Numerical Simulation of the Proppant Settlement in SC-CO2 Sand-Carrying Fluid in Fracturing Fractures

Abstract

1. Introduction

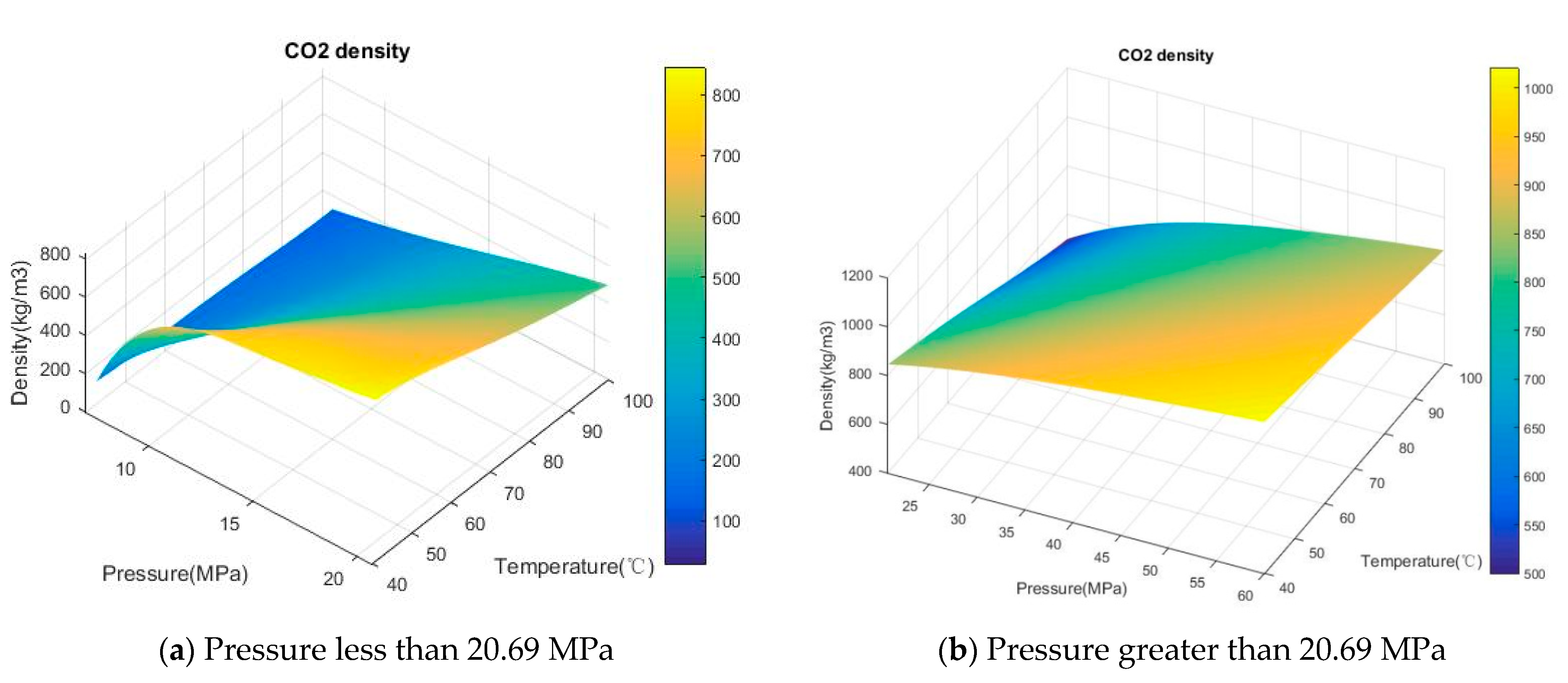

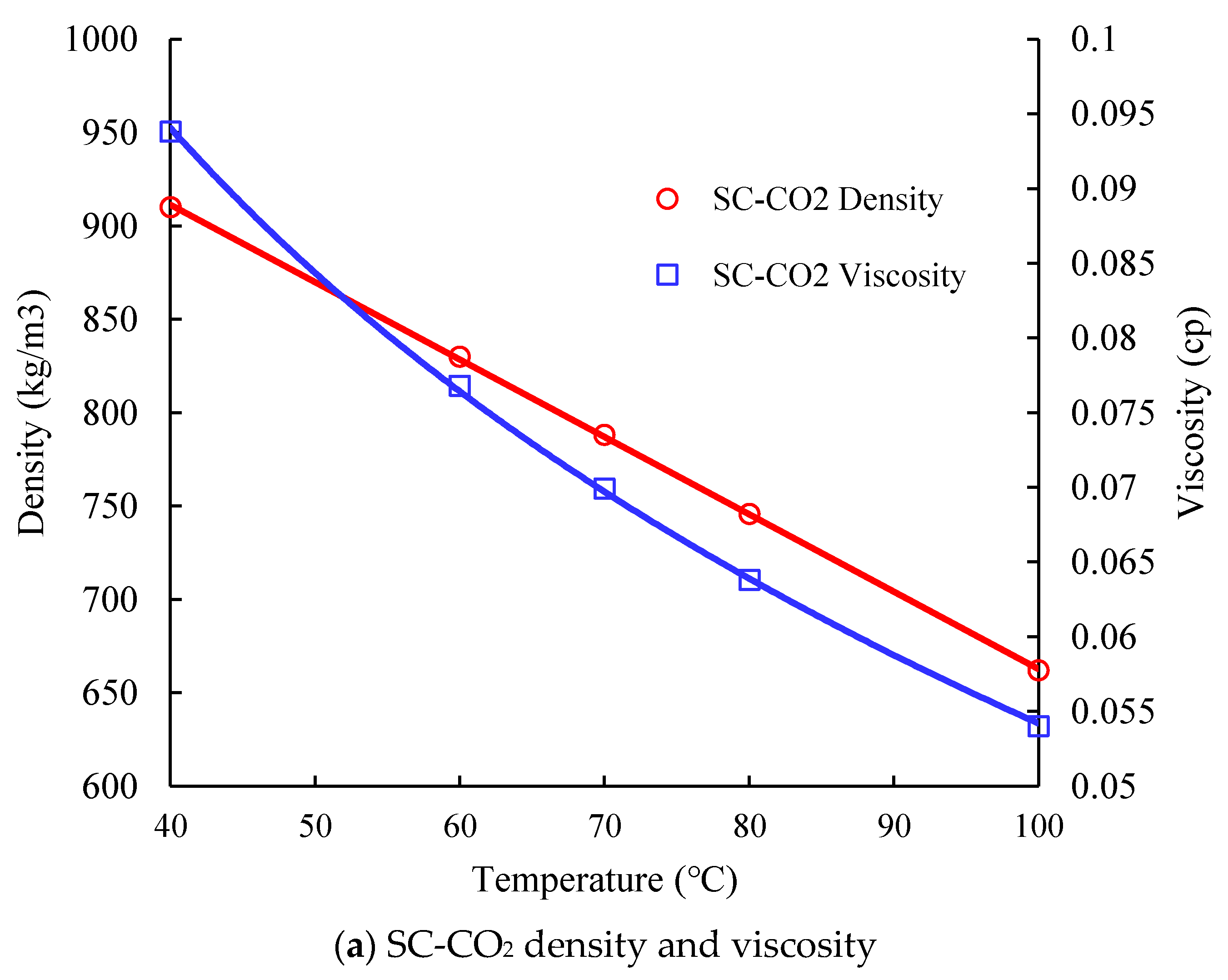

2. The Change Characteristics of SC-CO2 Density and Viscosity

2.1. SC-CO2 Density Variation

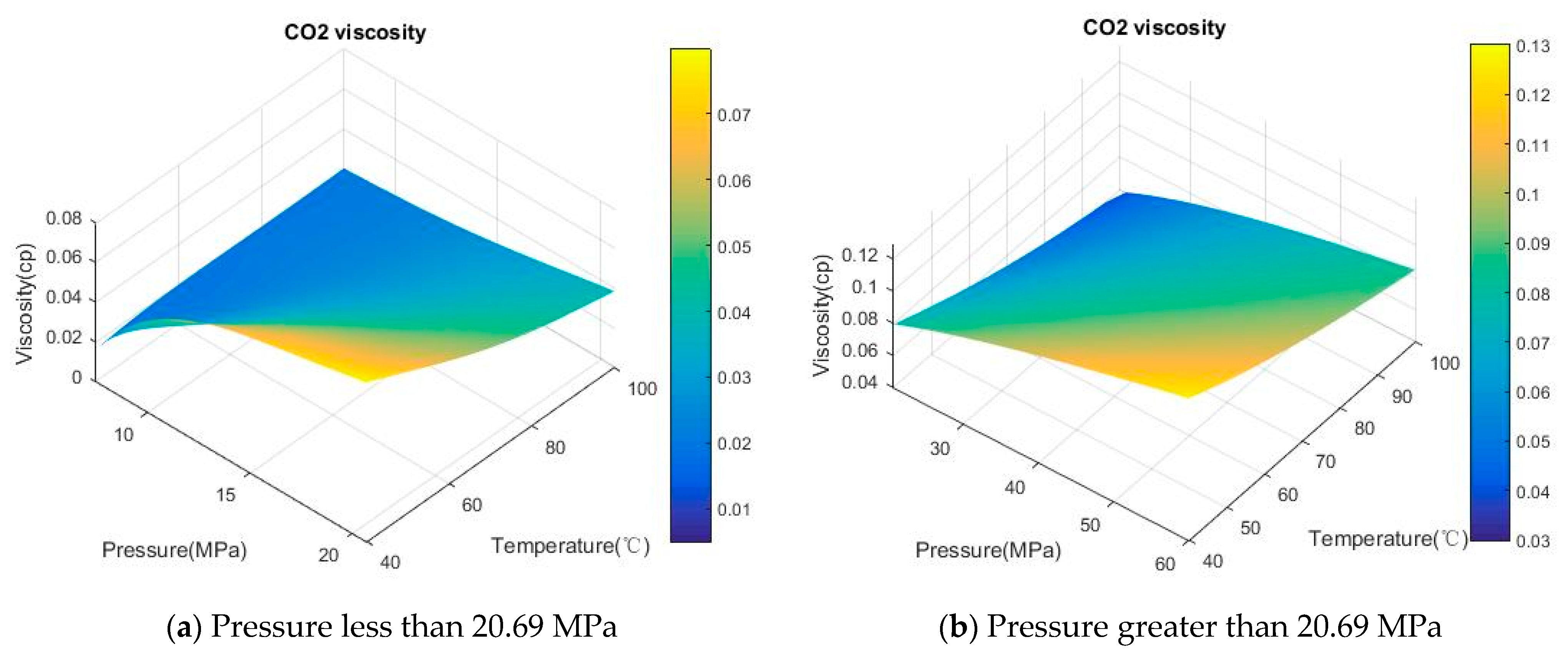

2.2. SC-CO2 Viscosity Variation

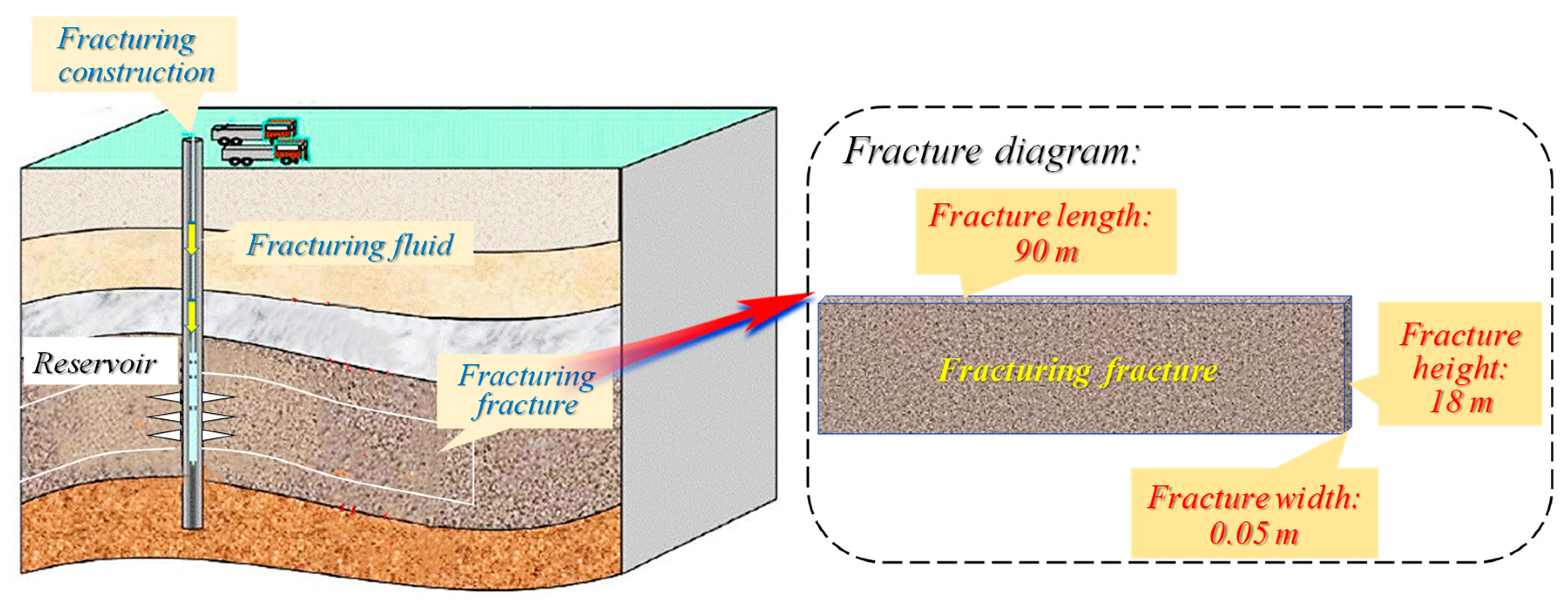

3. Numerical Simulation of Proppant Settlement

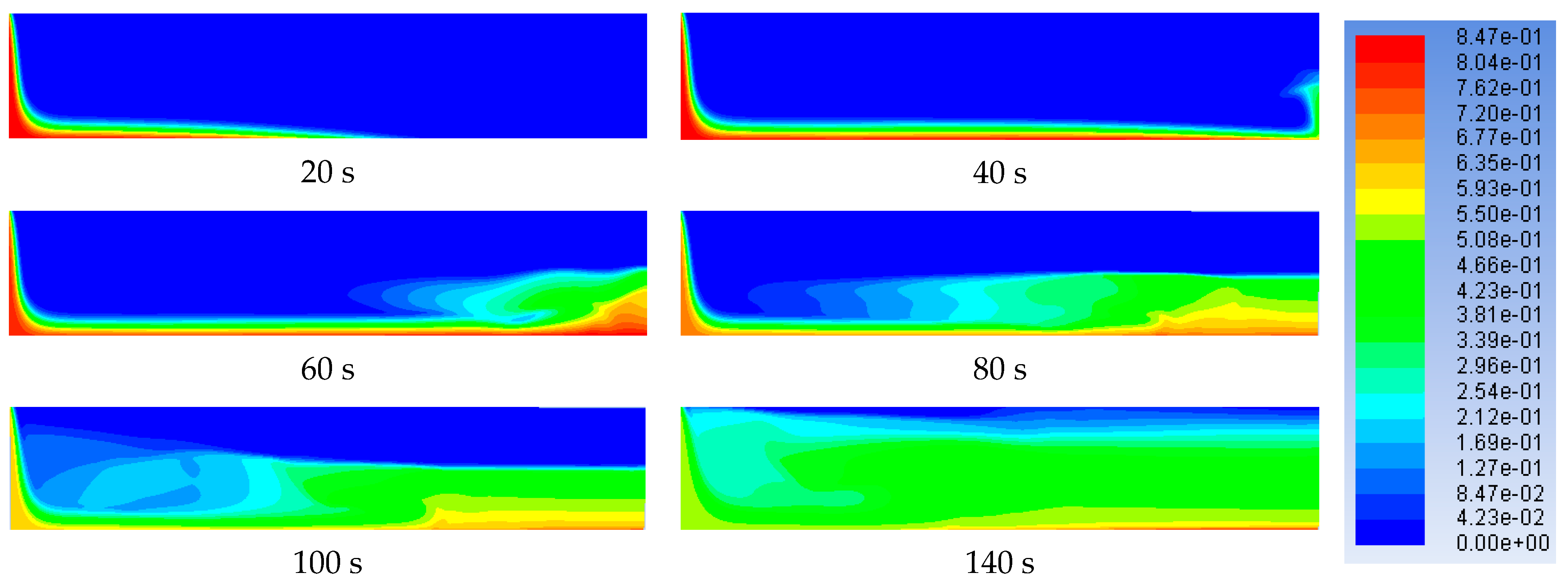

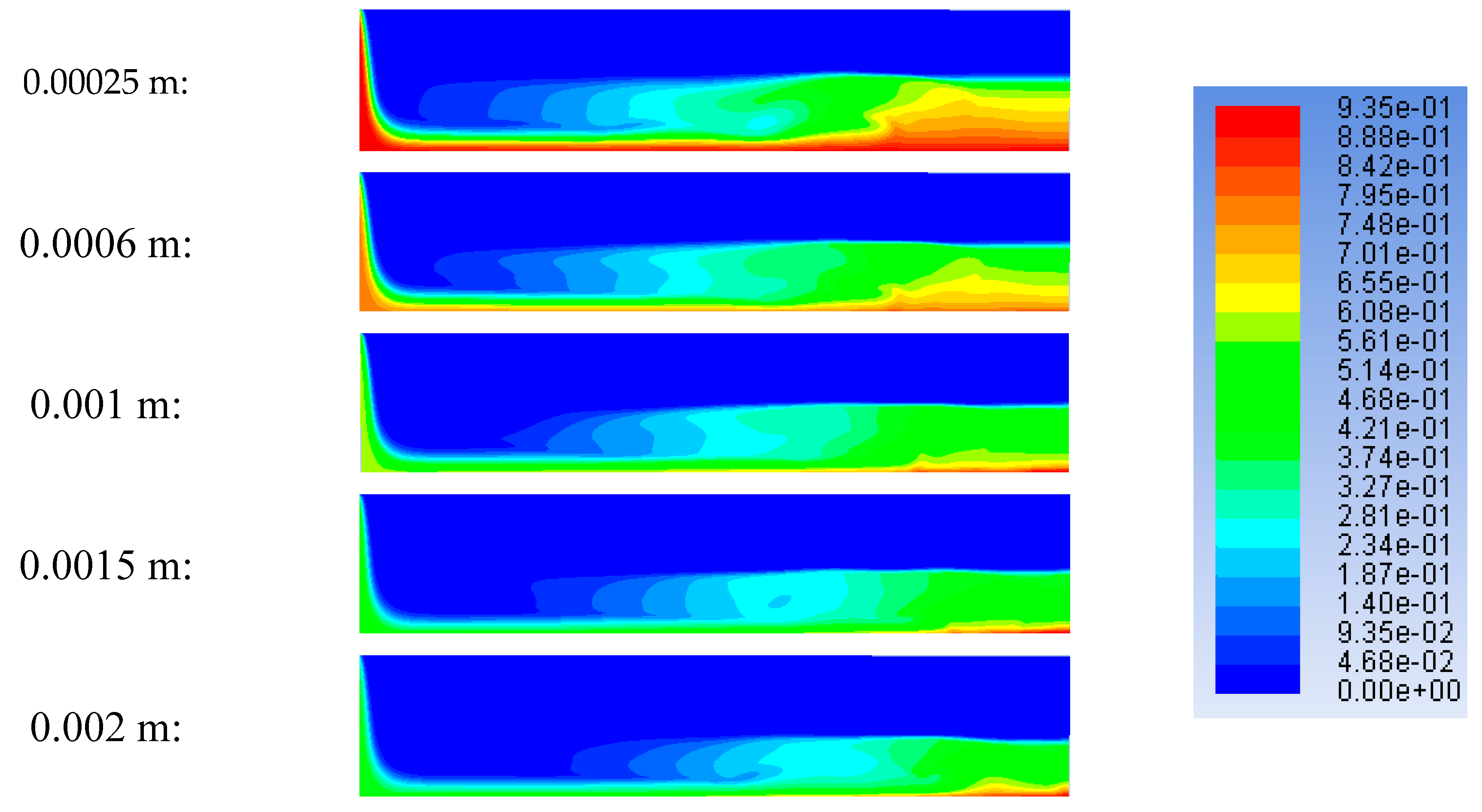

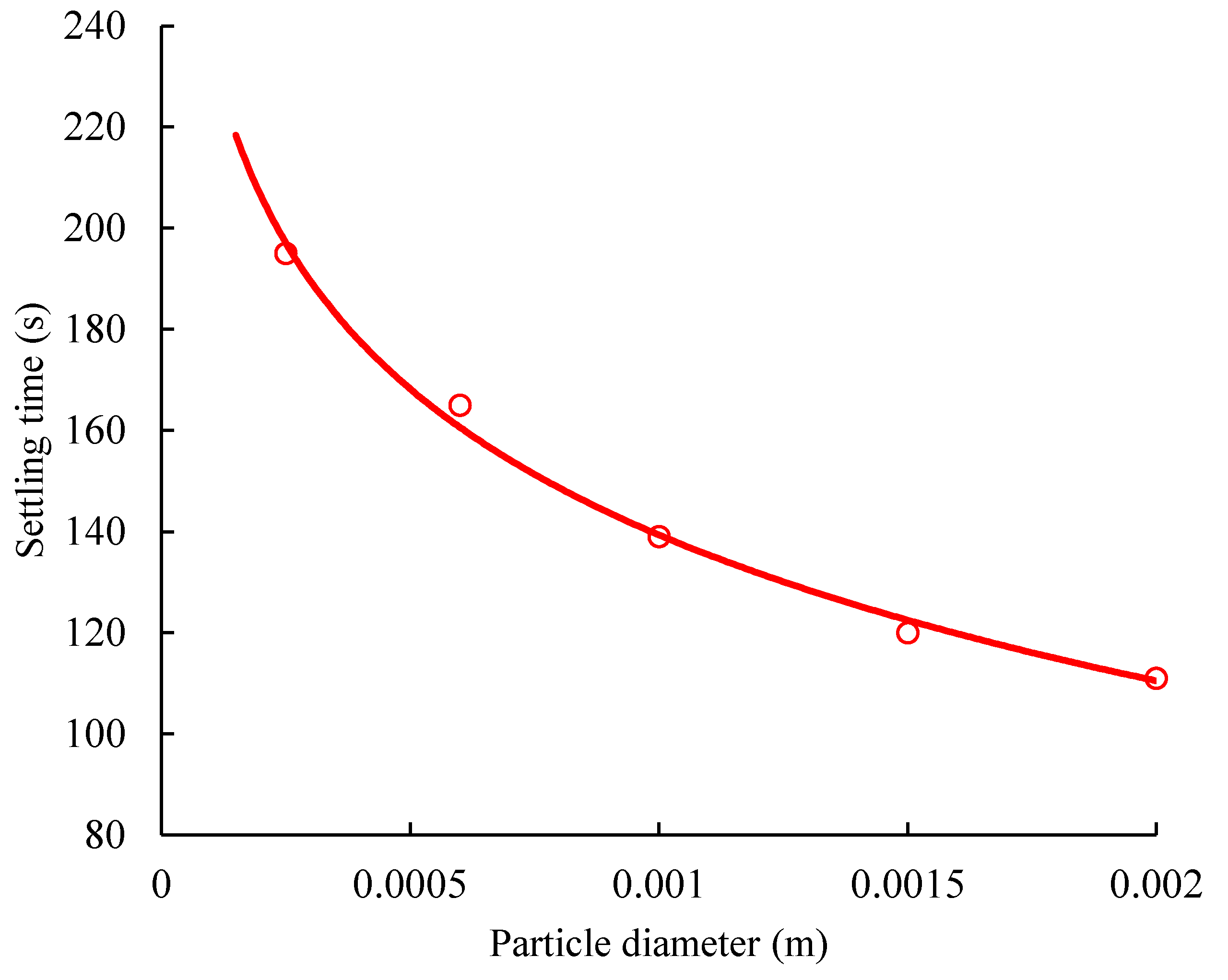

3.1. Solid Particle Diameter

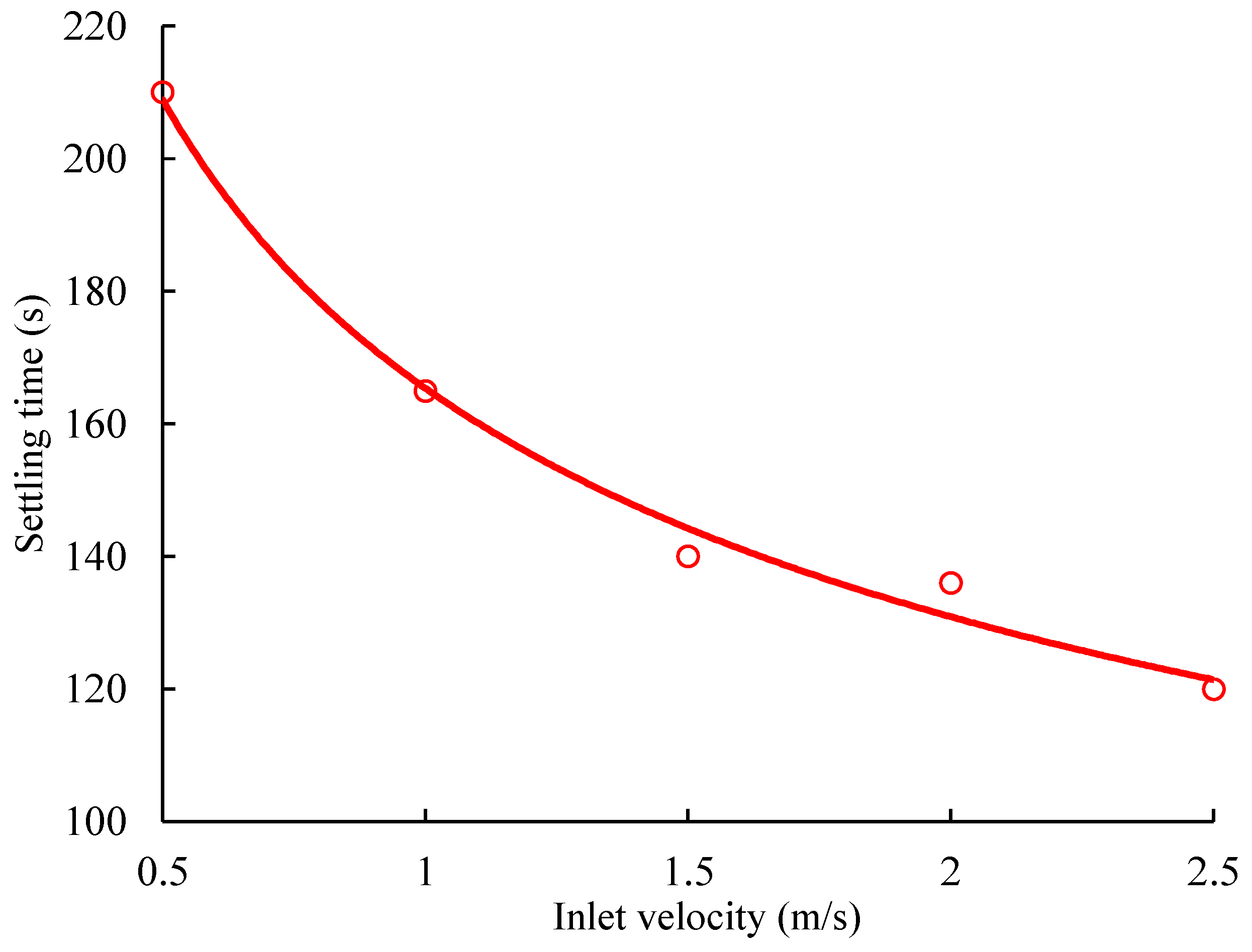

3.2. Fluid Velocity

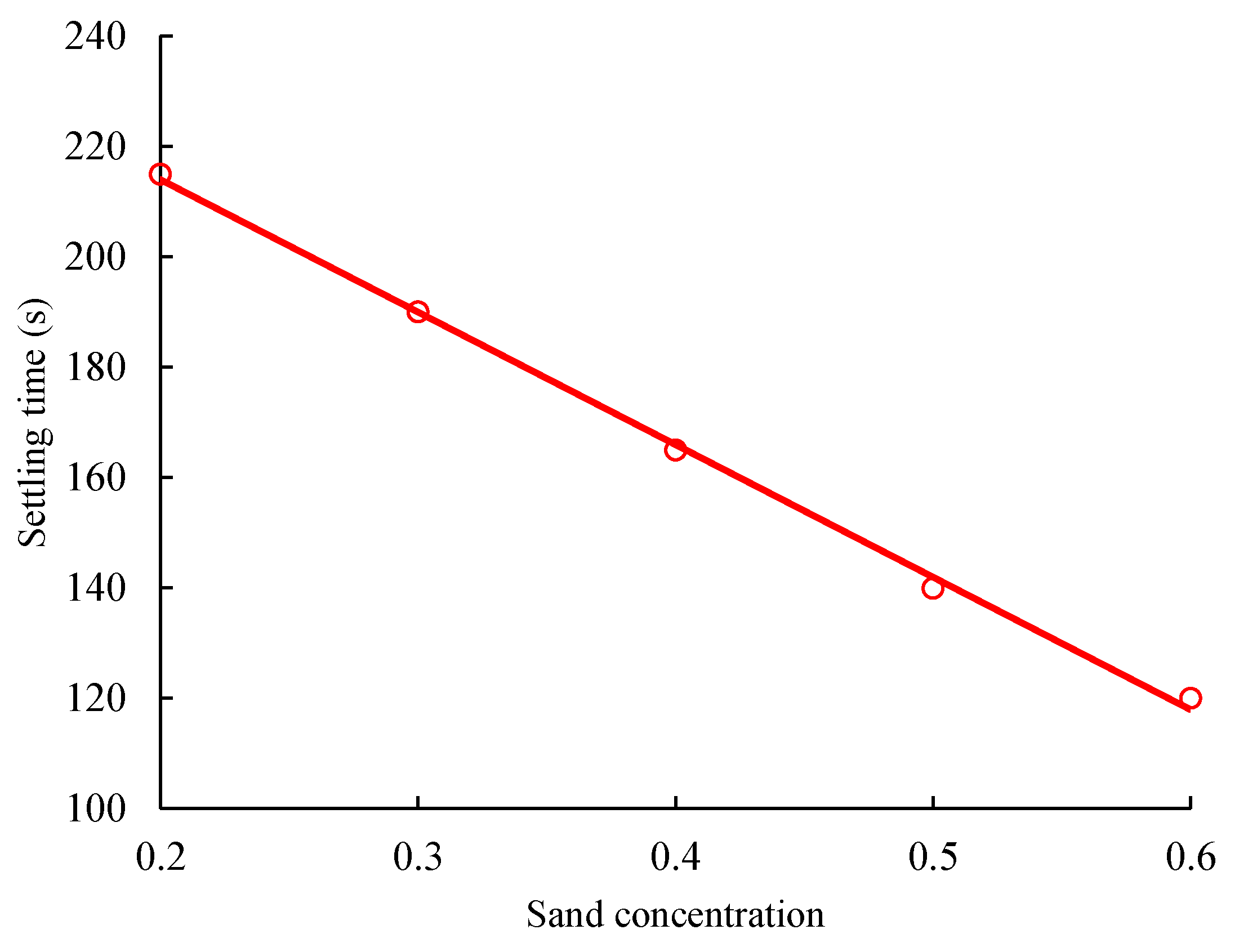

3.3. Sand Concentration

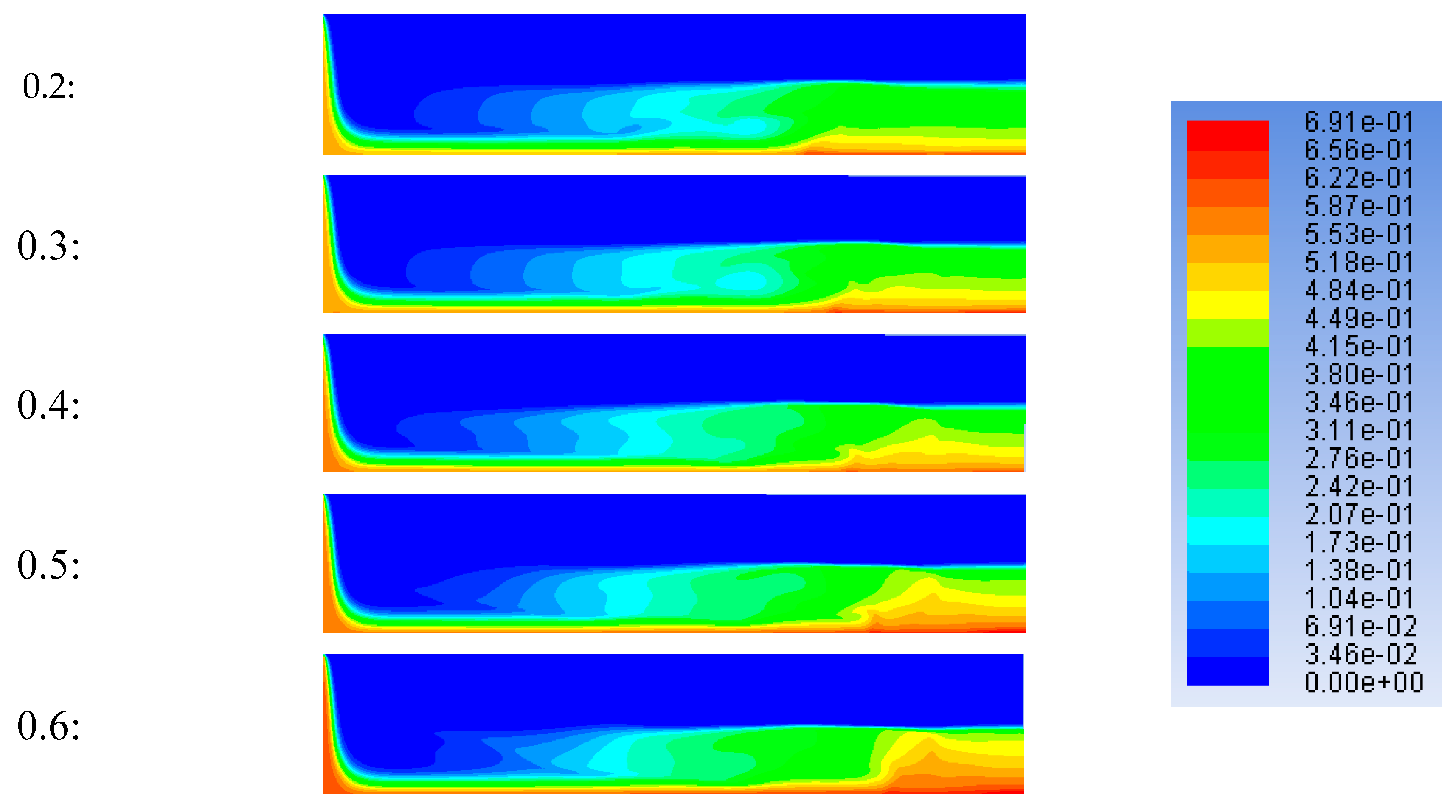

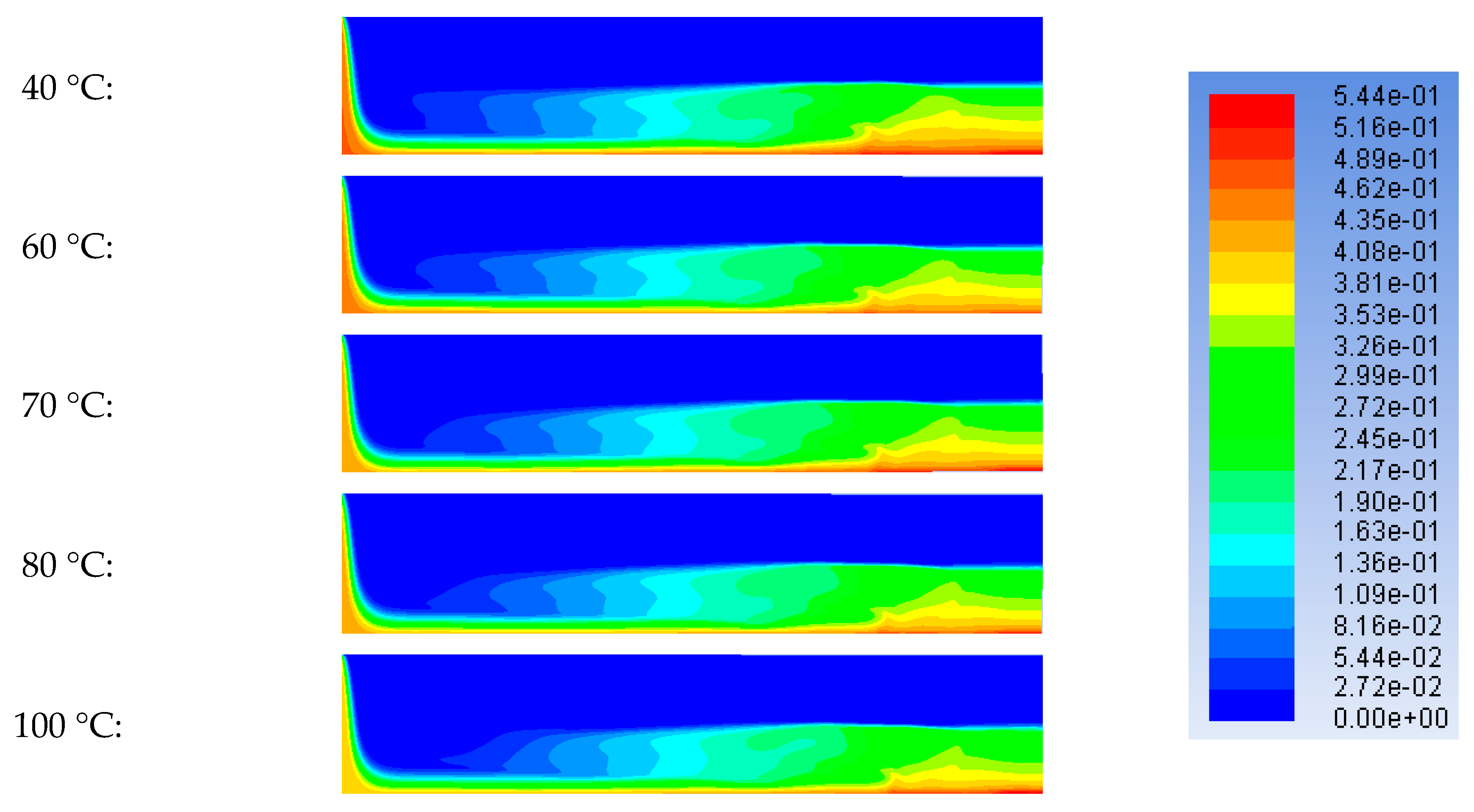

3.4. Flow Temperature

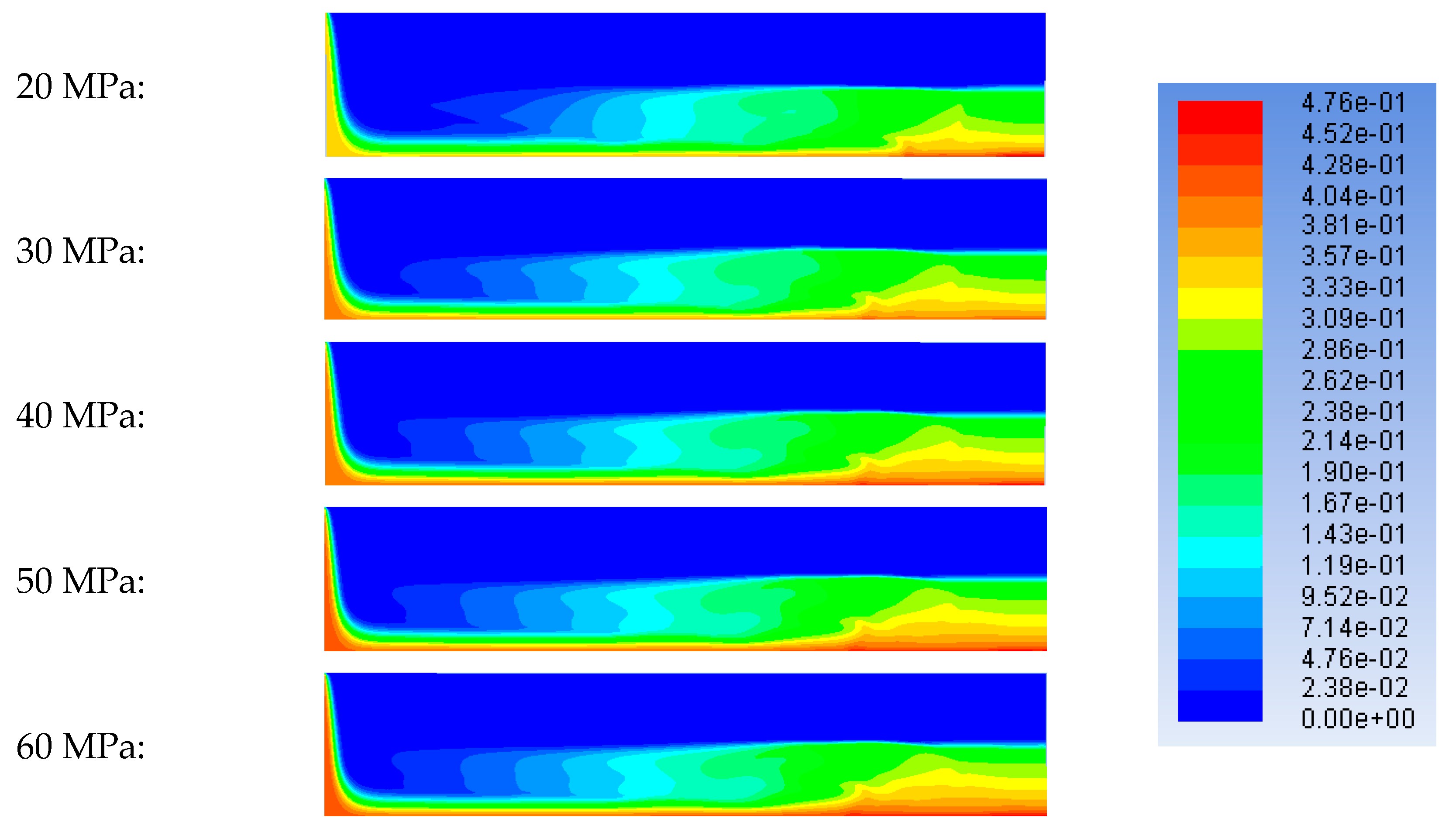

3.5. Average Pressure

4. Conclusions

- (1)

- For cracks with a certain height and length, when the SC-CO2 sand-carrying liquid enters the crack at a certain speed under the action of gravity and viscous forces, the proppant will continuously deposit and the accumulation and backflow will occur at the end of the crack.

- (2)

- The large sand diameters, high fluid flow rates, high sand concentrations, high reservoir temperatures, and low reservoir pressures can help to shorten deposition time, and shortening the sand deposition time can help to complete the fracturing efficiently.

- (3)

- The small particle size, high fluid flow rate, low sand concentration, low reservoir temperature, and high reservoir pressure help increase the uniformity of sand deposition, and increasing the deposition uniformity can improve the fracture conductivity.

- (4)

- According to the reservoir conditions, the reasonable adjustment of the fracturing parameters can significantly improve the fracturing effect, and we hope that the results of this study can play a guiding role in field construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. SC-CO2 Density Calculation Correlations

| Symbol | bi0 | bi1 | bi2 | bi3 | bi4 |

|---|---|---|---|---|---|

| i = 0 | −2.15 × 105 | 1.17 × 104 | −2.30× 102 | 1.97 | −6.18 × 10−3 |

| i = 1 | 4.76 × 102 | −2.62 × 10 | 5.22 × 10−1 | −4.49 × 10−3 | 1.42 × 10−5 |

| i = 2 | −3.71 × 10−1 | 2.07 × 10−2 | −4.17 × 10−4 | 3.62 × 10−6 | −1.16 × 10−8 |

| i = 3 | 1.23 × 10−4 | −6.93 × 10−6 | 1.41 × 10−7 | −1.23 × 10−9 | 3.95 × 10−12 |

| i = 4 | −1.47 × 10−8 | 8.34 × 10−10 | −1.70 × 10−11 | 1.50 × 10−13 | −4.84 × 10−16 |

| Symbol | bi0 | bi1 | bi2 | bi3 | bi4 |

|---|---|---|---|---|---|

| i = 0 | 6.90 × 102 | 2.73 | −2.25 × 10−2 | −4.65 × 10−3 | 3.44 × 10−5 |

| i = 1 | 2.21 × 10−1 | −6.55 × 10−3 | 5.98 × 10−5 | 2.27 × 10−6 | −1.89 × 10−8 |

| i = 2 | −5.12 × 10−5 | 2.02 × 10−6 | −2.31 × 10−8 | −4.08 × 10−10 | 3.89 × 10−12 |

| i = 3 | 5.52 × 10−9 | −2.42 × 10−10 | 3.12 × 10−12 | 3.17 × 10−14 | −3.56 × 10−16 |

| i = 4 | −2.18 × 10−13 | 1.01 × 10−14 | −1.41 × 10−16 | −8.96 × 10−19 | 1.22 × 10−20 |

Appendix B. SC-CO2 Viscosity Correlations

| Coefficient | Value | Coefficient | Value |

|---|---|---|---|

| a0 | 0.235156 | d11 | 4.071119 × 10−3 |

| a1 | −0.491266 | d21 | 7.198037 × 10−5 |

| a2 | 0.05211155 | d64 | 2.411697 × 10−17 |

| a3 | 0.05347906 | d81 | 2.971072 × 10−23 |

| a4 | −0.01537102 | d82 | −1.627888 × 10−23 |

References

- Sun, F.; Yao, Y.; Li, X.; Li, G.; Miao, Y.; Han, S.; Chen, Z. Flow Simulation of the Mixture System of Supercritical CO2 & Superheated Steam in Toe-Point Injection Horizontal Wellbores. J. Pet. Sci. Eng. 2018, 163, 199–210. [Google Scholar] [CrossRef]

- Jia, C.; Zheng, M.; Zhang, Y. Unconventional Hydrocarbon Resources in China and the Prospect of Exploration and Development. Pet. Explor. Dev. 2012, 39, 139–146. [Google Scholar] [CrossRef]

- Lillies, A.T. Sand Fracturing with Liquid Carbon Dioxide. In Proceedings of the Annual Technical Meeting, Calgary, AB, Canada, 6–9 June 1982. PETSOC-82-33-23. [Google Scholar] [CrossRef]

- Gupta, D.; Hlidek, B.; Hill, E.; Dinsa, H. Fracturing fluid for low-permeability gas reservoirs: Emulsion of carbon dioxide with aqueous methanol base fluid: Chemistry and applications. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, College Station, TX, USA, 29–31 January 2007. SPE-106304-MS. [Google Scholar] [CrossRef]

- Yost, A.B.; Mazza, R.L.; Remington, R.E. Analysis of Production Response to CO2/Sand Fracturing: A Case Study. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 8–10 November 1994. SPE-29191-MS. [Google Scholar] [CrossRef]

- Tulissi, M.G.; May, R.E. A Comparison of Results of Three Different CO2 Energized Frac Fluids: A Case History. In Proceedings of the SPE Gas Technology Symposium, Calgary, AB, Canada, 30 April–2 May 2002. SPE-75681-MS. [Google Scholar] [CrossRef]

- Friehauf, K.E.; Mukul, M.S.; Sullivan, R.B. Application of a New Compositional Model for Hydraulic Fracturing with Energized Fluids: A South Texas Case Study. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 19–21 January 2009. SPE-119265-MS. [Google Scholar] [CrossRef]

- Li, Y.; Chi, Y.; Zhao, C.; Miao, Y.; Han, S.; Chen, L. Modelling fluid flow in carbon fibre porous media based on X-ray microtomography and lattice Boltzmann method. Compos. Struct. 2022, 300, 116085. [Google Scholar] [CrossRef]

- Heidaryan, E.; Hatami, T.; Rahimi, M.; Moghadasi, J. Viscosity of Pure Carbon Dioxide at Supercritical Region: Measurement and Correlation Approach. J. Supercrit. Fluids 2011, 56, 144–151. [Google Scholar] [CrossRef]

- Pham, H.S.; Alpy, N.; Mensah, S.; Tothill, M.; Ferrasse, J.H.; Boutin, O.; Quenaut, J.; Rodriguez, G.; Saez, M. A Numerical Study of Cavitation and Bubble Dynamics in Liquid CO2 Near the Critical Point. Int. J. Heat Mass Transf. 2016, 102, 174–185. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, B.; Liu, Y.; Jiang, Y.; Zhang, Z.; Hou, M.; Li, Y. Gas-phase production equation for CBM reservoirs: Interaction between hydraulic fracturing and coal orthotropic feature. J. Pet. Sci. Eng. 2022, 213, 110428. [Google Scholar] [CrossRef]

- Sinal, M.L.; Lancaster, G. Liquid CO Fracturing: Advantages and Limitations. J. Can. Pet. Technol. 1987, 26, 26–30. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Shen, Z. A Feasibility Analysis on Shale Gas Exploitation with Supercritical Carbon Dioxide. Energy Sources Part A Recovery Util. Environ. Eff. 2012, 34, 1426–1435. [Google Scholar] [CrossRef]

- Wasp, E.J.; Aude, T.C. Deposition velocities, transition velocities, and spatial distribution of solids in slurry pipelines. In Proceedings of the 1st International British Hydromechanics Research Association Hydraulic Transport of Solids in Pipes Conference, War Wickshire University, Conventry, UK, 1–4 September 1970; Available online: https://trid.trb.org/view/19585 (accessed on 18 December 2022).

- Clifton, R.J.; Wang, J.-J. Multiple fluids, proppant transport, and thermal effects in three dimensional simulation of hydraulic fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988. SPE-18198-MS. [Google Scholar] [CrossRef]

- Barree, R.D.; Conway, M.W. Experiment and numerical modeling of convective proppant transport. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994. SPE-28564-MS. [Google Scholar] [CrossRef]

- Sharma, M.M.; Gadde, P.B. The Impact of Proppant Retardation on Propped Fracture Lengths. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. SPE-97106-MS. [Google Scholar] [CrossRef]

- Wood, W.D.; Wheeler, R.S. A New Correlation for Relating the Physical Properties of Fracturing Slurries to the Minimum Flow Velocity Required for Transport. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, College Station, TX, USA, 29–31 January 2007. SPE-106312-MS. [Google Scholar] [CrossRef]

- Clark, P.E.; Quadir, J.A. Prop transport in hydraulic fractures: A critical review of particle settling. In Proceedings of the SPE/DOE Low Permeability Gas Reservoirs Symposium, Denver, CO, USA, 27–29 May 1981. SPE-9866-MS. [Google Scholar] [CrossRef]

- Patankar, N.A.; Joseph, D.D.; Wang, J.; Barree, R.D.; Conway, M.; Asadi, M. Power Law Correlations for Sediment Transport in Pressure Driven Channel Flows. Int. J. Multiph. Flow 2002, 28, 1269–1292. [Google Scholar] [CrossRef]

- Gadde, P.B.; Liu, Y.; Norman, J.; Bonnecaze, R.; Sharma, M.M. Modeling Proppant Settling in Water-Fracs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. SPE-89875-MS. [Google Scholar] [CrossRef]

- Miao, Y.; Zhao, C.; Zhou, G. New rate-decline forecast approach for low-permeability gas reservoirs with hydraulic fracturing treatments. J. Pet. Sci. Eng. 2020, 190, 107112. [Google Scholar] [CrossRef]

- Miao, Y.; Zhao, C.; Zhou, G. Gas Flowrate Evaluation in Coal Coupling the Matrix Shrinkage Effect Caused by Water Extraction. J. Energy Resour. Technol. 2021, 144, 032301-2. [Google Scholar] [CrossRef]

- Zhang, X.; Tahmasebi, P. Micromechanical evaluation of rock and fluid interactions. Int. J. Greenh. Gas Control 2018, 76, 266–277. [Google Scholar] [CrossRef]

- Zhang, X.; Tahmasebi, P. Effects of grain size on deformation in porous media. Transp. Porous Media 2019, 129, 321–341. [Google Scholar] [CrossRef]

- Zhang, X.; Tahmasebi, P. Coupling irregular particles and fluid: Complex dynamics of granular flows. Comput. Geotech. 2022, 143, 104624. [Google Scholar] [CrossRef]

- Tsuji, Y.; Tanaka, T.; Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 1992, 71, 239–250. [Google Scholar] [CrossRef]

- Yang, S.; Luo, K.; Fang, M.; Zhang, K.; Fan, J. Parallel CFD–DEM modeling of the hydrodynamics in a lab-scale double slot-rectangular spouted bed with a partition plate. Chem. Eng. J. 2014, 236, 158–170. [Google Scholar] [CrossRef]

- Garg, R.; Galvin, J.; Li, T.; Pannala, S. Open-source MFIX-DEM software for gas-solids flows: Part I-verification studies. Powder Technol. 2012, 220, 122–137. [Google Scholar] [CrossRef]

- Gopalakrishnan, P.; Tafti, D. Development of parallel DEM for the open source code MFIX. Powder Technol. 2013, 235, 33–41. [Google Scholar] [CrossRef]

- Faizov, A.R.; Churakova, S.K.; Sidorov, G.M. Calculation of Pressure Drop in Unirrigated Packed Contact Devices Applying ANSYS Fluent Software. Chem. Pet. Eng. 2018, 54, 130–135. [Google Scholar] [CrossRef]

- Trofa, M.; D’Avino, G.; Sicignano, L. CFD-DEM simulations of particulate fouling in microchannels. Chem. Eng. J. 2019, 358, 99–100. [Google Scholar] [CrossRef]

- Licheng, M.A.; Lubin, W.E.I.; Xinyu, P.E.I. CFD-DEM simulations of particle separation characteristic in centrifugal compounding force field. Powder Technol. 2019, 343, 11–18. [Google Scholar]

- Wang, S.; Luo, K.; Hu, C. CFD-DEM study of the effect of ring baffles on system performance of a full-loop circulating fluidized bed. Chem. Eng. Sci. 2019, 196, 130–144. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, S.; Xiong, H.; Wu, K.; Shi, J. Optimal nanocone geometry for water flow. AIChE J. 2022, 68, e17543. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, B.; Yan, S.; Wang, S.; Wu, K.; Yu, W.; Li, Y.; Wang, S. Nanoconfined Methane Thermodynamic Behavior below Critical Temperature: Liquid–Vapor Coexistence Curve under Wettability Effect. Ind. Eng. Chem. Res. 2022, 61, 4971–4979. [Google Scholar] [CrossRef]

- Span, R.; Wagner, W. A New Equation of State for Carbon Dioxide Covering the Fluid Region from the Triple-Point Temperature to 1100 K at Pressures up to 800 MPa. J. Phys. Chem. Ref. Data 1996, 25, 1509–1596. [Google Scholar] [CrossRef]

- Ouyang, L.-B. New Correlations for Predicting the Density and Viscosity of Supercritical Carbon Dioxide Under Conditions Expected in Carbon Capture and Sequestration Operations. Open Pet. Eng. J. 2011, 5, 13–21. [Google Scholar] [CrossRef]

- Vesovic, V.; Wakeham, W.A.; Olchowy, G.A.; Sengers, J.V.; Watson, J.T.R.; Millat, J. The transport properties of carbon dioxide. J. Phys. Chem. Ref. Data 1990, 19, 763–808. [Google Scholar] [CrossRef]

- Fenghour, A.; Wakeham, W.A. The viscosity of carbon dioxide. J. Phys. Chem. Ref. Data 1998, 27, 31–44. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Archer, R. A three-dimensional coupled thermo-hydro-mechanical numerical model with partially bridging multi-stage contact fractures in horizontal-well enhanced geothermal system. Int. J. Rock Mech. Min. Sci. 2021, 143, 104787. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Archer, R. Techno-Economic feasibility of enhanced geothermal systems (EGS) with partially bridging Multi-Stage fractures for district heating applications. Energy Convers. Manag. 2022, 257, 115405. [Google Scholar] [CrossRef]

| Presenter | State Equation |

|---|---|

| Van der Waals (VdW) (1887) | |

| Redlich & Kwong (RK) equation (1949) | |

| Soave-Redlich-Kwong (SRK) (1972) | |

| Peng-Robinson (PR) (1976) | |

| Patel-teja (PT) (1982) | |

| Span & Wagner (1994) |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Reservoir temperature | 60 °C | Reservoir pressure | 30 MPa |

| Reservoir depth | 3650 m | Sand-carrying fluid | Supercritical CO2 |

| Porosity | 1.38% | Proppant | Ceramsites |

| Gas layer thickness | 34 m | Sand-carrying fluid inlet flow rate | 1 m/s |

| Gas content | 2.48 m3/t | Sand diameter | 0.6 mm |

| Organic carbon (TOC) mass fraction | 3.5% | Sand concentration | 0.4 |

| Vitrinite reflectance | 2.2% | Sand density | 2650 kg/m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Sun, Z. Numerical Simulation of the Proppant Settlement in SC-CO2 Sand-Carrying Fluid in Fracturing Fractures. Energies 2023, 16, 11. https://doi.org/10.3390/en16010011

Chen D, Sun Z. Numerical Simulation of the Proppant Settlement in SC-CO2 Sand-Carrying Fluid in Fracturing Fractures. Energies. 2023; 16(1):11. https://doi.org/10.3390/en16010011

Chicago/Turabian StyleChen, Dayong, and Zheng Sun. 2023. "Numerical Simulation of the Proppant Settlement in SC-CO2 Sand-Carrying Fluid in Fracturing Fractures" Energies 16, no. 1: 11. https://doi.org/10.3390/en16010011

APA StyleChen, D., & Sun, Z. (2023). Numerical Simulation of the Proppant Settlement in SC-CO2 Sand-Carrying Fluid in Fracturing Fractures. Energies, 16(1), 11. https://doi.org/10.3390/en16010011