1. Introduction

Wellbore instability is one of the main issues in the oil industry that causes a substantial yearly expenditure to drilling operators. Incidentally, an appropriate determination of mud weight window (MWW) is required to identify the physicochemical properties of underground formations [

1]. Ganguli and Sen [

2] reported that well instability in drilling operations is dominantly related to rock properties, in-situ stresses, and pore pressures. Before proceeding to the drilling wellbore, the underground formations are in equilibrium. Once drilling operations initiate, in-situ stresses are loaded to the wellbore due to the removal of rocks, and a load of stresses leads to failure in the wellbore wall. As a rebuttal to this point, it could be argued that drilling fluids would exert in-situ stress on the wellbore wall and redistribute the induced stress through rocks surrounding the wellbore in succession [

3]. To control induced stresses on the wellbore wall, it is essential to utilize drilling fluids with the appropriate MWW. Shear and tensile failures are the major causes of mechanical instability in boreholes [

4]. In this regard, borehole orientation with respect to in-situ stresses should be considered to avoid wellbore failure.

There are several important functions that drilling mud can provide. One of the most significant functions is an original contribution to cool and lubricate the drilling bit. Also, the drilling mud provides further support to the transport of cuttings to the surface area and controls the pressure of underground formations [

5]. The hydraulic energy is transmitted through the drillstring to the tools and drilling bit. The pressure of drilling mud is designed in the traditional system to control fluid flow from underground formations into the wellbore. According to Awal et al. [

6], the pressure of drilling mud ranges from 100 psi to 200 psi, and is greater than the pore pressure of underground formations. It is believed that a more significant amount of drilling mud pressure retains the wellbore stability while having in-situ pressure [

7]. Incidentally, other approaches should be undertaken to attain optimum drilling mud pressure (ODMP) by considering rock properties and the wellbore’s in-situ pressures. In addition, it is necessary to accurately determine rock strength as a crucial factor in wellbore stability because in-situ pressures affect the behavior of rocks [

8].

Moreover, by applying the facilities and requirements to exploit hydrocarbon from wells, drilling operations are more complicated as the parameters further affect well stability. Forecasting the wellbore wall’s stability is considered a critical point in drilling operations because wellbore instability leads to enormous costs and pauses the production process [

9]. Wellbore instability has mainly resulted from mechanical [

10] and chemical [

11] factors or a combination of both. The mechanical factor may refer to rock failure while drilling due to a low rate of rock strength. In addition, the chemical factor arises when the interaction between the rock and drilling fluid is damaged. There are various chemicals in the drilling fluid that physically and chemically interact with formations, result in the production of swelling stress, and alleviate the mechanical strength of the wellbore wall [

12]. Chemical treatments can focus on changing the chemical composition of formations and forming chemical sealants in fractures [

10,

13]. Also, wettability alteration treatments attempt to change filter cake from oil-wet to water-water in terms of enhancing fracture healing while using oil-based muds [

14].

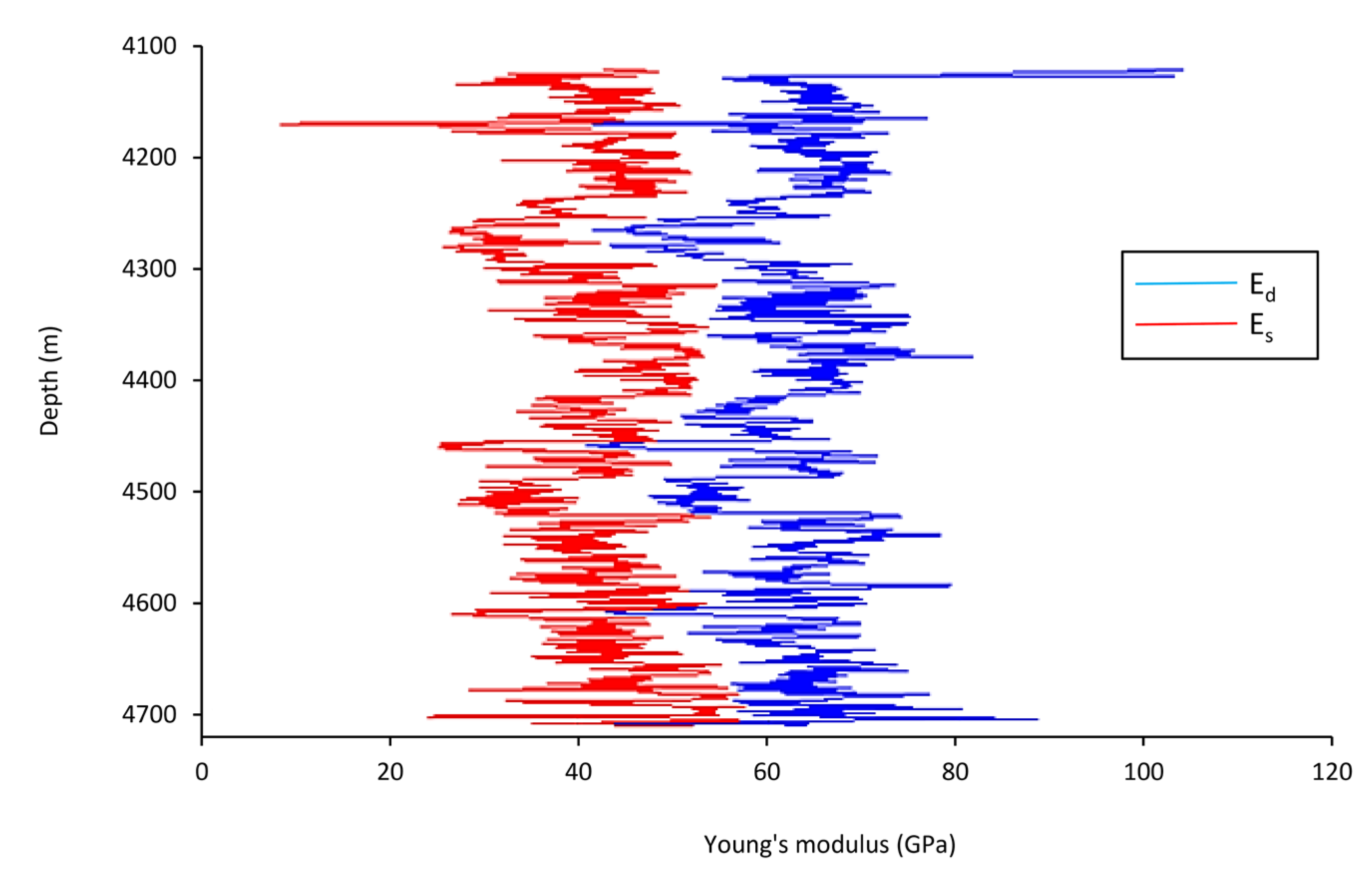

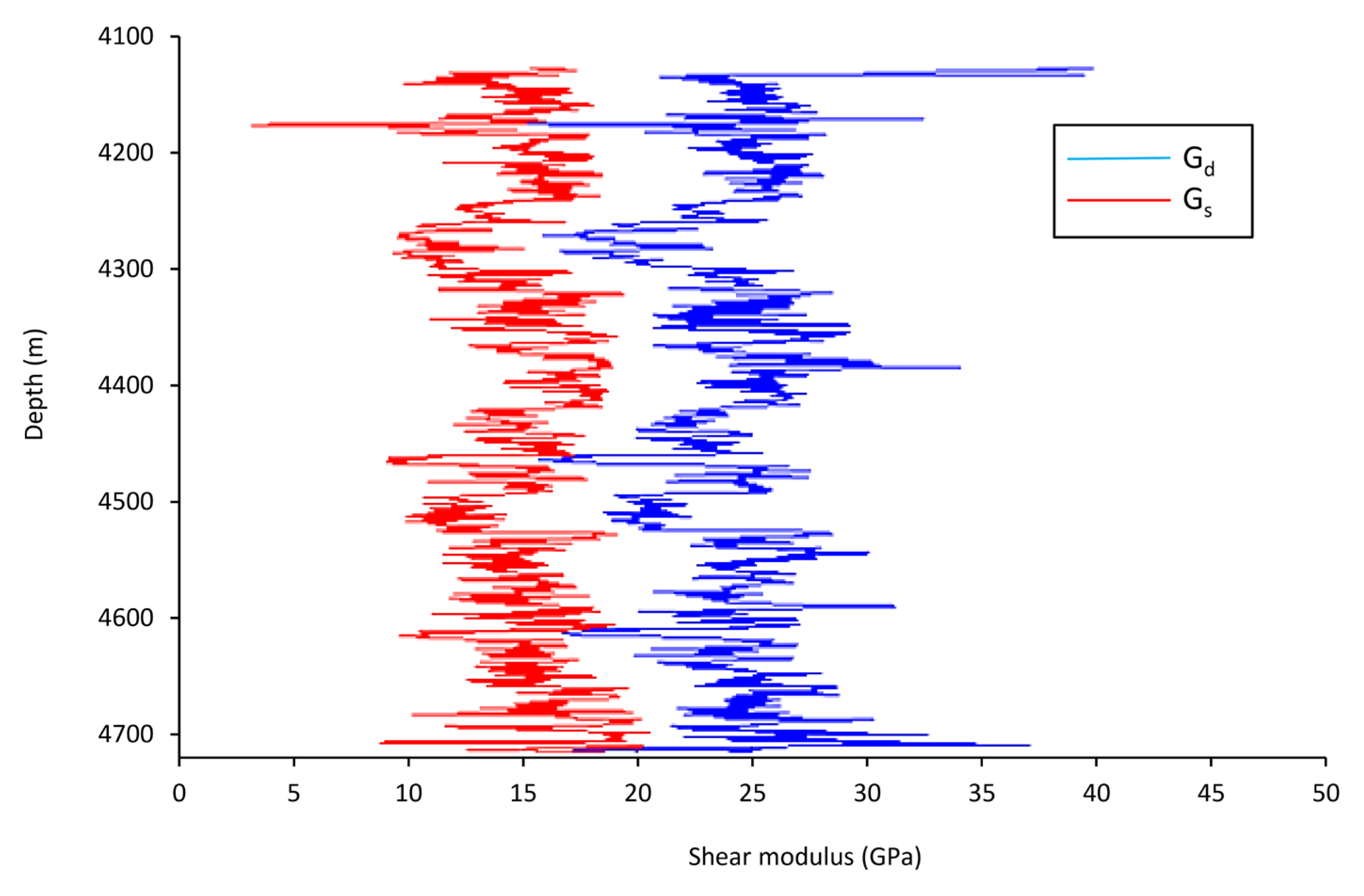

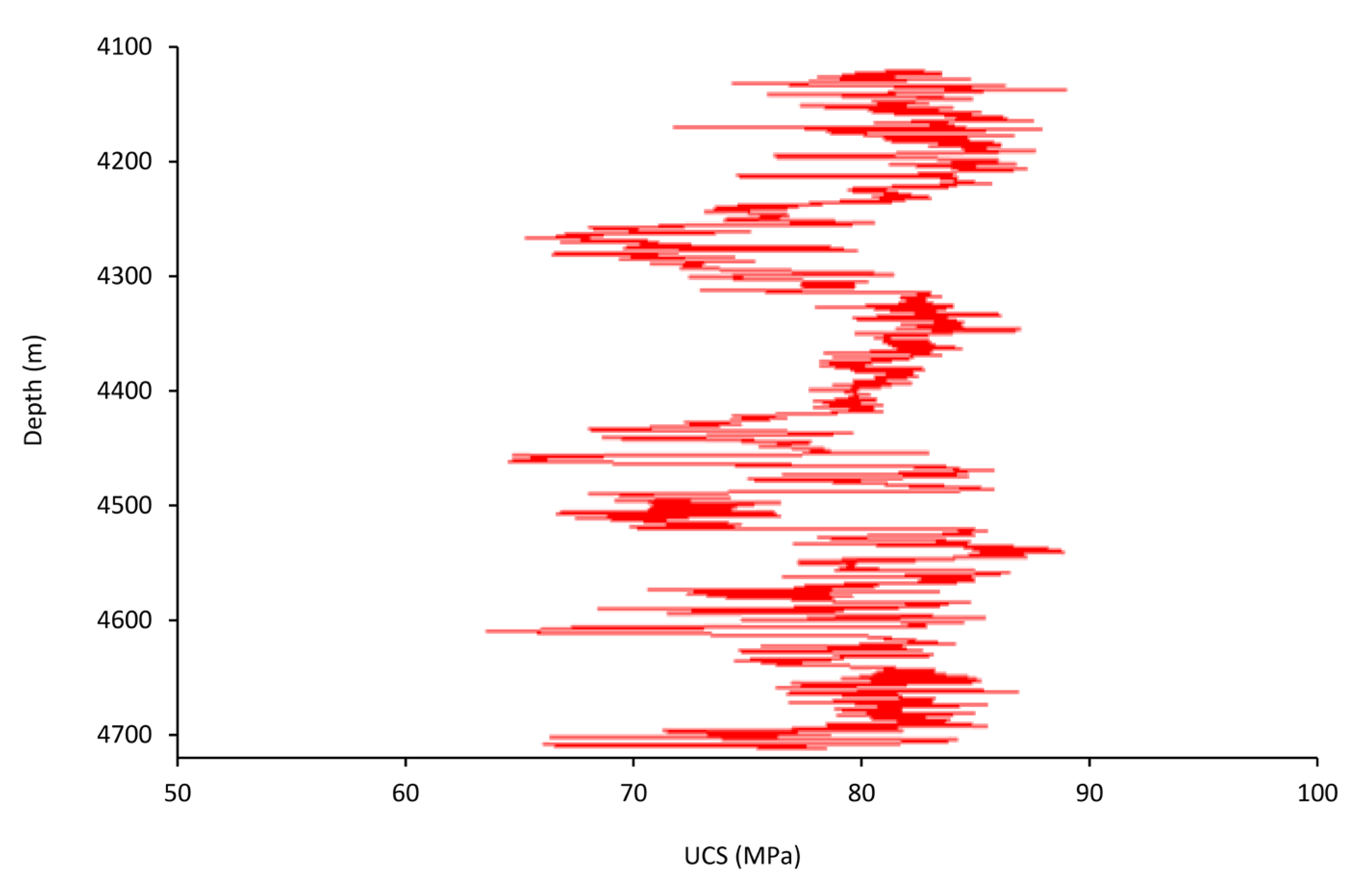

Despite all the efforts toward ensuring wellbore stability in recent years, the oil industry has several problems such as stuck pipes and lost circulation that lead to the collapse of wellbores. It is now well established from various studies that an appropriate plan is required to optimize drilling conditions, determine the MWW, and define the angle of deviation in terms of wellbore stability. Factors that influence drilling operations in underground formations are geo-mechanical factors such as in-situ stress and pore pressure, and mechanical properties such as Poisson’s ratio, Young’s modulus, and compressive strength [

15]. A systematic understanding of how these factors impact wellbore instability can help determine the MWW in drilling operations. This particular research points to the need for obtaining the lower limit of the mud weight window and determining the optimal path of the wellbore when using directional drilling technology.

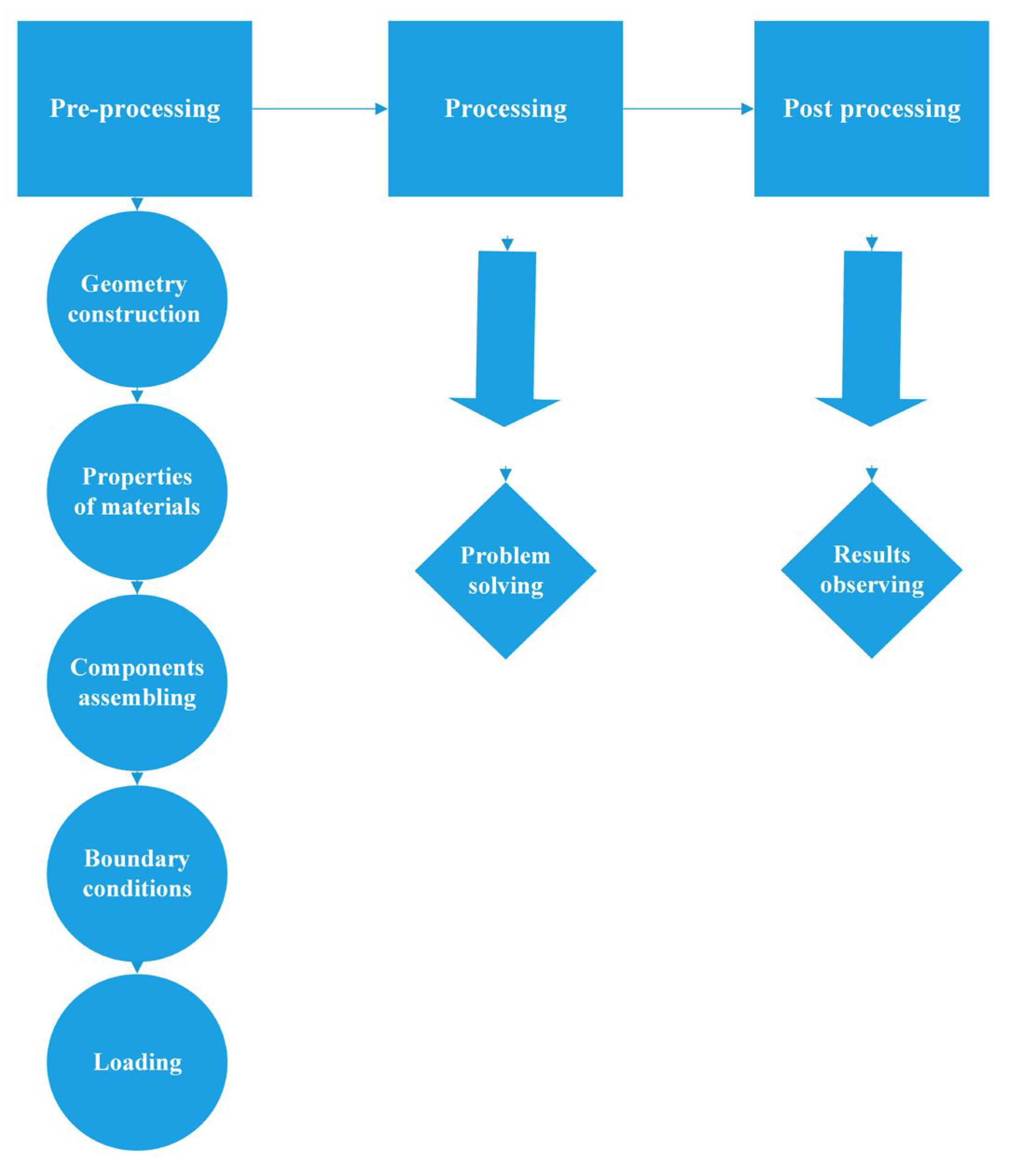

2. Numerical Modeling of Wellbore Stability

Several models of induced stress in a circular wellbore have been proposed, predicting the desirable mud pressure using 2D or 3D failure criteria. The linear elastic model is perhaps the most prevalent technique among the presented models. To predict borehole breakout, the Mohr–Coulomb failure criterion is frequently used, and is based on the concept that principal stresses of σ1 and σ2 rise in a linear manner during failure. By the way, there is no effect on rock strength from the intermediate principal stress of σ3.

Manshad et al. [

16] applied some reliable analytical and numerical methods, e.g., Mohr–Coulomb and modified Lade, to calculate wellbore instability and estimate Iran’s MWW and drilling direction. The accuracy of mud pressure results is validated by the finite difference method and elastoplastic model and has demonstrated the highest MMP (minimum mud pressure) from the Mohr–Coulomb method. Manshad et al. [

16] reported that an inclination of 20° is required to obtain the MMP for a wellbore. Yamamoto et al. [

17] analyzed chemical and geomechanical data from the Zakum field’s shale instability in the UAE and concluded that drilling fluid and bedding plane are the main cause of wellbore instability. A geomechanical model is also used to predict wellbore instability and estimate in-situ pressures [

18]. A necessary consequence of their study is the effect of wellbore inclination on breakout pressure. Waragai et al. [

19] presented an operation guideline to eliminate the severity of wellbore instability in Nahr Umr shale formation in the offshore field in UAE after the prohibition of using diesel in water-based drilling mud. This study found that mechanical failure is imputed from the mud invasion into a lamination, and effective wellbore cleaning plays a significant role, especially with a wellbore angle between 30° and 50°. As a result of the guideline implementation, no wellbore with sidetracking has been noticed. Waragai et al. [

19] inferred that the guideline works, and wellbore instability problems could be mitigated by following it. Han et al. [

20] showed that a combination of tectonic movements and inappropriate MWW cause fractures on shale formation in the Phu Horm field and, therefore, the wellbore instability issue. As a suggestion, the drilling strategy can be modified while applying proper components and inhibitors to prevent the intrusion of drilling mud [

21] into the fractures of underground formations.

Furthermore, a geo-mechanical model was applied by Alsubaih [

22] to determine the ODMP in the Tanuma shale formation, Iraq. The results from 45 deviated wellbores showed that shear failure of wellbores causes the pipes to stick. In a study investigating the wellbore stability, Tutuncu et al. [

23] reported that fundamental processes to prevent stuck pipes know about underground formations’ in-situ pressures and rock properties.

Moreover, Wang et al. [

24] applied a two-dimensional (2D) finite-element model to simulate symmetrical fractures on the wellbore wall affected by anisotropic in-situ stresses and fracture length. By the way, the stress distribution is also calculated by considering fracture breadth before and after fracture bridging. However, in this numerical research, the leaking-off of fluid from the wellbore wall and fracture surface is neglected, given no information about fracture behavior after bridging and the effect of fluid inside the rock. Gomar et al. [

25] used a finite-element model to assess the distribution of wellbore stress supported by the four failure criteria in terms of the wellbore wall’s stability. The results showed that a minimum MWW is required for wellbore stability. Chen et al. [

26] examined a series of 3D heterogeneous tunnel models considering varying joint dip angles with the aim of understanding the zonal disintegration phenomenon. They found that zonal disintegration is induced by the stress redistribution of surrounding rock masses. Chen et al. [

26] also realized that the model with a larger inclination angle is damaged further before the final collapse of the wellbore.

The literature on wellbore stability misses the importance of the wellbore’s deviation angle and azimuth. Concerning the availability of geo-mechanical data, this research investigates the optimization of the drilling route, i.e., the wellbore’s deviation angle and azimuth, in wellbore-D of the Azar oilfield, Iran. To this aim, a three-dimensional (3D) finite-element model in ABAQUS is simulated to analyze in-situ stresses and determine the MWW in the drilling operation of wellbore-D in the Azar oilfield. Drawing upon this strand of research into the appropriate plan, this research attempts to evaluate the mechanical properties of rock, elasticity modulus, properties of rock failure, pore pressure, and in-situ stress of wellbore in various deviation angles.

4. Stress Analysis Results

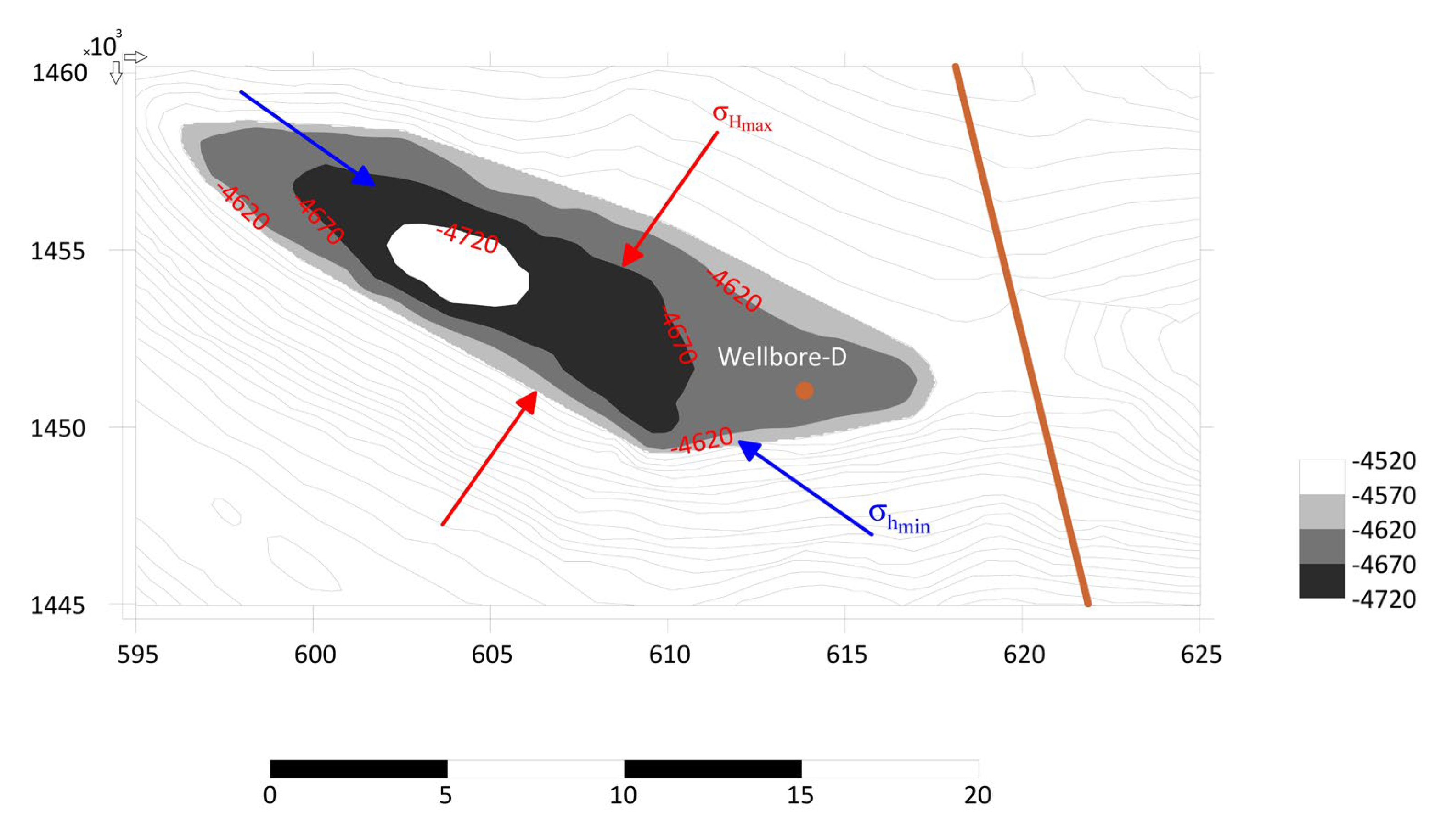

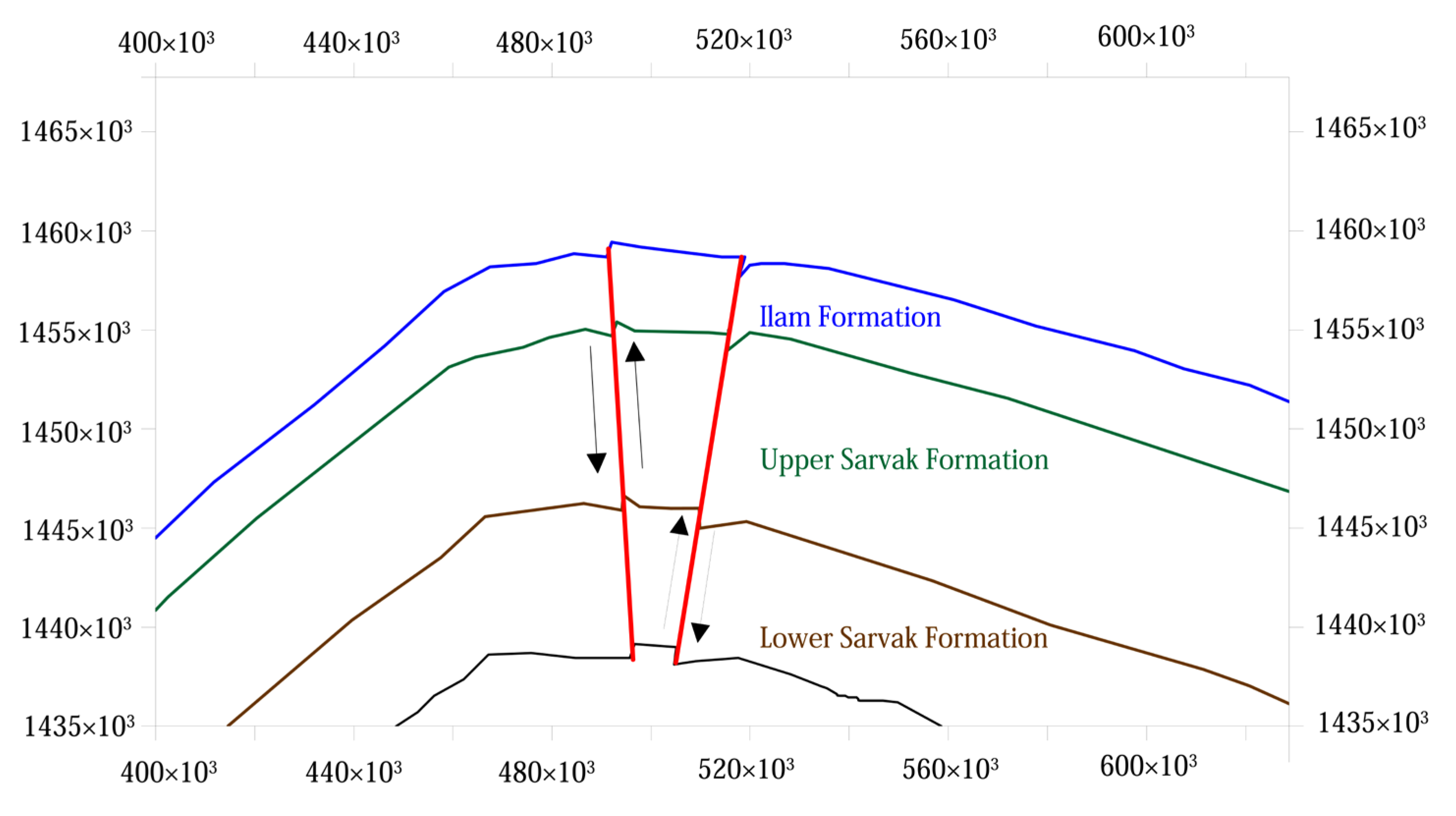

The stress analysis results from

Figure 8 and

Figure 9 show that the Azar oilfield is structurally under the impact of a complex tectonic system, dominated by two reverse faults representing a pressure system, especially across the Sarvak Formation. There is a perpendicular fault near the Azar oilfield, which no longer exists after the Asmari Formation. As per

Figure 8, the direction of minimum and maximum horizontal stresses is according to the reverse fault’s configuration (

σH >

σh >

σv) in the Azar oilfield. This configuration caused a horst in the central part of the Azar oilfield (

Figure 9).

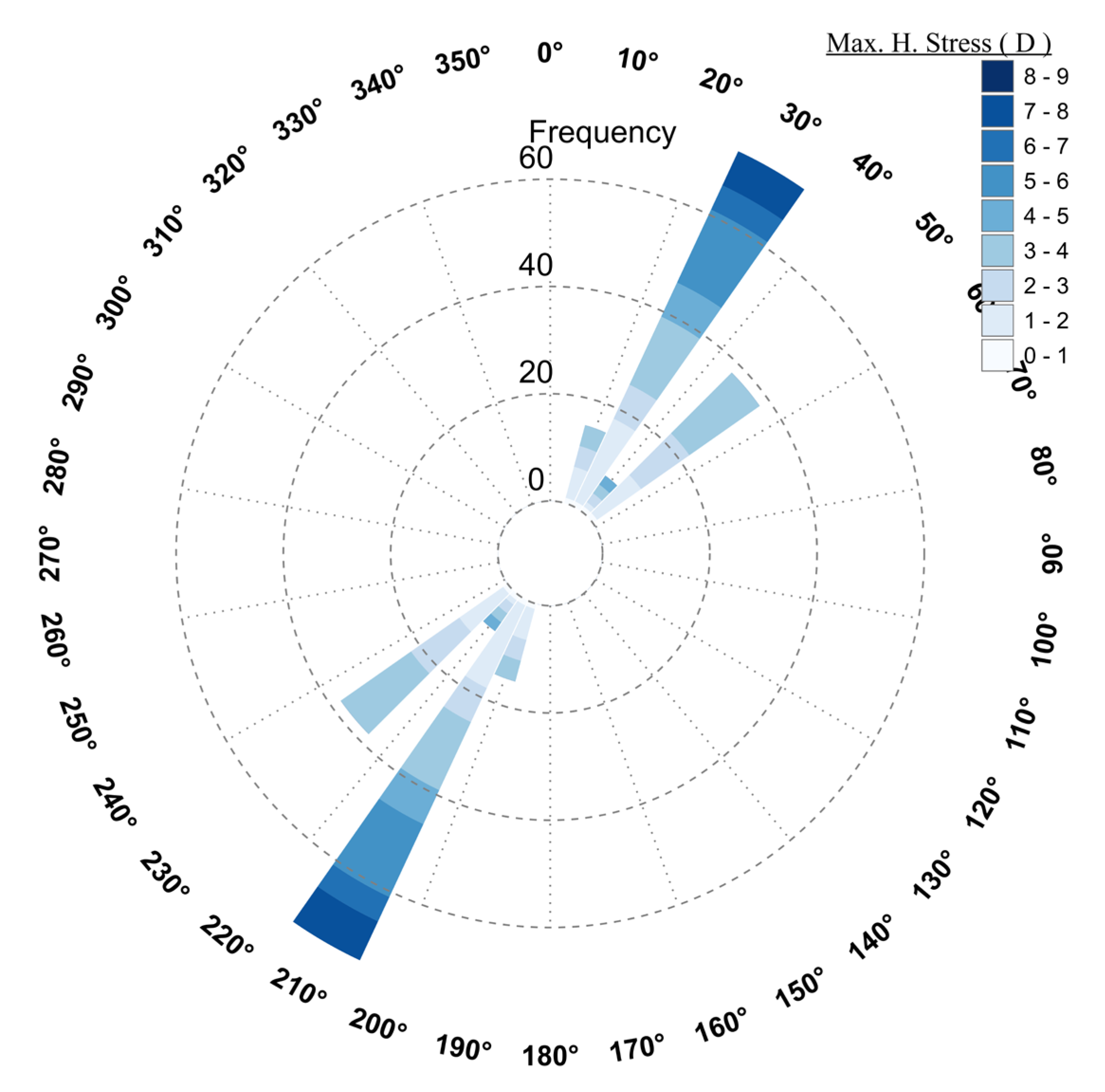

From the results of well instability analysis as a rose diagram (

Figure 10),

σH and

σh are directed at N30° E and N60° W, respectively. Inclination angles of 15°, 30°, 60°, and 90° are represented by circles with different radii. Each circle has 360°, representing azimuth angles of wellbores. The minimum mud density (MMD) values in g/cm

3 are shown in a color bar on the right side of the rose diagram. In this example, at a certain depth, for a wellbore with an inclination degree of 45° and an azimuth angle of N30° E, the MMD is 1 g/cm

3. One point to be noted in the hemisphere plot of the MMD is that all values are to avoid wellbore collapse or shear failure. Besides, the wellbore pressure is higher than the formation pore pressure to avoid a drilling kick [

30]. In the literature, the lower bound of the mud window is the minimum mud weight required to achieve the desired degree of wellbore stability. In this study, normal pore pressure is 1.01 g/cm

3, and therefore, the lower bound of MMW is the pore pressure plus the maximum swab pressure to avoid the drilling kick, rather than the MMD to avoid the wellbore collapse.

Figure 10 and

Figure 11 show rose diagram results of wellbore-D in the Azar oilfield. According to the results, induced tensile fractures occur in azimuth 30° and 210° of NE–SW, indicating the direction of maximum horizontal stress (

Figure 10). In contrast, the wellbore collapse in azimuth 120° and 300° shows the direction of minimum horizontal stress (

Figure 11).

The literature revealed that the issue of wellbore instability is referred to the mechanism of principal stresses [

31,

32], while the role of in-situ stresses is mainly neglected. In this study, the amount of in-situ stresses was determined to cover all mechanisms involved in the wellbore instability of the Azar oilfield. In this regard, overburden pressure or vertical stress

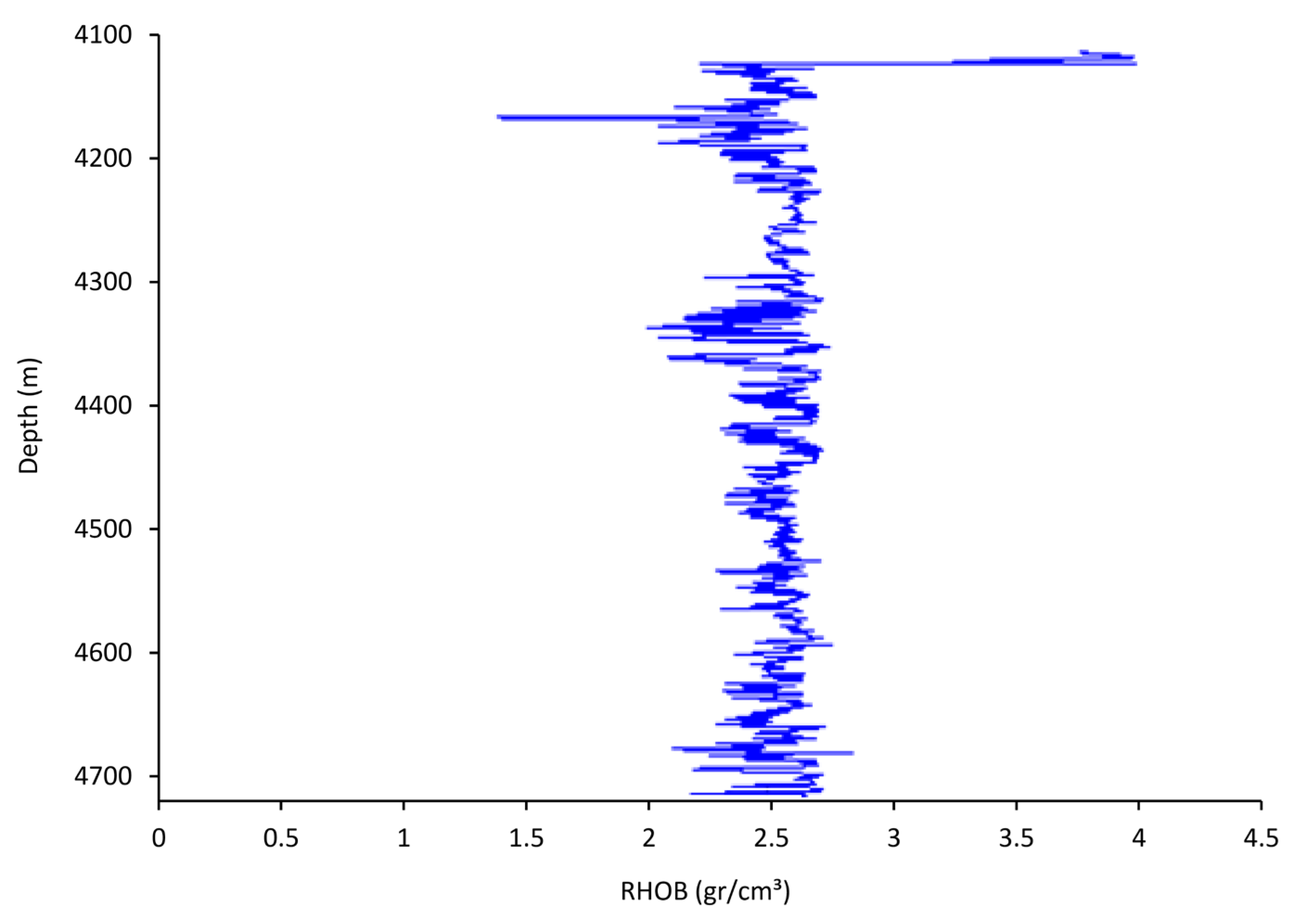

in an arbitrary depth of wellbore equals the weight of overburden above this depth. So, the vertical stress of wellbore-D in the Azar oilfield was obtained from Equation (5).

where

shows density as a function of depth (

), Earth’s gravity acceleration (

), and average density of overburden layers (

). Also, Equation (6) was proposed for offshore drilling operations in which a column of water exists above the formation.

where

denotes the density of water and

is the depth of water. The water density was assumed to be 1.03 gr/cm

3 [

31]. Due to the high cost of using the well-logging method, data collection is usually associated with a range of hydrocarbons contained, and routinely, there are sections in the upper parts of the wellbore where log-recording activities have not been performed. Hence, the density of these sections in the formation was assessed by the linear interpolation of data obtained from well logs. In this study, an average density of about 2.3 gr/cm

3 was considered for the Sarvak Formation. From

Figure 12, the

value for the depth of 4400 m is 99.17 MPa.

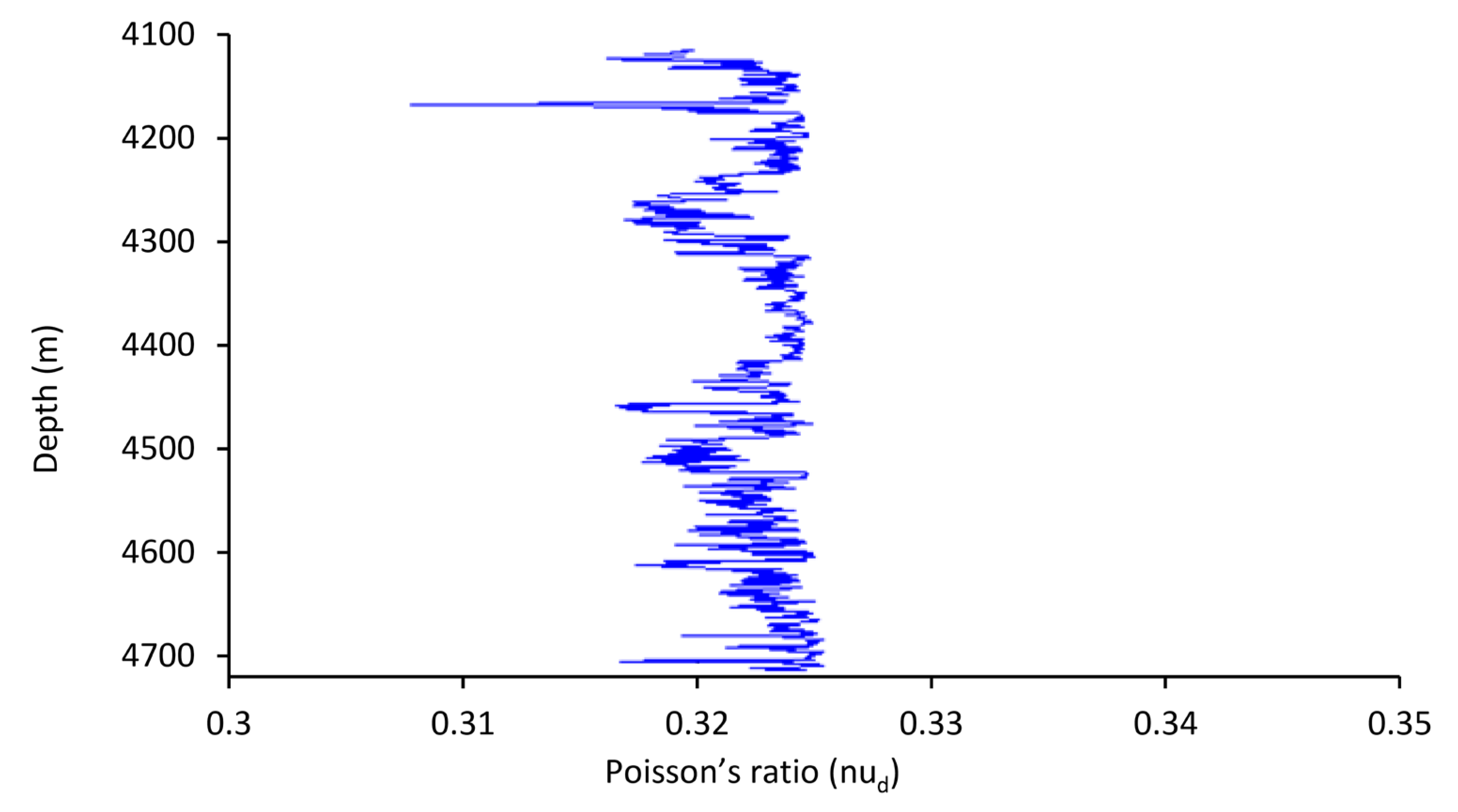

Moreover, existing pore pressure recognizes its critical role in the distribution of stress in wellbores. Equations (7) and (8) present the minimum (

) and maximum (

) horizontal stress values.

In these equations,

V is Poisson’s ratio,

is the Biot’s coefficient,

is the pore pressure,

and

are respectively the strain indicator in the direction of the minimum and maximum horizontal stress, and sentence

is recognized under the title of effective vertical stress. As there is no result of the leak-off test (LOT) in the Azar oilfield, parameters

and

are calculated using a trial-and-error method. The results from these strain parameters showed that the stress regime would be in reverse regime (i.e.,

. So, the minimum horizontal stress amount equals vertical stress, and therefore, the proportion of the maximum horizontal stress towards vertical stress is 1.05 (

Figure 13).

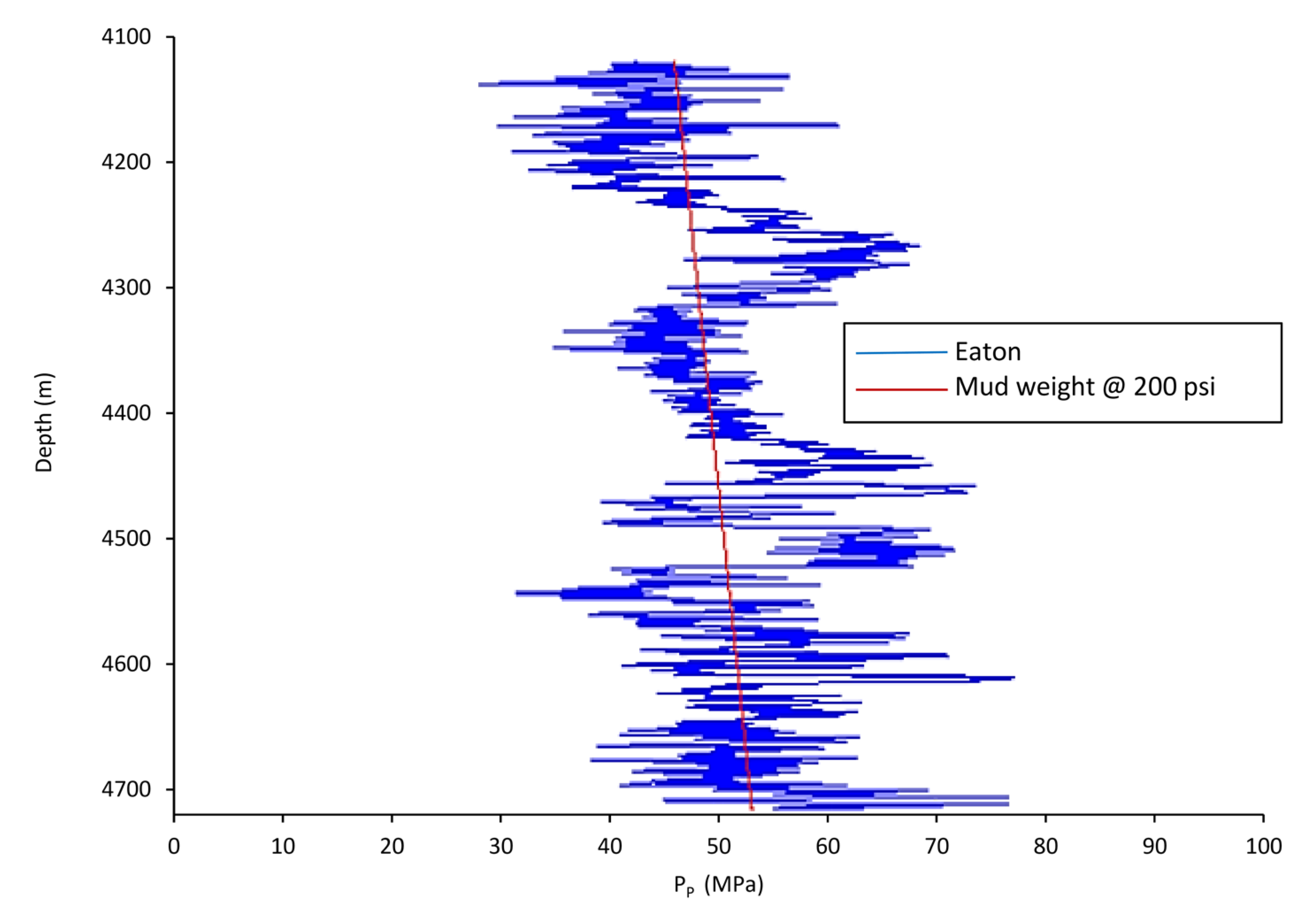

Furthermore, Eaton’s equation was applied to determine the amount of pore pressure in the wellbore-D of the Azar oilfield. The data reported here appear to support the assumption that the drilling operation is in an ultra-balance condition with a mud pressure of 200 pounds per square inch.

In Equation (9),

OBG and

are the overburden and hydrostatic pressure gradients, respectively.

, and

are the sonic compressional transit time (DTC) of formation, rock matrix, and mudline, respectively.

Z and

c denote the depth and compaction constant, respectively.

Figure 14 illustrates pore pressure changes from Eaton’s equation and mud pressure in the wellbore-D of the Azar oilfield. As shown in

Figure 14, the pore pressure gradient of the Sarvak Formation is about 11.5 MPa/km.

Figure 15 represents the results of in-situ stresses (i.e., the vertical, minimum, and maximum horizontal stress) and pore pressure obtained from wellbore-D of the Azar oilfield.

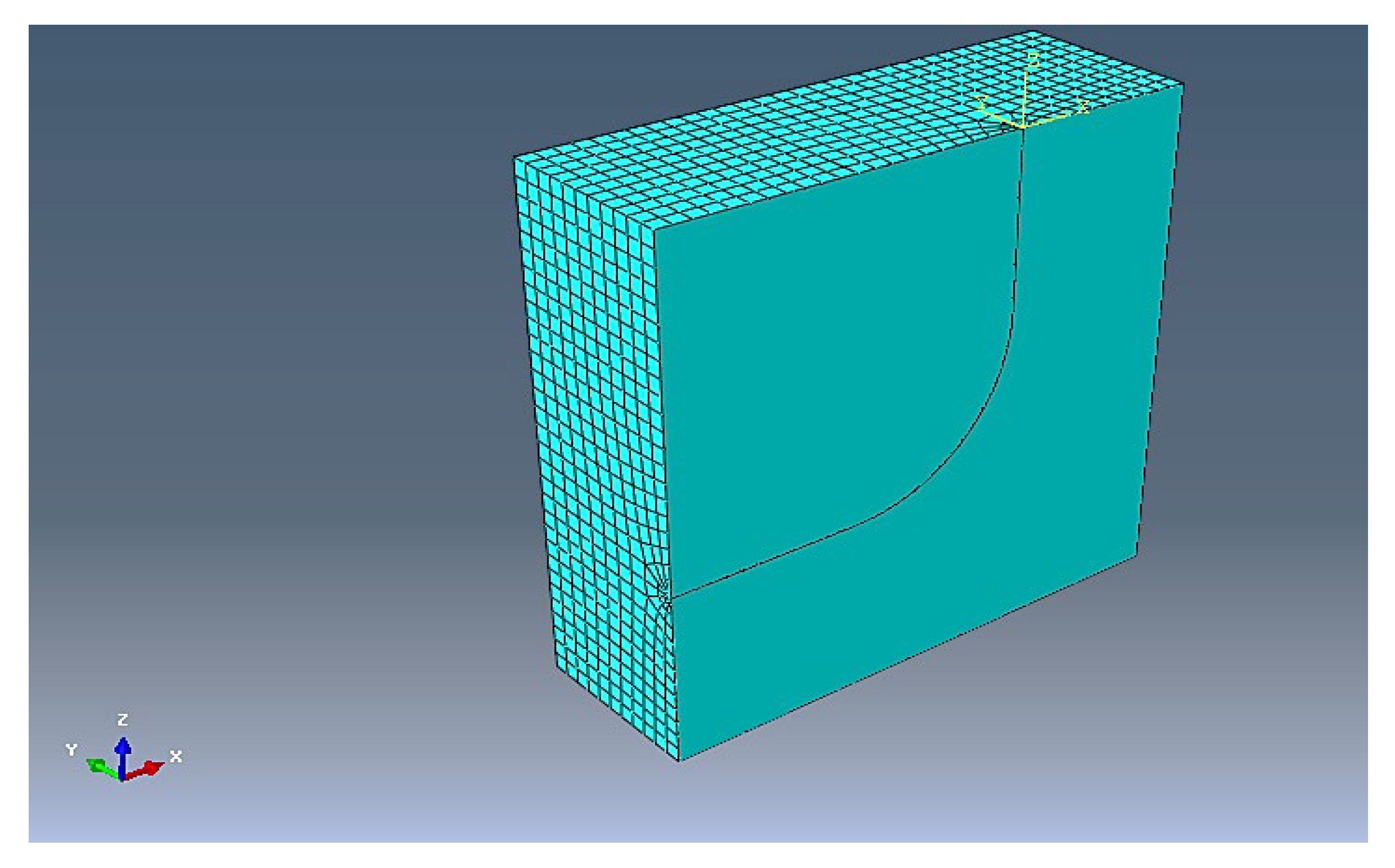

4.1. 3D Model’s Geometry

The first phase of the 3D model construction is the creation of intended geometry, including a block of porous media with a well diameter of 17.78 cm (7 inches). Dimensions of the constructed model are 583 × 400 × 583 cm. Since this study aims to determine the optimal route for drilling operations in the Azar oilfield, changes in the deviation angle or curvature beam should be considered.

Figure 16 illustrates a schematic view of the 3D model from the wellbore-D in the Azar oilfield. At first, the wellbore is vertical, and then it deviates from the vertical state with a 15-degree slope per 100 ft.

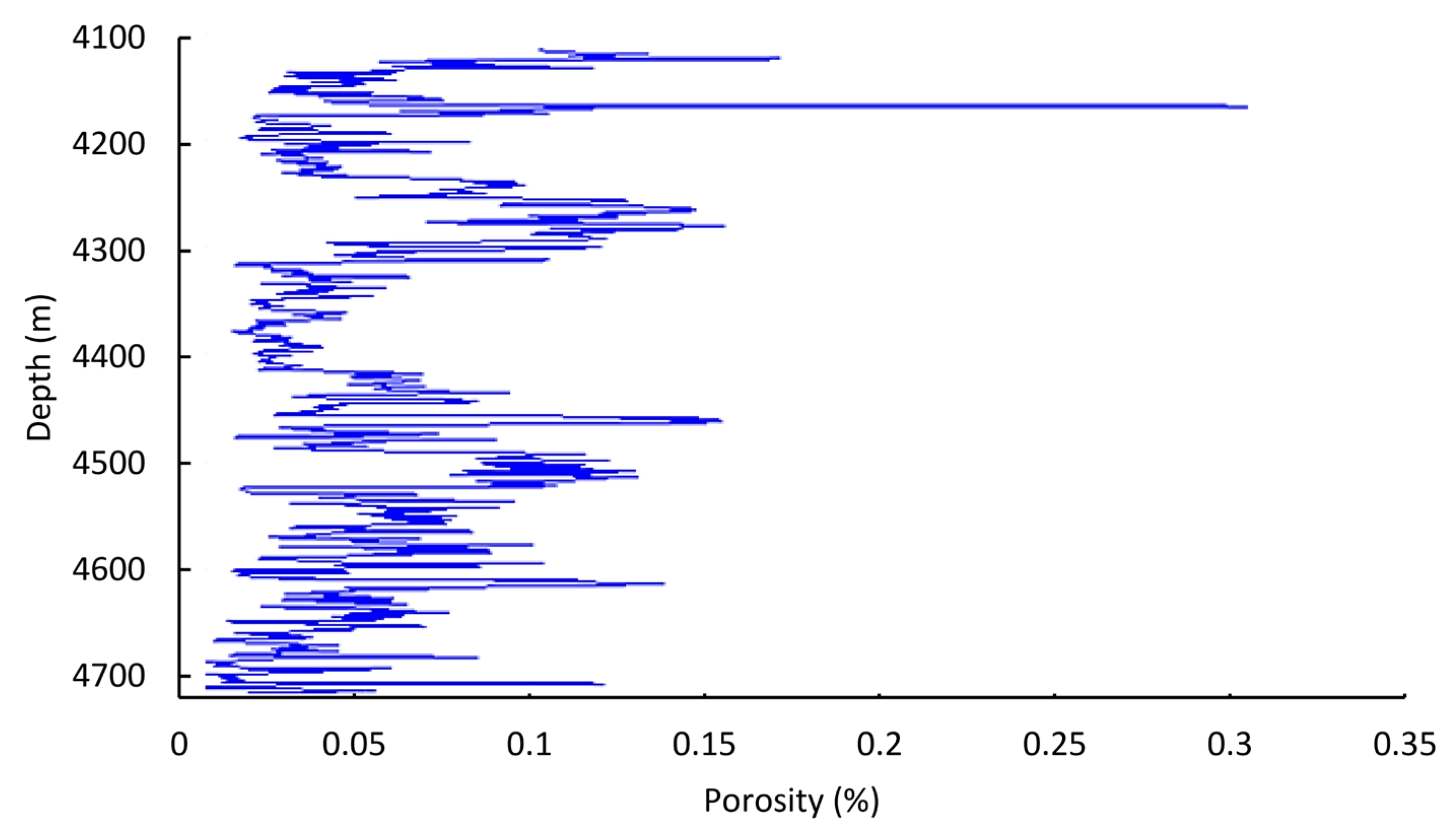

At last, the wellbore finds a horizontal state. With the porosity and fluid in rocks, the modeling analysis moved further to the depths and caused changes in the geo-mechanical behavior of the Sarvak Formation. On the other hand, an elastic model with no consideration of porosity and pore fluid creates a hypothesis with an immense error in understanding the process. This is because pore spaces [

33], pore fluids, and their connection within the wellbore play a crucial role in addressing the issues of the drilling operation. In this regard, lack of porosity causes an increase in shear and tensile strengths, resulting in an invalid outcome.

The top part of the model was located at a depth of 4000 m. In this field, the value of vertical stress resulting from the overburden weight at a depth of 4000 m is 90.15 MPa in the Z direction. The estimated minimum and maximum horizontal stresses are 90.15 MPa and 94.66 MPa, respectively. In other words: and . Also, pore pressure is 46 MPa, and the pore pressure gradient is 11.5 MPa/km.

4.2. Boundary Conditions and Modeling Steps

The boundary conditions of a numerical model include variables such as stress and displacement. If in the intended model the behavior of a material is elastic, the grid boundary distance to the center of mode from each side will be five times more than the dimensions of the model range, which is considered the highest amount in this study due to the poroelastic behavior of the material [

25,

34]. In the constructed models, the plates perpendicular to the coordinate axis have zero displacement, and the model’s surface has zero displacement along with the z-axis. Also, the circumstances of pore pressure on the external zones of models have been applied. By applying the initial conditions, the strata condition was simulated. In an ideal situation, information about in-situ stresses was obtained from the in-situ measurements in the Azar oilfield.

In the Azar oilfield, the pore pressure element of C3D8P, 8-node trilinear displacement, and pore pressure were used from ABAQUS by considering the freedom degree of pore pressure and 3D model. The shape of this element was categorized in the hexagonal type with a structured form of the mesh-scaling method. It is noteworthy that the mesh scaling’s size is partly changed and is finer, close to the wellbore, with no impact on the amount and distribution of displacements and stresses. In this numerical model, the elements and nodes are 26,957 and 29,738, respectively.

Moreover, there were two main phases in the proposed 3D model, including a geostatic step, creating a primary balanced model, and a drilling step. In the geostatic step, changing the shape and displacement of the model was negligible, and all initial conditions, including in-situ stresses, volumetric forces, boundary conditions, and pore pressure, were defined. In the drilling step, while drilling the wellbore, the number of stresses and displacements was increased in the wellbore-D. After the drilling operation, mud pressure was applied to the wellbore, resulting in a balance in changing the number of stresses and plastic strain in the wellbore wall. Since the regime stress is in the reverse state, the suitable azimuth for drilling accords maximum horizontal stress. Also, minimum mud pressure was related to the stability of the wellbore.

4.3. Verification Analysis of 3D Model

There were two stages that the proposed 3D model considers for modeling the drilling route in the wellbore-D of the Azar oilfield, including the azimuth of the wellbore in the directions of maximum and minimum horizontal stress. Analytical relations of Kirsch’s equation were applied to validate the numerical modeling process. These analytical relations can determine the distribution of stresses around the wellbore.

Figure 17 and

Figure 18 show the radial and axial stress distribution, respectively, around the wellbore-D in the Azar oilfield. The results indicated a good agreement between the numerical modeling and analytical solution with a modeling error of < 4%.

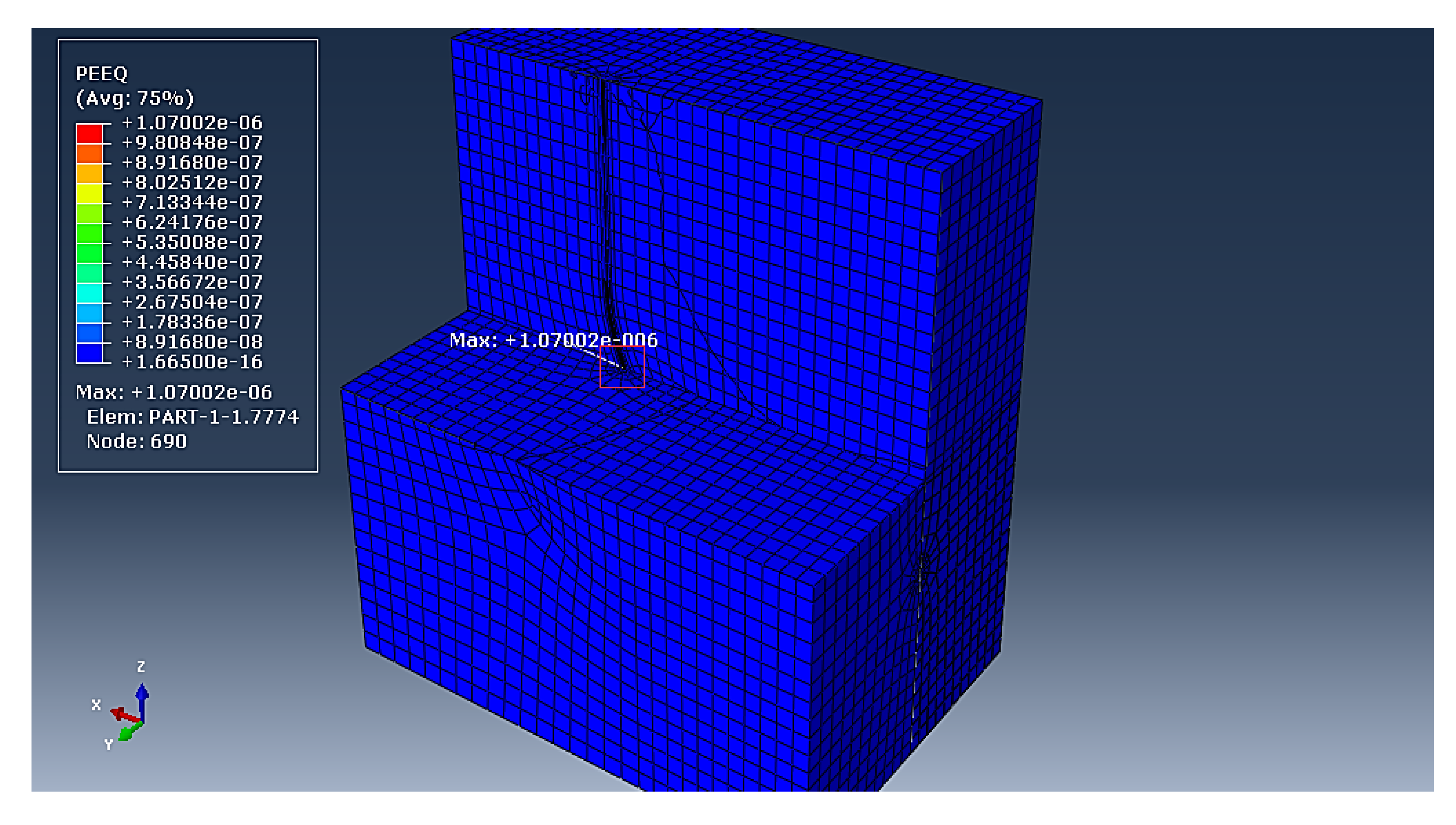

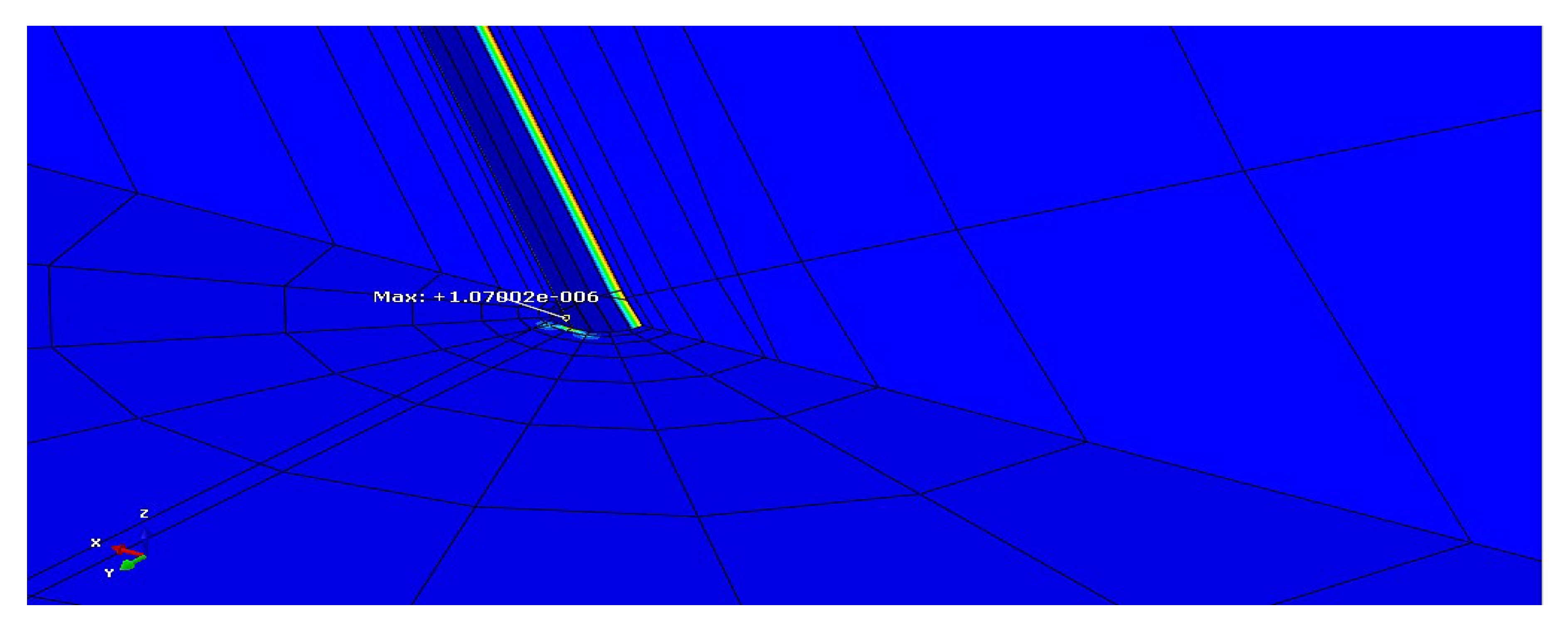

The modeling evidence on wellbore instability revealed that applying higher mud pressure leads to no shear failure in the wellbore-D’s wall. Incidentally, the lower limit of the mud window was determined to prevent any downfall of the wellbore-D’s wall in the Azar oilfield. ABAQUS modeling results showed that the lower limit of the MWW is 89 pcf. As indicated in

Figure 19, a value lower than the MWW leads to a shear failure around a 10-degree deviation angle of the wellbore wall. Taken together, these results support the notion that the drilling operation in the Sarvak Formation caused a downfall of the wellbore-D with the approximate MMW of 75 pcf.

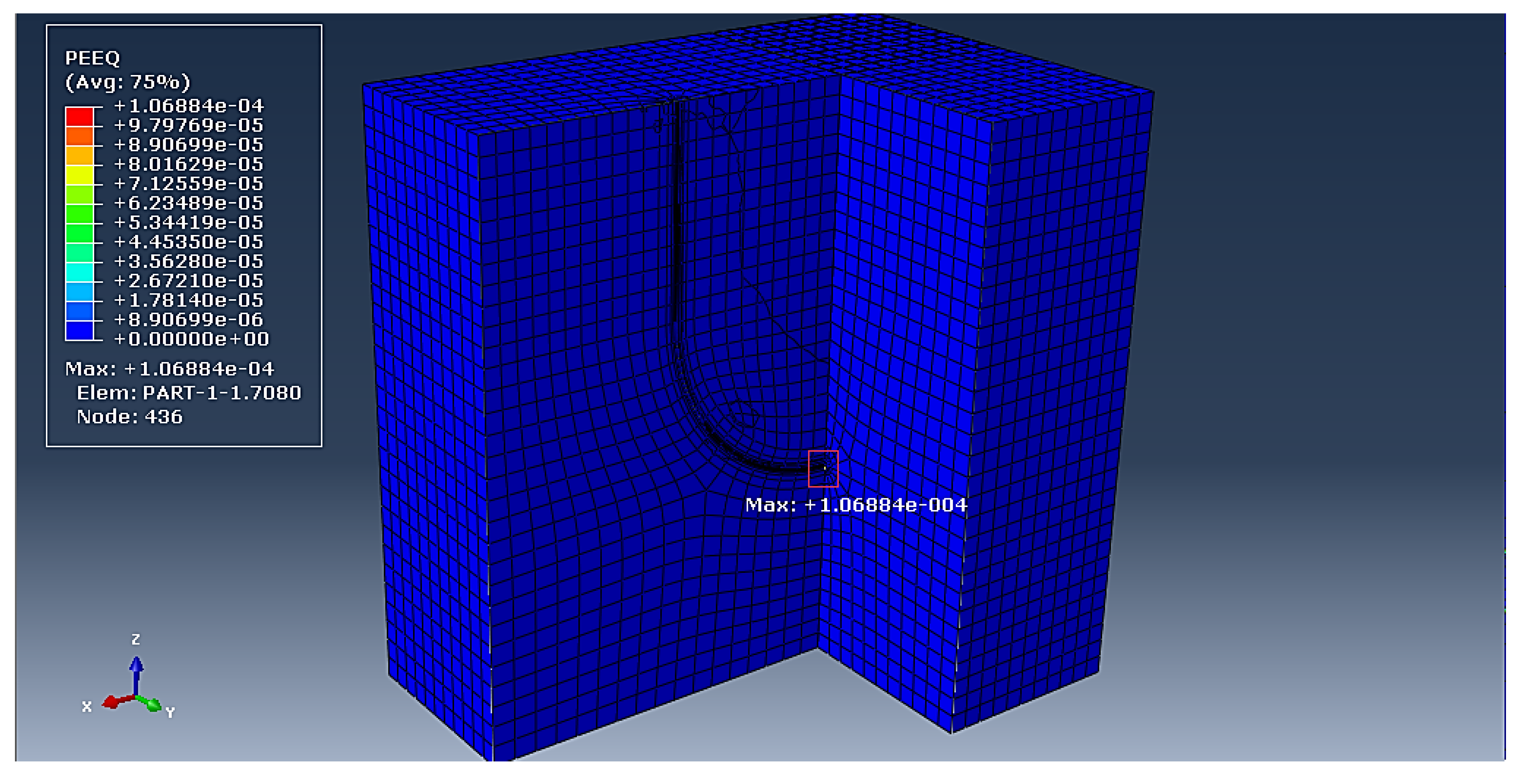

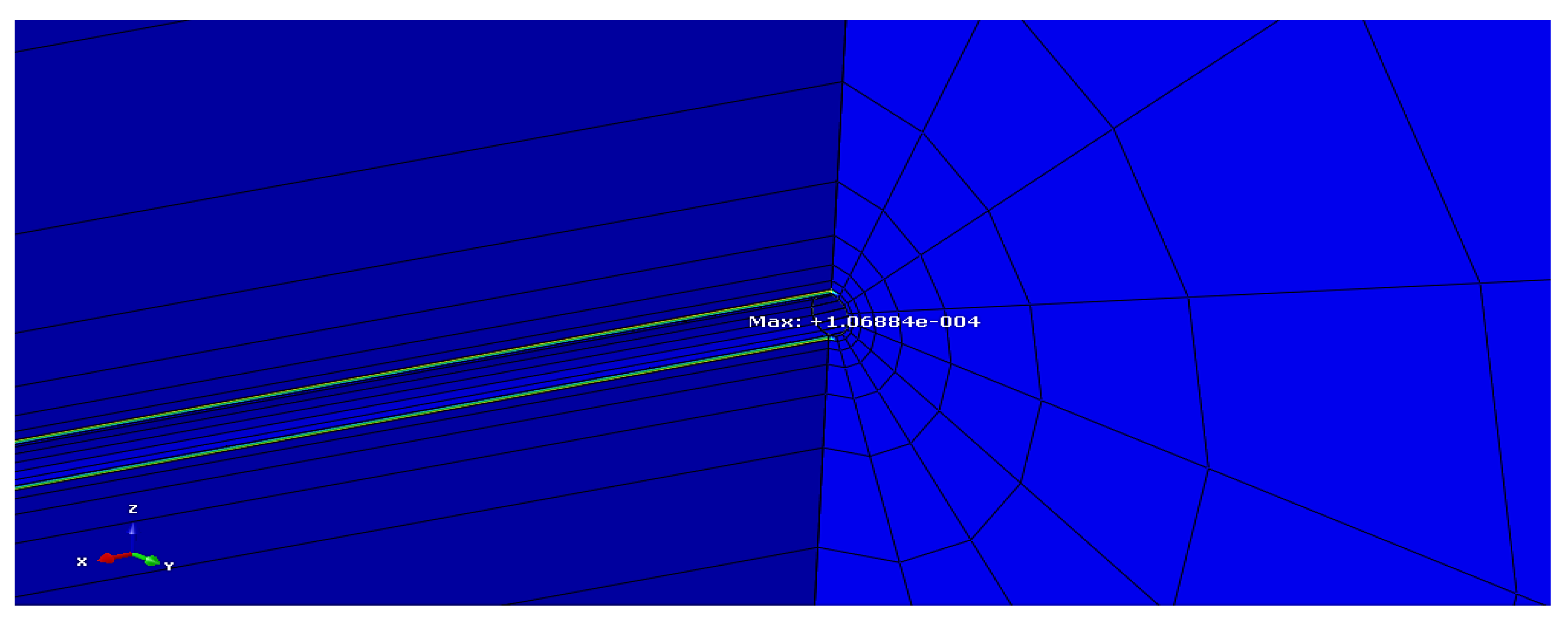

Also,

Figure 20 presents starting the plastic zone in the horizontal wellbore at a mud pressure less than the MWW. In this case, the lower limit of the MWW is 90.3 pcf. As a result, a shear failure occurs in the deviation angle of 90°. Therefore, drilling the wellbore with the azimuth of maximum horizontal stress requires less mud weight, which lessens the cost of the drilling operation. Together, these results follow essential aspects from the analysis performed before the modeling that points to the reverse and strike-slip faults regime in the Azar oilfield. It can be considered as the most appropriate azimuth for maximum horizontal stress with the slightest dispute.