Laboratory Testing of Small Scale Solar Facade Module with Phase Change Material and Adjustable Insulation Layer

Abstract

:1. Introduction

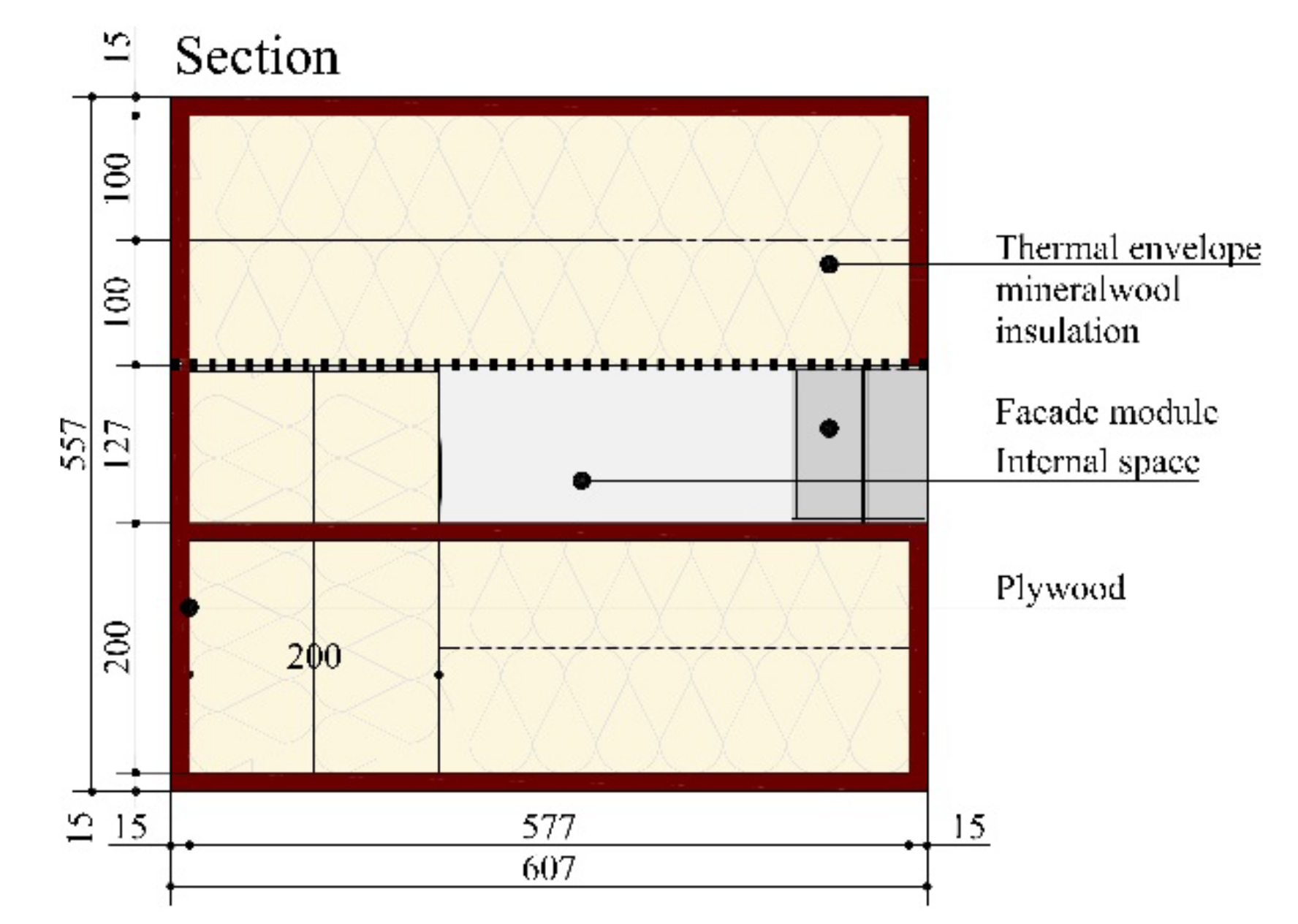

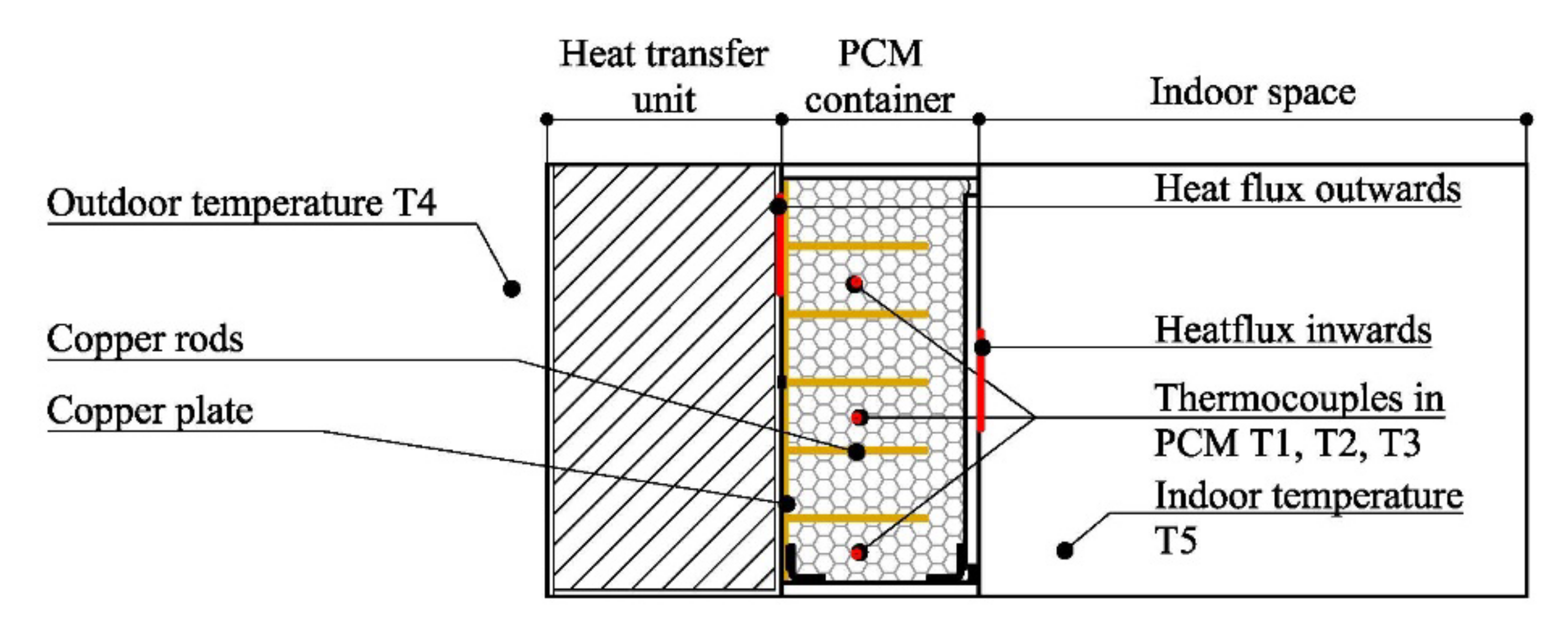

2. Materials and Methods

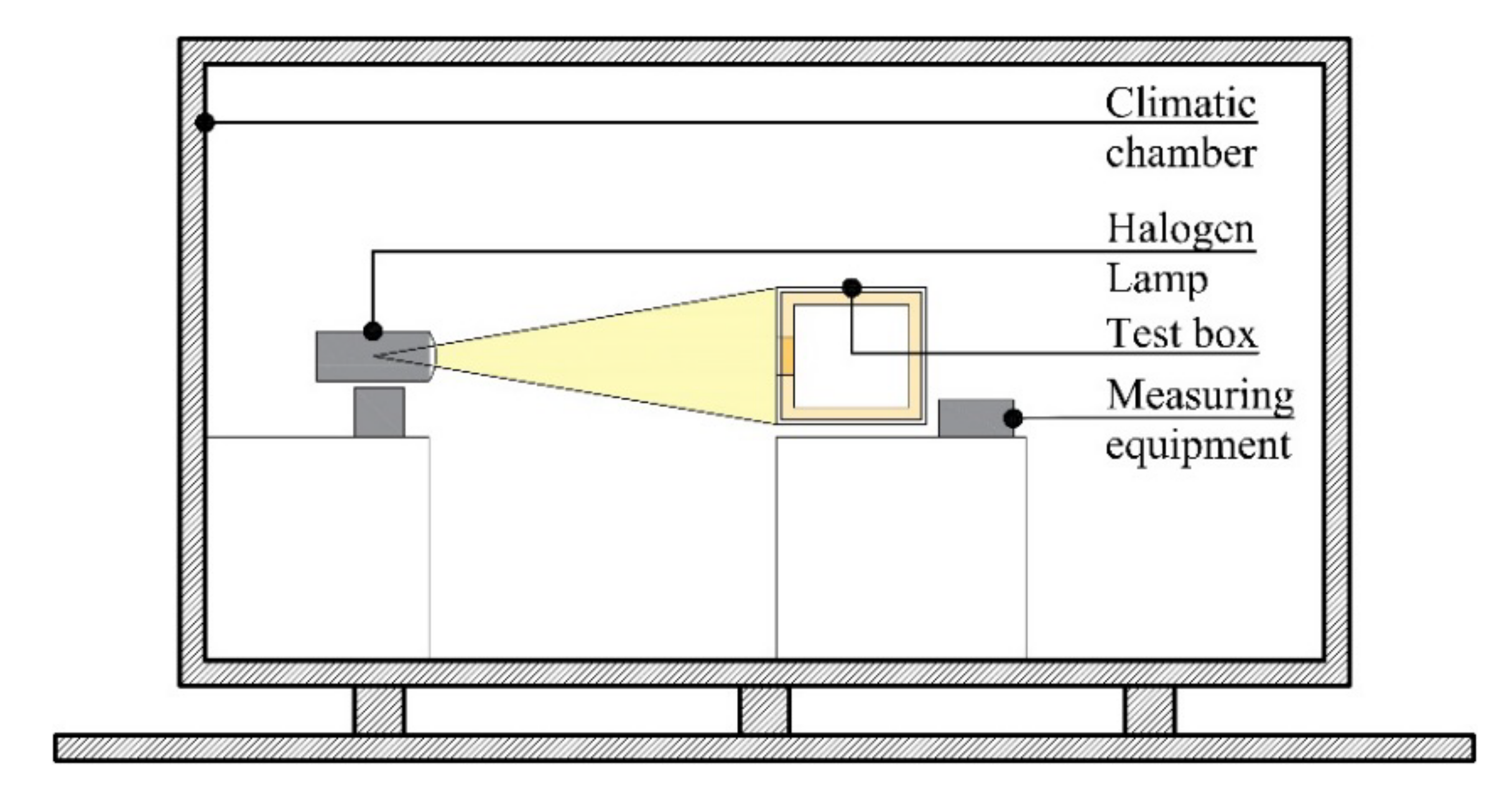

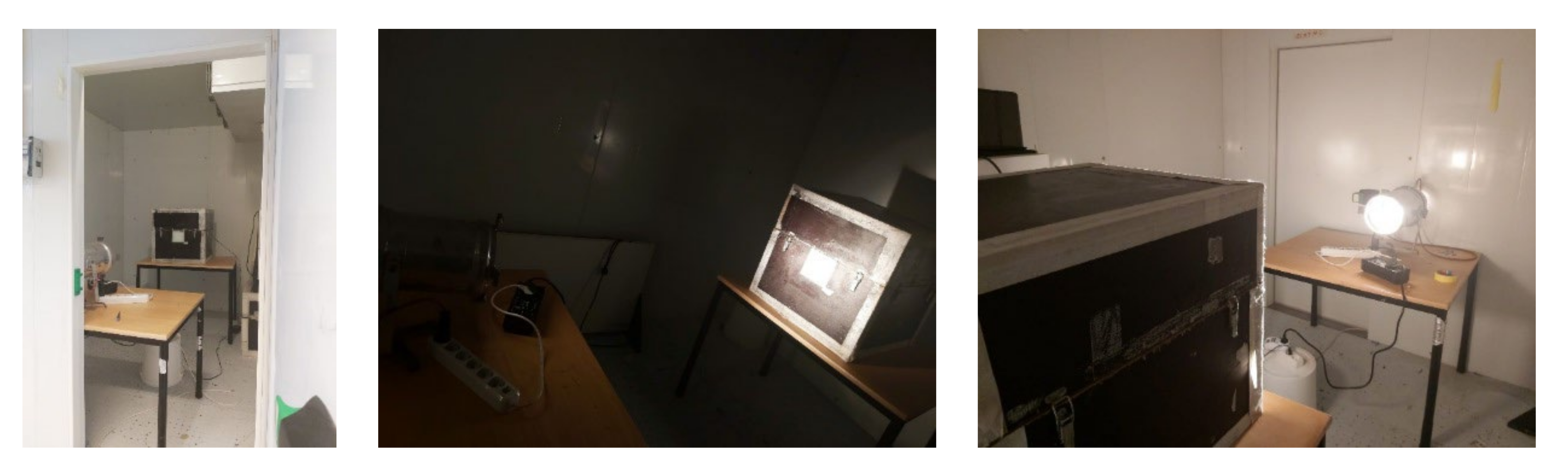

2.1. Experimental Setup

2.2. Experiment Plan

- (1)

- Initial state 10 °C. All solar wall module setups and the climate chamber itself is cooled to 10 °C before the start of the experiment. This temperature was determined considering the average outdoor temperature throughout the spring and autumn seasons in northern Europe. As these periods of the year demand space heating, there is a great potential to partly or fully cover them by using on-site solar energy in a particular climate zone.

- (2)

- In the heating phase, the temperature in the climate chamber is raised to 15 °C and a halogen lamp GE SUPER CP60 EXC VNS 230 V|1000 W G16d 3200 K|General Electric combined with dimmer UNI BAR Elation professional imitates solar radiation. The solar irradiance is set to 1000 W/m2 as this is considered a global standard in test conditions. The charging phase takes place for 7 h 39 min.

- (3)

- In the cooling phase, the lamp is switched off, and the temperature in the climate chamber is lowered to 10 °C. This phase is 40 h 21 min long.

2.3. Measuring Equipment

3. Results

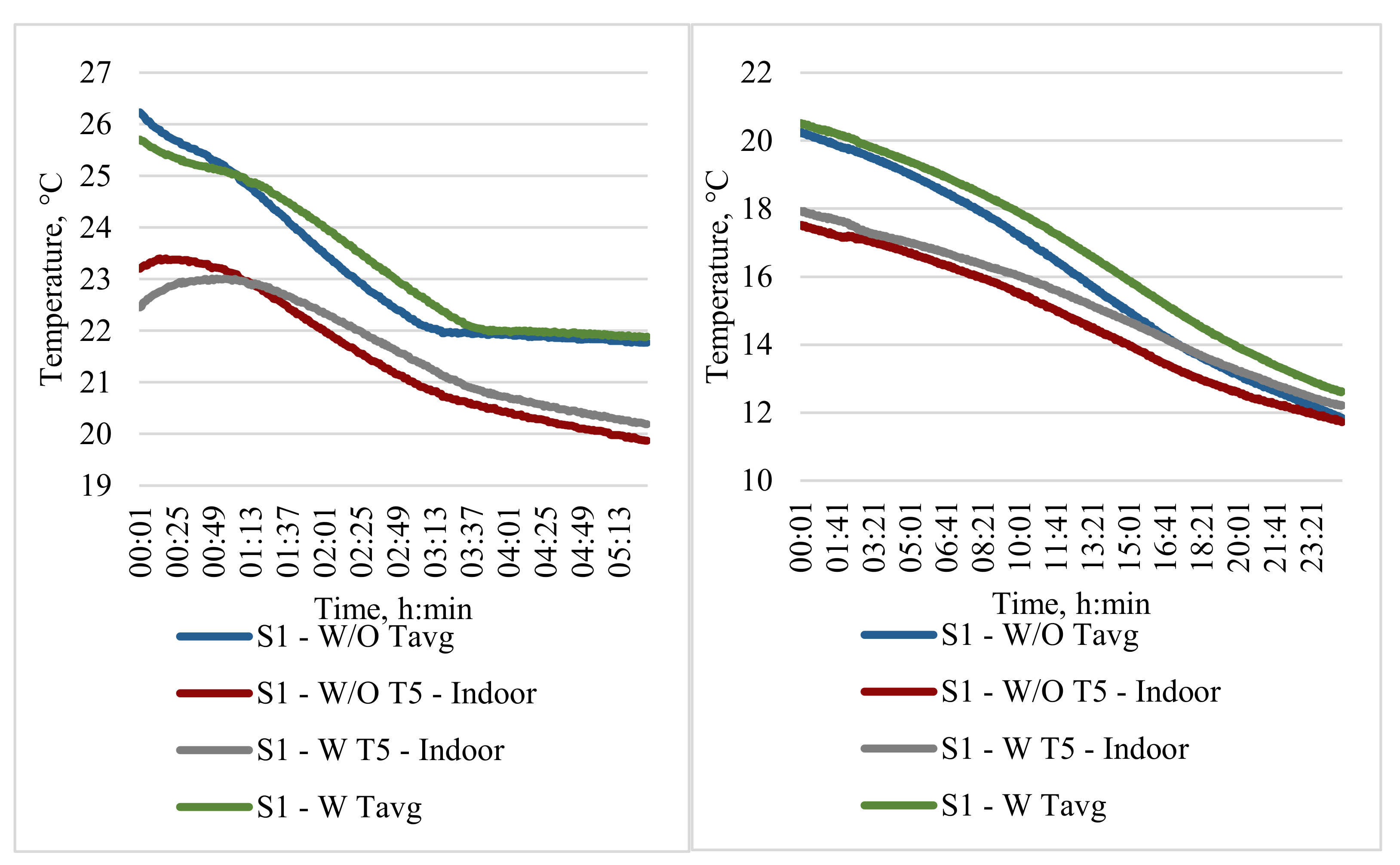

- Temperature and heat flux graphs (average temperature in PCM, “indoor space”, heat flux inwards and outwards) are compared for each of six basic setups—the performance of one particular setup with and without an adjustable insulation layer is compared.

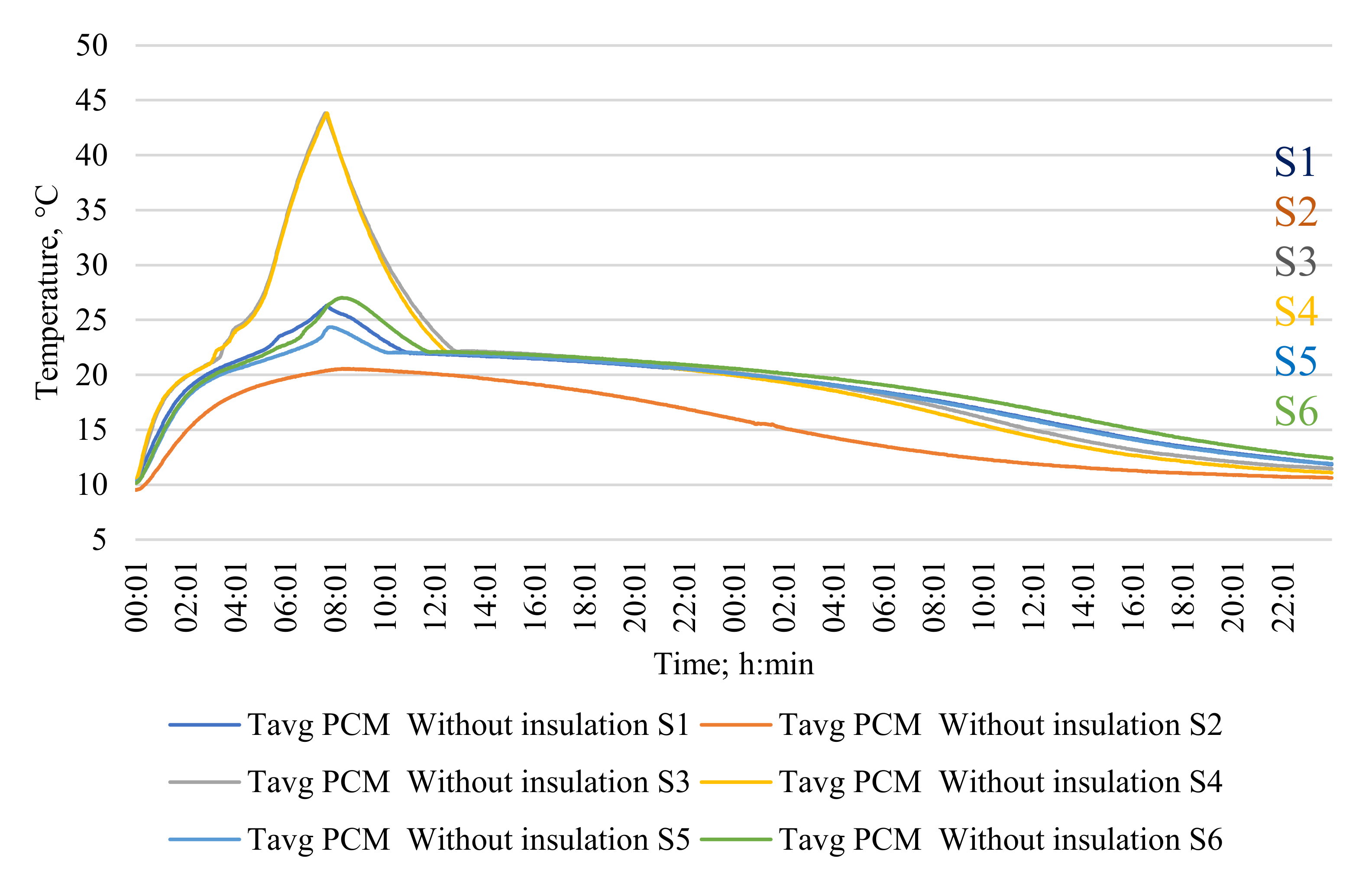

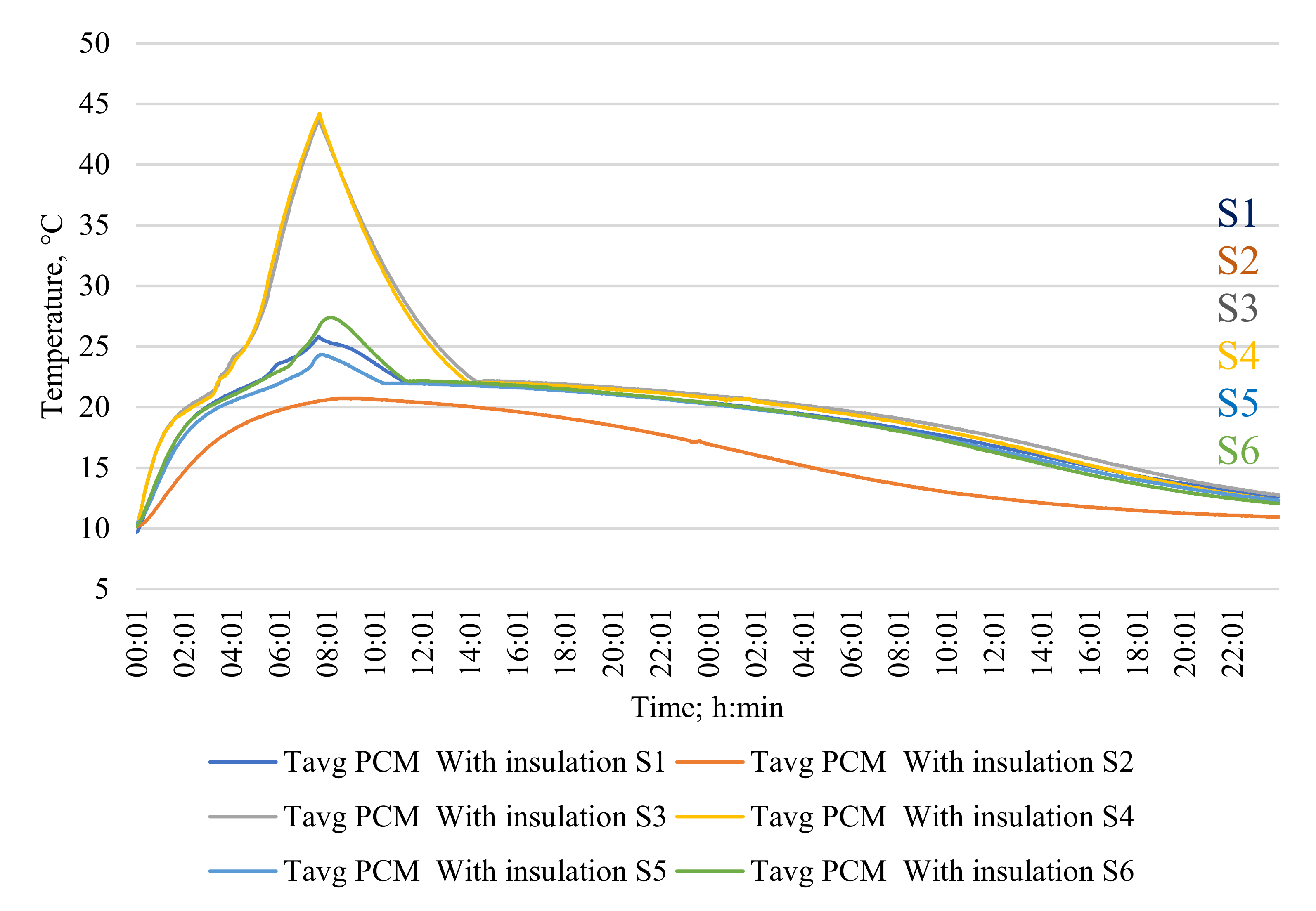

- Temperature graphs (average temperature in PCM and “indoor space”) are compared for six basic setups compiled—the performance of all setups with and without an adjustable insulation layer are compared.

- Heat flux graphs (inwards and outwards) are compared for six basic setups compiled—the performance of all setups with and without an adjustable insulation layer is compared.

3.1. Temperature and Heat Fluxes in Setups

3.2. Comparison of Setups

4. Conclusions and Discussion

- As expected, the average temperature in the phase-change material and “indoor space” was higher when the adjustable insulation layer was applied in all of the alterations; however, the most significant impact on the average PCM and indoor temperature was in modules with an air gap layer compared with more insulated modules.

- Modules with an air gap were more competitive among others (cone + aerogel and aerogel filling) as, after the solidification in the cooling phase, temperature splines in the graph lay closer together compared to modules without the adjustable insulation layer.

- Thus, we concluded that, when looking at the whole cycle (charging and discharging), more energy was gained and released in modules with the air gap; however, modules with different insulation layers took advantage of the latent heat storage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Clean energy for all Europeans. Euroheat Power 2019, 14, 3. [Google Scholar] [CrossRef]

- EU. Directive (EU) 2018/844 of the European Parliament and of the Council amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency. Off. J. Eur. Union 2018, L 156, 75–91. [Google Scholar]

- EU. Directive (EU) 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- Sergei, K.; Shen, C.; Jiang, Y. A review of the current work potential of a trombe wall. Renew. Sustain. Energy Rev. 2020, 130, 109947. [Google Scholar] [CrossRef]

- Hu, Z.; He, W.; Ji, J.; Zhang, S. A review on the application of Trombe wall system in buildings. Renew. Sustain. Energy Rev. 2016, 70, 976–987. [Google Scholar] [CrossRef]

- Heidenthaler, D.; Leeb, M.; Schnabel, T.; Huber, H. Comparative analysis of thermally activated building systems in wooden and concrete structures regarding functionality and energy storage on a simulation-based approach. Energy 2021, 233, 121138. [Google Scholar] [CrossRef]

- Ručevskis, S.; Akishin, P.; Korjakins, A. Parametric analysis and design optimisation of PCM thermal energy storage system for space cooling of buildings. Energy Build. 2020, 224, 110288. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Bozlar, M.; Liu, Z.; Guo, H.; Meggers, F. Active building envelope systems toward renewable and sustainable energy. Renew. Sustain. Energy Rev. 2019, 104, 470–491. [Google Scholar] [CrossRef]

- Wang, Y.; Shukla, A.; Liu, S. A state of art review on methodologies for heat transfer and energy flow characteristics of the active building envelopes. Renew. Sustain. Energy Rev. 2017, 78, 1102–1116. [Google Scholar] [CrossRef]

- Jouhara, H.; Milko, J.; Danielewicz, J.; Sayegh, M.; Szulgowska-Zgrzywa, M.; Ramos, J.; Lester, S. The performance of a novel flat heat pipe based thermal and PV/T (photovoltaic and thermal systems) solar collector that can be used as an energy-active building envelope material. Energy 2016, 108, 148–154. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Ibañez-Puy, M.; Martín-Gómez, C.; Bermejo-Busto, J.; Sacristán, J.A.; Ibañez-Puy, E. Ventilated Active Thermoelectric Envelope (VATE): Analysis of its energy performance when integrated in a building. Energy Build. 2018, 158, 1586–1592. [Google Scholar] [CrossRef]

- Diarce, G.; Urresti, A.; García-Romero, A.; Delgado, A.; Erkoreka, A.; Escudero, C.; Campos-Celador, A. Ventilated active façades with PCM. Appl. Energy 2013, 109, 530–537. [Google Scholar] [CrossRef]

- Laaouatni, A.; Martaj, N.; Bennacer, R.; Lachi, M.; El Omari, M.; El Ganaoui, M. Thermal building control using active ventilated block integrating phase change material. Energy Build. 2019, 187, 50–63. [Google Scholar] [CrossRef]

- Guo, J.; Dong, J.; Wang, H.; Jiang, Y.; Tao, J. On-site measurement of the thermal performance of a novel ventilated thermal storage heating floor in a nearly zero energy building. Build. Environ. 2021, 201, 107993. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Advances in switchable and highly insulating autonomous (self-powered) glazing systems for adaptive low energy buildings. Renew. Energy 2018, 126, 1003–1031. [Google Scholar] [CrossRef]

- Sheikh, W.T.; Asghar, Q. Adaptive biomimetic facades: Enhancing energy efficiency of highly glazed buildings. Front. Arch. Res. 2019, 8, 319–331. [Google Scholar] [CrossRef]

- Arranz, B.; Ruiz-Valero, L.; González, M.P.; Sánchez, S.V. Comprehensive experimental assessment of an industrialized modular innovative active glazing and heat recovery system. Energy 2020, 212, 118748. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, W.; Li, D.; Zhang, C.; Arıcı, M.; Yıldız, Ç.; Zhang, X.; Ma, Y. Energy efficiency optimization of PCM and aerogel-filled multiple glazing windows. Energy 2021, 222, 119916. [Google Scholar] [CrossRef]

- Schneider, A.K.M.; Kuhn, T.E. Building-Integrated Photovoltaics Moves from the Niche to the Mass Market Industrial Manufacture of Solar Building Components and Their Integration into the Building Planning Process Photovoltaic Building Components: Multiple Advantages for Building Owners PRESS RELEASE. Available online: https://www.ise.fraunhofer.de/content/dam/ise/en/documents/press-releases/2019/0719_ISE_e_PR_BIPV_final.pdf (accessed on 10 November 2021).

- Heier, J.; Bales, C.; Martin, V. Combining thermal energy storage with buildings—A review. Renew. Sustain. Energy Rev. 2015, 42, 1305–1325. [Google Scholar] [CrossRef]

- Kuznik, F.; Virgone, J.; Noel, J. Optimization of a phase change material wallboard for building use. Appl. Therm. Eng. 2008, 28, 1291–1298. [Google Scholar] [CrossRef] [Green Version]

- Lai, C.-M.; Hokoi, S. Thermal performance of an aluminum honeycomb wallboard incorporating microencapsulated PCM. Energy Build. 2014, 73, 37–47. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Soares, N.; Ferreira, V. Experimental testing and numerical modelling of masonry wall solution with PCM incorporation: A passive construction solution. Energy Build. 2012, 49, 235–245. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Numerical model for evaluating thermal performance of residential building roof integrated with inclined phase change material (PCM) layer. J. Build. Eng. 2019, 28, 101018. [Google Scholar] [CrossRef]

- De Gracia, A.; Navarro, L.; Castell, A.; Ruiz-Pardo, Á.; Alvárez, S.; Cabeza, L.F. Experimental study of a ventilated facade with PCM during winter period. Energy Build. 2013, 58, 324–332. [Google Scholar] [CrossRef]

- Gholamibozanjani, G.; Farid, M. A comparison between passive and active PCM systems applied to buildings. Renew. Energy 2020, 162, 112–123. [Google Scholar] [CrossRef]

- Soibam, J. Numerical Investigation of a Heat Exchanger Using Phase Change Materials (PCMs); NTNU: Trondheim, Norway, 2017. [Google Scholar]

- Ben Romdhane, S.; Amamou, A.; Ben Khalifa, R.; Saïd, N.M.; Younsi, Z.; Jemni, A. A review on thermal energy storage using phase change materials in passive building applications. J. Build. Eng. 2020, 32, 101563. [Google Scholar] [CrossRef]

- Lin, Y.; Alva, G.; Fang, G. Review on thermal performances and applications of thermal energy storage systems with inorganic phase change materials. Energy 2018, 165, 685–708. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef] [Green Version]

- Sirmelis, R.; Vanaga, R.; Freimanis, R.; Blumberga, A. Solar Facade Module for Nearly Zero Energy Building. Optimization Strategies. Environ. Clim. Technol. 2019, 23, 170–181. [Google Scholar] [CrossRef] [Green Version]

- Mols, T.; Vanaga, R.; Blumberga, A. Solar Facade Module for Nearly Zero Energy Building. Extended Test Period. Environ. Clim. Technol. 2020, 24, 442–453. [Google Scholar] [CrossRef]

- Martínez, S.; Erkoreka, A.; Eguía, P.; Granada, E.; Febrero, L. Energy characterization of a PASLINK test cell with a gravel covered roof using a novel methodology: Sensitivity analysis and Bayesian calibration. J. Build. Eng. 2018, 22, 1–11. [Google Scholar] [CrossRef]

| Heat Transfer Unit Variations | Cone + Aerogel | Unventilated Air Gap | Aerogel Filling |

|---|---|---|---|

| Fresnel Lens | S1—W/O | S3—W/O | S5—W/O |

| Polymethyl methacrylate (PMMA) | S2—W/O | S4—W/O | S6—W/O |

| Fresnel Lens + adjustable insulation | S1—W | S3—W | S5—W |

| PMMA + adjustable insulation | S2—W | S4—W | S6—W |

| Component | Characteristics |

|---|---|

| Phase-change material (PCM) | RUBITHERM RT21HC Melting area: 20–23 °C Congealing area: 21–19 °C |

| PCM glass container | Dimensions: 127 × 127 × 60 mm |

| Plastic box | Material: Polyethylene terephthalate glycol (PETG) |

| Cone | Material: Polyethylene terephthalate glycol (PETG) |

| Glass | Dimensions: 129 × 129 × 4 mm |

| Poly (methyl methacrylate) PMMA glass | Dimensions: 127 × 127 × 1.5 mm |

| Fresnel lens | Dimensions: 127 × 127 × 1.5 mm Focal length: 71.12 mm |

| Aerogel | LUMIRA translucent aerogel LA1000 |

| Component | Characteristics |

|---|---|

| Plywood | 15 mm λ = 0.13 W/mK |

| Mineral wool | 200 mm λ = 0.037 W/mK |

| Adjustable layer XPS insulation | 50 mm λ = 0.037 W/mK |

| Characteristics | Value |

|---|---|

| Spectral range (50% points) | 300 to 2800 nm |

| Sensitivity | 10 to 32 µV/W/m2 |

| Response time | 20 s |

| Zero offset A | <15 W/m2 |

| Zero offset B | <5 W/m2 |

| Directional response (up to 80° with 1000 W/m2 beam) | <20 W/m2 |

| Temperature dependence of sensitivity (−10 °C to +40 °C) | <4% |

| Operational temperature range | −40 °C to +80 °C |

| Maximum solar irradiance | 2000 W/m2 |

| Field of view | 180° |

| Characteristics | Value |

|---|---|

| Temperature range | −270 °C to 1260 °C |

| Accuracy | ±2.2 °C or ±0.75% |

| Without Adjustable Insulation Layer Tavg | With Adjustable Insulation Layer Tavg | Without Adjustable Insulation Layer Tindoor | With Adjustable Insulation Layer Tindoor | Tavg | Tin | Tavg | Tin | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | t, °C 24 h | t, °C 48 h | t, °C 24 h | t, °C 48 h | t, °C 24 h | t, °C 48 h | t, °C 24 h | t, °C 48 h | Max Δt, °C 24 h | Max Δt, °C 24 h | Max Δt, °C 48 h | Max Δt, °C 48 h | Time Delay, min |

| Setup 1 Fresnel lens, cone, aerogel | 20.1 | 11.8 | 20.4 | 12.6 | 17.4 | 11.7 | 17.8 | 12.2 | 0.98 | 0.78 | 0.77 | 0.49 | 30 |

| Setup 2 PMMA, cone, aerogel | 16.0 | 10.6 | 17.0 | 10.9 | 14.7 | 10.5 | 15.5 | 10.9 | 1.07 | 0.93 | 0.32 | 0.32 | - |

| Setup 3 Fresnel lens and air gap | 20.0 | 11.1 | 20.8 | 12.3 | 17.5 | 11.0 | 18.2 | 12.2 | 3.02 | 2.13 | 1.20 | 0.91 | 90 |

| Setup 4 PMMA and air gap | 20.2 | 11.5 | 21.0 | 12.7 | 18.2 | 11.4 | 18.8 | 12.2 | 2.82 | 1.98 | 1.29 | 1.00 | 95 |

| Setup 5 Fresnel lens and aerogel | 20.2 | 11.9 | 20.3 | 12.3 | 17.9 | 11.7 | 18.0 | 12.2 | 0.73 | 0.51 | 0.41 | 0.28 | 15 |

| Setup 6 PMMA and aerogel | 20.4 | 12.1 | 20.6 | 12.4 | 18.0 | 11.9 | 18.1 | 12.1 | 0.58 | 0.44 | 0.33 | 0.21 | 30 |

| Without Adjustable Insulation Layer | With Adjustable Insulation Layer | Without Adjustable Insulation Layer | With Adjustable Insulation Layer | Tavg | Tin | Tavg | Tin | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tavg | Tavg | Tindoor | Tindoor | ||||||||||

| t, °C | t, °C | t, °C | t, °C | t, °C | t, °C | t, °C | t, °C | Max Δt, °C 24 h | Max Δt, °C 24 h | Max Δt, °C | Max Δt, °C | Time Delay, min | |

| 24 h | 48 h | 24 h | 48 h | 24 h | 48 h | 24 h | 48 h | 48 h | 48 h | ||||

| Setup 1 | 3 | 3 | 4 | 2 | 5 | 2 | 5 | 1 | 4 | 4 | 3 | 3 | 3 |

| Fresnel lens, cone, aerogel | |||||||||||||

| Setup 2 | 5 | 6 | 6 | 5 | 6 | 5 | 6 | 3 | 3 | 3 | 5 | 4 | - |

| PMMA, cone, aerogel | |||||||||||||

| Setup 3 | 2 | 4 | 1 | 1 | 1 | 3 | 1 | 1 | 2 | 2 | 1 | 1 | 1 |

| Fresnel lens and air gap | |||||||||||||

| Setup 4 | 4 | 5 | 2 | 4 | 4 | 4 | 2 | 1 | 1 | 1 | 2 | 2 | 2 |

| PMMA and air gap | |||||||||||||

| Setup 5 | 2 | 2 | 5 | 4 | 2 | 2 | 4 | 1 | 5 | 5 | 4 | 5 | 4 |

| Fresnel lens and aerogel | |||||||||||||

| Setup 6 | 1 | 1 | 3 | 3 | 3 | 1 | 3 | 2 | 6 | 6 | 5 | 6 | 3 |

| PMMA and aerogel | |||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanaga, R.; Narbuts, J.; Freimanis, R.; Blumberga, A. Laboratory Testing of Small Scale Solar Facade Module with Phase Change Material and Adjustable Insulation Layer. Energies 2022, 15, 1158. https://doi.org/10.3390/en15031158

Vanaga R, Narbuts J, Freimanis R, Blumberga A. Laboratory Testing of Small Scale Solar Facade Module with Phase Change Material and Adjustable Insulation Layer. Energies. 2022; 15(3):1158. https://doi.org/10.3390/en15031158

Chicago/Turabian StyleVanaga, Ruta, Jānis Narbuts, Ritvars Freimanis, and Andra Blumberga. 2022. "Laboratory Testing of Small Scale Solar Facade Module with Phase Change Material and Adjustable Insulation Layer" Energies 15, no. 3: 1158. https://doi.org/10.3390/en15031158

APA StyleVanaga, R., Narbuts, J., Freimanis, R., & Blumberga, A. (2022). Laboratory Testing of Small Scale Solar Facade Module with Phase Change Material and Adjustable Insulation Layer. Energies, 15(3), 1158. https://doi.org/10.3390/en15031158