Accelerated Stress Tests for Solid Oxide Cells via Artificial Aging of the Fuel Electrode

Abstract

1. Introduction

2. Experimental

- Step 1. Determination of the oxidation level by in situ impedance monitoring of the changes in the Ni network resistance [66,67,68] during oxidation of bare anode. The oxidation depth is selected based on the preliminary chosen increase of the Ni network resistance. Since the impedance in reduced state has an inductive behavior, the oxidation should not change this state, thus ensuring preservation of the electronic conductivity network. More information about this step is given in the next section;

- Step 2. Once the appropriate experimental oxidation conditions are determined, they serve as internal standard for redox cycling and are applied on anode/electrolyte sample to check the effect of the selected procedure on the state of the interface anode/electrolyte;

- Step 3. Finally, the procedure is applied for redox cycling in full-cell configuration. In this stage, the experiments are performed on button cells. In principle, they could be carried out also on big cells and stacks.

3. Experimental Results and Discussion

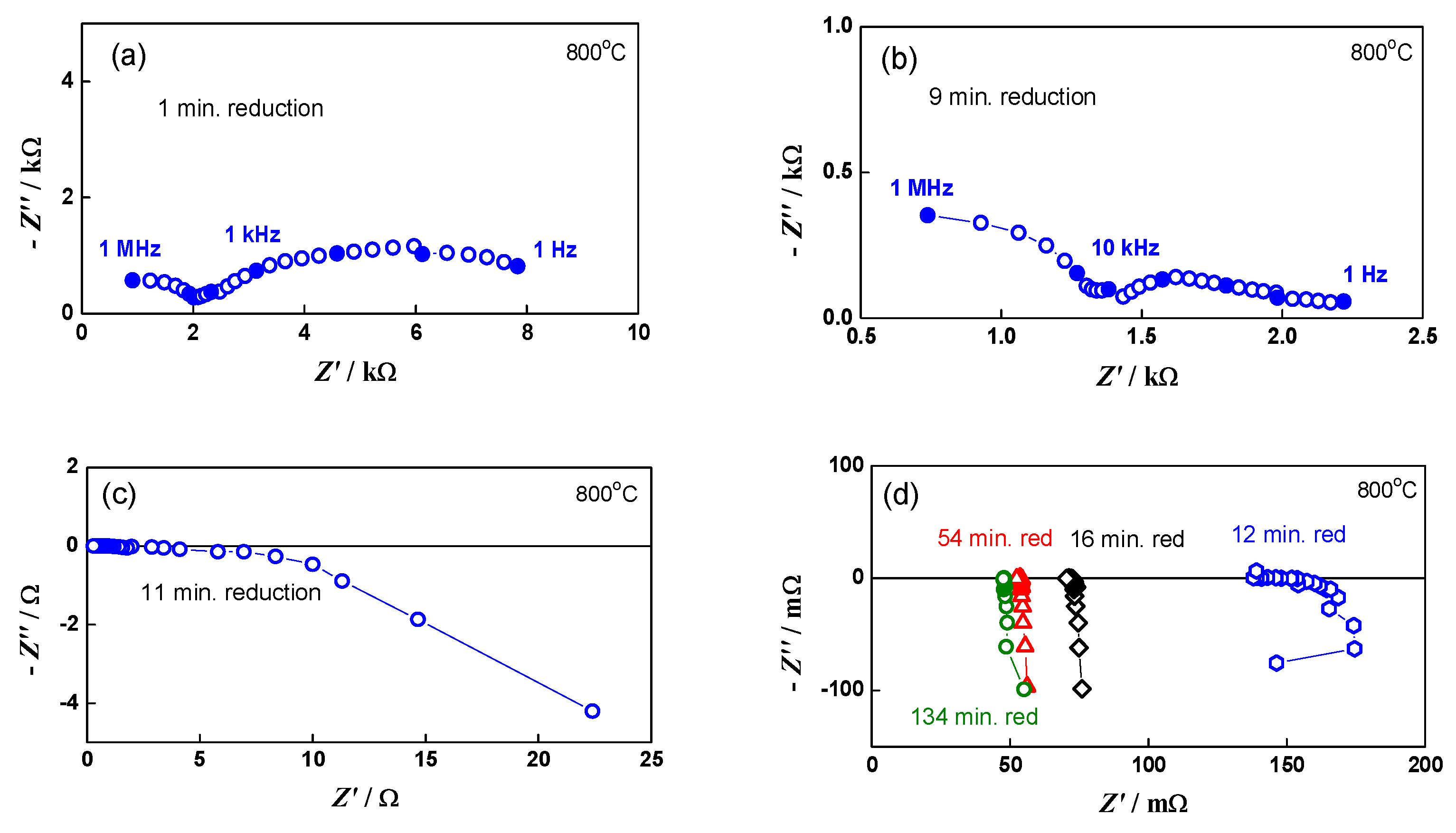

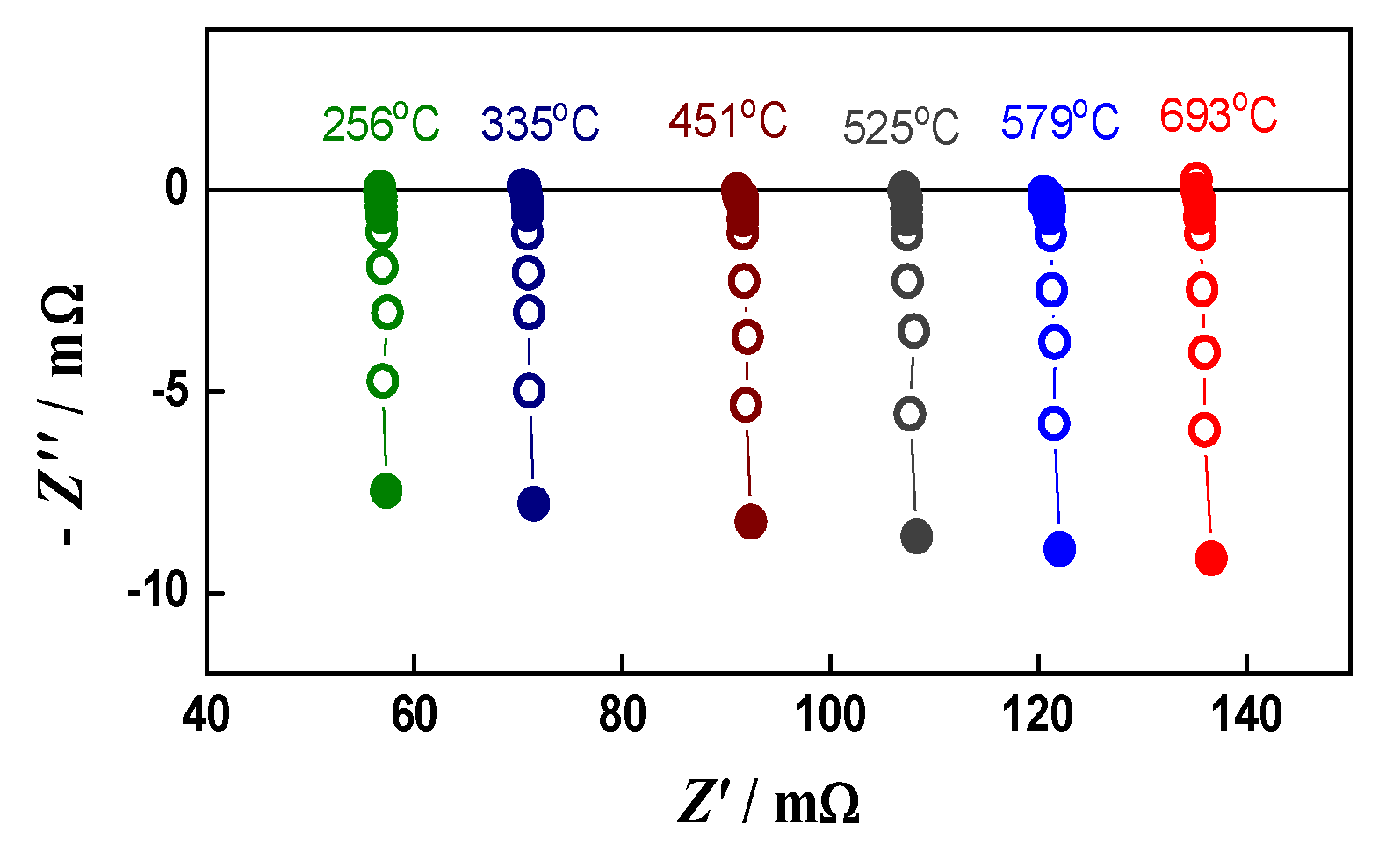

3.1. Initial Reduction

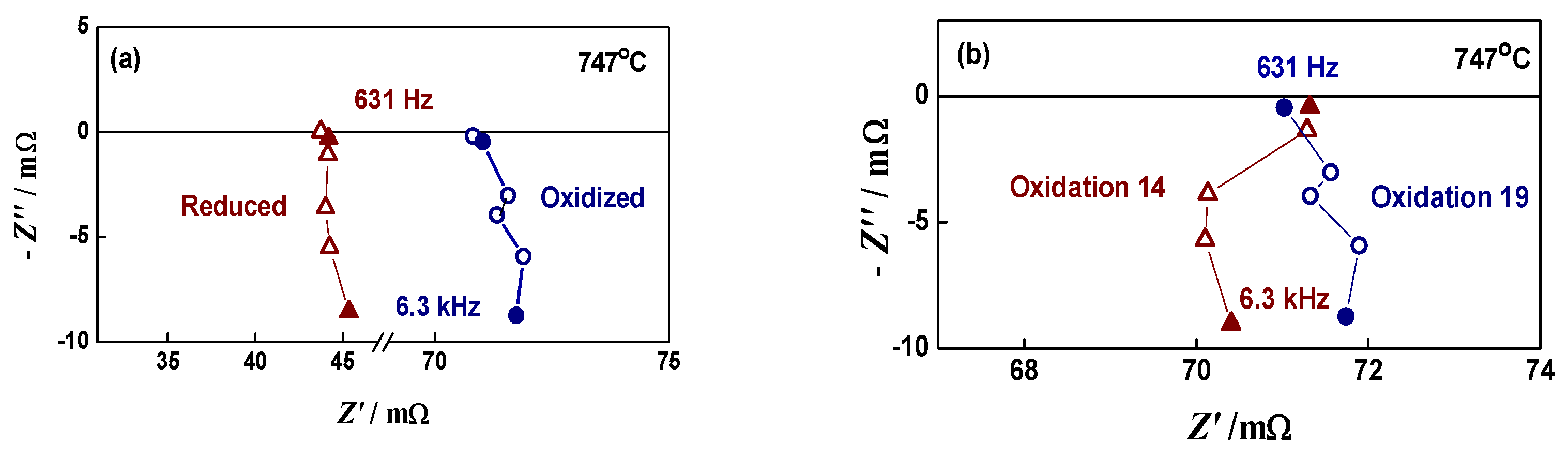

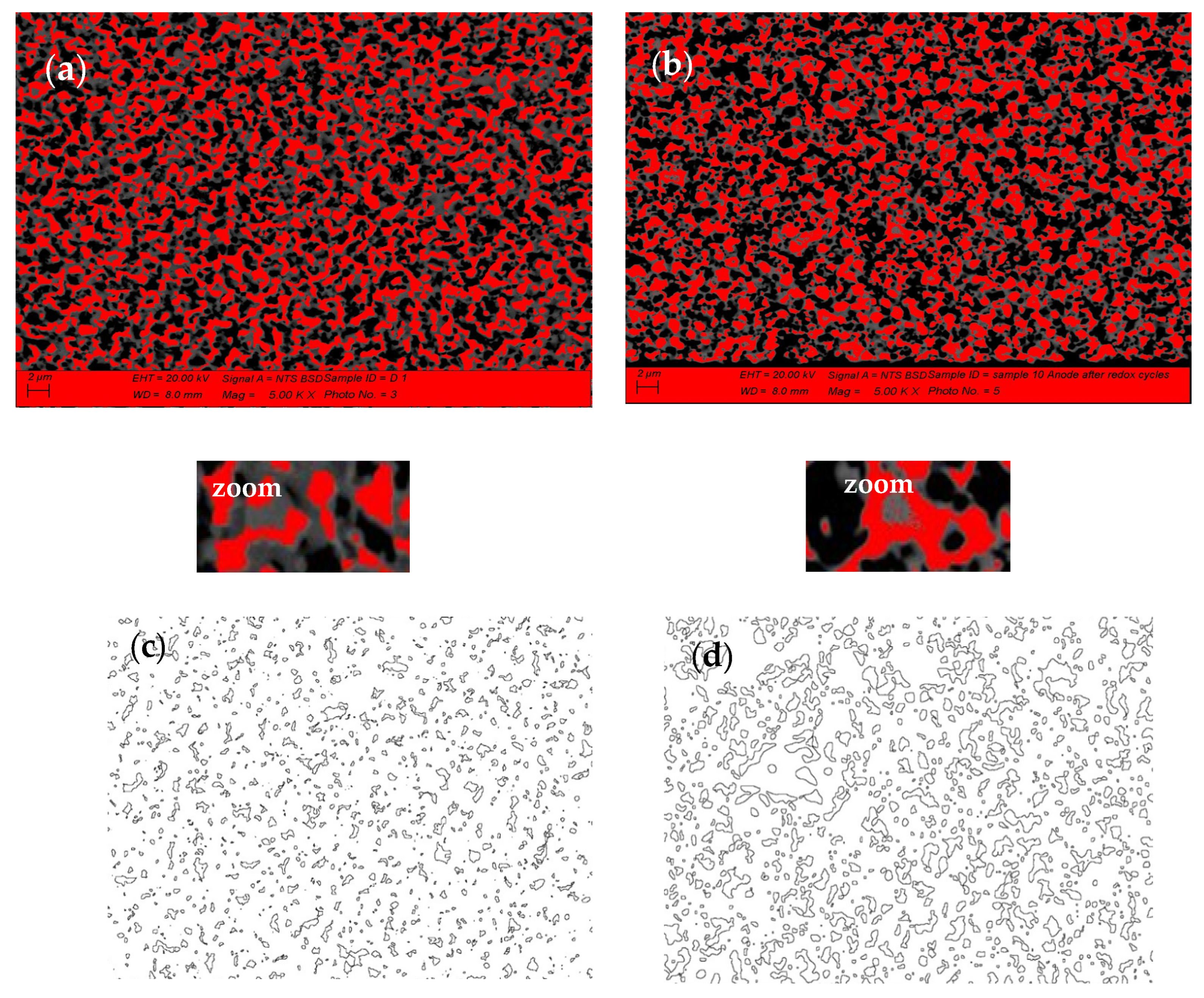

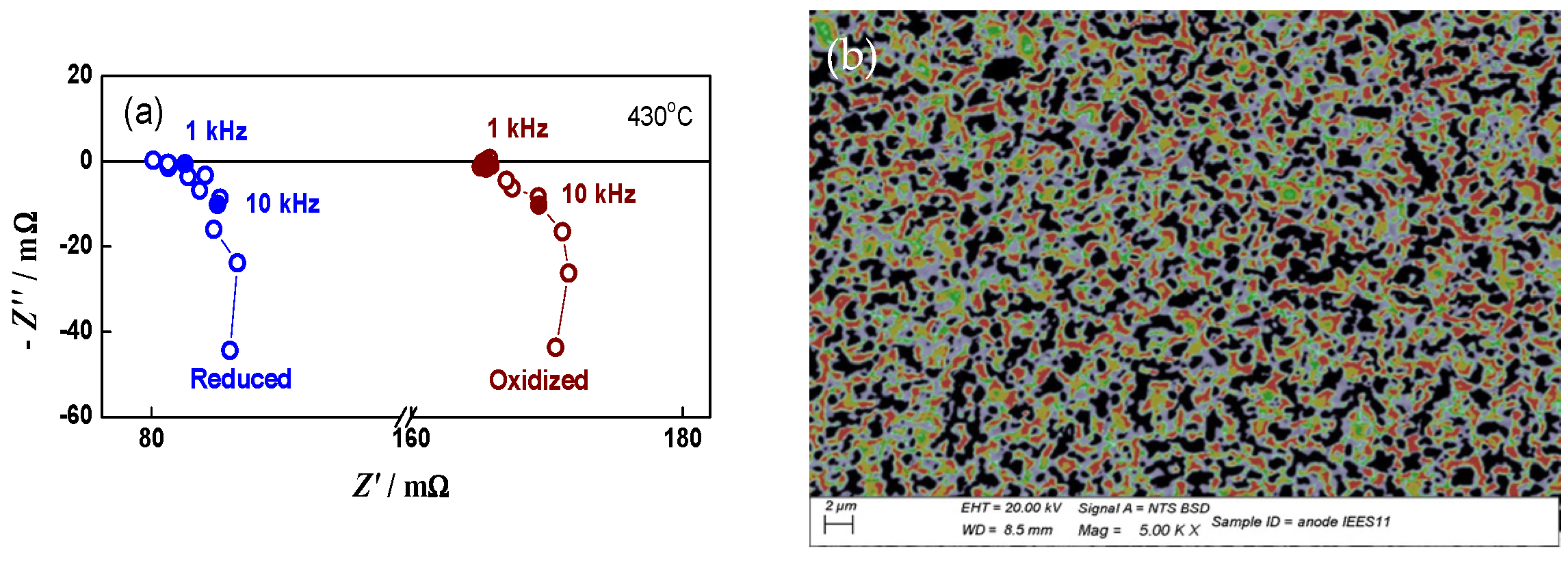

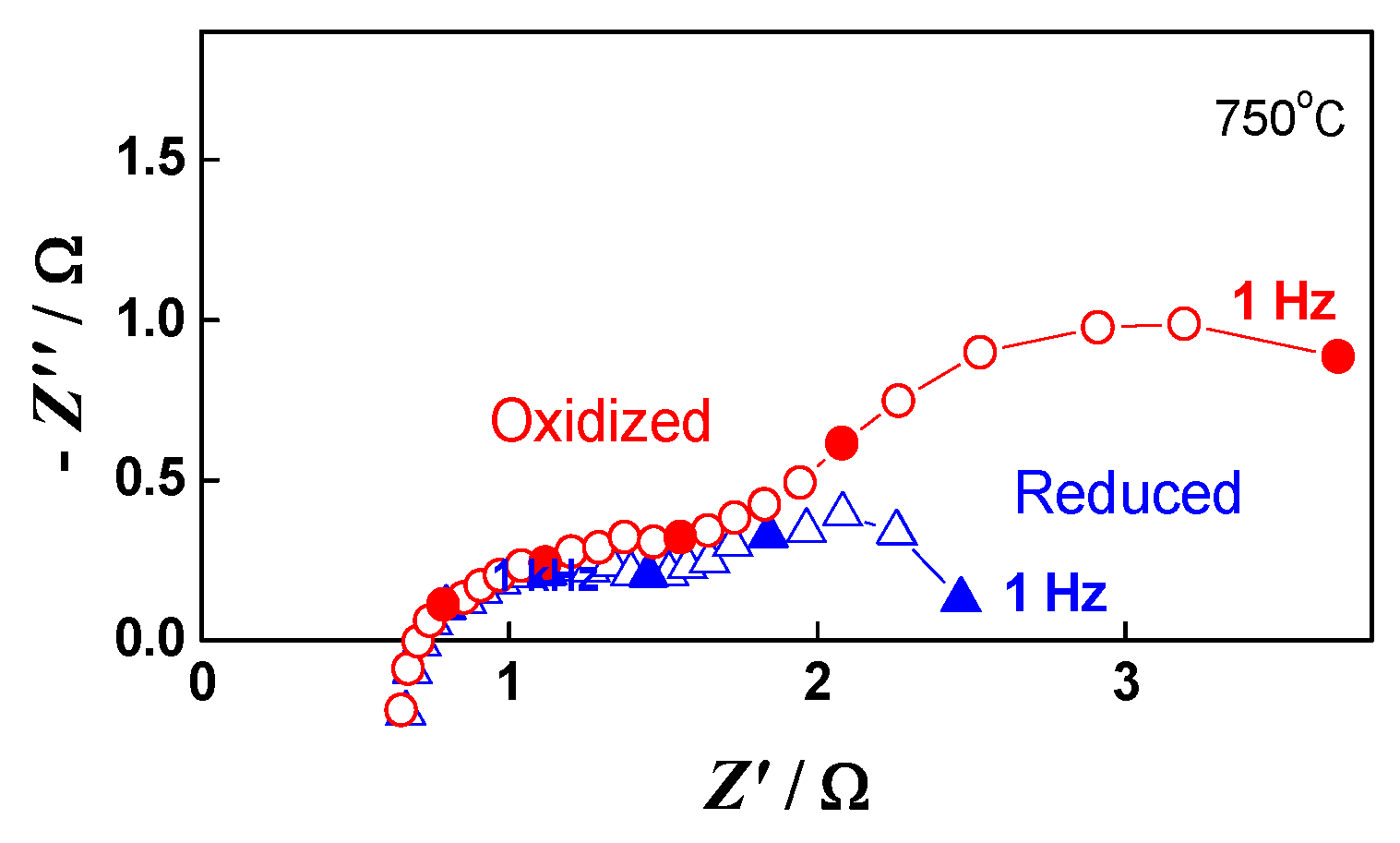

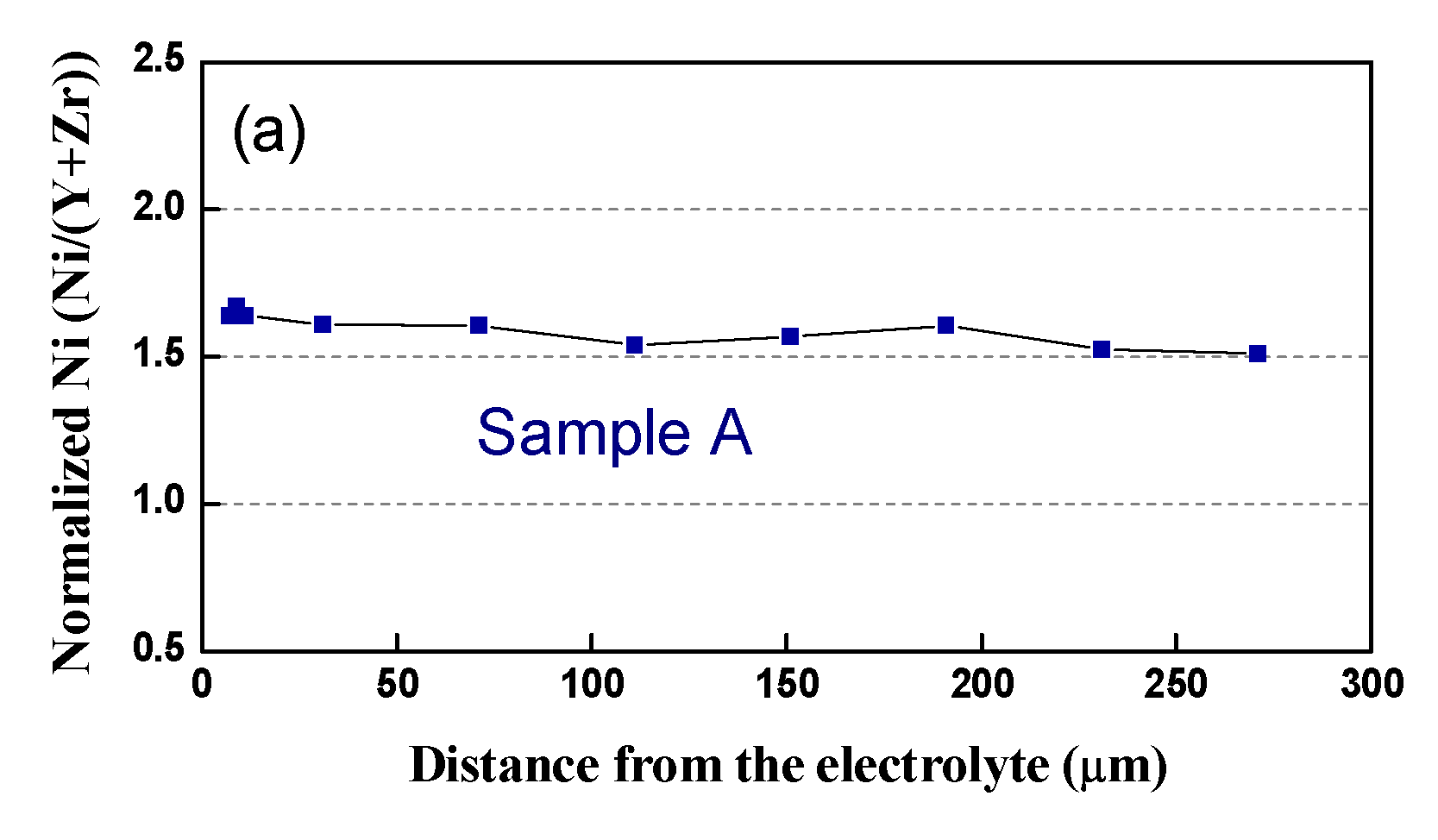

3.1.1. Artificial Aging of Bare Anode by Redox Cycling for Fine Tuning of the Experimental Conditions

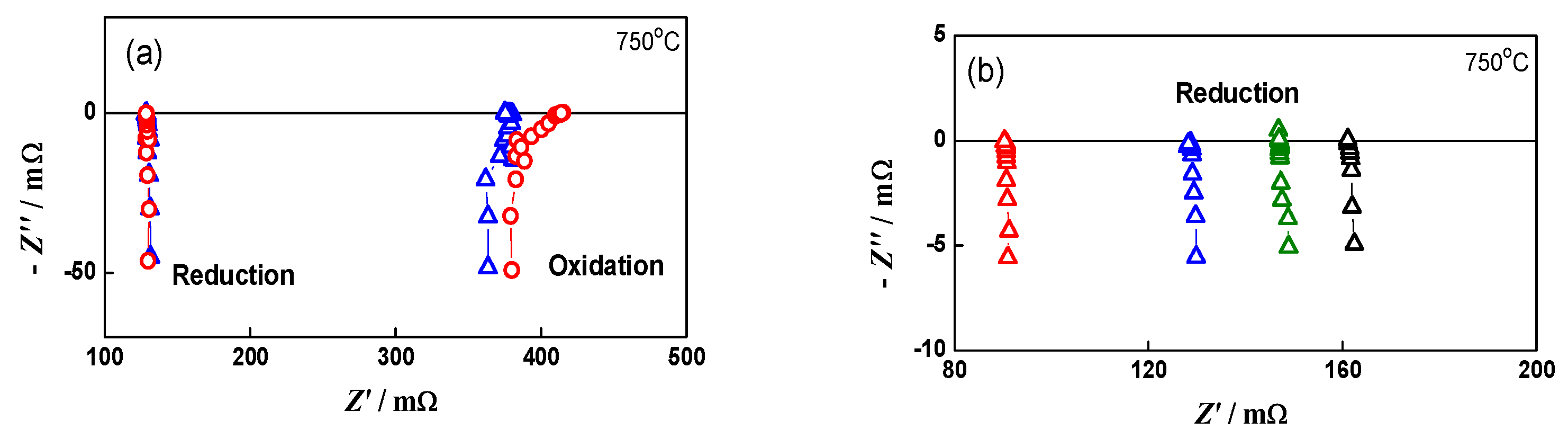

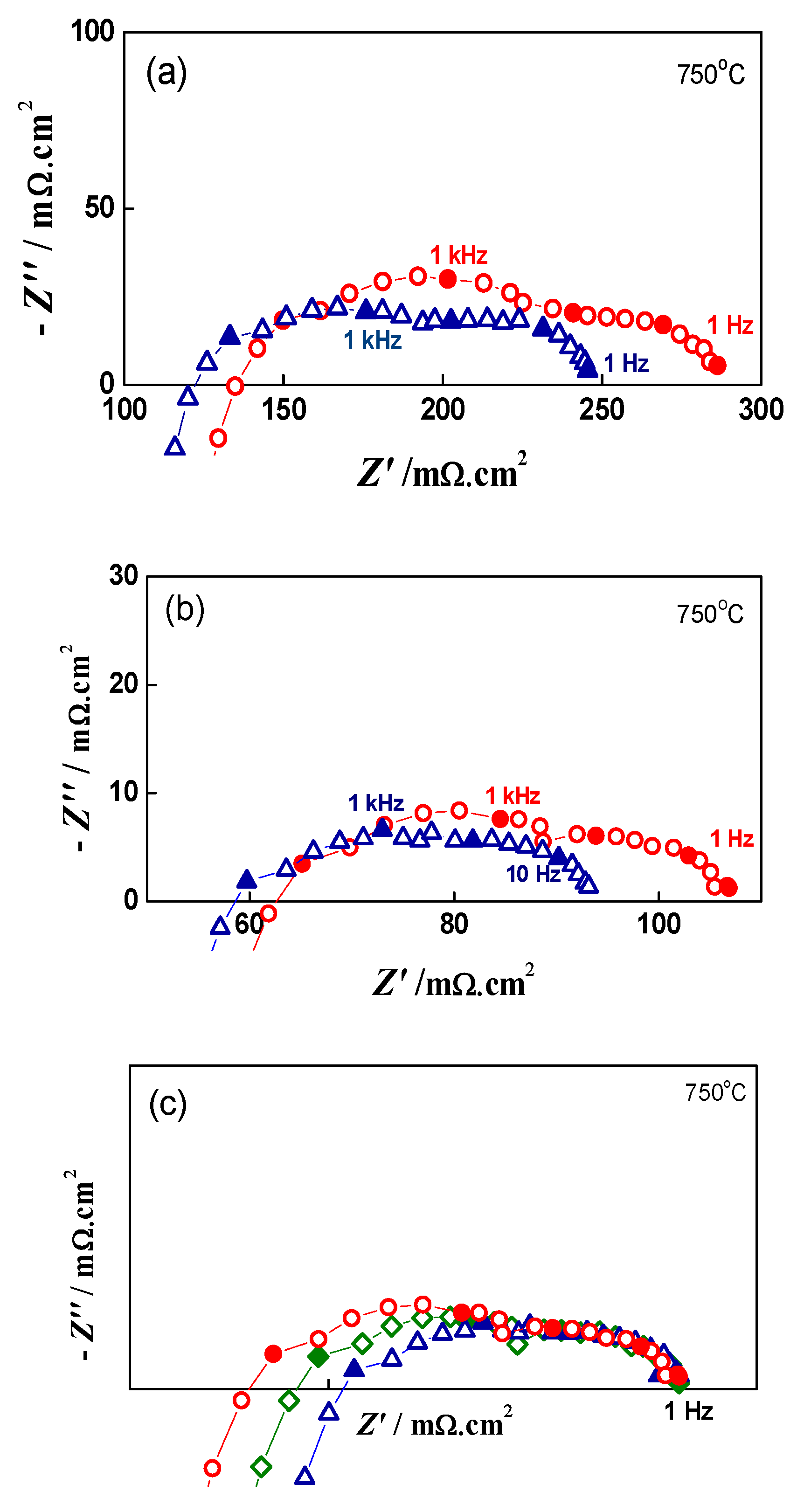

3.1.2. Artificial Aging of Anode/Electrolyte by Redox Cycling

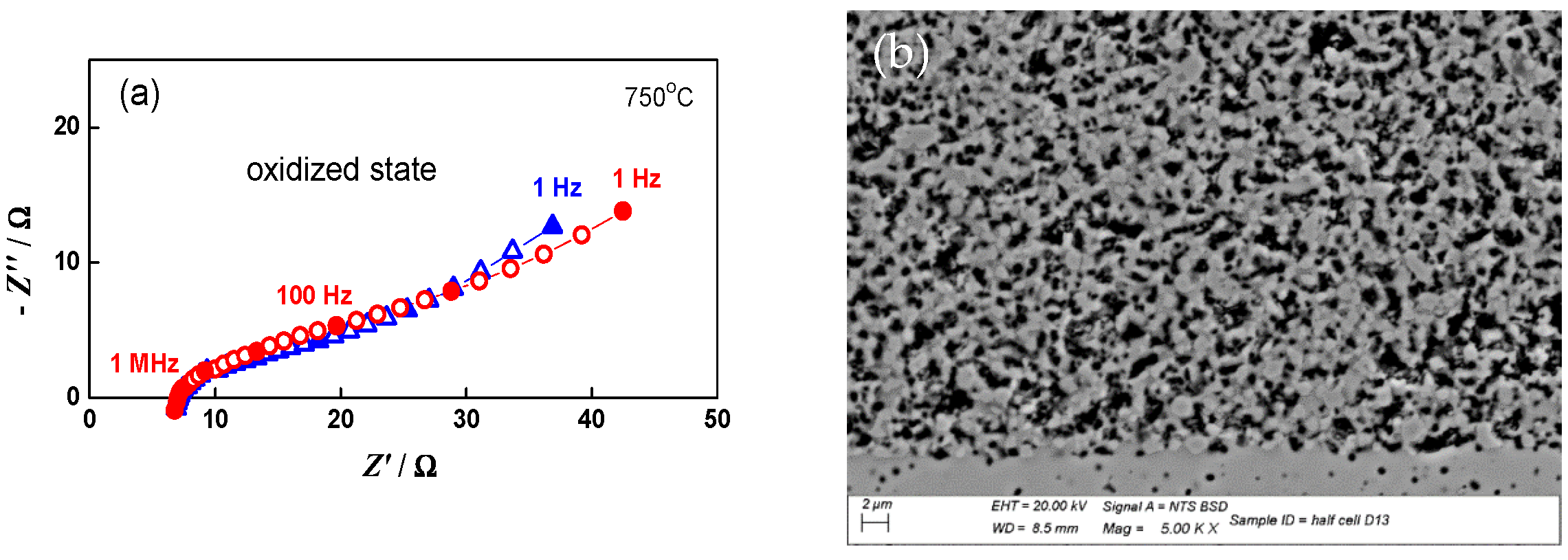

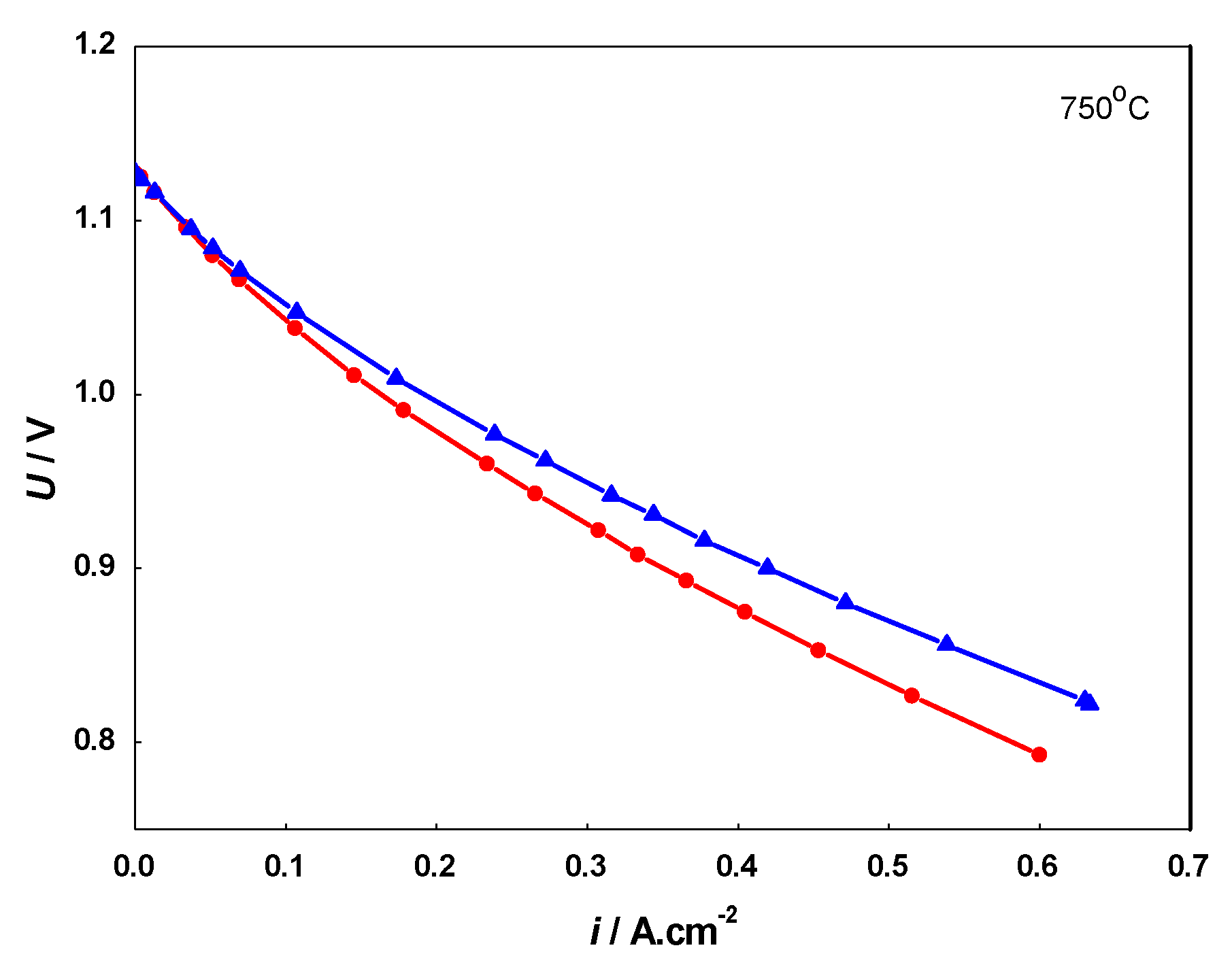

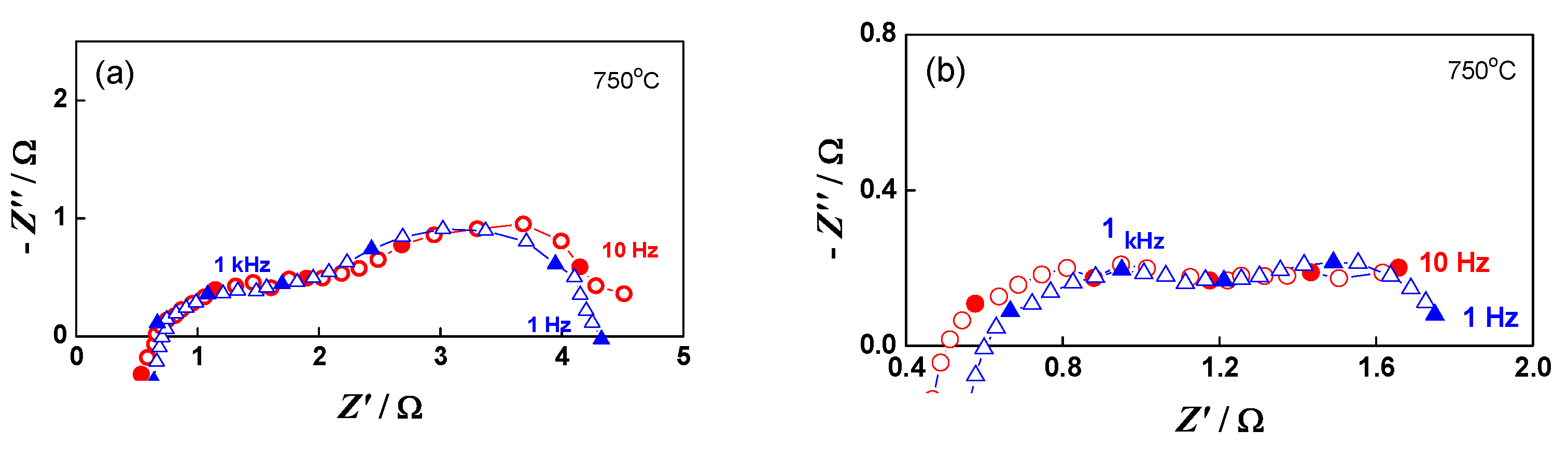

3.1.3. Artificial Aging of Button Cell by Redox Cycling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Polverino, P.; Pianese, C.; Sorrentino, M.; Marra, D. Model-based development of a fault signature matrix to improve solid oxide fuel cell systems on-site diagnosis. J. Power Sources 2015, 280, 320–338. [Google Scholar] [CrossRef]

- Hagen, A. SOFC: Cell, stack and system level. In Fuel Cells: Data, Facts and Figures; Stolten, D., Samsun, R.C., Garland, N., Eds.; WILEY-VCH: Weinheim, Germany, 2016; ISBN 978-3-527-33240-3. [Google Scholar]

- Irvine, J.T.S.; Neagu, D.; Verbraeken, M.C.; Chatzichristodoulou, C.; Graves, C.; Mogensen, M.B. Evolution of the electrochemical interface in high-temperature fuel cells and electrolysers. Nat. Energy 2016, 1, 15014. [Google Scholar] [CrossRef]

- Sohal, M.S.; O’Brien, J.E.; Stoots, C.M.; Sharma, V.I.; Yildiz, B.; Virkar, A. Degradation Issues in Solid Oxide Cells During High Temperature Electrolysis. J. Fuel Cell Sci. Technol. 2012, 9, 011017. [Google Scholar] [CrossRef]

- Skafte, T.L.; Hjelm, J.; Blennow, P.; Graves, C. Quantitative review of degradation and lifetime of solid oxide cells and stacks. In Proceedings of the 12th SOFC and SOE forum, Lucerne, Switzerland, 5–8 July 2016; p. B0501. [Google Scholar]

- Blum, L.; Batfalsky, P.; Fang, Q.; de Haart, L.G.J.; Malzbender, J.; Margaritis, N.; Menzler, N.; Peters, R. Solid Oxide Fuel Cell, Stack and System Development Status at Forschungszentrum Jülich. ECS Trans. 2015, 68, 157. [Google Scholar] [CrossRef]

- Kim, S.J.; Choi, M.; Park, M.; Kim, H.; Son, J.; Lee, J.; Kim, B.; Lee, H.; Kim, S.; Yoon, K.J. Acceleration tests: Degradation of anode-supported planar solid oxide fuel cells at elevated operating temperatures. J. Power Sources 2017, 360, 284–293. [Google Scholar] [CrossRef]

- Mougin, J.; Morel, B.; Ploner, A.; Caliandro, P.; Van Herle, J.; Boškoski, P.; Dolenc, B.; Gallo, M.; Polverino, P.; Pohjoranta, A.; et al. Monitoring and diagnostics of SOFC stacks and systems. ECS Trans. 2019, 91, 731. [Google Scholar] [CrossRef]

- Jørgensen, P.; Ebbehøj, S.; Hauch, A. Triple phase boundary specific pathway analysis for quantitative characterization of solid oxide cell electrode microstructure. J. Power Sources 2015, 279, 686–693. [Google Scholar] [CrossRef][Green Version]

- Vaßen, R.; Simwonis, D.; Stöver, D. Modelling of the agglomeration of Ni-particles in anodes of solid oxide fuel cells. J. Mater. Sci. 2001, 36, 147–151. [Google Scholar] [CrossRef]

- Ananyev, M.; Bronin, D.; Osinkin, D.; Eremin, V.; Steinberger-Wilckens, R.; de Haart, L.G.J.; Mertens, J. Characterization of Ni-cermet degradation phenomena I. Long term resistivity monitoring, image processing and X-ray fluorescence analysis. J. Power Sources 2015, 286, 414–426. [Google Scholar] [CrossRef]

- Tanasini, P.; Cannarozzo, M.; Costamagna, P.; Faes, A.; Van Herle, J.; Hessler-Wyser, A.; Comninellis, C. Experimental and Theoretical Investigation of Degradation Mechanisms by Particle Coarsening in SOFC Electrodes. Fuel Cells 2009, 9, 740–752. [Google Scholar] [CrossRef]

- Hubert, M.; Laurencin, J.; Cloetens, P.; Mougin, J.; Ferreira Sanchez, D.; Pylypko, S.; Morales, M.; Morata, A.; Morel, B.; Montinaro, D.; et al. Solid Oxide Cell Degradation Operated in Fuel Cell and Electrolysis Modes: A Comparative Study on Ni Agglomeration and LSCF Destabilization. ECS Trans. 2017, 78, 3167. [Google Scholar] [CrossRef]

- Villanova, J.; Laurencin, J.; Cloetens, P.; Bleuet, P.; Delette, J.; Suhonen, H.; Usseglio-Viretta, F. 3D phase mapping of solid oxide fuel cell YSZ/Ni cermet at the nanoscale by holographic X-ray nanotomography. J. Power Sources 2013, 243, 841–849. [Google Scholar] [CrossRef]

- Hubert, M.; Laurencin, J.; Cloetens, P.; Morel, B. Impact of Nickel agglomeration on Solid Oxide Cell operated in fuel cell and electrolysis modes. J. Power Sources 2018, 397, 240–251. [Google Scholar] [CrossRef]

- Spotorno, R.; Ferrari, T.; Nicolella, C.; Piccardo, P. Influence of Working Parameters and Degradation on Anode-Supported Cells studied by Electrochemical Impedance Spectroscopy. In Proceedings of the 12th European SOFC & SOE Forum, Lucerne, Switzerland, 5–8 July 2016; p. B1216. [Google Scholar]

- Hauch, A.; Mogensen, M.; Hagen, A. Ni/YSZ electrode degradation studied by impedance spectroscopy-Effect of p(H2O). Solid State Ion. 2011, 192, 547–551. [Google Scholar] [CrossRef]

- Hubert, M.; Laurencin, J.; Cloetens, P.; Da Silva, J.C.; Lefebvre-Joud, F.; Bleuet, P.; Nakajo, A.; Siebert, E. Role of microstructure on electrode operating mechanisms for mixed ionic electronic conductors: From synchrotron-based 3D recon struction to electrochemical modelling. Solid State Ion. 2016, 294, 90–107. [Google Scholar] [CrossRef]

- Miguel-Pérez, V.; Ouweltjes, J.P.; Tarancón, A.; Montinaro, D.; Morata, A. Degradation Studies and Sr Diffusion Behaviour in Anode Supported Cell after 3,000 h SOFC Short Stack Testing. ECS Trans. 2015, 68, 1803. [Google Scholar] [CrossRef]

- Kenney, B.; Karan, K. Engineering of microstructure and design of a planar porous composite SOFC cathode: A numerical analysis. Solid State Ion. 2007, 178, 297–306. [Google Scholar] [CrossRef]

- Jiang, S.P.; Chen, X. Chromium deposition and poisoning of cathodes of solid oxide fuel cells-A review. Int. J. Hydrogen Energy 2014, 39, 505–531. [Google Scholar] [CrossRef]

- Tallgren, J.; Himanen, O.; Bianco, M.; Mikkola, J.; Thomann, O.; Rautanen, M.; Kiviaho, J.; Van Herle, J. Method to Measure Area Specific Resistance and Chromium Migration Simultaneously from Solid Oxide Fuel Cell Interconnect Materials. Fuel Cells 2019, 19, 570–577. [Google Scholar] [CrossRef]

- Oum, M.; Andrews, J.; Steinberger-Wilckens, R. Modelling Microstructural and Chemical Degradation of Ferritic Stainless Steels for SOFC Interconnects. ECS Trans. 2017, 78, 1565. [Google Scholar] [CrossRef]

- Masi, A.; Bellusci, M.; McPhail, S.; Padella, F.; Reale, P.; Hong, J.-E.; Steinberger-Wilckens, R.; Carlini, M. The effect of chemical composition on high temperature behaviour of Fe and Cu doped Mn-Co spinels. Ceram. Int. 2017, 43, 2829–2835. [Google Scholar] [CrossRef]

- Yokokawa, H. Current Status of Rapid Evaluation of Durability of Six SOFC Stacks within NEDO Project. ECS Trans. 2015, 68, 1827. [Google Scholar] [CrossRef]

- Yoshikawa, M.; Yamamoto, T.; Asano, K.; Yasumoto, K.; Mugikura, Y. Performance Degradation Analysis of Different Type SOFCs. ECS Trans. 2015, 68, 2199. [Google Scholar] [CrossRef]

- Yokokawa, H.; Hori, Y.; Shigehisa, T.; Suzuki, M.; Inoue, M.; Suto, T.; Tomida, K.; Shimazu, M.; Kawakami, A.; Sumi, H.; et al. Recent Achievements of NEDO Durability Project with an Emphasis on Correlation between Cathode Overpotential and Ohmic Loss. Fuel Cells 2015, 15, 473. [Google Scholar] [CrossRef]

- Horita, T.; Choa, D.; Wanga, F.; Nishia, M.; Shimonosonoa, T.; Kishimotoa, H.; Yamajia, K.; Britoa, M.E.; Yokokawa, H. Degradation Mechanism with Impurities and Life Time Estimation for SOFCs. ECS Trans. 2012, 42, 297. [Google Scholar] [CrossRef]

- Pellegrinwlli, C.; Huang, Y.L.; Taillon, J.A.; Salamanca-Riba, L.G.; Wachsman, E.D. Investigating the Relationship between Operating Conditions and SOFC Cathode Degradation. ECS Trans. 2015, 68, 773. [Google Scholar] [CrossRef]

- Nakajo, A.; Wuillemin, Z.; Metzger, P.; Diethelm, S.; Schiller, G.; Van Herle, J.; Favrat, D. Electrochemical model of SOFC for simulation at the stack scale I. Calibration procedure on experimental data. J. Electrochem. Soc. 2011, 158, B1083. [Google Scholar] [CrossRef]

- Usseglio-Viretta, F.; Laurencin, J.; Delette, G.; Villanova, J.; Cloetens, P.; Leguillon, D. Quantitative microstructure characterization of a Ni-YSZ bi-layer coupled with simulated electrode polarisation. J. Power Sources 2014, 256, 394–403. [Google Scholar] [CrossRef]

- Nakajo, A.; Cocco, A.; De Gostin, M.; Peracchio, A.; Cassenti, B.; Cantoni, M.; Van Herle, J.; Chiu, W.K.S. Accessible triple-phase boundary length: A performance metric to account for transport pathways in heterogeneous electrochemical materials. J. Power Sources 2016, 325, 786–800. [Google Scholar] [CrossRef]

- Monaco, F.; Hubert, M.; Vulliet, J.; Ouweltjes, J.; Montinaro, D.; Cloetens, P.; Piccardo, P.; Lefebvre-Joud, F.; Laurencin, J. Degradation of Ni-YSZ Electrodes in Solid Oxide Cells: Impact of Polarization and Initial Microstructure on the Ni Evolution. J. Electrochem. Soc. 2019, 166, F1229. [Google Scholar] [CrossRef]

- Polverino, P.; Gallo, M.; Pianese, C. Development of mathematical transfer functions correlating Solid Oxide Fuel Cell degradation to operating conditions for Accelerated Stress Test protocols design. J. Power Sources 2021, 491, 229521. [Google Scholar] [CrossRef]

- Menzler, N.; Sebold, D.; Sohn, Y.; Zischke, S. Post-test characterization of a solid oxide fuel cell after more than 10 years of stack testing. J. Power Sources 2020, 478, 22888770. [Google Scholar] [CrossRef]

- Trini, M.; Hauch, A.; De Angelis, S.; Tong, X.; Vang Hendriksen, P.; Chen, M. Comparison of microstructural evolution of fuel electrodes in solid oxide fuel cells and electrolysis cells. J. Power Sources 2020, 450, 227599. [Google Scholar] [CrossRef]

- Rinaldi, G.; Nakajo, A.; Caliandro, P.; Navratilova, L. Effects of Polarization on the Microstructural Changes at the YSZ/Ni-YSZ Interface. ECS Trans. 2019, 91, 641. [Google Scholar] [CrossRef]

- Laguna-Bercero, M. Recent advances in high temperature electrolysis using solid oxide fuel cells: A review. J. Power Sources 2012, 203, 4–16. [Google Scholar] [CrossRef]

- Faes, A.; Hessler-Wyser, A.; Presvytes, D.; Vayenas, C.; Van Herle, J. Ni-zirconia anode degradation and triple phase boundary quantification from microstructural analysis. Fuel Cells 2009, 9, 841. [Google Scholar] [CrossRef]

- Nakajo, A.; Wuillemin, Z.; Van Herle, J.; Favrat, D. Simulation of thermal stresses in anode-supported SOFC stacks. Part I: Probability of failure of the cells. J. Power Sources 2009, 193, 203–215. [Google Scholar] [CrossRef]

- Nakajo, A.; Wuillemin, Z.; Van Herle, J.; Favrat, D. Simulation of thermal stresses in anode-supported SOFC stacks. Part II: Loss of gas-tightness, electrical contact and thermal buckling. J. Power Sources 2009, 193, 216–226. [Google Scholar] [CrossRef]

- Nakajo, A.; Kiss, A.; Cocco, A.; Harris, W.; DeGostin, M.; Greco, F.; Nelson, G.; Peracchio, A.; Cassenti, B.; Deriy, A.; et al. Characterization of cracks and their effects on the effective transport pathways in Ni-YSZ anodes after reoxidation using X-ray nanotomography. ECS Trans. 2015, 68, 1069. [Google Scholar] [CrossRef]

- Cho, H.; Choi, G. Effect of milling methods on performance of Ni-Y2O3-stabilized ZrO2 anode for solid oxide fuel cell. J. Power Sources 2008, 176, 96–101. [Google Scholar] [CrossRef]

- Pihlatie, M.; Kaiser, A.; Mogensen, M.; Chen, M. Electrical conductivity of Ni-YSZ composites: Degradation due to Ni particle growth. Solid State Ion. 2011, 189, 82–90. [Google Scholar] [CrossRef]

- Sato, K.; Okamoto, G.; Naito, M.; Abe, H. NiO/YSZ nanocomposite particles synthesized via co-precipitation method for electrochemically active Ni/YSZ anode. J. Power Sources 2009, 193, 185–188. [Google Scholar] [CrossRef]

- Baek, S.; Bae, J. Anodic behavior of 8Y2O3-ZrO2/NiO cermet using an anode-supported electrode. Int. J. Hydrogen Energy 2011, 36, 689–705. [Google Scholar] [CrossRef]

- Haslam, J.; Pham, A.; Chung, B.; DiCarlo, J.; Glass, R. Effects of the use of pore former on performance of an anode supported solid oxide fuel cell. J. Am. Seram. Soc. 2005, 88, 513–518. [Google Scholar] [CrossRef]

- Satikaya, A.; Petrovsky, V.; Dogan, F. Effect of the anode microstructure on the enhanced performance of solid oxide fuel cells. Int. J. Hydrogen Econ. 2012, 37, 11370–11377. [Google Scholar]

- Liu, B.; Zhang, Y.; Tu, B.; Dong, Y.; Cheng, M. Electrochemical impedance investigation of the redox behaviour of a Ni-YSZ anode. J. Power Sources 2007, 165, 114–119. [Google Scholar] [CrossRef]

- Waldbillig, D.; Wood, A.; Ivey, D. Electrochemical and microstructural characterization of the redox tolerance of solid oxide fuel cell anodes. J. Power Sources 2005, 145, 206–215. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Yashiro, K.; Sato, K.; Kawada, T.; Mizusaki, J. Microstructural changes of Ni/YSZ cermet under repeated redox reaction in environmental scanning electron microscope (ESEM). ECS Trans. 2007, 7, 1373. [Google Scholar] [CrossRef]

- Sarandaridis, D.; Rubkin, R.; Atkinson, A. On the redox cycling of anode-supported SOFCs: Mechanical properties and damage mechanisms. ECS Trans. 2007, 7, 1491. [Google Scholar] [CrossRef]

- Laurancin, J.; Roche, V.; Jaboutian, C.; Kieffer, I.; Mougin, J.; Steil, M. Ni-8YSZ cermet re-oxidation of anode supported solid oxide fuel cell: From kinetics measurements to mechanical damage prediction. Int. J. Hydrogen Energy 2012, 37, 12557–12573. [Google Scholar] [CrossRef]

- Song, B.; Trejo, E.; Bertei, A.; Brandon, N. Quantification of the degradation of Ni-YSZ anodes upon redox cycling. J. Power Sources 2018, 374, 61–68. [Google Scholar] [CrossRef]

- Kirtley, J.; McIntyre, M.; Halat, D.; Walker, R. (Invited) Insights into SOFC Ni/YSZ Anode Degradation Using In-Situ Spectrochronopotentiometrys. ECS Trans. 2013, 50, 3. [Google Scholar] [CrossRef]

- Tikekar, N.; Armstrong, T.; Virkar, A. Reduction and Reoxidation Kinetics of Nickel-Based SOFC Anodes. J. Electrochem. Soc. 2006, 153, A654. [Google Scholar] [CrossRef]

- Greco, F.; Nakajo, A.; Wuillemin, Z.; Van Herle, J. Thermo-mechanical reliability of SOFC stacks during combined long-term operation and thermal cycling. ECS Trans. 2015, 68, 1921. [Google Scholar] [CrossRef]

- Jeangros, Q.; Faes, A.; Hansen, J.; Aschauer, U.; Van Herle, J.; Hessler-Wyser, A.; Dunin-Borlowski, R. In situ redox cycle of a nickel-YSZ fuel cell anode in an environmental transmission electron microscope. Acta Mater. 2010, 58, 4578–4589. [Google Scholar] [CrossRef]

- Ettler, M.; Timmermann, H.; Weber, A.; Menzler, N.H. Durability of Ni anodes during reoxidation cycles. J. Power Sources 2010, 195, 5452–5467. [Google Scholar] [CrossRef]

- Khana, M.; Leea, S.; Song, R.; Lee, J.; Lim, T.; Park, S. Fundamental mechanisms involved in the degradation of nickel–yttria stabilized zirconia (Ni-YSZ) anode during solid oxide fuel cells operation: A review. Ceram. Int. 2016, 42, 35–48. [Google Scholar] [CrossRef]

- Sarantaridis, D.; Chater, R.J.; Atkinson, A. Changes in physical and mechanical properties of SOFC Ni-YSZ composites caused by redox cycling. J. Electrochem. Soc. 2008, 155, B467–B472. [Google Scholar] [CrossRef]

- Jiao, Z.; Takagi, N.; Shikazono, N.; Kasagi, N. Study on local morphological changes of nickel in solid oxide fuel cell anode using porous Ni pellet electrode. J. Power Sources 2011, 196, 1019–1029. [Google Scholar] [CrossRef]

- Mukhopadhyay, M.; Mukhopadhyay, J.; Das Sharma, A.; Basu, R.N. High performance planar solid oxide fuel cell fabricated with Ni-Yttria stabilized zirconia anode prepared by electroless technique. Int. J. Appl. Ceram. Technol. 2012, 9, 999–1010. [Google Scholar] [CrossRef]

- Grgicak, C.M.; Green, R.G.; Du, W.-F.; Giorgi, J.B. Synthesis and characterization of NiO-YSZ anode materials: Precipitation, calcination, and the effects on sintering. J. Am. Ceram. Soc. 2005, 88, 3081–3087. [Google Scholar] [CrossRef]

- Mewafy, B.; Paloukis, F.; Papazisi, K.; Balomenou, S.; Luo, W. Influence of surface state on the electrochemical performance of nickel-based cermet electrodes during steam electrolysis. ACS Appl. Energy Mater. 2019, 2, 7045–7055. [Google Scholar] [CrossRef]

- Vladikova, D.; Stoynov, Z.; Wuillemin, Z.; Montinaro, D.; Piccardo, P.; Genov, I.; Rolland, M. Impedance Studies of the Reduction Process in NiO-YSZ SOFC Anodes. ECS Trans. 2015, 68, 1161. [Google Scholar] [CrossRef]

- Burdin, B.; Sheikh, A.; Krapchanska, M.; Montinaro, D.; Spotorno, R.; Piccardo, P.; Vladikova, D. Redox-cycling—A Tool for Artificial Electrochemical Aging of Solid Oxide Cells. ECS Trans. 2021, 103, 1137–1149. [Google Scholar] [CrossRef]

- Stoynov, Z.; Vladikova, D. Impedance Spectroscopy of Electrochemical Power Sources. In Encyclopedia of Electrochemical Power Sources; Garche, U., Ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 632–642. [Google Scholar]

- Lide, D. (Ed.) Handbook of Chemistry and Physics, 85th ed.; CRS Press: Boca Raton, FL, USA, 2005; pp. 12–46. [Google Scholar]

- Stoynov, Z.; Vladikova, D.; Burdin, B. Differential Resistance Analysis—Current Achievements and Applications. Bulg. Chem. Commun. 2018, 50, 21–30. [Google Scholar]

- Stoynov, Z.; Vladikova, D.; Burdin, B.; Laurencin, J.; Montinaro, D.; Raikova, G.; Schiller, G.; Szabo, P. Differential analysis of SOFC current-voltage characteristics. Appl. Energy 2018, 228, 1584–1590. [Google Scholar] [CrossRef]

- Caliandro, P.; Nakajo, A.; Diethelm, S.; Van Herle, J. Model-assisted identification of solid oxide cell elementary processes by electrochemical impedance spectroscopy measurements. J. Power Sources 2019, 436, 226838. [Google Scholar] [CrossRef]

| Current Density i, A.cm−2 | Initial Voltage, U, mV | Voltage after 7 Redox Cycles U, mV | Voltage Drop for 7 Cycles ∆ U,% | Voltage after 20 Redox Cycles U, mV | Voltage Drop for 20 Redox Cycles ∆ U,% |

|---|---|---|---|---|---|

| 0.28 | 961 | 956 | 0.52 | 937 | 2.5 |

| 0.50 | 864 | 848 | 1.85 | 830 | 4.5 |

| Current Density i, A.cm−2 | Initial Voltage U, mV | Voltage after 4000 h U, mV | Voltage Drop after 4000 h ∆ U,% | Voltage after 6000 h U, mV | Voltage Drop after 6000 h ∆ U,% | Voltage after 9000 h U, mV | Voltage Drop after 4900 h ∆ U,% |

|---|---|---|---|---|---|---|---|

| 0.28 | 917 | 898 | 2.07 | 883 | 3.70 | 882 | 3.82 |

| 0.50 | 827 | 791 | 4.35 | 768 | 7.13 | 766 | 7.38 |

| ASR (mΩ.cm2) | ASR Increase (vs. 0 Cycles),% | ||||

|---|---|---|---|---|---|

| 0 Redox Cycles | 7 Redox Cycles | 20 Redox Cycles | 7 Redox Cycles | 20 Redox Cycles | |

| RΩ | 58.7 | 59.8 | 63.5 | +1.9 | +8.2 |

| Rp | 59.8 | 39.7 | 42.5 | +16.4 | +24.5 |

| RT | 92.8 | 99.5 | 106.0 | +7.2 | +14.2 |

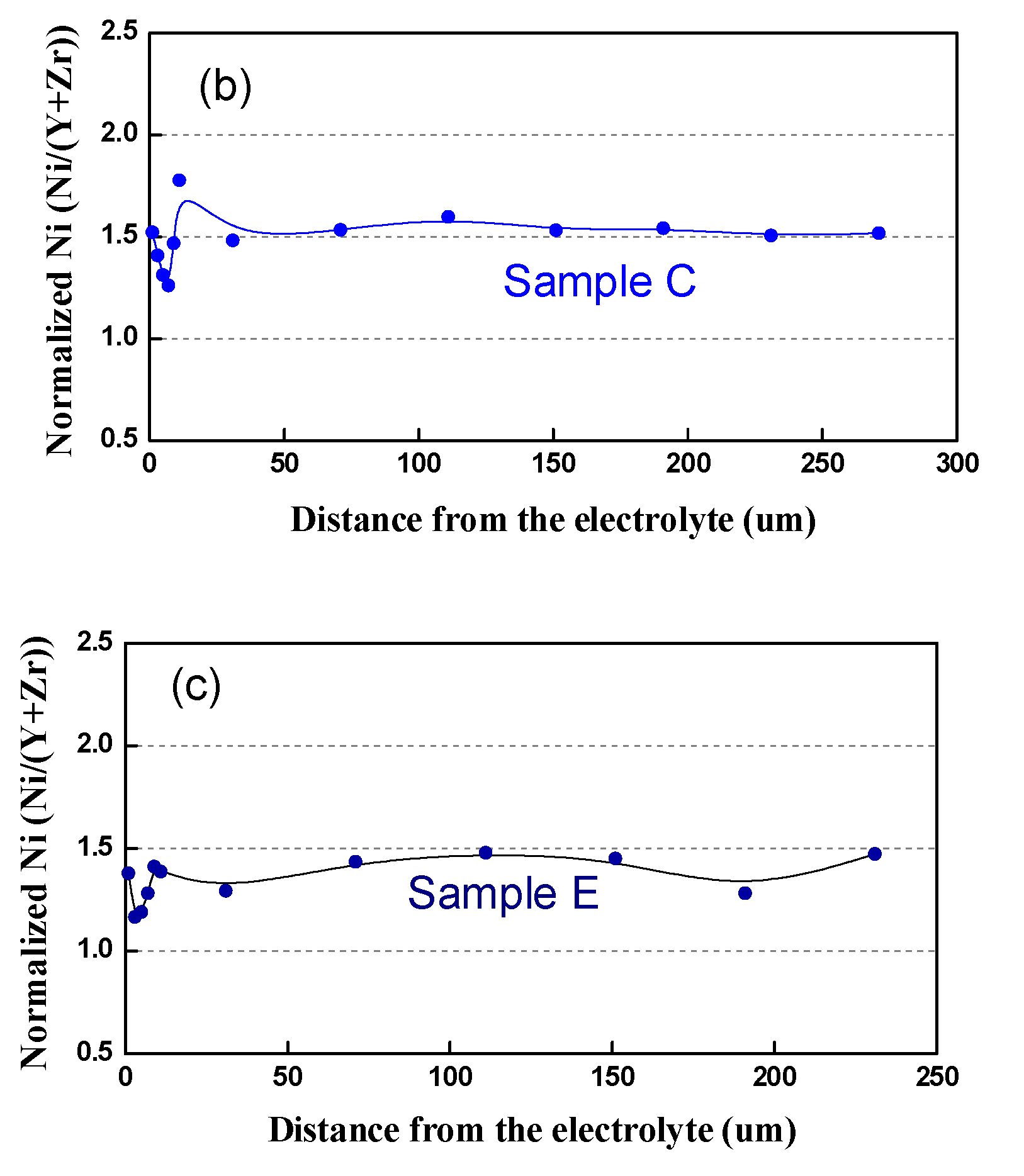

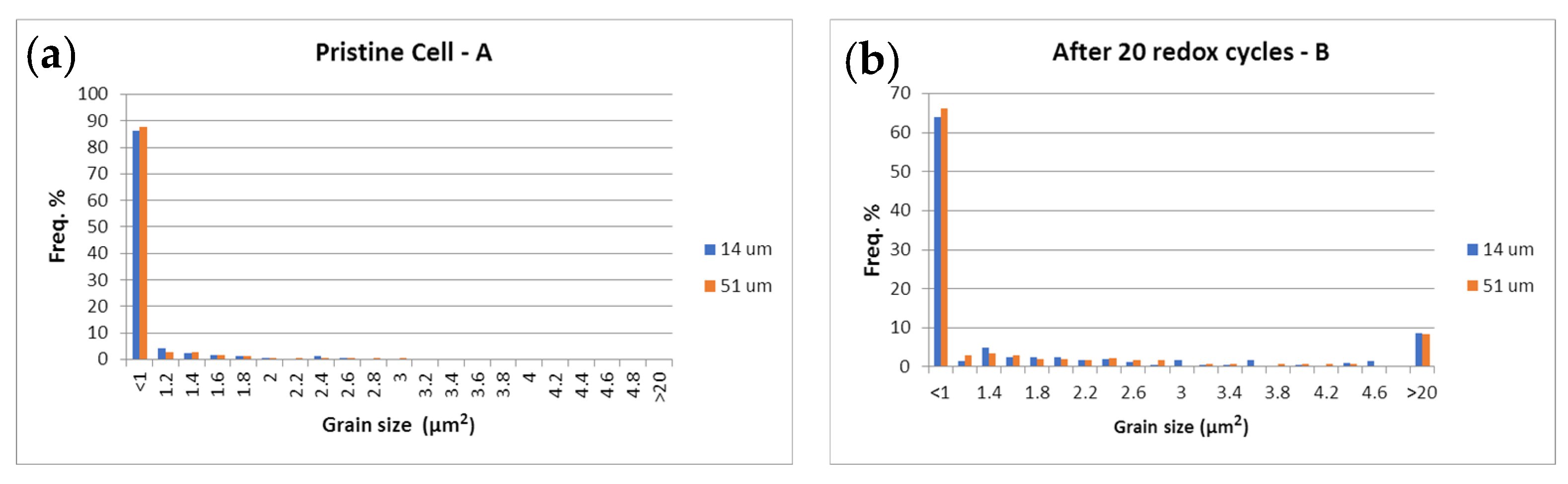

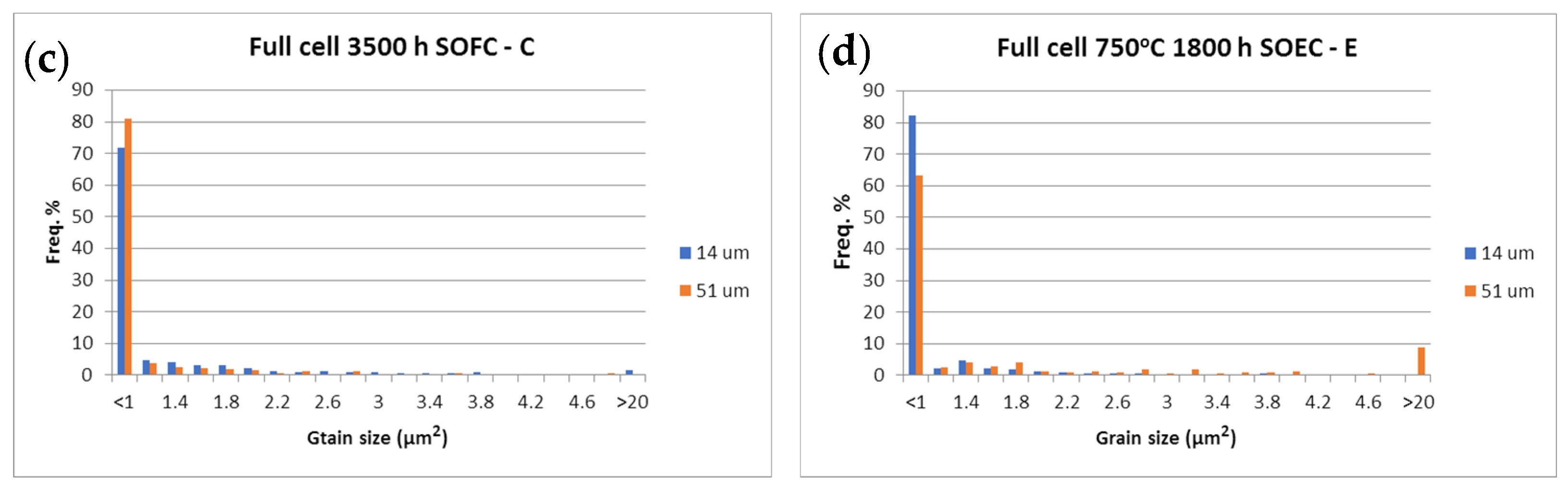

| Sample (Cell) | Testing Conditions |

|---|---|

| A | Pristine (after initial reduction) |

| B | After 20 redox cycles |

| C | 3500 h at constant operation conditions |

| D | 3000 h at changing operation conditions [72] |

| E | 1800 h in Electrolyzer mode (750 °C) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vladikova, D.; Burdin, B.; Sheikh, A.; Piccardo, P.; Krapchanska, M.; Montinaro, D.; Spotorno, R. Accelerated Stress Tests for Solid Oxide Cells via Artificial Aging of the Fuel Electrode. Energies 2022, 15, 3287. https://doi.org/10.3390/en15093287

Vladikova D, Burdin B, Sheikh A, Piccardo P, Krapchanska M, Montinaro D, Spotorno R. Accelerated Stress Tests for Solid Oxide Cells via Artificial Aging of the Fuel Electrode. Energies. 2022; 15(9):3287. https://doi.org/10.3390/en15093287

Chicago/Turabian StyleVladikova, Daria, Blagoy Burdin, Asrar Sheikh, Paolo Piccardo, Milena Krapchanska, Dario Montinaro, and Roberto Spotorno. 2022. "Accelerated Stress Tests for Solid Oxide Cells via Artificial Aging of the Fuel Electrode" Energies 15, no. 9: 3287. https://doi.org/10.3390/en15093287

APA StyleVladikova, D., Burdin, B., Sheikh, A., Piccardo, P., Krapchanska, M., Montinaro, D., & Spotorno, R. (2022). Accelerated Stress Tests for Solid Oxide Cells via Artificial Aging of the Fuel Electrode. Energies, 15(9), 3287. https://doi.org/10.3390/en15093287