Modelling of Energy Storage System from Photoelectric Conversion in a Phase Change Battery

Abstract

:1. Introduction

- combination of a ground source heat pump and a phase change storage [37],

- increase in energy efficiency of a heat pump cooperating with a PCM battery [34],

- use of PCM to lower the temperature in a greenhouse without the use of cooling systems [35],

- construction of external walls of greenhouses as PCM warehouses [39],

- searching for the optimal location of the PCM battery in the greenhouse [40],

- integration of different renewable energy technologies (solar, photovoltaic, photovoltaic, geothermal and biomass) to achieve a greenhouse with zero energy needs [41].

2. Purpose and Scope of Work

- -

- development of a model to optimize the power of a PV power plant cooperating with the analyzed PCM battery with a paraffin bed,

- -

- development of separate models of energy yield for three types of panels, i.e., monocrystalline, polycrystalline and CIGS,

- -

- analysis of the suitability of selected methods for modelling electricity yield from a PV power plant,

- -

- development of a model of energy storage in a PCM battery,

- -

- development of a model of energy losses in a real phase change accumulator,

- -

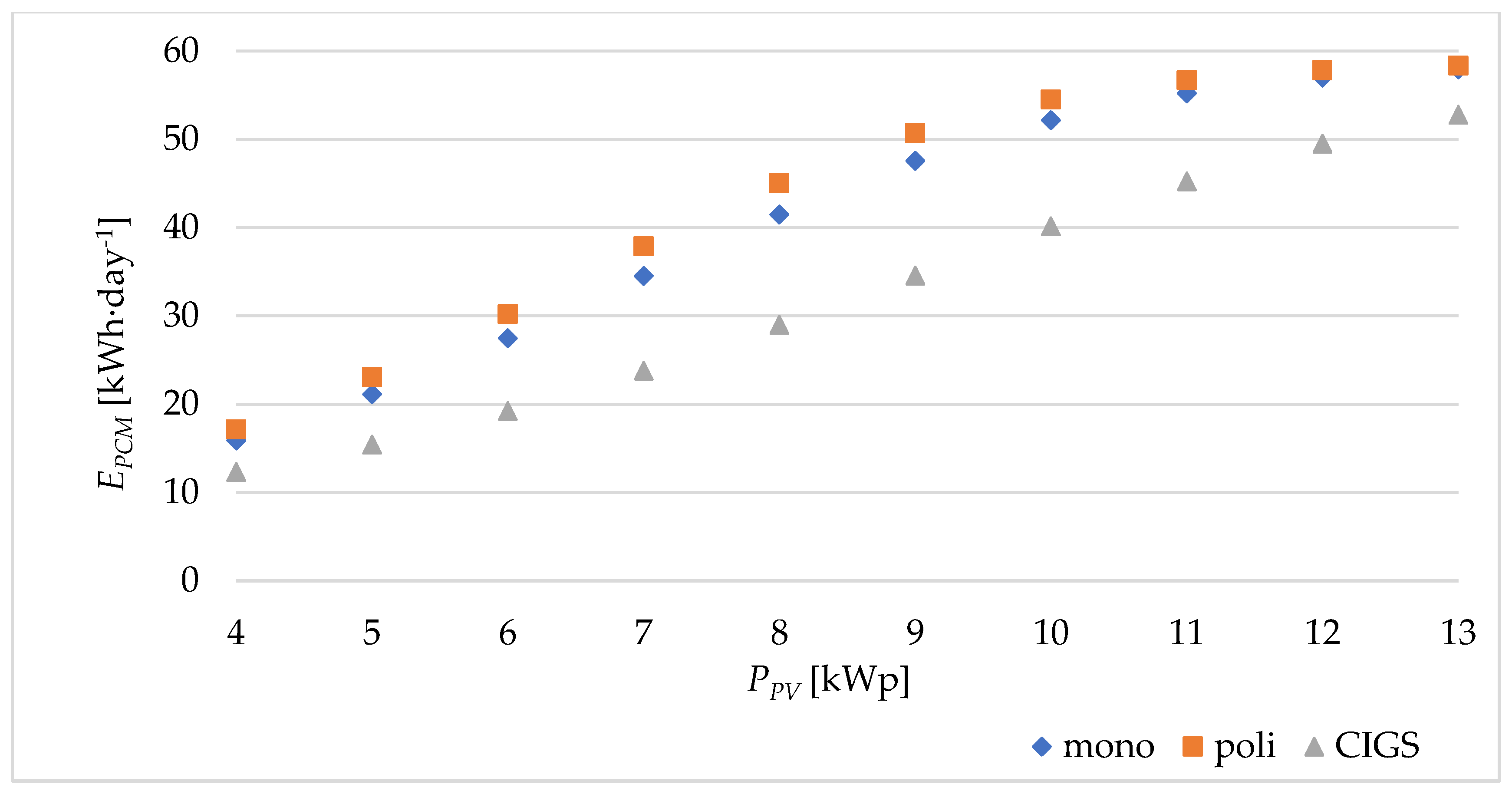

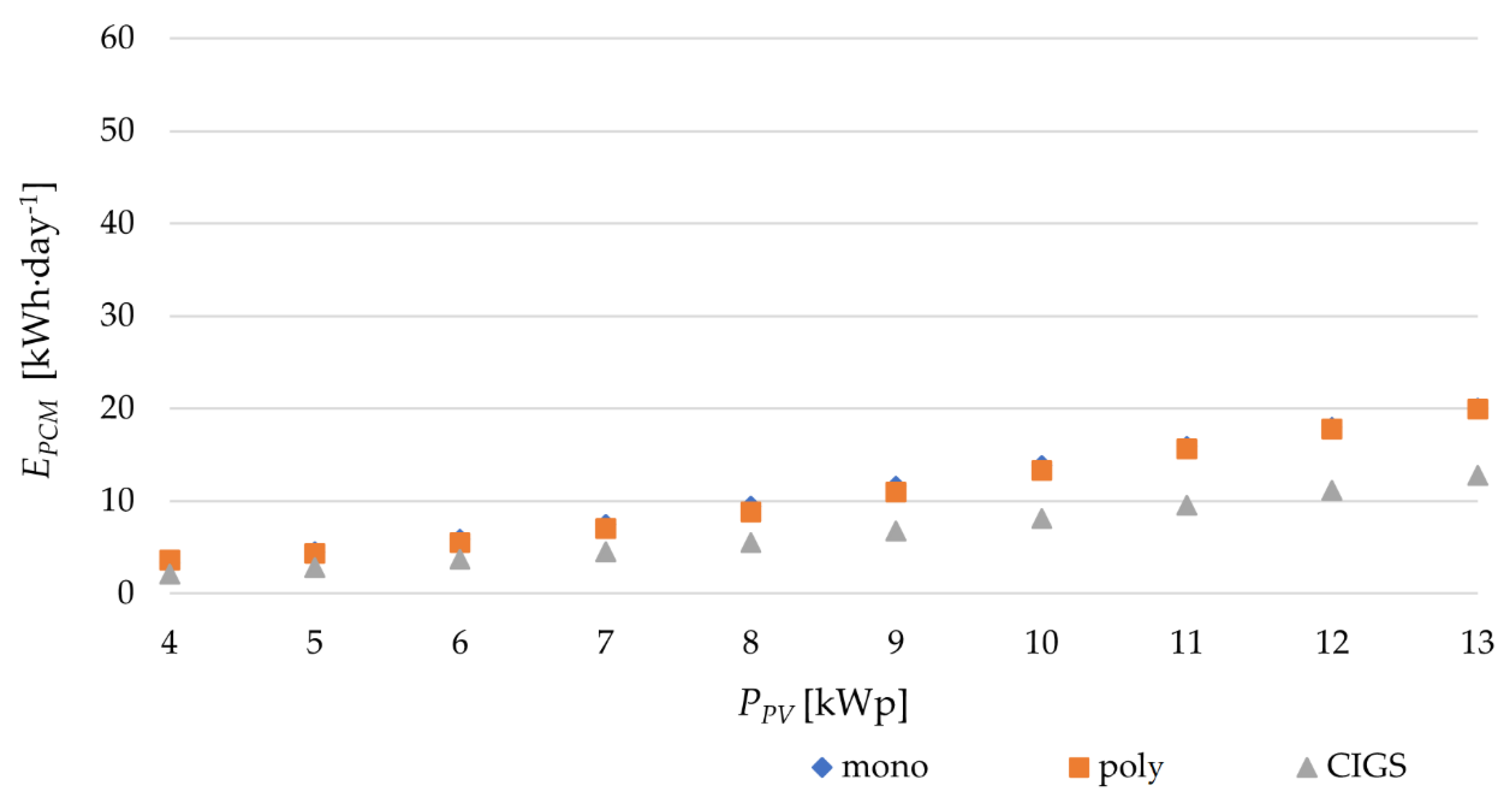

- analysis of the impact of the size of the PV plant on the operation of the PCM battery,

- -

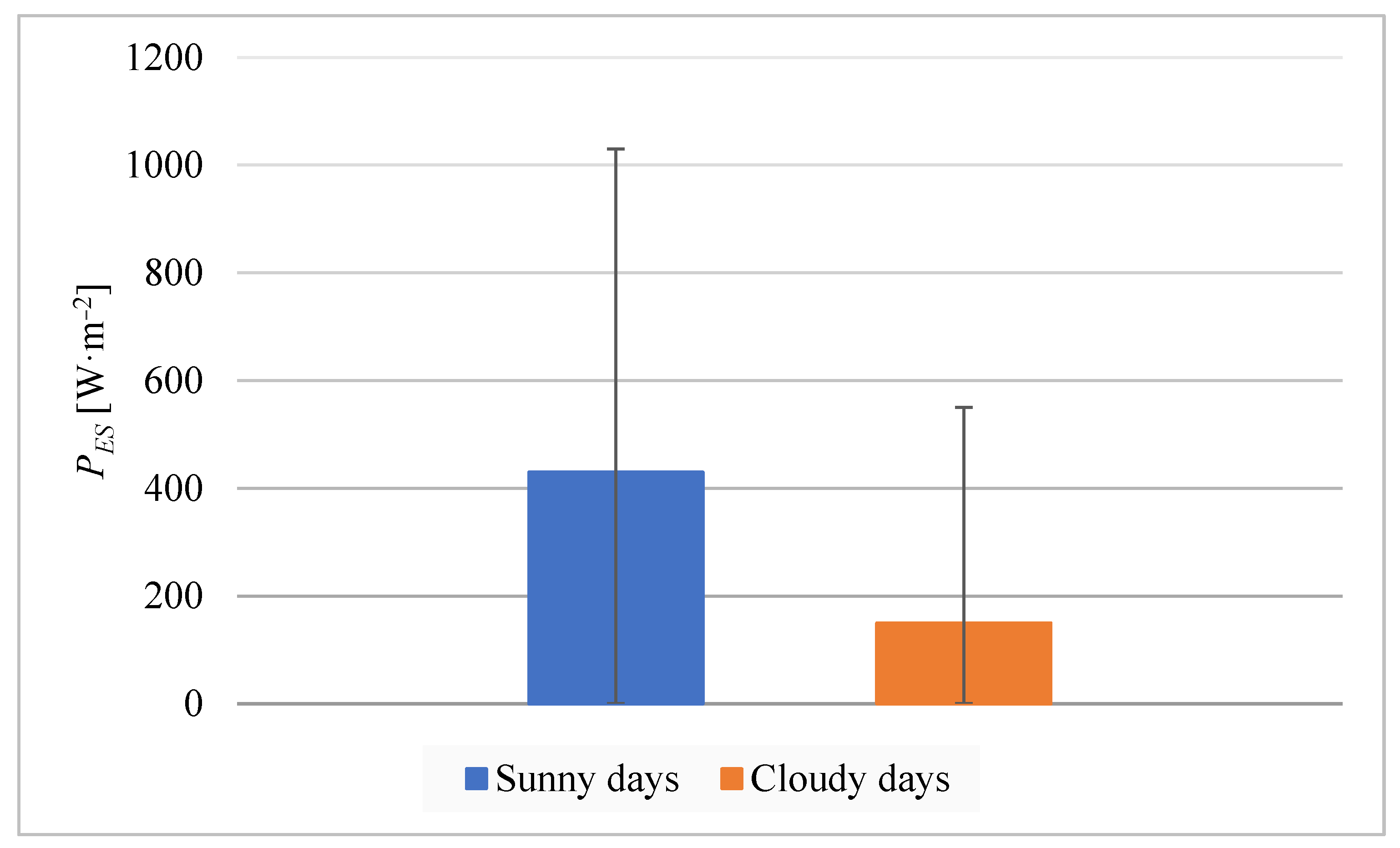

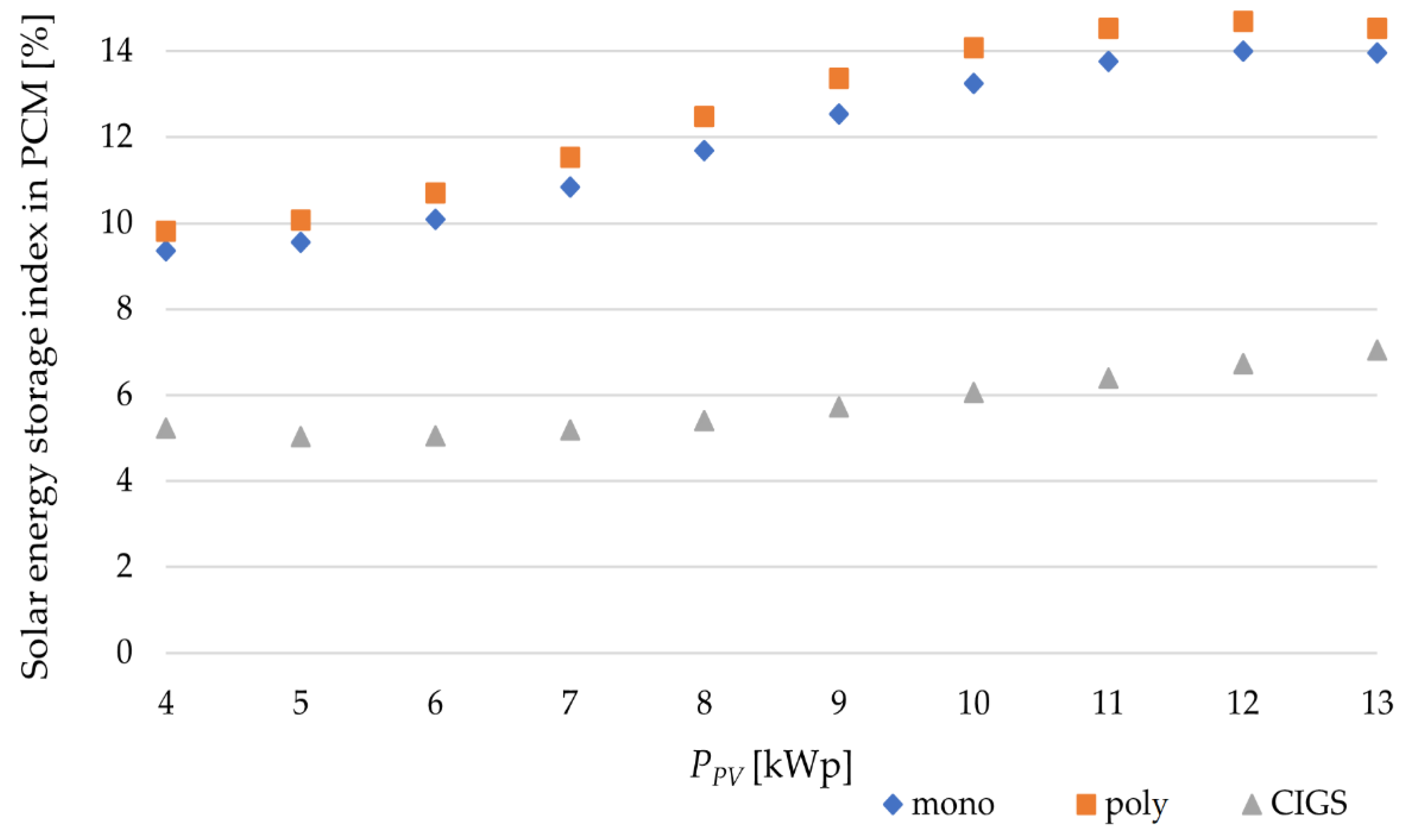

- determination of the energy storage index of solar radiation in PCM for sunny and cloudy days,

- -

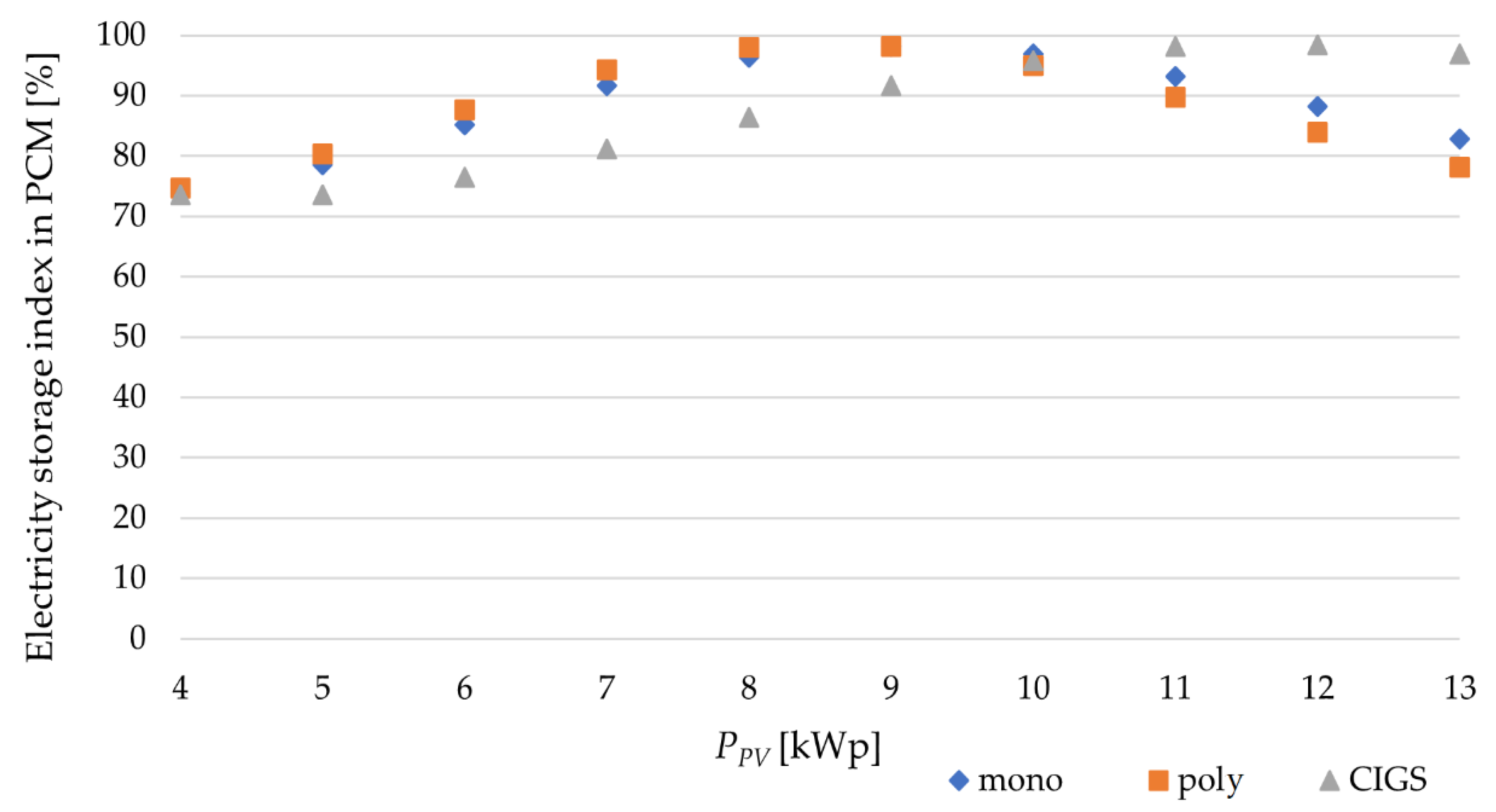

- determination of electricity storage index from PV in PCM for sunny and cloudy days,

- -

- determining the amount of installed power for individual types of PV panels as a function of maximizing the amount of energy stored from photoelectric conversion.

3. Materials and Methods

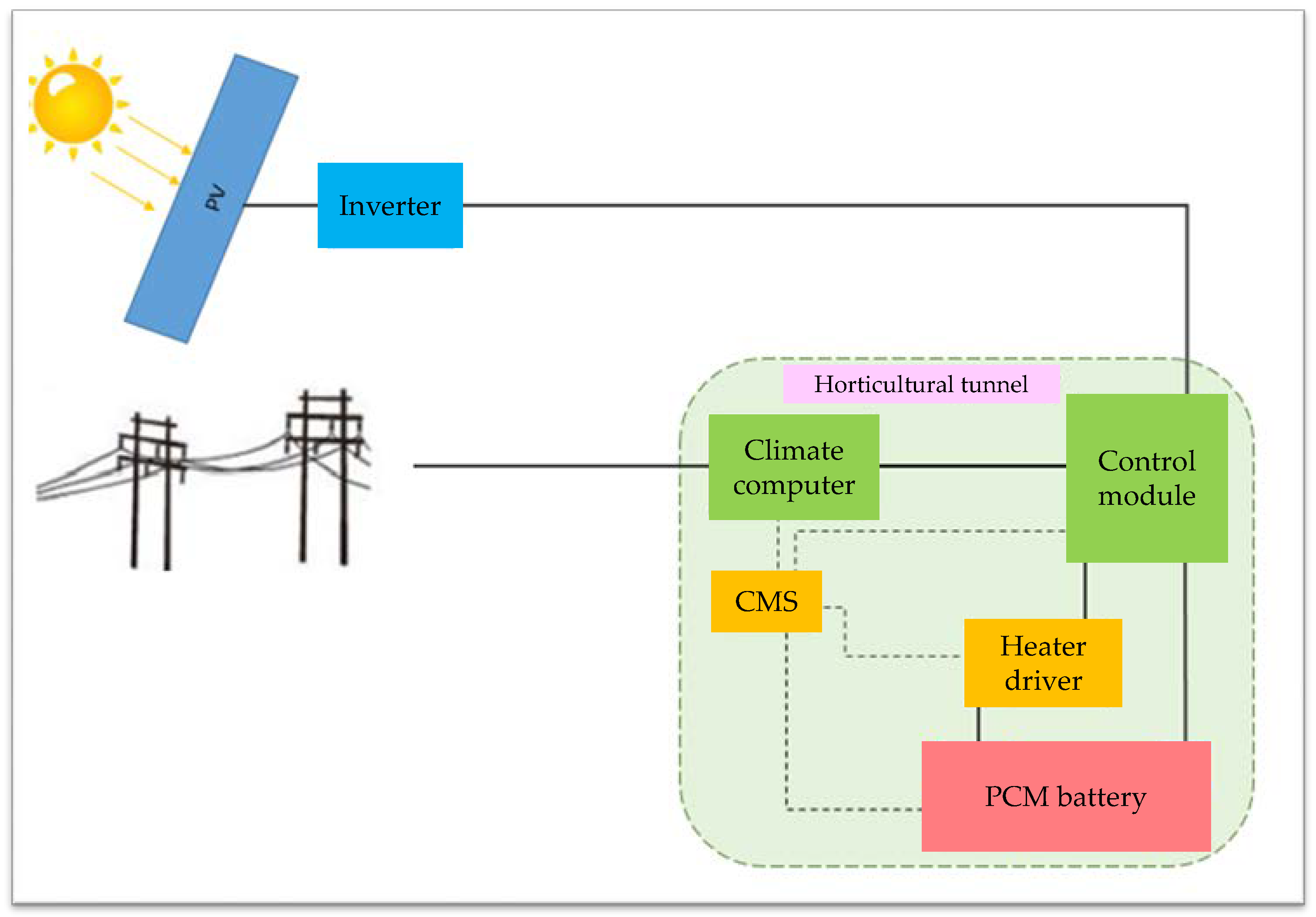

3.1. Photovoltaic Power Plant

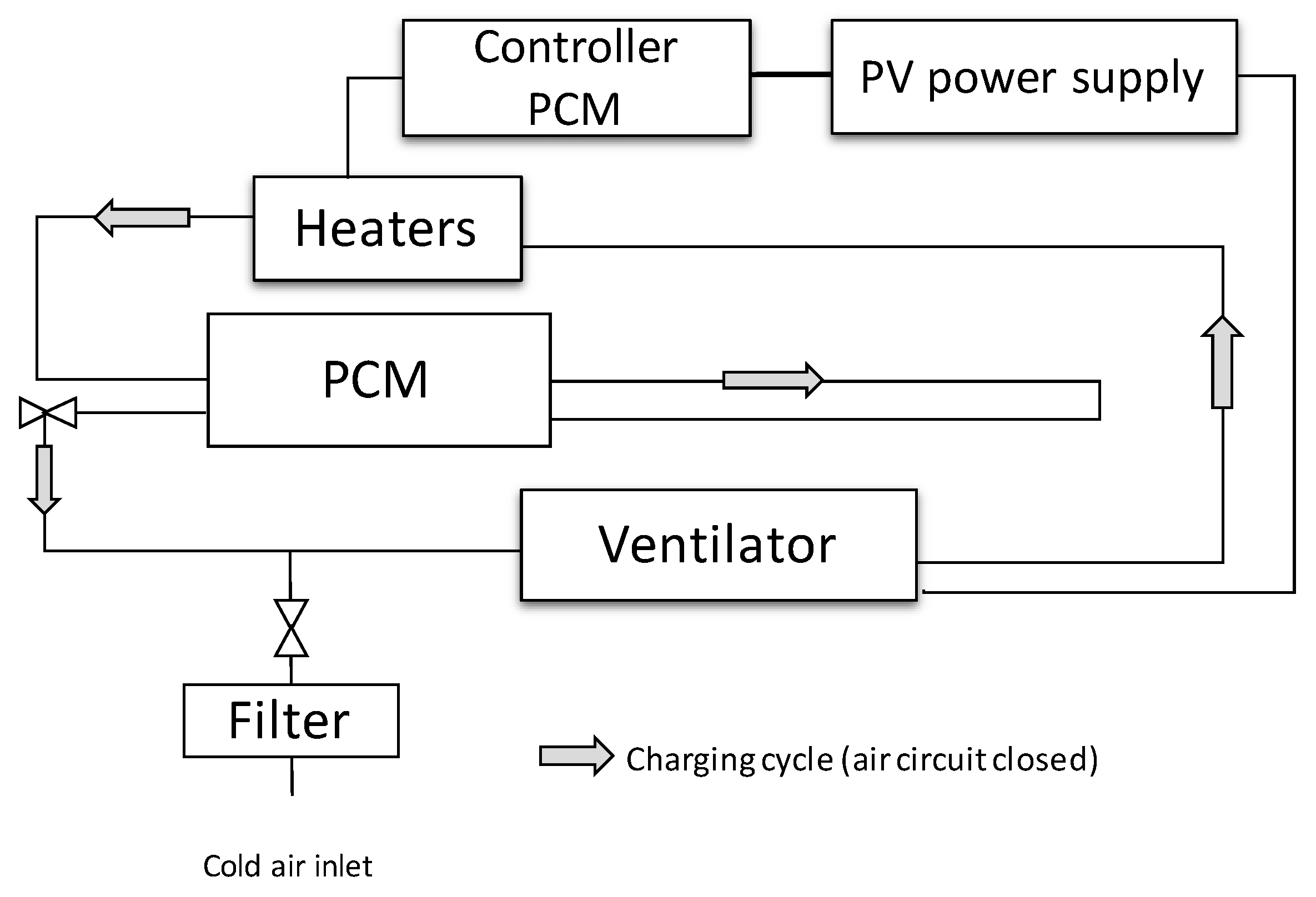

3.2. PCM Phase Conversion Battery

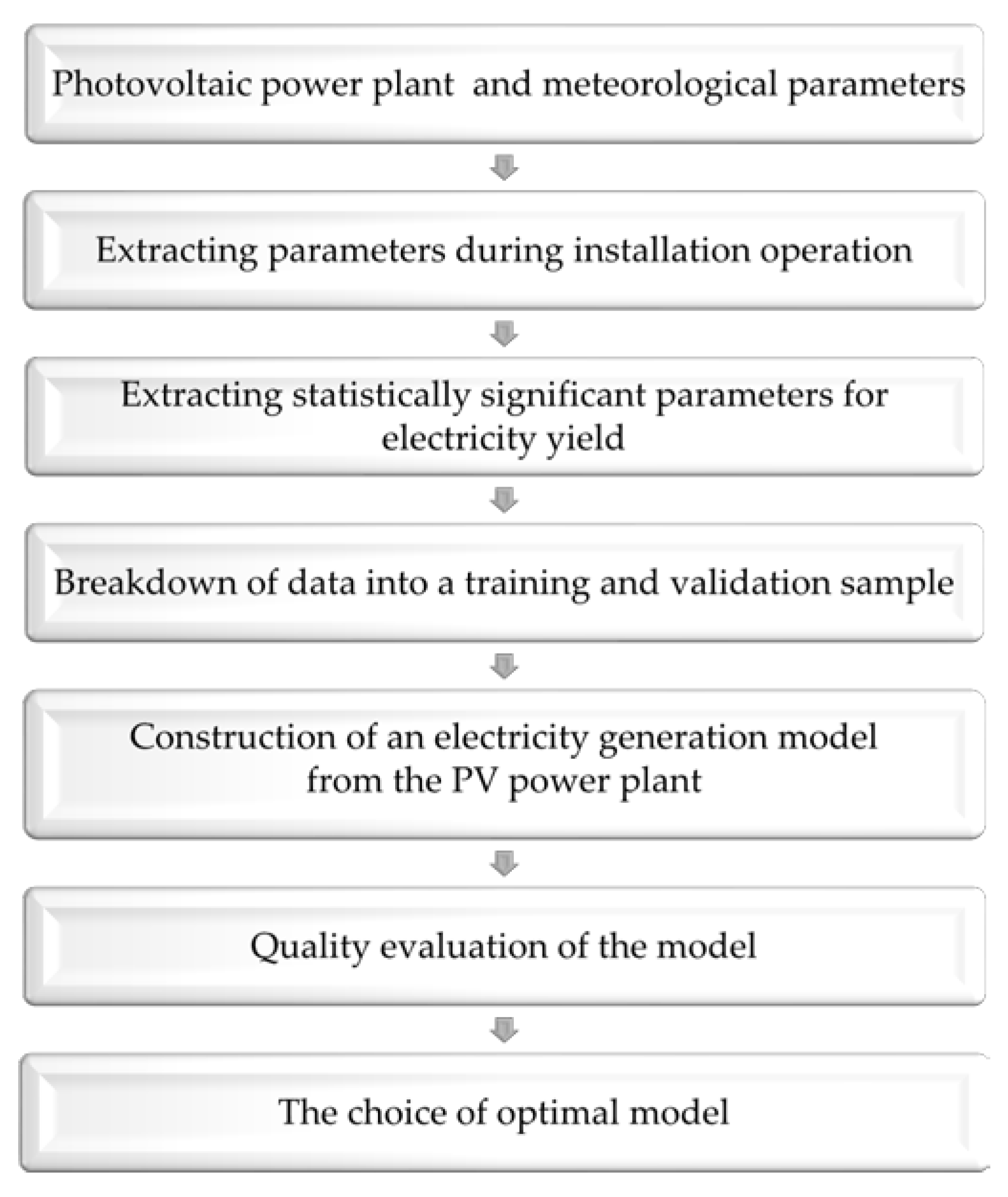

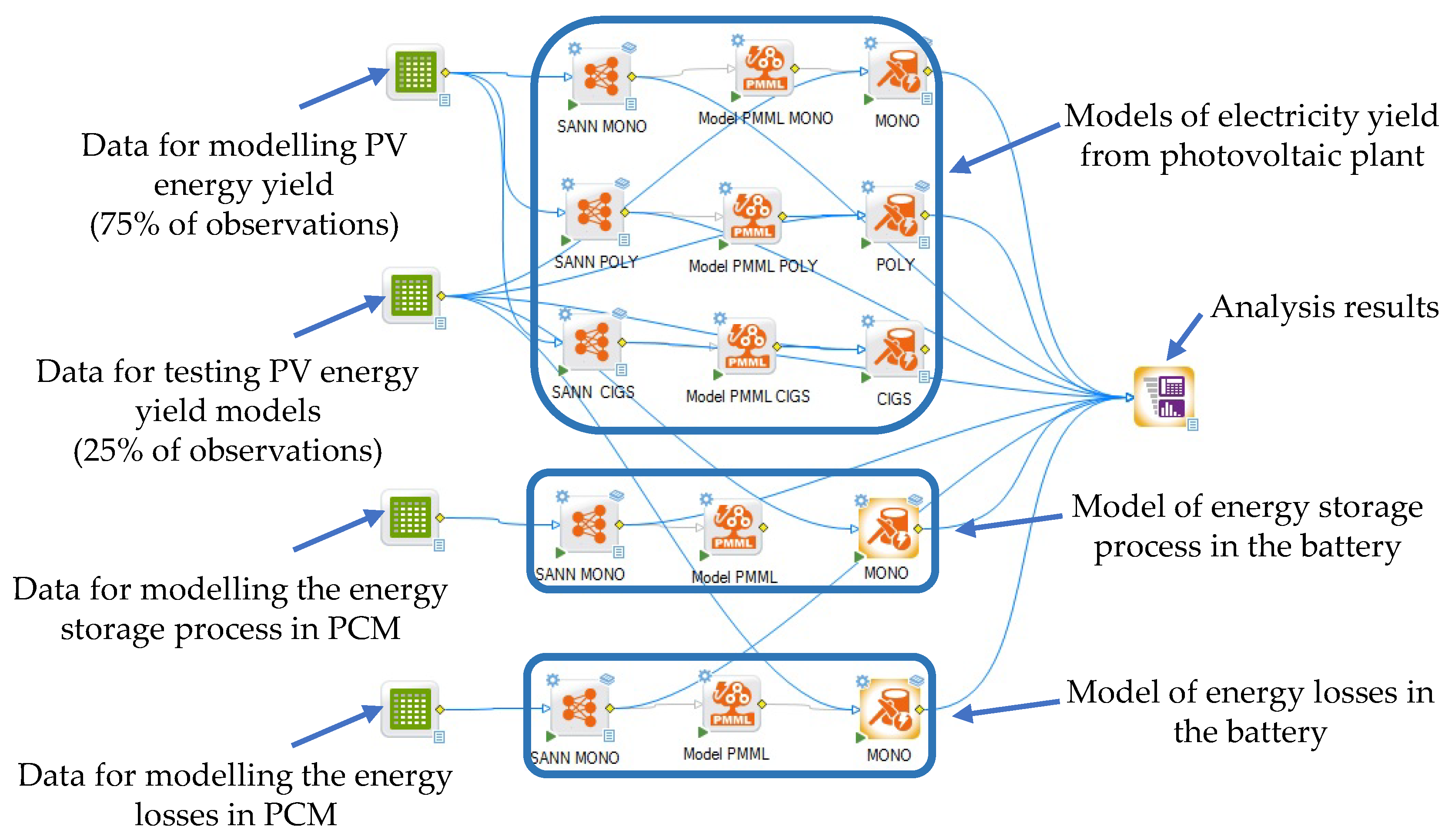

4. Methodology of Conducted Research

- (a)

- Model estimating the amount of electricity obtained from a photovoltaic power plant for each cell type.

- (b)

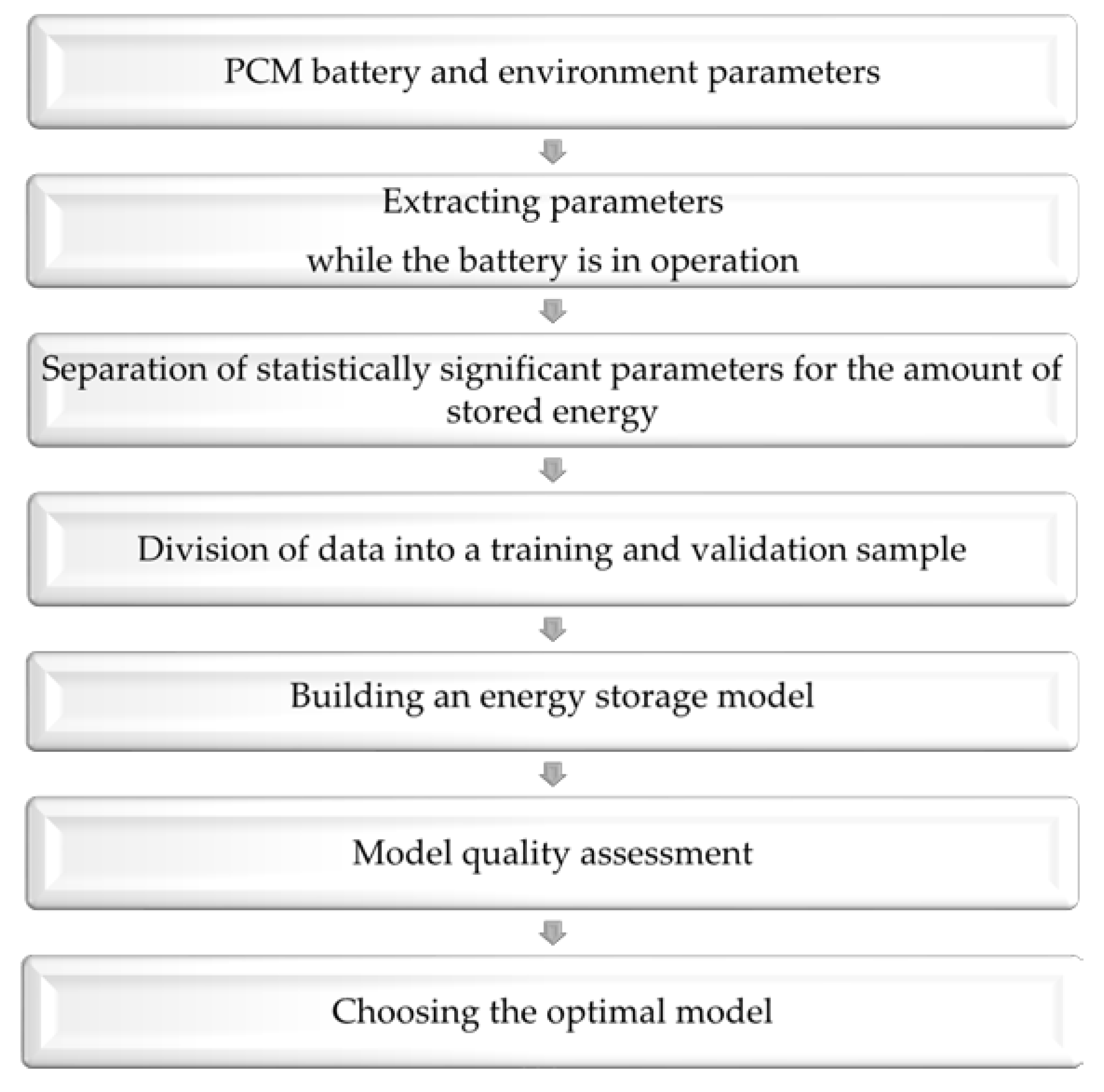

- Model estimating the amount of stored energy in a PCM battery.

- Model of the process of energy storage in an accumulator.

- Model of energy losses in the PCM battery.

4.1. Modelling of Electricity Yield from a Photovoltaic Power Plant

- ANN—an automatic designer was used which searched for the best network by changing the number of neurons in the hidden layer in the range from 3 to 11.

- BRT—the number of observations in a node is not less than 5, the maximum number of nodes is 1000, tree pruning based on the analysis of variance.

- CHAID—maximum number of trees—200, tree construction stop parameters: minimum number 5%, number of descendants between 1-10, maximum number of nodes 3.

- C&RT—minimum number of objects in a node 5, maximum number of nodes 1000, p level for division 0.05.

- RF—maximum number of trees 200, tree construction stop parameters: minimum number 5%, number of descendants from 1-10, maximum number of nodes 100, number of cycles to determine error 10, error reduction percentage 5%.

- MARS—maximum number of base functions 21, order of interaction 1 or 2, penalty for adding another base function 2.

4.2. Modelling the Amount of Stored Energy in a PCM Battery

4.3. Evaluation of the Quality of Predictive Models

- The absolute percentage error (APE)

- 2.

- The mean absolute percentage error (MAPE)

- 3.

- The share of balance differences in relation to the sum of the actual values (ΔESRt):

- Wrz—the actual value,

- Wp—the forecast value,

- n—the number of the last observations of the forecasted variable.

- −

- energy storage index of solar radiation in PCM

- −

- energy storage index from PV in PCM

5. Research Results

5.1. Modelling of Electricity Yield from PV Panels

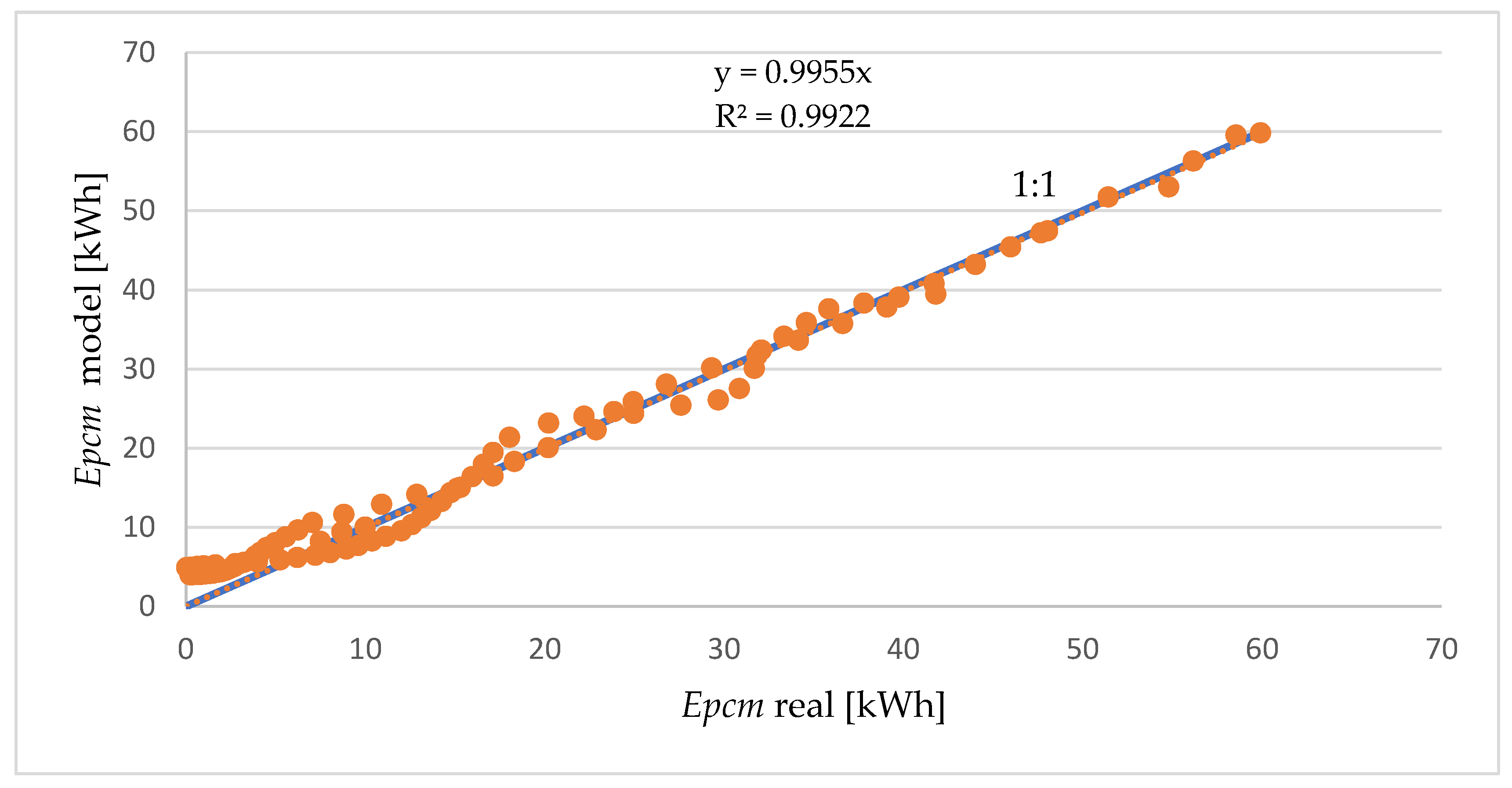

5.2. Modelling of the PCM Battery Charging Process

5.3. Modelling of Energy Storage from Photoelectric Conversion in the Form of an Increase in the Internal Energy of the Battery

- Model of electricity yield from a photovoltaic power plant.

- Model of the process of storing energy in an accumulator.

- Model of energy losses in the PCM battery.

- construction of hybrid models in order to better estimate the amount of available solar radiation energy based on the available forecasts of variables describing meteorological conditions,

- the course of the process of recovering the energy stored in the PCM battery and the impact of dynamics and the depth of its discharge on the efficiency of the process.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature, Parameters and Abbreviations

| ANN | artificial neural network |

| APE | absolute percentage error, [%] |

| BRT | boosting regression trees |

| CART | classification and regression trees |

| CHAID | chi-square automatic interaction detector |

| Cpl | specific heat of the liquid, [kJ∙(kg∙K)−1] |

| Cps | specific heat of the solid, [kJ∙(kg∙K)−1] |

| DSC | differential scanning calorimetry |

| dT | temperature difference |

| EPCM | energy accumulated in the phase change battery, [kWh] |

| EPV | energy from PV panels, [kWh] |

| ES | energy solar radiation, [kWh] |

| L | latent heat solid-solid, [kJ∙kg−1] |

| Lp | latent heat solid-liquid, [kJ∙kg−1] |

| m | paraffin mass, [kg] |

| MAPE | mean absolute percentage error, [%] |

| MARS | multivariate adaptive regression splines |

| PCM | phase change battery |

| PES | intensity of solar radiation, [W∙m−2] |

| PPV | power of photovoltaic plant, [Wp] |

| PV | photovoltaic plant |

| Q | amount of accumulated heat, [kJ] |

| RF | random forest |

| SMR | standard multiple regression, |

| T(p, pm1, pm2, pe1, m, e2, k) | paraffin temperature at characteristic points, [K] |

| WES_PCM | energy storage index of solar radiation in PCM, [%] |

| WPV_PCM | index of electricity storage from PV in PCM |

| ΔESRt | share of balance differences in relation to the sum of the actual values, [%] |

References

- Abhat, A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Anagnostos, D.; Schmidt, T.; Cavadias, S.; Soudris, D.; Poortmans, J.; Catthoor, F. A method for detailed, short-term energy yield forecasting ofphotovoltaic installations. Renew. Energy 2018, 130, 122–129. [Google Scholar] [CrossRef]

- Antonanzas, J.; Osorio, N.; Escobar, R.; Urraca, R.; Martinez-de-Pison, F.J.; Antonanzas-Torres, F. Review of photovoltaic power forecasting. Sol. Energy 2016, 136, 78–111. [Google Scholar] [CrossRef]

- Baczyński, D.; Wasilewski, J. Krótkoterminowe prognozowanie produkcji energii elektrycznej w systemach fotowoltaicznych. Rynek Energii 2011, 96, 47–51. [Google Scholar]

- Beveren, P.J.M.; Bontsema, J.; Stratenc, G.; Hentena, J. Optimal control of greenhouse climate using minimal energy and grower defined bounds. Appl. Energy 2015, 159, 509–519. [Google Scholar] [CrossRef]

- Blanc, P.; Gschwind, B.; Lefe’vre, M.; Wald, L. The HelioClim project: Surface solar irradiance data for climate applications. Remote Sens. 2011, 3, 343–361. [Google Scholar] [CrossRef] [Green Version]

- Blumberga, A.; Timma, L.; Romagnoli, F.; Blumberga, D. Dynamic modeling of a collection scheme of waste portable batteries for ecological and economic sustainability. J. Clean. Prod. 2015, 88, 224–233. [Google Scholar] [CrossRef]

- Bugała, A.; Zaborowicz, M.; Boniecki, P.; Janczak, D.; Koszela, K.; Czekała, W.; Lewicki, A. Short-term forecast of generation of electric energy in photovoltaic systems. Renew. Sustain. Energy Rev. 2018, 81, 306–312. [Google Scholar] [CrossRef]

- Camilo, F.M.; Castro, R.; Almeida, M.E.; Pires, V.F. Economic assessment of residential PV systems with self-consumption and storage in Portugal. Sol. Energy 2017, 150, 353–362. [Google Scholar] [CrossRef]

- Cecati, C.; Kolbusz, J.; Różycki, P.; Siano, P.; Wilamowski, B.M. A Novel RBF Training Algorithm for Short-Term Electric Load Forecasting and Comparative Studies. IEEE Trans. Ind. Electron. 2015, 62, 6519–6529. [Google Scholar] [CrossRef]

- Cococcioni, M.; ·Ducange, P.; Lazzerini, B.; Marcelloni, F. A Pareto-based multi-objective evolutionary approach to the identification of Mamdani fuzzy systems. Soft Comput. 2007, 11, 1013–1031. [Google Scholar] [CrossRef]

- Debnath, K.B.; Mourshed, M. Forecasting methods in energy planning models. Renew. Sustain. Energy Rev. 2018, 88, 297–325. [Google Scholar] [CrossRef] [Green Version]

- Diouf, B.; Pode, R. Potential of lithium-ion batteries in renewable energy. Renew. Energy 2015, 76, 375–380. [Google Scholar] [CrossRef]

- Dobrzańska, I.; Dąsal, K.; Łyp, J.; Popławski, T.; Sowiński, J. Prognozowanie w Elektroenergetyce: Zagadnienia Wybrane: Praca Zbiorowa; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 2002. [Google Scholar]

- Dudek, G. Systemy Uczące Się Oparte na Podobieństwie Obrazów do Prognozowania Szeregów Czasowych Obciążeń Elektroenergetycznych; Akademicka Oficyna Wydawnicza EXIT: Warszawa, Poland, 2012; ISBN 13978-83-7837-508-1. [Google Scholar]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Gańko, M. Technologie magazynowania energii elektrycznej. In Proceedings of the Nowoczesna Energetyka Europy Środkowo-Wschodniej, Warsaw, Poland, 14 October 2015. [Google Scholar]

- Huang, Y.; Lu, J.; Liu, C. Comparative study of power forecasting methods for PV stations. In Proceedings of the International Conference on Power System Technology (POWERCON), Virtual Event, 16 September 2010. [Google Scholar] [CrossRef]

- Huld, T.; Muller, R.; Gambardella, A. A new solar radiation database for estimating PV performance in Europe and Africa. Sol. Energy 2012, 86, 1803–1815. [Google Scholar] [CrossRef]

- Malko, J.; Wojciechowski, H. Magazynowanie energii—Nowe technologie. Nowa Energia 2015, 2–3, 4–10. [Google Scholar]

- Siwek, A.J. Metody Magazynowania Energii Elektrycznej i jej MOżLiwośCI Zastosowań w Procesach Konwersji Odnawialnych źRódeł Energii; Wydawnictwa AGH: Kraków, Poland, 2000. [Google Scholar]

- Al-Yasiri, Q.; Szabó, M. Incorporation of phase change materials into building envelope for thermal comfort and energy saving: A comprehensive analysis. J. Build. Eng. 2021, 36, 102–122. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Performance Assessment of Phase Change Materials Integrated with Building Envelope for Heating Application in Cold Locations. Eur. J. Energy Res. 2021, 1, 7–14. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Case study on the optimal thickness of phase change material incorporated composite roof under hot climate conditions. Case Stud. Constr. Mater. 2021, 14, e00522. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Effect of encapsulation area on the thermal performance of PCM incorporated concrete bricks: A case study under Iraq summer conditions. Case Stud. Constr. Mater. 2021, 15, e00686. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, B.; Zhang, X.; Zhang, T.; Li, D.; Ma, L. Energy performance of window with PCM frame. Sustain. Energy Technol. Assess. 2021, 45, 101–109. [Google Scholar] [CrossRef]

- Faraj, K.; Faraj, J.; Hachem, F.; Bazzi, H.; Khaled, M.; Castelain, C. Analysis of underfloor electrical heating system integrated with coconut oil-PCM plates. Appl. Therm. Eng. 2019, 158, 113778. [Google Scholar] [CrossRef]

- Vengadesan, E.; Senthil, R. A review on recent development of thermal performance enhancement methods of flat plate solar water heater. Sol. Energy 2020, 206, 935–961. [Google Scholar] [CrossRef]

- Khadraoui, A.E.; Bouadila, S.; Kooli, S.; Farhat, A.; Guizani, A. Thermal behavior of indirect solar dryer: Nocturnal usage of solar air collector with PCM. J. Clean. Prod. 2017, 148, 37–48. [Google Scholar] [CrossRef]

- Babar, O.A.; Arora, V.K.; Nema, P.K.; Kasara, A.; Tarafdar, A. Effect of PCM assisted flat plate collector solar drying of green chili on retention of bioactive compounds and control of aflatoxins development. Sol. Energy 2021, 229, 102–111. [Google Scholar] [CrossRef]

- Vigneshkumar, N.; Venkatasudhahar, M.; Kumar, P.M.; Ramesh, A.; Subbiah, R.; Stalin, P.M.J.; Suresh, V.; Kumar, M.N.; Monith, S.; Kumar, R.M.; et al. Investigation on indirect solar dryer for drying sliced potatoes using phase change materials (PCM). Mater. Today: Proc. 2021, 47, 5233–5238. [Google Scholar] [CrossRef]

- Moon, B.E.; Kim, H.T. Evaluation of thermal performance through development of a PCM-based thermal storage control system integrated unglazed transpired collector in experimental pig barn. Sol. Energy 2019, 194, 856–870. [Google Scholar] [CrossRef]

- Rahmanian, S.; Rahmanian-Koushkaki, H.; Omidvar, P.; Shahsavar, A. Nanofluid-PCM heat sink for building integrated concentrated photovoltaic with thermal energy storage and recovery capability. Sustain. Energy Technol. Assess. 2021, 46, 101223. [Google Scholar] [CrossRef]

- Kürklü, A. Energy storage applications in greenhouses by means of phase change materials (PCMs): A review. Renew. Energy 1998, 13, 89–103. [Google Scholar] [CrossRef]

- Najjar, A.; Hasan, A. Modeling of greenhouse with PCM energy storage. Energy Convers. Manag. 2008, 49, 3338–3342. [Google Scholar] [CrossRef]

- Kooli, S.; Bouadila, S.; Lazaar, M.; Farhat, A. The effect of nocturnal shutter on insulated greenhouse using a solar air heater with latent storage energy. Sol. Energy 2015, 115, 217–228. [Google Scholar] [CrossRef]

- Benli, H.; Durmuş, A. Evaluation of ground-source heat pump combined latent heat storage system performance in greenhouse heating. Energy Build. 2009, 41, 220–228. [Google Scholar] [CrossRef]

- Benli, H.; Durmuş, A. Performance analysis of a latent heat storage system with phase change material for new designed solar collectors in greenhouse heating. Sol. Energy 2009, 83, 2109–2119. [Google Scholar] [CrossRef]

- Berroug, F.; Lakhal, E.K.; Omari, M.E.; Faraji, M.; Qarnia, H.E. Thermal performance of a greenhouse with a phase change material north wall 2011. Energy Build. 2011, 43, 3027–3035. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Peña, J.; Rieradevall, J.; Montero, J.I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef] [Green Version]

- Gorjian, S.; Ebadi, H.; Najafi, G.; Chandel, S.S.; Yildizhan, H. Recent advances in net-zero energy greenhouses and adapted thermal energy storage systems. Sustain. Energy Technol. Assess. 2021, 43, 100940. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E. Organic phase change materials and their textile applications: An overview. Thermochim. Acta 2012, 540, 7–60. [Google Scholar] [CrossRef]

- Du, Y.; Zhou, T.; Zhao, C.; Ding, Y. Molecular dynamics simulation on thermal enhancement for carbon nano tubes (CNTs) based phase change materials (PCMs). Int. J. Heat Mass Transf. 2022, 182, 122017. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.; Ling, Z.; Fang, X.; Zhang, Z. RT100/expand graphite composite phase change material with excellent structure stability, photo-thermal performance and good thermal reliability. Sol. Energy Mater. Sol. Cells 2015, 140, 158–166. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Tang, B.; Zhang, S. Single-Walled Carbon Nanotube/Phase Change Material Composites: Sunlight-Driven, Reversible, Form-Stable Phase Transitions for Solar Thermal Energy Storage. Adv. Funct. Mater 2013, 23, 4354–4360. [Google Scholar] [CrossRef]

- Shanbedi, M.; Heris, S.Z.; Amiri, A.; Baniadam, M. Improvement in Heat Transfer of a Two-Phased Closed Thermosyphon Using Silver-Decorated MWCNT/Water. J. Dispers. Sci. Technol. 2014, 35, 1086–1096. [Google Scholar] [CrossRef]

- Atinafu, D.G.; Yun, B.Y.; Wi, S.; Kang, Y.; Kim, S. A comparative analysis of biochar, activated carbon, expanded graphite, and multi-walled carbon nanotubes with respect to PCM loading and energy-storage capacities. Environ. Res. 2021, 195, 110853. [Google Scholar] [CrossRef] [PubMed]

- Atinafu, D.G.; Dong, W.; Huang, X.; Gao, H.; Wang, G. Introduction of organic-organic eutectic PCM in mesoporous N-doped carbons for enhanced thermal conductivity and energy storage capacity. Appl. Energy 2018, 211, 1203–1215. [Google Scholar] [CrossRef]

- Zhu, X.; Han, L.; Yang, F.; Jiang, J.; Jia, X. Lightweight mesoporous carbon fibers with interconnected graphitic walls for supports of form-stable phase change materials with enhanced thermal conductivity. Sol. Energy Mater. Sol. Cells 2020, 208, 110361. [Google Scholar] [CrossRef]

- Chen, R.; Huang, X.; Deng, W.; Zheng, R.; Aftab, W.; Shi, J.; Xie, D.; Zou, R.; Mei, Y. Facile preparation of flexible eicosane/SWCNTs phase change films via colloid aggregation for thermal energy storage. Appl. Energy 2020, 260, 114320. [Google Scholar] [CrossRef]

- Li, B.; Nie, S.; Hao, Y.; Liu, T.; Zhu, J.; Yan, S. Stearic-acid/carbon-nanotube composites with tailored shape-stabilized phase transitions and light–heat conversion for thermal energy storage. Energy Convers. Manag. 2015, 98, 314–321. [Google Scholar] [CrossRef]

- Atinafu, D.G.; Jin Chang, S.; Kim, K.H.; Kim, S. Tuning surface functionality of standard biochars and the resulting uplift capacity of loading/energy storage for organic phase change materials. Chem. Eng. J. 2020, 394, 125049. [Google Scholar] [CrossRef]

- Tang, L.; Zhao, X.; Feng, C.; Bai, L.; Yang, J.; Bao, R.; Liu, Z.; Yang, M.; Yang, W. Bacterial cellulose/MXene hybrid aerogels for photodriven shape-stabilized composite phase change materials. Sol. Energy Mater. Sol. Cells 2019, 203, 110174. [Google Scholar] [CrossRef]

- Wang, X.L.; Li, B.; Qu, Z.G.; Zhang, J.F.; Jin, Z.G. Effects of graphite microstructure evolution on the anisotropic thermal conductivity of expanded graphite/paraffin phase change materials and their thermal energy storage performance. Int. J. Heat Mass Transf. 2020, 155, 119853. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Z.; Wu, Z.; Xu, Y. Numerical modeling and optimization of annual thermal characteristics of an office room with PCM active–passive coupling system. Energy Build. 2022, 254, 111629. [Google Scholar] [CrossRef]

- Kravchenko, E.; Liu, J.; Li, X. Numerical modeling of the thermal performance of soil containing microencapsulated PCM. Constr. Build. Mater. 2021, 298, 123865. [Google Scholar] [CrossRef]

- Voller, V.R. Fast Implicit Finite-Difference Method For The Analysis of Phase Change Problems. Numer. Heat Transf. Part B: Fundamentals 1990, 17, 155–169. [Google Scholar] [CrossRef]

- Kasibhatla, R.R.; König-Haagen, A.; Brüggemann, D. Numerical modelling of wetting phenomena during melting of PCM. Procedia Eng. 2016, 157, 139–147. [Google Scholar] [CrossRef] [Green Version]

- Thonon, M.; Fraisse, G.; Zalewski, L.; Pailha, M. Analytical modelling of PCM supercooling including recalescence for complete and partial heating/cooling cycles. Appl. Therm. Eng. 2021, 190, 116751. [Google Scholar] [CrossRef]

- Tian, S.; Bai, H.; Hui, N.; Gao, H.; Shao, S.; Sun, Z.; Liu, S. A dynamic analytical model to predict and parametrically analyze charging and discharging process of tube-in-tank PCM systems. Therm. Sci. Eng. Prog. 2021, 22, 100866. [Google Scholar] [CrossRef]

- Wijesuriya, S.; Tabares-Velasco, P.C.; Biswas, K.; Heim, D. Empirical validation and comparison of PCM modeling algorithms commonly used in building energy and hygrothermal software. Build. Environ. 2020, 173, 106750. [Google Scholar] [CrossRef]

- National Report of the President of Energy Regulatory Office 2020. Available online: https://www.ure.gov.pl (accessed on 17 November 2021).

| Panel | Error (%) | Metods | ||||||

|---|---|---|---|---|---|---|---|---|

| ANN | RF | BRT | MARS | SMR | CRT | CHAID | ||

| Validation | ||||||||

| MP | MAPE | 7.14 | 8.48 | 8.53 | 6.82 | 6.92 | 8.54 | 9.93 |

| ΔESRt | 7.03 | 7.52 | 8.04 | 6.81 | 6.66 | 8.50 | 8.59 | |

| PP | MAPE | 7.16 | 9.16 | 8.59 | 7.17 | 7.67 | 8.78 | 10.25 |

| ΔESRt | 7.06 | 7.77 | 7.92 | 6.71 | 6.93 | 8.26 | 8.50 | |

| CIGS | MAPE | 8.85 | 12.01 | 12.42 | 9.78 | 15.14 | 11.97 | 14.21 |

| ΔESRt | 8.28 | 9.32 | 9.85 | 8.31 | 8.84 | 10.28 | 10.43 | |

| Battery Working Range: | Average Amount of Energy Delivered kWh | Average Amount of Stored Energy kWh |

|---|---|---|

| to the end of I transformation | 26.10 ± 2.71 | 20.24 ± 1.29 |

| to the end of the II transformation | 68.35 ± 2.11 | 58.45 ± 0.84 |

| while charging | 69.59 ± 1.8 | 58.67 ± 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karbowniczak, A.; Latała, H.; Nęcka, K.; Kurpaska, S.; Książek, L. Modelling of Energy Storage System from Photoelectric Conversion in a Phase Change Battery. Energies 2022, 15, 1132. https://doi.org/10.3390/en15031132

Karbowniczak A, Latała H, Nęcka K, Kurpaska S, Książek L. Modelling of Energy Storage System from Photoelectric Conversion in a Phase Change Battery. Energies. 2022; 15(3):1132. https://doi.org/10.3390/en15031132

Chicago/Turabian StyleKarbowniczak, Anna, Hubert Latała, Krzysztof Nęcka, Sławomir Kurpaska, and Leszek Książek. 2022. "Modelling of Energy Storage System from Photoelectric Conversion in a Phase Change Battery" Energies 15, no. 3: 1132. https://doi.org/10.3390/en15031132

APA StyleKarbowniczak, A., Latała, H., Nęcka, K., Kurpaska, S., & Książek, L. (2022). Modelling of Energy Storage System from Photoelectric Conversion in a Phase Change Battery. Energies, 15(3), 1132. https://doi.org/10.3390/en15031132