

| 4000 | 824.8 | 910.3 | 9261 | 90.5 | 95.2 | 0.18 |

| 6000 | 776.4 | 910.9 | 4373 | 85.2 | 95.3 | 0.08 |

| 8000 | 695.6 | 909.6 | 2701 | 76.3 | 95.1 | 0.05 |

| 8000 (zoom 17 mm) | 644.9 | 906.9 | 401 | 70.7 | 94.8 | 0.008 |

| Measurement Accuracy | Recommended Minimum Number of Pixels to Ensure the Specified Accuracy of Average Luminance Measurement Lavr [-] | ||

|---|---|---|---|

| Laboratory ILMD Measured High-Luminance LED | Laboratory ILMD Measured Standard Luminance | Air Mobile ILMD Measured Standard Luminance | |

| 99 [%] | 20,000 | 140,000 | 660,000 |

| 95 [%] | 5000 | 14,000 | 144,000 |

| 90 [%] | 3000 | 3200 | 8900 |

| Measurement Accuracy | Recommended Minimum Number of Pixels to Ensure the Specified Accuracy of Maximum Luminance Measurement Lmax [-] | ||

|---|---|---|---|

| Laboratory ILMD Measured High-Luminance LED | Laboratory ILMD Measured Standard Luminance | Air Mobile ILMD Measured Standard Luminance | |

| 99 [%] | 50,000 | 98,000 | 91,000 |

| 95 [%] | 20,000 | 3100 | 1800 |

| 90 [%] | 2000 | for 2000 accuracy 94.5% | 400 |

| Required Parameter | Required Value |

|---|---|

| Average maintained illuminance (Ēm) | min. 300 [lx] |

| Illuminance uniformity (Uo) | min. 0.6 [-] |

| Colour rendering index (Ra) | min. 80 [-] |

| CIE Unified Glare Rating limit value (RUGL) | max. 22 [-] |

| Technical Parameter | Luminaire |

|---|---|

| Luminaire photometric intensity curves (LPIC) |  |

| Light source type | PL-C/2P |

| Number of source | 1 |

| Luminaire luminous flux | 900 [lm] |

| Luminaire power | 17.3 [W] |

| CCT | 4000 [K] |

| Ra | 80 [-] |

| Luminaire Photometric Distance | Number of Luminaires (Distribution) | Calculation ResultsĒm/Uo/Ra/RUGL | Power Installed | Power Density per 100 lx | Annual Energy Consumption | LENI |

|---|---|---|---|---|---|---|

| [mm] | [-] | [lx/-/-/-] | [W] | [W/m2/100 lx] | [kWh] | [kWh/m2] |

| 280 mm (reference) | 28 (7 × 4) | 304/0.72/80/22 | 484.4 | 9.96 | 920.36 | 57.52 |

| 1000 mm | 30 (6 × 5) | 302/0.72/80/21 | 519.0 | 10.73 | 986.10 | 61.63 |

| 4000 mm | 32 (8 × 4) | 315/0.72/80/21 | 553.6 | 10.98 | 1051.84 | 65.74 |

| 8000 mm | 36 (6 × 6) | 300/0.71/80/21 | 622.8 | 12.97 | 1183.32 | 73.96 |

| 8000 mm (zoom 17 mm) | 40 (8 × 5) | 309/0.71/80/21 | 692.0 | 14.00 | 1314.80 | 82.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czyżewski, D. The Influence of a Photometric Distance on Luminance Measurements. Energies 2023, 16, 4166. https://doi.org/10.3390/en16104166

Czyżewski D. The Influence of a Photometric Distance on Luminance Measurements. Energies. 2023; 16(10):4166. https://doi.org/10.3390/en16104166

Chicago/Turabian StyleCzyżewski, Dariusz. 2023. "The Influence of a Photometric Distance on Luminance Measurements" Energies 16, no. 10: 4166. https://doi.org/10.3390/en16104166

APA StyleCzyżewski, D. (2023). The Influence of a Photometric Distance on Luminance Measurements. Energies, 16(10), 4166. https://doi.org/10.3390/en16104166