Relationships between the Petrographic and Abrasive Properties of Sandstones in the Aspect of Their Cutting

Abstract

:1. Introduction

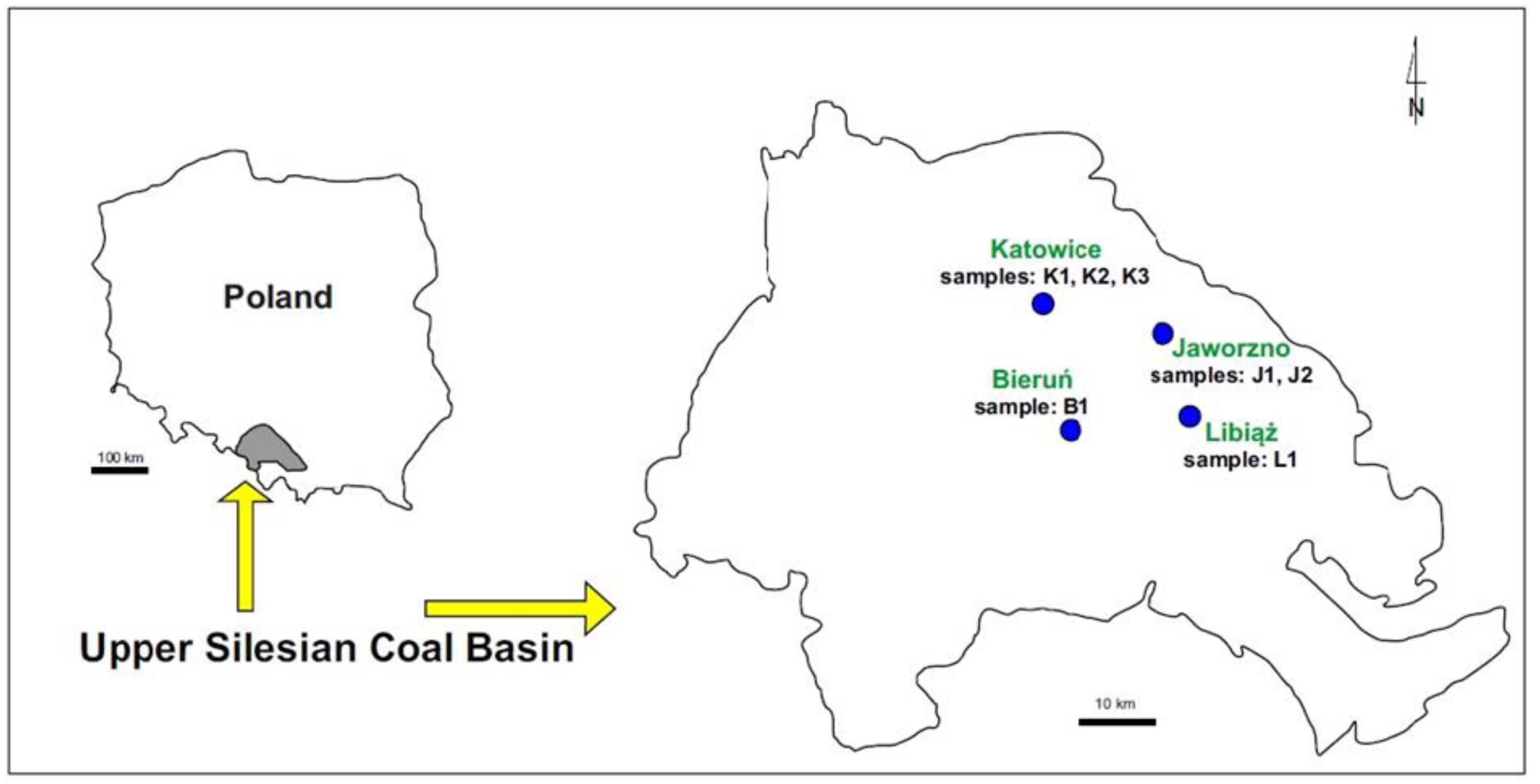

2. Research Material

3. Research Methodology

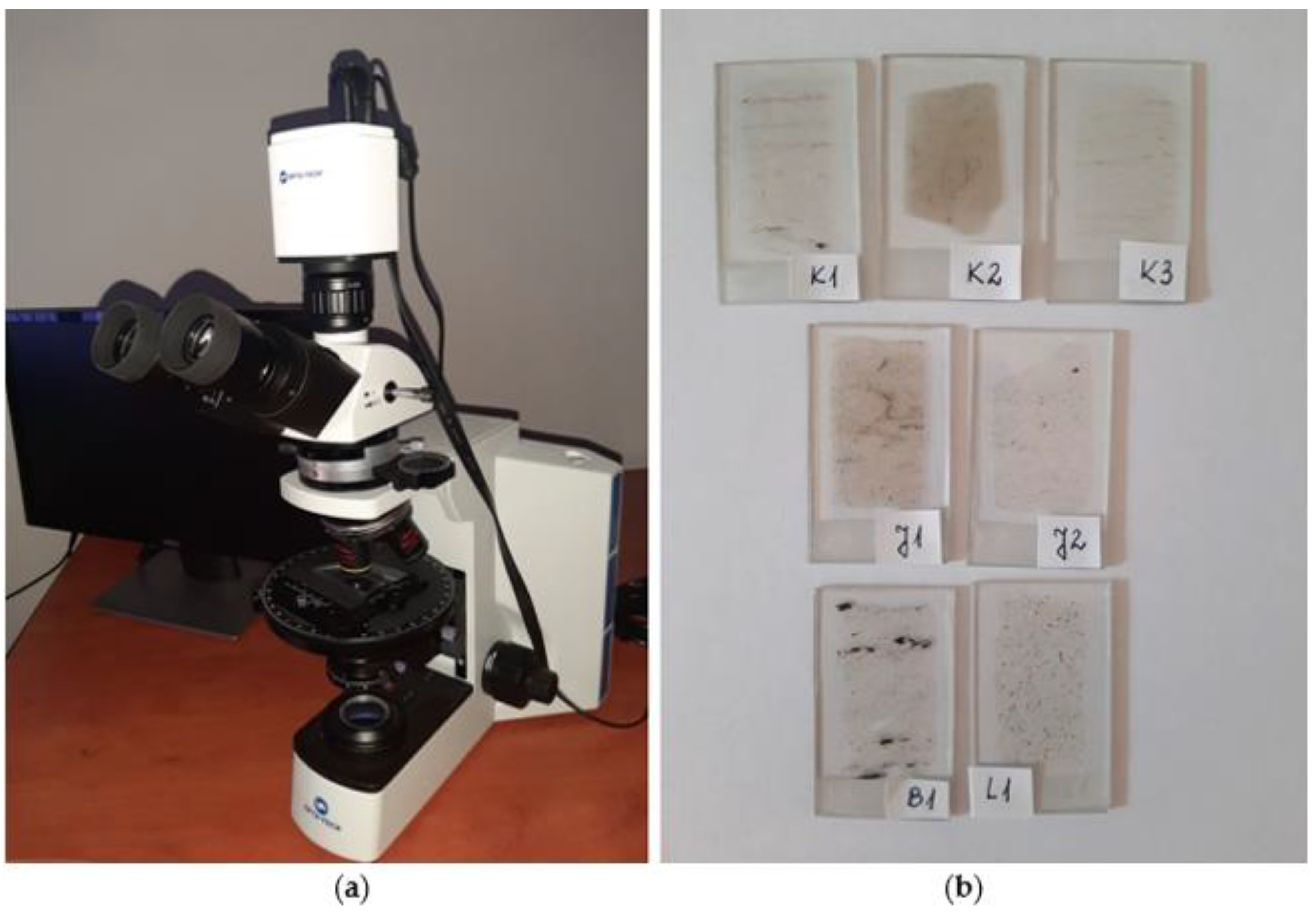

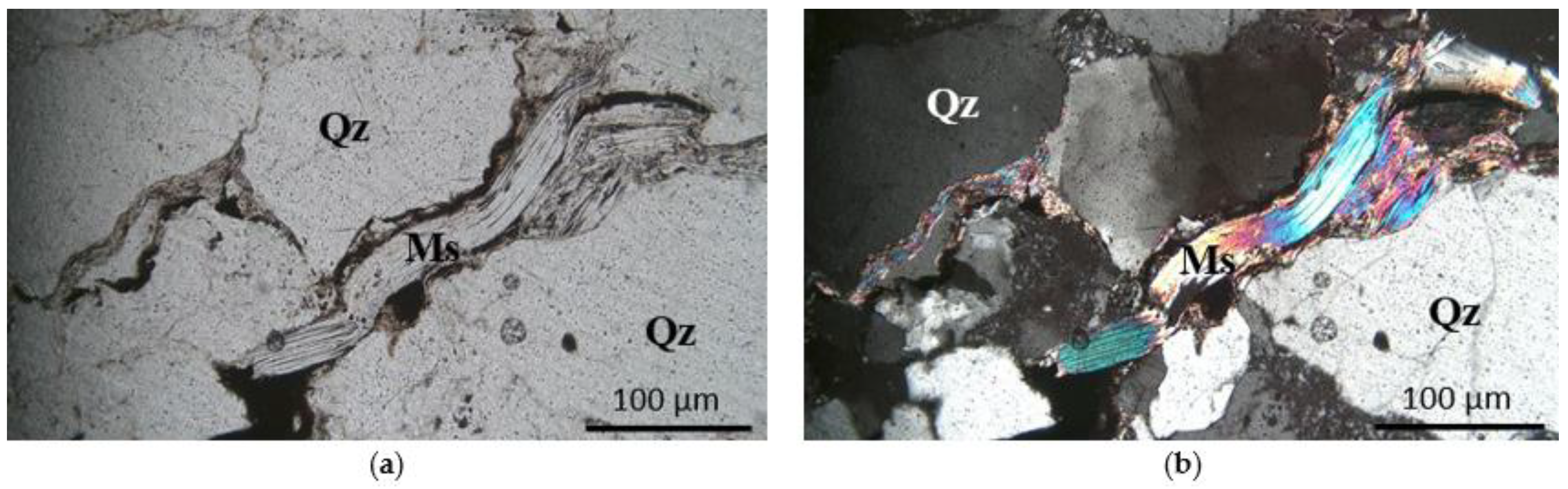

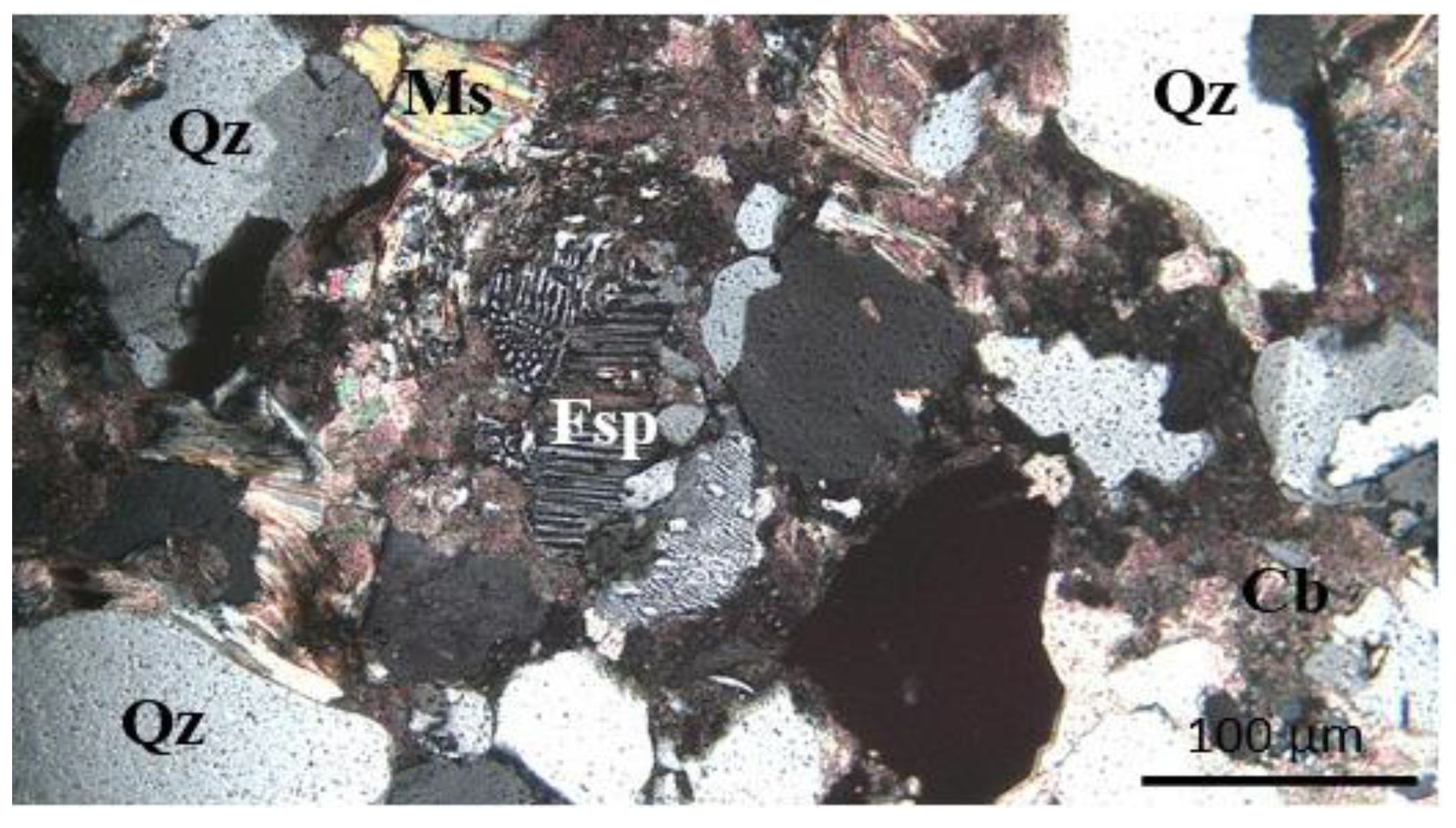

3.1. Petrographic and Mineralogical Analyses

3.2. Analysis of Physical Properties

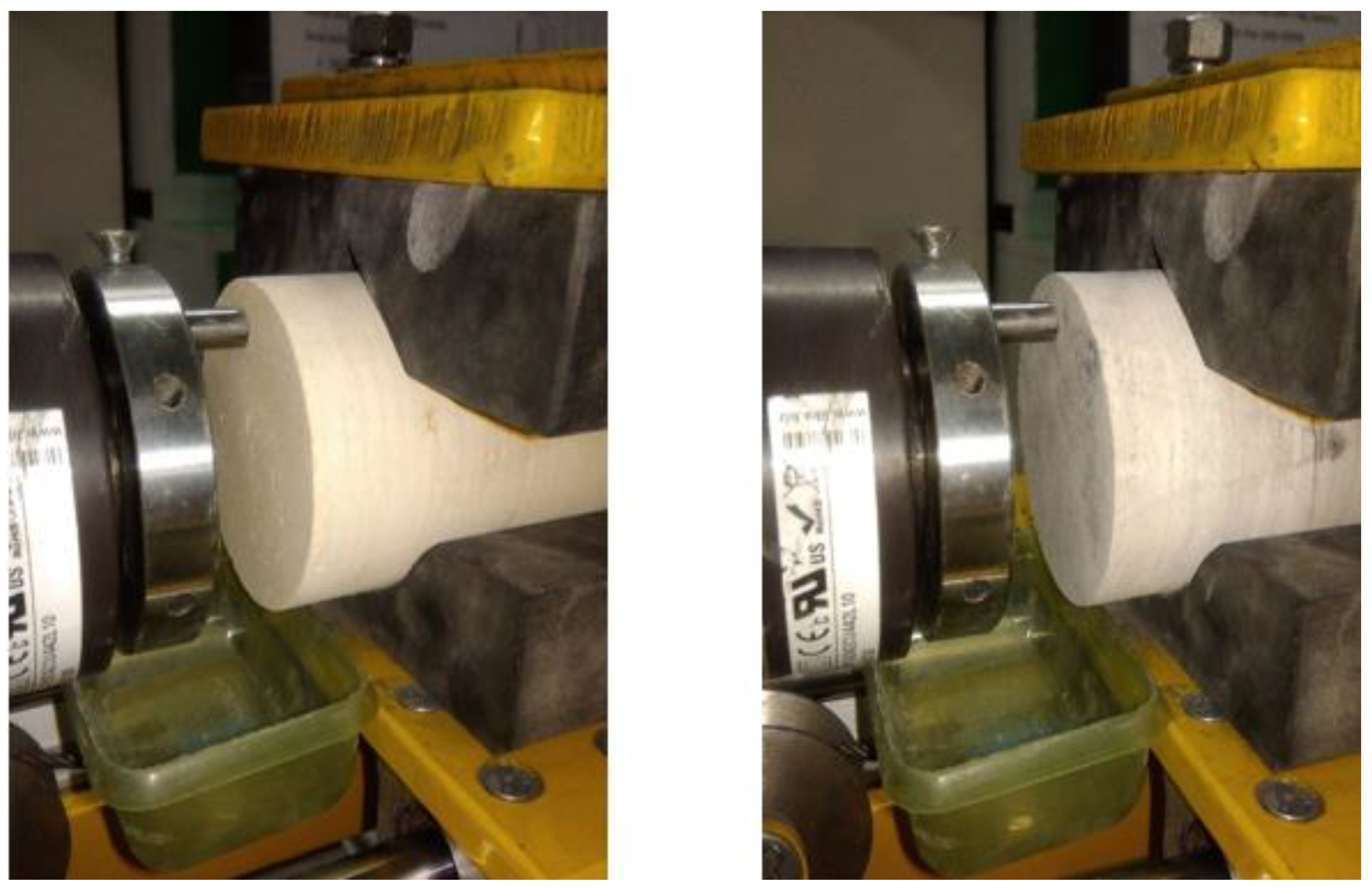

3.3. Analysis of Mechanical Properties

4. Results

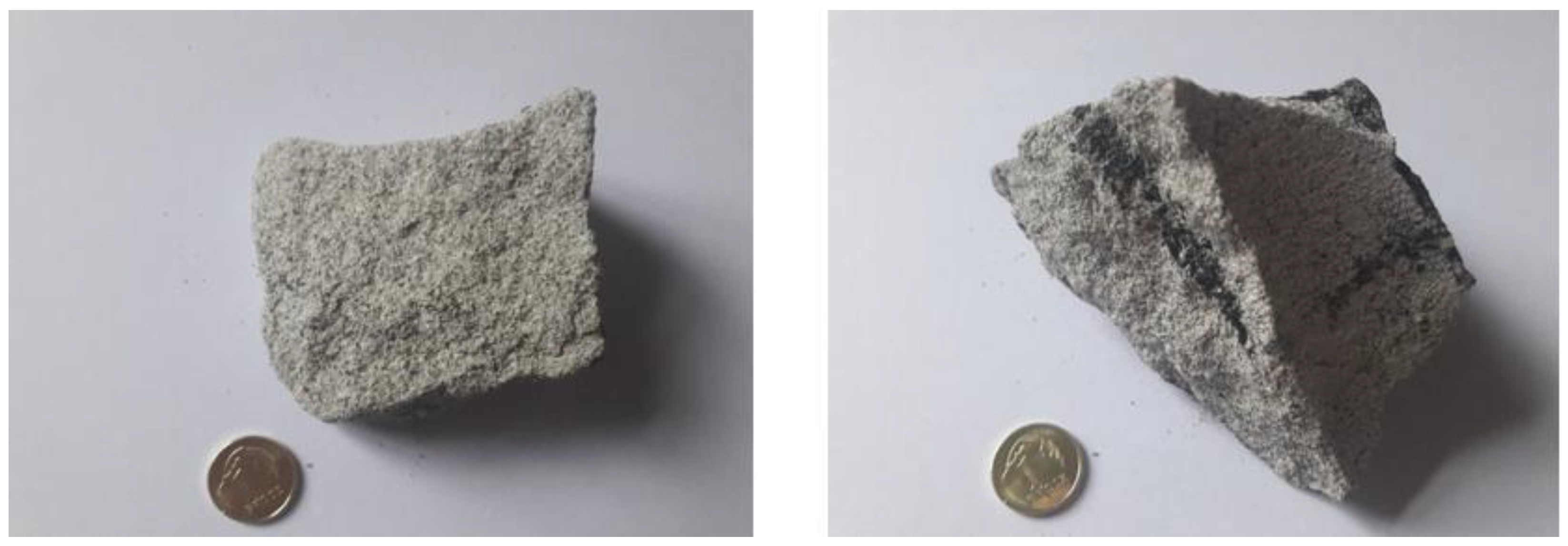

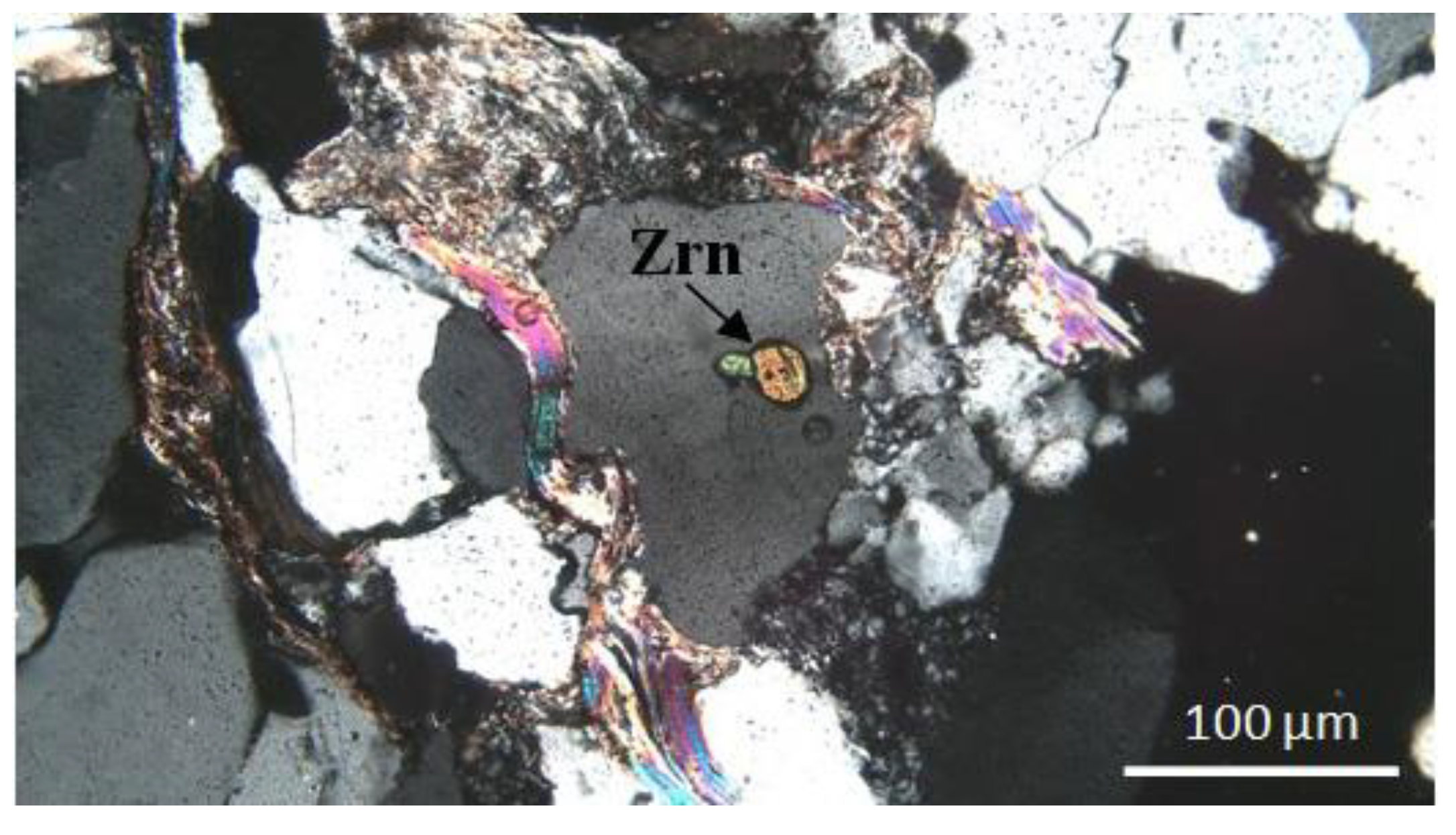

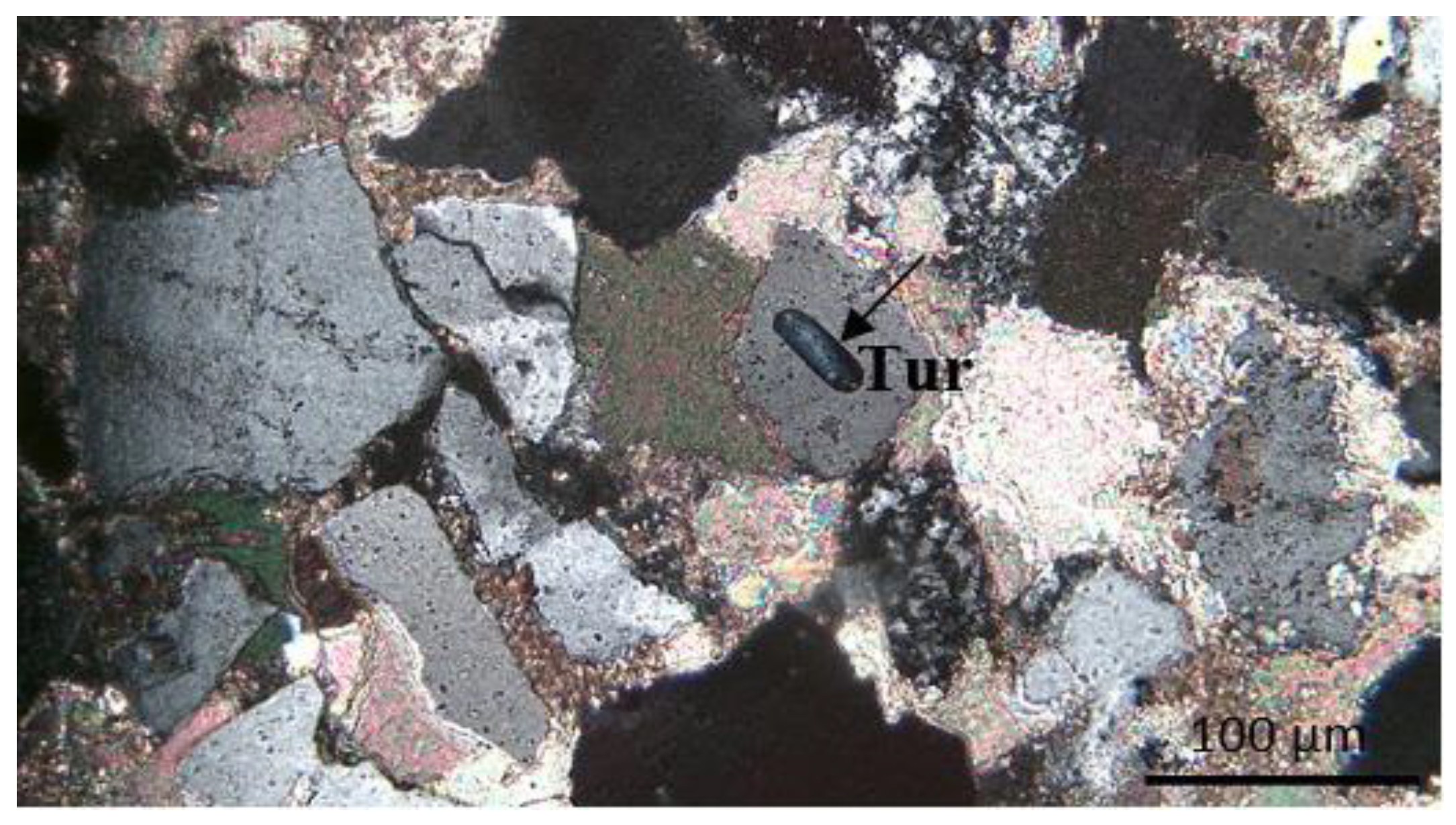

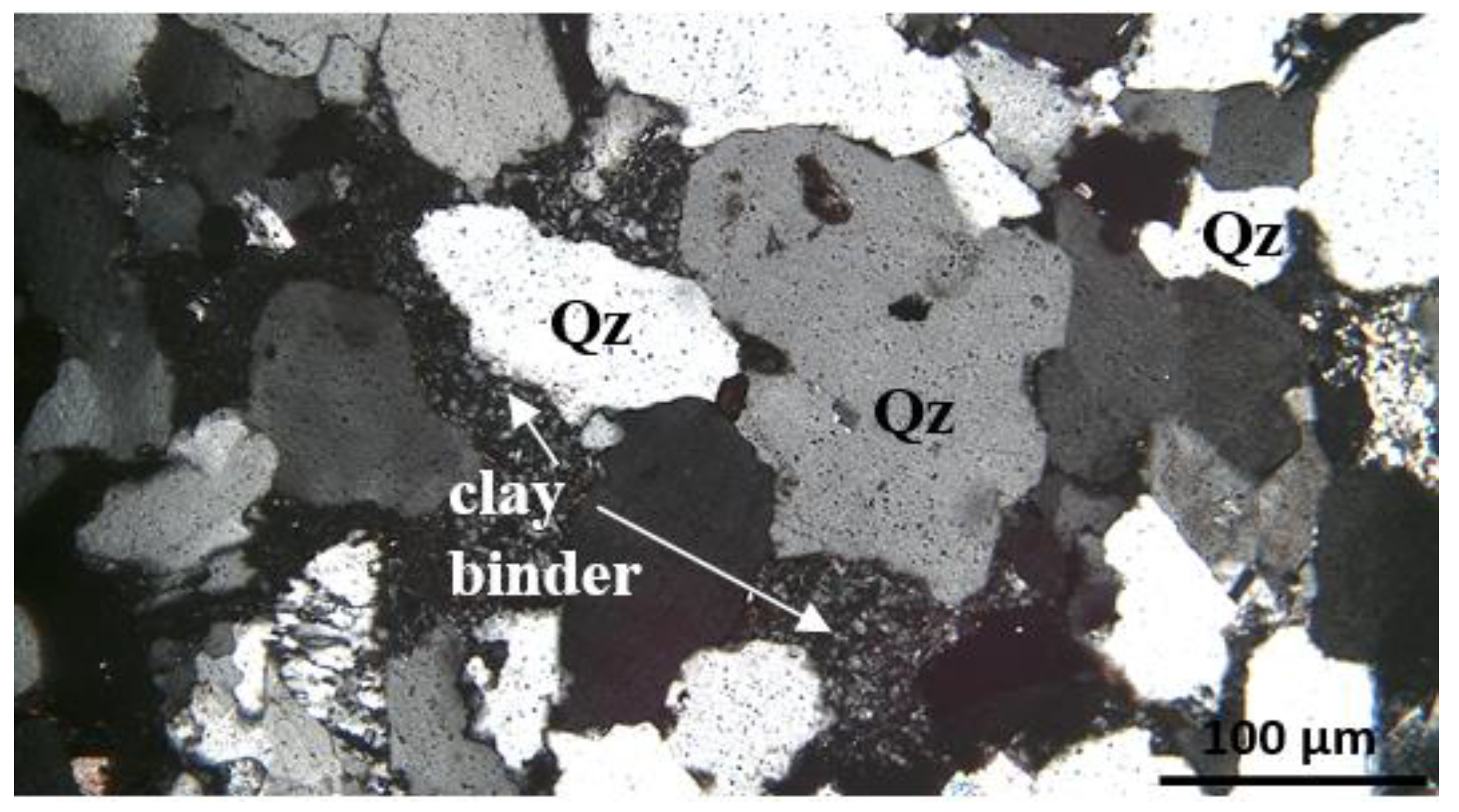

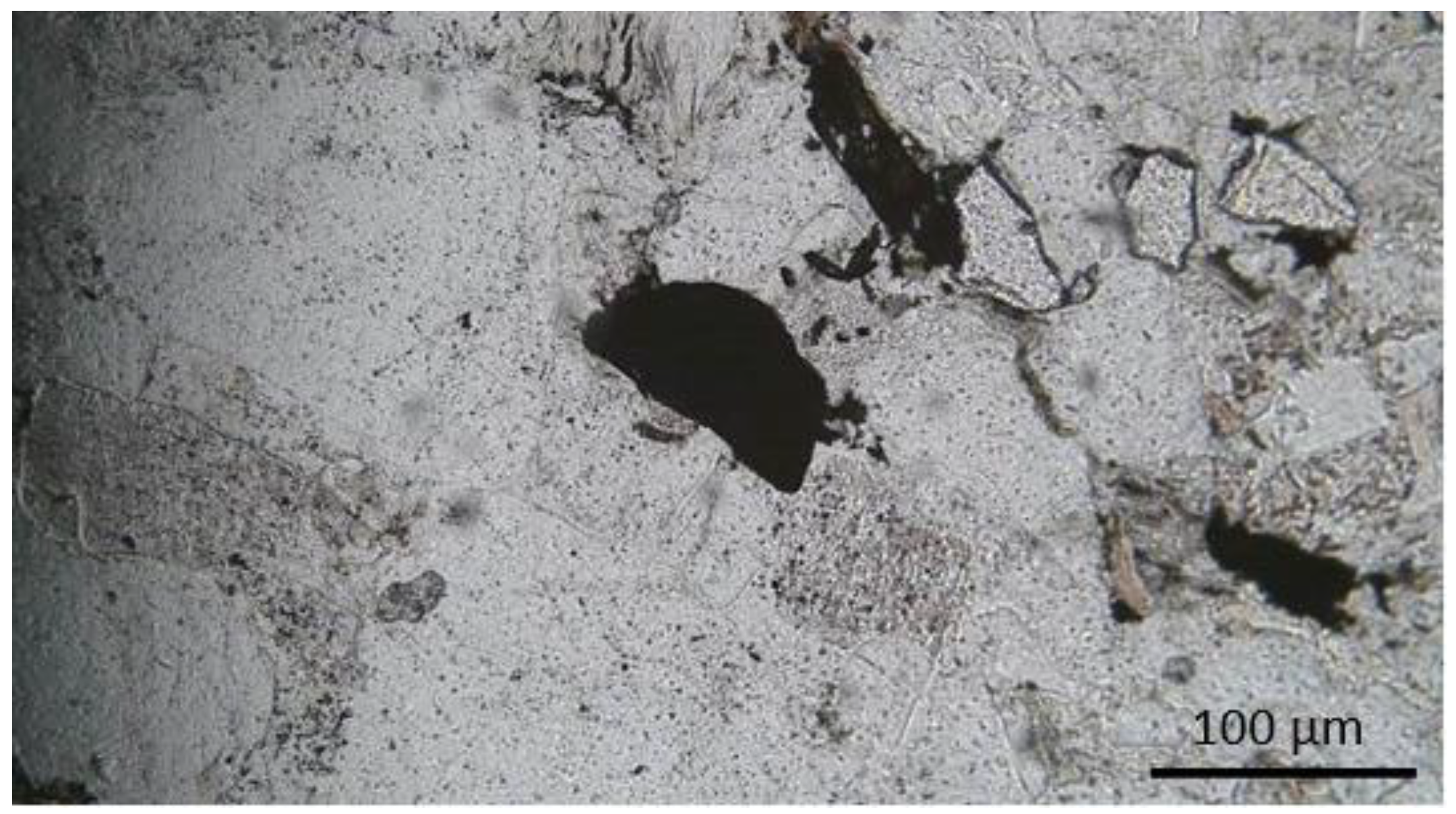

4.1. Mineralogical and Petrographic Characteristics of Sandstones

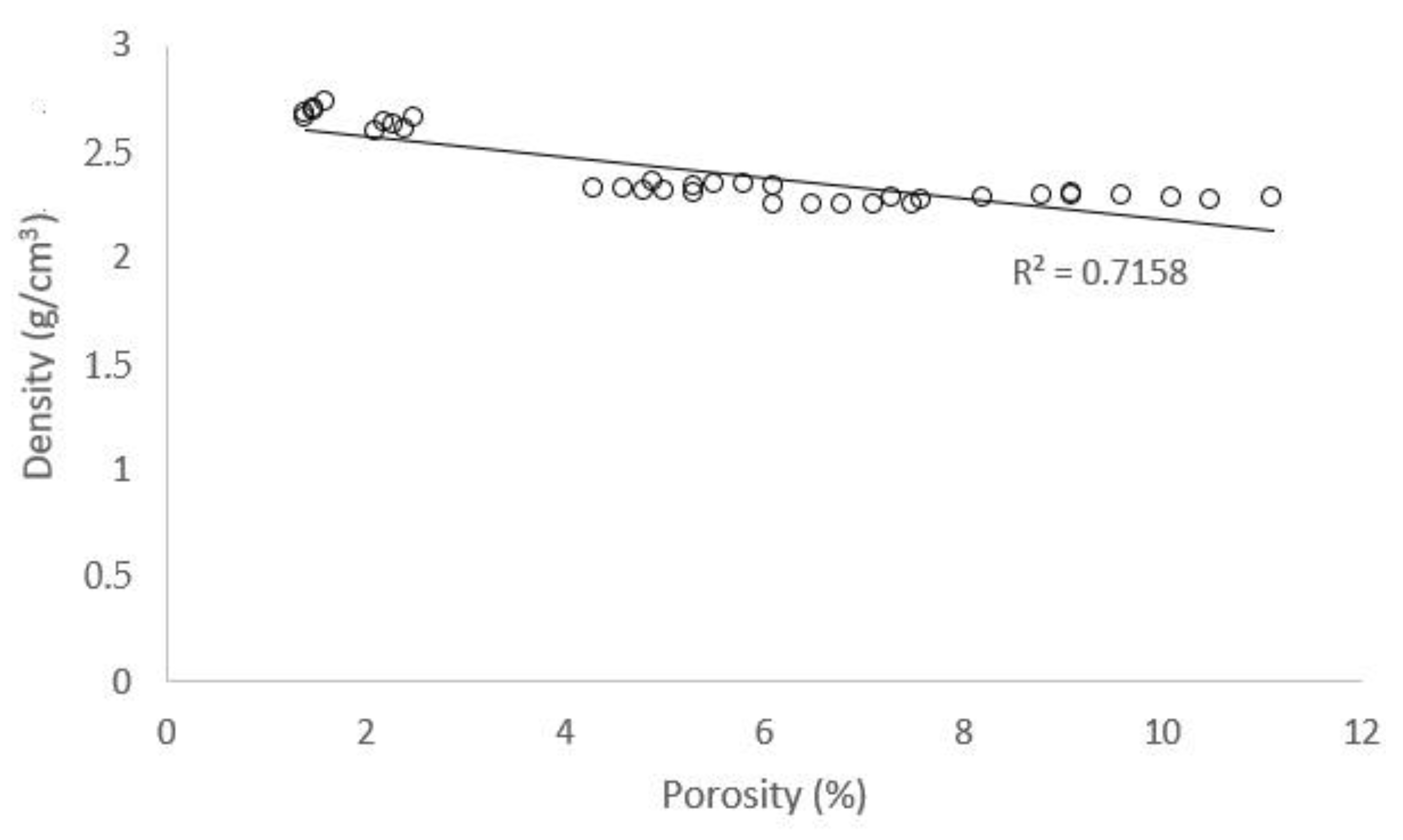

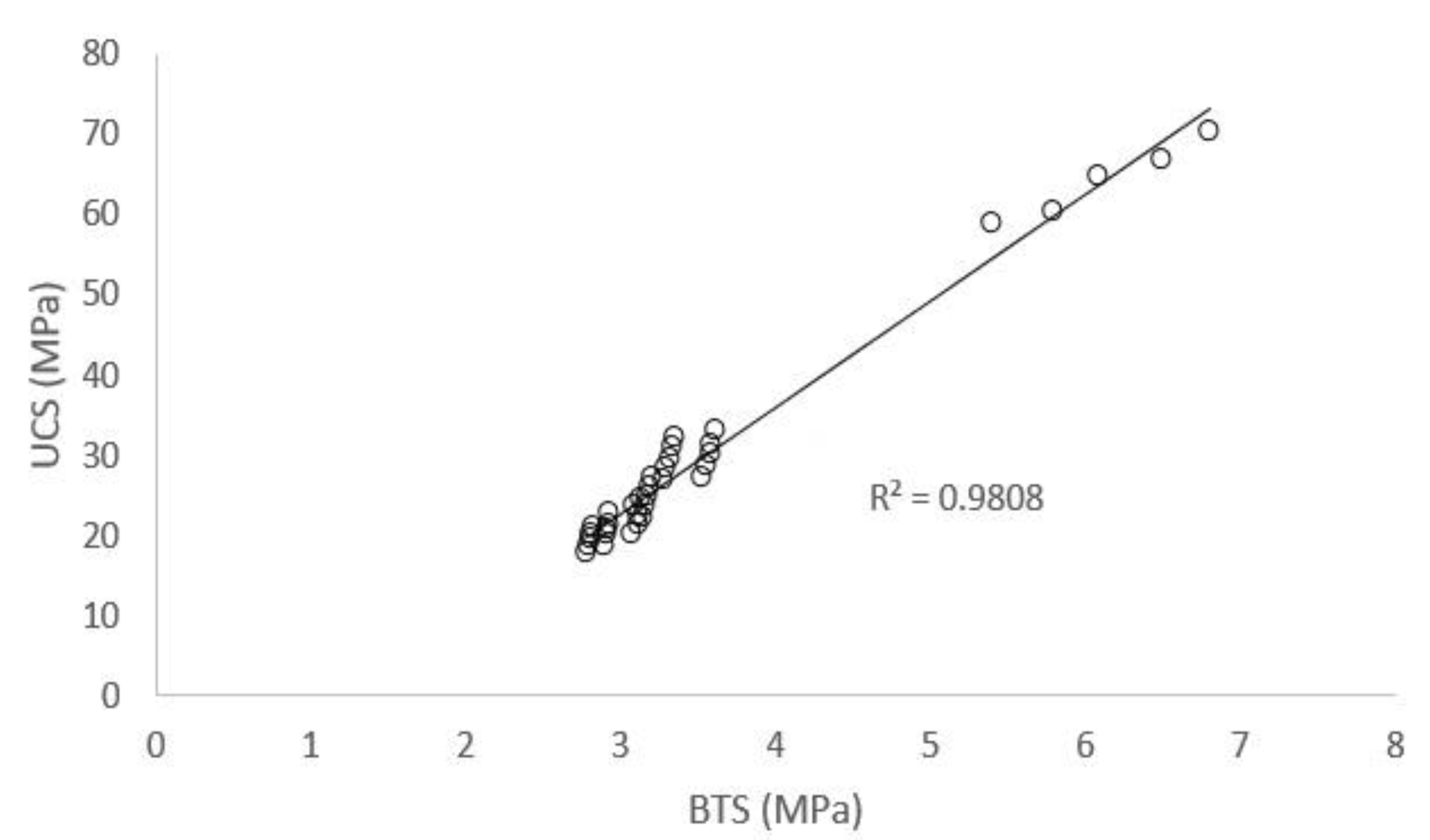

4.2. Characteristics of Physical and Mechanical Properties of Sandstones

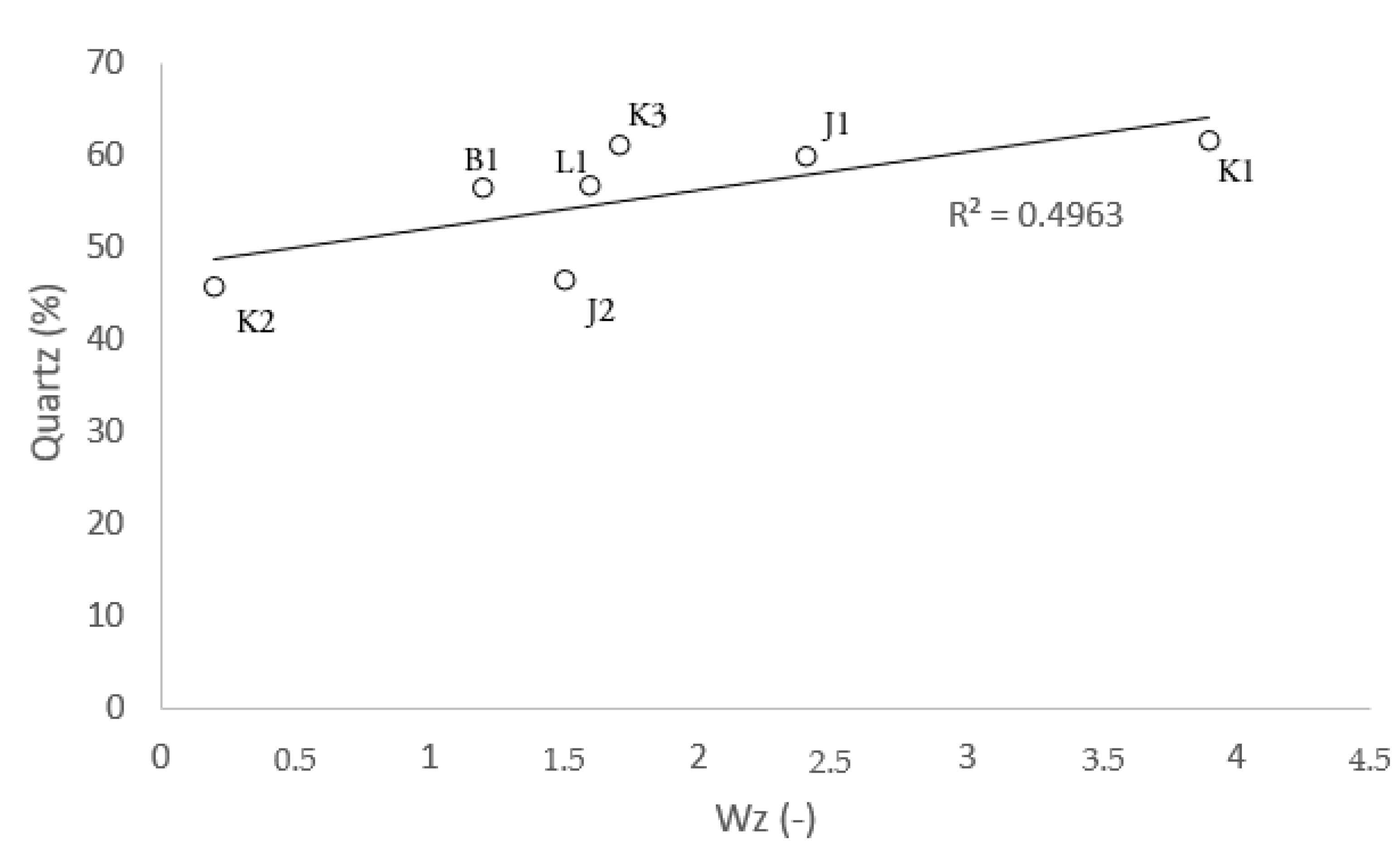

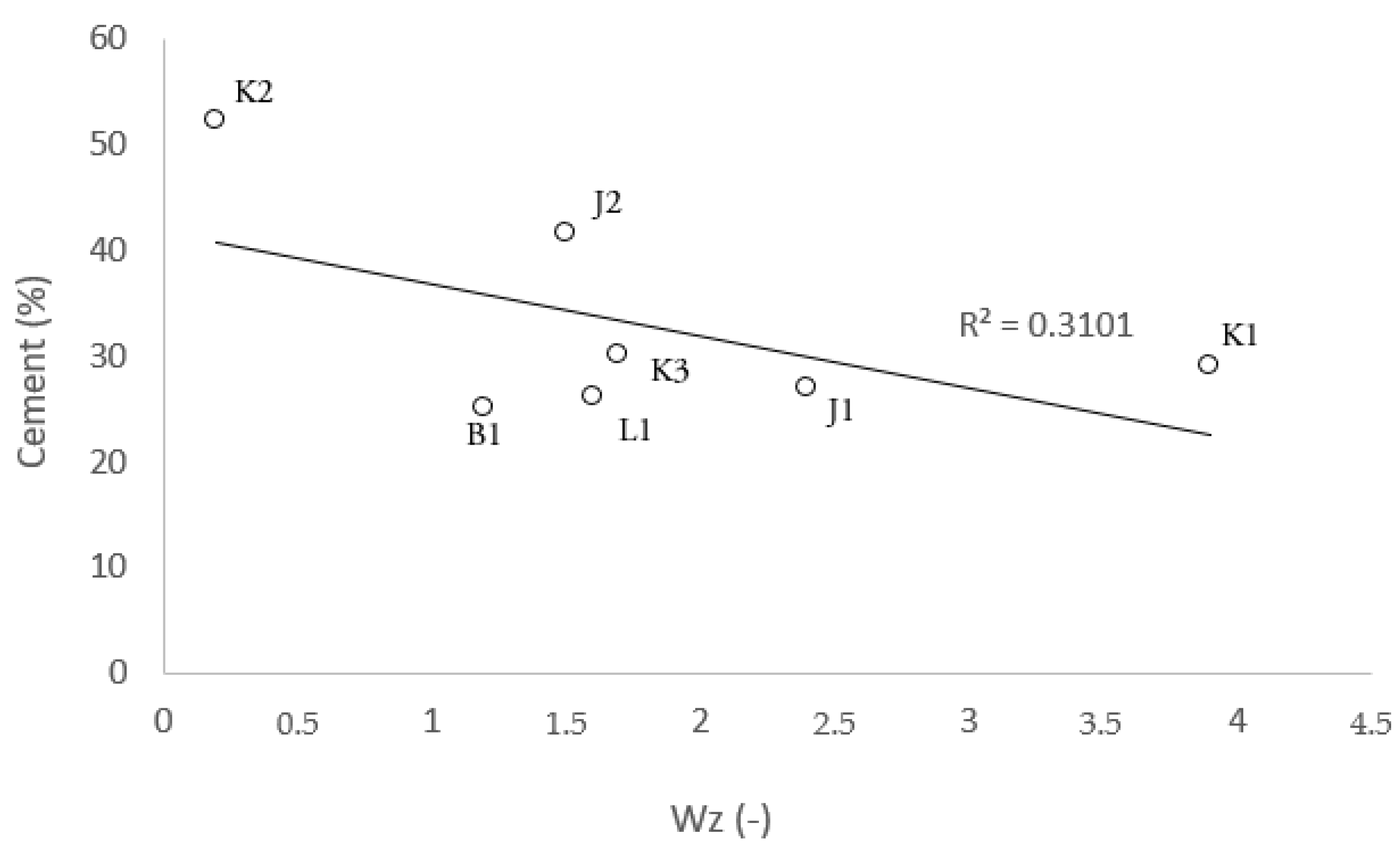

4.3. Influence of Petrographic Properties on Abrasive Properties of Tested Sandstones

5. Discussion

6. Conclusions

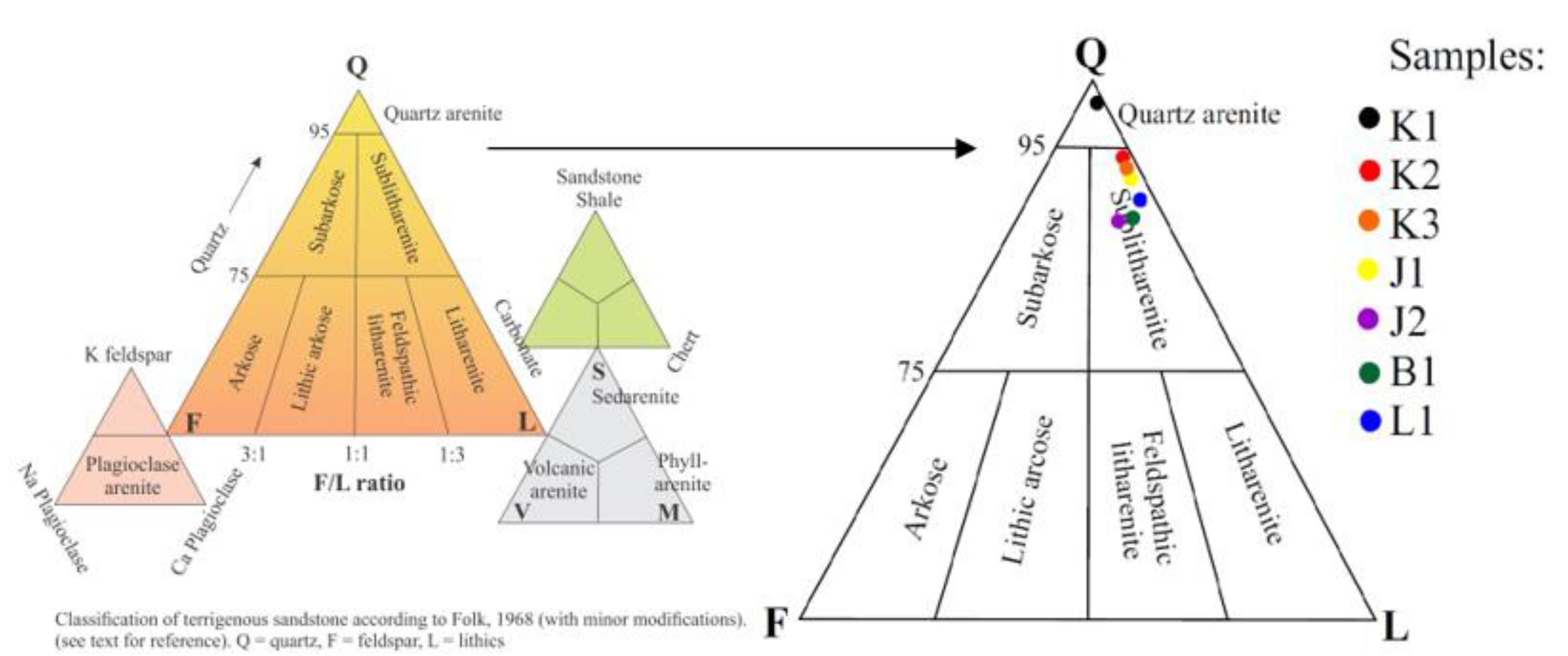

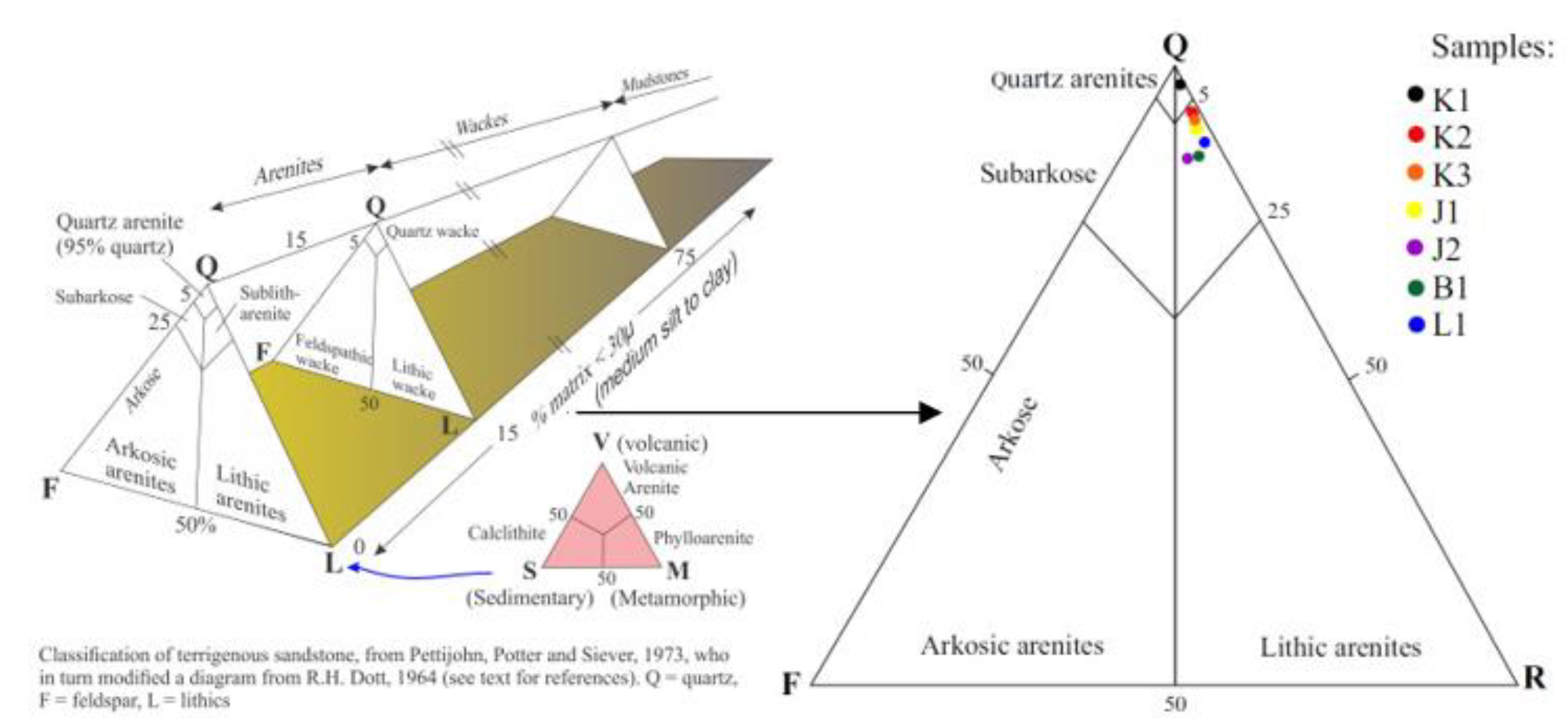

- According to the Folk classification, the sandstones were classified as sublitharenite, and according to the Dott–Pettijohn classification, sandstones were classified as subarcoses. The exception was sample K1, in which both classifications represented quartz arenite.

- Along with the decrease in the size of minerals and the increase in the amount of binder, the strength properties of sandstones increased.

- The determination of physical properties showed that the sandstones were diverse in porosity. The variable porosity was also associated with different water absorption values.

- Various engineering properties were found to characterize the sandstones. The determination of uniaxial compressive strength showed that most sandstones from the regions of Upper Silesia were characterized as rocks of low strength. Only the J2 sandstone was classified as a rock with medium strength.

- The abrasive properties of the sandstones were affected by their different grain structures. The sandstones were found to contain a relatively significant content of quartz of varying grains size from 0.1 to 1 mm, and they were also characterized by a high content of crumb material and a low binder content.

- The insignificant abrasivity of one of the sandstone samples was directly related to its fine-grained rock structure. It was also found that this type of sandstone was characterized by a lower share of crumb material concerning the binder content, which directly impacted its low porosity and water absorption.

- The rock workability was found to depend on the quartz percentage (more quartz grains lead to more difficulty in cutting), strength properties, and rock abrasivity (the higher the compressive strength and the value of the abrasivity index Wz, the more difficult it is to cut a rock).

- The rock properties were found to significantly influence the selection of the cutting tool because these properties are the main causes of tool wear during mining. For harder rocks, better quality tools should be selected, with special focus on the proper protection of their working parts (e.g., wear-resistant coatings and hard facing).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bartkowska, I. Program for the Hard Coal Mining Sector in Poland Ministry of Energy, Warsaw 2019, Poland. Available online: https://www.gov.pl/web/aktywa-panstwowe/program-dla-sektora-gornictwa-wegla-kamiennego-w-polsce (accessed on 15 February 2022).

- Kotwica, K. Atypical and innovative tool, holder and mining head designed for roadheaders used to tunnel and gallery drilling in hard rock. Tunn. Undergr. Space Technol. 2018, 82, 493–503. [Google Scholar] [CrossRef]

- Mucha, K. The new method for assessing rock abrasivity in terms of wear of conical picks. New Trends Prod. Eng. 2019, 2, 186–194. [Google Scholar] [CrossRef] [Green Version]

- Tiryaki, B.; Dikmen, A. Effects of Rock Properties on Specific Cutting Energy in Linear Cutting of Sandstones by Picks. Rock Mech. Rock Eng. 2005, 39, 89–120. [Google Scholar] [CrossRef]

- Cantisani, E.; Garzonio, C.; Ricci, M.; Vettori, S. Relationships between the petrographical, physical and mechanical properties of some Italian sandstones. Int. J. Rock Mech. Min. Sci. 2013, 60, 321–332. [Google Scholar] [CrossRef]

- Hobler, M. Badania Fizykomechanicznych Własności Skał; Państwowe Wydawnictwo Naukowe: Warszaw, Poland, 1977. [Google Scholar]

- Cobanoglu, I.; Celik, S.B.; Alkaya, D. Correlation between “Wide wheel abrasion (capon)” and “Bohme abrasion” test results for some carbonate rocks. Sci. Res. Essays 2010, 5, 3398–3404. [Google Scholar]

- Hydzik-Wiśniewska, J.; Bednarek, Ł. Statistical analysis of mechanical properties on the example of aggregates of Carpathian sandstones. Stud. Geotech. Mech. 2020, 42, 366–375. [Google Scholar] [CrossRef]

- Plinninger, R.J.; Restner, U. Abrasivity testing, Quo Vadis?—A commented overview of abrasivity testing methods. Geomech. Tunn. 2008, 1, 61–70. [Google Scholar] [CrossRef]

- Plinninger, R.; Käsling, H.; Thuro, K.; Spaun, G. Testing conditions and geomechanical properties influencing the CERCHAR abrasiveness index (CAI) value. Int. J. Rock Mech. Min. Sci. 2003, 40, 259–263. [Google Scholar] [CrossRef]

- Torrijo, F.J.; Garzón-Roca, J.; Company, J.; Cobos, G. Estimation of Cerchar abrasivity index of andesitic rocks in Ecuador from chemical compounds and petrographical properties using regression analyses. Bull. Eng. Geol. Environ. 2018, 78, 2331–2344. [Google Scholar] [CrossRef]

- Mucha, K. Ściernośćskał w Aspekcie Prognozowania Zużycia Noży Kombajnowych (Rock Abrasivity in Terms of Forecasting the Abrasive Wear of Cutting Picks). Ph. D. Thesis, AGH University of Science and Technology, Kraków, Poland, 2019. [Google Scholar]

- Käsling, H.; Thuro, K. Determining Abrasivity of Rock in the Laboratory. Engineering Geology. Technische Universität München, Germany 2010, 1973–1980. Available online: https://www.researchgate.net/profile/Kurosch-Thuro/publication/265206827_Determining_rock_abrasivity_in_the_laboratory/links/559f8bf408ae424c1e6a6dd9/Determining-rock-abrasivity-in-the-laboratory.pdf (accessed on 12 February 2022).

- Karaca, Z.; Yılmaz, N.G.; Goktan, R.M. Considerations on the European Standard EN 14157 Test Methods: Abrasion Resistance of Natural Stones Used for Flooring in Buildings. Rock Mech. Rock Eng. 2011, 45, 103–111. [Google Scholar] [CrossRef]

- Bukowska, M. The rockbursts in the Upper Silesian Coal Basin in Poland. J. Min. Sci. 2012, 48, 445–456. [Google Scholar] [CrossRef]

- Cabała, J.; Ćmiel, S.R.; Idziak, A.F. Environmental impact of mining activity in the Upper Silesian Coal Basin. Geol. Belg. 2004, 7, 225–230. [Google Scholar]

- He, M.; Zhang, Z.; Zhu, J.; Li, N. Correlation Between the Constant mi of Hoek–Brown Criterion and Porosity of Intact Rock. Rock Mech. Rock Eng. 2021, 55, 923–936. [Google Scholar] [CrossRef]

- Mucha, K.; Krauze, K. Planning experiment for laboratory tests on rock abrasivity. Min. Inform. Autom. Electr. Eng. 2018, 3, 535. [Google Scholar] [CrossRef]

- Karaman, K.; Cihangir, F.; Ercikdi, B.; Kesimal, A.; Demirel, S. Utilization of the Brazilian test for estimating the uniaxial compressive strength and shear strength parameters. J. South. Afr. Inst. Min. Met. 2015, 115, 185–192. [Google Scholar] [CrossRef]

- Gong, F.; Zhang, L.; Wang, S. Loading Rate Effect of Rock Material with the Direct Tensile and Three Brazilian Disc Tests. Adv. Civ. Eng. 2019, 2019, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Jonczy, I.; Borówka, B. Wykształcenie litologiczne warstw orzeskich na południowym skrzydle siodła głównego GZW. PrzeglądGórniczy 2015, 71, 52–55. [Google Scholar]

- Jonczy, I.; Borówka, B. Characteristics of Near-Surface Part of the Orzesze Beds in the Region of the Main Saddle in View of Weathering Processes. Gospod. Surowcami Miner. 2016, 32, 111–124. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.; Parsons, I. Diffusion-controlled and replacement microtextures in alkali feldspars from two pegmatites: Perth, Ontario and Keystone, South Dakota. Miner. Mag. 2015, 79, 1711–1735. [Google Scholar] [CrossRef] [Green Version]

- Garzanti, E. Petrographic classification of sand and sandstone. Earth Sci. Rev. 2018, 192, 545–563. [Google Scholar] [CrossRef]

- Geological Digressions. Available online: https://www.geological-digressions.com/classification-of-sandstones (accessed on 12 February 2022).

- West, G. A relation between abrasiveness and quartz content for some Coal Measures sediments. Geotech. Geol. Eng. 1986, 4, 73–78. [Google Scholar] [CrossRef]

- Yaralı, O.; Yaşar, E.; Bacak, G.; Ranjith, P. A study of rock abrasivity and tool wear in Coal Measures Rocks. Int. J. Coal Geol. 2008, 74, 53–66. [Google Scholar] [CrossRef]

- Nazir, R.; Momeni, E.; Armaghani, A.J.; Amin, M. Correlation between unconfined compressive strength and indirect tensile strength of limestone rock samples. EJGE 2013, 18, 1737–1746. [Google Scholar]

- Ribeiro, P.C.P.D.S.; Oliveira, M.M.; Nelson, P.P. Correlation Between Uniaxial Compressive Strength and Brazilian Tensile Strength Using Different Rock Types. In Proceedings of the ISRM VII Brazilian Symposium on Rock Mechanics-SBMR 2016, Belo Horizonte, Minas Gerais, Brazil, 19 October 2016. [Google Scholar] [CrossRef]

- Ukaszewski, P. Development of fracture processes in Silesian Carboniferous sandstones. Geol. Q. 2003, 47, 29–38. [Google Scholar]

- Karman, K.; Kesimal, A. Evaluation of the influence of porosity on the engineering properties of rocks form the Eastern Black Sea Region: NE Turkey. Arab. J. Geosci. 2015, 8, 557–564. [Google Scholar] [CrossRef]

- Abu Bakar, M.; Majeed, Y.; Rostami, J. Influence of moisture content on the LCPC test results and its implications on tool wear in mechanized tunneling. Tunn. Undergr. Space Technol. 2018, 81, 165–175. [Google Scholar] [CrossRef]

- Bołoz, Ł. Directions for increasing conical picks’ durability. New Trends Prod. Eng. 2019, 2, 277–286. [Google Scholar] [CrossRef] [Green Version]

- Krauze, K.; Bołoz, Ł.; Wydro, T.; Mucha, K. Durability testing of tangential-rotary picks made of different materials. Min. Inform. Autom. Electr. Eng. 2017, 1, 529. [Google Scholar] [CrossRef]

- Krzysztof, K.; Piotr, M. Methods of Mechanical Mining of Compact-Rock—A Comparison of Efficiency and Energy Consumption. Energies 2019, 12, 3562. [Google Scholar] [CrossRef] [Green Version]

| Mineral | Content of Minerals [%] | |||||||

|---|---|---|---|---|---|---|---|---|

| No of Sample | ||||||||

| K1 | K2 | K3 | J1 | J2 | B1 | L1 | ||

| Framework grains | Quartz | 61.5 | 45.7 | 61.3 | 60.0 | 46.4 | 56.3 | 56.6 |

| Feldspars | 2.0 | 1.0 | 4.5 | 3.5 | 3.4 | 2.1 | 5.2 | |

| Muscovite | 6.7 | - | 2.6 | 4.4 | 3.0 | 4.2 | 4.1 | |

| Biotite | - | - | 1.3 | 5.1 | 5.7 | 9.4 | 8.1 | |

| Lithic fragments | - | - | - | - | - | 3.0 | - | |

| Heavy minerals | 0.7 | 1.0 | - | - | - | - | - | |

| Cement | Microcrystalline quartz | 5.2 | 2.9 | 7.7 | 15.3 | 6.9 | 9.3 | 8.1 |

| Clay minerals | 14.2 | 3.8 | 11.6 | 6.5 | 6.6 | 6.3 | 15.6 | |

| Carbonates | 6.7 | 45.6 | 9.7 | 2.2 | 28.0 | 4.2 | 2.3 | |

| Iron compounds | - | - | 1.3 | 3.0 | - | - | - | |

| Carbonaceous matter | 3.00 | - | - | - | - | 5.2 | - | |

| Σ | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | |

| Component | Content [%] | ||||||

|---|---|---|---|---|---|---|---|

| No of Sample | |||||||

| K1 | K2 | K3 | J1 | J2 | B1 | L1 | |

| Framework grains | 70.9 | 47.7 | 69.7 | 73 | 58.5 | 75 | 74 |

| Cement | 29.1 | 52.3 | 30.3 | 27 | 41.5 | 25 | 26 |

| Σ | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Property | No of Sample | ||||||

|---|---|---|---|---|---|---|---|

| K1 | K2 | K3 | J1 | J2 | B1 | L1 | |

| γs [g/cm3] | 2.34 ± 0.01 | 2.69 ± 0.04 | 2.31 ± 0.01 | 2.25 ± 0.00 | 2.62 ± 0.03 | 2.28 ± 0.01 | 2.28 ± 0.01 |

| Pw [%] | 5.5 ± 0.6 | 1.5 ± 0.1 | 4.8 ± 0.5 | 6.8 ± 0.7 | 2.3 ± 0.2 | 10.1 ± 1.0 | 8.2 ± 0.9 |

| Ns [%] | 2.12 ± 0.48 | 0.58 ± 0.05 | 1.85 ± 0.20 | 2.62 ± 0.61 | 0.88 ± 0.07 | 3.88 ± 0.90 | 3.16 ± 0.72 |

| Property | No of Sample | ||||||

|---|---|---|---|---|---|---|---|

| K1 | K2 | K3 | J1 | J2 | B1 | L1 | |

| UCS [MPa] | 29.4 ± 2.7 | 24.7 ± 2.5 | 19.4 ± 1.6 | 22.4 ± 2.2 | 64.6 ± 5.8 | 30.1 ± 2.8 | 20.8 ± 2.0 |

| BTS [MPa] | 3.32 ± 0.04 | 3.18 ± 0.03 | 2.81 ± 0.02 | 3.11 ± 0.03 | 6.10 ± 0.7 | 3.58 ± 0.04 | 2.92 ± 0.02 |

| Wz [-] | 3.9 ± 0.3 | 0.2 ± 0.0 | 1.7 ± 0.2 | 2.4 ± 0.2 | 1.5 ± 0.1 | 1.2 ± 0.1 | 1.6 ± 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jonczy, I.; Mucha, K. Relationships between the Petrographic and Abrasive Properties of Sandstones in the Aspect of Their Cutting. Energies 2022, 15, 2692. https://doi.org/10.3390/en15072692

Jonczy I, Mucha K. Relationships between the Petrographic and Abrasive Properties of Sandstones in the Aspect of Their Cutting. Energies. 2022; 15(7):2692. https://doi.org/10.3390/en15072692

Chicago/Turabian StyleJonczy, Iwona, and Kamil Mucha. 2022. "Relationships between the Petrographic and Abrasive Properties of Sandstones in the Aspect of Their Cutting" Energies 15, no. 7: 2692. https://doi.org/10.3390/en15072692

APA StyleJonczy, I., & Mucha, K. (2022). Relationships between the Petrographic and Abrasive Properties of Sandstones in the Aspect of Their Cutting. Energies, 15(7), 2692. https://doi.org/10.3390/en15072692