Optimal Control of the Diesel–Electric Propulsion in a Ship with PMSM

Abstract

1. Introduction

2. Methods and Results

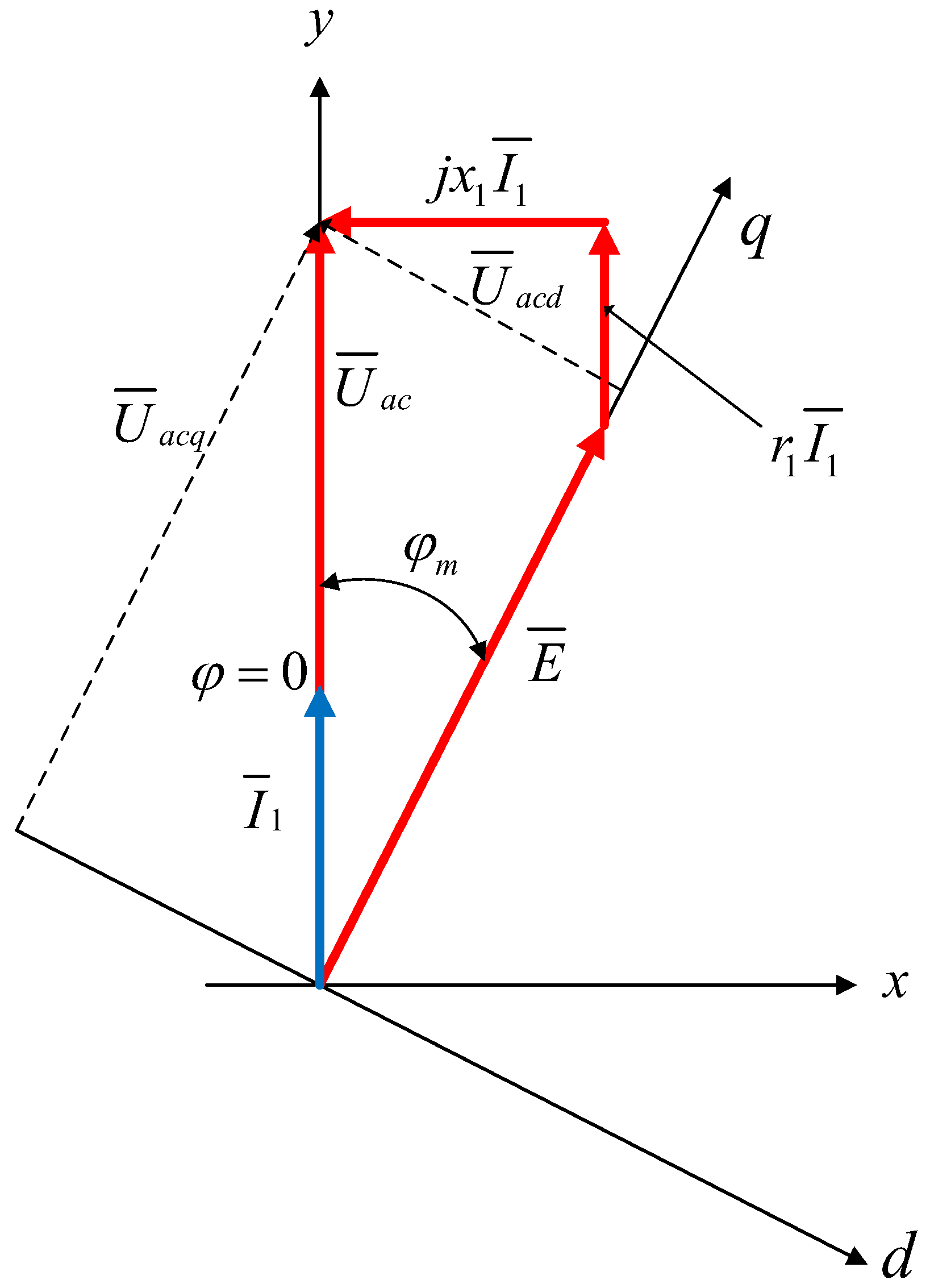

2.1. Energy Optimization of the PMSM Propulsion System in a Steady State Based on the Use of the Physical Properties of the System

- Voltage inverter composed of transistors (VT1–VT6) and diodes;

- Synchronous machine (PMSM);

- Rotor condition sensor (SPS);

- Coordinate transformation module (abc/d,q—Park–Gorev transformation);

- Coordinate transformation module (d,q/abc—Park–Gorev inverse transformation);

- Pulse width modulator (PWM);

- Speed controller (SC);

- Optimization block (OB).

2.2. Synthesis and Optimization of Dynamic and Static Control of a Propulsion System with PMSM

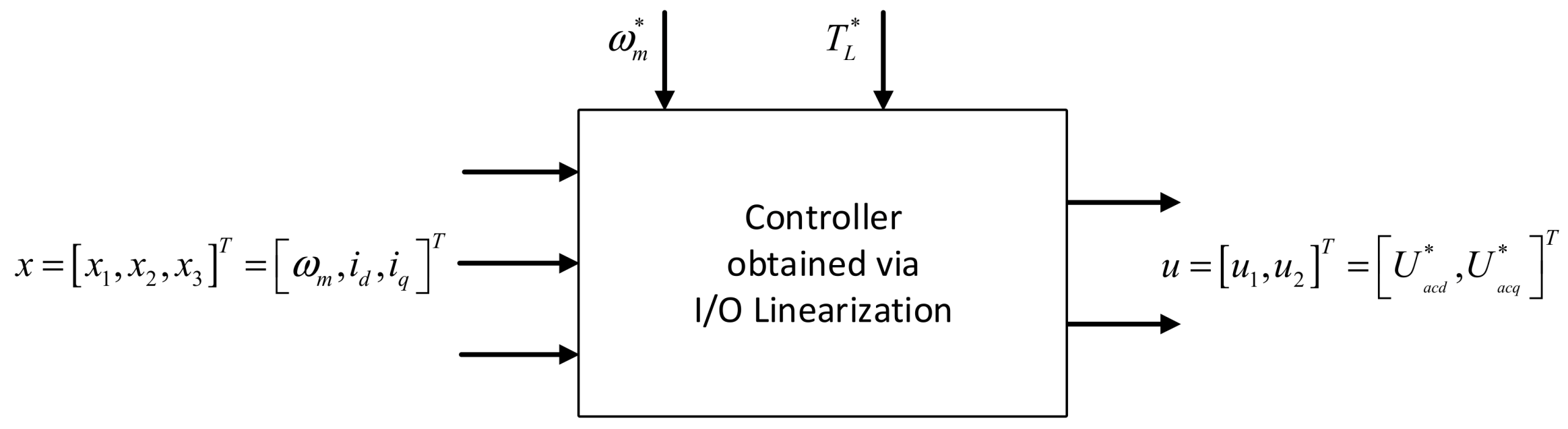

2.2.1. Design of the Main Controller via I/O Linearization Method

- x1 = Id, x2 = Iq, x3 = ωm;

- u1 = Uacd, u2 = Uacq.

2.2.2. Analysis of the System Zero Dynamics

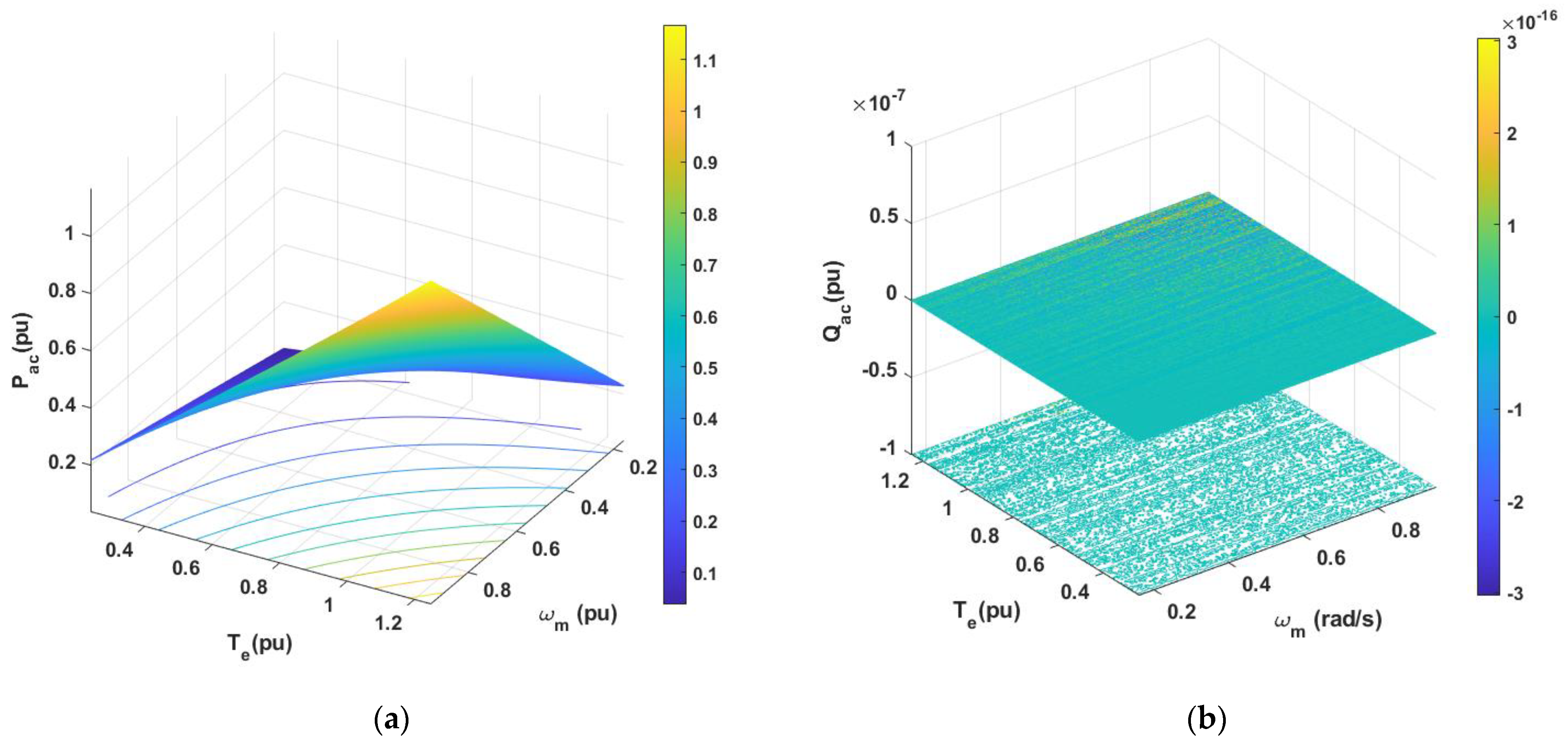

2.2.3. Energetic Optimization of the System Operation in Steady State

- a > 0—control parameter

- we have a chance (by an appropriate choice of the parameter a) to influence the value of variable x1 (in the steady state) without affecting the evolution (transient process) of the variables x1 and x2.

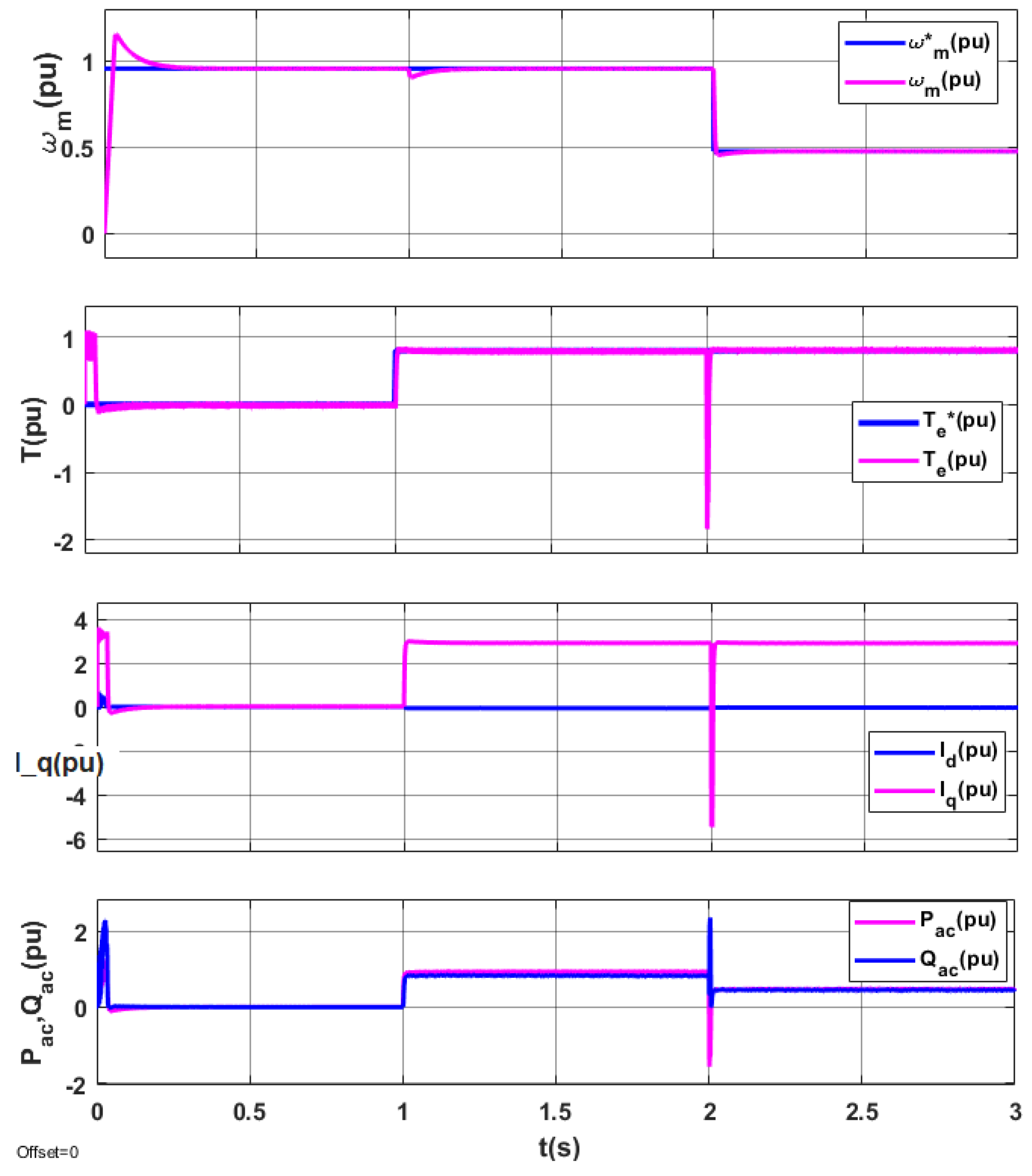

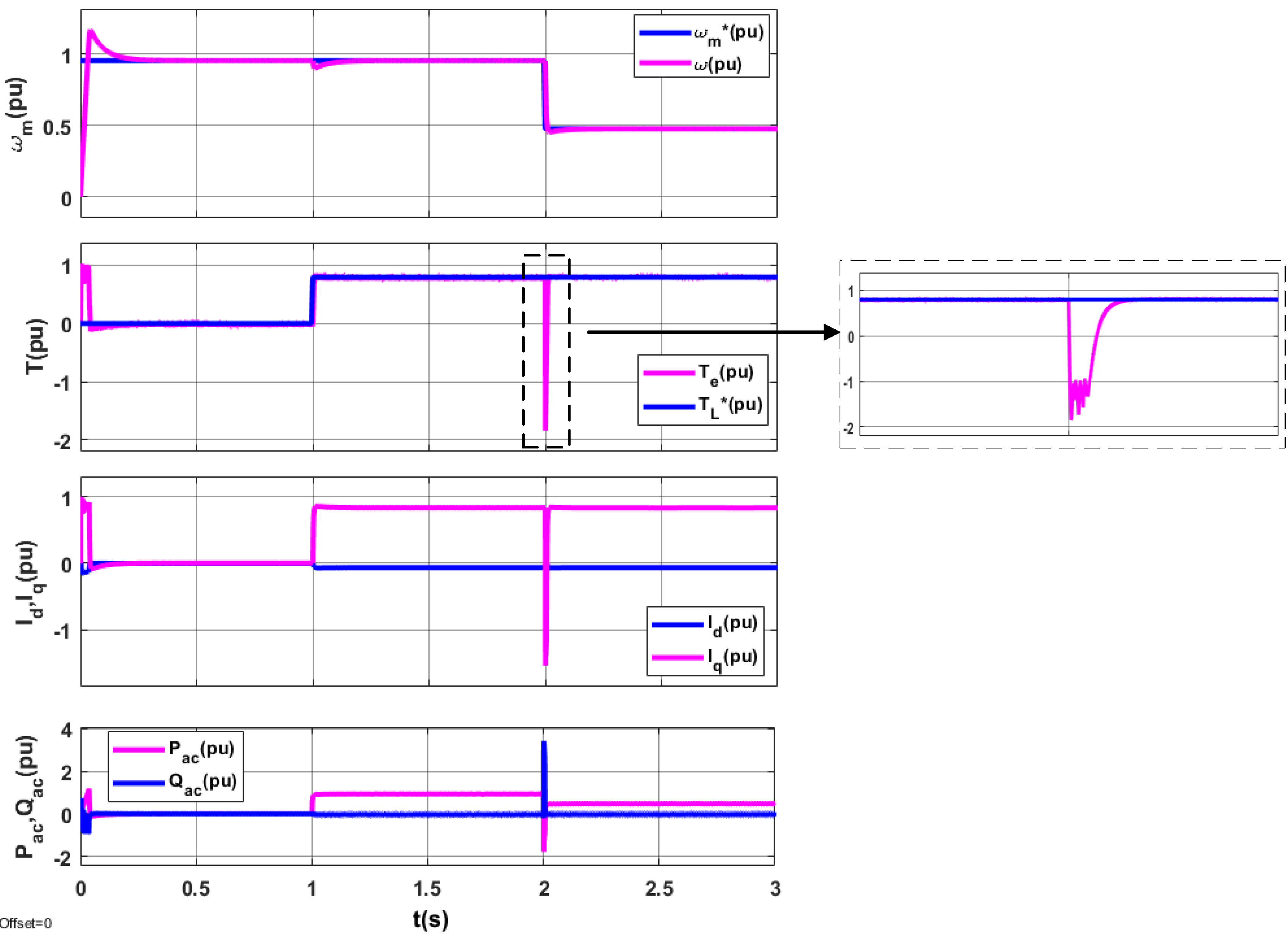

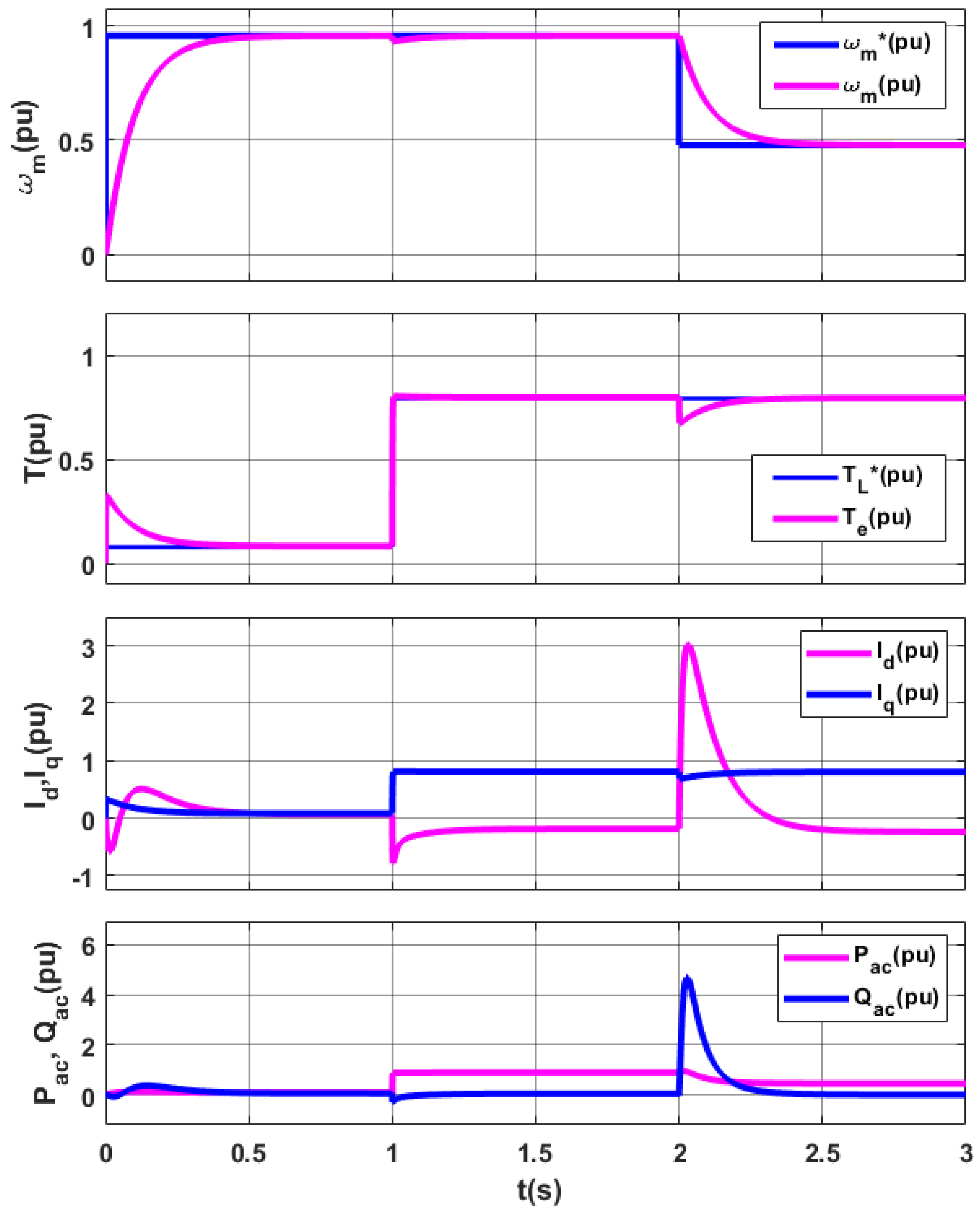

2.2.4. Tests of the Propulsion System with PMSM Using Synthesized Control

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UNCTAD. Review of Maritime Transport 2018; United Nations Publication: New York, NY, USA, 2018; pp. 23–26. Available online: https://unctad.org/system/files/official-document/rmt2018_en.pdf (accessed on 5 May 2022).

- IMO RESOLUTION MEPC.203(62) Adopted on 15 July 2011. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.203(62).pdf (accessed on 5 May 2022).

- Polakis, M.; Zachariadis, P.; Kat, J.O. The Energy Efficiency Design Index (EEDI). In Sustainable Shipping; Springer: New York, NY, USA, 2019; pp. 93–135. [Google Scholar] [CrossRef]

- International Maritime Organization. IMO Train the Trainer (TTT) Course on Energy Efficiency Ship Operation. In Module 2—Ship Energy Efficiency Regulations and Related Guidelines; International Maritime Organization: London, UK, 2016; Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/Air%20pollution/TTT%20trainers%20manual%20final2.pdf (accessed on 5 May 2022).

- Grljušić, M.; Medica, V.; Radica, G. Calculation of Efficiencies of a Ship Power Plant Operating with Waste Heat Recovery through Combined Heat and Power Production. Energies 2015, 8, 4273–4299. [Google Scholar] [CrossRef]

- Mrzljak, V.; Zarkovic, B.; Prpic-Orsic, J. Marine slow speed two-stroke diesel engine—Numerical analysis of efficiencies and im-portant operating parameters. Mach. Technol. Mater. 2017, 11, 481–484. [Google Scholar]

- Zaccone, R.; Campora, U.; Martelli, M. Optimization of a diesel-electric ship propulsion and power generation system using a genetic algorithm. J. Mar. Sci. Eng. 2021, 9, 587. [Google Scholar] [CrossRef]

- Hansen, J.F.; Wendt, F. History and State of the Art in Commercial Electric Ship Propulsion, Integrated Power Systems, and Future Trends. Proc. IEEE 2015, 103, 2229–2242. [Google Scholar] [CrossRef]

- Vossen, C. Diesel electric propulsion on ∑IGMA class corvettes. In Proceedings of the 2011 IEEE Electric Ship Technologies Symposium, Alexandria, VA, USA, 10–13 April 2011; pp. 288–291. [Google Scholar] [CrossRef]

- Acanfora, M.; Balsamo, F.; Fantauzzi, M.; Lauria, D.; Proto, D. Load levelling through Storage System for Hybrid Diesel Electric Ship Propulsion in Irregular Wave Conditions. In Proceedings of the 2022 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 22–24 June 2022; pp. 640–644. [Google Scholar] [CrossRef]

- Fan, Z.; Liang, C.; Dong, Y.; Chang, G.; Pan, W.; Shao, S. Control of the Diesel-Electric Hybrid Propulsion in a Practical Cruise Vessel. In Proceedings of the 2021 IEEE International Conference on Power, Intelligent Computing and Systems (ICPICS), Shenyang, China, 29–31 July 2021; pp. 311–316. [Google Scholar] [CrossRef]

- Veksler, A.; Johansen, T.J.; Skjetne, R.; Mathiesen, E. Thrust Allocation With Dynamic Power Consumption Modulation for Diesel-Electric Ships. IEEE Trans. Control Syst. Technol. 2016, 24, 578–593. [Google Scholar] [CrossRef][Green Version]

- Zhu, H.H.; Dong, Z. Modeling and Simulation of Hybrid Electric Ships with AC Power Bus—A Case Study. In Proceedings of the 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Oulu, Finland, 2–4 July 2018; pp. 1–8. [Google Scholar] [CrossRef]

- WARTSILA. Improving Efficiency. Available online: https://www.wartsila.com/sustainability/innovating-for-sustainability/improving-efficiency (accessed on 5 May 2022).

- Kozak, M. Alternating Current Electric Generator Machine Inverters in a Parallel Power Sharing Connection. IEEE Access 2019, 7, 32154–32165. [Google Scholar] [CrossRef]

- Kozak, M. New concept of ship’s power plant system with varying rotational speed gensets. In Proceedings of the 58th international conference of machine design departments (ICMD 2017), Prague, Czech Republic, 6–8 September 2017; pp. 170–175. [Google Scholar]

- Choi, I.C.; Jeung, Y.-C.; Lee, D.-C. Variable speed control of diesel engine-generator using sliding mode control. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Rezkallah, M.; Dubuisson, F.; Singh, S.; Singh, B.; Chandra, A.; Ibrahim, H.; Ghandour, M. Coordinated Control Strategy for Hybrid off-Grid System Based on Variable Speed Diesel Generator. IEEE Trans. Ind. Appl. 2022, 58, 4411–4423. [Google Scholar] [CrossRef]

- Hu, Y.; Cirstea, M.; McCormick, M.; Haydock, L. Modelling and simulation of a variable speed stand-alone generator system. In Proceedings of the 2000 Eighth International Conference on Power Electronics and Variable Speed Drives (IEE Conf. Publ. No. 475), London, UK, 18–19 September 2000; pp. 372–377. [Google Scholar] [CrossRef]

- Zhou, Z.; Camara, M.B.; Dakyo, B. Coordinated Power Control of Variable-Speed Diesel Generators and Lithium-Battery on a Hybrid Electric Boat. IEEE Trans. Veh. Technol. 2017, 66, 5775–5784. [Google Scholar] [CrossRef]

- German-Galkin, S.; Tarnapowicz, D. Energy Optimization of Ship’s Shaft Generator with Permanent Magnet Synchronous Generator. Nase More 2020, 67, 138–145. [Google Scholar] [CrossRef]

- Jamieson, P. Innovation in Wind Turbine Design, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2018; ISBN 978-1-119-13790-0. [Google Scholar]

- Ludwig, F.; Möckel, A. Operation method for AC grid powered PMSM with open-end winding in dual-inverter topology for power factor maximization. In Proceedings of the 8th IET International Conference on Power Electronics, Machines and Drives (PEMD 2016), Glasgow, UK, 19–21 April 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Jianbo, C.; Yuwen, H.; Wenxin, H.; Yong, L.; Jianfei, Y.; Mingjin, W. Direct active and reactive power control of PMSM. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009; pp. 1808–1812. [Google Scholar] [CrossRef]

- Lei, J.; Zhou, B.; Bian, J.; Qin Jiangsu, X. Unit power factor control of PMSM fed by indirect matrix converter. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 926–930. [Google Scholar] [CrossRef]

- Cimini, G.; Ippoliti, G.; Orlando, G.; Pirro, M. PMSM control with power factor correction: Rapid prototyping scenario. In Proceedings of the 4th International Conference on Power Engineering, Energy and Electrical Drives, Istanbul, Turkey, 13–17 May 2013; pp. 688–693. [Google Scholar] [CrossRef]

- Khalil, H.K. Nonlinear Systems, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002; pp. 509–521. ISBN 978-0130673893. [Google Scholar]

- Lewis, F.L.; Draguna Vrabie, D.; Syrmos, V.L. Optimal Control, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; ISBN 978-0470633496. [Google Scholar]

- German-Galkin, S.; Tarnapowicz, D. Energy Optimization of the ‘Shore to Ship’ System-A Universal Power System for Ships at Berth in a Port. Sensors 2020, 20, 3815. [Google Scholar] [CrossRef] [PubMed]

- German-Galkin, S.; Tarnapowicz, D. Optimization of the electric car’s drive system with PMSM. In Proceedings of the 12th International Science-Technical Conference AUTOMOTIVE SAFETY, Kielce, Poland, 21–23 October 2020. [Google Scholar] [CrossRef]

- Wu, B.; Lang, Y.; Zargari, N.; Kouro, S. Appendix B: Generator Parameters. In Power Conversion and Control of Wind Energy Systems; IEEE: Manhattan, NY, USA, 2011; pp. 319–326. [Google Scholar] [CrossRef]

- Zawirski, K. Permanent Magnet Synchronous Motor Control; Poznan University of Technology Publishing House: Poznań, Poland, 2005; ISBN 83-7143-337-9. [Google Scholar]

- Kaczmarek, T.; Zawirski, K. Drive Systems with Synchronous Motor; Poznan University of Technology Publishing House: Poznań, Poland, 2000; ISBN 978-83-7348-401-6. [Google Scholar]

- Kazmierkowski, M.P.; Tunia, H. Automatic Control of Converter-Fed Drives. In Studies in Electrical and Electronic Engineering, 1st ed.; PWN-Elsevier Science Publishers: Warsaw, Polland; Amsterdam, The Netherlands; New York, NY, USA; Tokyo, Japan, 1994; ISBN 13-978-0444986603. (In English) [Google Scholar]

- Aghili, F. Optimal Feedback Linearization Control of Interior PM Synchronous Motors Subject to Time-Varying Operation Conditions Minimizing Power Loss. IEEE Trans. Ind. Electron. 2018, 65, 5414–5421. [Google Scholar] [CrossRef]

- Fraga, R.; Sheng, L. Non linear and intelligent controllers for the ship rudder control. In Proceedings of the 2011 Saudi International Electronics, Communications and Photonics Conference (SIECPC), Riyadh, Saudi Arabia, 24–26 April 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Parvathy, A.K.; Devanathan, R.; Kamaraj, V. Application of quadratic linearization to control of Permanent Magnet synchronous motor. In Proceedings of the 2011 1st International Conference on Electrical Energy Systems, Chennai, India, 3–5 January 2011; pp. 158–163. [Google Scholar] [CrossRef]

- Do, T.D.; Kwak, S.; Choi, H.H.; Jung, J.-W. Suboptimal Control Scheme Design for Interior Permanent-Magnet Synchronous Motors: An SDRE-Based Approach. IEEE Trans. Power Electron. 2014, 29, 3020–3031. [Google Scholar] [CrossRef]

- Cheema, M.A.M.; Fletcher, J.E.; Xiao, D.; Rahman, M.F. A Linear Quadratic Regulator-Based Optimal Direct Thrust Force Control of Linear Permanent-Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2016, 63, 2722–2733. [Google Scholar] [CrossRef]

- Zwierzewicz, Z. Robust and Adaptive Path-Following Control of an Underactuated Ship. IEEE Access 2020, 8, 120198–120207. [Google Scholar] [CrossRef]

- Wang, F.; Mi, Z.; Yang, Q. Comparison between Periodic Function space based power theory and traditional power theory. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; pp. 2212–2216. [Google Scholar]

- Akagi, H.; Hirokazu-Watanabe, E.; Aredes, M. The Instantaneous Power Theory. In Instantaneous Power Theory and Applications to Power Conditioning; IEEE: Manhattan, NY, USA, 2017; pp. 37–109. [Google Scholar] [CrossRef]

- Ho, T.-Y.; Chen, M.-S.; Chen, L.-Y.; Yang, L.-H. The design of a PMSM motor drive with active power factor correction. In Proceedings of the 2011 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC), Dengfeng, China, 8–10 August 2011; pp. 4447–4450. [Google Scholar] [CrossRef]

- Tau, J.-H.; Tzou, Y.-Y. PFC control of electrolytic capacitor-less PMSM drives for home appliances. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 335–341. [Google Scholar] [CrossRef]

- Gokulapriya, R.; Pradeep, J. Shunt based active power factor correction circuit for direct torque controlled PMSM drive. In Proceedings of the 2017 Third International Conference on Science Technology Engineering & Management (ICONSTEM), Chennai, India, 23–24 March 2017; pp. 517–521. [Google Scholar] [CrossRef]

- Vimal, M.; Sojan, V. Vector controlled PMSM drive with power factor correction using zeta converter. In Proceedings of the 2017 International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017; pp. 289–295. [Google Scholar] [CrossRef]

| Parameter | Volume (Nominal Units) | Volume (Per Unit) |

|---|---|---|

| Rated Mechanical Power | 2.0 MW | 1 |

| Rated Apparent Power | 2.2419 MVA | 1 |

| Rated Line-to-Line Voltage | 690 V (rms) | 1 |

| Rated Phase Voltage | 398.4 V (rms) | 1 |

| Rated Stator Current | 1867.76 A (rms) | 1 |

| Rated Stator Frequency | 9.75 Hz | 1 |

| Rated Power Factor | 0.8921 | 1 |

| Rated Rotor Speed | 22.5 rpm | 1 |

| Number of Pole Pairs | 26 | 1 |

| Rated Mechanical Torque | 848.826 kNm | 1 |

| Rated Rotor Flux Linkage | 5.8264 Wb (rms) | 0.896 |

| Stator Winding Resistance, R1 | 0.821 mΩ | 0.00387 |

| Moment of Inertia, J | 6 kgm2 | 1 |

| d-Axis Synchronous Inductance, Ld | 1.5731 mH | 0.4538 |

| q-Axis Synchronous Inductance, Lq | 1.5731 mH | 0.4538 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zwierzewicz, Z.; Tarnapowicz, D.; German-Galkin, S.; Jaskiewicz, M. Optimal Control of the Diesel–Electric Propulsion in a Ship with PMSM. Energies 2022, 15, 9390. https://doi.org/10.3390/en15249390

Zwierzewicz Z, Tarnapowicz D, German-Galkin S, Jaskiewicz M. Optimal Control of the Diesel–Electric Propulsion in a Ship with PMSM. Energies. 2022; 15(24):9390. https://doi.org/10.3390/en15249390

Chicago/Turabian StyleZwierzewicz, Zenon, Dariusz Tarnapowicz, Sergey German-Galkin, and Marek Jaskiewicz. 2022. "Optimal Control of the Diesel–Electric Propulsion in a Ship with PMSM" Energies 15, no. 24: 9390. https://doi.org/10.3390/en15249390

APA StyleZwierzewicz, Z., Tarnapowicz, D., German-Galkin, S., & Jaskiewicz, M. (2022). Optimal Control of the Diesel–Electric Propulsion in a Ship with PMSM. Energies, 15(24), 9390. https://doi.org/10.3390/en15249390