Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations

Abstract

1. Introduction

2. Types of Transparent and Semi-Transparent BIPV: T-BIPV and ST-BIPV

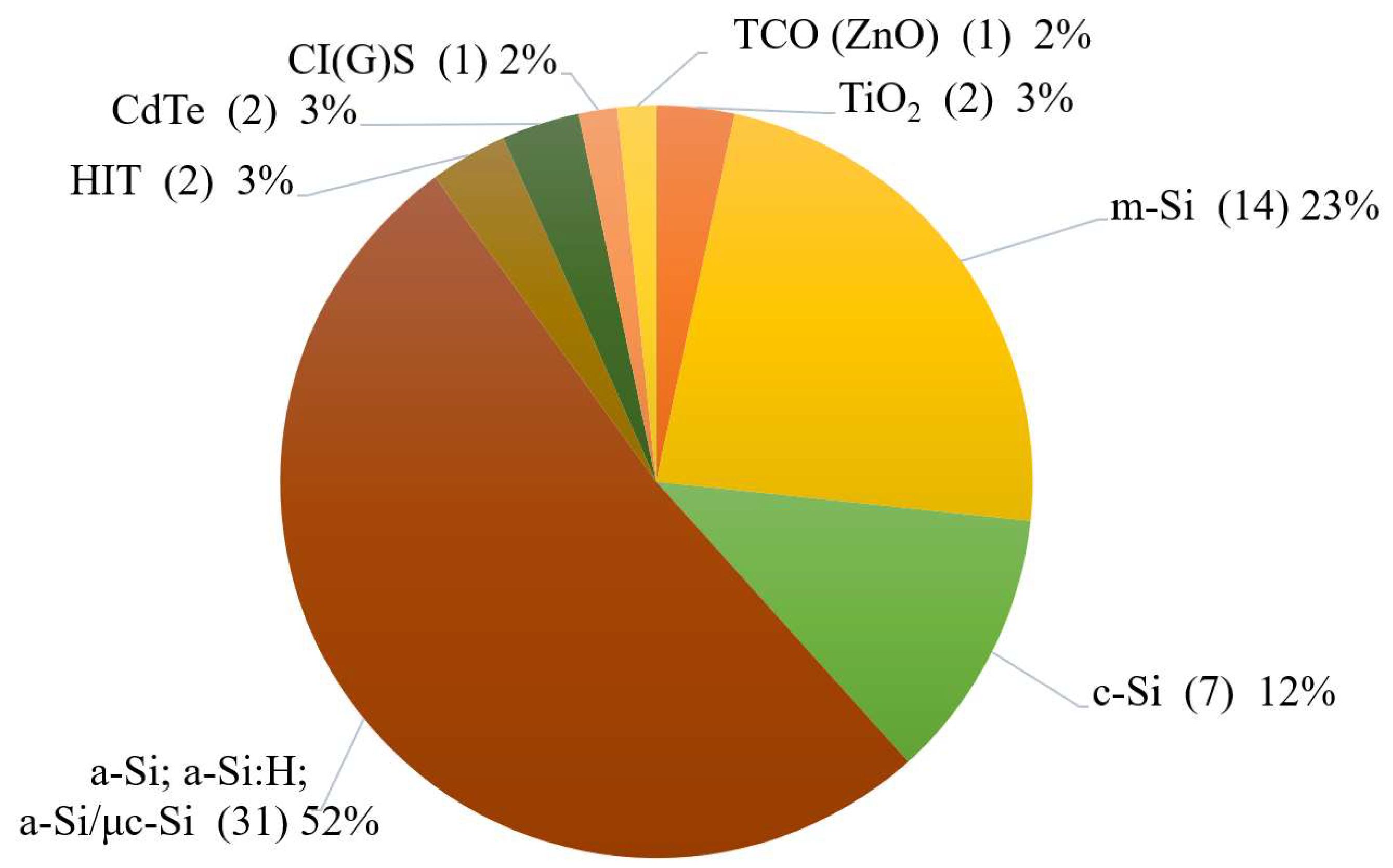

2.1. Semi-Transparent and Transparent PV Cells

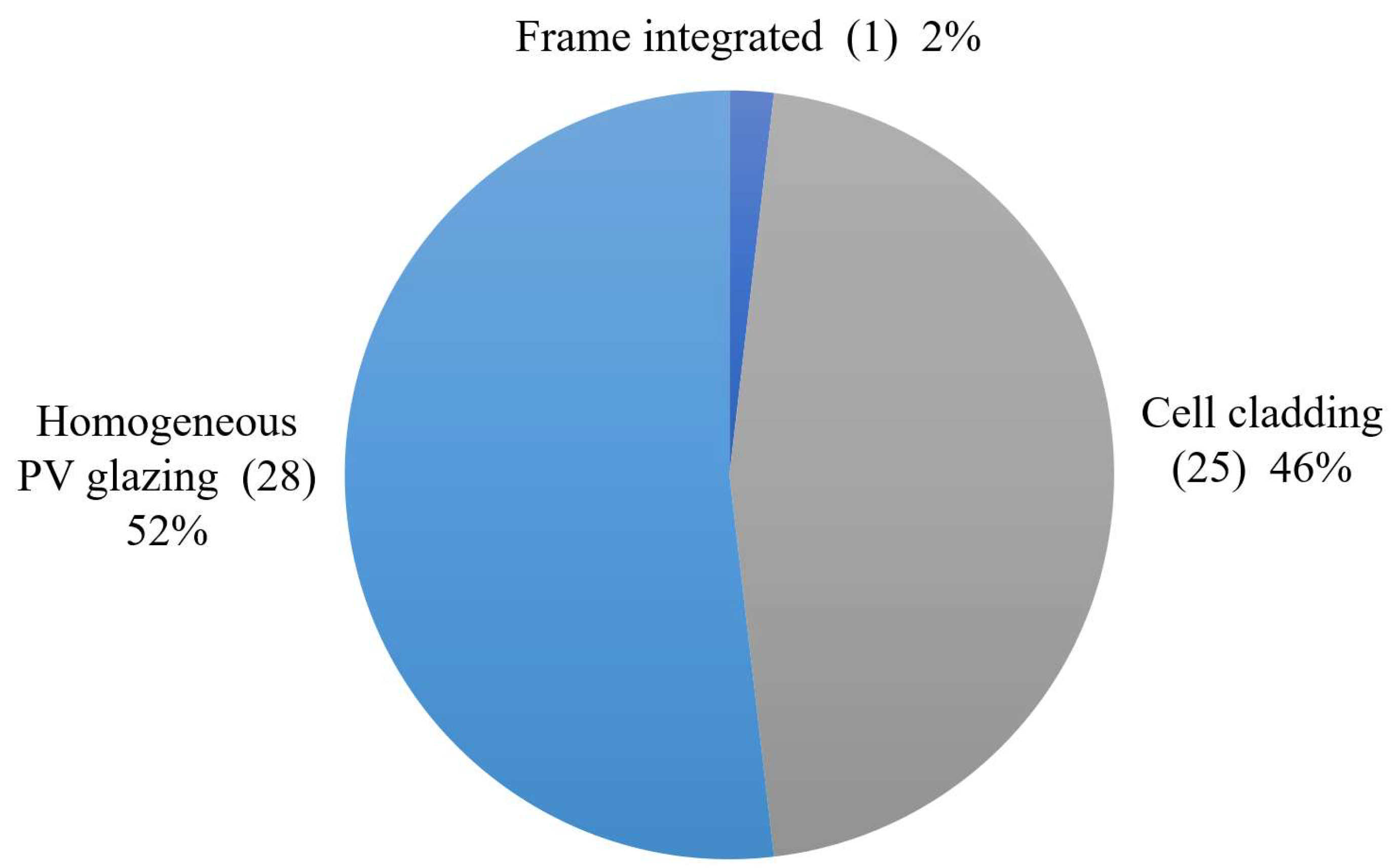

2.2. Semi-Transparent and Transparent BIPV

2.2.1. Cell Cladding

2.2.2. Cell Cladding/Homogeneous PV Glazing

2.2.3. Homogeneous PV Glazing

2.2.4. Frame-Integrated

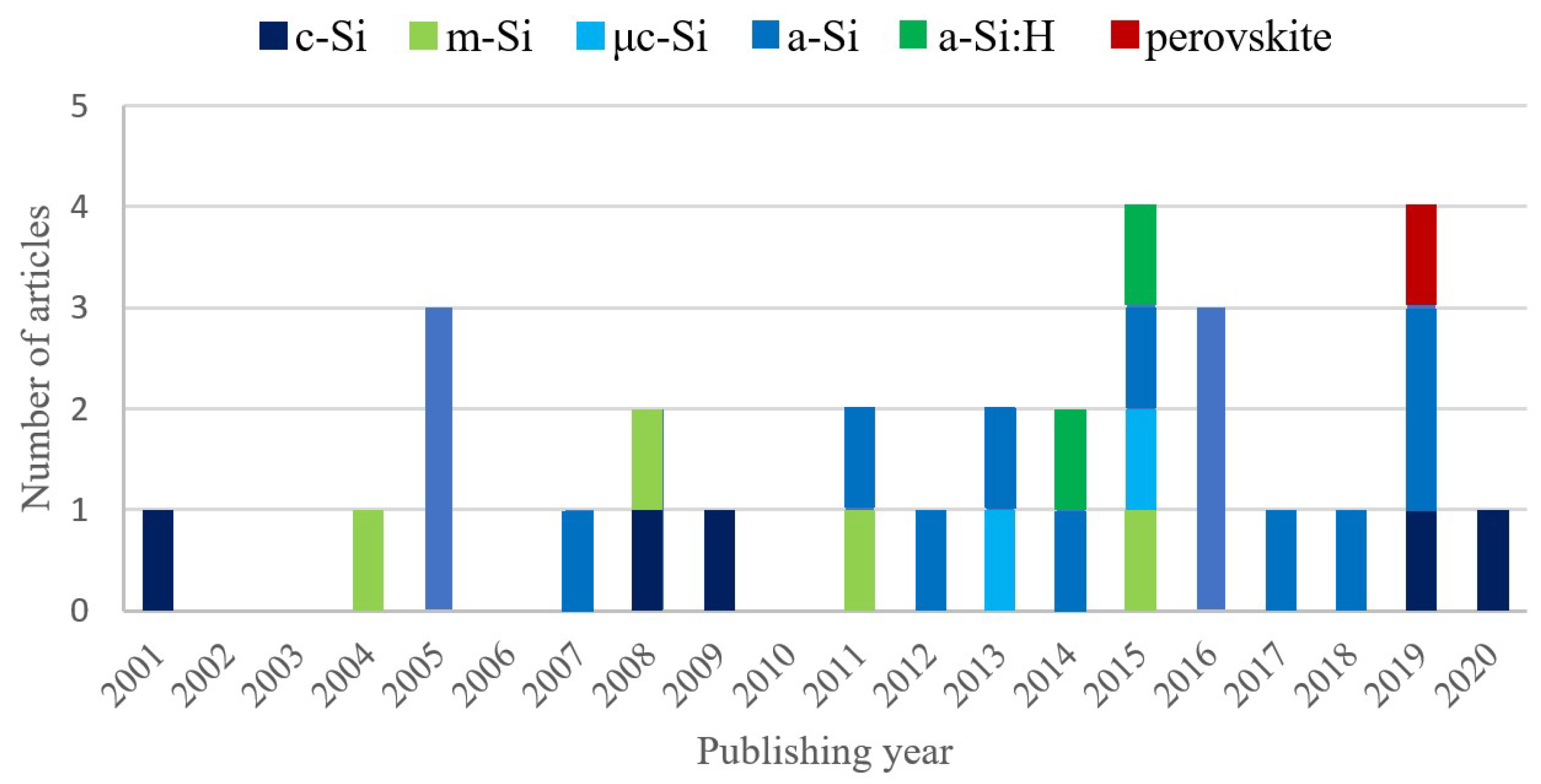

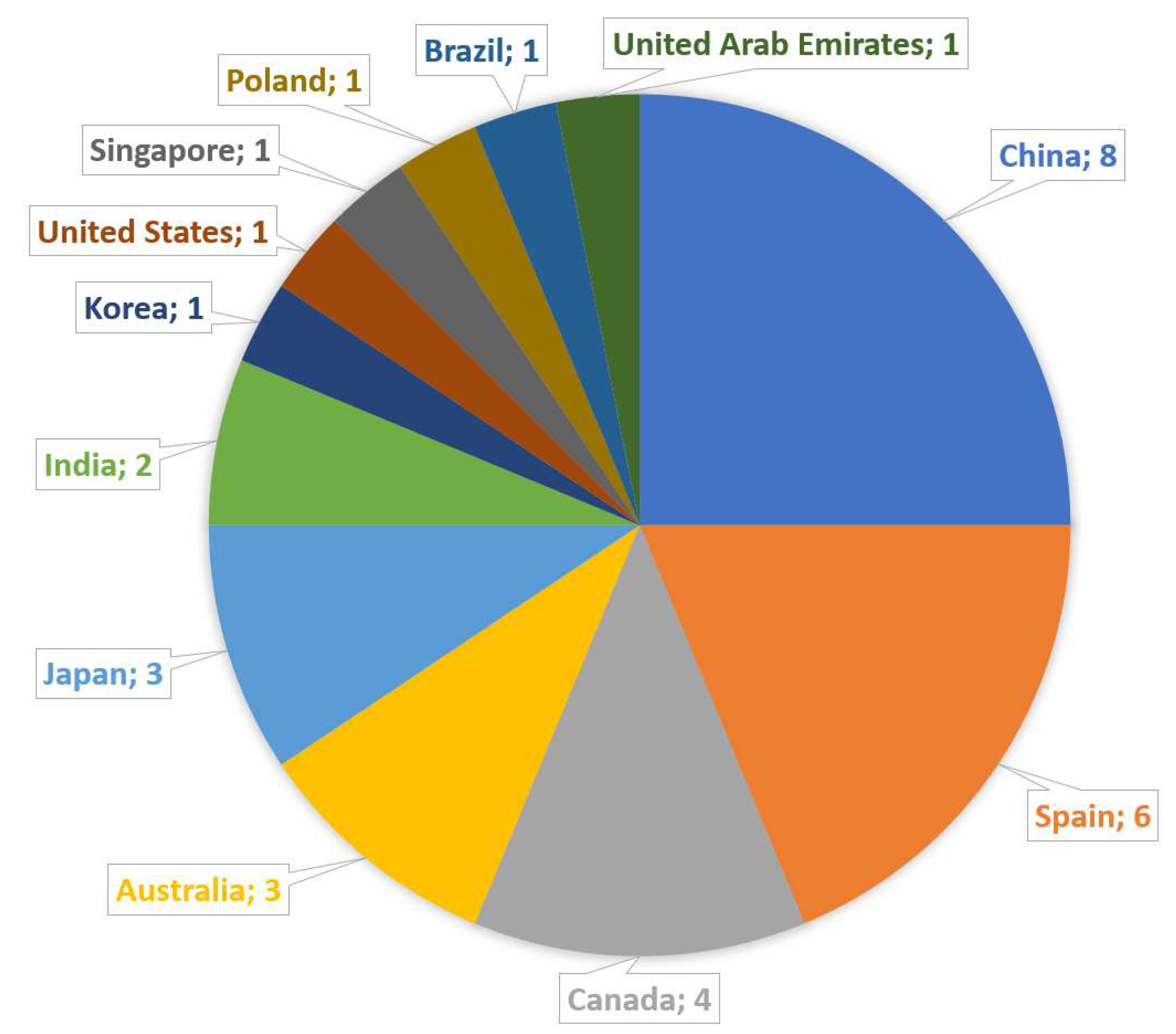

3. Semi-Transparent and Transparent BIPV Modeling for Fenestration Applications

3.1. T- and ST-BIPV Custom Models

3.1.1. Models for the Estimation of Window Parameters

3.1.2. D for Cell Temperature and Efficiency Calculation

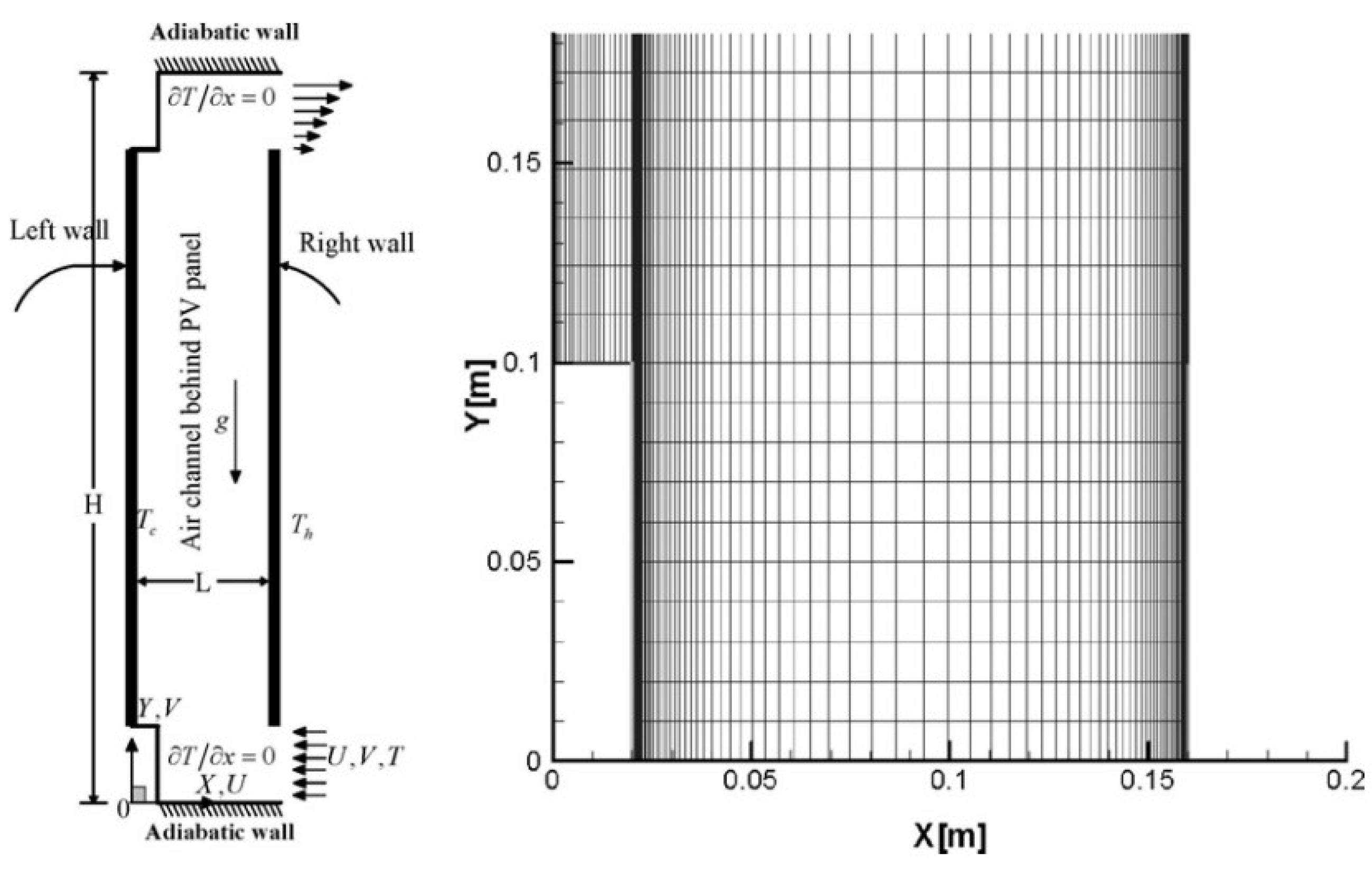

3.1.3. D models to Study Ventilation and Convection Effects within Air Gaps or Rooms

3.1.4. Other Models

3.2. Modeling T- and ST-BIPV in Building Simulation Tools

3.2.1. EnergyPlus

3.2.2. TRNSYS

3.2.3. ESP-r

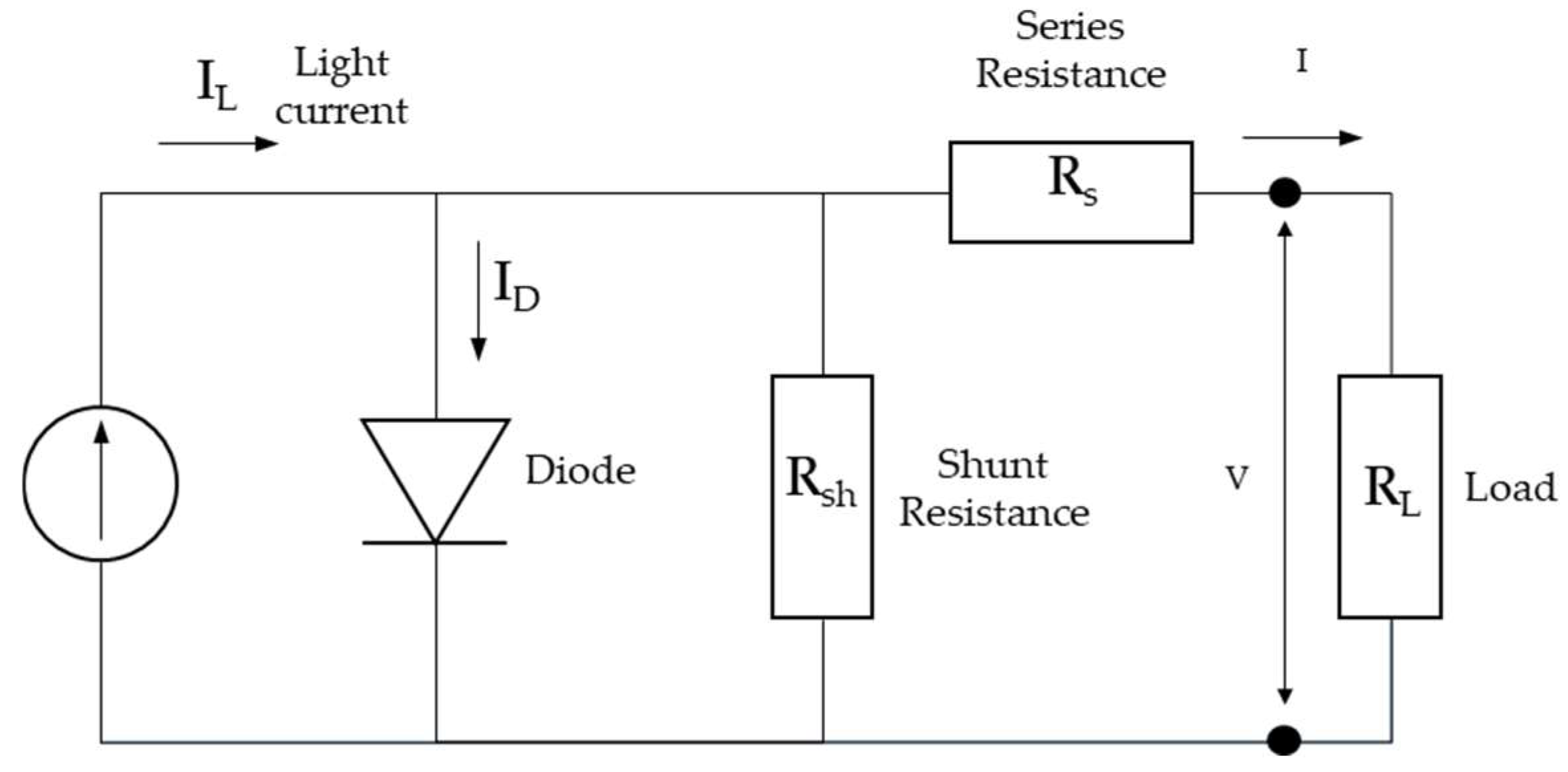

3.3. Electrical Modeling of T- and ST-BIPV

| Location | Year | Tool | Cell Type | Integration Type | Optical Model | Thermal Model | Electric Model | Ref. |

|---|---|---|---|---|---|---|---|---|

| Spain (Madrid) | 2001 | TRNSYS | c-Si | Single-pane cell cladding | TRNSYS | TRNSYS. PV effect not included in the energy balance. | Temperature-dependent, but not specified. | [115] |

| Spain (Mataró) | 2004 | Custom | m-Si | Double-skin ventilated façade with outside skin cell cladding | Not specified | 1D (longwave radiation considered for PV thermal model) | Not specified | [62] |

| Japan (Tokyo) | 2005 | EnergyPlus | a-Si | Double-glazed window with homogeneous PV glazing | EnergyPlus. Solar cell optical properties constant in all spectra. | EnergyPlus. No mention of inclusion of PV generation into the window energy balance. | Evans and Florschuetz [97] | [87] |

| Japan (Osaka) | 2005 | Custom | p-Si a-Si | Single-pane cell cladding (p-Si) or homogeneous PV glazing (a-Si) | Constant optical properties. | Custom 1D model. 1 node per layer plus surface nodes. Thermal mass considered. PV production introduced in energy balance. | Modified Evans and Florschuetz [97] | [72] |

| China (Hong Kong) | 2007 | FORTRAN EnergyPlus | a-Si | Double-glazed window with PV cell cladding | Ray tracing. Daylighting with EnergyPlus. | 2D model with one node per layer in depth direction. | Evans and Florschuetz [97] | [99] |

| Japan (Kagoshima, Osaka, Matsumoto, Aomori, Sapporo) | 2008 | Custom + EnergyPlus | - | Double-glazed window with cell cladding | EnergyPlus | 1D model considering one node per material in the laminate, plus nodes in the inner and outer surfaces coupled to EnergyPlus. | Evans and Florschuetz [97] | [58] |

| China (Hong Kong) | 2008 | Custom | m-Si | Single-pane cell cladding | Fresnel relations | 1D model, several nodes. | Not specified | [60] |

| United Arab Emirates (Dubai) | 2008 | TRNSYS | - | Homogeneous PV glazing | TRNSYS | TRNSYS | Not specified | [68] |

| Canada (Yellowknife, Montreal, Iqaluit) | 2008 | Custom | c-Si | Double- and triple-pane window withcell cladding | Not specified | Custom 1D model with one node per glass. PV output included in the PV laminate energy balance. | Evans and Florschuetz [97] modified to include low radiation effect. | [98] |

| Spain (Lleida) | 2008 | TRNSYS | - | Cell cladding | TRNSYS for transparent part. IAM for beam radiation with Fresnel equations for opaque cells. | 1D finite elements. Includes thermal mass. Does not include PV production. | Temperature- and radiation-dependent. Uses transmittance-absorptance factor modified by IAM. | [120] |

| China (Hong Kong) | 2009 | ESP-r | - | Double-skin ventilated façade with homogeneous PV glazing | Simplified diffuse irradiance model for tilted surface from [124] | ESP-r | ESP-r expression developed in the frame of JOULE PV-HYBRID-PAS project [125]. | [89] |

| Canada (Montreal) | 2009 | Custom | c-Si | Cell cladding | Radiosity theory after infinite interreflections from [103] | None. Nominal operating cell temperature. | Evans and Florschuetz [97] | [101] |

| Korea (Yongin) | 2011 | ESP-r | a-Si | PV glazing | ESP-r | ESP-r | Not specified | [88] |

| Standard operation conditions | 2011 | Custom | m-Si | Single-pane cell cladding | Constant | Power balance of window. Includes electrical output and thermal mass. | Evans and Florschuetz [97] | [96] |

| Spain (Almería) | 2012 | Custom | a-Si | Cell cladding | - | - | Experimental data used to train artificial neural network for predicting PV output. | [67] |

| Brazil (Fortaleza, Florianopolis), Germany (Frankfurt) | 2013 | EnergyPlus | a-Si | Double-pane homogeneous PV glazing | EnergyPlus multi-layered system. Solar radiation reflection modified to simulate PV effect. | EnergyPlus multi-layered system. | Evans and Florschuetz [97] | [78] |

| Hong Kong | 2013 | Custom | - | Double-skin façade homogeneous PV glazing | Not specified | 2D, applied to cavity air flow. | Not used | [85] |

| Singapore. | 2013 | EnergyPlus | μc-Si | Double-glazed homogeneous PV glazing | EnergyPlus | EnergyPlus | Not specified | [81] |

| United States (Miami, Phoenix, Los Angeles, Baltimore, Chicago, Duluth) | 2014 | EnergyPlus | a-Si:H | Double-glazed homogeneous PV glazing | EnergyPlus. Data from experimental measurements. Model from [107,126]. | EnergyPlus | One-diode model. Decoupled from building calculation. | [84] |

| Spain (Madrid) | 2014 | EnergyPlus COMFEN PVsyst | a-Si | Homogeneous PV glazing | EnergyPlus (energy calculation). COMFEN (visual comfort). | EnergyPlus (electrical generation not included). | PVsyst | [79] |

| Poland (Lodz) | 2015 | ESP-r | a-Si:H | Triple-glazed homogeneous PV glazing | ESP-r | ESP-r multi-layered. Energy balance of special node representing PV cell, where electricity production is subtracted from absorbed solar radiation. | WATSUN-PV. Empirical one-diode model assuming maximum power point operation. Consider temperature dependent short circuit current and open voltage, but constant shape factor. | [82] |

| Toronto (Canada) | 2015 | EnergyPlus DaySim | m-Si a-Si/μc-Si | Double-glazed cell cladding Double-glazed homogeneous PV glazing | EnergyPlus (energy). DaySim (visual comfort). | EnergyPlus (electrical generation included in the energy balance). | One-diode model [127] | [73] |

| China (Hong Kong) | 2016 | EnergyPlus | a-Si | Double-skin façade homogeneous PV glazing | EnergyPlus multi-layer model. | EnergyPlus multi-layer model. PV integrated in outside surface face of window. | Sandia Power Module for thin-film model [128] | [123] |

| China (Hong Kong). | 2016 | EnergyPlus | a-Si | Double-glazed homogeneous PV glazing | EnergyPlus | EnergyPlus | Sandia Power Module [128] | [110] |

| China (Hong Kong). | 2016 | EnergyPlus | a-Si | Single-pane homogeneous PV glazing | EnergyPlus | EnergyPlus. PV electrical generation included in energy balance. | EnergyPlus. Sandia Array Performance Model. Parameters validated in [129]. | [38] |

| Australia (Sydney) | 2017 | TRNSYS | a-Si | Double-skin façade with homogeneous PV glazing. | TRNSYS | TRNSYS + TRNflow for ventilated façade. PV electrical generation not included. | Evans and Florschuetz [97] | [117] |

| Australia (Sydney) | 2018 | TRNSYS | a-Si | Double-skin façade with homogeneous PV glazing. | TRNSYS | TRNSYS + TRNflow for ventilated façade. PV electrical generation not included. | Evans and Florschuetz [97] | [118] |

| India (New Delhi) | 2019 | MATLAB | - | Cell cladding | Constant optical properties. | MATLAB 1D single-node model for the whole device. | Evans and Florschuetz [97] | [22] |

| Spain (Madrid) | 2019 | MATLAB | - | Single-pane cell cladding | Constant optical properties. | MATLAB 1D model with a node per material in the laminate. | Evans and Florschuetz [97] | [21] |

| China (Shenzen) | 2019 | FLUENT | a-Si | Single-pane homogeneous PV glazing | Constant optical properties. | 2D (height/depth) window model. Room air distribution model with FLUENT. Room air distribution model with FLUENT. | Evans and Florschuetz [97] | [83] |

| Canada (Ontario) | 2019 | TRNSYS | c-Si | Single-pane cell cladding | TRNSYS simple window. Cladding modeled with effective approach, area weighting the opaque and transparent sections. | TRNSYS simple window. PV effect modeled as negative heat gain on the outdoor surface. | Evans and Florschuetz [97] | [24] |

| Australia (Sydney, Darwin, Canberra) | 2019 | TRNSYS | a-Si, Perovskite | PV glazing and double-skin façade | TRNSYS | TRNSYS + TRNflow for ventilated façade. | None | [119] |

| India (Varandi) | 2020 | MATLAB | c-Si | Single-pane cell cladding | Constant optical properties. | MATLAB 1D single node model for the whole device. | Evans and Florschuetz [97] | [57] |

4. Discussion

5. Conclusions

- Uniform reporting of ST- and T- BIPV properties;

- Inclusion and validation of default T- and ST-BIPV models in the building simulation tools;

- Economic evaluation accounting for variable electricity prices and feed-in tariffs in scenarios of a high penetration of renewable energies;

- Evaluation of emerging PV technologies’ impact on the building environment;

- Evaluation of the low-latitude impact on PV performance;

- Evaluation of the impact on thermal and visual comfort.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AVT | Average visible light transmittance |

| BIPV | Building-integrated photovoltaics |

| BSDF | Bidirectional scattering distribution function |

| a-Si | Amorphous silicon |

| a-Si:H | Hydrogenated amorphous silicon |

| CdTe | Cadmium telluride |

| CI(G)S | Copper indium (gallium) selenide |

| CRI | Color rendering index |

| c-Si | Crystalline silicon |

| DSF | Double-skin façade |

| DSSC | Dye-sensitized solar cells |

| EBI | Energy balance index |

| Fc | Solar reduction ratio |

| gtrans | Solar gain |

| gvent | Ventilation solar gain |

| GaAs | Gallium arsenide |

| GHG | Greenhouse gases |

| HIT | Silicon heterojunction solar cell |

| HOE | Holographic optical elements |

| IAQ | Indoor air quality |

| LCA | Life cycle cost analysis |

| LCC | Life cycle cost |

| m-Si | Multi-crystalline silicon |

| NEB | Net electricity benefit |

| NOCT | Nominal operating cell temperature |

| NZEB | Net-zero energy building |

| PV | Photovoltaic |

| PVT | Photovoltaic–thermal |

| QD | Quantum dot |

| SHGC | Solar heat gain coefficient |

| STPV | Semi-transparent photovoltaic |

| ST-BIPV | Semi-transparent building-integrated photovoltaics |

| T-BIPV | Transparent building-integrated photovoltaics |

| TCO | Transparent conducting oxide |

| TiO2 | Titanium dioxide |

| TSC | Transparent solar cells |

| Utrns | Thermal transmittance |

| Uvent | Ventilation thermal transmittance |

| ZnO | Zinc oxide |

References

- International Energy Agency. Global Status Report for Buildings and Construction 2019—Analysis; IEA: Paris, France, 2019. [Google Scholar]

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Muhd, M.Z. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- International Energy Agency. Tracking Buildings 2020—Analysis; IEA: Paris, France, 2020. [Google Scholar]

- The Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C, An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- UN Environment and International Energy Agency. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector, Global Status Report 2017; 2017; ISBN 978-92-807-3686-1. Available online: https://www.worldgbc.org/sites/default/files/UNEP%20188_GABC_en%20%28web%29.pdf (accessed on 20 April 2022).

- The European Commission. Directive 2010/31/EU on the Energy Performance of Buildings; European Parliamentary Research Service: Brussels, Belgium, 2010. [Google Scholar]

- The European Commission. The European Green Deal; The European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Attoye, D.E.; Aoul, K.A.T.; Hassan, A. A Review on Building Integrated Photovoltaic Façade Customization Potentials. Sustainability 2017, 9, 2287. [Google Scholar] [CrossRef]

- Bayoumi, M. Impacts of window opening grade on improving the energy efficiency of a façade in hot climates. Build. Env. 2017, 119, 31–43. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Building Energy Research Center of Tsinghua University. China Building Energy Use 2018; Tsinghua University: Tsinghua, China, 2018. [Google Scholar]

- Henemann, A. BIPV: Built-in solar energy. Renew. Energy Focus 2008, 9, 14–19. [Google Scholar] [CrossRef]

- Maghrabie, H.M.; Abdelkareem, M.A.; Al-Alami, A.H.; Ramadan, M.; Mushtaha, E.; Wilberforce, T.; Olabi, A.G. State-of-the-Art Technologies for Building-Integrated Photovoltaic Systems. Buildings 2021, 11, 383. [Google Scholar] [CrossRef]

- Quesada, G.; Rousse, D.; Dutil, Y.; Badache, M.; Hallé, S. A comprehensive review of solar facades. Transparent and translucent solar facades. Renew Sustain. Energy Rev. 2012, 16, 2643–2651. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C.; Drolsum Røkenes, H. Building integrated photovoltaic products: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef]

- Fraunhofer ISE. Photovoltaics Report; Fraunhofer Institute for Solar Energy Systems: Freiburg, Germany, 2020. [Google Scholar]

- Ramanujam, J.; Bishop, D.M.; Todorov, T.K.; Gunawan, O.; Rath, J.; Nekovei, R.; Artegiani, E.; Romeo, A. Flexible CIGS, CdTe and a-Si:H based thin film solar cells: A review. Prog. Mater. Sci. 2020, 110, 100619. [Google Scholar] [CrossRef]

- Lunt, R.R. Theoretical limits for visibly transparent photovoltaics. Appl. Phys. Lett. 2012, 101, 43902. [Google Scholar] [CrossRef]

- Lu, S.; Li, Z.; Zhao, Q.; Jiang, F. Modified calculation of solar heat gain coefficient in glazing façade buildings. Energy Procedia. 2017, 122, 151–156. [Google Scholar] [CrossRef]

- Sánchez-Palencia, P.; Martín-Chivelet, N.; Chenlo, F. Modeling temperature and thermal transmittance of building integrated photovoltaic modules. Sol. Energy 2019, 184, 153–161. [Google Scholar] [CrossRef]

- Meraj, M.; Khan, M.E. Thermal modeling of opaque and semi-transparent photovoltaic (PV) module. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 3271–3276. [Google Scholar]

- Pranith, S.; Bhatti, T.S. Modeling and Parameter Extraction Methods of PV Modules-Review. In Proceedings of the 2015 International Conference on Recent Developments in Control, Automation and Power Engineering (RDCAPE), Noida, India, 12-13 March 2015; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2015; pp. 72–76. [Google Scholar]

- Bambara, J.; Athienitis, A.K. Energy and economic analysis for the design of greenhouses with semi-transparent photovoltaic cladding. Renew. Energy 2019, 131, 1274–1287. [Google Scholar] [CrossRef]

- Taffesse, F.; Verma, A.; Singh, S.; Tiwari, G.N. Periodic modeling of semi-transparent photovoltaic thermal-trombe wall (SPVT-TW). Sol. Energy 2016, 135, 265–273. [Google Scholar] [CrossRef]

- Kamel, R.S.; Fung, A.S. Modelling and characterization of transparent building integrated PV/T collector. Energy Procedia 2015, 78, 1871–1876. [Google Scholar] [CrossRef]

- Gevers, R.H.; Pretorius, J.H.C.; van Rhyn, P. Novel approach for concentrating and harvesting solar radiation in hybrid transparent photovoltaic façade’s in Southern Africa. Renew. Energy Power Qual. J. 2015, 1, 245–250. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Mitchell, R. Developing a method and simulation model for evaluating the overall energy performance of a ventilated semi-transparent photovoltaic double-skin facade. Prog. Photovolt. Res. Appl. 2016, 24, 781–799. [Google Scholar] [CrossRef]

- Husain, A.A.F.; Hasan, W.Z.W.; Shafie, S.; Hamidon, M.N.; Pandey, S.S. A review of transparent solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2018, 94, 779–791. [Google Scholar] [CrossRef]

- Rehman, S.; Bader, M.A.; Al-Moallem, S.A. Cost of solar energy generated using PV panels. Renew. Sustain. Energy Rev. 2007, 11, 1843–1857. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2019; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Lee, K.; Um, H.-D.; Choi, D.; Park, J.; Kim, N.; Kim, H.; Seo, K. The Development of Transparent Photovoltaics. Cell Rep. Phys. Sci. 2020, 1, 100143. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, J.; Ma, X.; Gao, J.; Xu, C.; Yang, K.; Wang, Z.; Zhang, J.; Zhang, F. A critical review on semitransparent organic solar cells. Nano Energy 2020, 78, 105376. [Google Scholar] [CrossRef]

- Traverse, C.J.; Pandey, R.; Barr, M.C.; Lunt, R.R. Emergence of highly transparent photovoltaics for distributed applications. Nat. Energy 2017, 2, 849–860. [Google Scholar] [CrossRef]

- Kumar, A.; Bieri, M.; Reindl, T.; Aberle, A.G. Economic Viability Analysis of Silicon Solar Cell Manufacturing: Al-BSF versus PERC. Energy Procedia 2017, 130, 43–49. [Google Scholar] [CrossRef]

- Horowitz, K.A.; Remo, T.W.; Smith, B.; Ptak, A.J. A Techno-Economic Analysis and Cost Reduction Roadmap for III-V Solar Cells; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2018. [Google Scholar]

- Bauhuis, G.J.; Haverkamp, E.; van Deelen, J. Thin Film GaAs Solar Cells with Improved Radiation Hardness. In Proceedings of the 20th European Photovoltaic Solar Energy Conference, Barcelona, Spain, 6–10 June 2005. [Google Scholar]

- Zhang, W.; Lu, L.; Peng, J.; Song, A. Comparison of the overall energy performance of semi-transparent photovoltaic windows and common energy-efficient windows in Hong Kong. Energy Build. 2016, 128, 511–518. [Google Scholar] [CrossRef]

- Pulli, E.; Rozzi, E.; Bella, F. Transparent photovoltaic technologies: Current trends towards upscaling. Energy Convers. Manag. 2020, 219, 112982. [Google Scholar] [CrossRef]

- Bahramian, A.; Vashaee, D. In-situ fabricated transparent conducting nanofiber-shape polyaniline/coral-like TiO2 thin film: Application in bifacial dye-sensitized solar cells. Sol. Energy Mater. Sol. Cells 2015, 143, 284–295. [Google Scholar] [CrossRef]

- Xue, Q.; Xia, R.; Brabec, C.J.; Yip, H.L. Recent advances in semi-transparent polymer and perovskite solar cells for power generating window applications. Energy Env. Sci. 2018, 11, 1688–1709. [Google Scholar] [CrossRef]

- Bailie, C.D.; Christoforo, M.G.; Mailoa, J.P.; Bowring, A.R.; Unger, E.L.; Nguyen, W.H.; Burschka, J.; Pellet, N.; Lee, J.Z.; Grätzel, M.; et al. Semi-transparent perovskite solar cells for tandems with silicon and CIGS. Energy Env. Sci 2015, 8, 956–963. [Google Scholar] [CrossRef]

- Lunt, R.R.; Bulovic, V. Transparent, near-infrared organic photovoltaic solar cells for window and energy-scavenging applications. Appl. Phys. Lett. 2011, 98, 113305. [Google Scholar] [CrossRef]

- Chen, K.S.; Salinas, J.F.; Yip, H.L.; Huo, L.; Hou, J.; Jen, A.K.Y. Semi-transparent polymer solar cells with 6% PCE, 25% average visible transmittance and a color rendering index close to 100 for power generating window applications. Energy Env. Sci. 2012, 5, 9551–9557. [Google Scholar] [CrossRef]

- Pappas, S. Facts About Silicon|Live Science 2018. Available online: https://www.livescience.com/28893-silicon.html (accessed on 17 August 2020).

- Mei, A.; Li, X.; Liu, L.; Ku, Z.; Liu, T.; Rong, Y.; Xu, M.; Hu, M.; Chen, J.; Yang, Y.; et al. A hole-conductor-free, fully printable mesoscopic perovskite solar cell with high stability. Science 2014, 345, 295–298. [Google Scholar] [CrossRef]

- Eperon, G.E.; Paternò, G.M.; Sutton, R.J.; Zampetti, A.; Haghighirad, A.A.; Cacialli, F.; Snaith, H.J. Inorganic caesium lead iodide perovskite solar cells. J. Mater. Chem. A 2015, 3, 19688–19695. [Google Scholar] [CrossRef]

- Wang, R.; Mujahid, M.; Duan, Y.; Wang, Z.K.; Xue, J.; Yang, Y. A Review of Perovskites Solar Cell Stability. Adv. Funct. Mater. 2019, 29, 1808843. [Google Scholar] [CrossRef]

- Roldán-Carmona, C.; Malinkiewicz, O.; Betancur, R.; Longo, G.; Momblona, C.; Jaramillo, F.; Jaramillo, F.; Camachob, L.; Bolink, H.J. High efficiency single-junction semitransparent perovskite solar cells. Energy Env. Sci. 2014, 7, 2968–2973. [Google Scholar] [CrossRef]

- Grätzel, M. Dye-sensitized solar cells. J. Photochem. Photobiol. C Photochem. Rev. 2003, 4, 145–153. [Google Scholar] [CrossRef]

- Balakirev, D.O.; Luponosov, Y.N.; Mannanov, A.L.; Savchenko, P.S.; Minenkov, Y.; Paraschuk, D.Y.; Ponomarenko, S.A. Star-shaped benzotriindole-based donor-acceptor molecules: Synthesis, properties and application in bulk heterojunction and single-material organic solar cells. Dye. Pigment. 2020, 181, 108523. [Google Scholar] [CrossRef]

- Sagdullina, D.K.; Kuznetsov, I.E.; Akkuratov, A.V.; Kuznetsova, L.I.; Troyanov, S.I.; Troshin, P.A. New alternating thiophene-benzothiadiazole electron donor material for small-molecule organic solar cells and field-effect transistors. Synth. Met. 2019, 250, 7–11. [Google Scholar] [CrossRef]

- Chen, X.; Jia, Z.; Chen, Z.; Jiang, T.; Bai, L.; Tao, F.; Chen, J.; Chen, X.; Liu, T.; Xu, X.; et al. Efficient and Reproducible Monolithic Perovskite/Organic Tandem Solar Cells with Low-Loss Interconnecting Layers. Joule 2020, 4, 1594–1606. [Google Scholar] [CrossRef]

- Bagher, A.M. Comparison of organic solar cells and inorganic solar cells. Int. J. Renew. Sustain. Energy 2014, 3, 53–58. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Jiang, L.; Gong, L.; Xie, H.; Gao, Y.; He, H.; Fang, Z.; Fan, J.; Chao, Z. All-inorganic, hole-transporting-layer-free, carbon-based CsPbIBr2 planar solar cells with ZnO as electron-transporting materials. J. Alloy. Compd. 2020, 817, 152768. [Google Scholar] [CrossRef]

- Spanos, I.; Duckers, L. Expected cost benefits of building-integrated PVs in UK, through a quantitative economic analysis of PVs in connection with buildings, focused on UK and Greece. Renew. Energy 2004, 29, 1289–1303. [Google Scholar] [CrossRef]

- Mishra, G.K.; Tiwari, G.N. Performance evaluation of 7.2 kWp standalone building integrated semi-transparent photovoltaic thermal system. Renew. Energy 2020, 146, 205–222. [Google Scholar] [CrossRef]

- Wong, P.W.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Semi-transparent PV: Thermal performance, power generation, daylight modelling and energy saving potential in a residential application. Renew. Energy 2008, 33, 1024–1036. [Google Scholar] [CrossRef]

- Akata, E.A.; Martial, A.; Njomo, D.; Agrawal, B. Thermal energy optimization of building integrated semi-transparent photovoltaic thermal systems. Int. J. Renew. Energy Dev. 2015, 4, 113–123. [Google Scholar]

- Fung, T.Y.Y.; Yang, H. Study on thermal performance of semi-transparent building-integrated photovoltaic glazings. Energy Build. 2008, 40, 341–350. [Google Scholar] [CrossRef]

- Bloem, J.J. Evaluation of a PV-integrated building application in a well-controlled outdoor test environment. Build. Env. 2008, 43, 205–216. [Google Scholar] [CrossRef]

- Infield, D.; Mei, L.; Eicker, U. Thermal performance estimation for ventilated PV facades. Sol. Energy 2004, 76, 93–98. [Google Scholar] [CrossRef]

- Park, K.E.; Kang, G.H.; Kim, H.I.; Yu, G.J.; Kim, J.T. Analysis of thermal and electrical performance of semi-transparent photovoltaic (PV) module. Energy 2010, 35, 2681–2687. [Google Scholar] [CrossRef]

- Lu, L.; Law, K.M. Overall energy performance of semi-transparent single-glazed photovoltaic (PV) window for a typical office in Hong Kong. Renew. Energy 2013, 49, 250–254. [Google Scholar] [CrossRef]

- Ng, P.K.; Mithraratne, N. Lifetime performance of semi-transparent building-integrated photovoltaic (BIPV) glazing systems in the tropics. Renew. Sustain. Energy Rev. 2014, 31, 736–745. [Google Scholar] [CrossRef]

- Chen, F.; Wittkopf, S.K.; Ng, P.K.; Du, H. Solar heat gain coefficient measurement of semi-transparent photovoltaic modules with indoor calorimetric hot box and solar simulator. Energy Build. 2012, 53, 74–84. [Google Scholar] [CrossRef]

- Pérez-Alonso, J.; Pérez-García, M.; Pasamontes-Romera, M.; Callejón-Ferre, A.J. Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renew. Sustain. Energy Rev. 2012, 16, 4675–4685. [Google Scholar] [CrossRef]

- Bahaj, A.B.S.; James, P.A.B.; Jentsch, M.F. Potential of emerging glazing technologies for highly glazed buildings in hot arid climates. Energy Build. 2008, 40, 720–731. [Google Scholar] [CrossRef]

- Vats, K.; Tiwari, G.N. Performance evaluation of a building integrated semitransparent photovoltaic thermal system for roof and faade. Energy Build. 2012, 45, 211–218. [Google Scholar] [CrossRef]

- Vats, K.; Tomar, V.; Tiwari, G.N. Effect of packing factor on the performance of a building integrated semitransparent photovoltaic thermal (BISPVT) system with air duct. Energy Build. 2012, 53, 159–165. [Google Scholar] [CrossRef]

- Peng, C.; Huang, Y.; Wu, Z. Building-integrated photovoltaics (BIPV) in architectural design in China. Energy Build. 2011, 43, 3592–3598. [Google Scholar] [CrossRef]

- Wah, W.P.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Field Study and Modeling of Semi-Transparent PV in Power, Thermal and Optical Aspects. J. Asian Arch. Build. Eng. 2005, 4, 549–556. [Google Scholar] [CrossRef][Green Version]

- Kapsis, K.; Athienitis, A.K. A study of the potential benefits of semi-transparent photovoltaics in commercial buildings. Sol. Energy 2015, 115, 120–132. [Google Scholar] [CrossRef]

- Ordenes, M.; Marinoski, D.L.; Braun, P.; Rüther, R. The impact of building-integrated photovoltaics on the energy demand of multi-family dwellings in Brazil. Energy Build. 2007, 39, 629–642. [Google Scholar] [CrossRef]

- Polo López, C.S.; Sangiorgi, M. Comparison assessment of BIPV façade semi-transparent modules: Further insights on human comfort conditions. Energy Procedia 2014, 48, 1419–1428. [Google Scholar] [CrossRef]

- Phani, G.; Tulloch, G.; Vittorio, D.; Skryabin, I. Titania solar cells: New photovoltaic technology. Renew. Energy 2001, 22, 303–309. [Google Scholar] [CrossRef]

- Mercaldo, L.V.; Addonizio, M.L.; Noce MDella Veneri, P.D.; Scognamiglio, A.; Privato, C. Thin film silicon photovoltaics: Architectural perspectives and technological issues. Appl. Energy 2009, 86, 1836–1844. [Google Scholar] [CrossRef]

- Leite Didoné, E.; Wagner, A. Semi-transparent PV windows: A study for office buildings in Brazil. Energy Build. 2013, 67, 136–142. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamaño-Martín, E.; Moralejo-Vázquez, F.J.; Martín-Chivelet, N.; Olivieri, F.; Neila-Gonzalez, F.J. Energy saving potential of semi-transparent photovoltaic elements for building integration. Energy 2014, 76, 572–583. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Yang, H. Thermal behavior of a novel type see-through glazing system with integrated PV cells. Build. Env. 2009, 44, 2129–2136. [Google Scholar] [CrossRef]

- Ng, P.K.; Mithraratne, N.; Kua, H.W. Energy analysis of semi-transparent BIPV in Singapore buildings. Energy Build. 2013, 66, 274–281. [Google Scholar] [CrossRef]

- Heim, D.; Knera, D.; Machniewicz, A. Modelling of thermo-optical properties of amorphous and microcrystalline silicon semitransparent PV layer. Energy Procedia 2015, 78, 430–434. [Google Scholar] [CrossRef][Green Version]

- Yang, J.; Cheng, Y.; Jia, J.; Du, Z.; Shi, Z.; Han, J. The impact of indoor air distributions on the thermal performance of a single layer semi-transparent photovoltaic facade. Build. Simul. 2019, 12, 69–77. [Google Scholar] [CrossRef]

- Chae, Y.T.; Kim, J.; Park, H.; Shin, B. Building energy performance evaluation of building integrated photovoltaic (BIPV) window with semi-transparent solar cells. Appl. Energy 2014, 129, 217–227. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Peng, J.; Yang, H. Performance of ventilated double-sided PV façade compared with conventional clear glass façade. Energy Build. 2013, 56, 204–209. [Google Scholar] [CrossRef]

- Koyunbaba, B.K.; Yilmaz, Z. The comparison of Trombe wall systems with single glass, double glass and PV panels. Renew. Energy 2012, 45, 111–118. [Google Scholar] [CrossRef]

- Miyazaki, T.; Akisawa, A.; Kashiwagi, T. Energy savings of office buildings by the use of semi-transparent solar cells for windows. Renew. Energy 2005, 30, 281–304. [Google Scholar] [CrossRef]

- Yoon, J.H.; Song, J.; Lee, S.J. Practical application of building integrated photovoltaic (BIPV) system using transparent amorphous silicon thin-film PV module. Sol. Energy 2011, 85, 723–733. [Google Scholar] [CrossRef]

- Chow, T.T.; Qiu, Z.; Li, C. Potential application of “see-through” solar cells in ventilated glazing in Hong Kong. Sol. Energy Mater. Sol. Cells 2009, 93, 230–238. [Google Scholar] [CrossRef]

- Eke, R.; Demircan, C. Shading effect on the energy rating of two identical PV systems on a building façade. Sol. Energy 2015, 122, 48–57. [Google Scholar] [CrossRef]

- Yeop Myong, S.; Won Jeon, S. Design of esthetic color for thin-film silicon semi-transparent photovoltaic modules. Sol. Energy Mater. So.l Cells 2015, 143, 442–449. [Google Scholar] [CrossRef]

- Song, J.H.; An, Y.S.; Kim, S.G.; Lee, S.J.; Yoon, J.H.; Choung, Y.K. Power output analysis of transparent thin-film module in building integrated photovoltaic system (BIPV). Energy Build. 2008, 40, 2067–2075. [Google Scholar] [CrossRef]

- Alnaser, N.W.; Flanagan, R.; Alnaser, W.E. Potential of making-Over to sustainable buildings in the Kingdom of Bahrain. Energy Build. 2008, 40, 1304–1323. [Google Scholar] [CrossRef]

- Law, K. Thermal and Power Behaviors of Semi-Transparent Single-Glazed Photovoltaic (PV) Window for Office Buildings in Hong Kong. Master’s Thesis, Hong Kong Polytechnic University, Hong Kong, China, 2009. [Google Scholar]

- Izmaylov, A.Y.; Dorokhov, A.S.; Vershinin, V.S.; Gusarov, V.A.; Majorov, V.A.; Saginov, L.D. Window frame installed photovoltaic module for feeding of low power devices. Int. J. Renew. Energy Res. 2019, 9, 187–193. [Google Scholar]

- Misara, S.; Henze, N.; Sidelev, A. Thermal Behaviours of BIPV-Modules (U-Value and g-Value). In Proceedings of the 26th European Photovoltaic Solar Energy Conference and Exhibition (26th EU PVSEC), Hamburg, Germany, 5–9 September 2011; pp. 4107–4115. [Google Scholar]

- Evans, D.L.; Florschuetz, L.W. Cost studies on terrestrial photovoltaic power systems with sunlight concentration. Sol. Energy 1977, 19, 255–262. [Google Scholar] [CrossRef]

- Delisle, V. Modelling and Performance Study of a Building Integrated Photovoltaic Facade in Northern Canadian Climate; Eurosun: Lisbon, Portugal, 2008. [Google Scholar]

- Chow, T.T.; Fong, K.F.; He, W.; Lin, Z.; Chan, A.L.S. Performance evaluation of a PV ventilated window applying to office building of Hong Kong. Energy Build. 2007, 39, 643–650. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Hemisphere: New York, NY, USA, 1980. [Google Scholar]

- Robinson, L.; Athienitis, A. Design Methodology for Optimization of Electricity Generation and Daylight Utilization for Façade with Semi-Transparent Photovoltaics. In Proceedings of the Eleventh International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009; pp. 811–818. [Google Scholar]

- Athienitis, A.K.; Tzempelikos, A. A methodology for simulation of daylight room illuminance distribution and light dimming for a room with a controlled shading device. Sol. Energy 2002, 72, 271–281. [Google Scholar] [CrossRef]

- Robinson, L.E.; Atienitis, A.; Tzempelikos, A. Development of a Design Methodology for Integrating Semi-Transparent photovoltaics in Building Facades. In Proceedings of the 3rd Canadian Solar Buildings Conference, Fredericton, NB, Canada, 20–22 August 2008. [Google Scholar]

- U.S Department of energy (DOE). EnergyPlus; 2020. Available online: https://energyplus.net/ (accessed on 20 April 2022).

- Lawrence Berkeley National Laboratory. WINDOW 7; 2019. Available online: https://windows.lbl.gov/software/window (accessed on 20 April 2022).

- ISO 15099:2003–Thermal Performance of Windows, Doors and Shading Devices—Detailed Calculations; 2003. Available online: https://www.iso.org/standard/26425.html (accessed on 20 April 2022).

- Finlayson, E.U.; Arasteh, D.K.; Huizenga, C.; Rubin, M.D. WINDOW 4.0: Documentation of Calculation Procedures. Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1993. [Google Scholar]

- Lawrence Berkeley National Laboratory. COMFEN 5; 2018. Available online: https://windows.lbl.gov/software/comfen (accessed on 20 April 2022).

- Reinhart, C.F. DaySim; Version 4.0; 2016. Available online: https://daysim.software.informer.com/4.0/ (accessed on 20 April 2022).

- Wang, M.; Peng, J.; Li, N.; Lu, L.; Ma, T.; Yang, H. Assessment of energy performance of semi-transparent PV insulating glass units using a validated simulation model. Energy 2016, 112, 538–548. [Google Scholar] [CrossRef]

- TESS. TRNSYS 18; 2017. Available online: https://www.trnsys.com/ (accessed on 20 April 2022).

- TRANSSOLAR. TRNSYS 18-A Transient System Simulation Program: Multizone Building Modelling with Type56; University of Wisconsin-Madison: Madison, WI, USA, 2018; Volume 5. [Google Scholar]

- Laboratory Lawrence Berkeley National. OPTICS; 2013. Available online: https://windows.lbl.gov/software/optics (accessed on 20 April 2022).

- Bambara, J.; Athienitis, A.K. Comparison of Two Modelling Approaches for Semi-Transparent Photovoltaic Cladding in Greenhouses and Experimental Calibration. In Proceedings of the eSIM 2016, Hamilton, Canada, 3 June 2016. [Google Scholar]

- De Boer, B.J.; Van Helden, W.G.J. PV MOBI-PV Modules Optimised for Building Integration; NorthSun: Leiden, The Netherlands, 2001. [Google Scholar]

- Thermal Energy Systems Specialists. TEESLibs 17: Component Libraries of the TRNSYS Simulation Environment; Electrical Library: Madison, WI, USA, 2017; Volume 3. [Google Scholar]

- Yang, S.; Fiorito, F.; Sproul, A.; Prasad, D. Studies on Optimal Application of Building-Integrated Photovoltaic/Thermal Facade for Commercial Buildings in Australia. In Proceedings of the ISES Solar World Congress 2017-IEA SHC International Conference on Solar Heating and Cooling for Buildings and Industry 2017, Abu Dhabi, UAE, 29 October–02 November 2017; pp. 672–681. [Google Scholar]

- Yang, S.; Fiorito, F.; Sproul, A.; Prasad, D. Study of Building Integrated Photovoltaic/Thermal Double-Skin Facade for Commercial Buildings in Sydney, Australia. In Proceedings of the Final Conference Cost Action Tu1403–Adaptive Facades Network, Lucerne, Switzerland, 26–27 November 2018. [Google Scholar]

- Yang, S.; Cannavale, A.; Prasad, D.; Sproul, A.; Fiorito, F. Numerical simulation study of BIPV/T double-skin facade for various climate zones in Australia: Effects on indoor thermal comfort. Build. Simul. 2019, 12, 51–67. [Google Scholar] [CrossRef]

- Cipriano, J.; Lodi, C.; Chemisana, D.; Houzeaux, G.; Perpiñan, O. Development and characterization of semitransparent double skin PV façades. Eurosun 2008, 2008, 156–163. [Google Scholar]

- ESP-r Software, Building Energy Simulation Code; University of Strathclyde: Glasgow, UK, 2005.

- Rus-Casas, C.; Aguilar, J.D.; Rodrigo, P.; Almonacid, F.; Pérez-Higueras, P.J. Classification of methods for annual energy harvesting calculations of photovoltaic generators. Energy Convers. Manag. 2014, 78, 527–536. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Perez, R.; Seals, R.; Ineichen, P.; Stewart, R.; Menicucci, D. A new simplified version of the perez diffuse irradiance model for tilted surfaces. Sol. Energy 1987, 39, 221–231. [Google Scholar] [CrossRef]

- Clarke, J.A.; Hand, J.W.; Janak, M.; Johnstone, C.; Strachan, P. PV-HYBRID-PAS Final Report: Modelling Annex Report 6 on Simulation Case Study: Elsa Building; Technical Report; JOULE III, PASLINK EEIG Contract JOR3-CT96-0092: Ispra, Italy, 1998. [Google Scholar]

- Rubin, M.; Arasteh, D.; Hartmann, J. A correlation between normal and hemispherical emissivity of low-emissivity coatings on glass. Int. Commun. Heat Mass Transf. 1987, 14, 561–565. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- King, D.L.; Boyson, W.E.; Kratochvill, J.A. Photovoltaic Array Performance Model; SANDIA Report; Sandia National Laboratories: Albuquerque, NM, USA, 2004; Available online: http://www.mauisolarsoftware.com/MSESC/xPerfModel2003.pdf (accessed on 20 April 2022).

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Validation of the Sandia model with indoor and outdoor measurements for semi-transparent amorphous silicon PV modules. Renew. Energy 2015, 80, 316–323. [Google Scholar] [CrossRef]

- Denholm, P.; O’Connell, M.; Brinkman, G.; Jorgenson, J. Overgeneration from Solar Energy in California: A Field Guide to the Duck Chart; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2015. [Google Scholar]

- PVSITES 2016. Available online: https://www.pvsites.eu/ (accessed on 24 November 2020).

- Baenas, T.; Machado, M. On the analytical calculation of the solar heat gain coefficient of a BIPV module. Energy Build. 2017, 151, 146–156. [Google Scholar] [CrossRef]

- BIPV Boost 2020. Available online: https://bipvboost.eu/ (accessed on 24 November 2020).

- IEA PVPS Task 15 Enabling Framework for the Development of BIPV 2016. Available online: https://iea-pvps.org/research-tasks/enabling-framework-for-the-development-of-bipv/ (accessed on 24 November 2020).

- Neves, G.; Vilela, W.; Pereira, E.; Yamasoe, M.; Nofuentes, G. Spectral impact on PV in low-latitude sites: The case of southeastern Brazil. Renew. Energy 2021, 164, 1306–1319. [Google Scholar] [CrossRef]

| PV Technology | Best Research—Cell Efficiency (%) | Average Visible Transmittance (AVT) | Cost (€/W) | Operating Lifetime (Years) | Potential ST- and T-BIPV Applications | References | |

|---|---|---|---|---|---|---|---|

| Crystalline Si | Single-crystal (c-Si) | 26.1 | Opaque | 0.40–0.55 | >20 | Cell cladding | [17,29,31,35] |

| Multi-crystalline (m-Si) | 23.3 | Opaque | >20 | Cell cladding | |||

| Si heterostructures (HIT) | 27.6 | Opaque | >20 | Cell cladding | |||

| Thin-film crystal | 21.2 | - | >20 | Cell cladding | |||

| Single-junction GaAs | Single-crystal | 27.8 | Opaque | >30 | >20 | - | [17,36] |

| Concentrator | 30.5 | Opaque | >20 | - | |||

| Thin-film crystal | 29.1 | Opaque | >20 | - | [17,36,37] | ||

| Multijunction | Two-junction (concentrator) | 35.5 | Opaque | >>30 | >20 | - | [17,36] |

| Two-junction (non-concentrator) | 32.9 | Opaque | >20 | - | |||

| Three-junction (concentrator) | 44.4 | Opaque | >20 | - | |||

| Three-junction (non-concentrator) | 37.9 | Opaque | >20 | - | |||

| Four-junction or more (non-concentrator) | 39.2 | Opaque | >20 | - | |||

| Thin-film | CIGS | 23.4 | <30% | ~0.55 | ~20 | Homogeneous/cell cladding | [17,18,31] |

| CdTe | 22.1 | ~30% | ~0.50 | >10 | Homogeneous/cell cladding | [17,18,31] | |

| Amorphous Si:H stabilized (a-Si) | 14.0 | 10–25% | ~0.35 | >20 | Homogeneous | [17,18,29,31,38] | |

| Emerging PV 1 | Dye-sensitized cells (DSSC) | 12.3 | 10–50% | Expected <0.25 | - | Homogeneous | [17,29,32,39,40] |

| Perovskite cells | 25.2 | ~30% | - | Homogeneous | [17,29,32,39,41] | ||

| Perovskite/Si- and perovskite/CIGS-tandem | 29.1/24.2 | 30–77% | - | Homogeneous/cell cladding | [17,29,32,39,42] | ||

| Organic cells (various types) and organic tandem cells | 17.4/14.2 | 20–65% | - | Homogeneous | [17,29,32,39,43] | ||

| Inorganic cells | 12.6 | 20–55% | - | Homogeneous | [17,32,39,44] | ||

| Quantum dot (QD) cells | 16.6 | 20–30% | - | - | - | [17,29,32,39] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romaní, J.; Ramos, A.; Salom, J. Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations. Energies 2022, 15, 3286. https://doi.org/10.3390/en15093286

Romaní J, Ramos A, Salom J. Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations. Energies. 2022; 15(9):3286. https://doi.org/10.3390/en15093286

Chicago/Turabian StyleRomaní, Joaquim, Alba Ramos, and Jaume Salom. 2022. "Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations" Energies 15, no. 9: 3286. https://doi.org/10.3390/en15093286

APA StyleRomaní, J., Ramos, A., & Salom, J. (2022). Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations. Energies, 15(9), 3286. https://doi.org/10.3390/en15093286