Modelling of the Electric Energy Storage Process in a PCM Battery

Abstract

:1. Introduction

2. Purpose and Scope of Work

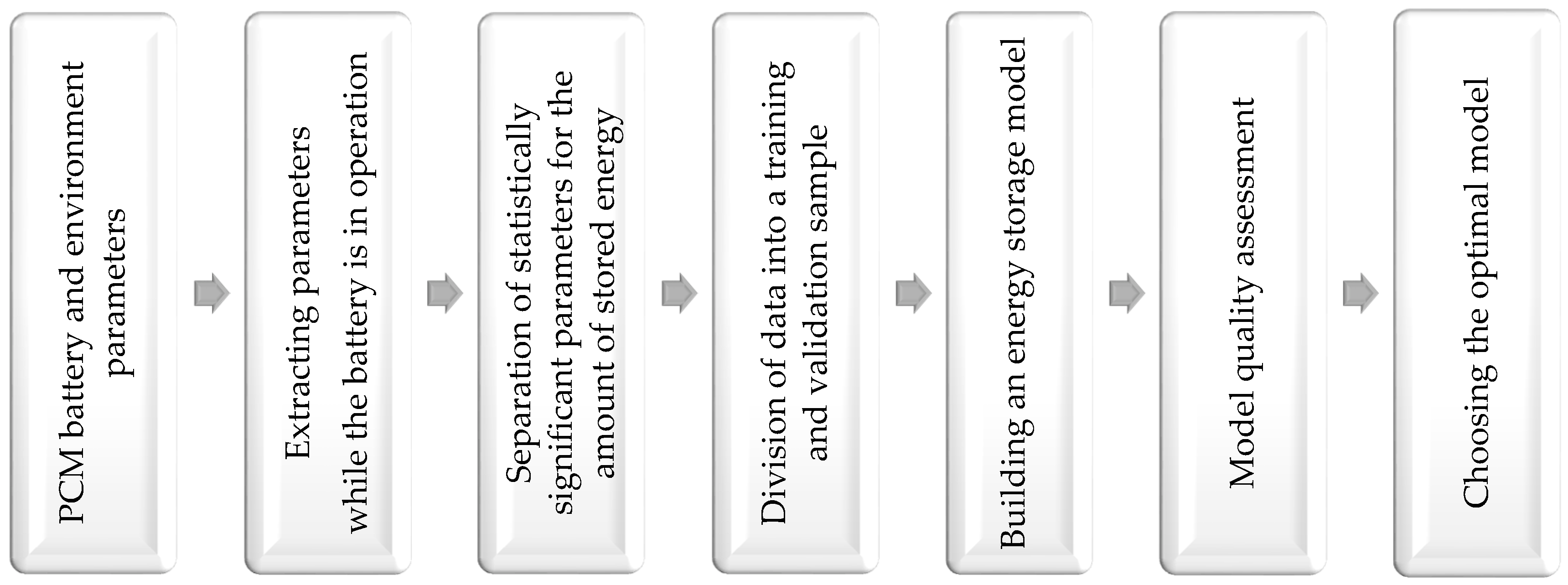

3. Materials and Methods

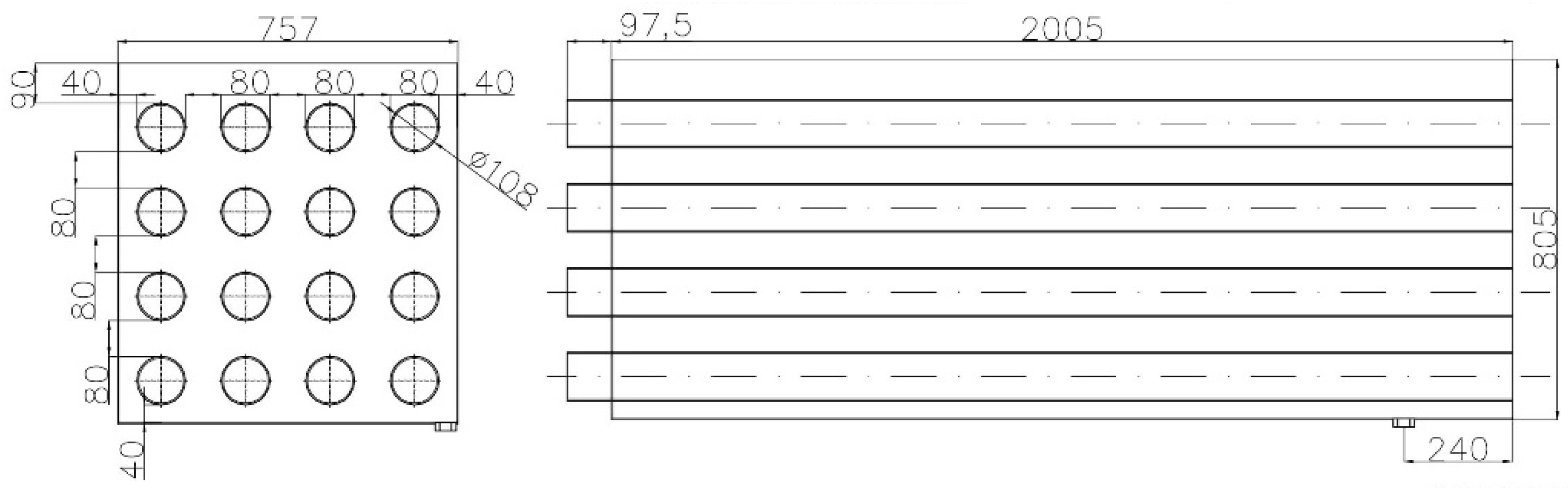

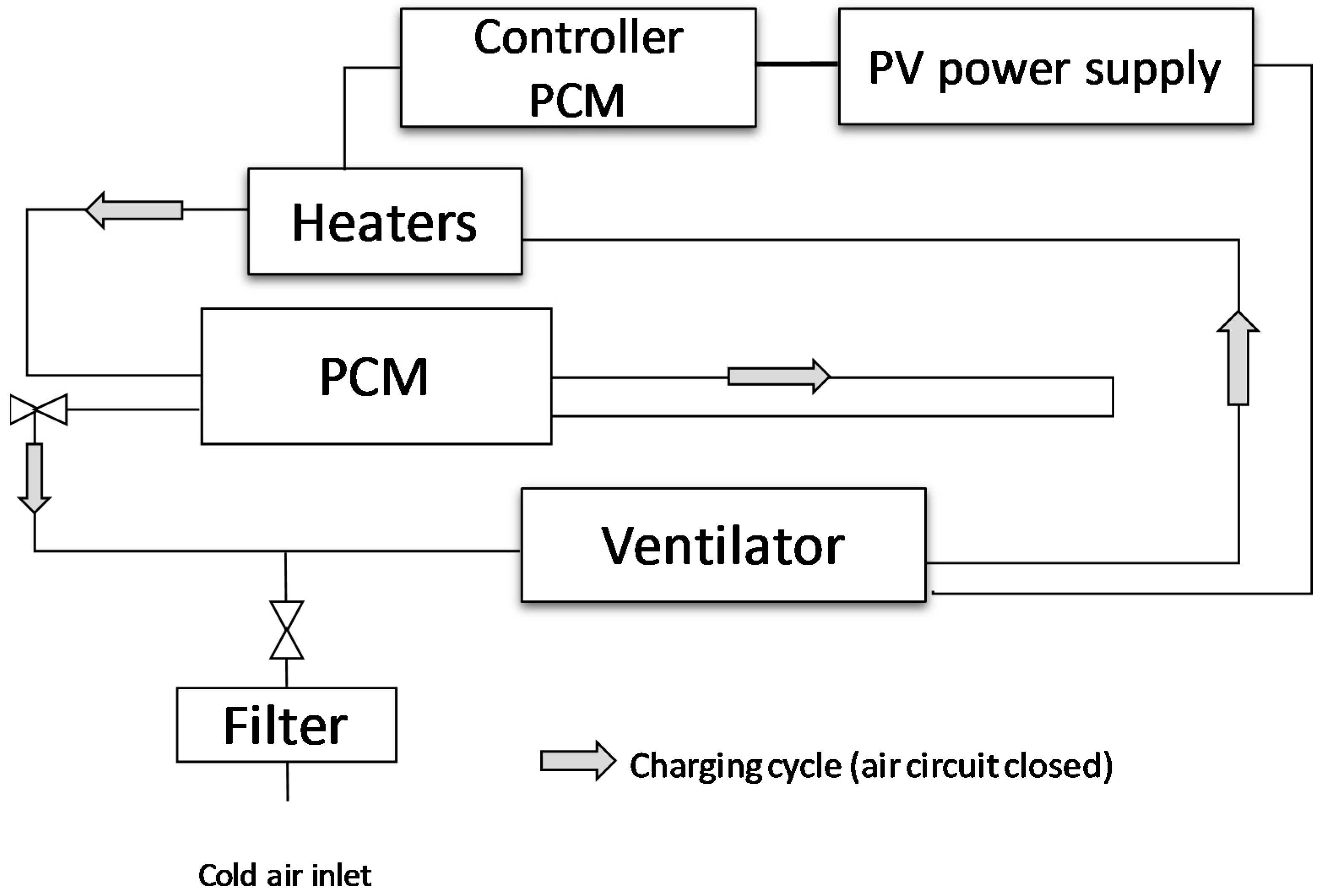

3.1. PCM Phase Conversion Battery

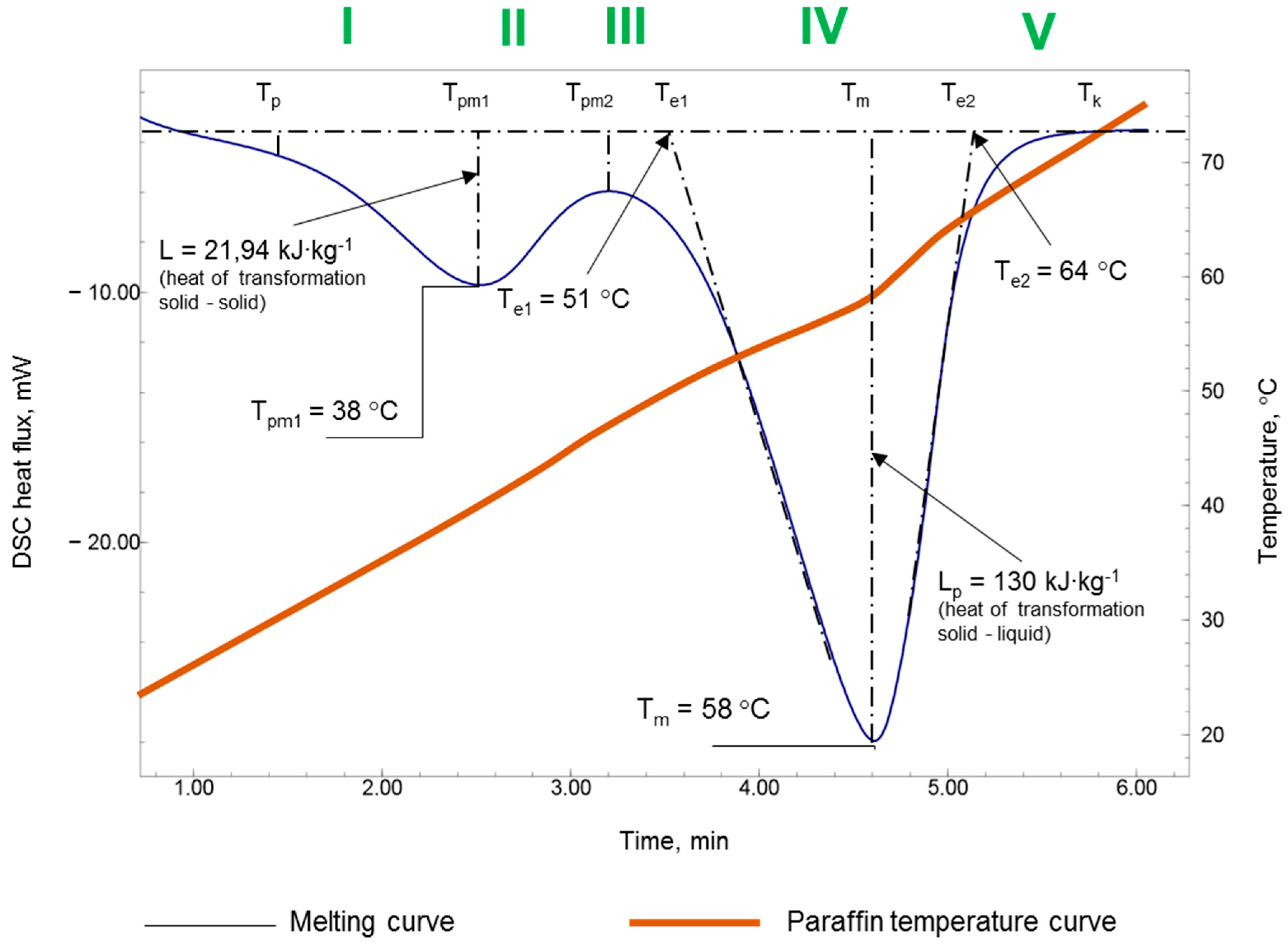

3.2. Storage Medium

- Phase change temperature,

- Latent heat,

- Specific heat.

4. Methodology of Conducted Research

- Model of the energy storage process in the battery.

- Model of energy losses in the PCM battery.

4.1. Modeling of the Energy Storage Process in a PCM Battery

- ANN—the construction of a neural model required, first of all, the determination of the optimal network architecture (number of neurons in the hidden layer, number of layers, network type). It was also necessary to select the method of signal propagation in the network, the learning algorithm and the activation function of individual layers.

- BRT—the minimum number of nodes was 5 observations, the maximum number of nodes was 1000, tree pruning stops were made on the basis of variance analysis.

- CHAID—learning coefficient—0.1, number of trees—200, proportion for subsets—0.5, retention parameters: minimum number, 5%; minimum n child, 1; maximum number of descendants, 10; maximum number of nodes, 3.

- CRT—minimum number of objects in a node, 5; maximum number of nodes, 1000; p level for division, 0.05.

- RF—number of trees, 100; the stopping parameters were: minimum frequency, 5%; minimum n child, 5; maximum number of descendants, 10; maximum number of nodes, 100; number of cycles to determine error, 10; error reduction percentage, 5%.

- MARS—maximum number of base functions, 21; order of interaction, 1 or 2; penalty for adding another base function 2.

4.2. Modelling of Energy Losses in a PCM Battery

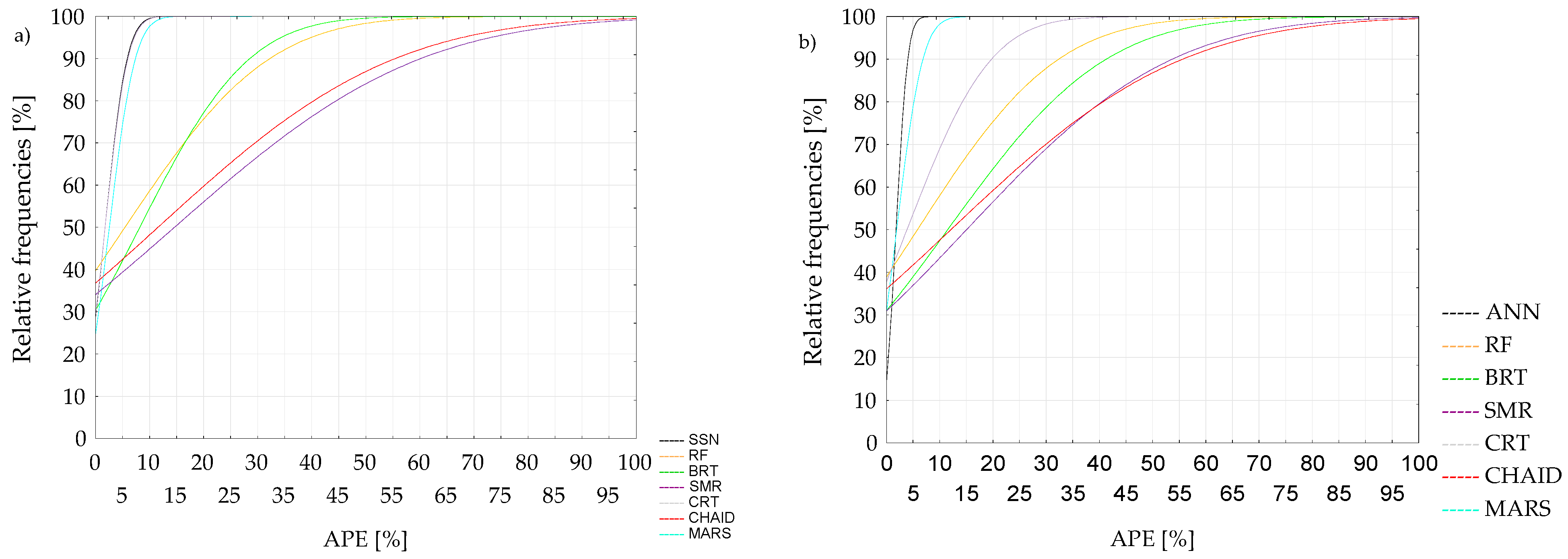

4.3. Evaluation of the Quality of Predictive Models

- The absolute percentage error (APE)

- 2.

- The mean absolute percentage error (MAPE)

- 3.

- The share of balance differences in relation to the sum of the actual values (ΔESRt):

5. Research Results

5.1. Determination of the Physical Properties of R58 Paraffin

5.2. Modeling the Battery Charging Process PCM

5.3. Modeling the Process of Accumulating Electricity in a PCM Battery

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature, Parameters and Abbreviations

| ANN | Artificial neural network | |

| APE | Absolute percentage error | [%] |

| BRT | Boosting regression trees | |

| CRT | Classification and regression trees | |

| CHAID | Chi-square automatic interaction detector | |

| Cpl | Specific heat of the liquid | [kJ∙(kg∙K)−1] |

| Cps | Specific heat of the solid | [kJ∙(kg∙K)−1] |

| DSC | Differential scanning calorimetry | |

| dT | Temperature difference | |

| EPCM | Energy accumulated in the phase change battery | [kWh] |

| L | Latent heat solid-solid | [kJ∙kg−1] |

| Lp | Latent heat solid-liquid | [kJ∙kg−1] |

| m | Paraffin mass | [kg] |

| MAPE | Mean absolute percentage error | [%] |

| MARS | Multivariate adaptive regression splines | |

| PCM | Phase change battery | |

| PES | Intensity of solar radiation | [W∙m−2] |

| PPV | Power of photovoltaic plant | [Wp] |

| PV | Photovoltaic plant | |

| Q | Amount of accumulated heat | [kJ] |

| RF | Random forest | |

| SMR | Standard multiple regression | |

| T(p, pm1, pm2, pe1, m, e2, k) | Paraffin temperature at characteristic points | [K] |

| WES_PCM | Energy storage index of solar radiation in PCM | [%] |

| WPV_PCM | Index of electricity storage from PV in PCM | |

| ΔESRt | Share of balance differences in relation to the sum of the actual values | [%] |

References

- Piwowar, A.; Dzikuć, M. Proekologiczna gospodarka energetyczna w rolnictwie i na obszarach wiejskich w Polsce—Stan aktualny i perspektywy rozwoju. Wieś Rol. 2015, 3, 107–115. [Google Scholar]

- Blanc, P.; Gschwind, B.; Lefevre, M.; Wald, L. The HelioClim project: Surface solar irradiance data for climate applications. Remote Sens. 2011, 3, 343–361. [Google Scholar] [CrossRef] [Green Version]

- Huld, T.; Muller, R.; Gambardella, A. A new solar radiation database for estimating PV performance in Europe and Africa. Sol. Energy 2012, 86, 1803–1815. [Google Scholar] [CrossRef]

- Suri, M.; Huld, T.; Dunlop, E.; Ossenbrink, H. Potential of solar electricity generation in the European Union member states and candidate countries. Sol. Energy 2007, 81, 1295–1305. [Google Scholar] [CrossRef]

- Remund, J.; Kunz, S. METEONORM: Global Meteorological Database for Solar Energy and Applied Climatology; Meteotest: Bern, Switzerland, 1997. [Google Scholar]

- Antonanzas, J.; Osorio, N.; Escobar, R.; Urraca, R.; Martinez-de-Pison, F.J.; Antonanzas-Torres, F. Review of photovoltaic power forecasting. Sol. Energy 2016, 136, 78–111. [Google Scholar] [CrossRef]

- Debnath, K.B.; Mourshed, M. Forecasting methods in energy planning models. Renew. Sustain. Energy Rev. 2018, 88, 297–325. [Google Scholar] [CrossRef] [Green Version]

- Almonacid, F.; Pérez-Higueras, P.; Fernández, E.F.; Hontoria, L. A methodology based on dynamic artificial neural network for short-term forecasting of the power output of a PV generator. Energy Convers. Manag. 2014, 85, 389–398. [Google Scholar] [CrossRef]

- Anagnostos, D.; Schmidt, T.; Cavadias, S.; Soudris, D.; Poortmans, J.; Catthoor, F. A method for detailed, short-term energy yield forecasting of photovoltaic installations. Renew. Energy 2018, 130, 122–129. [Google Scholar] [CrossRef]

- Bugała, A.; Zaborowicz, M.; Boniecki, P.; Janczak, D.; Koszela, K.; Czekała, W.; Lewicki, A. Short-term forecast of generation of electric energy in photovoltaic systems. Renew. Sustain. Energy Rev. 2018, 81, 306–312. [Google Scholar] [CrossRef]

- Sobri, S.; Koohi-Kamalia, S.; Rahima, N.A. Solar photovoltaic generation forecasting methods: A review. Energy Convers. Manag. 2018, 156, 459–497. [Google Scholar] [CrossRef]

- Cococcioni, M.; Ducange, P.; Lazzerini, B.; Marcelloni, F. A Pareto-based multi-objective evolutionary approach to the identification of Mamdani fuzzy systems. Soft Comput. 2007, 11, 1013–1031. [Google Scholar] [CrossRef]

- Tao, C.; Shanxu, D.; Changsong, C. Forecasting power output for gridconnected photovoltaic power system without using solar radiation measurement. In Proceedings of the 2nd IEEE International Symposium on Power Electronics for Distributed Generation Systems, Hefei, China, 16–18 June 2010. [Google Scholar] [CrossRef]

- Piotrowski, P. Analiza zastosowań sztucznych sieci neuronowych do krótkoterminowego prognozowania mocy oraz produkcji energii elektrycznej w systemach fotowoltaicznych. Przegląd Elektrotechniczny 2015, 91, 162–165. [Google Scholar] [CrossRef]

- Baczyński, D.; Wasilewski, J. Krótkoterminowe prognozowanie produkcji energii elektrycznej w systemach fotowoltaicznych. Rynek Energii 2011, 96, 47–51. [Google Scholar]

- Huang, Y.; Lu, J.; Liu, C. Comparative study of power forecasting methods for PV stations. In Proceedings of the International Conference on Power System Technology (POWERCON), Hangzhou, China, 24–28 October 2010. [Google Scholar] [CrossRef]

- Mellit, A.; Pavan, A.M. A 24-h forecast of solar irradiance using artificial neural network: Application for performance prediction of a grid-connected PV plant at Trieste, Italy. Sol. Energy 2010, 84, 807–821. [Google Scholar] [CrossRef]

- Monteiro, C.; Fernandez-Jimenez, L.A.; Ramirez-Rosado, I.; Muñoz-Jimenez, A.; Santillan, L.P. Short-term forecasting models for photovoltaic plants: Analytical versus soft-computing techniques. Math. Probl. Eng. 2013, 2013, 767284. [Google Scholar] [CrossRef] [Green Version]

- Yona, A.; Senjyu, T.; Saber, A.Y.; Funabashi, T.; Sekine, H.; Kim, C.H. Application of neural network to 24-h head generating power forecasting for PV system. In Proceedings of the Power and Energy Society General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008. [Google Scholar] [CrossRef]

- Wu, Y.K.; Chen, C.R.; Rahman, H.A. A novel hybrid model for short-term forecasting in PV power generation. Int. J. Photoenergy 2014, 2014, 569249. [Google Scholar] [CrossRef] [Green Version]

- Zeng, J.; Qiao, W. Short-term solar power prediction using a support vector machine. Renew. Energy 2013, 52, 118–127. [Google Scholar] [CrossRef]

- Cecati, C.; Kolbusz, J.; Różycki, P.; Siano, P.; Wilamowski, B.M. A novel RBF training algorithm for short-term electric load forecasting and comparative studies. IEEE Trans. Ind. Electron. 2015, 62, 6519–6529. [Google Scholar] [CrossRef]

- Yu, S.; Wang, K.; Wei, Y.M. A hybrid self-adaptive particle swarm optimization–genetic algorithm–radial basis function model for annual electricity demand prediction. Energy Convers. Manag. 2015, 91, 176–185. [Google Scholar] [CrossRef]

- Piotrowski, P. Analiza Implementacji Sztucznych Sieci Neuronowych w Zadaniu Prognozowania Ultrakrótkoterminowego Oraz Sformułowanie Wytycznych Dotyczących Prognozowania, Praca na Zlecenie; Globema Sp. z o.o.: Warsaw, Poland, 2012. [Google Scholar]

- Xu, R.; Chen, H.; Sun, X. Short-term photovoltaic power forecasting with weighted support vector machine. In Proceedings of the IEEE International Conference on Automation and Logistics (ICAL), Zhengzhou, China, 15–17 August 2012; pp. 248–253. [Google Scholar] [CrossRef]

- Yang, C.; Thatte, A.A.; Xie, L. Multitime-scale data-driven spatio-temporal forecast of photovoltaic generation. IEEE Trans. Sustain. Energy 2015, 6, 104–112. [Google Scholar] [CrossRef]

- Leva, S.; Dolara, A.; Grimaccia, F.; Mussetta, M.; Ogliari, E. Analysis and validation of 24 h ahead neural network forecasting of photovoltaic output power. Math. Comput. Simul. 2017, 131, 88–100. [Google Scholar] [CrossRef] [Green Version]

- Pedro, H.T.; Coimbra, C.F. Assessment of forecasting techniques for solar power production with no exogenous inputs. Sol. Energy 2012, 86, 2017–2028. [Google Scholar] [CrossRef]

- Liu, J.; Fang, W.; Zhang, X.; Yang, C. An improved photovoltaic power forecasting model with the assistance of aerosol index data. IEEE Trans. Sustain. Energy 2015, 6, 434–442. [Google Scholar] [CrossRef]

- Rana, M.; Koprinska, I.; Agelidis, V.G. Forecasting solar power generated by grid connected PV systems using ensembles of neural networks. In Proceedings of the International Joint Conference on Neural Networks (IJCNN), Killarney, Ireland, 12–17 July 2015; pp. 1–8. [Google Scholar]

- Almeida, M.P.; Perpiñán, O.; Narvarte, L. PV power forecast using a nonparametric PV model. Sol. Energy 2015, 115, 354–368. [Google Scholar] [CrossRef] [Green Version]

- Camilo, F.M.; Castro, R.; Almeida, M.E.; Pires, V.F. Economic assessment of residential PV systems with self-consumption and storage in Portugal. Sol. Energy 2017, 150, 353–362. [Google Scholar] [CrossRef]

- Núñez-Reyes, A.; Marcos Rodríguez, D.; Bordons Alba, C.; Ridao Carlini, M.A. Optimal scheduling of grid-connected PV plants with energy storage for integration in the electricity market. Sol. Energy 2017, 144, 502–516. [Google Scholar] [CrossRef]

- Diouf, B.; Pode, R. Potential of lithium-ion batteries in renewable energy. Renew. Energy 2015, 76, 375–380. [Google Scholar] [CrossRef]

- Gańko, M. Technologie Magazynowania Energii Elektrycznej Nowoczesna Energetyka Europy Środkowo-Wschodniej 2015—Materiały Konferencyjne.

- Malko, J.; Wojciechowski, H. Magazynowanie energii—Nowe technologie. Nowa Energ. 2015, 2, 1–9. [Google Scholar]

- Siwek, A.J. Metody Magazynowania Energii Elektrycznej i jej Możliwości Zastosowań w Procesach Konwersji Odnawialnych Źródeł Energii; Wydawnictwa AGH: Kraków, Poland, 2000. [Google Scholar]

- Blumberga, A.; Timma, L.; Romagnoli, F.; Blumberga, D. Dynamic modeling of a collection scheme of waste portable batteries for ecological and economic sustainability. J. Clean. Prod. 2015, 88, 224–233. [Google Scholar] [CrossRef]

- Abhat, A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Al-Maghalseh, M.; Mahkamov, K. Methods of heat transfer intensification in PCM thermal storage systems: Review paper. Renew. Sustain. Energy Rev. 2018, 92, 62–94. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Saidur, R.; Al-Sulaiman, F.A. A review for phase change materials (PCMs) in solar absorption refrigeration systems. Renew. Sustain. Energy Rev. 2017, 76, 105–137. [Google Scholar] [CrossRef]

- Neumann, H.; Gamisch, S.; Gschwander, S. Comparison of RC-model and FEM-model for a PCM-plate storage including free convection. Appl. Therm. Eng. 2021, 196, 117232. [Google Scholar] [CrossRef]

- Dobri, A.; Tsiantis, A.; Papathanasiou, T.D.; Wang, Y. Investigation of transient heat transfer in multi-scale PCM composites using a semi-analytical model. Int. J. Heat Mass Transf. 2021, 175, 121389. [Google Scholar] [CrossRef]

- Roccamena, L.; El Mankibi, M.; Stathopoulos, N. Development and validation of the numerical model of an innovative PCM based thermal storage system. J. Storage Mater. 2019, 24, 100740. [Google Scholar] [CrossRef]

- Morovat, N.; Athienitis, A.K.; Candanedo, J.A.; Dermardiros, V. Simulation and performance analysis of an active PCM-heat exchanger intended for building operationoptimization. Energy Build. 2019, 199, 47–61. [Google Scholar] [CrossRef]

- Zhang, Y. Modified computational methods using effective heat capacity model for the thermal evaluation of PCM outfitted walls. Int. Commun. Heat Mass Transf. 2019, 108, 104278. [Google Scholar] [CrossRef]

- Fateh, A.; Borelli, D.; Weinlader, H.; Devia, F. Cardinal orientation and melting temperaturę effects for PCM-enhanced light-walls in different climates. Sustain. Cities Soc. 2019, 51, 101766. [Google Scholar] [CrossRef]

- Markarian, E.; Fazelpour, F. Multi-objective optimization of energy performance of a building considering different configurations and types of PCM. Sol. Energy 2019, 191, 481–496. [Google Scholar] [CrossRef]

- Cao, Y.; Faghri, A. A numerical analysis of phase-change problems including natural convection. J. Heat Transf. 1990, 112, 812–816. [Google Scholar] [CrossRef]

- Eyres, N.R.; Hartree, D.R.; Ingham, J.; Jackson, R.; Sarjant, R.J.; Wagstaff, J.B. The calculation of variable heat flow in solids. Philos. Trans. R. Soc. A Athem. Phys. Eng. Sci. 1946, 1, 1–57. [Google Scholar] [CrossRef]

- AL-Saadi, N.S.; Zhai, Z. Modeling phase change materials embedded in building enclosure: A review. Renew. Sustain. Energy Rev. 2013, 21, 659–673. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Z.; Wu, Z.; Xu, Y. Numerical modeling and optimization of annual thermal characteristics of an office room with PCM active–passive coupling system. Energy Build. 2022, 254, 111629. [Google Scholar] [CrossRef]

- Kravchenko, E.; Liu, J.; Li, X. Numerical modelling of the thermal performance of soil containing microencapsulated PCM. Construct. Build. Mater. 2021, 298, 123865. [Google Scholar] [CrossRef]

- Thonon, M.; Fraisse, G.; Zalewski, L.; Pailha, M. Analytical modelling of PCM supercooling including recalescence for complete and partial heating/cooling cycles. Appl. Therm. Eng. 2021, 190, 116751. [Google Scholar] [CrossRef]

- Bennon, W.D.; Incropera, F.P. A continuum model for momentum, heat and species transport in binary solid-liquid phase change systems—I. model formulation. Int. J. Heat Mass Transf. 1987, 30, 2161–2170. [Google Scholar] [CrossRef]

- Bennon, W.D.; Incropera, F.P. A continuum model for momentum, heat and species transport in binary solid-liquid phase change systems. II: Application to solidification in a rectangular cavity. Int. J. Heat Mass Transf. 1987, 30, 2171–2187. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, K.; He, J.P.; Yang, L.; Li, Y.J. Impact factors analysis of the enthalpy method and the effective heat capacity method on the transient nonlinear heat transfer in phase change materials (PCMs)—Numerical heat transfer, part A: Applications. Int. J. Comput. Methodol. 2014, 65, 66–83. [Google Scholar] [CrossRef]

- Kasibhatla, R.R.; König-Haagen, A.; Brüggemann, D. Numerical modelling of wetting phenomena during melting of PCM. Procedia Eng. 2016, 157, 139–147. [Google Scholar] [CrossRef] [Green Version]

- Voller, V.R.; Prakash, C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- Voller, V.; Cross, M. An explicit numerical method to. Int. J. Heat Mass Transf. 1983, 26, 147–150. [Google Scholar] [CrossRef]

- Hashemi, T.H.; Sliepcevich, C.M. A numerical method for solving two-dimensional problems of heat conduction with change of phase. Chem. Eng. Prog. Symp. Ser. 1968, 63, 34–41. [Google Scholar]

- Mahdi, M.S.; Mahood, H.B.; Mahdi, J.M.; Khadom, A.A.; Campbell, A.N. Improved PCM melting in a thermal energy storage system of double-pipe helical-coil tube. Energy Convers. Manag. 2020, 203, 112238. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Mohammed, H.I.; Hashim, E.T.; Talebizadehsardari, P.; Nsofor, E.C. Solidification enhancement with multiple PCMs, cascaded metal foam and nanoparticles in the shell-and-tube energy storage system. Appl. Energy 2020, 257, 113993. [Google Scholar] [CrossRef]

- Gholamibozanjani, G.; Farid, M. Experimental and mathematical modeling of an air PCM heat exchanger operating under static and dynamic loads. Energy Build. 2019, 202, 109354. [Google Scholar] [CrossRef]

- Jaworski, M. Mathematical model of heat transfer in PCM incorporated fabrics subjected to different thermal loads. Appl. Therm. Eng. 2019, 150, 506–511. [Google Scholar] [CrossRef]

- El Khadraoui, A.; Bouadila, S.; Kooli, S.; Farhat, A.; Guizani, A. Thermal behavior of indirect solar dryer: Nocturnal usage of solar air collector with PCM. J. Clean. Prod. 2017, 148, 37–48. [Google Scholar] [CrossRef]

- Babar, O.A.; Arora, V.K.; Nema, P.K.; Kasara, A.; Tarafdar, A. Effect of PCM assisted flat plate collector solar drying of green chili on retention of bioactive compounds and control of aflatoxins development. Sol. Energy 2021, 229, 102–111. [Google Scholar] [CrossRef]

- Vigneshkumar, N. Investigation on indirect solar dryer for drying sliced potatoes using phase change materials (PCM). Mater. Today Proc. 2021, 47, 5233–5238. [Google Scholar] [CrossRef]

- Vengadesan, E.; Senthil, R. A review on recent development of thermal performance enhancement methods of flat plate solar water heater. Sol. Energy 2020, 206, 935–961. [Google Scholar] [CrossRef]

- Najjar, A.; Hasan, A. Modeling of greenhouse with PCM energy storage. Energy Convers. Manag. 2008, 49, 3338–3342. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Peña, J.; Rieradevall, J.; Montero, I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef] [Green Version]

- Kürklü, A. Energy storage applications in greenhouses by means of phase change materials (PCMs): A review. Renew. Energy 1998, 13, 89–103. [Google Scholar] [CrossRef]

- Beveren, P.J.M.; Bontsema, J.; Stratenc, G.; Hentena, J. Optimal control of greenhouse climate using minimal energy and grower defined bounds. Appl. Energy 2015, 159, 509–519. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- DSC-60 Plus Addresses the Various DSC Applications. Available online: https://www.shimadzu.com/an/products/thermal-analysis/differential-scanning-calorimeters/dsc-60-plus-series/index.html (accessed on 20 October 2021).

- PerkinElmer DSC 7. Available online: https://www.labx.com/product/perkin-elmer-dsc-7 (accessed on 20 October 2021).

- Kass, G.V. An exploratory technique for investigating large quantities of categorical data. Appl. Stat. 1980, 29, 119–127. [Google Scholar] [CrossRef]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Wadsworth & Brooks/Cole Advanced Books & Software: Monterey, CA, USA, 1984. [Google Scholar] [CrossRef]

- Ripley, B.D. Pattern Recognition and Neural Networks; Cambridge University Press: Cambridge, UK, 1996; ISBN 0-521-46086-7. [Google Scholar]

- Friedman, J. Multivariate adaptive regression splines (with discussion). Ann. Stat. 1991, 19, 79–141. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J.H. The Elements of Statistical Learning: Data Mining, Inference, and Prediction; Springer: New York, NY, USA, 2001. [Google Scholar]

| Description | Dimensions |

|---|---|

| Total length *) | 3 m |

| Width | 1.1 m |

| Height | 1.6 m |

| Diameter of the connection piece on the inlet and outlet | 0.315 m |

| The diameter of the heat exchanger tubes | DN100 mm |

| Thermal insulation thickness **) | 100 mm |

| Circulation pipe diameter | 0.315 m |

| Heat transfer surface area | 13.5 m2 |

| The mass of the battery structure | 1000 kg |

| Measured Parameter | Unit | Condition of the Material Tested | |

|---|---|---|---|

| I Transformation Solid–Solid | I Transformation Solid–Liquid | ||

| Melting temperature | °C | 38 | 58 |

| Heat of a phase transition of melting | kJ∙kg−1 | 21.94 | 130 |

| Specific heat | kJ∙(kg∙K)−1 | 6.37 | 23 |

| Dependent Variable | Correlation Coefficient | ||

|---|---|---|---|

| Energy Supplied to the Battery | Paraffin Temperature | Temperature Inside the Object | |

| Energy stored in the battery | 0.99 | 0.98 | 0.43 |

| The Name of the Network | Learning Algorithm | Error Function | Activation (Hidden) | Activation (Starting) | Error (Learning) | Error (Testing) | Error (Validation) |

|---|---|---|---|---|---|---|---|

| MLP 3-11-1 | BFGS 278 | SOS | Logistic | Tanh | 0.042 | 0.168 | 0.602 |

| MLP 3-4-1 | BFGS 84 | SOS | Tanh | Logistic | 0.125 | 0.202 | 0.319 |

| MLP 3-10-1 | BFGS 238 | SOS | Tanh | Logistic | 0.043 | 0.160 | 0.219 |

| MLP 3-5-1 | BFGS 105 | SOS | Logistic | Tanh | 0.096 | 0.139 | 0.403 |

| MLP 3-4-1 | BFGS 93 | SOS | Logistic | Linear | 0.132 | 0.278 | 0.346 |

| ANN | Model Sensitivity Index for the Independent Variable [-]: | ||

|---|---|---|---|

| Paraffin Temperature | Energy Supplied to the Battery | Temperature Inside the Object | |

| MLP 3-11-1 | 542.75 | 330.49 | 8.23 |

| MLP 3-4-1 | 854.54 | 611.90 | 16.32 |

| MLP 3-10-1 | 716.79 | 732.63 | 11.01 |

| MLP 3-5-1 | 1339.36 | 227.60 | 18.32 |

| MLP 3-4-1 | 948.34 | 627.67 | 8.11 |

| Error [%] | Methods | ||||||

|---|---|---|---|---|---|---|---|

| ANN | RF | BRT | MARS | SMR | CRT | CHAID | |

| Teaching | |||||||

| MAPE [%] | 1.79 | 5.45 | 8.18 | 2.57 | 14.59 | 1.79 | 11.55 |

| ∆ESRt [%] | 0.97 | 1.65 | 4.26 | 1.35 | 6.48 | 0.88 | 4.31 |

| Validation | |||||||

| MAPE [%] | 1.82 | 5.81 | 11.51 | 1.93 | 15.05 | 3.86 | 12.09 |

| ∆ESRt [%] | 1.31 | 1.97 | 5.44 | 0.90 | 6.93 | 1.40 | 4.83 |

| Error | Methods | ||||||

|---|---|---|---|---|---|---|---|

| ANN | RF | BRT | MARS | SMR | CRT | CHAID | |

| Teaching | |||||||

| MAPE [%] | 0.097 | 1.765 | 1.807 | 0.118 | 0.127 | 1.911 | 2.327 |

| ∆ESRt [%] | 0.091 | 1.812 | 1.712 | 0.113 | 0.125 | 2.203 | 2.368 |

| Validation | |||||||

| MAPE [%] | 0.057 | 1.715 | 2.147 | 0.082 | 0.088 | 1.851 | 2.496 |

| ∆ESRt [%] | 0.056 | 1.674 | 2.046 | 0.080 | 0.092 | 2.016 | 2.285 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karbowniczak, A.; Latała, H.; Nęcka, K.; Kurpaska, S.; Bergel, T. Modelling of the Electric Energy Storage Process in a PCM Battery. Energies 2022, 15, 735. https://doi.org/10.3390/en15030735

Karbowniczak A, Latała H, Nęcka K, Kurpaska S, Bergel T. Modelling of the Electric Energy Storage Process in a PCM Battery. Energies. 2022; 15(3):735. https://doi.org/10.3390/en15030735

Chicago/Turabian StyleKarbowniczak, Anna, Hubert Latała, Krzysztof Nęcka, Sławomir Kurpaska, and Tomasz Bergel. 2022. "Modelling of the Electric Energy Storage Process in a PCM Battery" Energies 15, no. 3: 735. https://doi.org/10.3390/en15030735

APA StyleKarbowniczak, A., Latała, H., Nęcka, K., Kurpaska, S., & Bergel, T. (2022). Modelling of the Electric Energy Storage Process in a PCM Battery. Energies, 15(3), 735. https://doi.org/10.3390/en15030735