Influence of Temperature on Lightning Performance of Mineral Oil

Abstract

:1. Introduction

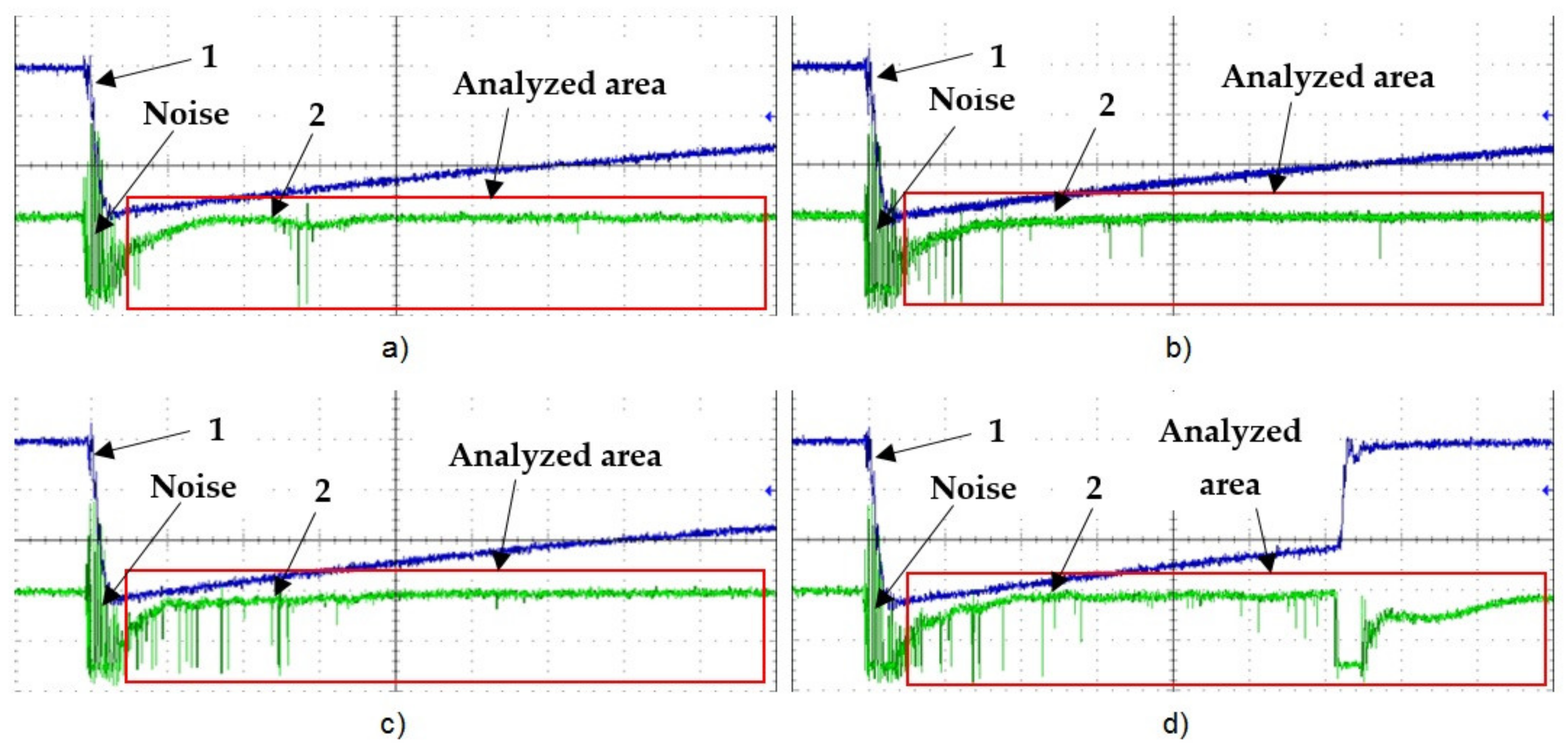

2. Methodology of the Studies

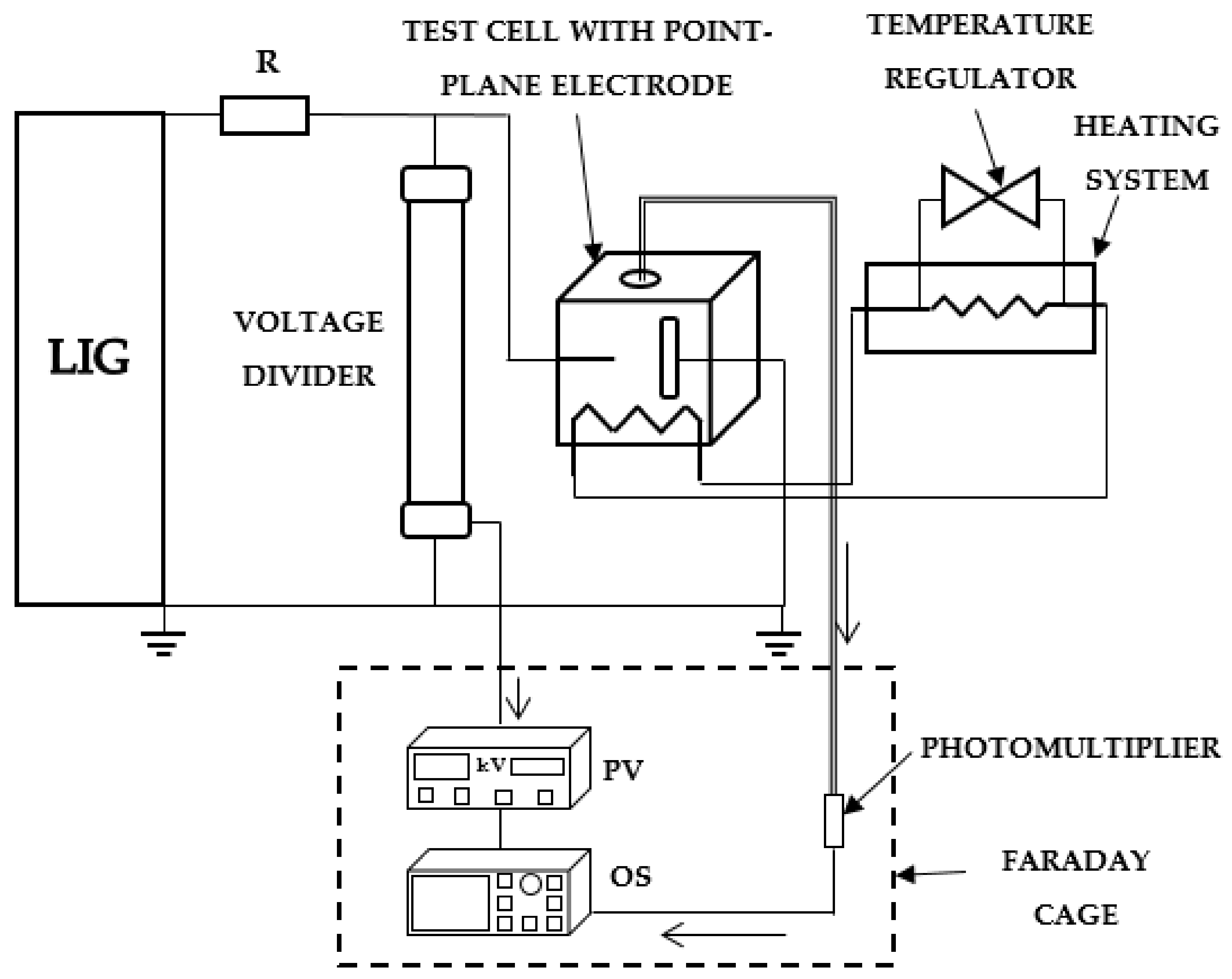

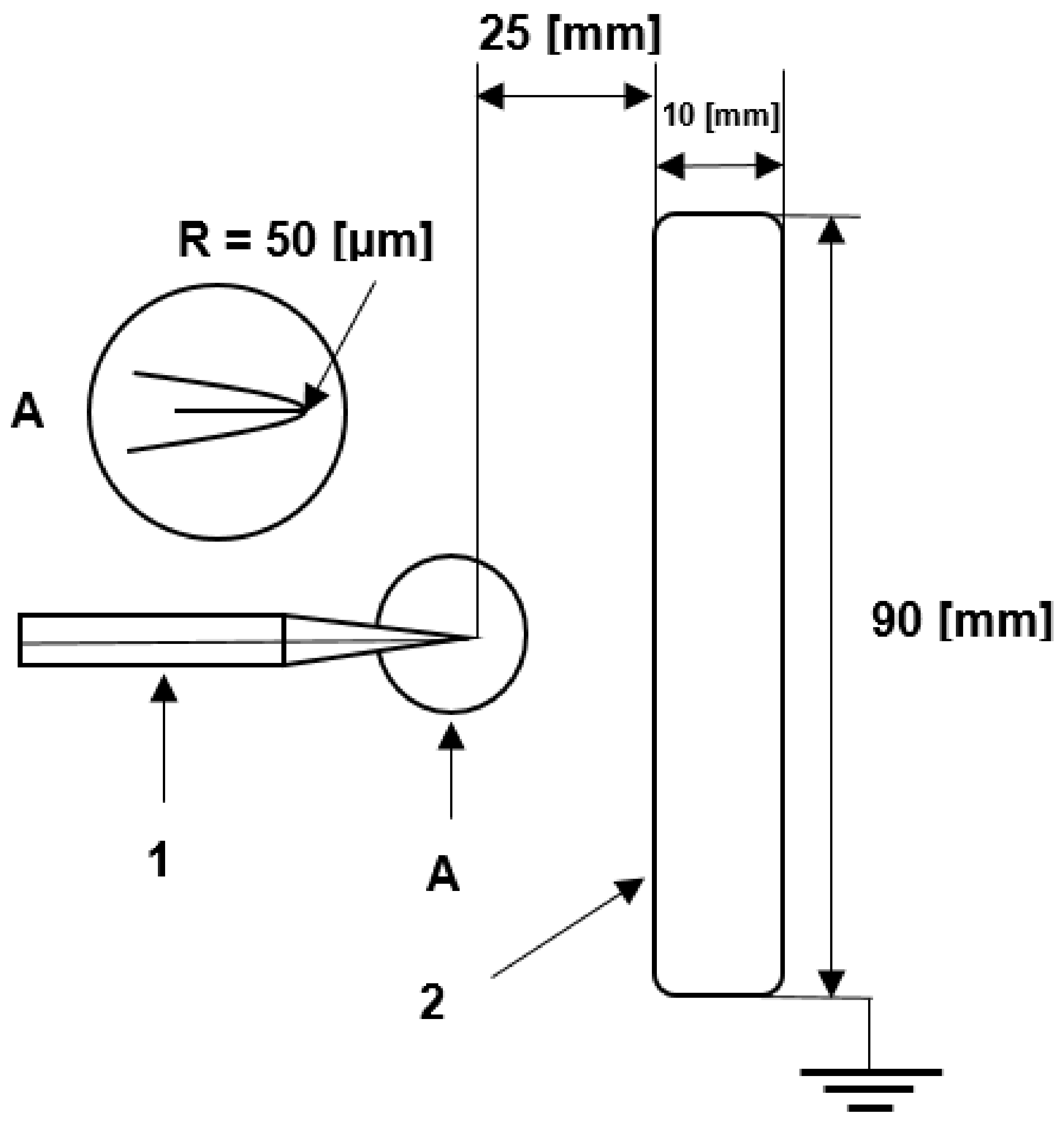

2.1. Measurement Setup

2.2. Measurement Procedure

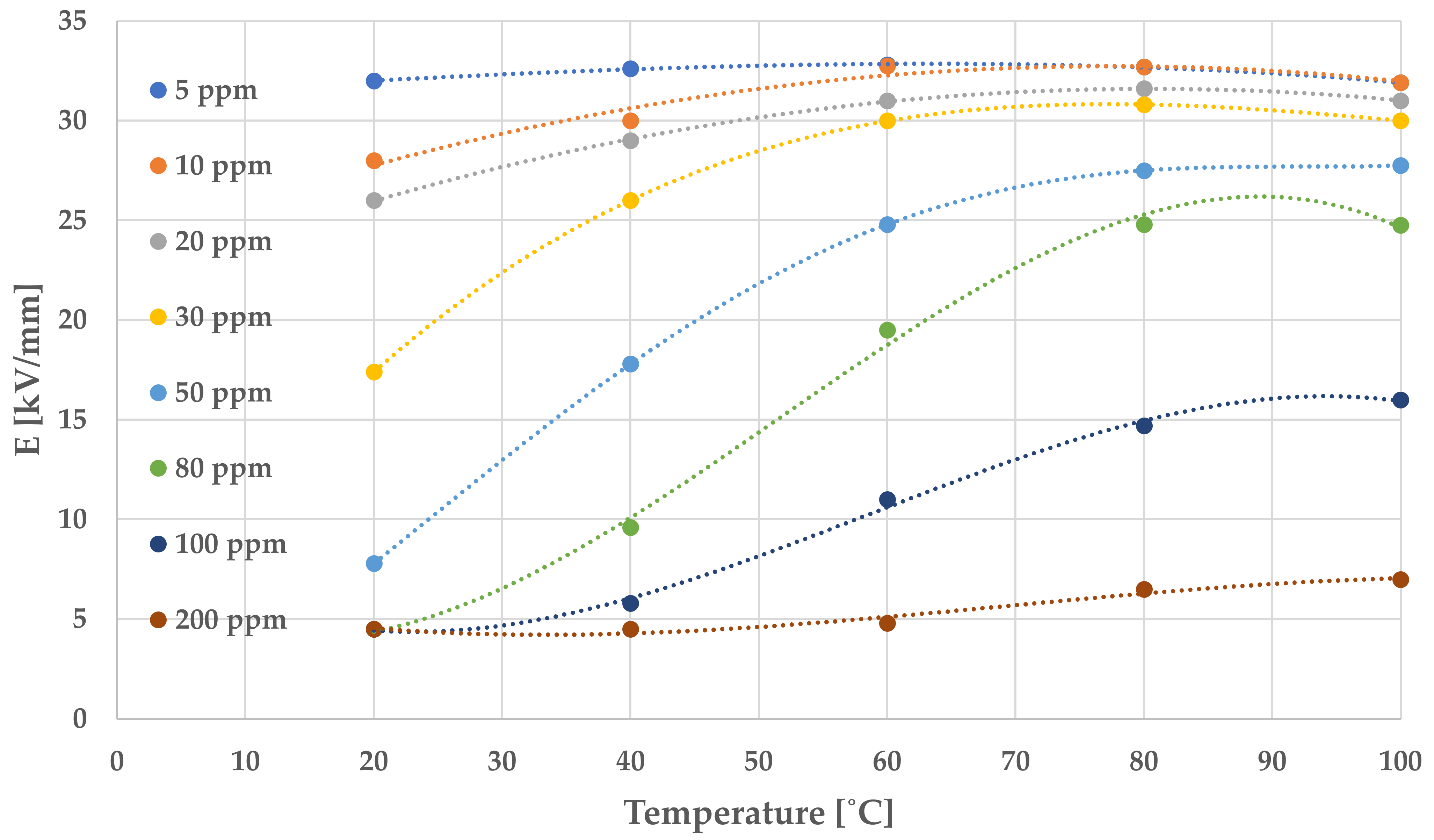

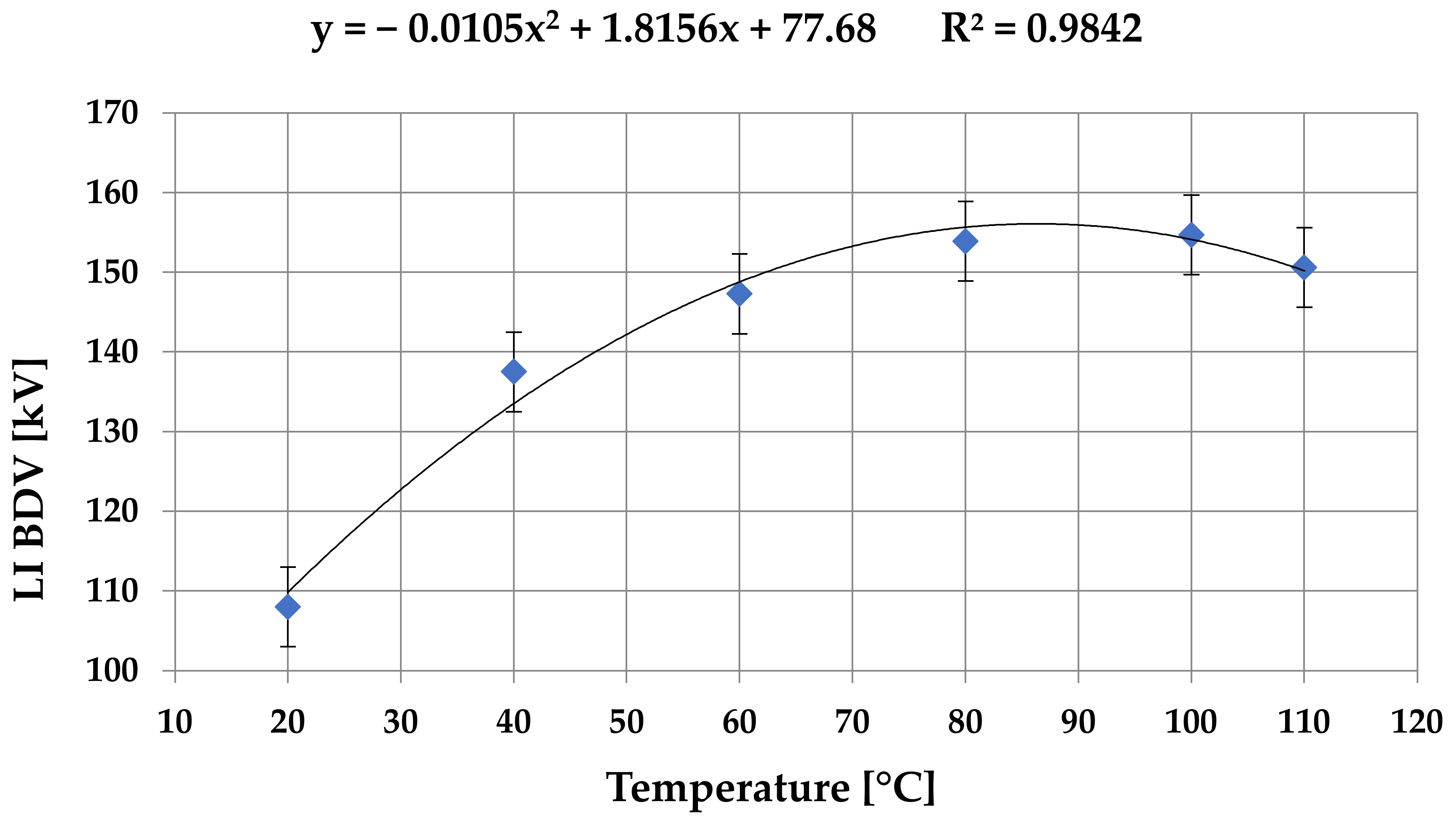

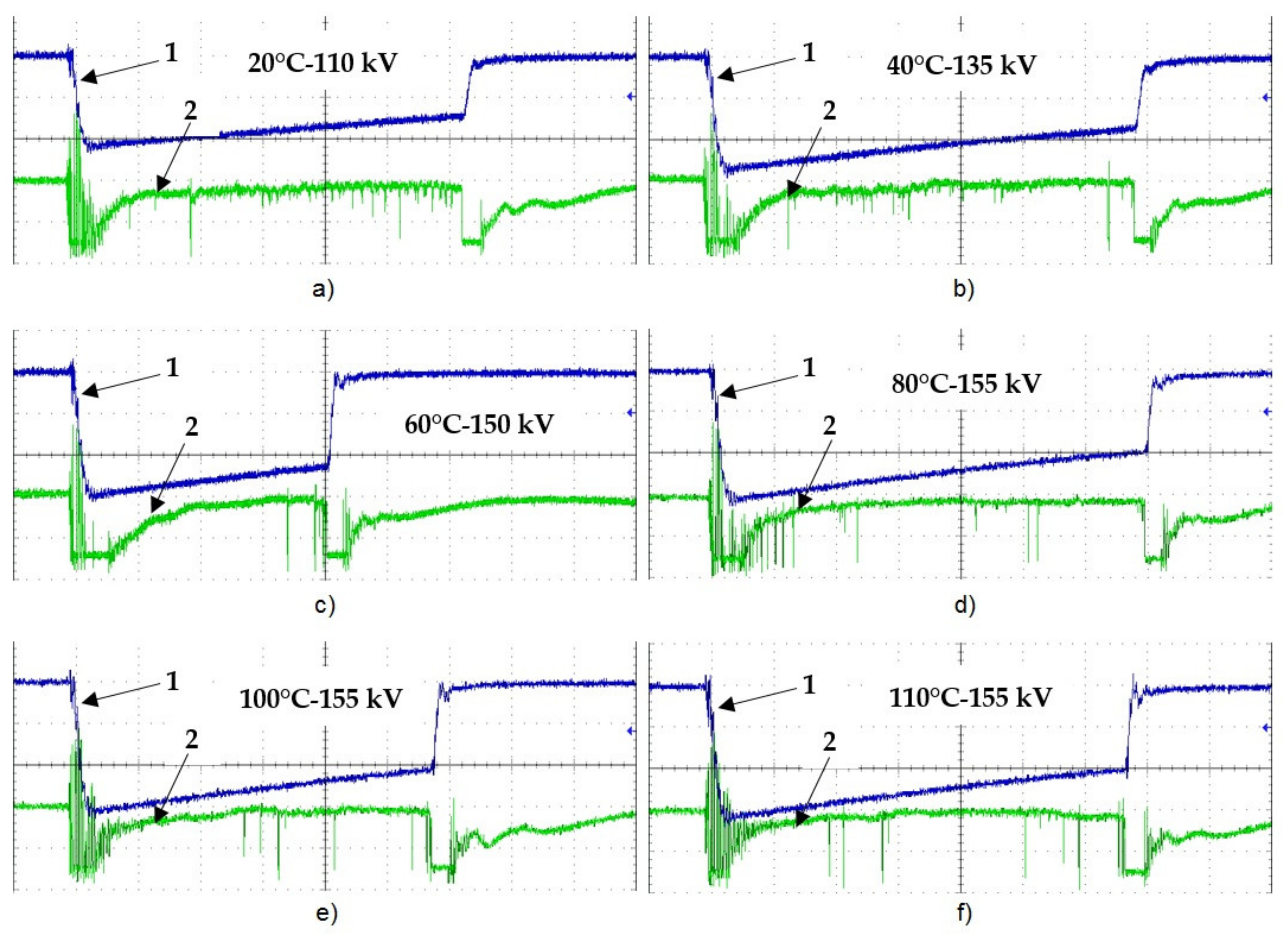

3. Results

4. Discussion

5. Conclusions

- (1)

- An increase in the temperature of mineral transformer oil leads to an increase in its LI BDV up to a temperature of approximately 100 °C. Above this value, the LI BDV decreases. This confirms that the oil stressed by LI voltage behaves similarly to AC voltage-based stress. Due to the volatile conditions in oil power transformers, this is undoubtedly a favourable property that increases the reliability of a used insulation system. Of course, there is a critical temperature above which BDV starts to decrease, but it is a temperature which does not appear in the normal conditions of transformer operation.

- (2)

- An interesting relationship is observed in terms of times to breakdown and the average propagation velocity of streamers leading to breakdown. The shortest time (higher velocities) concern lower temperatures (20–60 °C), which are characterized by lower breakdown voltages; for higher temperatures, these times are longer (velocities lower), which is also a positive finding in the context of the analysed phenomena.

- (3)

- Two different explanations of the observed relationship between LI BDV and temperature are possible: viscosity dependent processes responsible for increasing the LI BDV with temperatures up to 100 °C; and bubble formation processes for temperatures equal to and higher than 100 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- Mohan Rao, U.; Fofana, I.; Jaya, T.; Rodriguez-Celis, E.M.; Jalbert, J.; Picher, P. Alternative dielectric fluids for transformer insulation system: Research progress, challenges, and future prospects. IEEE Access 2019, 7, 184552–184571. [Google Scholar] [CrossRef]

- Rozga, P.; Beroual, A.; Przybylek, P.; Jaroszewski, M.; Strzelecki, K. A review on synthetic ester liquids for transformer applications. Energies 2020, 13, 6429. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, F.; Wang, Z.; Li, J. A critical review of plant-based insulating fluids for transformer: 30-year development. Renew. Sustain. Energy Rev. 2021, 141, 110783. [Google Scholar] [CrossRef]

- Piotrowski, T.; Rozga, P.; Kozak, R. Analysis of excessive hydrogen generation in transformers in service. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3600–3607. [Google Scholar] [CrossRef]

- Bochenski, B.; Mosinski, F.; Piotrowski, T. Monitoring and forecasting of power transformer ratings using DTR computer program. In Proceedings of the International. Conference “Computer as a Tool” (EUROCON), Warsaw, Poland, 9–12 September 2007; pp. 1373–1377. [Google Scholar] [CrossRef]

- Nossier, A.; El-Debeiky, S.; Hashad, I.F.; A-Barry, H. Effect of temperature on the breakdown probability of liquid dielectrics. IEEE Trans. Electr. Insul. 1981, 15, 502–505. [Google Scholar] [CrossRef]

- Fleszynski, J.; Lutynski, B.; Skowronski, J.I. Effect of impurities on the breakdown of insulating oil in long gaps. J. Electrost. 1979, 7, 47–55. [Google Scholar] [CrossRef]

- Klimkin, V.F.; Korobeynikov, S.M. Impulse Breakdown of Liquids; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Piotrowski, T.; Wojciak, M. Repeatability of measurement results of breakdown voltage of moistened and contaminated transformer oil. In Proceedings of the International Conference on Power Transformers “Transformer 19”, Torun, Poland, 7–9 May 2019; pp. 83–94. [Google Scholar]

- Wilson, M.P.; Timoshkin, I.V.; Given, M.J.; Macgregor, S.J.; Wang, T.; Sinclair, M.A.; Thomas, K.J.; Lehr, J.M. Breakdown of mineral oil: Effect of electrode geometry and rate of voltage rise. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1657–1664. [Google Scholar] [CrossRef] [Green Version]

- Rozga, P.; Hantsz, D. Influence of volume effect on electrical discharge initiation in mineral oil in the setup of insulated electrodes. Electr. Eng. 2017, 99, 179–186. [Google Scholar] [CrossRef] [Green Version]

- Danikas, M.; Sarathi, R.; Morsalin, S. A short review of some of the factors affecting the breakdown strength of insulating oil for power transformers. Eng. Technol. Appl. Sci. Res. 2020, 10, 5742–5747. [Google Scholar] [CrossRef]

- Rozga, P.; Rapp, K.J.; Stanek, M. Lightning properties of selected insulating synthetic esters and mineral oil in point-to-sphere electrode system. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1699–1705. [Google Scholar] [CrossRef]

- Beroual, A.; Tobazeon, R. Effects of hydrostatic pressure on the prebreakdown phenomena in dielectric liquids. In Proceedings of the Conference on Electrical Insulation & Dielectric Phenomena-Annual Report 1985, Amherst, NY, USA, 20–24 October 1985; pp. 44–49. [Google Scholar] [CrossRef]

- Musil, R.; Baur, M.; Pfister, W. Testing practices for the AC breakdown voltage testing of insulation liquids. IEEE Electr. Insul. Mag. 1995, 11, 21–26. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, X.; Pan, C.; Tang, J. Role of air bubbles in the breakdown of flowing transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1752–1760. [Google Scholar] [CrossRef]

- IEC 60156: 2018; Insulating Liquids—Determination of the Breakdown Voltage at Power Frequency—Test Method. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- Chana, J.C.; Cometa, E.T. Impulse breakdown characteristics of insulating oils and their behaviour in oil-paper composites. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Leesburg, VA, USA; pp. 447–452. [CrossRef]

- Mohan Rao, U.; Fofana, I.; Beroual, A.; Rozga, P.; Pompili, M.; Calcara, L.; Rapp, K.J. A review on pre-breakdown phenomena in ester fluids: Prepared by the international study group of IEEE DEIS liquid dielectrics technical committee. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1546–1560. [Google Scholar] [CrossRef]

- Beroual, A.; Zahn, M.; Badent, A.; Kist, K.; Schwabe, A.J.; Yamashita, H.; Yamazawa, K.; Danikas, M.; Chadband, W.D.; Torshin, Y. Propagation and structure of streamers in liquid dielectrics. IEEE Electr. Insul. Mag. 1998, 14, 6–17. [Google Scholar] [CrossRef] [Green Version]

- Adamczewski, I. Ionization, Conductivity and Breakdown in Dielectric Liquids; Taylor and Francis LTD: Abingdon, UK, 1969. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| AC BDV | kV | 66.8 |

| density | g/mL | 0.882 |

| water content | ppm | 24.6 |

| dielectric permittivity | - | 2.24 |

| dielectric loss factor at 90 °C | - | 0.0042 |

| surface tension | mN/m | 29.5 |

| Temperature | 20 [°C] | 40 [°C] | 60 [°C] | 80 [°C] | 100 [°C] | 110 [°C] |

|---|---|---|---|---|---|---|

| Breakdown Voltage:Average Value [kV] for the Five Series of Measurements | ||||||

| Series 1 | 112.5 | 136.5 | 148.5 | 155.5 | 154 | 150.5 |

| Series 2 | 105.0 | 138.5 | 151.5 | 157.5 | 155.5 | 151.0 |

| Series 3 | 110.0 | 142.1 | 147.0 | 154.0 | 157.5 | 153.0 |

| Series 4 | 107.0 | 133.0 | 142.5 | 150,5 | 152.0 | 152.0 |

| Series 5 | 104.5 | 137.5 | 147.0 | 152.0 | 154.5 | 146.5 |

| Breakdown Voltage:Average Value for All Measurements [kV] | ||||||

| 108 | 137.5 | 147.3 | 153.9 | 154.7 | 150.6 | |

| Standard Deviation [kV] for the Five Series of Measurements | ||||||

| Series 1 | 9.8 | 11.3 | 18.1 | 15.9 | 7.0 | 7.2 |

| Series 2 | 6.9 | 12.3 | 12.7 | 11.6 | 11.4 | 7.4 |

| Series 3 | 13.2 | 10.3 | 16.9 | 11.0 | 8.6 | 10.1 |

| Series 4 | 10.9 | 8.9 | 11.1 | 7.6 | 8.2 | 8.6 |

| Series 5 | 9.0 | 7.5 | 11.8 | 9.8 | 6.4 | 8.8 |

| Standard Deviation for All Measurements [kV] | ||||||

| 9.9 | 10.1 | 14.1 | 11.2 | 8.3 | 8.4 | |

| Temperature | 20 [°C] | 40 [°C] | 60 [°C] | 80 [°C] | 100 [°C] | 110 [°C] |

|---|---|---|---|---|---|---|

| Time to Breakdown:Average Value [µs]for the Five Series of Measurements | ||||||

| Series 1 | 22.2 | 22.8 | 21.5 | 27.7 | 27.3 | 28.2 |

| Series 2 | 23.5 | 19.7 | 22.8 | 25.2 | 25.0 | 24.9 |

| Series 3 | 22.8 | 19.1 | 19.2 | 24.5 | 22.9 | 24.6 |

| Series 4 | 22.7 | 22.5 | 24.8 | 28.5 | 21.1 | 25.5 |

| Series 5 | 23.5 | 18.3 | 24.1 | 24.5 | 25.3 | 19.7 |

| Time to breakdown:Average Valuefor All Measurements [µs] | ||||||

| 22.9 | 20.5 | 22.5 | 26.1 | 24.3 | 24.8 | |

| Standard Deviation of Time to Breakdown [µs] for the Five Series of Measurements | ||||||

| Series 1 | 3.9 | 5.5 | 4.3 | 9.4 | 12.2 | 9.1 |

| Series 2 | 2.2 | 4.9 | 5.7 | 5.2 | 5.5 | 6.0 |

| Series 3 | 2.7 | 4.7 | 3.1 | 5.6 | 4.5 | 6.1 |

| Series 4 | 4.0 | 3.0 | 7.9 | 9.2 | 3.6 | 9.4 |

| Series 5 | 1.8 | 3.1 | 11.3 | 2.4 | 6.1 | 4.1 |

| Standard Deviation of Time to Breakdown for All Measurements [µs] | ||||||

| 3.1 | 4.7 | 7.4 | 7.1 | 7.4 | 7.8 | |

| Average Propagation Velocity [mm/µs] | ||||||

| 1.09 | 1.22 | 1.11 | 0.96 | 1.03 | 1.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rozga, P.; Stuchala, F.; Piotrowski, T.; Beroual, A. Influence of Temperature on Lightning Performance of Mineral Oil. Energies 2022, 15, 1063. https://doi.org/10.3390/en15031063

Rozga P, Stuchala F, Piotrowski T, Beroual A. Influence of Temperature on Lightning Performance of Mineral Oil. Energies. 2022; 15(3):1063. https://doi.org/10.3390/en15031063

Chicago/Turabian StyleRozga, Pawel, Filip Stuchala, Tomasz Piotrowski, and Abderrahmane Beroual. 2022. "Influence of Temperature on Lightning Performance of Mineral Oil" Energies 15, no. 3: 1063. https://doi.org/10.3390/en15031063

APA StyleRozga, P., Stuchala, F., Piotrowski, T., & Beroual, A. (2022). Influence of Temperature on Lightning Performance of Mineral Oil. Energies, 15(3), 1063. https://doi.org/10.3390/en15031063