Comparative Study of Non-Rare-Earth and Rare-Earth PM Motors for EV Applications

Abstract

:1. Introduction

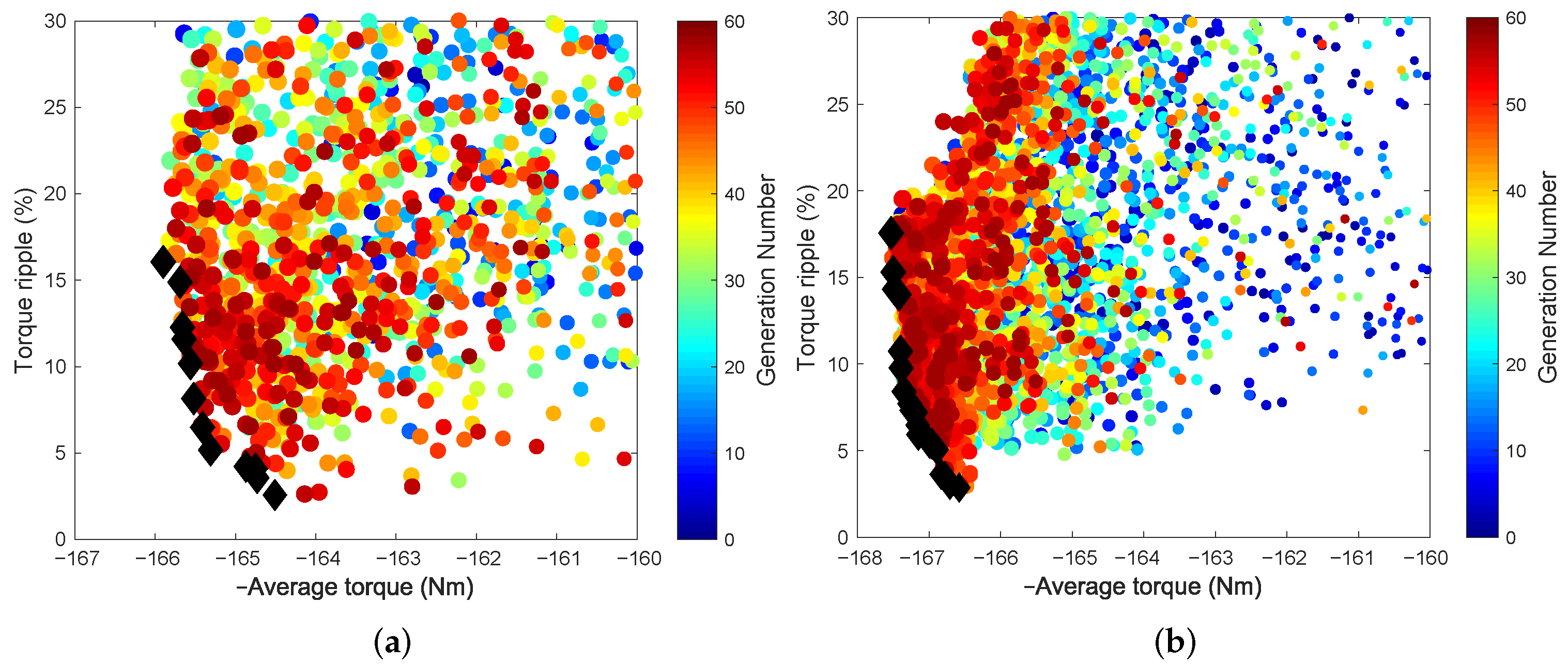

2. SynRM Rotor Optimization with DE Algorithm

2.1. DE Algorithm

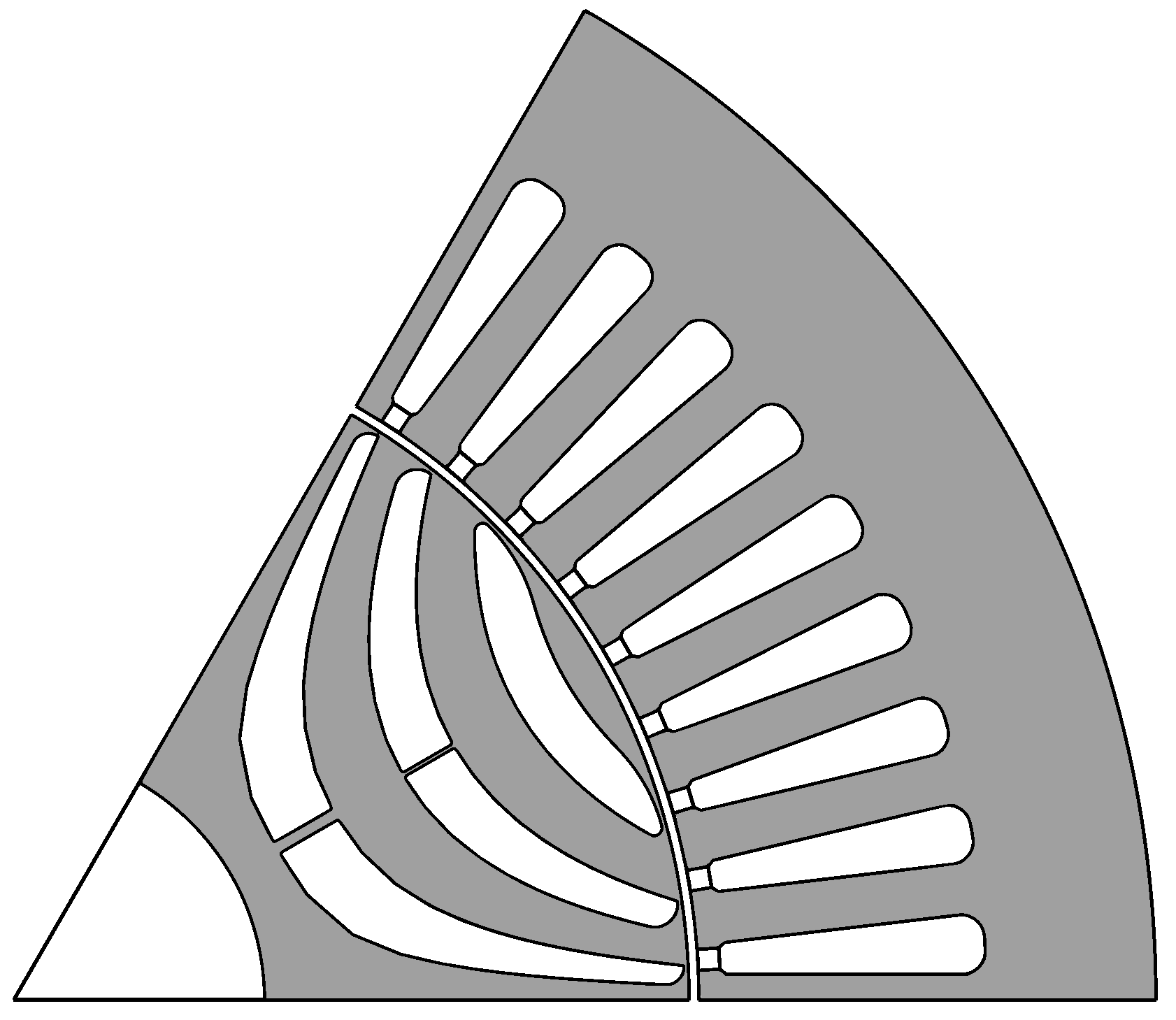

2.2. SynRM Rotor with Three and Four Flux Barriers

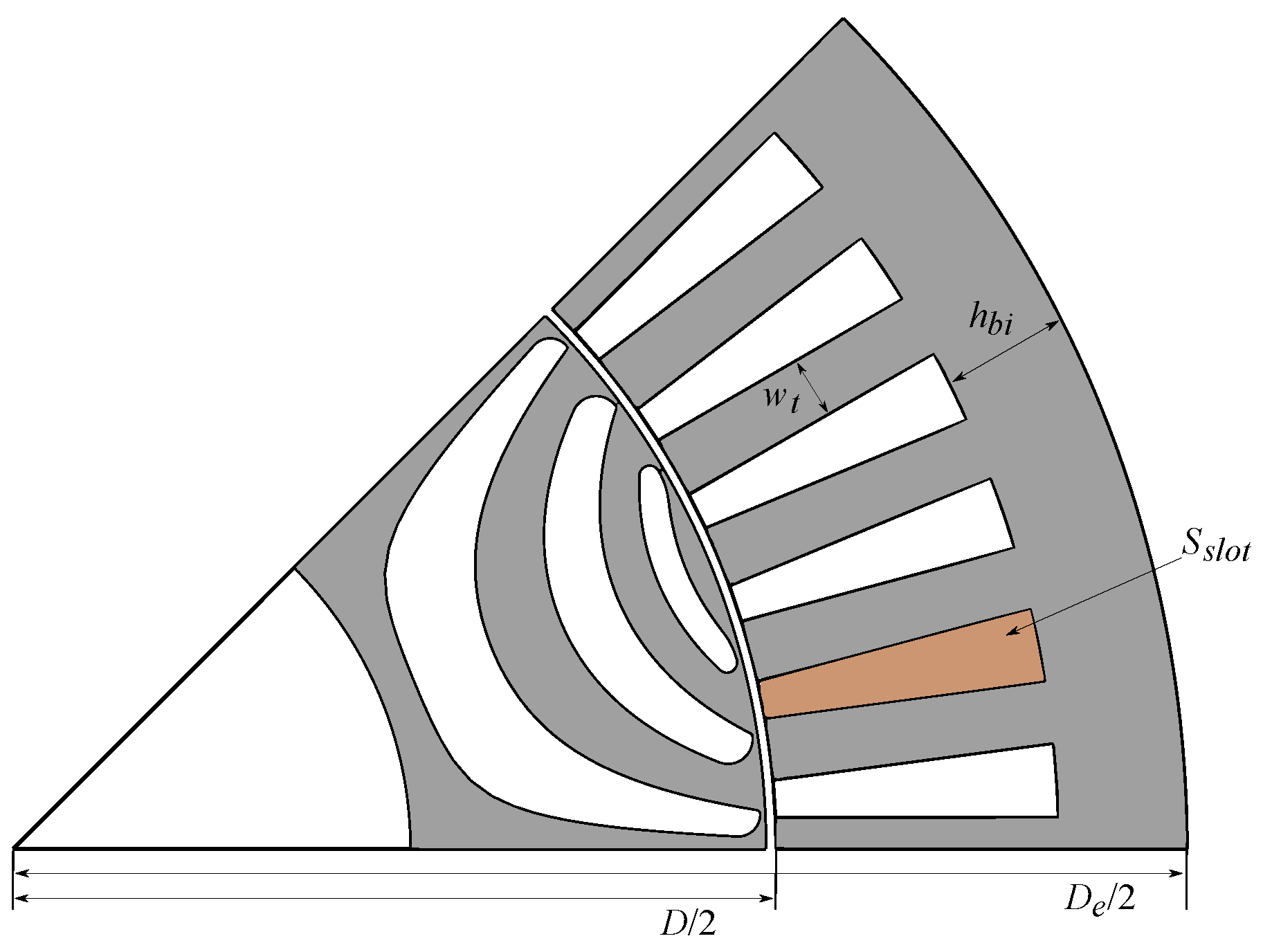

3. Reconsideration of the SynRM Design

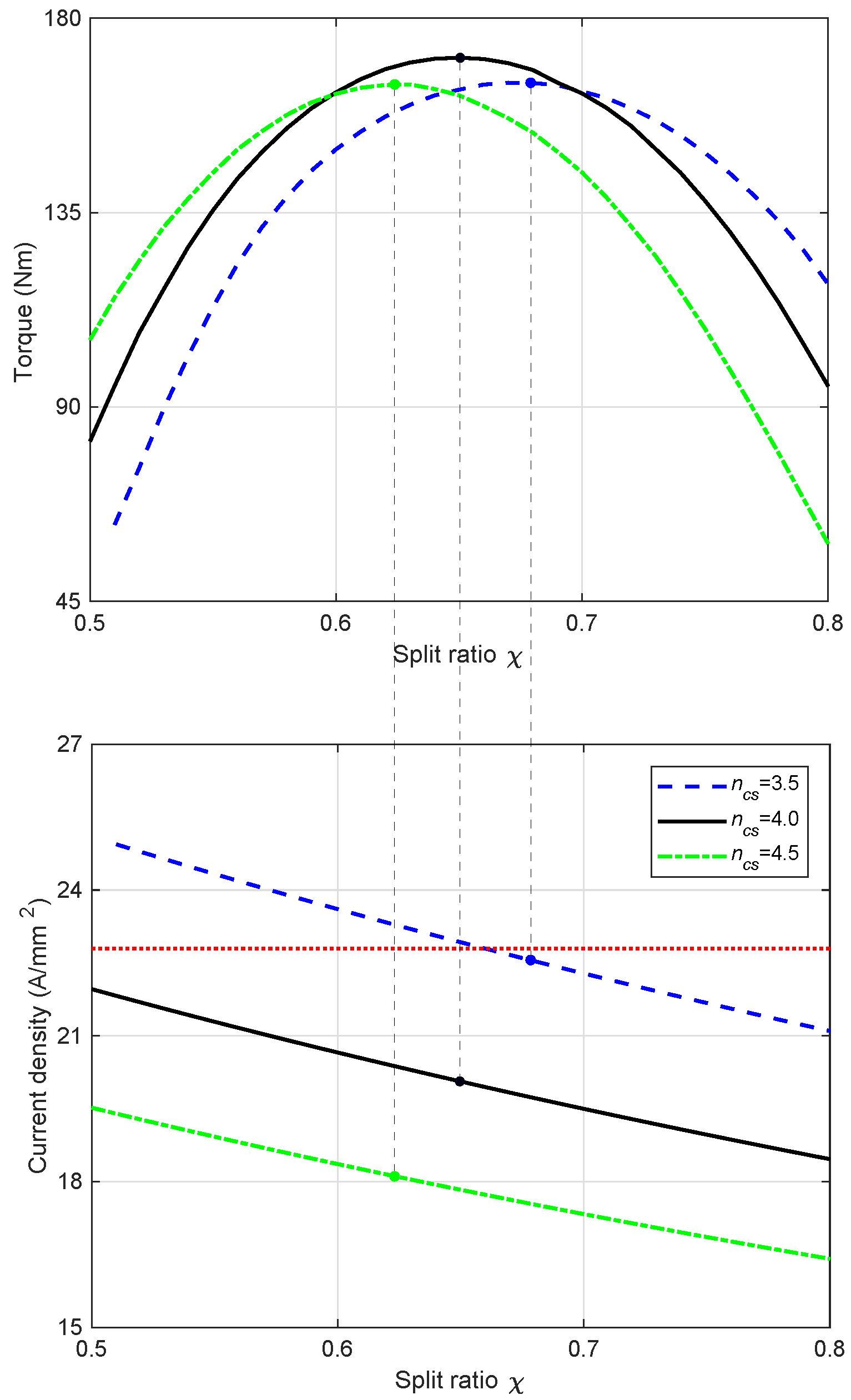

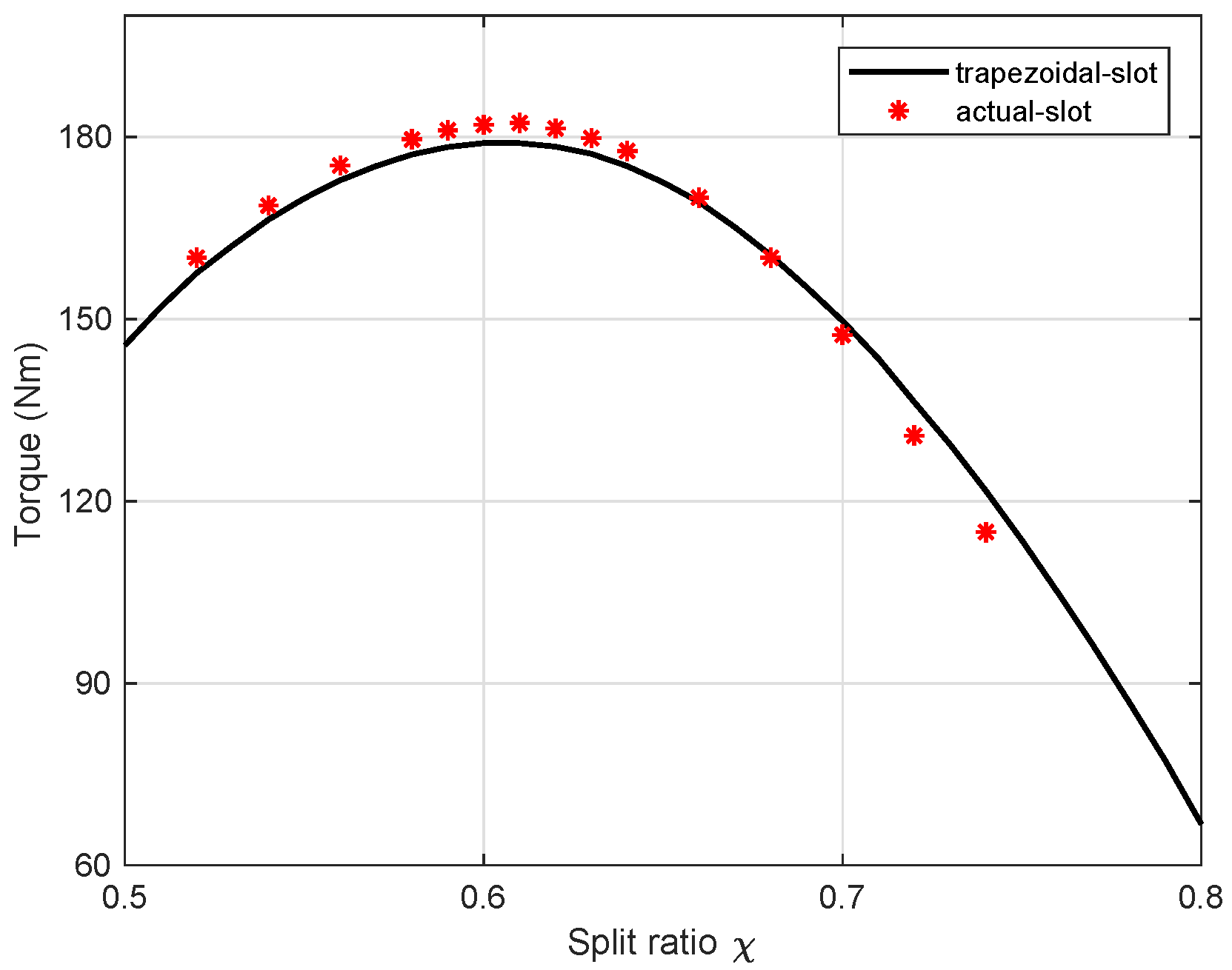

3.1. Split Ratio Optimization

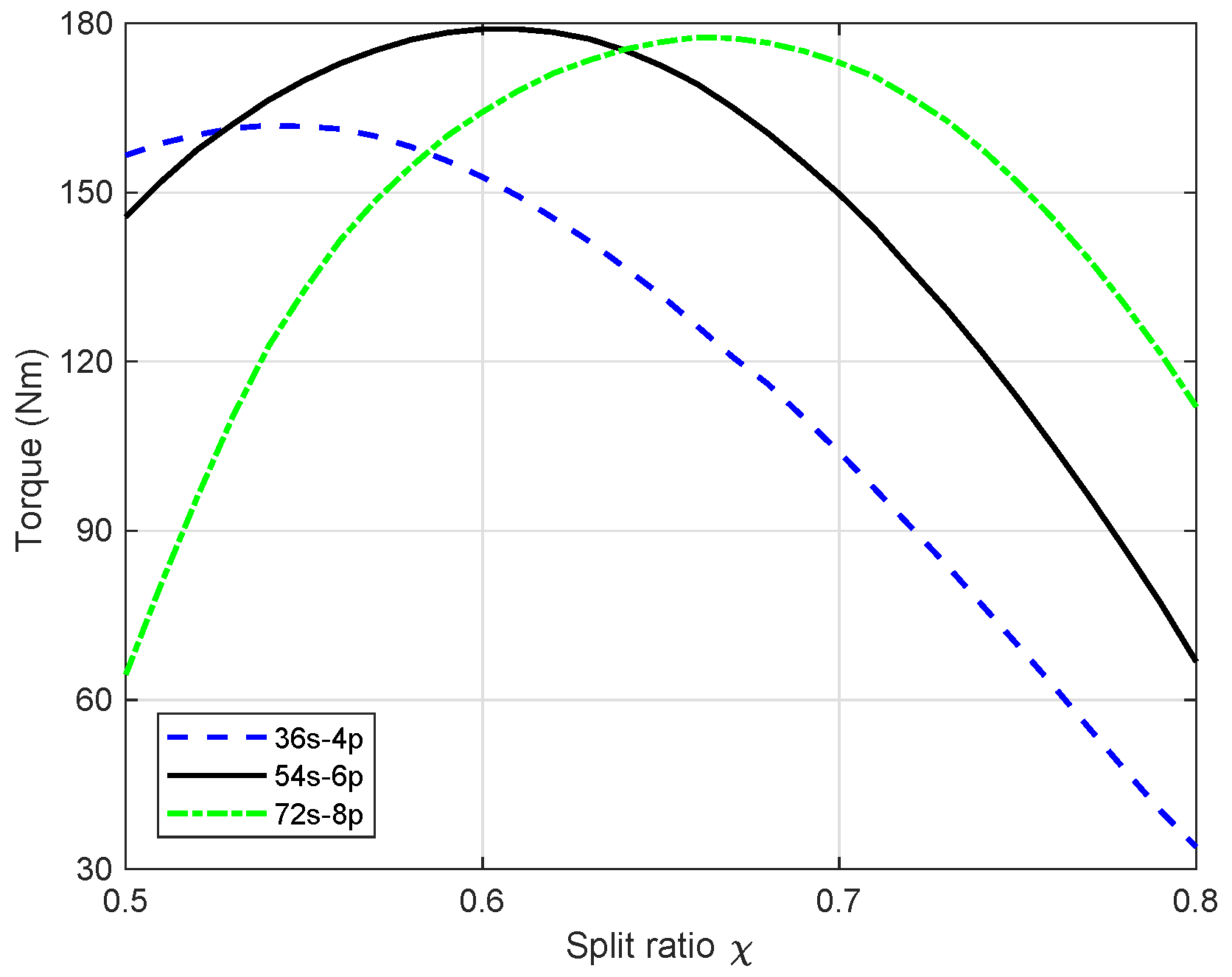

3.2. Slot–Pole Combinations

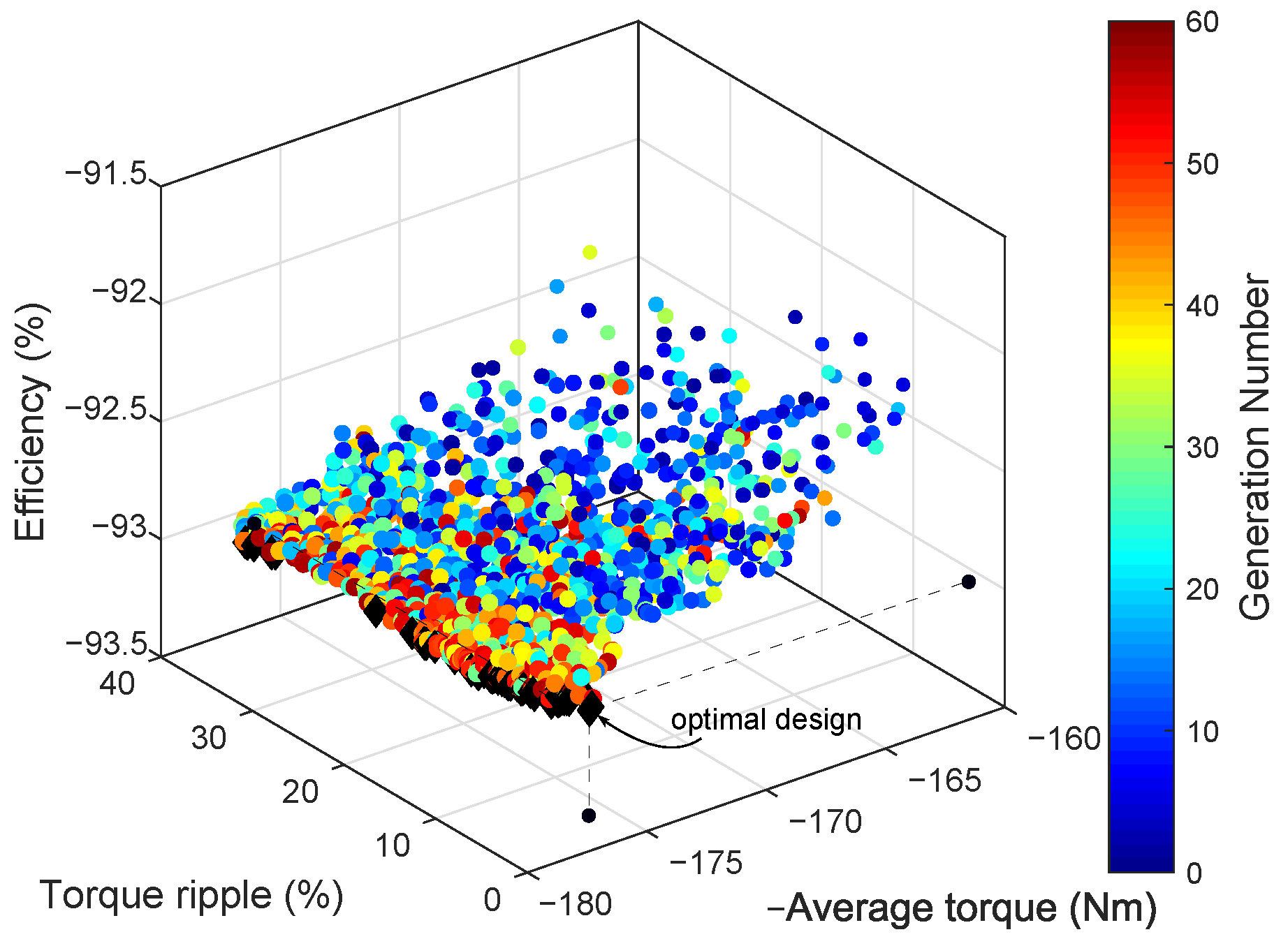

3.3. Rotor Optimization

3.4. Rotor Structure Enhancement

4. Performance Comparison among the Motors

4.1. Design Features

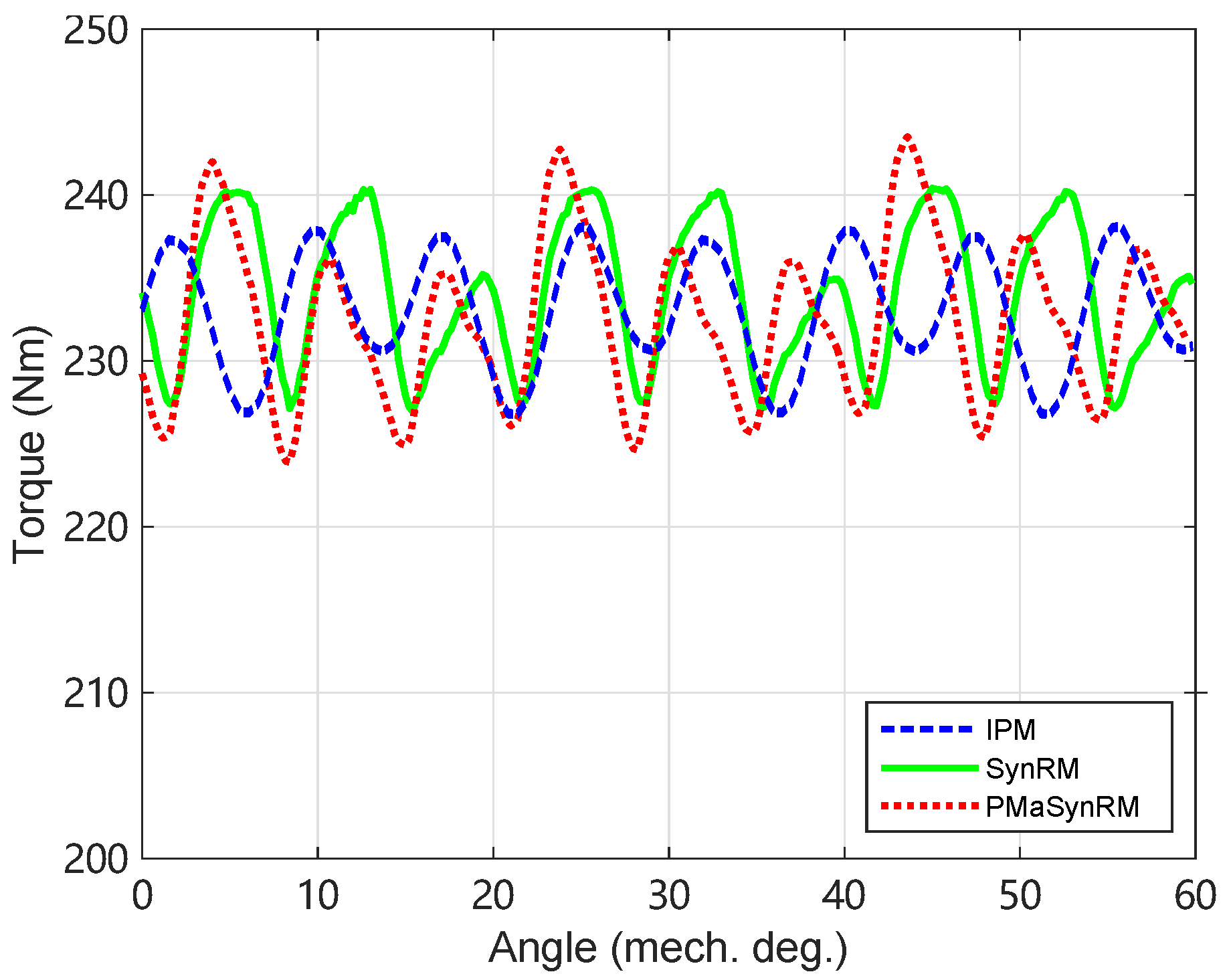

4.2. Torque and Power Capabilities

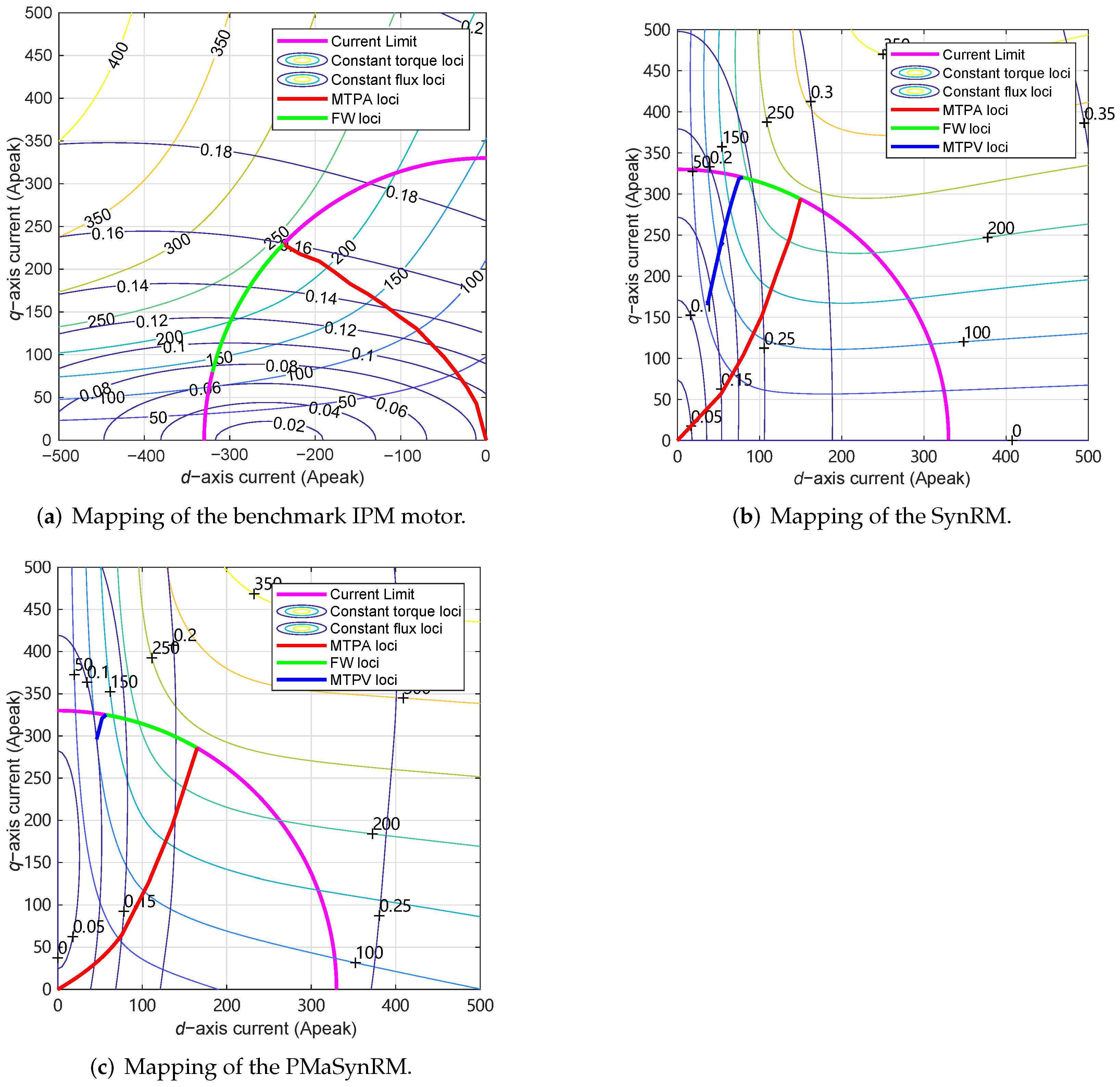

4.3. High-Speed Flux-Weakening Capability

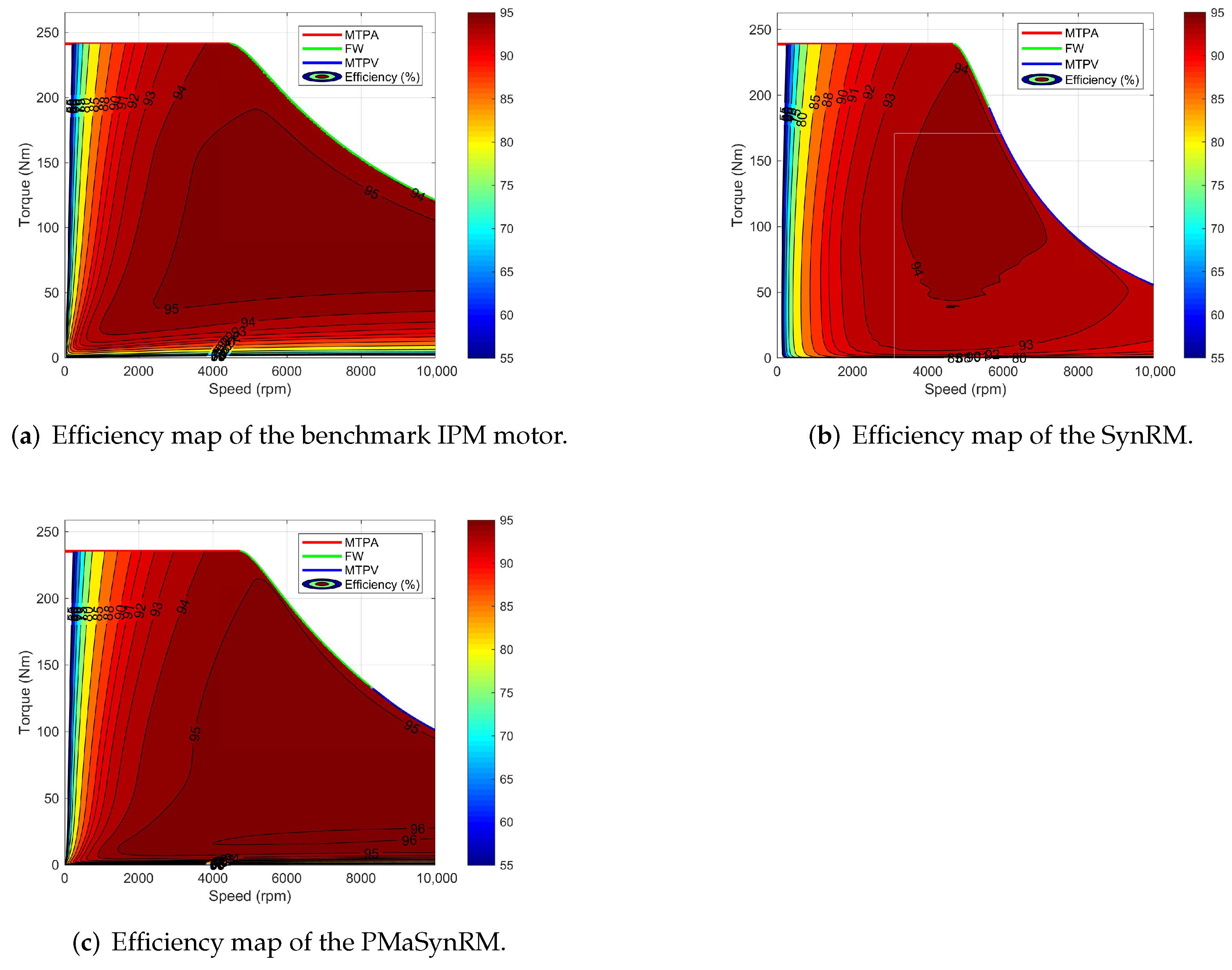

4.4. Efficiency

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Chau, K.; Chan, C.; Liu, C. Overview of Permanent-Magnet Brushless Drives for Electric and Hybrid Electric Vehicles. IEEE Trans. Ind. Electron. 2008, 55, 2246–2257. [Google Scholar] [CrossRef] [Green Version]

- Vagati, A.; Pellegrino, G.; Guglielmi, P. Comparison between SPM and IPM motor drives for EV application. In Proceedings of the 2010 International Conference on Electrical Machines (ICEM), Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- EL-Refaie, A.M.; Alexander, J.P.; Galioto, S.; Reddy, P.B.; Huh, K.K.; de Bock, P.; Shen, X. Advanced High-Power-Density Interior Permanent Magnet Motor for Traction Applications. IEEE Trans. Ind. Appl. 2014, 50, 3235–3248. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Chu, W.Q.; Guan, Y. Quantitative comparison of electromagnetic performance of electrical machines for HEVs/EVs. CES Trans. Electr. Mach. Syst. 2017, 1, 37–47. [Google Scholar] [CrossRef]

- Dorrell, D.G.; Knight, A.M.; Popescu, M.; Evans, L.; Staton, D.A. Comparison of different motor design drives for hybrid electric vehicles. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 3352–3359. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D. Electrical Machines and Drives for Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Pellegrino, G.; Vagati, A.; Boazzo, B.; Guglielmi, P. Comparison of Induction and PM Synchronous Motor Drives for EV Application Including Design Examples. IEEE Trans. Ind. Appl. 2012, 48, 2322–2332. [Google Scholar] [CrossRef] [Green Version]

- Chiba, A.; Takano, Y.; Takeno, M.; Imakawa, T.; Hoshi, N.; Takemoto, M.; Ogasawara, S. Torque Density and Efficiency Improvements of a Switched Reluctance Motor Without Rare-Earth Material for Hybrid Vehicles. IEEE Trans. Ind. Appl. 2011, 47, 1240–1246. [Google Scholar] [CrossRef]

- Kiyota, K.; Kakishima, T.; Chiba, A. Comparison of Test Result and Design Stage Prediction of Switched Reluctance Motor Competitive with 60-kW Rare-Earth PM Motor. IEEE Trans. Ind. Electron. 2014, 61, 5712–5721. [Google Scholar] [CrossRef]

- Lan, Y.; Benomar, Y.; Deepak, K.; Aksoz, A.; Baghdadi, M.E.; Bostanci, E.; Hegazy, O. Switched Reluctance Motors and Drive Systems for Electric Vehicle Powertrains: State of the Art Analysis and Future Trends. Energies 2021, 14, 2079. [Google Scholar] [CrossRef]

- Kiyota, K.; Kakishima, T.; Chiba, A.; Rahman, M.A. Cylindrical Rotor Design for Acoustic Noise and Windage Loss Reduction in Switched Reluctance Motor for HEV Applications. IEEE Trans. Ind. Appl. 2016, 52, 154–162. [Google Scholar] [CrossRef]

- Vagati, A.; Franceschini, G.; Marongiu, I.; Troglia, G. Design criteria of high performance synchronous reluctance motors. In Proceedings of the Conference Record of the 1992 IEEE Industry Applications Society Annual Meeting, Houston, TX, USA, 4–9 October 1992; Volume 1, pp. 66–73. [Google Scholar] [CrossRef]

- Lipo, T.A. Synchronous Reluctance Machines-A Viable Alternative for AC Drives? Electr. Mach. Power Syst. 1991, 19, 659–671. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Bon, D.; Pre, M.D. Rotor Flux-Barrier Design for Torque Ripple Reduction in Synchronous Reluctance and PM-Assisted Synchronous Reluctance Motors. IEEE Trans. Ind. Appl. 2009, 45, 921–928. [Google Scholar] [CrossRef]

- Wang, Y.; Bacco, G.; Bianchi, N. Geometry Analysis and Optimization of PM-Assisted Reluctance Motors. IEEE Trans. Ind. Appl. 2017, 53, 4338–4347. [Google Scholar] [CrossRef]

- Gedara, I.P.A.H. Design Optimization and Performance Improvement of Synchronous Reluctance Machines. Ph.D. Thesis, University of Manitoba, Winnipeg, MB, Canada, 2019. [Google Scholar]

- Pellegrino, G.; Cupertino, F.; Gerada, C. Automatic Design of Synchronous Reluctance Motors Focusing on Barrier Shape Optimization. IEEE Trans. Ind. Appl. 2015, 51, 1465–1474. [Google Scholar] [CrossRef]

- Mirazimi, M.S.; Kiyoumarsi, A. Magnetic Field Analysis of SynRel and PMASynRel Machines with Hyperbolic Flux Barriers Using Conformal Mapping. IEEE Trans. Transp. Electrif. 2020, 6, 52–61. [Google Scholar] [CrossRef]

- Alani, M.; Degano, M.; Bianchi, N.; Mahmoud, H.; Gerada, C. Analysis and Design of Dual-Rotor Synchronous Reluctance Machine. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 4376–4383. [Google Scholar] [CrossRef]

- Boldea, I.; Tutelea, L.; Pitic, C.I. PM-assisted reluctance synchronous motor/generator (PM-RSM) for mild hybrid vehicles: Electromagnetic design. IEEE Trans. Ind. Appl. 2004, 40, 492–498. [Google Scholar] [CrossRef]

- Jahns, T. Getting Rare-Earth Magnets Out of EV Traction Machines: A review of the many approaches being pursued to minimize or eliminate rare-earth magnets from future EV drivetrains. IEEE Electrif. Mag. 2017, 5, 6–18. [Google Scholar] [CrossRef]

- Tahanian, H.; Aliahmadi, M.; Faiz, J. Ferrite Permanent Magnets in Electrical Machines: Opportunities and Challenges of a Non-Rare-Earth Alternative. IEEE Trans. Magn. 2020, 56, 1–20. [Google Scholar] [CrossRef]

- Armando, E.; Guglielmi, P.; Pastorelli, M.; Pellegrino, G.; Vagati, A. Performance of IPM-PMASR Motors with Ferrite Injection for Home Appliance Washing Machine. In Proceedings of the 2008 IEEE Industry Applications Society Annual Meeting, Edmonton, AB, Canada, 5–9 October 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Vagati, A.; Boazzo, B.; Guglielmi, P.; Pellegrino, G. Ferrite assisted synchronous reluctance machines: A general approach. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1315–1321. [Google Scholar]

- Guan, Y.; Zhu, Z.Q.; Afinowi, I.A.A.; Mipo, J.C.; Farah, P. Design of synchronous reluctance and permanent magnet synchronous reluctance machines for electric vehicle application. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 1853–1859. [Google Scholar] [CrossRef]

- Reddy, P.B.; El-Refaie, A.M.; Galioto, S.; Alexander, J.P. Design of Synchronous Reluctance Motor Utilizing Dual-Phase Material for Traction Applications. IEEE Trans. Ind. Appl. 2017, 53, 1948–1957. [Google Scholar] [CrossRef]

- Grace, K.; Galioto, S.; Bodla, K.; El-Refaie, A.M. Design and Testing of a Carbon-Fiber-Wrapped Synchronous Reluctance Traction Motor. IEEE Trans. Ind. Appl. 2018, 54, 4207–4217. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.; Lin, H.; Fang, S.; Wang, W. A Novel Magnet-Axis-Shifted Hybrid Permanent Magnet Machine for Electric Vehicle Applications. Energies 2019, 12, 641. [Google Scholar] [CrossRef] [Green Version]

- Burress, T.A.; Coomer, C.L.; Campbell, S.L.; Wereszczak, A.A.; Cunningham, J.P.; Marlino, L.D.; Seiber, L.E.; Lin, H.T. Evaluation of the 2008 Lexus LS 600h Hybrid Synergy Drive System; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2009. [Google Scholar]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Adaptive Scheme for Global Optimization over Continuous Spaces; International Computer Science Institute: Berkeley, CA, USA, 1995. [Google Scholar]

- Chakraborty, U.K. Advances in Differential Evolution; Springer: Berlin, Germany, 2008. [Google Scholar]

- Prado, R.S.; Silva, R.C.P.; Guimarães, F.G.; Neto, O.M. Using differential evolution for combinatorial optimization: A general approach. In Proceedings of the 2010 IEEE International Conference on Systems, Man and Cybernetics, Istanbul, Turkey, 10–13 October 2010; pp. 11–18. [Google Scholar] [CrossRef]

- Sizov, G.Y.; Zhang, P.; Ionel, D.M.; Demerdash, N.A.O.; Rosu, M. Automated Multi-Objective Design Optimization of PM AC Machines Using Computationally Efficient FEA and Differential Evolution. IEEE Trans. Ind. Appl. 2013, 49, 2086–2096. [Google Scholar] [CrossRef]

- Zarko, D.; Ban, D.; Lipo, T.A. Analytical Solution for Cogging Torque in Surface Permanent-Magnet Motors Using Conformal Mapping. IEEE Trans. Magn. 2008, 44, 52–65. [Google Scholar] [CrossRef]

- Bianchi, N.; Jahns, T.M. Design, analysis, and control of interior PM synchronous machines. In Proceedings of the IEEE Industry Applications Society Annual Meeting, CLEUP, Seattle, WA, USA, 3 October 2004. [Google Scholar]

- Bianchi, N.; Bolognani, S.; Grezzani, G. PM Motors for Very High Dynamic Applications. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Dresden, Germany, 16 June 2005; pp. 1332–1338. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, Z.Q.; Ombach, G.; Koch, M.; Zhang, S.; Xu, J. Optimal slot/pole and flux-barrier layer number combinations for synchronous reluctance machines. In Proceedings of the 2013 Eighth International Conference and Exhibition on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 27–30 March 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Liang, J.; Jiang, J.W.; Bilgin, B.; Emadi, A. Shaft Design for Electric Traction Motors. IEEE Trans. Transp. Electrif. 2018, 4, 720–731. [Google Scholar] [CrossRef]

- The World Centre for Industrial Metals Pricing… Hedging… Trading. Available online: https://www.lme.com/en/ (accessed on 1 January 2022).

- Available online: https://www.kedemagnetics.com/kede-about.html (accessed on 1 January 2022).

| Design Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Number of stator slots | 48 | – | |

| Number of poles | 8 | – | |

| Stator outer diameter | 200 | mm | |

| Stator inner diameter | D | 130.86 | mm |

| Shaft diameter | 53 | mm | |

| Active stack length | 135.4 | mm | |

| Airgap thickness | g | 0.89 | mm |

| p | q | Winding Factor | ||||

|---|---|---|---|---|---|---|

| 24 | 2 | 2 | 0.966 | 7.5 | 0.54 | 154.5 |

| 36 | 2 | 3 | 0.960 | 5.0 | 0.54 | 161.9 |

| 48 | 2 | 4 | 0.958 | 3.5 | 0.56 | 158.9 |

| 36 | 3 | 2 | 0.966 | 5.0 | 0.61 | 171.5 |

| 54 | 3 | 3 | 0.960 | 3.5 | 0.60 | 179.0 |

| 72 | 3 | 4 | 0.958 | 2.5 | 0.62 | 176.3 |

| 48 | 4 | 2 | 0.966 | 4.0 | 0.65 | 170.9 |

| 72 | 4 | 3 | 0.960 | 2.5 | 0.66 | 177.5 |

| 96 | 4 | 4 | 0.958 | 2.0 | 0.65 | 176.8 |

| Parameters | ||||

|---|---|---|---|---|

| Values | 15.0 | 21.5 | 27.2 |

| Benchmark IPM Motor | SynRM | PMaSynRM | Unit | |

|---|---|---|---|---|

| Number of stator slots | 48 | 54 | 54 | – |

| Number of poles | 8 | 6 | 6 | – |

| Stator outer diameter | 200 | 200 | 200 | mm |

| Stator inner diameter | 130.86 | 120 | 120 | mm |

| Airgap thickness | 0.89 | 0.89 | 0.89 | mm |

| Shaft diameter | 53 | 44 | 44 | mm |

| Active stack length | 135.4 | 182 | 135.4 | mm |

| Active volume | 4.25 | 5.72 | 4.25 | L |

| Stator core mass | 15.15 | 21.09 | 15.69 | kg |

| Stator core cost | 21.2 | 29.5 | 22.0 | $ |

| Copper mass | 3.59 | 5.40 | 4.51 | kg |

| Copper cost | 35.2 | 52.9 | 44.2 | $ |

| Rotor mass | 9.60 | 7.97 | 5.96 | kg |

| Rotor cost | 13.4 | 11.2 | 8.3 | $ |

| Magnet mass | 1.35 | 0 | 2.68 | kg |

| Magnet cost | 170.4 | 0 | 8.6 | $ |

| Total mass | 29.69 | 34.46 | 28.84 | kg |

| Total material cost | 240.2 | 93.6 | 83.1 | $ |

| DC-bus voltage | 650 | 874 | 650 | V |

| Current | 330 | 330 | 330 | A |

| Maximum torque | 233.4 | 234.1 | 231.7 | Nm |

| Maximum power | 110.0 | 110.3 | 109.2 | kW |

| Power density | 25.9 | 19.3 | 25.2 | kW/L |

| Specific power | 3.7 | 3.2 | 3.8 | kW/kg |

| Power factor | 0.78 | 0.58 | 0.76 | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Bianchi, N.; Qu, R. Comparative Study of Non-Rare-Earth and Rare-Earth PM Motors for EV Applications. Energies 2022, 15, 2711. https://doi.org/10.3390/en15082711

Wang Y, Bianchi N, Qu R. Comparative Study of Non-Rare-Earth and Rare-Earth PM Motors for EV Applications. Energies. 2022; 15(8):2711. https://doi.org/10.3390/en15082711

Chicago/Turabian StyleWang, Yawei, Nicola Bianchi, and Ronghai Qu. 2022. "Comparative Study of Non-Rare-Earth and Rare-Earth PM Motors for EV Applications" Energies 15, no. 8: 2711. https://doi.org/10.3390/en15082711

APA StyleWang, Y., Bianchi, N., & Qu, R. (2022). Comparative Study of Non-Rare-Earth and Rare-Earth PM Motors for EV Applications. Energies, 15(8), 2711. https://doi.org/10.3390/en15082711