Efficiency of Utilization of Wastes for Green Energy Production and Reduction of Pollution in Rural Areas

Abstract

1. Introduction

2. Literature Review Results

3. Materials and Methods

4. Results

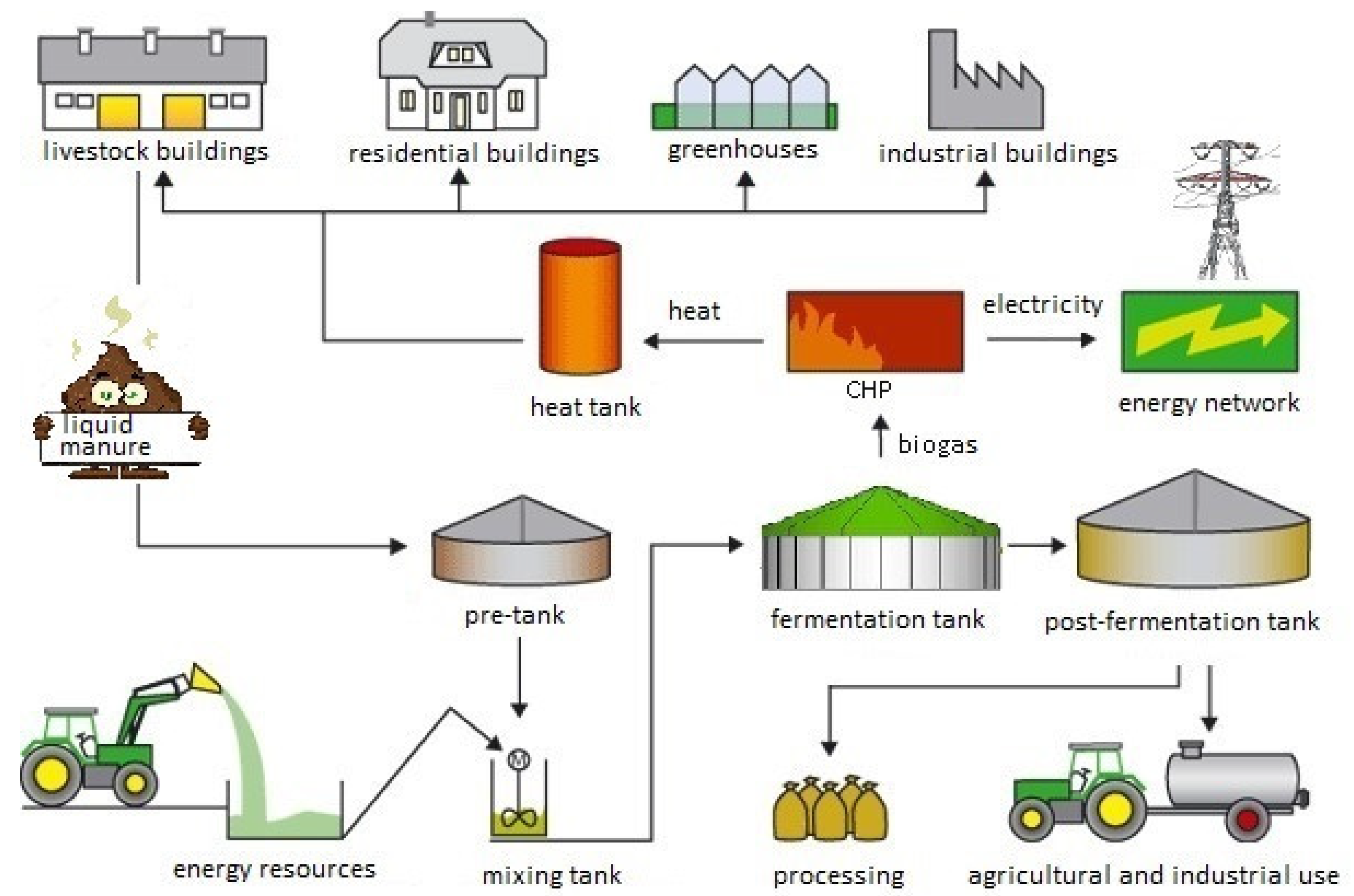

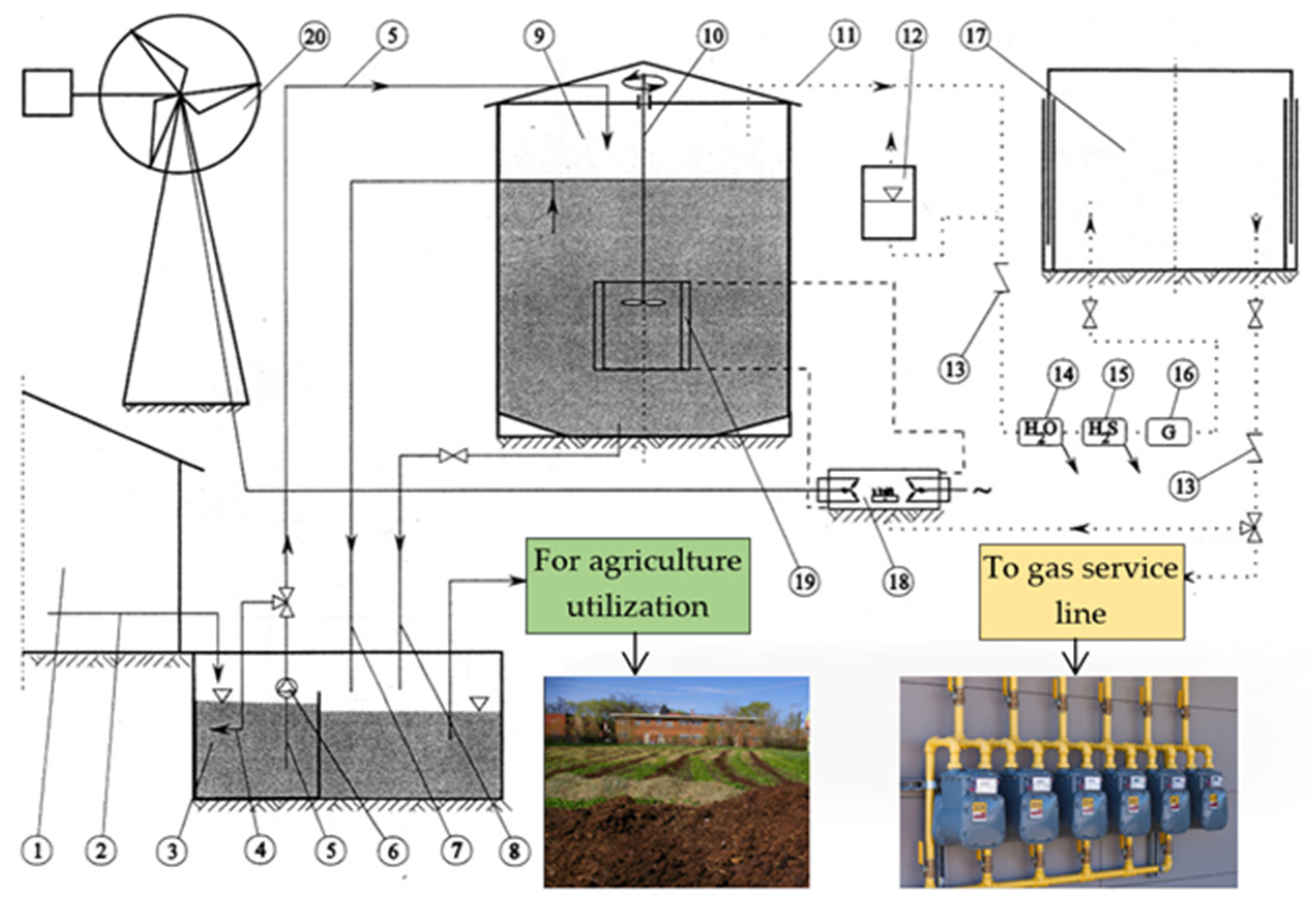

- For the production of electricity and heat in cogeneration systems (CHP);

- For heat production in industry or residential construction;

- In transport—biogas purified to the quality of natural gas can be used as fuel for vehicles if they are equipped with a natural gas installation.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aftab, T.; Roychoudhury, A. (Eds.) Plant Perspectives to Global Climate Changes: Developing Climate-Resilient Plants; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Borowski, P.F. Production Processes Related to Conventional and Renewable Energy in Enterprises and in the Circular Economy. Processes 2022, 10, 521. [Google Scholar] [CrossRef]

- Czatzkowska, M.; Harnisz, M.; Korzeniewska, E.; Koniuszewska, I. Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspect: A review. Energy Sci. Eng. 2020, 8, 1880–1897. [Google Scholar] [CrossRef]

- Borowski, P.F. Nexus between water, energy, food and climate change as challenges facing the modern global, European and Polish economy. AIMS Geosci. 2020, 6, 397–421. [Google Scholar] [CrossRef]

- Simona, G. A Sustainable Nutritional Behavior in the Era of Climate Changes. In Smart and Sustainable Technology for Resilient Cities and Communities. Advances in Sustainability Science and Technology; Howlett, R.J., Jain, L.C., Littlewood, J.R., Balas, M.M., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The review of biomass potential for agricultural biogas production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Matos, J.S.; Barberino, A.T.M.S.; de Araujo, L.P.; Lôbo, I.P.; de Almeida Neto, J.A. Potentials and Limitations of the Bioconversion of Animal Manure Using Fly Larvae. Waste Biomass Valorization 2020, 12, 3497–3520. [Google Scholar] [CrossRef]

- Yevstafiieva, Y.; Levytska, V.; Terenov, D. Biogas Production as a Component of Green Energy Generation. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2018; pp. 755–764. [Google Scholar]

- Apdini, T.; Al Zahra, W.; Oosting, S.J.; de Boer, I.J.; de Vries, M.; Engel, B.; van Middelaar, C.E. Understanding variability in greenhouse gas emission estimates of smallholder dairy farms in Indonesia. Int. J. Life Cycle Assess. 2021, 26, 1160–1176. [Google Scholar] [CrossRef]

- FAO Statistical Yearbook. Available online: https://www.fao.org/3/cb4477en/cb4477en.pdf (accessed on 22 November 2022).

- Borowski, P.F. Water and Hydropower—Challenges for the Economy and Enterprises in Times of Climate Change in Africa and Europe. Water 2022, 14, 3631. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J.; Martinat, S.; Kulla, M.; Novotný, L. Renewables projects in peripheries: Determinants, challenges and perspectives of biogas plants–insights from Central European countries. Reg. Stud. Reg. Sci. 2020, 7, 362–381. [Google Scholar] [CrossRef]

- Manni, M.; Coccia, V.; Cavalaglio, G.; Nicolini, A.; Petrozzi, A. Best practices for recovering rural abandoned towers through the installation of small-scale biogas plants. Energies 2017, 10, 1224. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Black, A.; Tormey, D.; Bartlett, J. Biogas production from small-scale anaerobic digestion plants on European farms. Renew. Sustain. Energy Rev. 2021, 139, 110580. [Google Scholar] [CrossRef]

- Piekutin, J.; Puchlik, M.; Haczykowski, M.; Dyczewska, K. The Efficiency of the Biogas Plant Operation Depending on the Substrate Used. Energies 2021, 14, 3157. [Google Scholar] [CrossRef]

- Pilloni, M.; Hamed, T.A. Small-size biogas technology applications for rural areas in the context of developing countries. In Anaerobic Digestion in Built Environments; Sikora, A., Ed.; IntechOpen: London, UK, 2021. [Google Scholar]

- Surendra, K.C.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Shaibur, M.R.; Husain, H.; Arpon, S.H. Utilization of cow dung residues of biogas plant for sustainable development of a rural community. Curr. Res. Environ. Sustain. 2021, 3, 100026. [Google Scholar] [CrossRef]

- Jurgutis, L.; Šlepetienė, A.; Šlepetys, J.; Cesevičienė, J. Towards a full circular economy in biogas plants: Sustainable management of digestate for growing biomass feedstocks and use as biofertilizer. Energies 2021, 14, 4272. [Google Scholar] [CrossRef]

- Bedoić, R.; Jurić, F.; Ćosić, B.; Pukšec, T.; Čuček, L.; Duić, N. Beyond energy crops and subsidised electricity—A study on sustainable biogas production and utilisation in advanced energy markets. Energy 2020, 201, 117651. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Pastor-Perez, L.; Wang, Q.; Reina, T.R. Bio-methane and bio-methanol co-production from biogas: A profitability analysis to explore new sustainable chemical processes. J. Clean. Prod. 2020, 265, 121909. [Google Scholar] [CrossRef]

- Iqbal, N.; Sakhani, M.A.; Khan, A.R.; Ajmal, Z.; Khan, M.Z. Socioeconomic impacts of domestic biogas plants on rural households to strengthen energy security. Environ. Sci. Pollut. Res. 2021, 28, 27446–27456. [Google Scholar] [CrossRef]

- Rzeznik, W.; Mielcarek, P. Agricultural biogas plants in Poland. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; pp. 23–25. [Google Scholar]

- D’Adamo, I.; Ribichini, M.; Tsagarakis, K.P. Biomethane as an energy resource for achieving sustainable production: Economic assessments and policy implications. Sustain. Prod. Consum. 2023, 35, 13–27. [Google Scholar] [CrossRef]

- D’Adamo, I.; Sassanelli, C. A mini-review of biomethane valorization: Managerial and policy implications for a circular resource. Waste Manag. Res. 2022, 40, 1745–1756. [Google Scholar] [CrossRef]

- Smurzyńska-Łukasik, A. Jak Radzić Sobie z Siarkowodorem i Dwutlenkiem Węgla w Bio-Gazowni? Energia i Recykling 2/2020 (26). Available online: https://portalkomunalny.pl/plus/artykul/jak-radzic-sobie-z-siarkowodorem-i-dwutlenkiem-wegla-w-biogazowni/ (accessed on 22 November 2022).

- In Finlandia. Available online: http://www.fotovoltaicosulweb.it/guida/in-finlandia-si-trova-la-piu-grande-centrale-di-biogas-del-mondo.html (accessed on 15 October 2022).

- Barwicki, J.; Mazur, K.; Borek, K. Some aspects of using automated electronic systems in development of modern agriculture. Mater. Eng. 2020, 4, 13–18. [Google Scholar] [CrossRef]

- Barwicki, J.; Mazur, K.; Kierończyk, M.; Borek, K.; Wardal, W.J.; Roman, K.K. Influence of liquid manure acidification with sulfuric acid on selected physicochemical properties of soils on exemplary crops. Chem. Ind. 2020, 11, 1600–1604. [Google Scholar] [CrossRef]

- Borowski, P.F. Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants. Energies 2022, 15, 1928. [Google Scholar] [CrossRef]

- Ciszewski, M. Biogazownie Najlepszym Rozwiązaniem. Available online: https://agronews.com.pl/artykul/biogazownie-najlepszym-rozwiazaniem-na-obszary-wiejskie/ (accessed on 18 November 2022).

- Ekielski, A.; Żelaziński, T.; Mishra, P.K.; Skudlarski, J. Properties of Biocomposites Produced with Thermoplastic Starch and Digestate: Physicochemical and Mechanical Characteristics. Materials 2021, 14, 6092. [Google Scholar] [CrossRef] [PubMed]

- Biogas Legislation. Available online: https://www.biogasworld.com/news/biogas-legislations-funding-opportunities-start-looking/ (accessed on 22 November 2022).

| Title of the Paper | Main Issues Discussed in the Paper |

|---|---|

| Renewables projects in peripheries: determinants, challenges, and perspectives of biogas plants—insights from Central European countries | In the transition to a low-carbon economy, agricultural biogas plants can be a very useful and sustainable element of the energy transformation carried out in rural areas [12]. |

| Best practices for recovering rural abandoned towers through the installation of small-scale biogas plants. | The systematic development of renewable energy systems makes it possible to achieve the assumptions and goals created in Europe in the field of environmental protection and sustainable development. For production of agricultural biogas, the existing infrastructure in rural areas can be used, after minor modification [13]. |

| Biogas production from small-scale anaerobic digestion plants on European farms | The technology of processing of animal manure and the organic fraction of waste can be implemented on a small scale by anaerobic digestion. Anaerobic digestion systems can convert organic matter into biogas (a mixture of mainly carbon dioxide and methane), making the technology suitable for a variety of applications in energy, agriculture and potentially in the emerging bioproducts and bioprocesses sector [14]. |

| The efficiency of the biogas plant operation depending on the substrate used | Studies conducted among agricultural biogas plants have shown that the best efficiency is achieved by biogas plants processing: silage, cattle manure and chicken manure as well as slaughterhouse waste [15]. |

| Small-size biogas technology applications for rural areas in the context of developing countries | In terms of net energy production, anaerobic digestion of methane is more competitive and more efficient than other forms of biomass energy production. This applies to both production costs and environmental impact. Therefore, in economic and ecological terms, biogas is a good solution for the economy [16]. |

| Biogas as a sustainable energy source for developing countries: Opportunities and challenges | In areas of energy poverty, existing biomass resources (i.e., animal manure, crop residues, kitchen waste and green waste) can be converted to cleaner and more efficient energy carriers such as anaerobic biogas, which has the unique potential to provide clean and reliable energy [17]. |

| Utilization of cow dung residues of a biogas plant for sustainable development of a rural community | In rural areas, biogas plants produce biogas and huge amounts of organic residues. Solid and slurry wastes are widely used as part of waste management and biogas production. The residues are used as organic fertilizer and biogas as fuel [18]. |

| Towards a full circular economy in biogas plants: Sustainable management of digestate for growing biomass feedstocks and use as biofertilizer | Digestate is an excellent biofertilizer. The use of digestate on land characterized by low fertility, especially in areas located near biogas plants, allows the production of up to three times more biomass, which is then used for biogas production [19]. |

| Beyond energy crops and subsidised electricity—A study on sustainable biogas production and utilisation in advanced energy markets | Production of biogas is a costly investment, therefore the profitability of biogas production without subsidies depends on the price of alternative fuels [20]. |

| Bio-methane and bio-methanol co-production from biogas: A profitability analysis to explore new sustainable chemical processes | The prices of electricity, natural gas and biomethanol can significantly affect the overall profitability of a biogas plant. A large biogas production plant can produce biomethanol with a profitable margin. On the other hand, small production requires subsidies or grants [21]. |

| Socioeconomic impacts of domestic biogas plants on rural households to strengthen energy security. | Public participation should be increased in order to widely use biogas technologies as an alternative energy source. The positive impact of home biogas plants on farms should be presented [22]. |

| The review of biomass potential for agricultural biogas production in Poland. | Appropriate management of biomass residues produced by the agri-food industry can reduce their negative impact on the environment. An alternative use of agricultural waste is the production of biogas. The most common agricultural and food residues used as substrates for biogas plants in Poland are maize silage, slurry and distillery waste [6]. |

| Agricultural biogas plants in Poland. | A characteristic trend of changes in the development of agriculture is the growing importance of non-food use of raw materials of agricultural origin. In addition to ensuring food security, agriculture can also perform other functions, including those related to energy security. Agricultural biogas plants are a chance for diversification of agriculture and multifunctional development of rural areas [23]. |

| Biomethane as an energy resource for achieving sustainable production: Economic assessments and policy implications. | Biomethane is a possible energy source that can meet the requirements of sustainable production. Circular bioeconomy models have been developed to reduce dependence on non-renewable and unsustainable resources, among others by including biogas in the green taxonomy [24]. |

| A mini-review of biomethane valorization: Managerial and policy implications for a circular resource | The ecological transformation is based, among others, on based on renewable energy sources, so the role of biomass is very important. When producing energy from biomass and waste, the circulation of resources is promoted if sustainable substrates are used. The production of biomethane from waste is important for combating climate change and energy self-sufficiency. The closed circulation of resources uses substarts and thanks to this, from the point of view of environmental protection, the appropriate waste is valorised [25]. |

| Initial Material | Content of Hydrogen Sulphide [ppm] |

|---|---|

| cattle excrement | 500–8000 |

| pig excrement | 500–10,000 |

| poultry excrement | 500–10,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borowski, P.F.; Barwicki, J. Efficiency of Utilization of Wastes for Green Energy Production and Reduction of Pollution in Rural Areas. Energies 2023, 16, 13. https://doi.org/10.3390/en16010013

Borowski PF, Barwicki J. Efficiency of Utilization of Wastes for Green Energy Production and Reduction of Pollution in Rural Areas. Energies. 2023; 16(1):13. https://doi.org/10.3390/en16010013

Chicago/Turabian StyleBorowski, Piotr F., and Jan Barwicki. 2023. "Efficiency of Utilization of Wastes for Green Energy Production and Reduction of Pollution in Rural Areas" Energies 16, no. 1: 13. https://doi.org/10.3390/en16010013

APA StyleBorowski, P. F., & Barwicki, J. (2023). Efficiency of Utilization of Wastes for Green Energy Production and Reduction of Pollution in Rural Areas. Energies, 16(1), 13. https://doi.org/10.3390/en16010013