A Method for Evaluating the Dominant Seepage Channel of Water Flooding in Layered Sandstone Reservoir

Abstract

:1. Introduction

2. Methods

2.1. Water-Cut Derivative Characteristics of a Reservoir with DSC

2.1.1. Curve Feature of Water-Cut

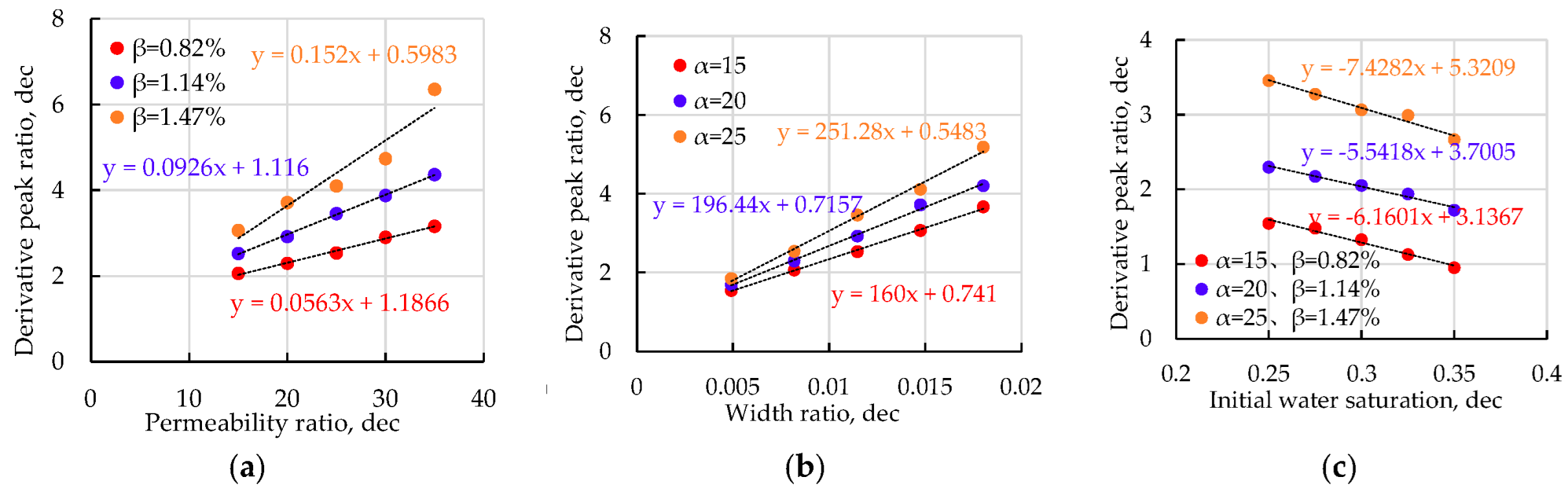

2.1.2. Relation of Feature Points in Derivative Curve

2.2. Evaluation Index and Classification Criteria

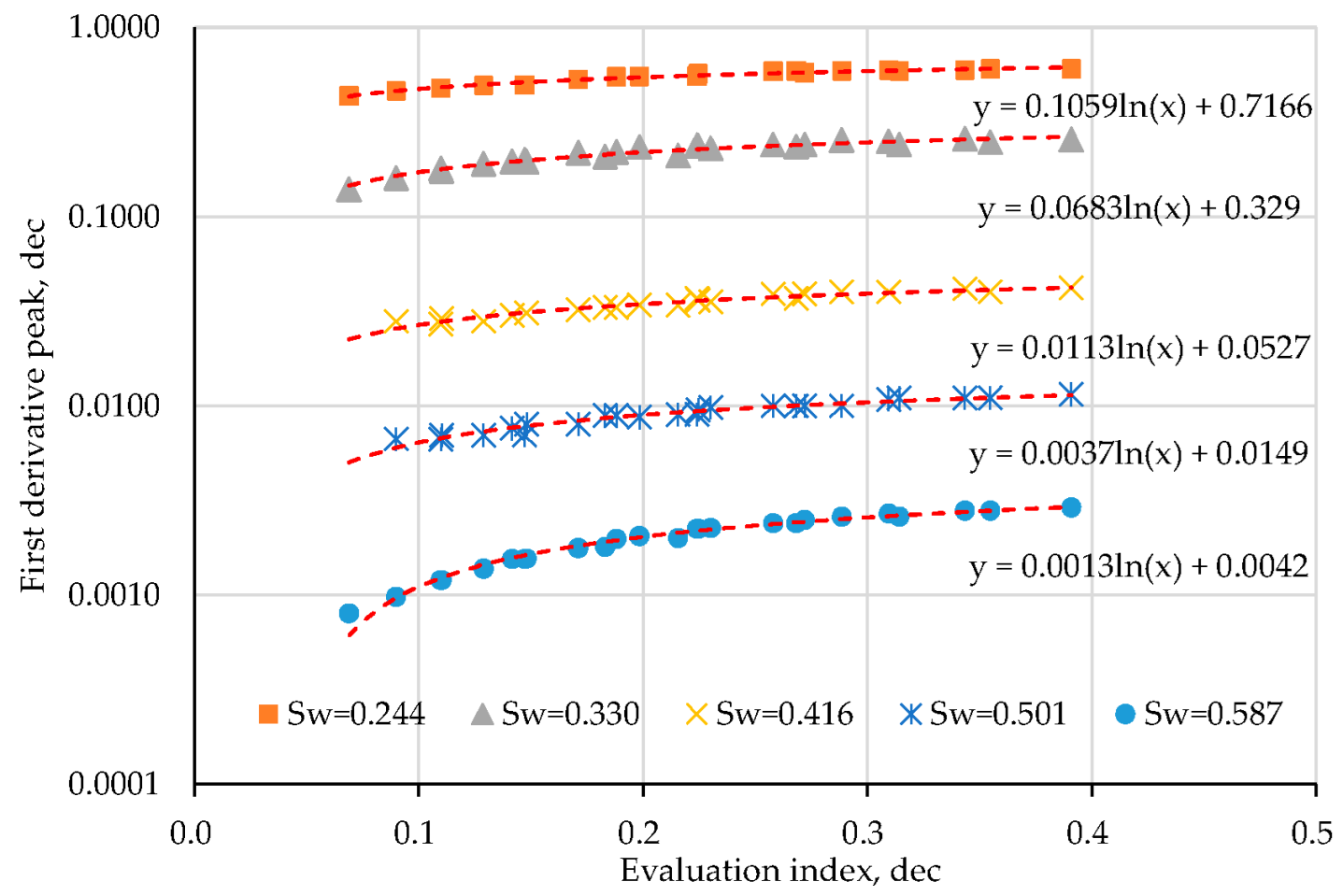

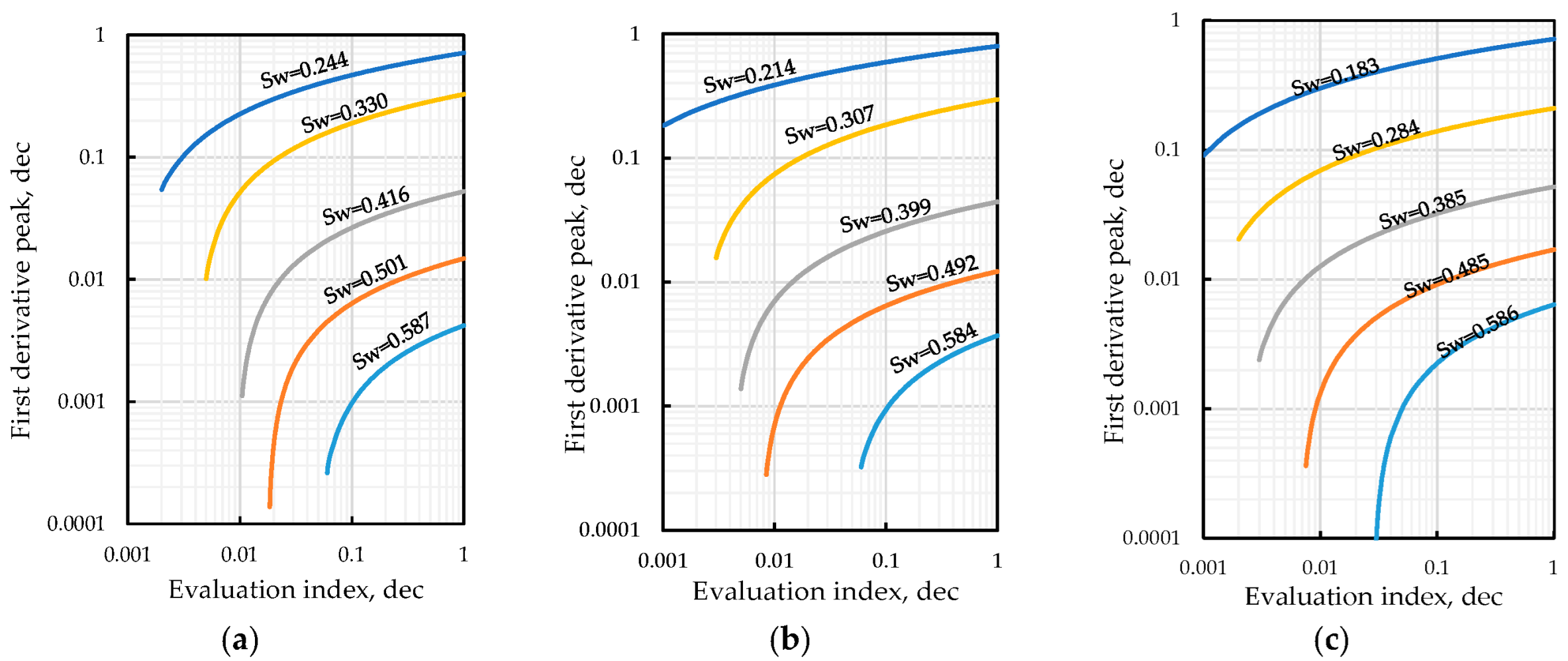

2.3. Classification Chart of DSCs

2.3.1. Method for Establishing Classification Chart

2.3.2. Fwcr Chart

2.3.3. M and N Charts

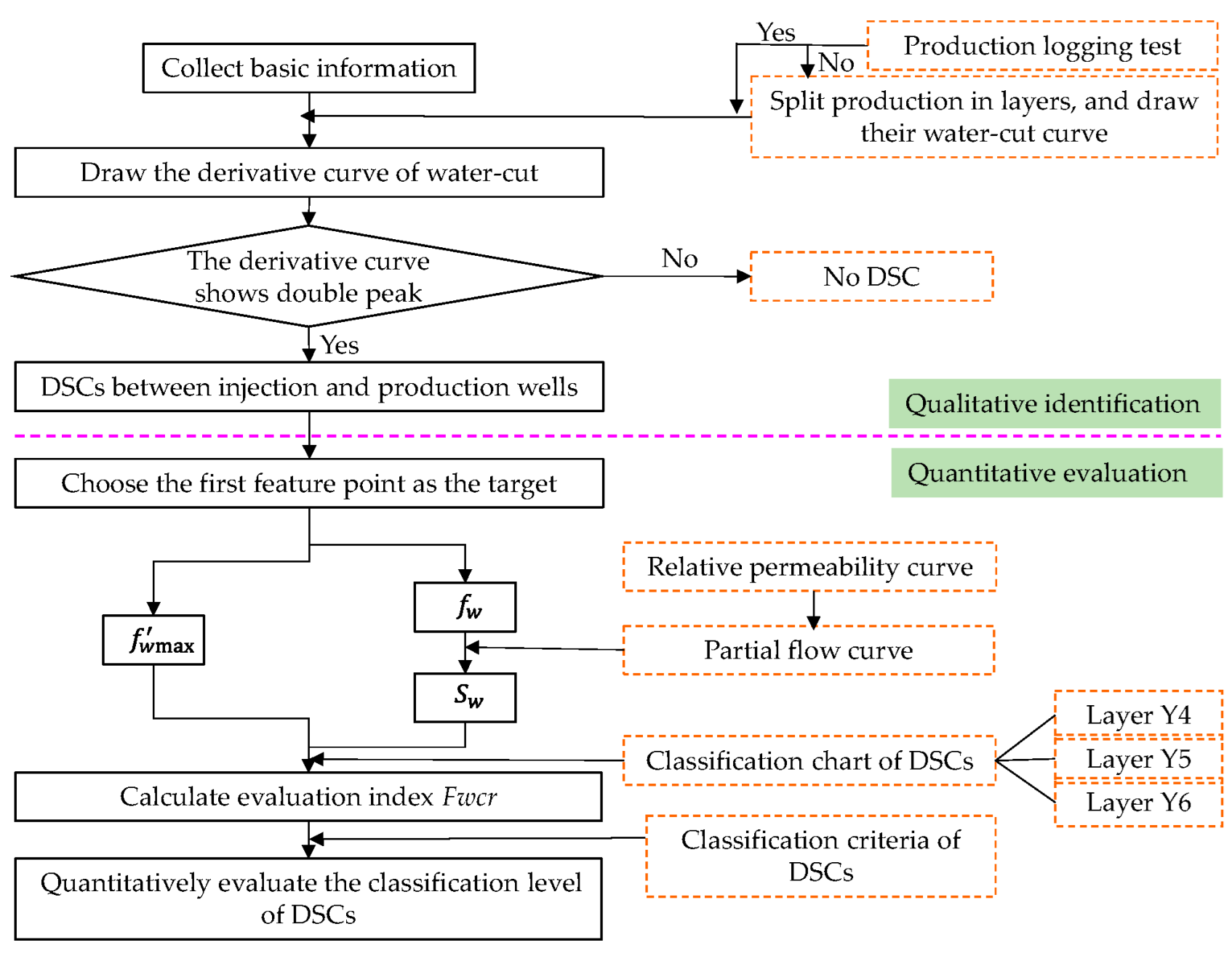

2.4. Evaluation Process of DSCs

- (1)

- Qualitative identification of DSCs. Based on the production data of the injection well group, the curve of the water-cut and its derivative with dimensionless time is drawn. If the derivative curve shows double peaks, there is a DSC between the injection and production wells. Otherwise, there is no DSC.

- (2)

- Identification of DSC among layers. If the DSC exists in the reservoir between injection and production wells, the DSCs among layers can be qualitatively judged and evaluated. It can be carried out in the following two steps:

3. Application and Discussions

4. Conclusions

- A method to identify DSCs is established. The derivative curve of the water-cut in the reservoir with the DSC shows double peaks, while the curve without the DSC shows a single peak. After the DSC develops in the reservoir, the derivative curve can be divided into five stages and two feature points. The derivative peak ratio shows obvious regularity;

- A method to evaluate DSCs is established. A new parameter is proposed as the classification index. Combining the characteristic parameters of the derivative curve, the index can be obtained quickly by querying the established Fwcr chart. Furthermore, the development degree of DSC can be evaluated according to the classification criteria.

- The evaluation method of DSCs proposed in this paper is effective in practical applications. The evaluation results show that there are obvious DSCs in some areas. The development degrees are quite different. Corresponding measures are proposed for the area with different development degrees.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| tD | Dimensionless time, dec; |

| qi | Production rate, m3/day; |

| t | Production time, day; |

| A | Reservoir area, m2; |

| Porosity, dec; | |

| Porosity; | |

| h | Reservoir thickness, m; |

| Water-cut derivative, dec; | |

| Water-cut, dec; | |

| Derivative peak of water-cut corresponding to the first feature point, dec; | |

| Derivative peak of water-cut corresponding to the second feature point, dec; | |

| Dimensionless time of water-cut corresponding to the first feature point, dec; | |

| Dimensionless time of water-cut corresponding to the second feature point, dec; | |

| K1 | Permeability of DSC, mD; |

| K | Permeability of non-DSC, mD; |

| w | Equivalent width of DSC, m; |

| a | Total equivalent width of reservoir, m; |

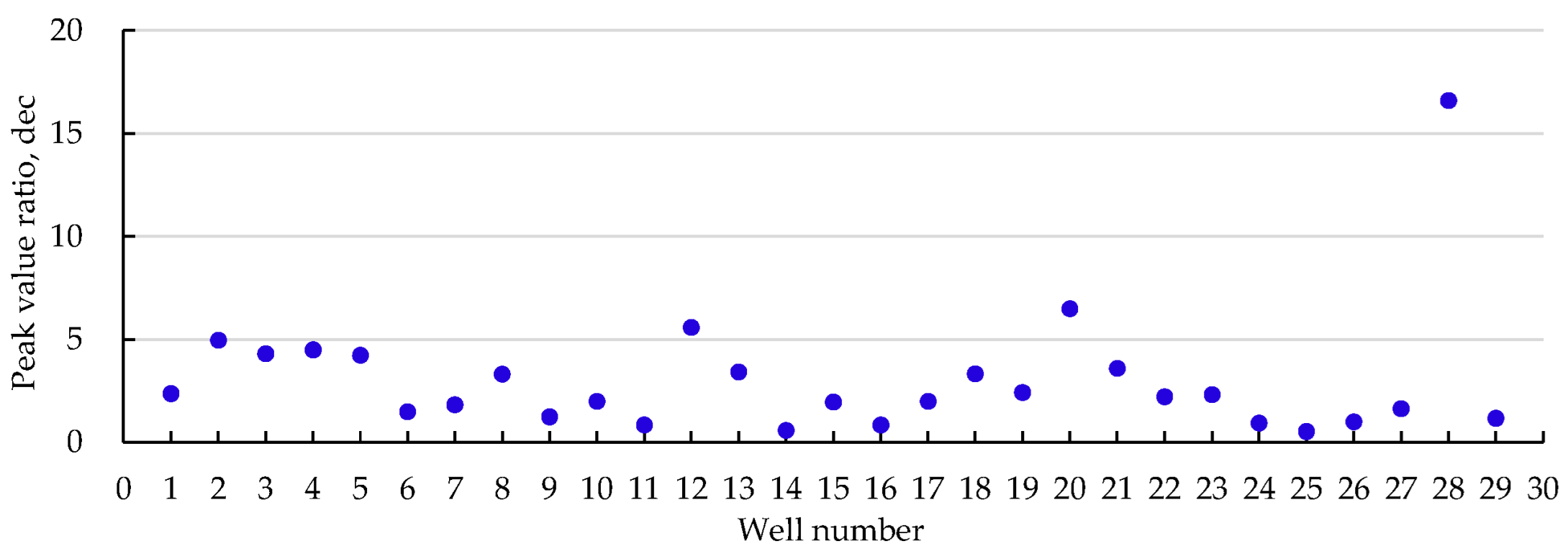

| M | Derivative peak ratio, dec; |

| N | Time ratio, dec; |

| α | Permeability ratio, dec; |

| β | Width ratio, dec; |

| qw1 | The amount of water flowing into the production well along the DSC, m3; |

| qw2 | The amount of water flowing into the production well along non-the DSC,m3 |

| Krw | The relative permeability of water phase, dec; |

| Swi | Initial water saturation, dec; |

| Sw | Water saturation, dec; |

| μw | Water viscosity, mPa·s; |

| dp/dx | The pressure gradient, MPa/m; |

| Fwcr | Evaluation index, dec. |

References

- Ding, S.; Jiang, H.; Zhao, Y.; Li, J.; Zhou, D.; Kuang, X. Review on identification of dominant channels in waterflood sandstone reservoirs. Pet. Geol. Eng. 2015, 29, 132–136. [Google Scholar]

- Zhao, F.; Zhang, G.; Sun, Q.; Xie, T.; Wang, F. Studies on channel plugging in a reservoir by using as a profile control agent in a double-fluid method. Acta Pet. Sin. 1994, 1, 56–65. [Google Scholar]

- Jiang, H. Early-warning and differentiated adjustment methods for channeling in oil reservoirs at ultra-high water cut stage. J. China Univ. Pet. 2013, 37, 114–119. [Google Scholar]

- Zeng, L.; Liu, B.; Liu, Y.; Zhang, Y. Study on the influence of dominant channel on water flooding development effect. J. Jianghan Pet. Inst. 2004, 26, 126–127. [Google Scholar]

- Meng, F.; Sun, T.; Zhu, Y.; Fen, Q. A study on the method to identify large pore paths using conventional well logging data in sandstone reservoirs. Period. Ocean. Univ. China 2007, 37, 463–468. [Google Scholar]

- Liu, S.; Liang, J. Discussion on the method of identifying invalid injection-production water circulation channel by welltest technology. Welltesting 2004, 13, 27–30. [Google Scholar]

- Deng, X.; Zhang, X.; Zhu, J.; An, Y. Pattern of preferential reservoir water flow passage and discriminator analysis. Oil Drill. Prod. Technol. 2014, 36, 69–74. [Google Scholar]

- Wu, S.; Li, Z. The study on identifying macropore path technology. Xinjiang Pet. Sci. Technol. 2010, 20, 27–29. [Google Scholar]

- Chan, K. Water Control Diagnostic Plots; Society of Petroleum Engineers: Dallas, TX, USA, 1995. [Google Scholar]

- Yortsos, Y.C.; Choi, Y.; Yang, Z.; Shah, P.C. Analysis and interpretation of water/oil ratio in waterfloods. SPE J. 1999, 4, 413–424. [Google Scholar] [CrossRef]

- Wang, X.; Xia, Z.; Zhang, H.; Liu, X.; Li, X.; Zhang, L. Study on identification of large orifice with water injection profile logging data. Welltest Technol. 2002, 2, 162–164. [Google Scholar]

- Shi, L. The application of the micro material inter-well tracing technology in recognizing high capacity channels in oil layer. Pet. Geol. Oilfield Dev. Daqing 2007, 26, 130–132. [Google Scholar]

- Izgec, B.; Kabir, S. Identification and characterization of high-Conductive layers in waterfloods. SPE Reserv. Eval. Eng. 2011, 14, 113–119. [Google Scholar] [CrossRef]

- Oftedal, A.; Davies, J.; Kalia, N.; Van Dongen, H. Interwell Communication as a Means to Detect a Thief Zone Using DTS in a Danish Offshore Well; Offshore Technology Conference: Houston, TX, USA, 2013. [Google Scholar]

- Hao, J. Qualitative identification of prevailing channel by dimensionless pressure index. Spec. Oil Gas Reserv. 2014, 21, 123–125. [Google Scholar]

- Huang, Y.; Lei, X.; Zhang, Q.; Li, S. Identification technology and application of dominant seepage channel in complex fault block oilfield. Neijiang Technol. 2015, 36, 43–44. [Google Scholar]

- Ding, S.; Jiang, H.; Wang, L.; Liu, G.; Li, N.; Liang, B. Identification and Characterization of High-Permeability Zones in Waterflooding Reservoirs with an Ensemble of Methodologies; Society of Petroleum Engineers: West Java, Indonesia, 2015. [Google Scholar]

- Alotaibi, S.; Cinar, Y.; Alshehri, D. Analysis of Water/Oil Ratio in Complex Carbonate Reservoirs under Water-Flood; Society of Petroleum Engineers: Manama, Bahrain, 2019. [Google Scholar]

- Gu, W. New Method of Water Channeling Identification in Unconsolidated Sandstone Reservoir; Society of Petroleum Engineers: West Java, Indonesia, 2019. [Google Scholar]

- Lu, C.; Jiang, H.; You, C.; Wang, F.; Xu, F.; Li, J. Determination the levels of thief zones based on machine learning. In Proceedings of the International Petroleum Technology Conference, Virtual, 16 March 2021. [Google Scholar]

- Ma, R.; Zhao, Z.; Li, Y.; Zou, C.; Hu, D.; Chen, Y.; Zhang, L. A Novel Correction Method for Pressure Transient Analysis Results of Horizontal Wells in Stratified Carbonate Reservoir with High Permeability Zone; Society of Petroleum Engineers: Houston, TX, USA, 2022. [Google Scholar]

- Fu, L.; Zhao, L.; Chen, S.; Xu, A.; Ni, J.; Li, X. A prediction method for development indexes of waterflooding reservoirs based on modified capacitance–resistance models. Energies 2022, 15, 6768. [Google Scholar] [CrossRef]

- Kausalysh, N.; Harun, A.R.; Mohd, F.; Rizal, B. Managing Accelerated Water Breakthrough in High Permeability Contrast Waterflood Reservoirs, and Achieving Production Conformance through Injection Redistribution Strategy; Society of Petroleum Engineers: Dubai, UAE, 2022. [Google Scholar]

- Qi, Q.; Iraj, E. Modeling of Injection-Induced Particle Movement Leading to the Development of Thief Zones; Society of Petroleum Engineers: Houston, TX, USA, 2017. [Google Scholar]

- Albertoni, A.; Lake, L.W. Inferring inter-well connectivity only from well-rate fluctuations in waterfloods. SPE Reserv. Eval. Eng. 2003, 6, 6–16. [Google Scholar] [CrossRef]

- Weber, D. The Use of Capacitance-Resistance Models to Optimize Injection Allocation and Well Location in Water Floods. Ph.D. Thesis, University of Texas, Austin, TX, USA, 2009. [Google Scholar]

- Parekh, B.; Kabir, C.S. A case study of improved understanding of reservoir connectivity in an evolving waterflood with surveillance data. J. Pet. Sci. Eng. 2013, 102, 1–9. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Zhang, D. Water flooding performance prediction by multi-layer capacitance-resistive models combined with the ensemble Kalman filter. J. Pet. Sci. Eng. 2015, 127, 1–19. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Meng, L.; Jiang, R.; Fan, H. The numerical simulation study of the oil-water seepage behavior dependent on the polymer concentration in polymer flooding. Energies 2020, 13, 5125. [Google Scholar] [CrossRef]

- Negash, B.M.; Yaw, A.D. Artificial neural network based production forecasting for a hydrocarbon reservoir under water injection. Pet. Explor. Dev. 2020, 47, 357–365. [Google Scholar] [CrossRef]

| Degree | Primary | Medium | High | Extra-High |

|---|---|---|---|---|

| Fwcr | 0.00–0.01 | 0.01–0.10 | 0.10–0.30 | 0.30–1.00 |

| Model Parameters | Values of Y4 | Values of Y5 | Values of Y6 |

|---|---|---|---|

| Model size | 30 × 41 × 1 | 30 × 41 × 1 | 30 × 41 × 1 |

| K (mD) | 1650 | 2800 | 3000 |

| w (m) | 0.5–4.5 | 0.5–4.5 | 0.5–4.5 |

| K1 (mD) | 8250–41,250 | 14,000–70,000 | 15,000–75,000 |

| Grid size (m) | 30 × 10 × 2 | 30 × 10 × 2 | 30 × 10 × 2 |

| Swi (dec) | 0.244 | 0.214 | 0.183 |

| BHP (MPa) | 5.0 | 5.0 | 5.0 |

| qi (m3/day) | 150 | 150 | 300 |

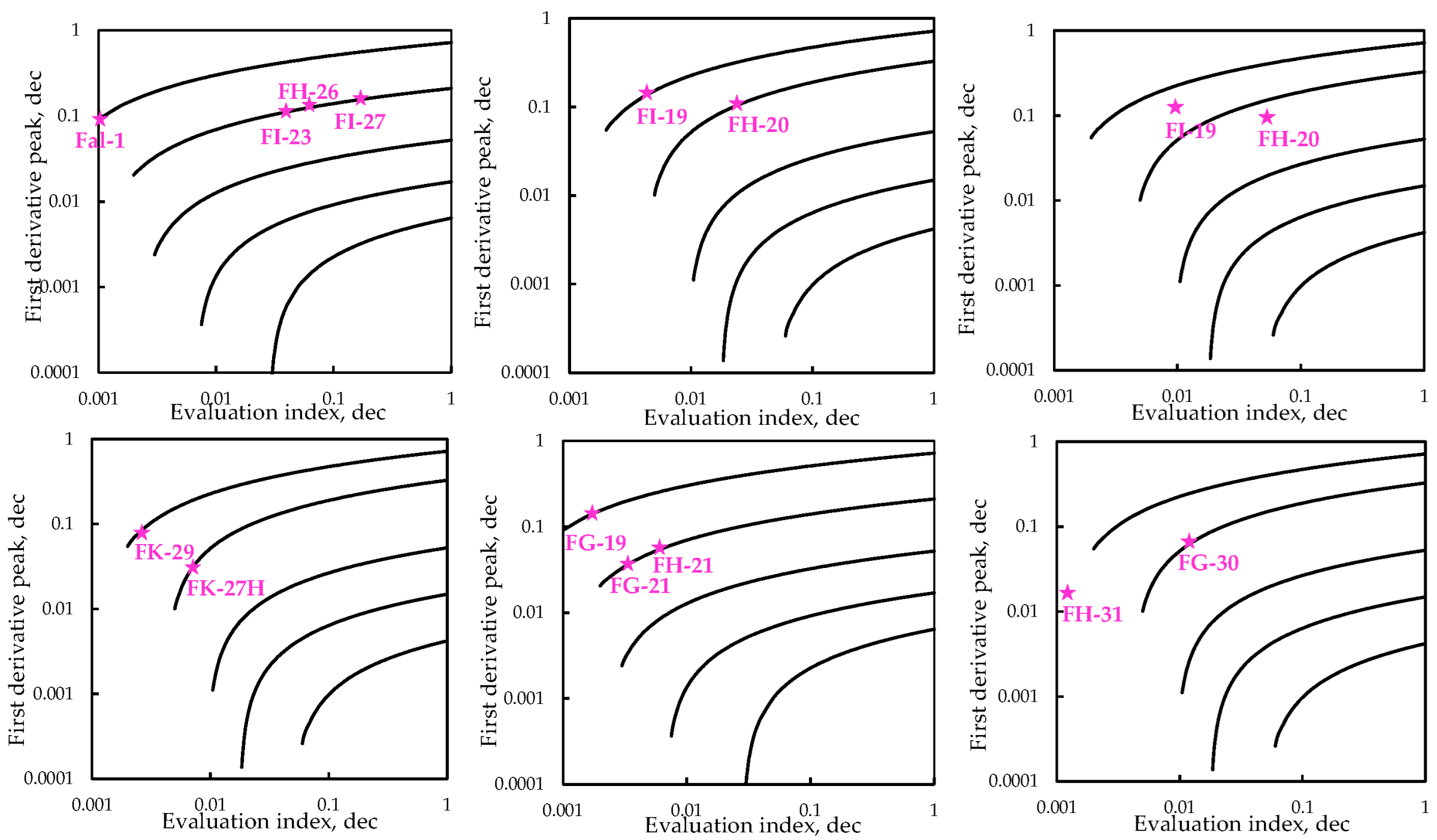

| Injection Group | Production Wells | Layers with DSC | Fwcr | Degree |

|---|---|---|---|---|

| FI-25 | FI-23 | Y6 | 0.0325 | Medium |

| FH-26 | Y6 | 0.0480 | Medium | |

| FI-27 | Y6 | 0.1928 | High | |

| Y5 | 0.0589 | Medium | ||

| Fal-1 | Y6 | 0.0010 | Primary | |

| FI-21 | FI-19 | Y6 | 0.0020 | Primary |

| FH-20 | Y6 | 0.0320 | Medium | |

| FH-23 | Y6 | 0.0568 | Medium | |

| FI-23 | Y6 | 0.0424 | Medium | |

| FK-27 | FK-27H | Y6 | 0.0027 | Primary |

| FK-29 | Y6 | 0.0008 | Primary | |

| FG-19 | Y6 | 0.0011 | Primary | |

| FG-20 | FH-20 | Y6 | 0.0037 | Primary |

| FH-21 | Y6 | 0.0081 | Primary | |

| FG-31 | FG-21 | Y6 | 0.0026 | Primary |

| FG-30 | Y4 | 0.0203 | Medium | |

| FH-31 | Y6 | 0.0016 | Primary |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, C.; Liao, X.; Wang, R.; Chen, J.; Wu, J.; Feng, M. A Method for Evaluating the Dominant Seepage Channel of Water Flooding in Layered Sandstone Reservoir. Energies 2022, 15, 8833. https://doi.org/10.3390/en15238833

Liao C, Liao X, Wang R, Chen J, Wu J, Feng M. A Method for Evaluating the Dominant Seepage Channel of Water Flooding in Layered Sandstone Reservoir. Energies. 2022; 15(23):8833. https://doi.org/10.3390/en15238833

Chicago/Turabian StyleLiao, Changlin, Xinwei Liao, Ruifeng Wang, Jing Chen, Jiaqi Wu, and Min Feng. 2022. "A Method for Evaluating the Dominant Seepage Channel of Water Flooding in Layered Sandstone Reservoir" Energies 15, no. 23: 8833. https://doi.org/10.3390/en15238833

APA StyleLiao, C., Liao, X., Wang, R., Chen, J., Wu, J., & Feng, M. (2022). A Method for Evaluating the Dominant Seepage Channel of Water Flooding in Layered Sandstone Reservoir. Energies, 15(23), 8833. https://doi.org/10.3390/en15238833