3.1. Types of Algorithm

The fault diagnosis with the use of the

or

is conducted in two ways [

10]:

Column reasoning, also known as signature-based reasoning [

9,

11], or parallel reasoning [

13];

Row reasoning, also known as reasoning based on symptoms [

24] or sequential reasoning [

13].

The diagnostic reasoning algorithms based on columns and rows can be used in the following variants:

Using binary or trivalent diagnostic signals, which correspond to the use of the or , respectively;

Using knowledge of the Elementary Sequence condition () or without that knowledge.

Thus, the following methods can be specified:

All of the methods listed above relate to Passive Fault Diagnosis (PFD) using only signals recorded during the normal operation of the diagnosed process. In the last few years, Active Fault Diagnosis methods (AFD) have also been developed, where deliberate test stimulations have been used [

31,

32].

The practical usability of these methods is due to the fact that they use models representing the state of the process without the faults’ influence. It is not necessary to know the quantitative effect of the faults on residuals. Depending on the method, only binary knowledge of the sensitivity (or absence) of diagnostic signals to the faults () is used or, additionally, the sign of this effect () is considered. In addition, heuristic knowledge of elementary symptom sequences for particular faults can be used.

3.2. Assumptions of the Reasoning Algorithms

In the first studies in the field of FDI, an assumption was made that only single faults occur. However, this assumption is not valid for complex systems. In the DX approach, there is no limit to the number of possible simultaneous faults. Therefore, this assumption was not taken into account in the comparative studies.

The following common assumptions are made in diagnostic inference based on columns and rows:

Assumption 1. Activation of a symptom (the value of the diagnostic signal is not zero) indicates the occurrence of at least one fault to which the diagnostic signal is sensitive.

The above assumption is adopted both in the FDI and DX approaches [

9,

10,

11] and, therefore, applies to all cases of reasoning based on columns or rows. In a DX approach where process components are considered, a difference between a valid model and observations must mean that the component is damaged.

Assumption 2. After their activation, all symptoms of the faults persist throughout the fault isolation process.

The other assumptions for reasoning based on columns and rows are not the same. In the case of signature-based reasoning, the following assumption is used:

Assumption 3. The zero value of the diagnostic signal means that none of the faults to which the signal is sensitive have occurred.

This assumption is better known as the

exoneration assumption [

9]. Two variants are distinguished, for single and multiple faults:

Assumption 3a. Single fault exoneration assumption, which leads to the elimination from the diagnosis of such faults, for which sensitive diagnostic signals take zero values (ARR is satisfied).

Assumption 3b. Multi-fault exoneration assumption, which leads to the exclusion from the diagnosis the states for which sensitive diagnostic signals take zero values.

Assumption 3b is a generalisation of Assumption 3a.

In the case of multiple faults, Assumption 3 means the use of an additional assumption related to the lack of the possibility of mutual compensation of the impact of faults on the value of residuals.

Assumption 4. It is not possible to compensate the effect of the faults on the values of binary-evaluated residuals.

The above assumption is related to multiple faults and is made in the case of binary diagnostic signals and reasoning based on columns. This assumption is not used in the algorithms of diagnosing based on columns, with a three-value residual evaluation [

19]. The DX approach also accepts the possibility of the effect of the compensation of the fault effect on residuals [

15].

In reasoning based on signatures, if the uncertainty of the symptoms is not taken into account, then another assumption is made:

Assumption 5. All theoretical fault symptoms must occur (symptom completeness).

This assumption (made in FDI approaches) is not used in the DX approach, where symptoms can be incomplete. This is justified as follows [

9]: if the model is satisfied in a certain context, this means that it operates correctly in this context. In another context, it may not necessarily work correctly.

Assumption 6. All symptoms must be activated simultaneously.

This assumption is used tacitly in some column-based reasoning approaches. In fact, there are always many delays in symptoms, so the reasoning algorithm has to deal with this problem.

In [

5], a comparison of inference algorithms based on rows was carried out. This paper focused on the analysis of reasoning methods based on columns, for the same diagnosed process and the same set of models used for the generation of residuals. The aim was to compile and compare the examined indicators of the quality of diagnosis for all the above-mentioned algorithms.

3.3. Algorithm Properties

The differences in reasoning algorithms results in a differentiation of their properties. Some properties are tested and widely known; others require analysis and research. The following known features of column-based and row-based reasoning algorithms are initially characterised:

- 1.

Fault distinguishability:

The three-value assessment of residuals provides a higher distinguishability of faults compared to the

, as shown in [

14,

17,

18,

21]. The use of knowledge about the sequence of symptoms also leads to an increase in distinguishability [

5,

10,

16]. The increase is greater the more complete is the knowledge about the relationships between symptom delays.

Low fault distinguishability in the case of the DX method (as well as other methods of reasoning based on rows) results not only from the binary evaluation of the residuals, but also from the abandonment of the exoneration assumption. Only conflicts that have arisen are taken into account during the reasoning. The lack of other conflicts does not result in excluding the elements belonging to them from the possible faults.

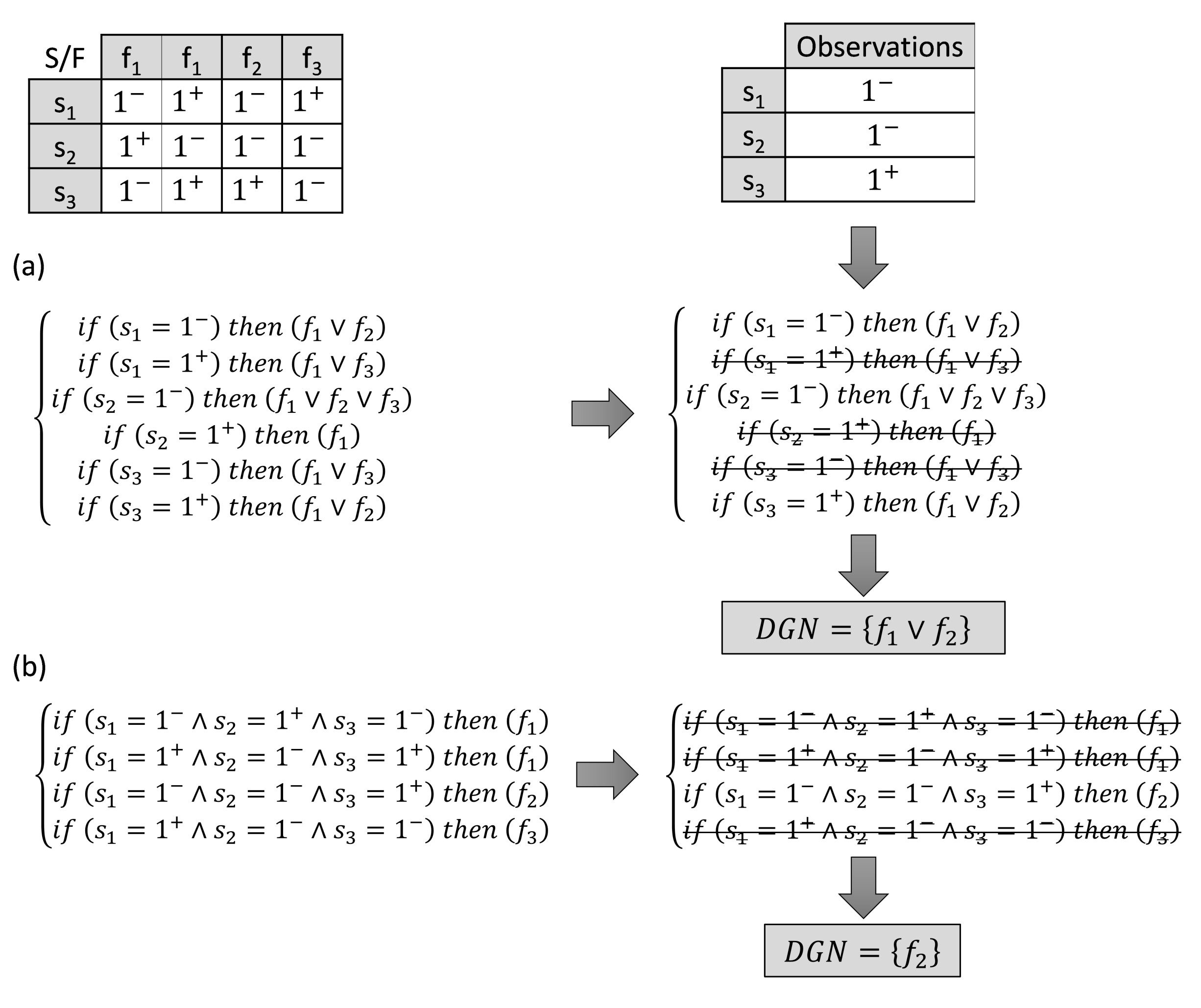

Signature-based reasoning provides higher fault distinguishability than row-based reasoning. The main reason for this is the use of the

exoneration assumption, but not only that. It can be shown that even in the absence of zeros in the signatures, reasoning based on columns can provide higher distinguishability. This is illustrated by the example shown in

Figure 1.

The reason for this is the use of additional information on the mutual relations of symptoms in simple signatures (

Figure 1), which cannot be derived directly from the analysis of the rules corresponding to the FIS rows, as well as from columns in the form of complex signatures (

13). Such a situation may occur only in the case of a multivalued residual assessment. When replacing a complex signature with simple signatures, it often turns out that some combinations of diagnostic signal values are physically impossible. The number of real simple signatures is smaller than the theoretical number of different combinations of diagnostic signal values. In theory, as shown in

Section 5.2, eight simple signatures may appear for measurement faults

, but only two are physically possible. The elimination of physically impossible combinations can lead to increased fault distinguishability.

The above statements regarding the distinguishability of faults are qualitative. There are a few examples of studies in which the impact of various elements of diagnostic reasoning algorithms on the indices of fault distinguishability were quantified. They are necessary for a more precise understanding of the impact of the methods of diagnosing and the properties of the diagnosed process on the indicators of distinguishing faults/states of the process;

- 2.

Resistance to symptom delays:

The problem of unequal delays of fault symptoms is well known and was analysed in [

10,

16,

20,

22,

24,

25,

26,

27]. Disregarding the dynamics of symptom formation may lead to the generation of temporary false diagnoses [

10,

22]. This applies to reasoning methods based on columns in which both symptoms and zero values of diagnostic signals are taken into account. The final diagnosis is made only in the steady state of all residuals. In transient states, the temporary values of diagnostic signals may indicate other faults/states of the process than the real one. This is how temporary false diagnoses arise.

All algorithms of reasoning based on rows, in which only fault symptoms are analysed, are resistant to symptom delays in the sense that they do not generate temporary false diagnoses;

- 3.

Resistance to structural changes (set of variables):

The method of reasoning also affects the resistance of the diagnostic system to structural changes of the diagnosed process, e.g., changes of the set of correctly functioning measurements. Measurement devices can be faulty or temporarily disconnected for calibration purposes, etc. The above changes result in the variability of the set of calculated residuals. In addition, each indication of an existing fault requires the introduction of automatic changes to the diagnostic system to ensure its proper functioning with a new process state. The set of active diagnostic signals should be reduced by those signals that are sensitive to the detected fault.

During the operation of the diagnostic system, the generated set of residuals changes. This leads to the necessity to change the fault signatures accordingly. Without such changes, column-based reasoning is not resistant to the structural changes of the diagnosed process. Moreover, in the case of large-scale systems, where the number of calculated residuals is very large, the signatures corresponding to the columns of the binary diagnostic matrix or information system are inconvenient, due to their large size.

A resistant method of notation of the diagnostic relationship in terms of possible changes in the structure of the object is the rules of the form of (

14) and (

15), in which particular symptoms are assigned to subsets of faults causing these symptoms. This relationship does not change. In the case of changes in the structure of the process or as a result of previous diagnoses, such a rule may be temporarily eliminated from the set of active rules, but its form remains unchanged. Moreover, such a rule has a compact form, also because the number of possible faults indicated in the conclusion is not large, in the case of using partial models;

- 4.

Resistance to compensation effect:

The compensation effect occurs in the case of multiple faults, when the influences of two or more faults compensate for each other and the residual value does not exceed the decision threshold. This phenomenon can occur only when the signs of the fault influence on the residual are opposite.

Reasoning based on columns with binary diagnostic signals is not immune to the compensation effect. The DX method assumes the possibility of compensation of the fault influence on the residual; however, the signs of fault interaction on the residuals are not taken into account. Therefore, the property of correct reasoning commonly attributed to this method in situations of fault compensation sometimes fails. Potentially incorrect diagnoses, inconsistent with the existing state, may be generated, which was demonstrated in [

19]. It was shown that diagnosing on the basis of the three-value residual assessment was an effective method of eliminating reasoning errors caused by compensation effects. The rules for determining signatures for states with double faults are given;

- 5.

Possibility of making diagnoses inconsistent with the actual state:

The binary assessment of the residual values/conflicts in the FDI and DX approaches may be the cause of incorrect diagnoses, not necessarily related to the compensation effect [

19]. Logically correct, but physically impossible diagnoses arise even in the absence of modelling errors, disturbances, and measurement noise. The reason for this is the loss of information about the residuum sign. The use of the three-value residual assessment and the principle of determining signatures for states with double faults given in the above work eliminate such diagnoses.