Thermal Investigations of Hemispherical Shell Vapor Chamber Heat Sink

Abstract

:1. Introduction

2. Experiment

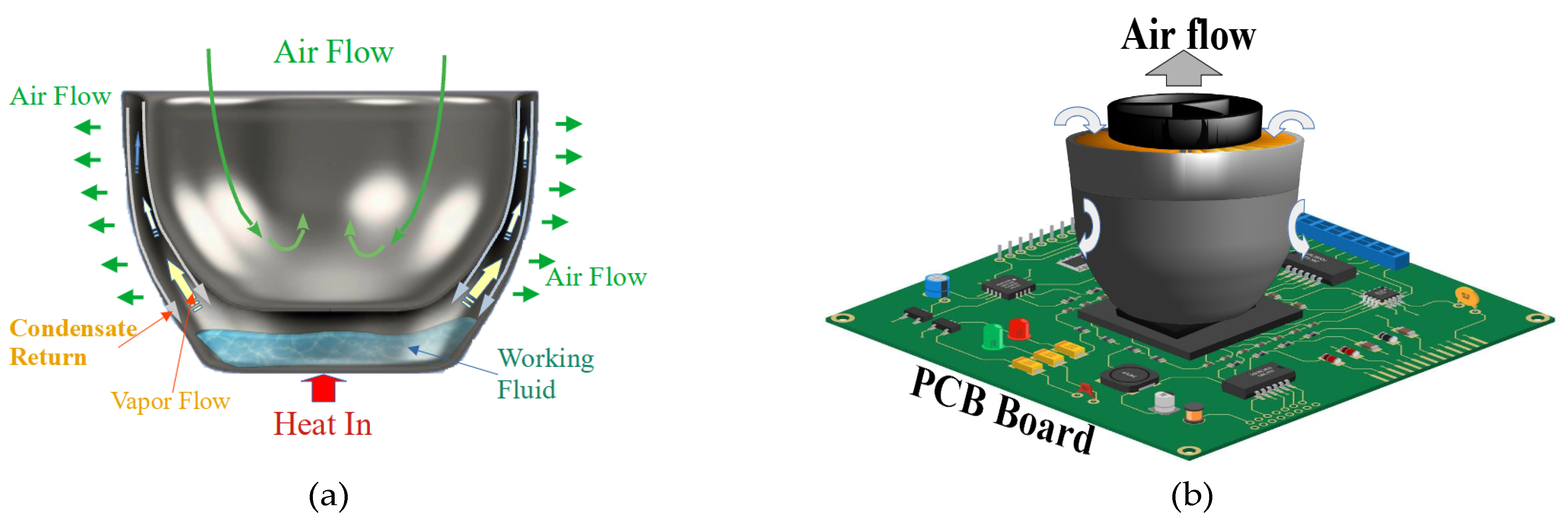

2.1. Main Assembly of the Hemispherical Shell-Shaped Vapor Chamber

2.2. Uncertainty Analysis

2.3. Experimental Procedure

2.4. Data Reduction

3. One-Dimensional Simulation Model Based on the Resistance Network

3.1. Thermal Resistance Network

3.2. Operating Limit

4. Results and Discussion

4.1. Experimental Results

- Effect of the Quantity of the Working Fluid, VF

- Effect of Air Flow Velocity, vair

- Effect of the Heat Load

- Temperature profiles along the vapor flow

- Temperature profiles in different angular positions (A, B, and C lines)

- Effect of the Orientation

- Transient Temperature Variation

- Effect of Non-Condensable Gas

- Comparison with previous works in the literature

4.2. Model Validation of the Thermal Resistance Model

4.3. Numerical Method by CFD Analysis

- -

- Incompressible flow was assumed for all phases.

- -

- The vapor flowed in a turbulent manner.

- -

- The pressure in the inner space was about 25,000 Pa as a result of measuring using a vacuum gauge. Based on the measured pressure value and the experimental temperature data, the saturation temperature and operating pressure values were set to 338.15 K and 25041.6 Pa, respectively.

- -

- Components other than the heating and cooling section were insulated.

- -

4.3.1. Governing Equations and the Simulation Model

4.3.2. Mesh Sensitivity Analysis

4.3.3. CFD Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Area, | |

| Specific heat capacity, W/m2 | |

| Diameter, m | |

| Energy | |

| Generation of turbulence kinetic energy due to buoyancy | |

| Gravity, m/s2 | |

| Generation of turbulence kinetic energy owing to mean velocities | |

| Height of the vapor chamber, m | |

| Convective heat transfer coefficient, W/m2 °C | |

| Latent heat, kJ/kg | |

| Electric current, A | |

| Diffusion flux | |

| Thermal conductivity, | |

| Boltzmann constant as | |

| Effective thermal conductivity, °C | |

| Kn | Knudsen number, the ratio of the molecular mean free path length/a representative physical length, dimensionless quantity |

| L | Length, m |

| m | Length, m |

| M | Molar mass, kg/mol |

| Ma | Mach number, local velocity/sound speed, dimensionless quantity |

| Mass transfer, kg/s | |

| Mass transfer rate from the liquid to the vapor phase, kg/s | |

| Nu | Nusselt number, hD/k, dimensionless number |

| Average Nusselt number, hD/k, dimensionless number | |

| Pr | Prandtl number, μcp/k, dimensionless number |

| Static pressure, | |

| Capillary pressure, | |

| Heat transfer rate, W | |

| Thermal resistance, W/K | |

| Rayleigh number as , dimensionless number, Gr = (gβ(Twall −Tair)x3)/ν2 | |

| Reynolds number as , dimensionless number | |

| Interface radius of tube, m | |

| SIMPLE | Semi-Implicit Method for Pressure Linked Equations. |

| Energy source | |

| Volumetric heat source | |

| Static temperature, | |

| Saturated temperature, | |

| ∆TBT | Average temperature difference between the bottom and top surface of the HSVC |

| ∆Te | Overall temperature difference of the HSVC, T1-Tair of Figure 5 |

| WF | Working fluid |

| U | Uncertainty |

| Voltage, V | |

| VF | Volume fraction of the charged working fluid, (VWorking Fluid/VTotal Volume) × 100 |

| Ve | Evaporator volume (m3) |

| VHPHC | Total effective volume (m3) |

| VH,I+ | Dimensionless working fluid volume, VLP/Ve |

| VLP | Volume of the liquid pool (m3) |

| WF | Working fluid |

| x | Uncertainty variable |

| Term of the mass percentage | |

| Greek | |

| Volume fraction of the phase | |

| Absorption coefficient | |

| Kronecker delta | |

| Dissipation rate, | |

| Dissipation rate tensor | |

| Dynamic viscosity, | |

| Density, | |

| Surface tension coefficient, | |

| Stress tensor | |

| Specific heat ratio | |

| Subscripts | |

| a | Adiabatic |

| air | Air flow |

| base | Fin base |

| BT | Between bottom and top surfaces |

| cond | Condenser |

| cond_i | Condenser’s inner area |

| cond_o | Condenser’s outer area |

| c_i_surf | Condenser’s inner surface |

| c_i_w_e | Condenser’s inner wick |

| c_i_wall | Condenser’s inner wall |

| c_i_wick | Condenser’s inner wick |

| c_i_air | Condenser’s inner side air |

| c_o_air | Condenser’s outer side air |

| c_o_wall | Condenser’s outer wall |

| c_o_w_e | Condenser’s outer wick |

| c_o_wick | Condenser’s outer wick |

| c_o_surf | Condenser’s outer surface |

| cr | Critical |

| e | Evaporation, evaporator |

| e,e | Effective evaporator |

| e,c | Effective condenser |

| ev | Evaporator |

| ev_w_e | Evaporator wick effective |

| ev_wall | Evaporator wall |

| ev_Wick | Evaporator wick |

| f | Fluid |

| fin | Fin |

| g | Gas, vapor state |

| h | Heater, hot |

| i | Inner |

| l | Liquid |

| o | Outer |

| pad | Thermal pad |

| tot | Total |

| v | Vapor |

| Vapor | Vapor |

| VC | Vapor chamber |

| Wall | Vapor chamber wall |

References

- Lips, S.; Sartre, V.; Lefevre, F.; Khandekar, S.; Bonjour, J. Overview of Heat Pipe Studies during the Period 2010–2015. Interfacial Phenom. Heat Transf. 2016, 4, 33–53. [Google Scholar] [CrossRef]

- Blet, N.; Lips, S.; Sartre, V. Heats Pipes for Temperature Homogenization: A Literature Review. Appl. Ther. Eng. 2017, 118, 490–509. [Google Scholar] [CrossRef] [Green Version]

- Faghri, A. Review and Advances in Heat Pipe Science and Technology. J. Heat Transf. 2012, 134, 123001. [Google Scholar] [CrossRef]

- Mohamed, A. A Review: On the Heat Pipe and Its Applications. In Proceedings of the 4th International Conference on Energy Engineering Faculty of Energy Engineering, Aswan, Egypt, 26–28 December 2017. [Google Scholar]

- Jouhara, H.; Chauhan, A.; Nannou, T.; Almahmoud, S.; Delpech, B.; Wrobel, L.C. Heat Pipe Based Systems—Advances and Applications. Energy 2017, 128, 729–754. [Google Scholar] [CrossRef]

- Rhi, S.H.; Lee, K.B.; Chae, H.I. 3-Dimensional Radial Heat Sink. Korea Patent 10-2019-0133834, 25 October 2019. [Google Scholar]

- Han, S.; Yang, L.; Tian, Z.; Yuan, X.; Lu, H. Research on a Simplified Model of an Aluminum Vapor Chamber in a Heat Dissipation System. Entropy 2020, 22, 35. [Google Scholar] [CrossRef] [Green Version]

- Bose, J.; Ahammed, N.; Lazarus, G. Thermal Performance of a Vapor Chamber for Electronic Cooling Applications. J. Mech. Sci. Technol. 2017, 31, 1995–2003. [Google Scholar] [CrossRef]

- Tsai, M.C.; Kang, S.W.; Paiva, K. Experimental Studies of Thermal Resistance in a Vapor Chamber Heat Spreader. Appl. Ther. Eng. 2013, 56, 38–44. [Google Scholar] [CrossRef]

- Egbo, M. A Review of the Thermal Performance of Vapor Chambers and Heat Sinks: Critical Heat Flux, Thermal Resistances, and Surface Temperatures. Int. J. Heat Mass Transf. 2022, 183, 122108. [Google Scholar] [CrossRef]

- Mochizuki, M.; Nguyen, T. Review of Various Thin Heat Spreader Vapor Chamber Designs, Performance, Lifetime Reliability and Application. Front. Heat Mass Transf. 2019, 13, 12. [Google Scholar] [CrossRef]

- Bulut, M.; Kandlikar, S.G.; Sozbir, N. A Review of Vapor Chambers. Heat Transf. Eng. 2019, 40, 1551–1573. [Google Scholar] [CrossRef]

- Elnaggar, M.; Hatab, M.A.; Edwan, E. A Brief Review of Heat Sink, Heat Pipe, and Vapor Chamber as a Key Function of Thermal Solution for Electronic Devices. Eur. J. Eng. Technol. Res. 2020, 5, 1297–1300. [Google Scholar] [CrossRef]

- Faghri, A. Heat Pipe Science and Technology; Taylor and Francis: Washington, DC, USA, 1995. [Google Scholar]

- Zohuri, B. Heat Pipe Design and Technology: Modern Applications for Practical Thermal Management, 2nd ed.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Reay, D.A.; Kew, P.A.; McGlen, R.J. Heat Pipes Theory, Design and Applications, 6th ed.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 207–225. [Google Scholar]

- Hada, S.S.; Jain, P.K. Influence of Different Parameters on Heat Pipe Performance. Int. J. Eng. Res. Appl. 2015, 5, 93–98. [Google Scholar]

- Sharma, C.; Sharma, S. A Review of Heat Pipes: Its Types and Applications. Int. J. Eng. Res. Technol. 2019, 8, 103–106. [Google Scholar]

- Mochizuki, M.; Saito, Y.; Kiyooka, F.; Nguyen, T.; Nguyen, T.; Wuttijumnong, V. Advanced Micro-Channel Vapor Chamber for Cooling High Power Processors. In Proceedings of the ASME 2007 InterPACK Conference Collocated with the ASME/JSME 2007 Thermal Engineering Heat Transfer Summer Conference, Vancouver, BC, Canada, 8–12 July 2007. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Z.; Zhang, G.; Zhang, M. Experimental Investigations of Flat Plate Heat Pipes with Interlaced Narrow Grooves or Channels as Capillary Structure. Exp. Therm. Fluid Sci. 2013, 48, 222–229. [Google Scholar] [CrossRef]

- Wong, S.; Lin, Y.; Liou, J. Visualization and Evaporator Resistance Measurement in Heat Pipes Charged with Water, Methanol or Acetone. Int. J. Ther. Sci. 2012, 52, 154–160. [Google Scholar] [CrossRef]

- Hwang, G.S.; Nam, Y.; Fleming, E.; Dussinger, P.; Ju, Y.S.; Kaviany, M. Multi-Artery Heat Pipe Spreader: Experiment. Int. J. Heat Mass Transf. 2010, 53, 2662–2669. [Google Scholar] [CrossRef]

- Berhe, M.K. Ergonomic Temperature Limits for Handheld Electronic Devices. In Proceedings of the ASME 2007 InterPACK Conference Collocated with the ASME/JSME 2007 Thermal Engineering Heat Transfer Summer Conference, Vancouver, BC, Canada, 8–12 July 2007. ASME Paper No. IPACK2007-33873. [Google Scholar]

- Go, J.S. Quantitative Thermal Performance Evaluation of a Cost-Effective Vapor Chamber Heat Sink Containing a Metal-Etched Micro Wick Structure for Advanced Microprocessor Cooling. Sens. Actuat. A 2005, 121, 549–556. [Google Scholar] [CrossRef]

- Koito, Y.; Imura, H.; Mochizuki, M.; Saito, Y.; Torii, S. Numerical Analysis and Experimental Verification on Thermal Fluid Phenomena in a Vapor Chamber. Appl. Therm. Eng. 2006, 26, 1669–1676. [Google Scholar] [CrossRef]

- Ming, Z.; Liu, Z.; Ma, G. The Experimental and Numerical Investigation of a Grooved Vapor Chamber. Appl. Ther. Eng. 2009, 29, 422–430. [Google Scholar] [CrossRef]

- Liu, W.; Gou, J.; Luo, Y.; Zhang, M. The Experimental Investigation of a Vapor Chamber with Compound Columns under the Influence of Gravity. Appl. Ther. Eng. 2018, 140, 131–138. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chien, K.H.; Wang, C.C.; Hung, T.S.; Pei, B.S. A Simplified Three-Dimensional Model for Estimating the Thermal Performance of the Vapor Chambers. Appl. Ther. Eng. 2006, 26, 2087–2094. [Google Scholar] [CrossRef]

- Wiriyasart, S.; Naphon, P. Thermal Performance Enhancement of Vapor Chamber by Coating Mini-Channel Heat Sink with Porous Sintering Media. Int. J. Heat Mass Transf. 2018, 126, 116–122. [Google Scholar] [CrossRef]

- Yao, F.; Miao, S.; Zhang, M.; Chen, Y. An Experimental Study of an Anti-Gravity Vapor Chamber with a Tree-Shaped Evaporator. Appl. Ther. Eng. 2018, 141, 1000–1008. [Google Scholar] [CrossRef]

- Chang, S.W.; Chiang, K.; Cai, W. Thermal Performance Evaluation of Thin Vapor Chamber. Appl. Ther. Eng. 2019, 149, 220–230. [Google Scholar] [CrossRef]

- Patankar, G.; Weibel, J.A.; Garimella, S.V. On the Transient Thermal Response of Thin Vapor Chamber Heat Spreaders: Governing Mechanisms and Performance Relative to Metal Spreaders. Int. J. Heat Mass Transf. 2019, 136, 995–1005. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.H.; Zhao, H.; Xu, Z.; Li, J.R.; Deng, D. Numerical Analysis on the Thermal Hydraulic Performance of a Composite Porous Vapor Chamber with Uniform Radial Grooves. Int. J. Heat Mass Transf. 2019, 142, 118458. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Z.; Ma, G. The Experimental Investigation on Thermal Performance of a Flat Two-Phase Thermosyphon. Int. J. Ther. Sci. 2008, 47, 1195–1203. [Google Scholar] [CrossRef]

- Hsieh, S.S.; Lee, R.Y.; Shyu, J.C.; Chen, S.W. Analytical Solution of Thermal Resistance of Vapor Chamber Heat Sink with and without Pillar. Energy Convers. Manag. 2007, 48, 2708–2717. [Google Scholar] [CrossRef]

- Hsieh, S.S.; Lee, R.Y.; Shyu, J.C.; Chen, S.W. Thermal Performance of Flat Vapor Chamber Heat Spreader. Energy Convers. Manag. 2008, 49, 1774–1784. [Google Scholar] [CrossRef]

- Ghanbarpour, A.; Hosseini, M.; Ranjbar, A.A.; Rahimi Bahrampoury, R.; Ghanbarpour, M. Evaluation of Heat Sink Performance Using PCM and Vapor Chamber/Heat Pipe. Renew. Energy 2021, 163, 698–719. [Google Scholar] [CrossRef]

- Kim, J.S.; Shin, D.H.; You, S.M.; Lee, J.H. Thermal Performance of Aluminum Vapor Chamber for EV Battery Thermal Management. Appl. Ther. Eng. 2021, 185, 116337. [Google Scholar] [CrossRef]

- Koukoravas, Y.P.; Damoulakis, G.; Megaridis, C.M. Experimental Investigation of a Vapor Chamber Featuring Wettability-Patterned Surfaces. Appl. Ther. Eng. 2020, 178, 115522. [Google Scholar] [CrossRef]

- Liu, T.; Marc, T.D.; Jung, K.W.; Chen, B.; Asheghi, M.; Goodson, K.E. Characterization and Thermal Modeling of a Miniature Silicon Vapor Chamber for Die-Level Heat Redistribution. Int. J. Heat Mass Transf. 2020, 152, 119569. [Google Scholar] [CrossRef]

- Huang, G.; Liu, W.; Luo, Y.; Li, Y. A Novel Ultra-Thin Vapor Chamber for Heat Dissipation in Ultra-Thin Portable Electronic Devices. Appl. Ther. Eng. 2020, 167, 114726. [Google Scholar] [CrossRef]

- Chen, L.; Deng, D.; Huang, Q.; Xu, X.; Xie, Y. Development and Thermal Performance of a Vapor Chamber with Multi-Artery Reentrant Microchannels for High-Power LED. Appl. Ther. Eng. 2020, 166, 114686. [Google Scholar] [CrossRef]

- Li, B.; Yin, X.; Tang, W.; Zhang, J. Optimization Design of Grooved Evaporator Wick Structures in Vapor Chamber Heat Spreaders. Appl. Ther. Eng. 2019, 166, 114657. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, W.; Huang, G. Fabrication and Experimental Investigation of the Bionic Vapor Chamber. Appl. Ther. Eng. 2019, 168, 114889. [Google Scholar] [CrossRef]

- Ayad, M.; Jubori, A.; Jawad, Q.A. Computational Evaluation of Thermal Behavior of a Wickless Heat Pipe under Various Conditions. Case Stud. Ther. Eng. 2020, 22, 100767. [Google Scholar] [CrossRef]

- Błasiak, P.; Opalski, M.; Parmar, P.; Czajkowski, C.; Pietrowicz, S. The Thermal—Flow Processes and Flow Pattern in a Pulsating Heat Pipe—Numerical Modelling and Experimental Validation. Energies 2021, 14, 5952. [Google Scholar] [CrossRef]

- Fadhl, B.; Wrobel, W.C.; Jouhara, H. Modelling of the Thermal Behaviour of Heat Pipes. WIT Trans. Eng. Sci. 2014, 83, 377–389. [Google Scholar]

- Zhao, Z.; Zhang, Y.; Zhang, Y.; Zhou, Y.; Hu, H. Numerical Study on the Transient Thermal Performance of a Two-Phase Closed Thermosyphon. Energies 2018, 11, 1433. [Google Scholar] [CrossRef] [Green Version]

- Girish, S.; Lavanya, K.; Krishna, P.G. CFD Analysis of Pulsating Heat Pipe Using Different Fluids. Int. J. Mech. Eng. Technol. (IJMET) 2017, 8, 804–812. [Google Scholar]

- Kloczko, S. Experimental Investigation and Numerical Simulation of Loop Thermosyphons. Master’s Thesis, University of Connecticut, Connecticut, CT, USA, 2019. [Google Scholar]

- Alizadehdakhel, A.; Rahimi, M.; Alsairafi, A.A. CFD Modeling of Flow and Heat Transfer in a Thermosyphon. Int. Commun. Heat Mass Transf. 2010, 37, 312–318. [Google Scholar] [CrossRef]

- Song, E.-H.; Lee, K.-B.; Rhi, S.-H. Thermal and Flow Simulation of Concentric Annular Heat Pipe with Symmetric or Asymmetric Condenser. Energies 2021, 14, 3333. [Google Scholar] [CrossRef]

- Holman, J.P. Experimental Method for Engineers, 6th ed.; McGraw-Hill: Singapore, 1994. [Google Scholar]

- Hewitt, G.F.; Shiress, G.L.; Bott, T.R. Process Heat Transfer; CRC Press: London, UK, 1994. [Google Scholar]

- Bejan, A. Heat Transfer; Wiley: New York, NY, USA, 1993. [Google Scholar]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill Book Company: New York, NY, USA, 2010. [Google Scholar]

- Imura, H.; Sasaguchi, K.; Kozai, H. Critical Heat Flux in a Two Phase Closed Thermosyphon. Int. J. Heat Transf. 1993, 26, 1181–1188. [Google Scholar] [CrossRef]

- Attia, A.; El-Assal, B. Experimental Investigation of Vapor Chamber with Different Working Fluids at Different Charge Ratios. Ain Shams Eng. J. 2012, 3, 289–297. [Google Scholar] [CrossRef] [Green Version]

- Gibson, M.A. Thermosyphon Flooding in Reduced Gravity Environments. Master’s Thesis, Case Western Reserve University, Cleveland, OH, USA, 2013. [Google Scholar]

- Ansys, I. Ansys Fluent 14.0: User’s Guide; Ansys Inc.: Canonsburg, PA, USA, 2011. [Google Scholar]

- Shinmoto, Y.; Yamamoto, D.; Fujii, D.; Ohta, H. Heat Transfer Characteristics during Boiling of Immiscible Liquids Flowing in Narrow Rectangular Heated Channels. Front. Mech. Eng. 2017, 3, 16. [Google Scholar] [CrossRef] [Green Version]

- Katsuyuki, T. Measurements of Vapor Pressure and Saturated Liquid Density for HFO–1234ze(E) and HFO–1234ze(Z). J. Chem. Eng. Data 2016, 61, 1645–1648. [Google Scholar] [CrossRef]

- Sun, D.; Xu, J.; Chen, Q. Modeling of the Evaporation and Condensation Phase-Change Problems with FLUENT. Numer. Heat Transf. Part B Fundam. 2014, 66, 326–342. [Google Scholar] [CrossRef]

- Tayler, B.D. Transient Evaporation Induced by High Energy Laser-Matter Interaction. Master’s Thesis, Pennsylvania State University, Pennsylvania, PA, USA, 2012. [Google Scholar]

- Kim, Y.C.; Choi, J.W.; Kim, S.C.; Zhang, Y. Effects of Mass Transfer Time Relaxation Parameters on Condensation in a Thermosyphon. J. Mech. Sci. Technol. 2015, 29, 5497–5505. [Google Scholar] [CrossRef]

- Fadhl, B.; Wrobel, L.C.; Hussam, J. Numerical Modelling of the Temperature Distribution in a Two-Phase Closed Thermosyphon. Appl. Ther. Eng. 2013, 60, 122–131. [Google Scholar] [CrossRef] [Green Version]

| Models | Wick | Fin | Working Fluid | Charged Ratio (%) | Orientation (Degree) | Air Flow Velocity (m/s) |

|---|---|---|---|---|---|---|

| 1 | No | No | Water, Methanol | 5, 10, 15, 20, 30, 40, 50 | 10, 20, 30, 40, 50, 60. 70, 80, 90 | 0, 1, 2, 3 |

| 2 | No | Inner space, Trapezoid-Shaped Finned, 30 mm top, 47 mm bottom, 0.35 mm thickness, 32 Fins | Water, Methanol | 10, 20, 30, 40, 50 | 10, 20, 30, 40, 50, 60. 70, 80, 90 | 0, 1, 2, 3 |

| 3 | Cooper 100 Mesh, 1 layer | No | Water, Methanol | 5, 10, 15, 20, 30, 40, 50 | 10, 20, 30, 40, 50, 60. 70, 80, 90 | 0, 1, 2, 3 |

| Boundary Condition | |

|---|---|

| Initial Temperature of the Liquid | 337.15 K |

| Initial Saturation Temperature | 338.15 K |

| Operating Pressure | 25041.6 Pa |

| Free stream Temperature | 298.15 K |

| Element Size (m) | Number of Elements | Skewness | Orthogonal Quality | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Average | Max | Min | Average | Max | ||||

| Case 1 | 0.005 | 1184 | 1.31 × 10−10 | 0.377 | 0.677 | 0.323 | 0.85 | 0.999 | 26.907 |

| Case 2 | 0.003 | 5012 | 0.286 | 0.647 | 0.353 | 0.895 | 1 | 27.232 | |

| Case 3 | 0.001 | 118,809 | 0.189 | 0.566 | 0.696 | 0.951 | 1 | 26.921 | |

| Case 4 | 0.00098 | 124,080 | 0.17 | 0.568 | 0.705 | 0.957 | 1 | 26.767 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, J.-H.; Rhi, S.-H.; Lee, J.-S.; Kim, K.-B. Thermal Investigations of Hemispherical Shell Vapor Chamber Heat Sink. Energies 2022, 15, 1161. https://doi.org/10.3390/en15031161

Ahn J-H, Rhi S-H, Lee J-S, Kim K-B. Thermal Investigations of Hemispherical Shell Vapor Chamber Heat Sink. Energies. 2022; 15(3):1161. https://doi.org/10.3390/en15031161

Chicago/Turabian StyleAhn, Jae-Hyun, Seok-Ho Rhi, Ji-Su Lee, and Ki-Bum Kim. 2022. "Thermal Investigations of Hemispherical Shell Vapor Chamber Heat Sink" Energies 15, no. 3: 1161. https://doi.org/10.3390/en15031161

APA StyleAhn, J.-H., Rhi, S.-H., Lee, J.-S., & Kim, K.-B. (2022). Thermal Investigations of Hemispherical Shell Vapor Chamber Heat Sink. Energies, 15(3), 1161. https://doi.org/10.3390/en15031161